Temperature Distribution in Insulated Temperature-Controlled Container by Numerical Simulation

Abstract

1. Introduction

2. Materials and Methods

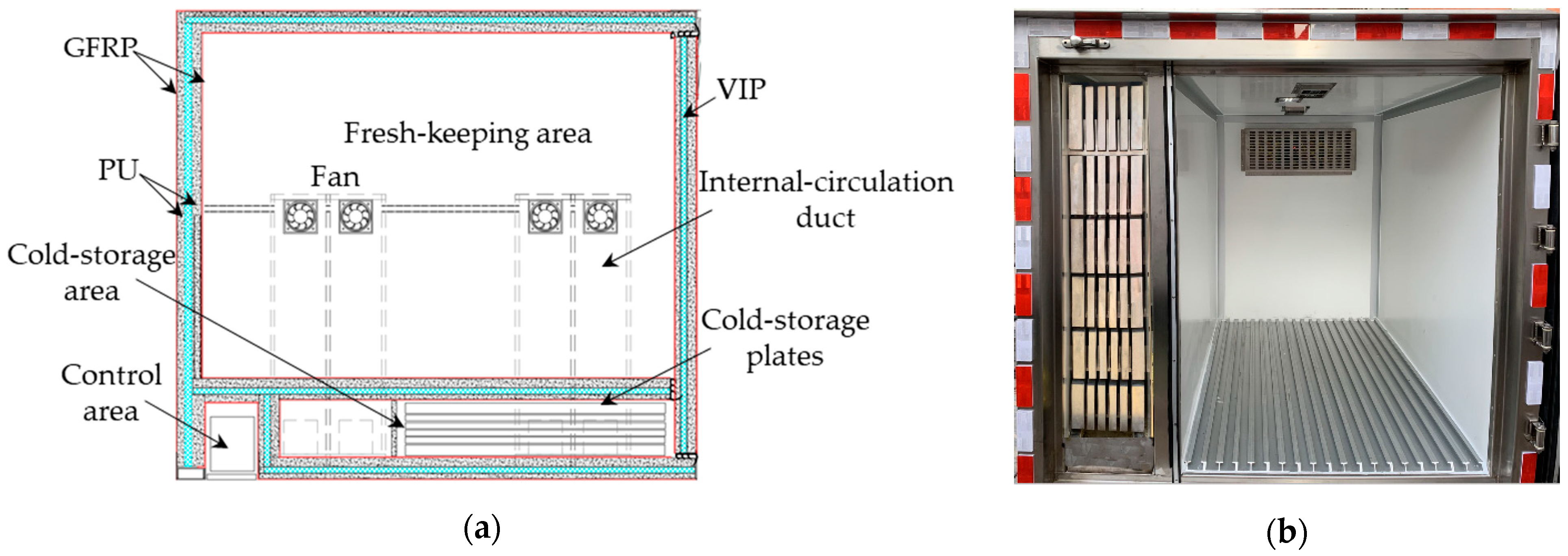

