Switching Frequency Determination of SiC-Inverter for High Efficiency Propulsion System of Railway Vehicle

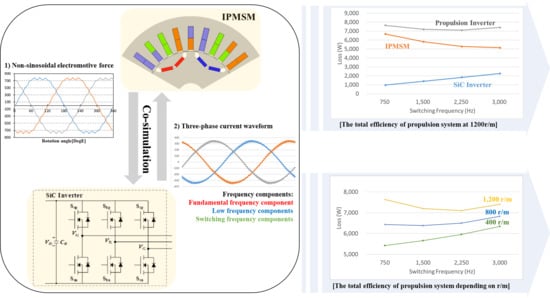

Abstract

1. Introduction

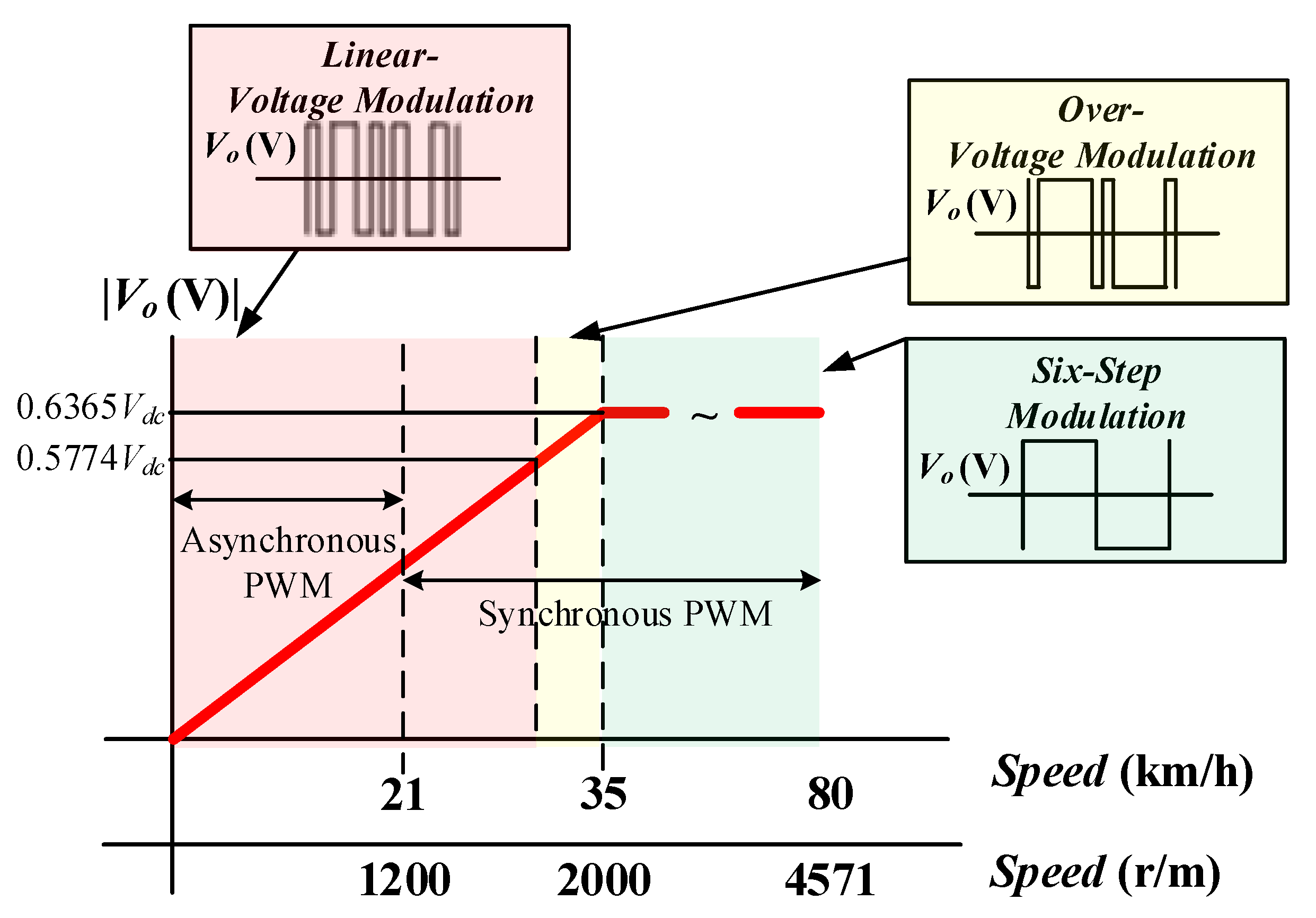

