Plasma Assisted Combustion as a Cost-Effective Way for Balancing of Intermittent Sources: Techno-Economic Assessment for 200 MWel Power Unit

Abstract

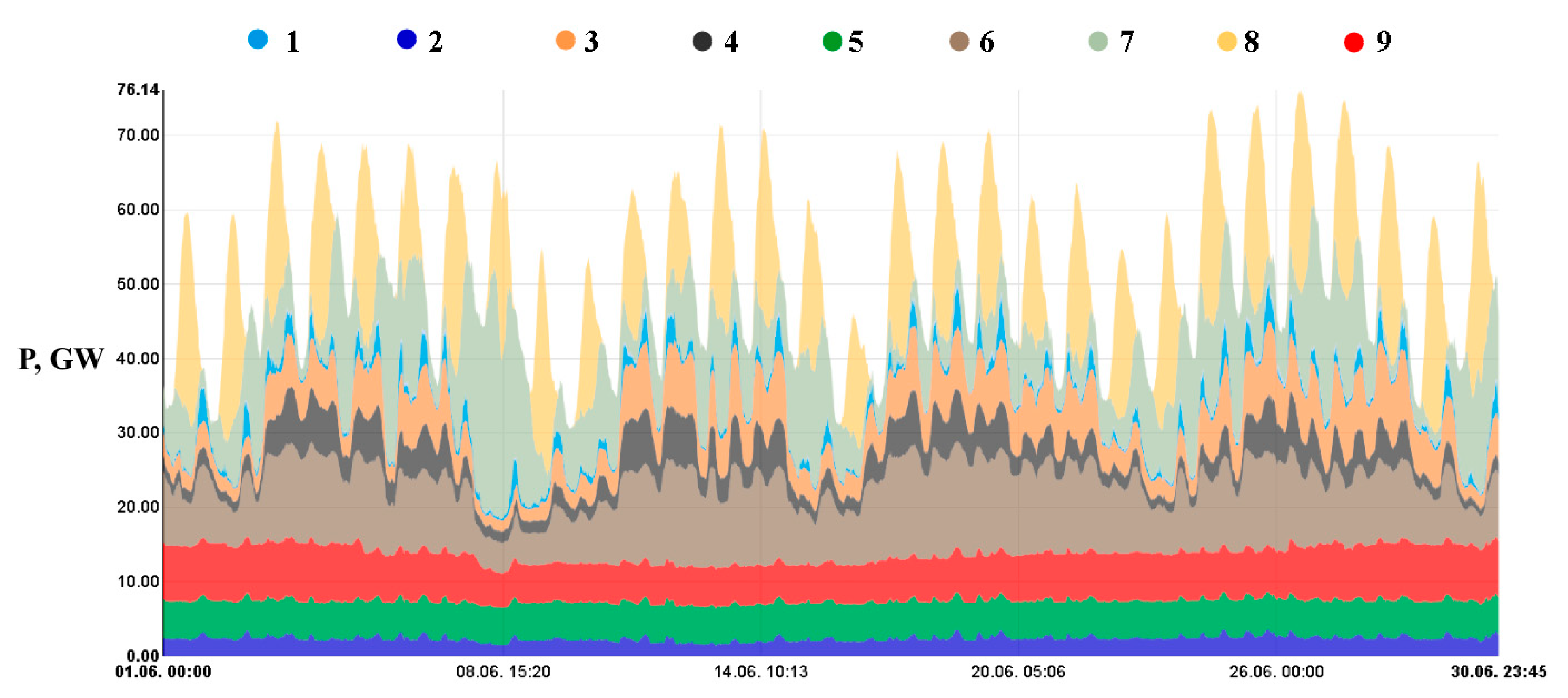

1. Introduction

- Intermittent—the energy supply is not controlled, or a such control is severely limited;

- Controllable, inflexible—the energy supply can be controlled, but due to the low flexibility of the sources they cannot be used to balance variations in the energy supply from uncontrollable sources;

- Controllable, flexible—it is possible to flexibly respond to changes in electricity demand and supply in the electric power system, thereby guaranteeing energy supply security.

2. Potential of Plasma Technologies for Increasing the Flexibility of Power Units

3. Capacity Market

4. Method of the Analysis

4.1. NPV Method

- CFi—cash flow in the i-th period;

- n—number of periods;

- r—expected rate of return.

4.2. Assumptions Made Prior to the Analysis

- —assumed relative power of the plasma torch used to stabilize combustion, as % the burner’s thermal power;

- —current boiler/generating unit technical minimum, as % of the rated boiler/generating unit power;

- —assumed boiler/generating unit technical minimum achievable with plasma assistance, as % of the rated boiler/generating unit power;

- —required relative power of the plasma torch installed on the burner, as % of the burner’s thermal power.