2.1. Materials

2.2. Mathematical Model

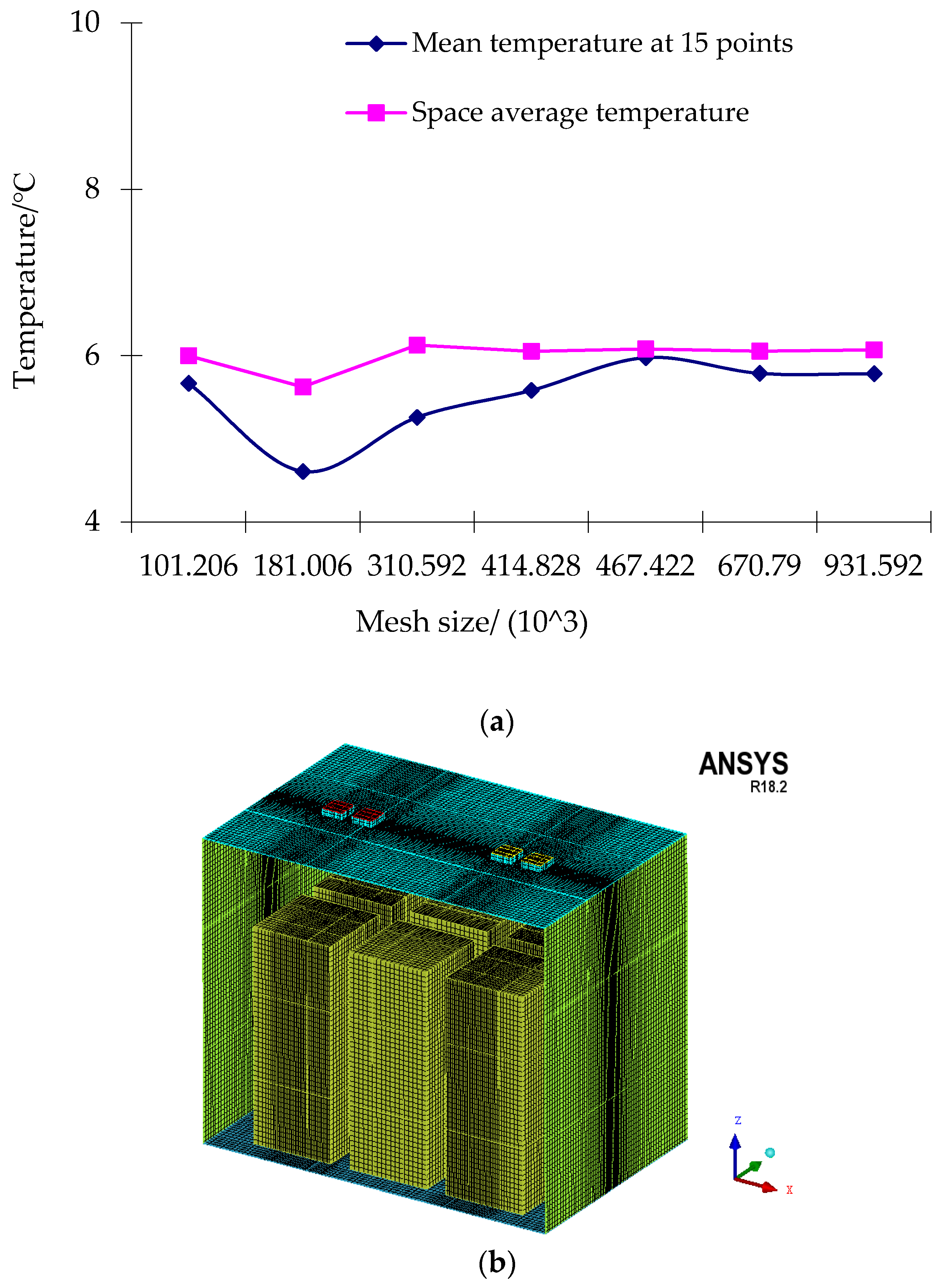

2.3. Numerical Method