2. PWM Strategy for SiC Inverter

3. Permanent Magnet Synchronous Motor Control

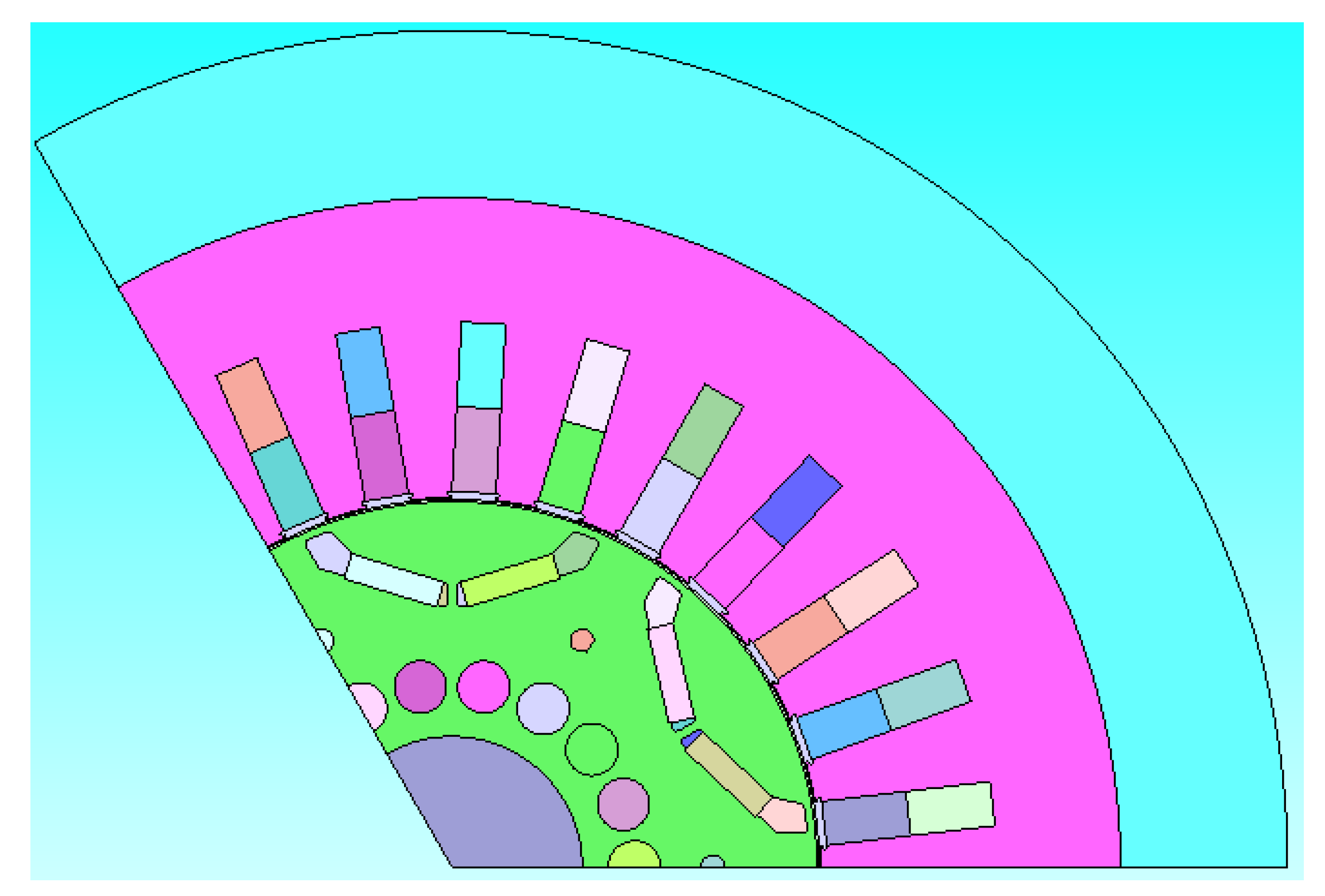

3.1. Permanent Magnet Synchronout Motor