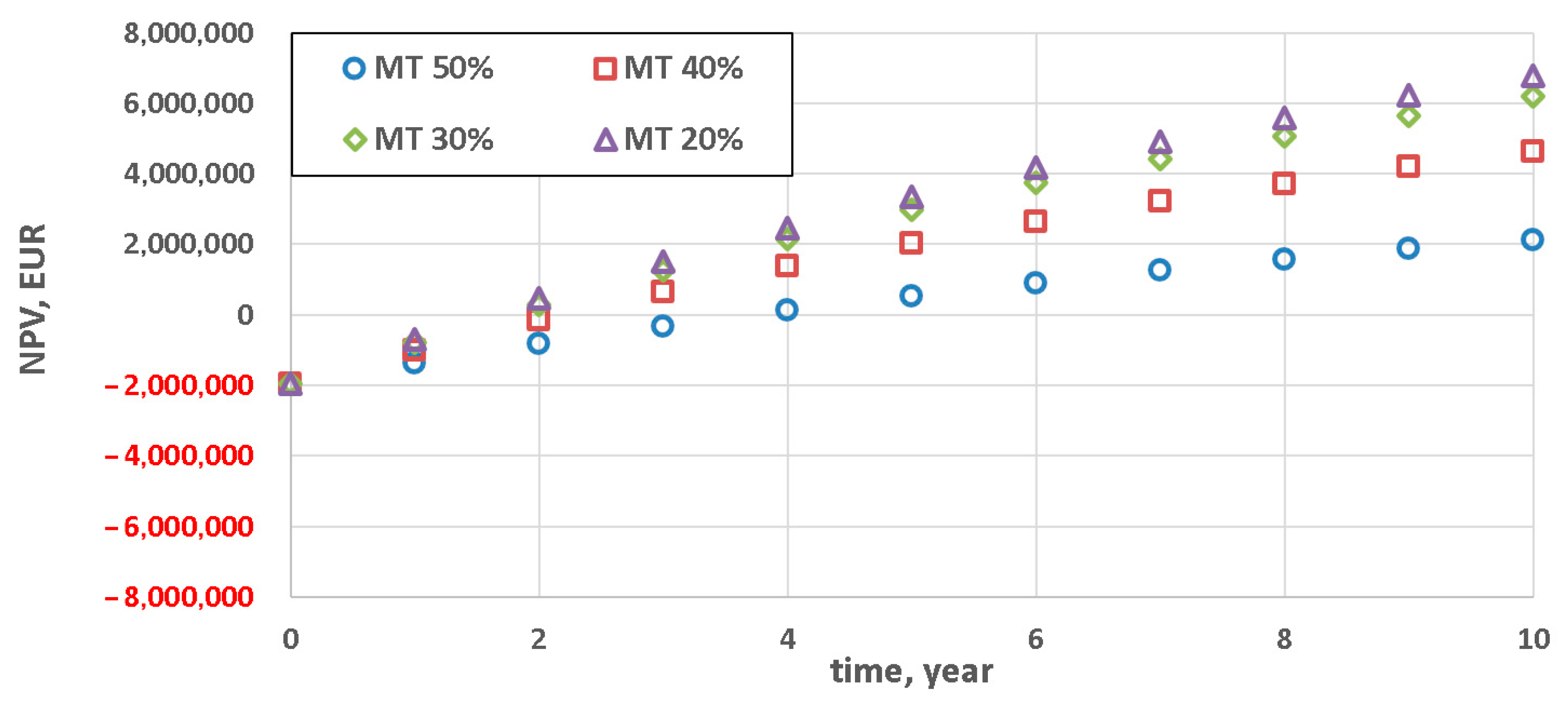

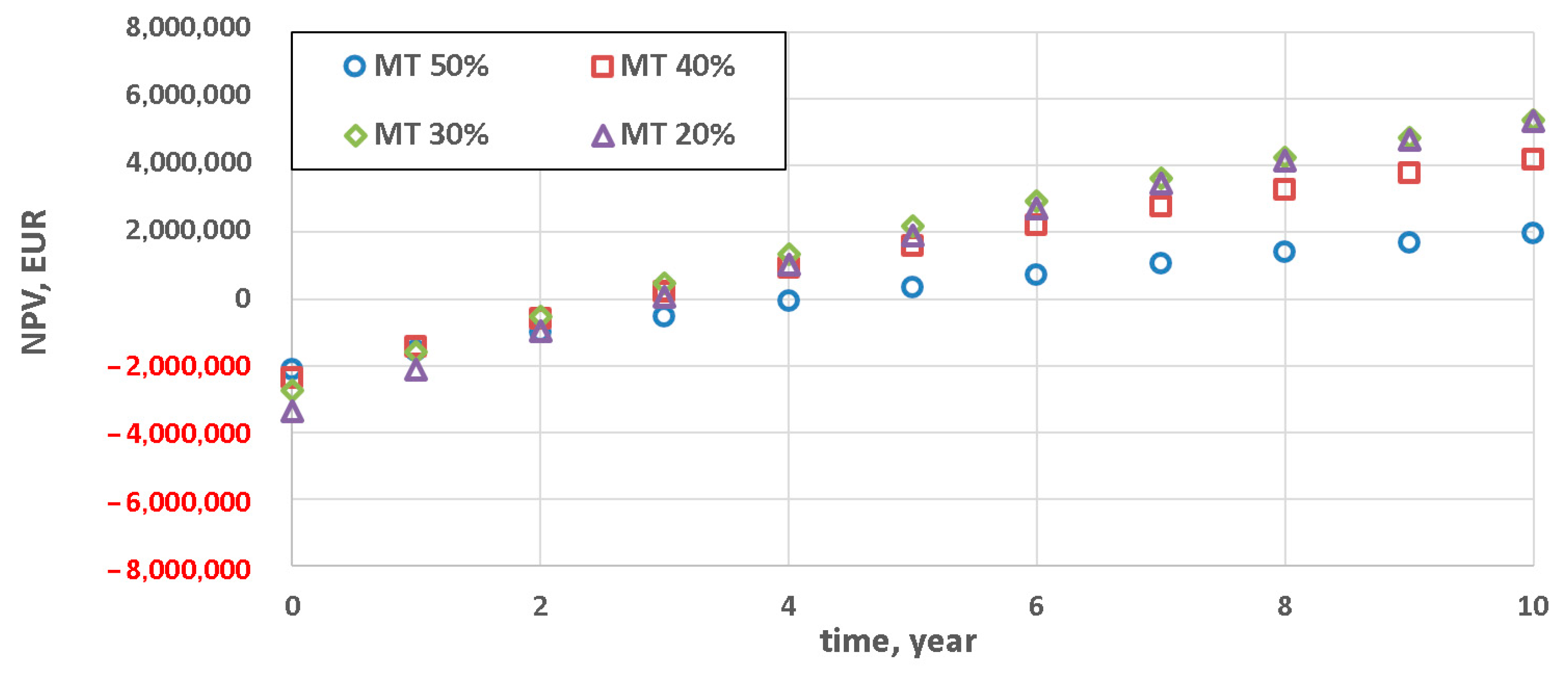

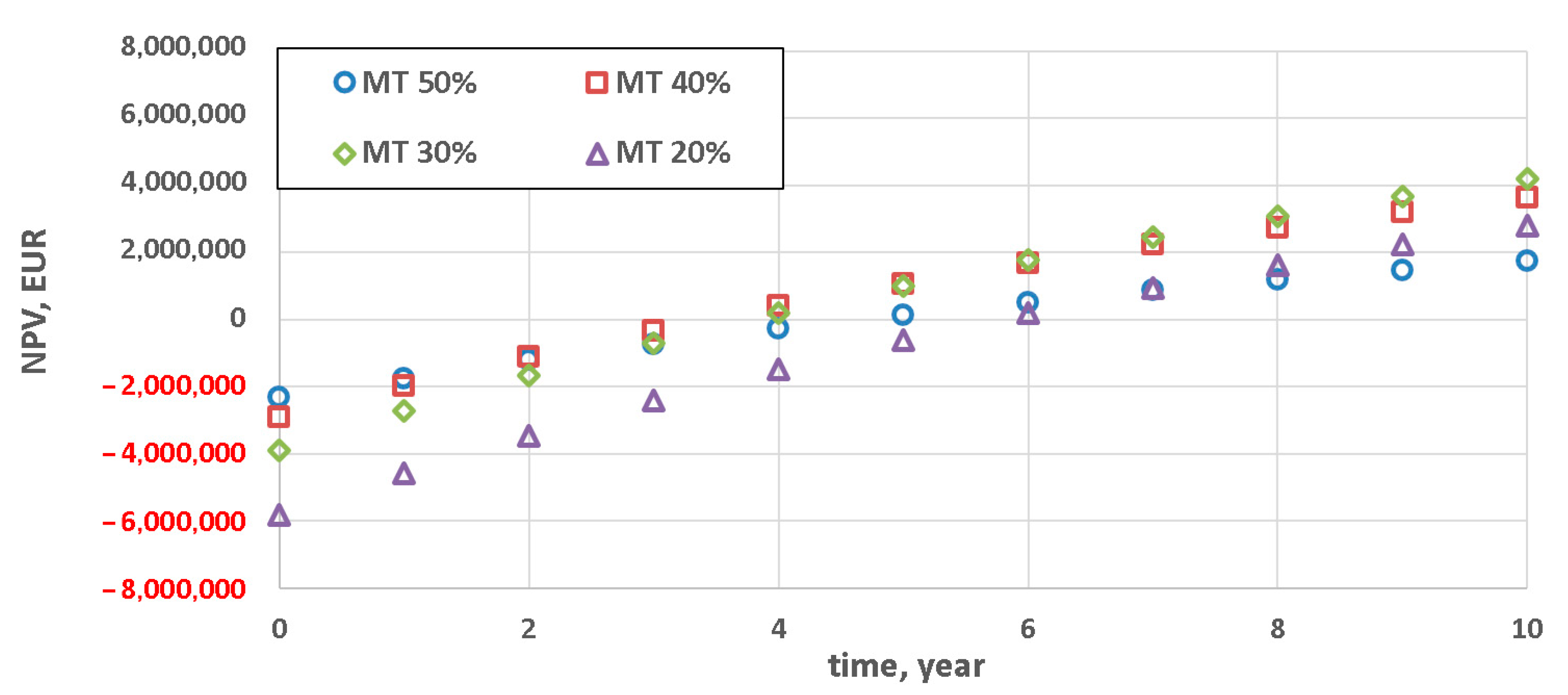

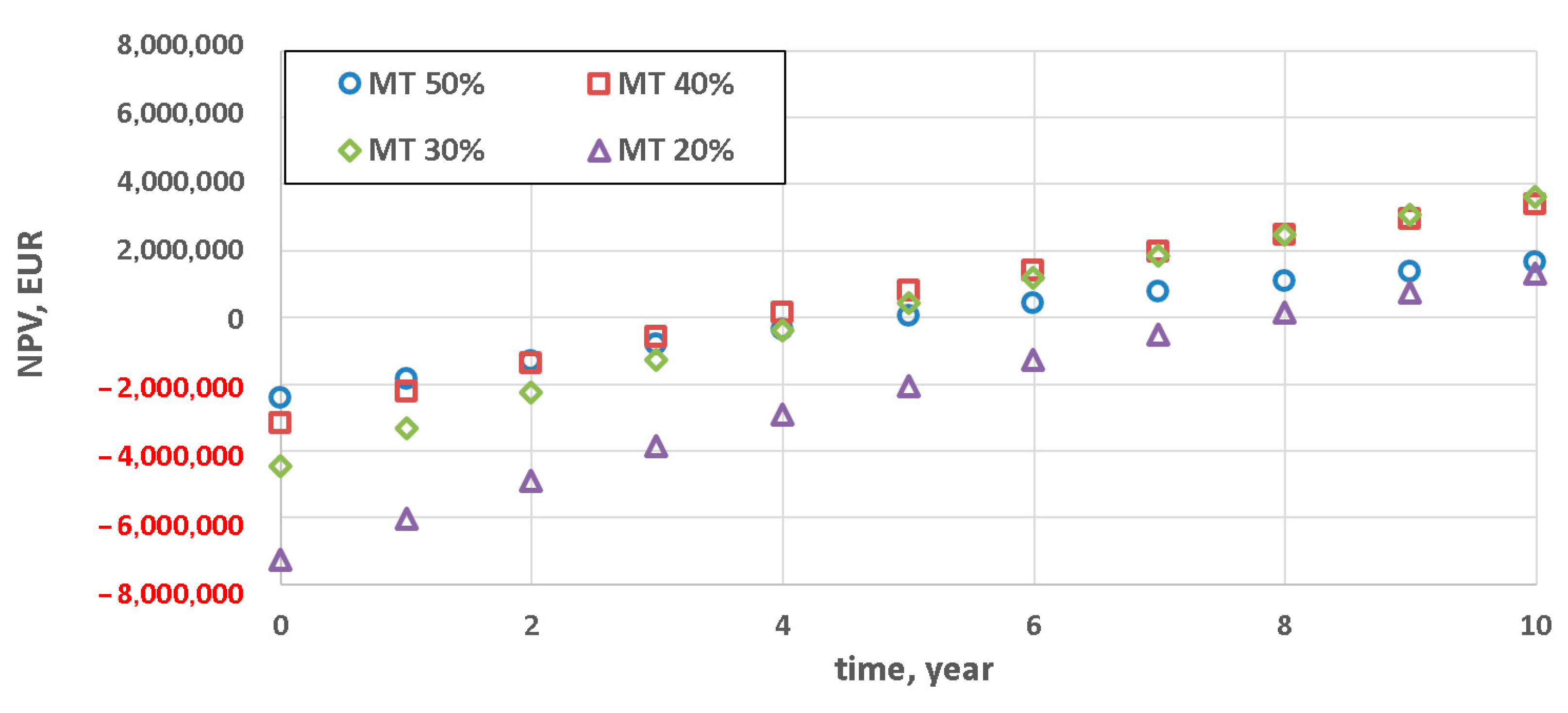

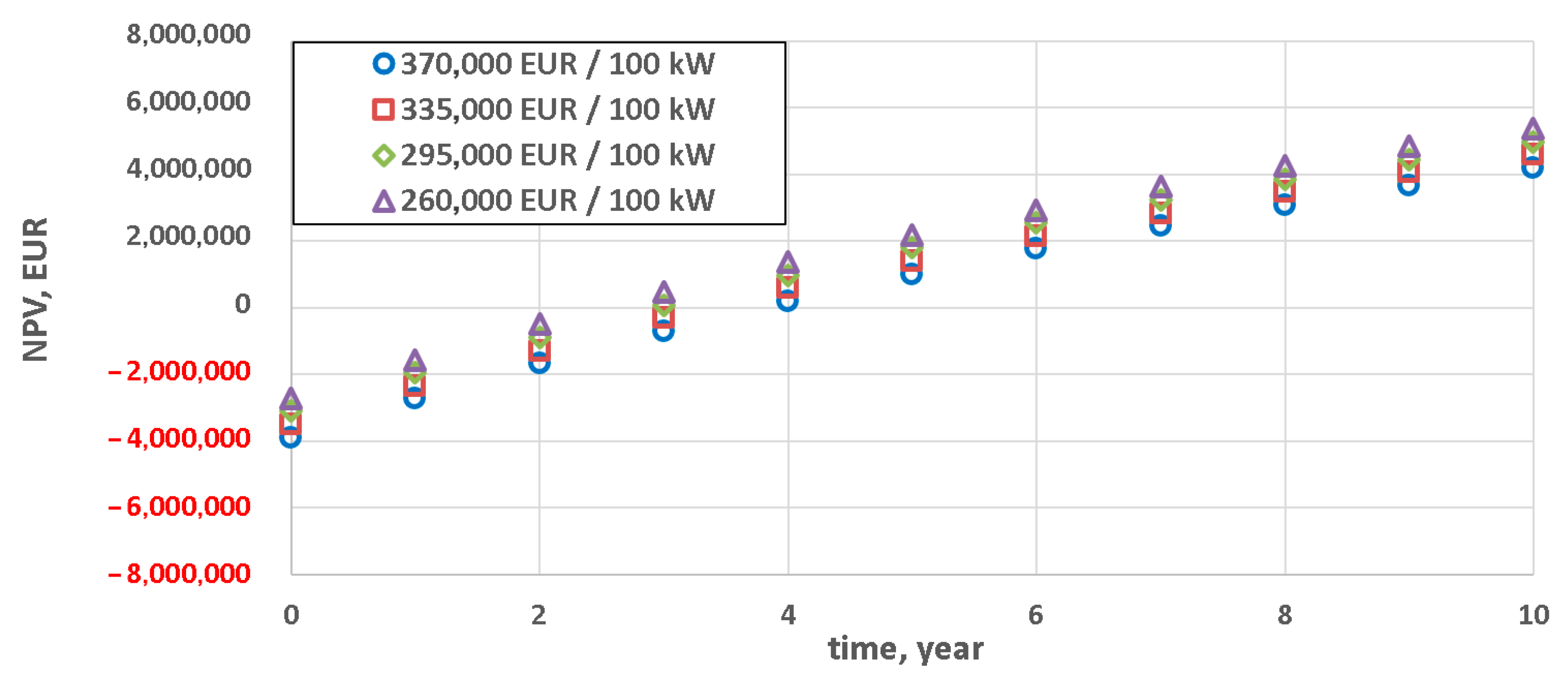

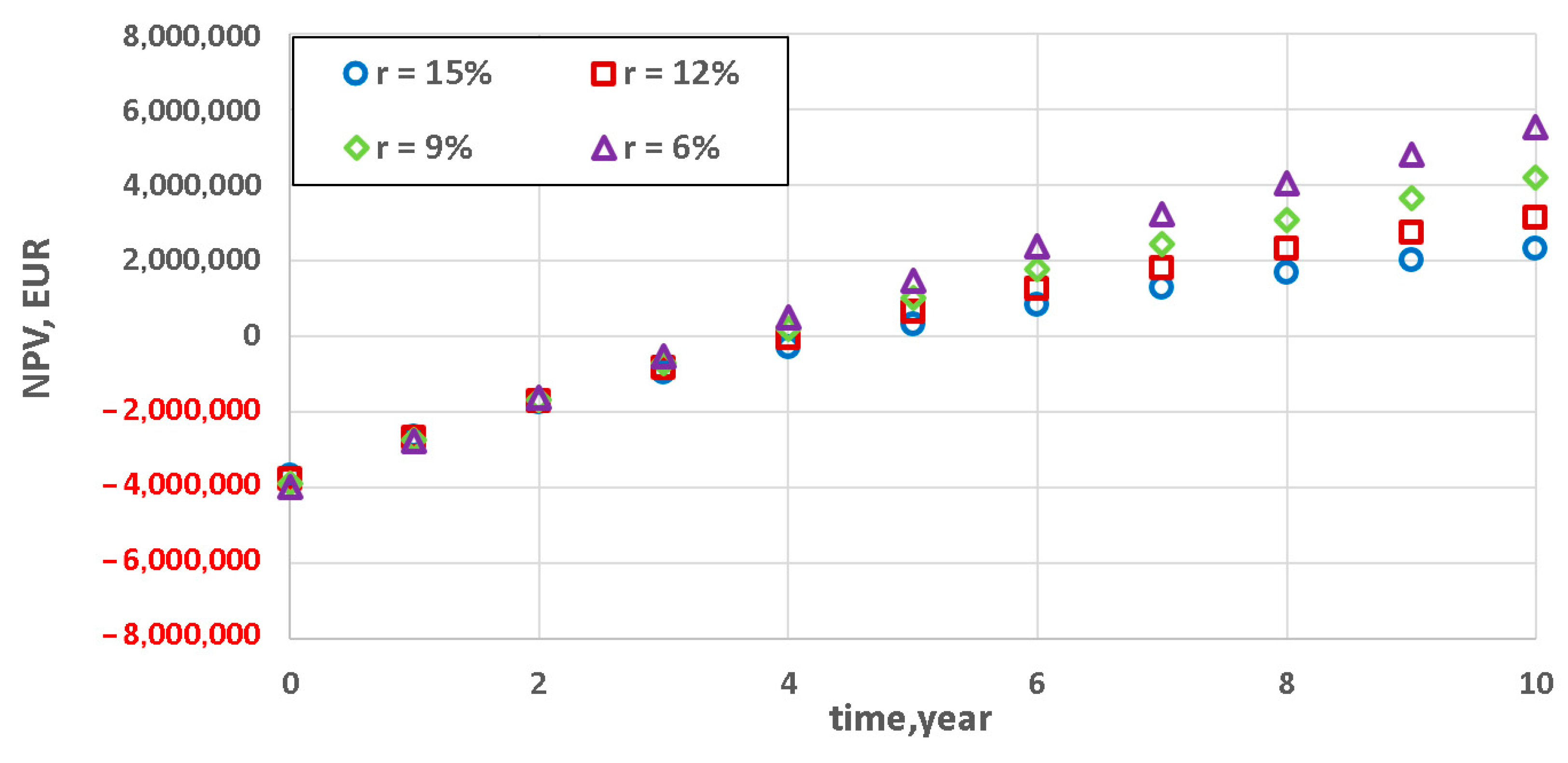

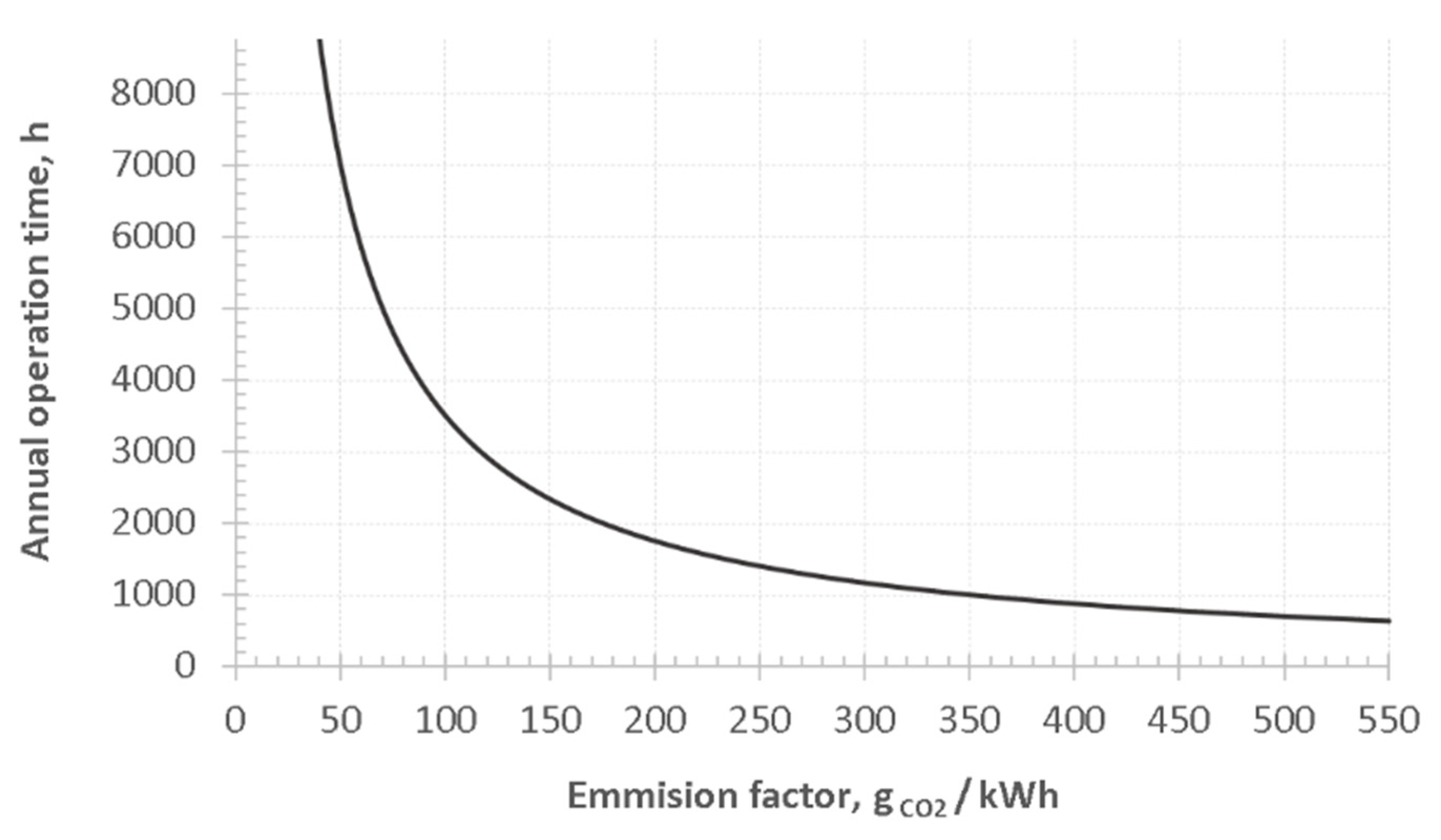

5. Results and Discussion

5.1. Results of Performed Analysis

5.2. Non-Technical Risks of Investment in Plasma-Assisted Combustion Solution and Risk Mitigation Strategies

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stanek, W.; Czarnowska, L.; Gazda, W.; Simla, T. Thermo-ecological cost of electricity from renewable energy sources. Renew. Energy 2018, 115, 87–96. [Google Scholar] [CrossRef]

- Gazda, W.; Stanek, W. Energy and environmental assessment of integrated biogas trigeneration and photovoltaic plant as more sustainable industrial system. Appl. Energy 2016, 169, 138–149. [Google Scholar] [CrossRef]

- Stanek, W.; Simla, T.; Gazda, W. Exergetic and thermo-ecological assessment of heat pump supported by electricity from renewable sources. Renew. Energy 2019, 131, 404–412. [Google Scholar] [CrossRef]