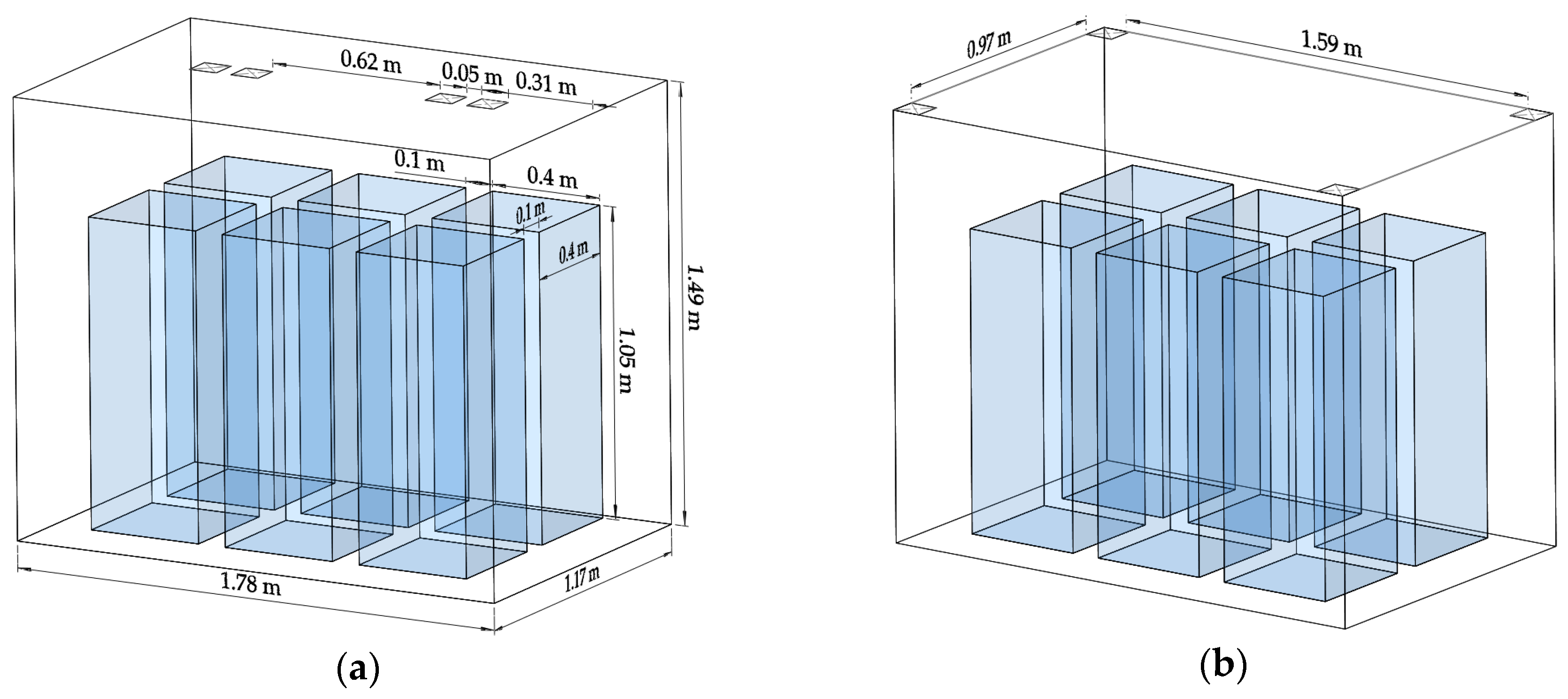

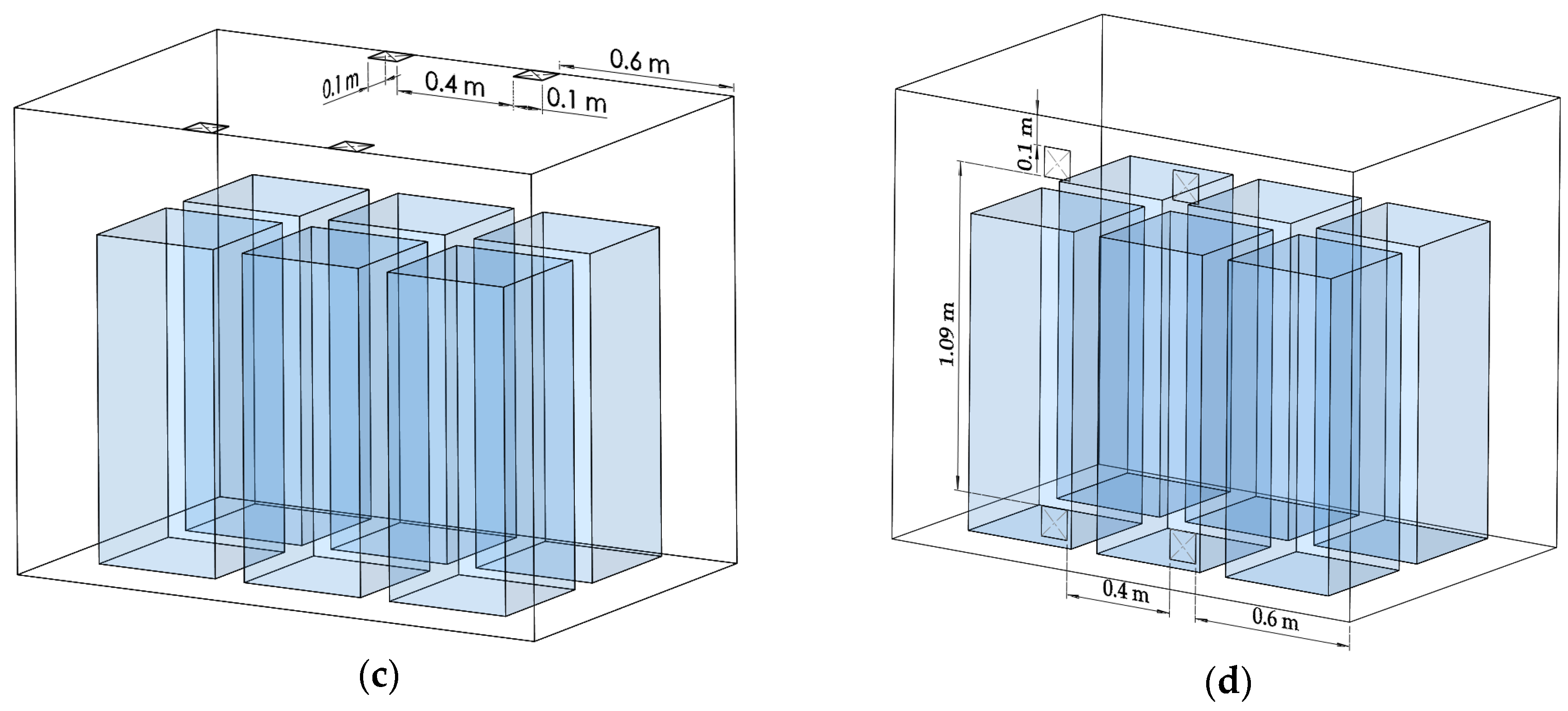

2.4. Physical Model