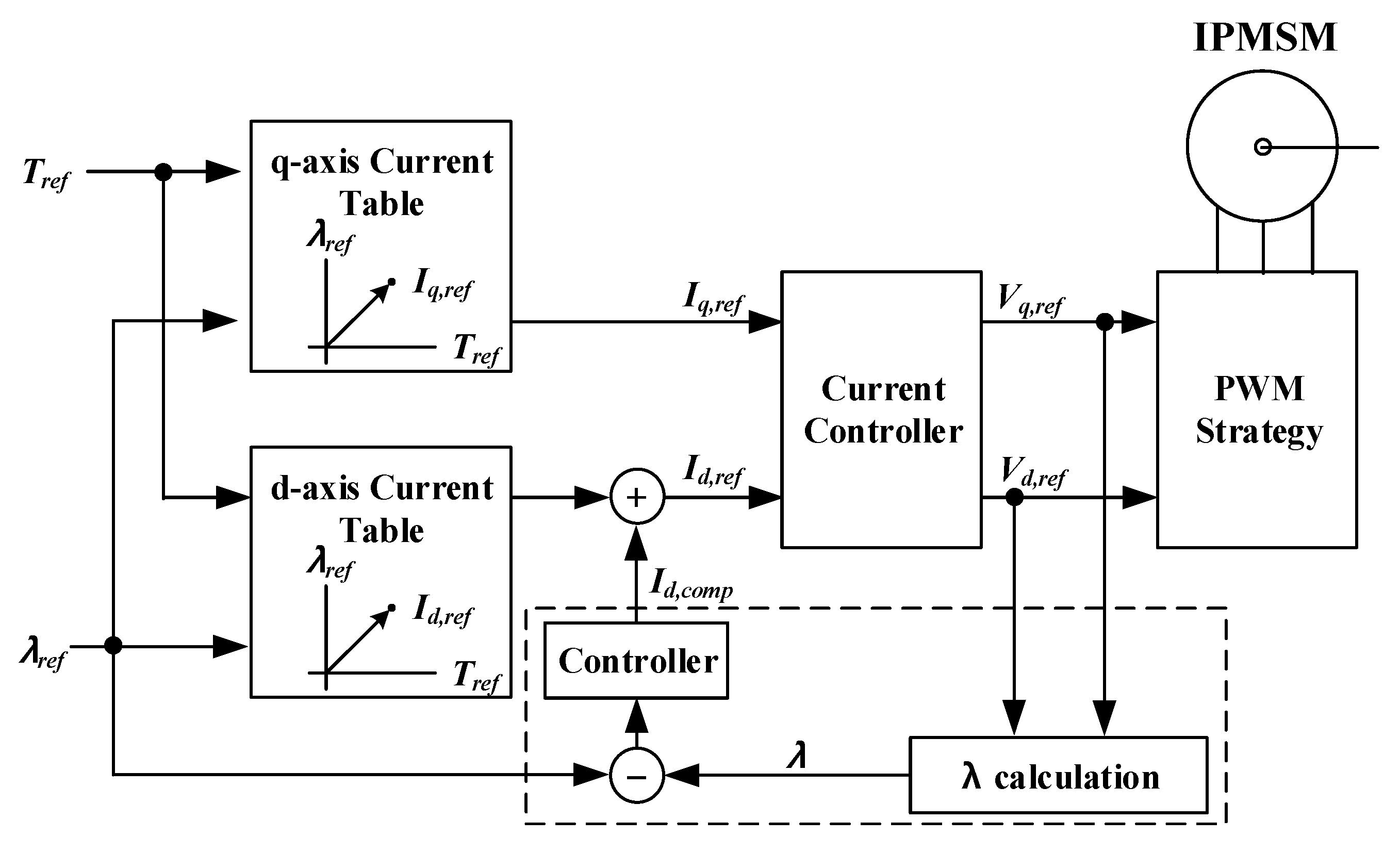

3.2. Control Method

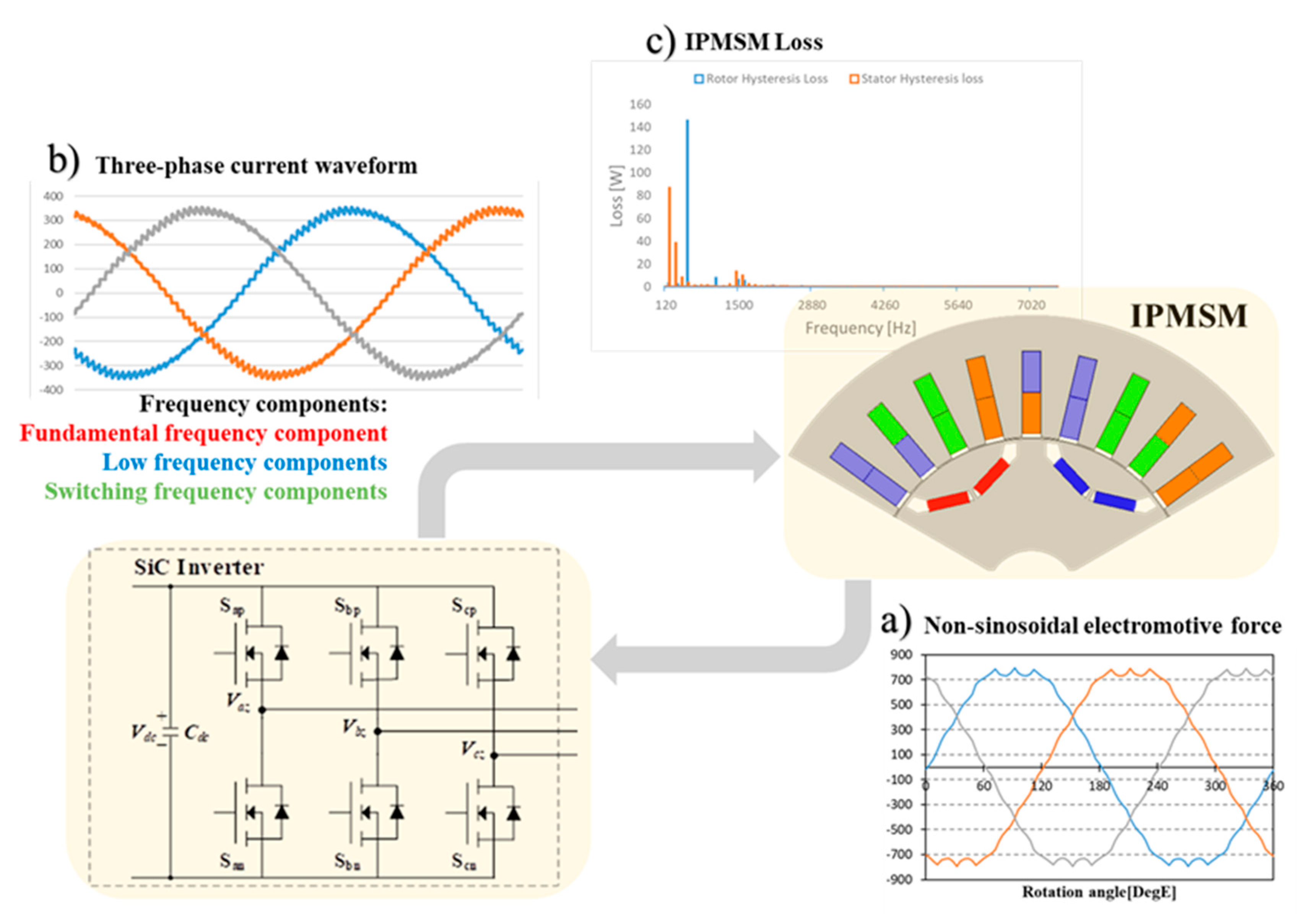

4. Loss Analysis of Propulsion System

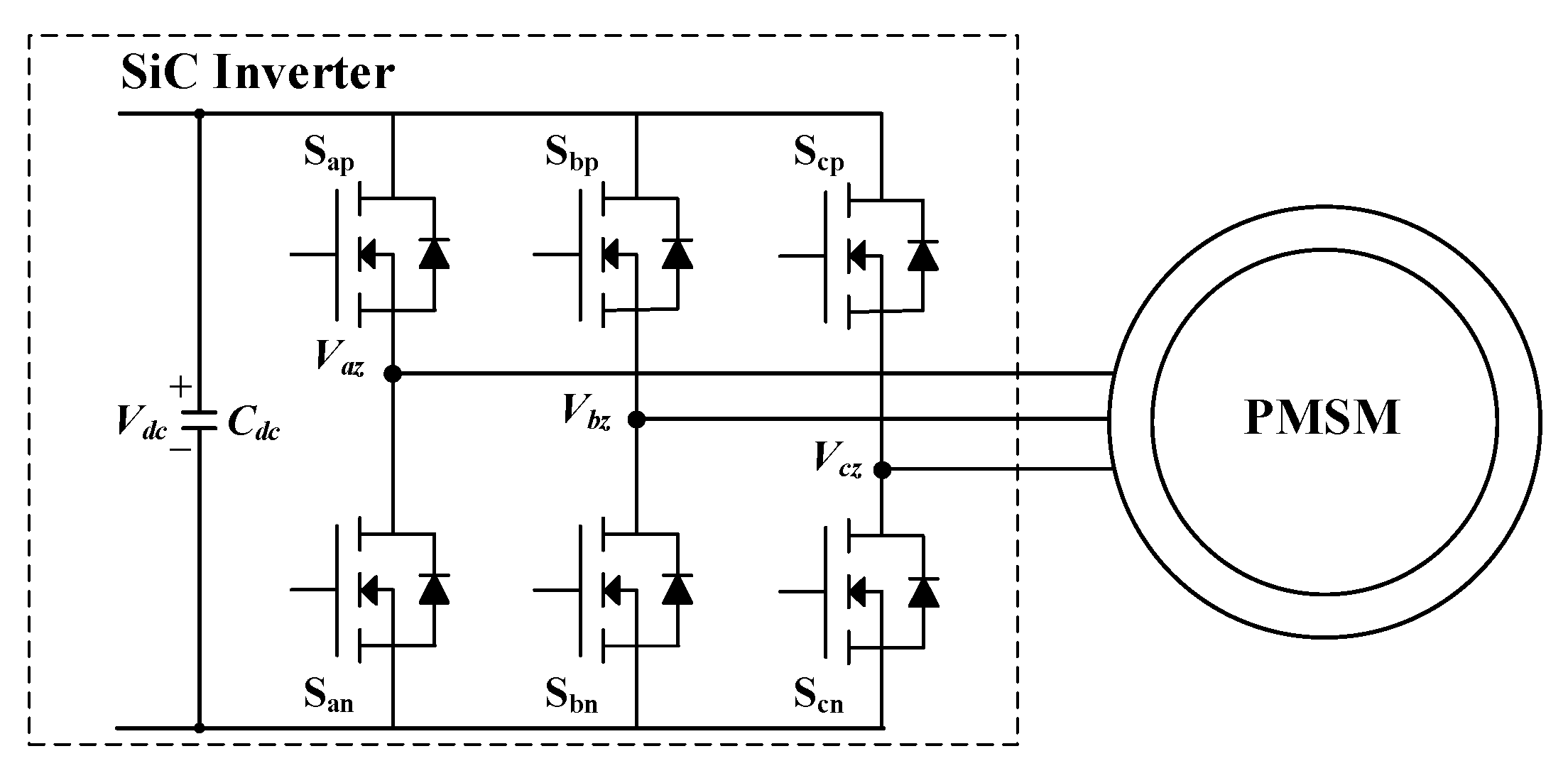

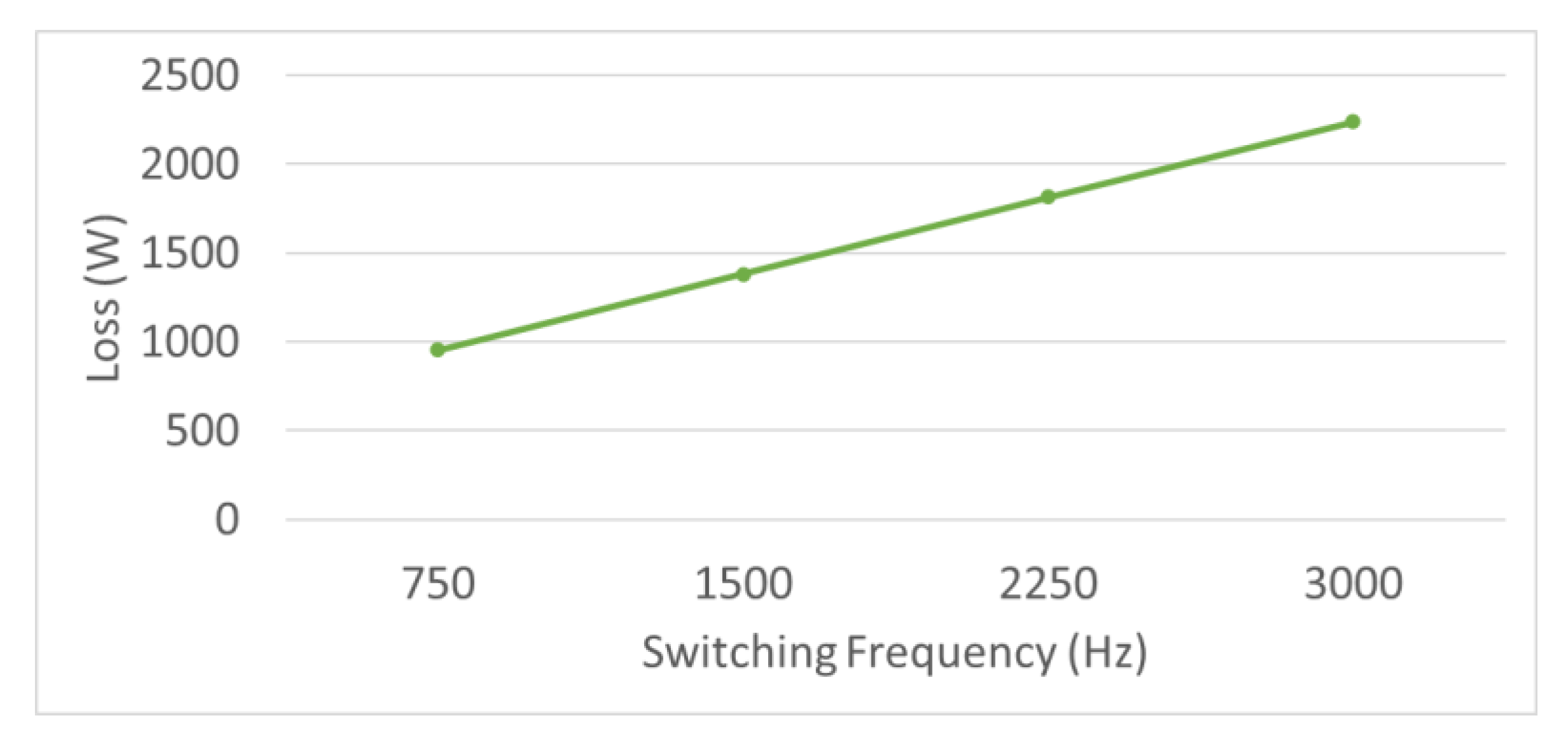