- Baum, Z.; Palatnik, R.R.; Ayalon, O.; Elmakis, D.; Frant, S. Harnessing households to mitigate renewables intermittency in the smart grid. Renew. Energy 2019, 132, 1216–1229. [Google Scholar] [CrossRef]

- Mesfun, S.; Sanchez, D.L.; Leduc, S.; Wetterlund, E.; Lundgren, J.; Biberacher, M.; Kraxner, F. Power-to-gas and power-to-liquid for managing renewable electricity intermittency in the Alpine Region. Renew. Energy 2017, 107, 361–372. [Google Scholar] [CrossRef]

- Tarroja, B.; Mueller, F.; Eichman, J.D.; Brouwer, J.; Samuelsen, S. Spatial and temporal analysis of electric wind generation intermittency and dynamics. Renew. Energy 2011, 36, 3424–3432. [Google Scholar] [CrossRef]

- Xia, S.; Chan, K.W.; Luo, X.; Bu, S.; Ding, Z.; Zhou, B. Optimal sizing of energy storage system and its cost-benefit analysis for power grid planning with intermittent wind generation. Renew. Energy 2018, 122, 472–486. [Google Scholar] [CrossRef]

- Jacobson, M.Z.; Delucchi, M.A.; Cameron, M.A.; Mathiesen, B.V. Matching demand with supply at low cost in 139 countries among 20 world regions with 100% intermittent wind, water, and sunlight (WWS) for all purposes. Renew. Energy 2018, 123, 236–248. [Google Scholar] [CrossRef]