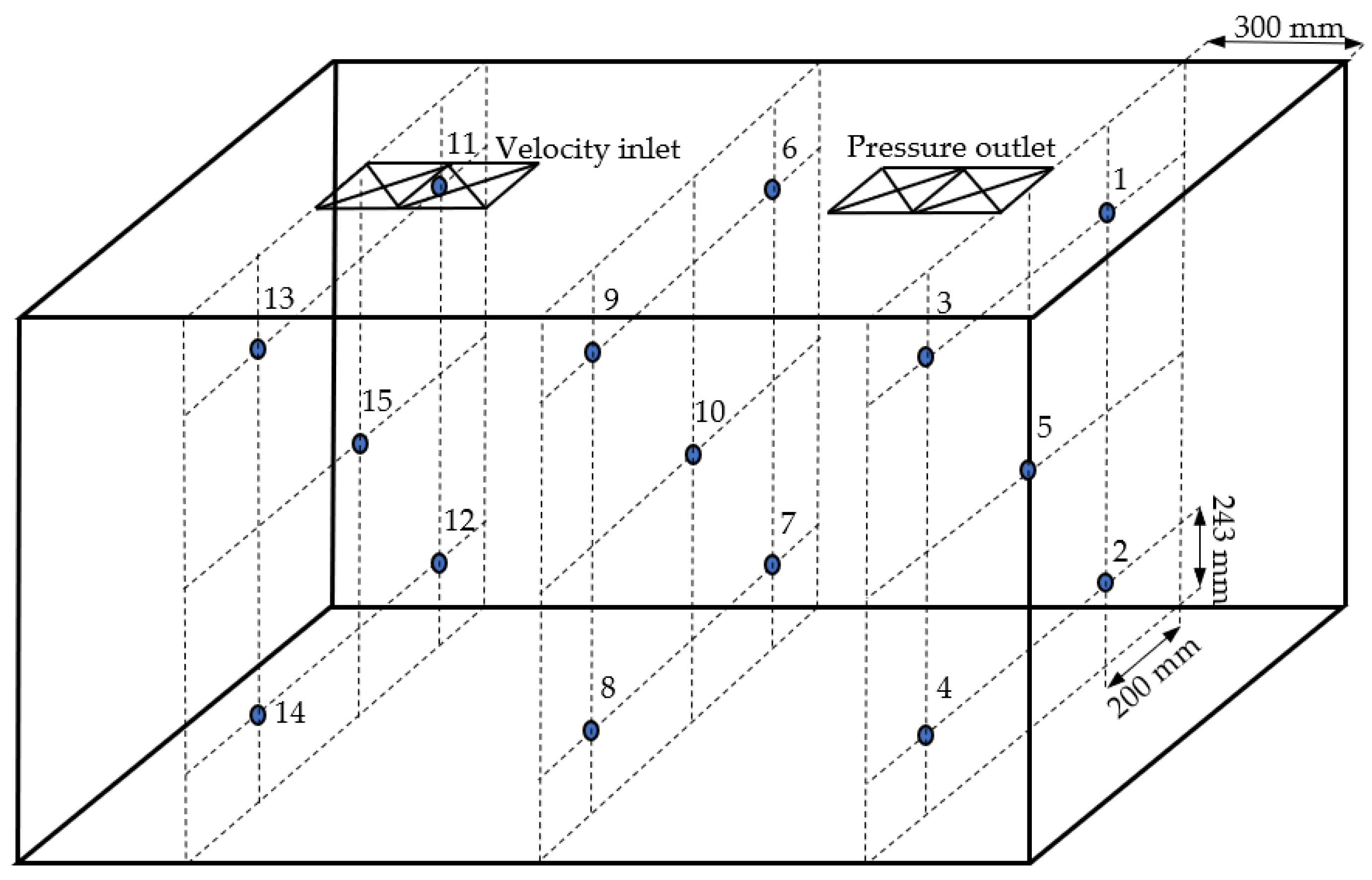

2.5. Experimental Research

3. Results