4.1. SiC Inverter

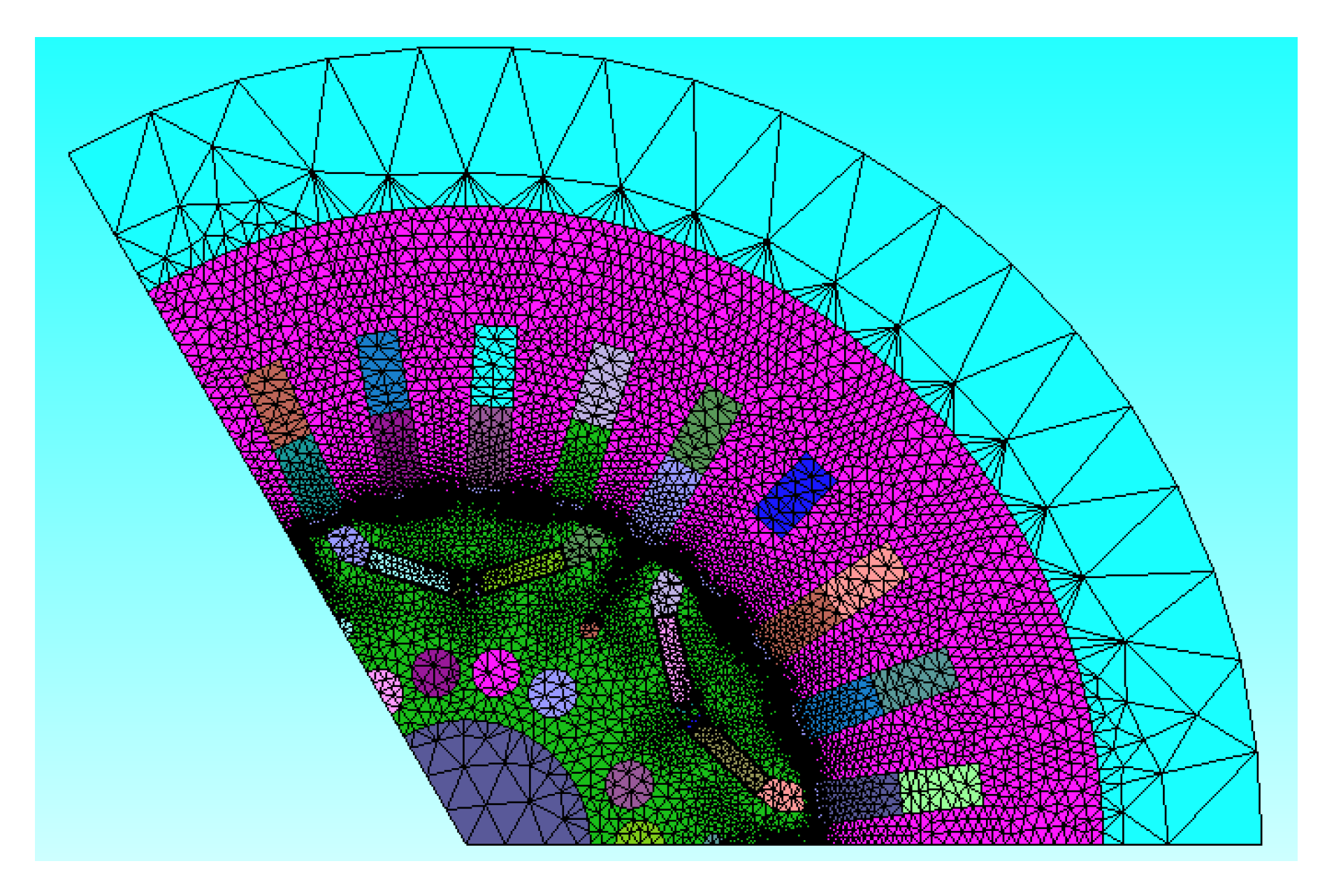

4.2. IPMSM

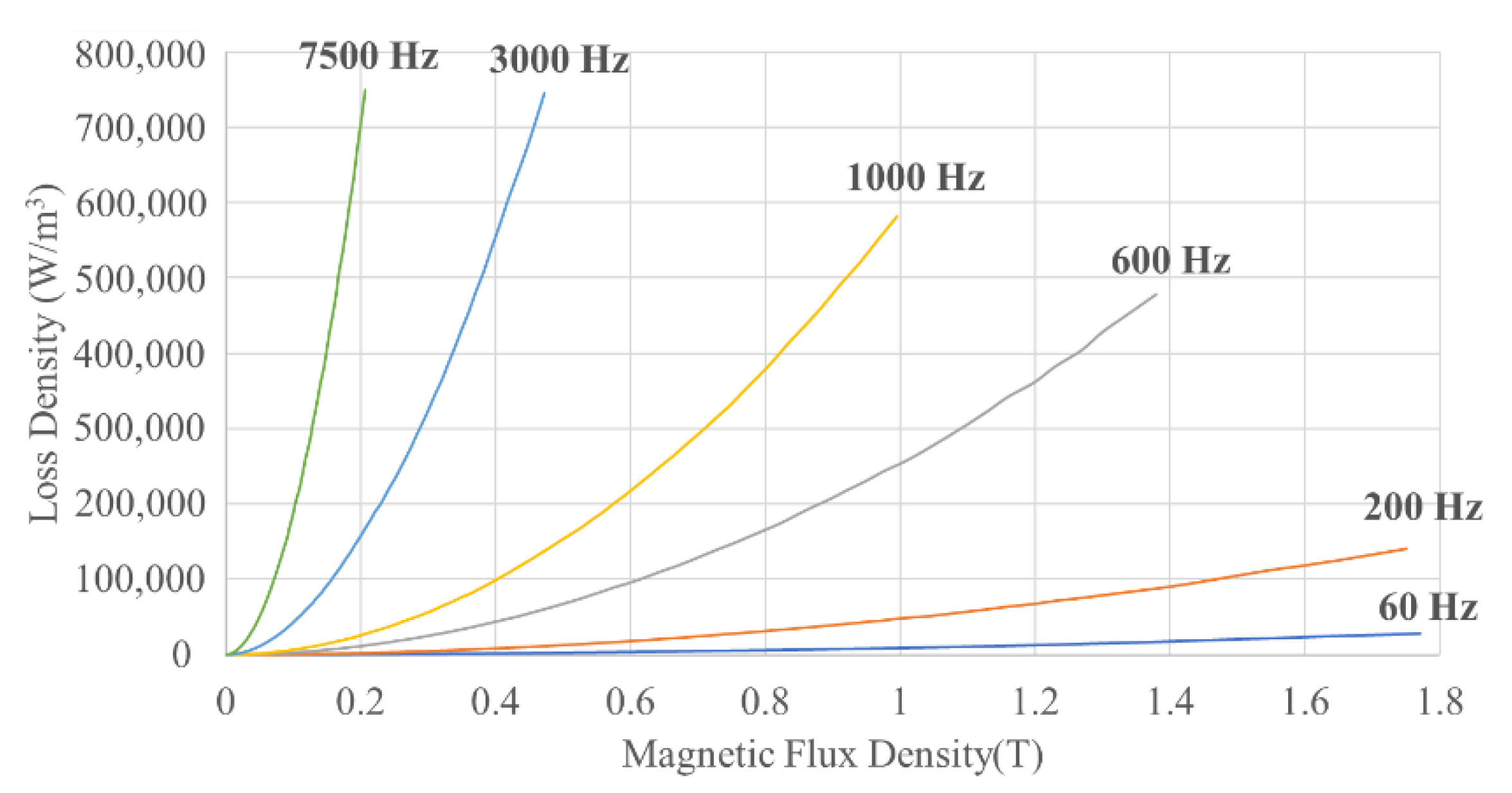

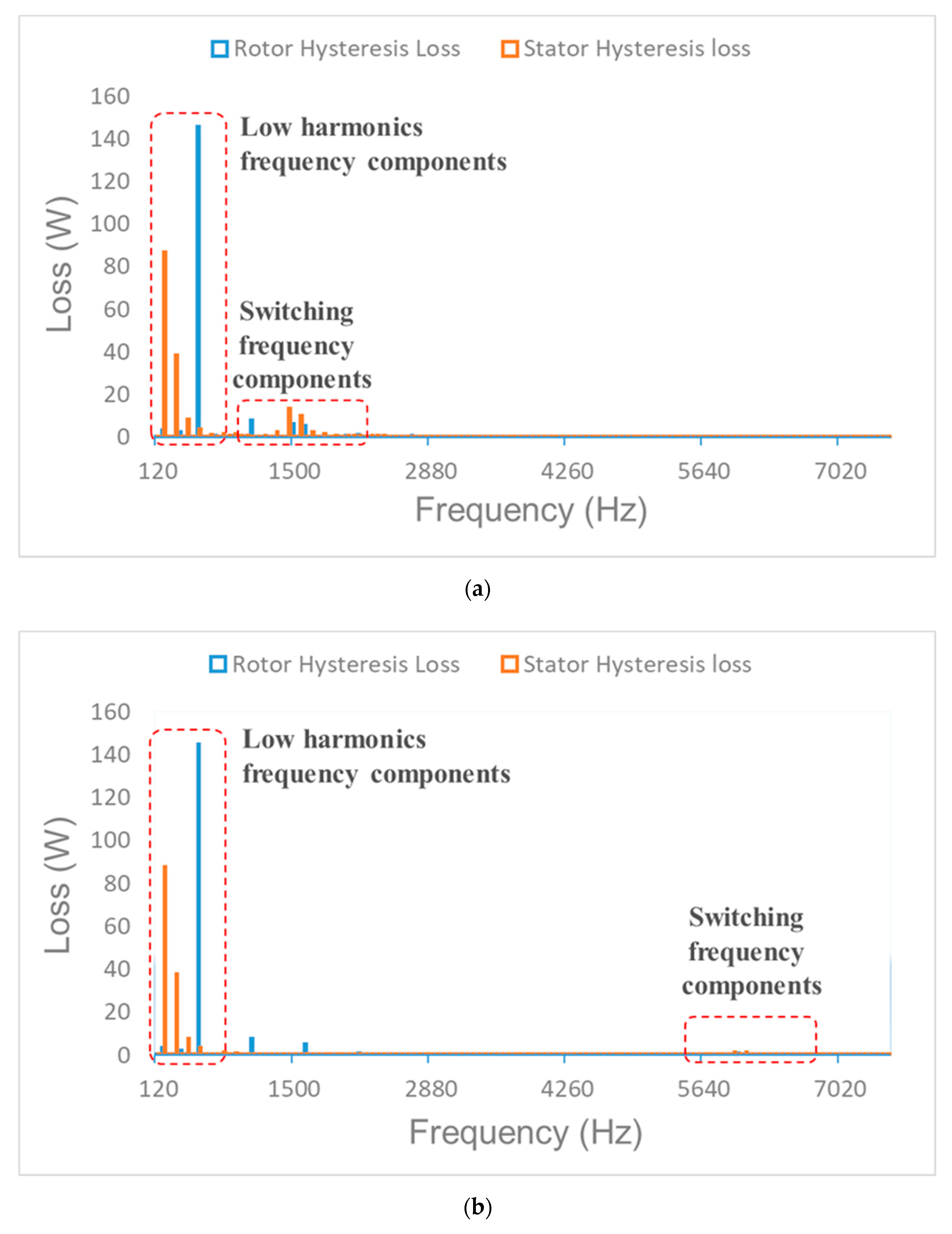

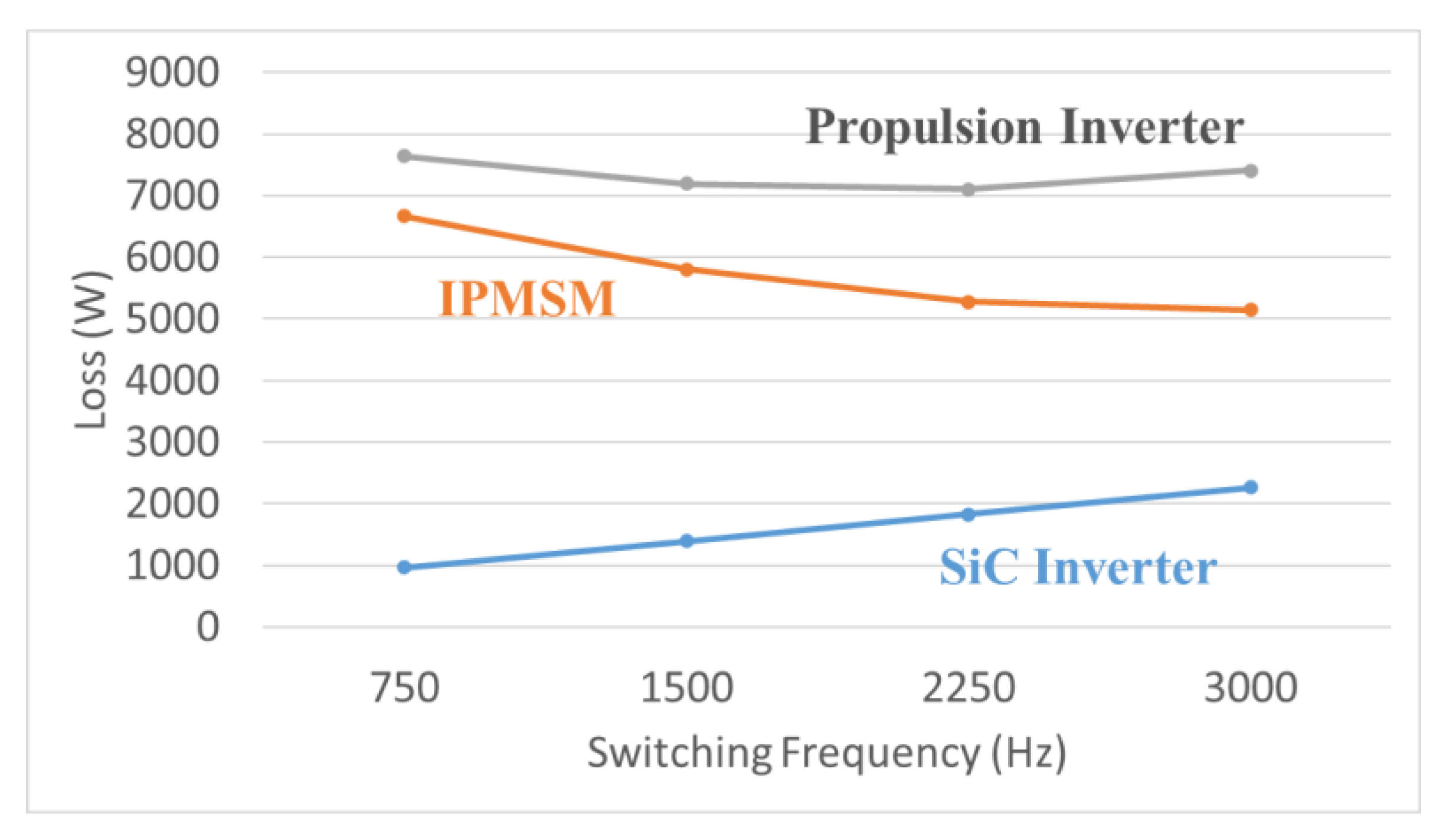