- Fiedler, T. Simulation of a power system with large renewable penetration. Renew. Energy 2019, 130, 319–328. [Google Scholar] [CrossRef]

- Stein-Brzozowska, G.; Bergins, C. The Current Trends in Conventional Power Plant Technology on Two Continents from the Perspective of Engineering, Procurement, and Construction Contractor and Original Equipment Manufacturer. J. Energy Resour. Technol. 2016, 138. [Google Scholar] [CrossRef]

- Bakr, H.M.; Shaaban, M.F.; Osman, A.H.; Sindi, H.F. Optimal Allocation of Distributed Generation Considering Protection. Energies 2020, 13, 2402. [Google Scholar] [CrossRef]

- Installed Capacity of Units above 1 MW, Aggregated per Production Type—RTE Services Portal. Available online: https://www.services-rte.com/en/view-data-published-by-rte/production-installed-capacity.html (accessed on 31 August 2019).

- Installed Power|Energy Charts. Available online: https://www.energy-charts.de/power_inst.htm (accessed on 31 August 2019).

- Electricity Production|Energy Charts. Available online: https://energy-charts.de/power.htm (accessed on 31 August 2019).

- Simla, T.; Stanek, W. Reducing the impact of wind farms on the electric power system by the use of energy storage. Renew. Energy 2020, 145, 772–782. [Google Scholar] [CrossRef]

- Pawlak-Kruczek, H.; Niedźwiecki, Ł.; Ostrycharczyk, M.; Czerep, M.; Plutecki, Z. Potential and methods for increasing the flexibility and efficiency of the lignite fired power unit, using integrated lignite drying. Energy 2019, 181, 1142–1151. [Google Scholar] [CrossRef]

- Avagianos, I.; Atsonios, K.; Nikolopoulos, N.; Grammelis, P.; Polonidis, N.; Papapavlou, C.; Kakaras, E. Predictive method for low load off-design operation of a lignite fired power plant. Fuel 2017, 209, 685–693. [Google Scholar] [CrossRef]

- Ju, Y.; Sun, W. Plasma assisted combustion: Dynamics and chemistry. Prog. Energy Combust. Sci. 2015, 48, 21–83. [Google Scholar] [CrossRef]

- Wnukowski, M. Decomposition of tars in microwave plasma - preliminary results. J. Ecol. Eng. 2014, 15, 23–28. [Google Scholar] [CrossRef]

- Hwang, J.; Bae, C.; Park, J.; Choe, W.; Cha, J.; Woo, S. Microwave-assisted plasma ignition in a constant volume combustion chamber. Combust. Flame 2016, 167, 86–96. [Google Scholar] [CrossRef]

- Askari, O. Thermodynamic Properties of Pure and Mixed Thermal Plasmas Over a Wide Range of Temperature and Pressure. J. Energy Resour. Technol. Trans. ASME 2018, 140. [Google Scholar] [CrossRef]

- Taki, H.; Asai, H.; Kitagawa, K.; Oyama, H.; Gupta, A.K. Laser-induced plasma spectrometry with chemical seeding and application to flow mixing analysis in methane-air flames. J. Energy Resour. Technol. Trans. ASME 2015, 137. [Google Scholar] [CrossRef]

- Kim, K.; Askari, O. Understanding the Effect of Capacitive Discharge Ignition on Plasma Formation and Flame Propagation of Air-Propane Mixture. J. Energy Resour. Technol. Trans. ASME 2019, 141. [Google Scholar] [CrossRef]

- Jamróz, P.; Kordylewski, W.; Wnukowski, M. Microwave plasma application in decomposition and steam reforming of model tar compounds. Fuel Process. Technol. 2018, 169, 1–14. [Google Scholar] [CrossRef]

- Wnukowski, M.; Jamróz, P. Microwave plasma treatment of simulated biomass syngas: Interactions between the permanent syngas compounds and their influence on the model tar compound conversion. Fuel Process. Technol. 2018, 173, 229–242. [Google Scholar] [CrossRef]

- Fernandes, C.; Frías, P.; Reneses, J. Participation of intermittent renewable generators in balancing mechanisms: A closer look into the Spanish market design. Renew. Energy 2016, 89, 305–316. [Google Scholar] [CrossRef]

- Zigan, L. Overview of electric field applications in energy and process engineering. Energies 2018, 11, 1361. [Google Scholar] [CrossRef]

- Leonov, S. Electrically Driven Supersonic Combustion. Energies 2018, 11, 1733. [Google Scholar] [CrossRef]

- Tholin, F.; Lacoste, D.A.; Bourdon, A. Influence of fast-heating processes and O atom production by a nanosecond spark discharge on the ignition of a lean H2-air premixed flame. Combust. Flame 2014, 161, 1235–1246. [Google Scholar] [CrossRef]

- Zare, S.; Lo, H.W.; Askari, O. Flame Stability in Inverse Coaxial Injector using Repetitive Nanosecond Pulsed Plasma. J. Energy Resour. Technol. 2020, 142, 1–10. [Google Scholar] [CrossRef]

- Starikovskiy, A.; Aleksandrov, N. Plasma-assisted ignition and combustion. Prog. Energy Combust. Sci. 2013, 39, 61–110. [Google Scholar] [CrossRef]

- Lacoste, D.A.; Moeck, J.P.; Roberts, W.L.; Chung, S.H.; Cha, M.S. Analysis of the step responses of laminar premixed flames to forcing by non-thermal plasma. Proc. Combust. Inst. 2017, 36, 4145–4153. [Google Scholar] [CrossRef]

- Gray, J.A.T.; Lacoste, D.A. Enhancement of the transition to detonation of a turbulent hydrogen–air flame by nanosecond repetitively pulsed plasma discharges. Combust. Flame 2019, 199, 258–266. [Google Scholar] [CrossRef]

- Messerle, V.E.; Karpenko, E.I.; Ustimenko, A.B.; Lavrichshev, O.A. Plasma preparation of coal to combustion in power boilers. Fuel Process. Technol. 2013, 107, 93–98. [Google Scholar] [CrossRef]

- Kobel, P.; Kordylewski, W. Zastosowanie plazmotronu zasilanego powietrzem do stabilizacji płomienia pyłowego. Arch. Spal. 2008, 8, 55–62. [Google Scholar]

- Bukowski, P.; Kobel, P.; Kordylewski, W.; Mączka, T. Use of cavity plasmatron in pulverized coal muffle burner for start-up of a boiler. Rynek Energii 2010, 86, 132–136. [Google Scholar] [CrossRef]

- Kobel, P. Systemy wykorzystujące plazmę jako alternatywna metoda rozruchu kotłów pyłowych. In Interdyscyplinarność Badań Naukowych; Szrek, J., Ed.; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Poland, 2010; ISBN 9788374935203. [Google Scholar]

- Pawlak-Kruczek, H.; Niedźwiecki, Ł. Stabilnie w zmiennych warunkach. Problem stabilności kotłów energetycznych w warunkach zmiennych obciążeń. Nowe wyzwania—wzrost mocy zainstalowanej w niesterowalnych OZE. Energetyka Cieplna i Zawodowa 2017, 6, 46–52. Available online: http://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-1e49d8ec-94a5-4e67-bf6c-29b68784af4a (accessed on 31 August 2019).

- Messerle, V.E.; Askarova, A.S.; Bolegenova, S.A.; Yu Maximov, V.; Nugymanova, A.O. 3D-modelling of Kazakhstan low-grade coal burning in power boilers of thermal power plant with application of plasma gasification and stabilisation technologies. J. Phys. Conf. Ser. 2019, 1261. [Google Scholar] [CrossRef]

- Karpenko, E.I.; Messerle, V.E.; Ustimenko, A.B. Plasma-aided solid fuel combustion. Proc. Combust. Inst. 2007, 31, 3353–3360. [Google Scholar] [CrossRef]

- Messerle, V.E.; Karpenko, E.I.; Ustimenko, A.B. Plasma assisted power coal combustion in the furnace of utility boiler: Numerical modeling and full-scale test. Fuel 2014, 126, 294–300. [Google Scholar] [CrossRef]

- Ke, Z.; Lin, L.; Schröder, H.; Guoqing, F. Plasma ignition system for oil free power plant Zetes in Turkey and its advantages fort the changed circumstance of energy market. VGB PowerTech. 2017, 7, 77–81. [Google Scholar]

- Kobel, P.; Mączka, T. Plasma-assisted kindling of pulverized coal fired boilers. In XXI International Symposium on Combustion Processes; Wydawnictwo Uczelniane Zachodniopomorskiego Uniwersytetu Technologicznego: Międzyzdroje, Poland, 2010; pp. 33–34. [Google Scholar]

- Kobel, P.; Kordylewski, W.; Mączka, T.; Kordas, R.; Milewicz, R.; Modrzejewski, M. Zastosowanie plazmotronu wnękowego w muflonowym palniku pyłowym do rozruchu kotła energetycznego. In Aktualne Problemy Budowy i Eksploatacji Kotłów: Jubileuszowa Konferencja Kotłowa 2009 z Okazji 60-lecia Fabryki Kotłów RAFAKO SA; Instytut Maszyn i Urządzeń Energetycznych—Politechnika Śląska: Szczyrk, Poland, 2009; pp. 33–46. [Google Scholar]

- Kordylewski, W.; Kobel, P.; Mączka, T.; Kordas, R. Eliminacja zakłóceń elektromagnetycznych podczas plazmowego rozruchu kotłów. In Systemy, Technologie i Urządzenia Energetyczne: Praca Zbiorowa. T. 1; Wydawnictwo Politechniki Krakowskiej: Kraków, Poland, 2010; pp. 235–244. [Google Scholar]