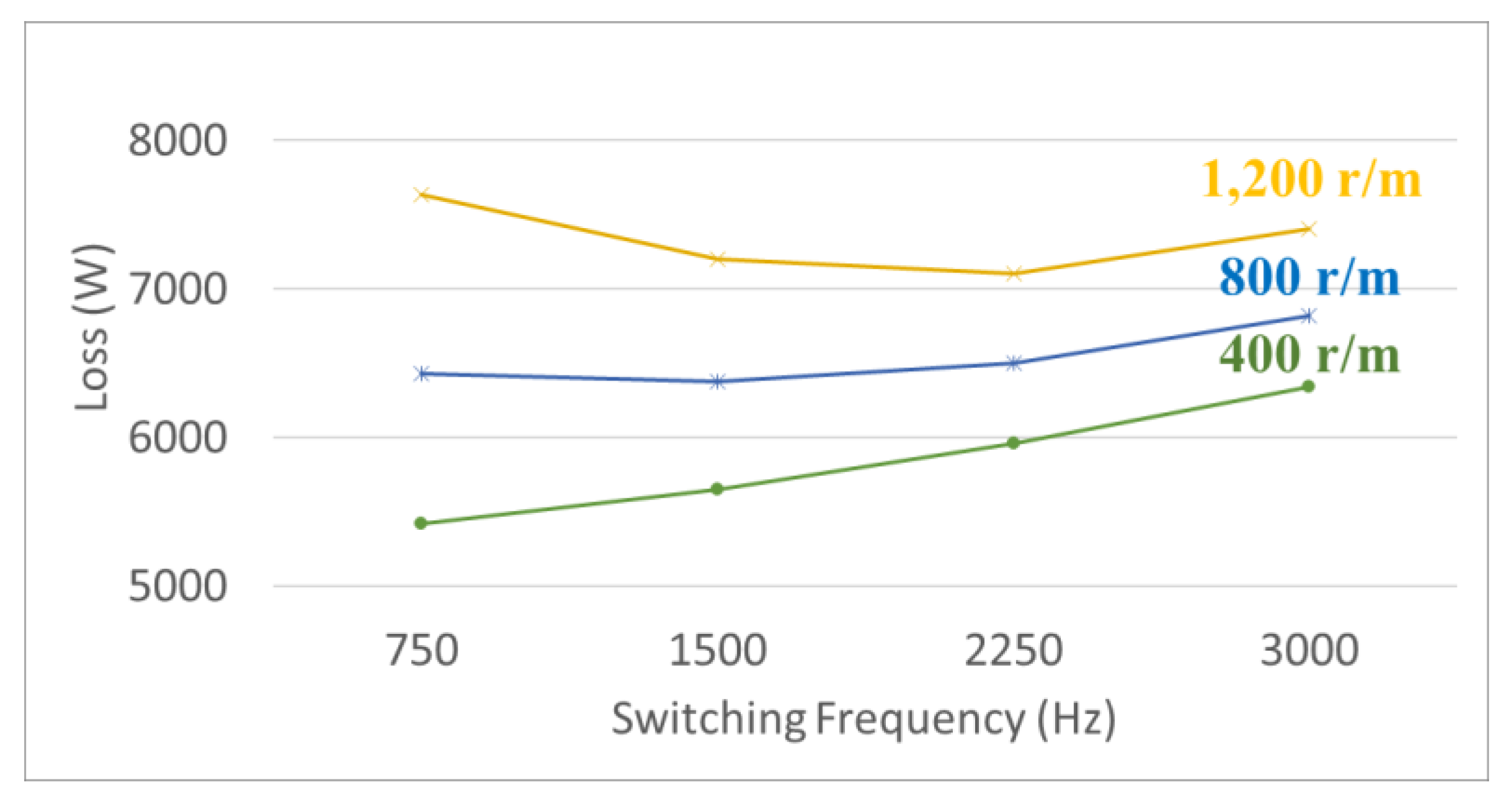

4.3. fsw Determination for Propulstion System

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ronanki, D.; Singh, S.A.; Williamson, S. Comprehensive Topological Overview of Rolling Stock Architectures and Recent Trends in Electric Railway Traction Systems. IEEE Trans. Transp. Electrif. 2017, 3, 724–738. [Google Scholar] [CrossRef]

- Yang, X.; Li, X.; Ning, B.; Tang, T. A Survey on Energy-Efficient Train Operation for Urban Rail Transit. IEEE Trans. Intell. Transp. Syst. 2016, 17, 2–13. [Google Scholar] [CrossRef]

- Diao, L.-J.; Tang, J.; Loh, P.C.; Yin, S.; Wang, L.; Liu, Z. An Efficient DSP–FPGA-Based Implementation of Hybrid PWM for Electric Rail Traction Induction Motor Control. IEEE Trans. Power Electron. 2018, 33, 3276–3288. [Google Scholar] [CrossRef]

- Shikata, K.; Kawai, H.; Nomura, H.; Aoki, H.; Fukasawa, S.; Tasaka, Y. PMSM propulsion system for Tokyo Metro. In Proceedings of the 2012 Electrical Systems for Aircraft, Railway and Ship Propulsion, Bologna, Italy, 16–18 October 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Negishi, T.; Tsuda, R.; Ota, K.; Iura, S.; Yamaguchi, H. 3.3-kV All-SiC Power Module for Traction System Use. In Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 16–18 May 2017. [Google Scholar]

- Mouawad, B.; Hussein, A.; Castellazzi, A. A 3.3 kV SiC MOSFET Half-Bridge Power Module. In Proceedings of the 10th International Conference on Integrated Power Electronics Systems, Stuttgart, Germany, 20–22 March 2018. [Google Scholar]

- Ke, H.; Chang, G.; Zhou, W.; Li, C.; Peng, Y.; Dai, X. 3.3kV/500A SiC Power Module for Railway Traction Application. In Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Shanghai, China, 26–28 June 2018. [Google Scholar]

- Skudenly, H.-C.; Weinhardt, M. An Investigation of the Dynamic Response of Two Induction Motors in a Locomotive Truck Fed by a Common Inverter. IEEE Trans. Ind. Appl. 1984, 20, 173–179. [Google Scholar] [CrossRef]

- Broche, C.; Lobry, J.; Colignon, P.; Labart, A. Harmonic reduction in DC link current of a PWM induction motor drive by active filtering. IEEE Trans. Power Electron. 1992, 7, 633–643. [Google Scholar] [CrossRef]

- Oh, S.Y.; Cho, S.-Y.; Han, J.-H.; Lee, J.; Ryu, G.-H.; Kang, D.; Lee, J. Design of IPMSM Rotor Shape for Magnet Eddy-Current Loss Reduction. IEEE Trans. Magn. 2014, 50, 841–844. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, W.; Chen, Z.; Mao, S.; Meng, T.; Peng, J.; Jiao, N. A Time-Delay Compensation Method for IPMSM Hybrid Sensorless Drives in Rail Transit Applications. IEEE Trans. Ind. Electron. 2018, 66, 6715–6726. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, W.; Chen, Z.; Jiao, N.; Zhao, D. Comparison analysis of low-switching-frequency-based IPMSM sensorless drives considering regulators, observer and inverter non-linearity. IET Electr. Power Appl. 2019, 13, 1022–1031. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, X.; Fang, Y.; Zhang, H. DC-link-Fluctuation-Resistant Predictive Torque Control for Railway Traction Permanent Magnet Synchronous Motor in Six-Step Operation. IEEE Trans. Power Electron. 2020, 35, 10982–10993. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, W.; Xiao, F.; Lian, C.; Gao, S. Six-Step Mode Control of IPMSM for Railway Vehicle Traction Eliminating the DC Offset in Input Current. IEEE Trans. Power Electron. 2019, 34, 8981–8993. [Google Scholar] [CrossRef]

- Kwon, Y.-C.; Kim, S.; Sul, S.-K. Six-Step Operation of PMSM with Instantaneous Current Control. IEEE Trans. Ind. Appl. 2014, 50, 2614–2625. [Google Scholar] [CrossRef]

- Bolognani, S.; Zigliotto, M. Novel digital continuous control of SVM inverters in the overmodulation range. IEEE Ind. Appl. 1997, 33, 525–530. [Google Scholar] [CrossRef]

- Yuan, G.; Hou, X.; Zheng, C.; Li, Z.; Yin, Y.; Liang, R. Restarting with speed for IPMSM based on hybrid synchronized PWM control schemes for rail train traction system. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, Australia, 11–14 August 2017; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2017; pp. 1–5. [Google Scholar]

- Wang, W.; Cheng, M.; Zhang, B.; Zhu, Y.; Ding, S. A Fault-Tolerant Permanent-Magnet Traction Module for Subway Applications. IEEE Trans. Power Electron. 2014, 29, 1646–1658. [Google Scholar] [CrossRef]

- Casarin, J.; Ladoux, P.; Chauchat, B.; Dedecius, D.; Laugt, E. Evaluation of high voltage SiC diodes in a medium frequency AC/DC converter for railway traction. In Proceedings of the International Symposium on Power Electronics Power Electronics, Electrical Drives, Automation and Motion, Sorrento, Italy, 20–22 June 2012. [Google Scholar]

- Wu, D.; Xiao, C.; Zhang, H.; Liang, W. Development of auxiliary converter based on 1700V/325A full SiC MOSFET for urban rail transit vehicles. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Chicago, IL, USA, 22–24 June 2017; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2017. [Google Scholar]

- Helsper, M.; Ocklenburg, M.A. SiC MOSFET based Auxiliary Power Supply for rail vehicles. In Proceedings of the 20th European Conference on Power Electronics and Applications, Riga, Latvia, 17–21 September 2018. [Google Scholar]

- Rujas, A.; López, V.M.; Garcia-Bediaga, A.; Berasategi, A.; Nieva, T.; López-Martín, V. Railway traction DC–DC converter: Comparison of Si, SiC-hybrid, and full SiC versions with 1700 V power modules. IET Power Electron. 2019, 12, 3265–3271. [Google Scholar] [CrossRef]

- Rujas, A.; Lopez, V.M.; Villar, I.; Nieva, T.; Larzabal, I. SiC-hybrid based railway inverter for metro application with 3.3kV low inductance power modules. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2019; pp. 1992–1997. [Google Scholar]

- Ishikawa, K.; Ogawa, K.; Yukutake, S.; Kameshiro, N.; Kono, Y. Traction Inverter that Applies Compact 3.3 kV/1200 A SiC Hybrid Module. In Proceedings of the International Power Electronics Conference, Hiroshima, Japan, 18–21 May 2014. [Google Scholar]