- Kordylewski, W.; Mączka, T.; Kordas, R. Urządzenia rozruchowe plazmotronu dużej mocy. Przegląd Elektrotech. 2009, 85, 116–119. [Google Scholar]

- Kordylewski, W.; Kobel, P.; Mączka, T.; Bukowski, P. Plazmowy rozruch i stabilizacja spalania w kotłach pyłowych. In XII Międzynarodowa Konferencja Naukowo-Techniczna: Forum Energetyków GRE; Oficyna Wydawnicza Politechniki Opolskiej: Szczyrk, Poland, 2010. [Google Scholar]

- Maczka, T. Technologia Plazmowego Zgazowania Biomasy i Odpadów Organicznych dla Wytwarzania Paliw Płynnych; Wydawnictwo Książkowe Instytutu Elektrotechniki: Warszawa, Poland, 2014; ISBN 978-83-61956-32-7. [Google Scholar]

- Coibion, A.; Pickett, J.; Capacity mechanisms. Reigniting Europe’s energy markets. Linklaters. 2014. Available online: https://www.linklaters.com/pdfs/mkt/london/6883_LIN_Capacity_Markets_Global_Web_Single_Final_1.pdf (accessed on 31 August 2019).

- Komar, D. Rynek mocy na każdy mix elektroenergetyczny. Energetyka Cieplna i Zawodowa 2017, 5, 158–160. Available online: http://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-73c20c67-9fdb-48d7-8690-45d1493f01a4 (accessed on 31 August 2019).

- UK Office of Gas and Electricity Markets (OFGEM). Consolidated Version of the Capacity Market Rules. 2018. Available online: https://www.ofgem.gov.uk/system/files/docs/2018/07/consolidated_capacity_market_rules.pdf (accessed on 31 August 2019).

- Benalcazar, P.; Nalepka, P. The Polish capacity market proposal vs. the British model. Polityka Energ. Energy Policy J. 2017, 20, 59–72. [Google Scholar]

- UK Department of Energy and Climate Change. Provisional Auction Results: T-4Capacity Market Auction. 2018. Available online: https://www.emrdeliverybody.com/Capacity%20Markets%20Document%20Library/Provisional%20T-4%20Results%20DY%202021-22.pdf (accessed on 31 August 2019).

- Sören, A. Kerstine Appunn Germany’s New Power Market Design|Clean Energy Wire. Available online: https://www.cleanenergywire.org/factsheets/germanys-new-power-market-design (accessed on 9 September 2018).

- Forsström, J.; Koreneff, G.; Similä, L. Electricity Market Designs and Flexibility; Research Report VTT-R-04621-1; VTT Technical Research Centre of Finland Ltd.: Espoo, Finland, 2016. [Google Scholar]

- Nordic Council of Ministers. Demand Side Flexibility in the Nordic Electricity Market; Nordic Council of Ministers Publication Unit: Copenhagen, Denmark, 2017. [Google Scholar]

- Oluleye, G.; Allison, J.; Hawker, G.; Kelly, N.; Hawkes, A.D. A two-step optimisation model for quantifying the flexibility potential of power-to-heat systems in dwellings. Appl. Energy 2018, 228, 215–228. [Google Scholar] [CrossRef]

- Oualmakran, Y.; Espeche, J.M.; Sisinni, M.; Messervey, T.; Lennard, Z. Residential Electricity Tariffs in Europe: Current Situation, Evolution and Impact on Residential Flexibility Markets. Proceedings 2017, 1, 1104. [Google Scholar] [CrossRef]

- Olivella-Rosell, P.; Lloret-Gallego, P.; Munné-Collado, Í.; Villafafila-Robles, R.; Sumper, A.; Ottessen, S.Ø.; Rajasekharan, J.; Bremdal, B.A. Local flexibility market design for aggregators providing multiple flexibility services at distribution network level. Energies 2018, 11, 822. [Google Scholar] [CrossRef]

- Chojnacki, I. Na 2021 Rok w Rynku Mocy Zakontraktowane Ponad 22 tys. MW—Energetyka. Available online: https://energetyka.wnp.pl/na-2021-rok-w-rynku-mocy-zakontraktowane-ponad-22-tys-mw,335173_1_0_0.html (accessed on 1 December 2018).

- Caprabianca, M.; Falvo, M.C.; Papi, L.; Promutico, L.; Rossetti, V.; Quaglia, F. Replacement Reserve for the Italian Power System and Electricity Market. Energies 2020, 13, 2916. [Google Scholar] [CrossRef]

- Skorek, J.; Kalina, J. Gazowe Układy Kogeneracyjne; Wydawnictwo Naukowo-Techniczne WNT: Warsaw, Poland, 2005; ISBN 83-204-3103-4. [Google Scholar]

- Nikolopoulos, N.; Agraniotis, M.; Violidakis, I.; Karampinis, E.; Nikolopoulos, A.; Grammelis, P.; Papapavlou, C.; Tzivenis, S.; Kakaras, E. Parametric investigation of a renewable alternative for utilities adopting the co-firing lignite/biomass concept. Fuel 2013, 113, 873–897. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Margaritis, N.K.; Grammelis, P. Experimental and economic study of a gasification plant fuelled with olive industry wastes. Energy Sustain. Dev. 2014, 23, 247–257. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, J.; Meng, F.; Zoras, S.; McKechnie, J.; Chu, J. Energy assessment and economic sensitivity analysis of a grid-connected photovoltaic system. Renew. Energy 2020, 150, 101–115. [Google Scholar] [CrossRef]

- Zografidou, E.; Petridis, K.; Petridis, N.E.; Arabatzis, G. A financial approach to renewable energy production in Greece using goal programming. Renew. Energy 2017, 108, 37–51. [Google Scholar] [CrossRef]

- Heine, K.; Thatte, A.; Tabares-Velasco, P.C. A simulation approach to sizing batteries for integration with net-zero energy residential buildings. Renew. Energy 2019, 139, 176–185. [Google Scholar] [CrossRef]

- European Commission. Energy Prices and Costs in Europe; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Parliament and Council. Regulation (EU) 2019/943 of 5 June 2019 on the Internal Market for Electricity; European Parliament and Council: Brussels, Belgium, 2019; Volume 158, pp. 54–124. [Google Scholar]

- Li, J.; Brzdekiewicz, A.; Yang, W.; Blasiak, W. Co-firing based on biomass torrefaction in a pulverised coal boiler with aim of 100% fuel switching. Appl. Energy 2012, 99, 344–354. [Google Scholar] [CrossRef]

- European Union Agency for Cooperation of Energy Regulators. Opinion No 22/2019 of European Union Agency for Cooperation of Energy Regulators of 17 December 2019 on the Calculation of the Values of CO2 Emission Limits Referred to in the First Subparagraph of Article 22(4) of Regulation (EU) 2019/943 of 5 June 2019; European Parliament and Council: Brussels, Belgium, 2019. [Google Scholar]

- European Parliament and Council. Directive (EU) 2018/2001 of the European Parliament and of the Council on the Promotion of the Use of Energy from Renewable Sources; European Parliament and Council: Brussels, Belgium, 2018; Volume 328, pp. 82–209. [Google Scholar]