- Sugiyama, A.; Okitsu, H.; Ishimaru, T.; Kishimoto, Y.; Kadooka, S.; Sawakami, T. Verification Tests of 3.3kV SiC (Silicon Carbide) Hybrid IGBT Inverter for Nishi-Nippon Railroad Co., Ltd 3000 Series. In Proceedings of the International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles, Aachen, Germany, 3–5 March 2015. [Google Scholar]

- Makishima, S.; Fujimoto, K.; Kondo, K. The Direct Benefit of SiC Power Semiconductor Devices for Railway Vehicle Traction Inverters. In Proceedings of the International Power Electronics Conference, Niigata, Japan, 20–24 May 2018. [Google Scholar]

- Sato, K.; Kato, H.; Fukushima, T. Development of SiC Applied Traction System for Shinkansen High-speed Train. In Proceedings of the International Power Electronics Conference, Niigata, Japan, 20–24 May 2018. [Google Scholar]

- Yıldırım, D.; Akşit, M.H.; Yolaçan, C.; Pul, T.; Ermiş, C.; Aghdam, B.H.; Çadırcı, I.; Ermiş, M. Full-Scale Physical Simulator of All SiC Traction Motor Drive with Onboard Supercapacitor ESS for Light-Rail Public Transportation. IEEE Ind. Electron. 2020, 67, 6290–6301. [Google Scholar] [CrossRef]

- Kogure, H.; Ishikawa, K.; Kohno, Y.; Sakai, T.; Ishigaki, T. Development of Low Loss Inverter System Adopted Lower Harmonic Losses Technology and Ultra Compact Inverters Adopted High Power Density SiC Module. In Proceedings of the 20th European Conference on Power Electronics and Applications, Riga, Latvia, 17–21 September 2018. [Google Scholar]

- Bober, P.; Ferkova, Z. Comparison of an Off-Line Optimized Firing Angle Modulation and Torque Sharing Functions for Switched Reluctance Motor Control. Energies 2020, 13, 2435. [Google Scholar] [CrossRef]

- Nakata, T.; Sanada, M.; Morimoto, S.; Inoue, Y. Automatic Design of IPMSMs Using a Genetic Algorithm Combined with the Coarse-Mesh FEM for Enlarging the High-Efficiency Operation Area. IEEE Trans. Ind. Electron. 2017, 64, 9721–9728. [Google Scholar] [CrossRef]

- Di, C.; Petrov, I.; Pyrhonen, J.J. Modeling and Mitigation of Rotor Eddy-Current Losses in High-Speed Solid-Rotor Induction Machines by a Virtual Permanent Magnet Harmonic Machine. IEEE Trans. Magn. 2018, 54, 1–12. [Google Scholar] [CrossRef]

- Kwon, T.-S.; Sul, S.-K. Novel Antiwindup of a Current Regulator of a Surface-Mounted Permanent-Magnet Motor for Flux-Weakening Control. IEEE Trans. Ind. Appl. 2006, 42, 1293–1300. [Google Scholar] [CrossRef]

- Lai, C.; Feng, G.; Tjong, J.; Kar, N.C. Direct Calculation of Maximum-Torque-Per-Ampere Angle for Interior PMSM Control Using Measured Speed Harmonic. IEEE Trans. Power Electron. 2018, 33, 9744–9752. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; Gan, C.; Sun, Q.; Kong, W. Efficiency Optimization of PMSM Drives Using Field-Circuit Coupled FEM for EV/HEV Applications. IEEE Access 2018, 6, 15192–15201. [Google Scholar] [CrossRef]

- Letellier, A.; Dubois, M.R.; Trovão, J.P.F.; Maher, H. Calculation of Printed Circuit Board Power-Loop Stray Inductance in GaN or High di/dt Applications. IEEE Trans. Power Electron. 2018, 34, 612–623. [Google Scholar] [CrossRef]

- Letellier, A.; Dubois, M.R.; Trovao, J.P.F.; Maher, H. Gallium Nitride Semiconductors in Power Electronics for Electric Vehicles: Advantages and Challenges. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC), Montreal, QC, Canada, 19–22 October 2015. [Google Scholar]

- Liew, G.S.; Tsang, E.C.Y.; Ertugrul, N.; Soong, W.L. Analysis of a Segmented Brushless PM Machine Utilising Soft Magnetic Composites. In Proceedings of the 33rd Annual Conference of the IEEE Industrial Electronics Society, Taipei, Taiwan, 5–8 November 2007. [Google Scholar]

- Han, S.-H.; Jahns, T.; Zhu, Z. Analysis of Rotor Core Eddy-Current Losses in Interior Permanent-Magnet Synchronous Machines. IEEE Trans. Ind. Appl. 2009, 46, 196–205. [Google Scholar] [CrossRef]

- Chai, W.; Lipo, T.; Kwon, B.-I. Design and Optimization of a Novel Wound Field Synchronous Machine for Torque Performance Enhancement. Energies 2018, 11, 2111. [Google Scholar] [CrossRef]

- Gonzalez, D.A.; Saban, D.M. Study of the Copper Losses in a High-Speed Permanent-Magnet Machine with Form-Wound Windings. IEEE Trans. Ind. Electron. 2013, 61, 3038–3045. [Google Scholar] [CrossRef]

- Hargreaves, P.A.; Mecrow, B.C.; Hall, R. Calculation of Iron Loss in Electrical Generators Using Finite-Element Analysis. IEEE Trans. Ind. Appl. 2012, 48, 1460–1466. [Google Scholar] [CrossRef]

| Specification | Value | Specification | Value |

|---|---|---|---|

| Type | IPMSM | Pole/Slot | 6/27 |

| Rated Current (Iphase) | 236 Arms | Stator Core Material | 35PN230 |

| Rated Torque | 1522 Nm | Rotor Core Material | 35PN230 |

| Rated Speed | 2080 r/m | Magnet Material | NdFeB |

| Stator an external diameter | 500 mm | Rotor an external diameter | 280 mm |

| Stator an internal diameter | 283 mm | Rotor an internal diameter | 80 mm |

| Air gap length | 1.5 mm | Laminated length (height) | 235 mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, J.-H.; Lee, J.-H.; Lee, J.-S. Switching Frequency Determination of SiC-Inverter for High Efficiency Propulsion System of Railway Vehicle. Energies 2020, 13, 5035. https://doi.org/10.3390/en13195035

Ryu J-H, Lee J-H, Lee J-S. Switching Frequency Determination of SiC-Inverter for High Efficiency Propulsion System of Railway Vehicle. Energies. 2020; 13(19):5035. https://doi.org/10.3390/en13195035

Chicago/Turabian StyleRyu, Joon-Hyoung, June-Hee Lee, and June-Seok Lee. 2020. "Switching Frequency Determination of SiC-Inverter for High Efficiency Propulsion System of Railway Vehicle" Energies 13, no. 19: 5035. https://doi.org/10.3390/en13195035

APA StyleRyu, J.-H., Lee, J.-H., & Lee, J.-S. (2020). Switching Frequency Determination of SiC-Inverter for High Efficiency Propulsion System of Railway Vehicle. Energies, 13(19), 5035. https://doi.org/10.3390/en13195035