- Moscicki, K.J.; Niedzwiecki, L.; Owczarek, P.; Wnukowski, M. Commoditization of biomass: Dry torrefaction and pelletisation-a review. J. Power Technol. 2014, 94, 233–249. [Google Scholar]

- Nunes, L.J.R.; Matias, J.C.O.; Catalao, J.P.S. A review on torrefied biomass pellets as a sustainable alternative to coal in power generation. Renew. Sustain. Energy Rev. 2014, 40, 153–160. [Google Scholar] [CrossRef]

- Hasan, M.; Haseli, Y. An Oxyfuel Combustion-Based Torrefaction Process: Technoeconomic Analysis. J. Energy Resour. Technol. 2020, 142. [Google Scholar] [CrossRef]

- Jagodzińska, K.; Czerep, M.; Kudlek, E.; Wnukowski, M.; Pronobis, M.; Yang, W. Torrefaction of Agricultural Residues: Effect of Temperature and Residence Time on the Process Products Properties. J. Energy Resour. Technol. 2020, 142, 1–8. [Google Scholar] [CrossRef]

- Sun, M.; Yang, Y.; Zhang, M. A Temperature Model for Synchronized Ultrasonic Torrefaction and Pelleting of Biomass for Bioenergy Production. J. Energy Resour. Technol. 2019, 141, 102205. [Google Scholar] [CrossRef]

- Rokni, E.; Liu, Y.; Ren, X.; Levendis, Y.A. Nitrogen-Bearing Emissions from Burning Corn Straw in a Fixed-Bed Reactor: Effects of Fuel Moisture, Torrefaction, and Air Flowrate. J. Energy Resour. Technol. 2019, 141, 082202. [Google Scholar] [CrossRef]

- Akinyemi, O.S.; Jiang, L.; Buchireddy, P.R.; Barskov, S.O.; Guillory, J.L.; Holmes, W. Investigation of Effect of Biomass Torrefaction Temperature on Volatile Energy Recovery Through Combustion. J. Energy Resour. Technol. 2018, 140. [Google Scholar] [CrossRef]

- Khalsa, J.H.A.; Leistner, D.; Weller, N.; Darvell, L.I.; Dooley, B. Torrefied biomass pellets—Comparing grindability in different laboratory mills. Energies 2016, 9, 794. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.J.; Oh, K.C.; Cho, L.H.; Kim, M.J.; Jeong, I.S.; Lee, C.G.; Kim, D.H. Characteristic analysis of torrefied pellets: Determining optimal torrefaction conditions for agri-byproduct. Energies 2020, 13, 423. [Google Scholar] [CrossRef]

- Bajcar, M.; Zaguła, G.; Saletnik, B.; Tarapatskyy, M.; Puchalski, C. Relationship between torrefaction parameters and physicochemical properties of torrefied products obtained from selected plant biomass. Energies 2018, 11, 2919. [Google Scholar] [CrossRef]

- Dyjakon, A.; Noszczyk, T.; Smȩdzik, M. The influence of torrefaction temperature on hydrophobic properties of waste biomass from food processing. Energies 2019, 12, 4609. [Google Scholar] [CrossRef]

- Boylan, D.M.; Roberts, G.K.; Zemo, B.R.; Wilson, J.L. Torrefied Wood Field Tests at a Coal-Fired Power Plant. IEEE Trans. Ind. Appl. 2016, 52, 751–757. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Pawlak-Kruczek, H.; Yang, W.; Kruczek, P.; Blasiak, W. Process simulation of co-firing torrefied biomass in a 220 MWe coal-fired power plant. Energy Convers. Manag. 2014, 84, 503–511. [Google Scholar] [CrossRef]

- Batidzirai, B.; Mignot, A.P.R.; Schakel, W.B.; Junginger, H.M.; Faaij, A.P.C. Biomass torrefaction technology: Techno-economic status and future prospects. Energy 2013, 62, 196–214. [Google Scholar] [CrossRef]

- Thran, D.; Witt, J.; Schaubach, K.; Kiel, J.; Carbo, M.; Maier, J.; Ndibe, C.; Koppejan, J.; Alakangas, E.; Majer, S.; et al. Moving torrefaction towards market introduction—Technical improvements and economic-environmental assessment along the overall torrefaction supply chain through the SECTOR project. Biomass Bioenergy 2015, 89, 184–200. [Google Scholar] [CrossRef]

- Huéscar Medina, C.; Maccoitir, B.; Sattar, H.; Slatter, D.J.F.; Phylaktou, H.N.; Andrews, G.E.; Gibbs, B.M. Comparison of the explosion characteristics and flame speeds of pulverised coals and biomass in the ISO standard 1 m3 dust explosion equipment. Fuel 2015, 151, 91–101. [Google Scholar] [CrossRef]

- Huéscar Medina, C.; Sattar, H.; Phylaktou, H.N.; Andrews, G.E.; Gibbs, B.M. Explosion reactivity characterisation of pulverised torrefied spruce wood. J. Loss Prev. Process Ind. 2015, 36, 287–295. [Google Scholar] [CrossRef]

| Category | Cost, EUR |

|---|---|

| Power supply (incl. wires) | 99,100.00 |

| Plasma source (100 kW) | 15,000.00 |

| Control system | 12,000.00 |

| Torch cooling system | 18,000.00 |

| Air supply system | 5500.00 |

| Labor cost | 135,000.00 |

| Overheads | 85,380.00 |

| Total | 369,980.00 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mączka, T.; Pawlak-Kruczek, H.; Niedzwiecki, L.; Ziaja, E.; Chorążyczewski, A. Plasma Assisted Combustion as a Cost-Effective Way for Balancing of Intermittent Sources: Techno-Economic Assessment for 200 MWel Power Unit. Energies 2020, 13, 5056. https://doi.org/10.3390/en13195056

Mączka T, Pawlak-Kruczek H, Niedzwiecki L, Ziaja E, Chorążyczewski A. Plasma Assisted Combustion as a Cost-Effective Way for Balancing of Intermittent Sources: Techno-Economic Assessment for 200 MWel Power Unit. Energies. 2020; 13(19):5056. https://doi.org/10.3390/en13195056

Chicago/Turabian StyleMączka, Tadeusz, Halina Pawlak-Kruczek, Lukasz Niedzwiecki, Edward Ziaja, and Artur Chorążyczewski. 2020. "Plasma Assisted Combustion as a Cost-Effective Way for Balancing of Intermittent Sources: Techno-Economic Assessment for 200 MWel Power Unit" Energies 13, no. 19: 5056. https://doi.org/10.3390/en13195056

APA StyleMączka, T., Pawlak-Kruczek, H., Niedzwiecki, L., Ziaja, E., & Chorążyczewski, A. (2020). Plasma Assisted Combustion as a Cost-Effective Way for Balancing of Intermittent Sources: Techno-Economic Assessment for 200 MWel Power Unit. Energies, 13(19), 5056. https://doi.org/10.3390/en13195056