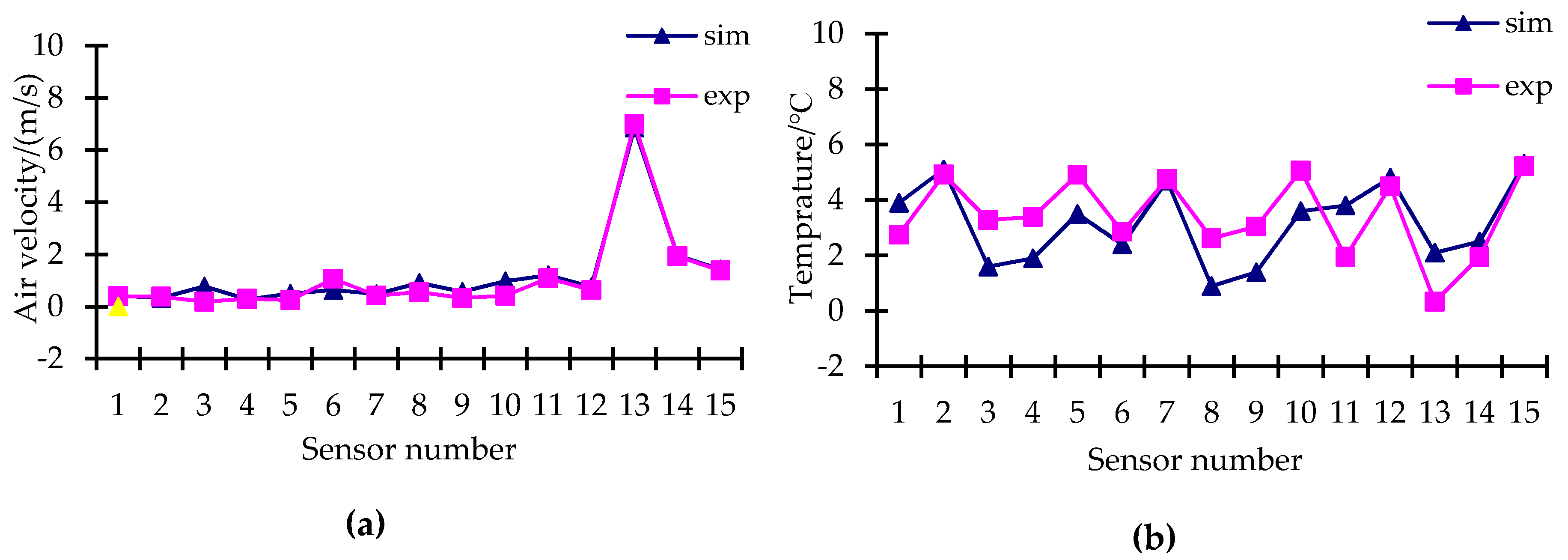

3.1. Model Verification

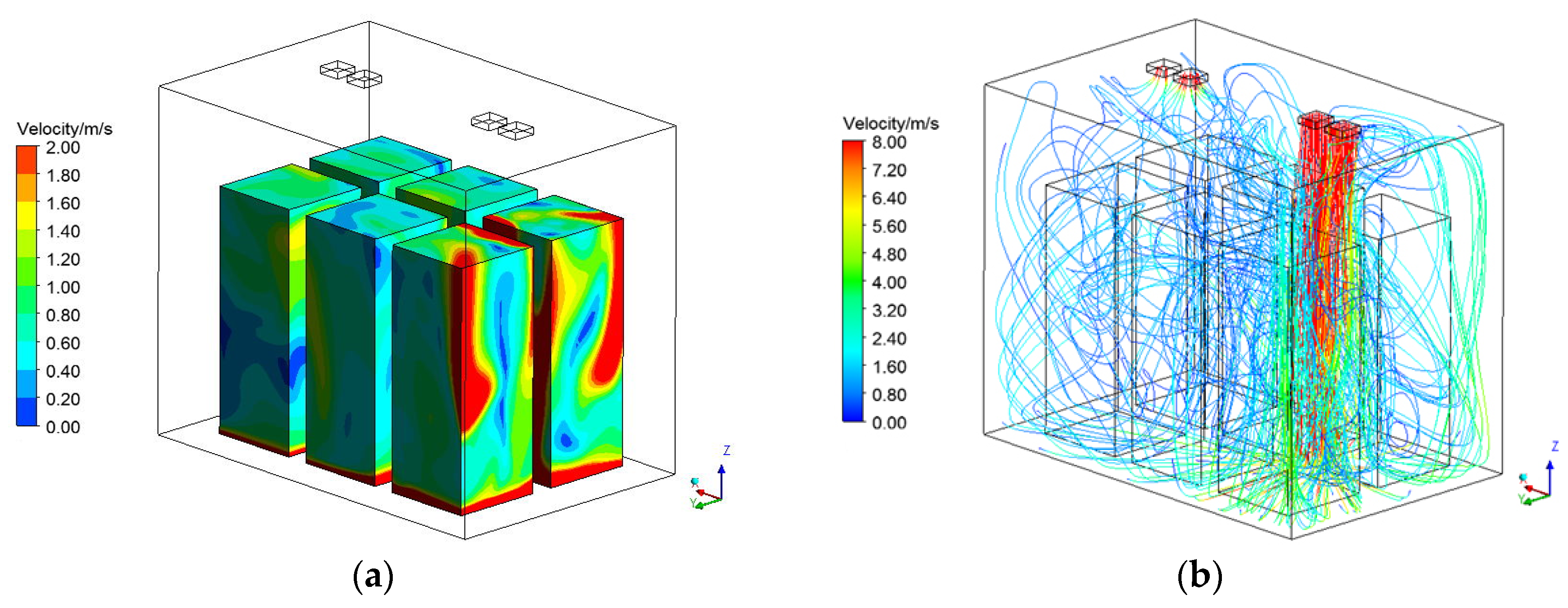

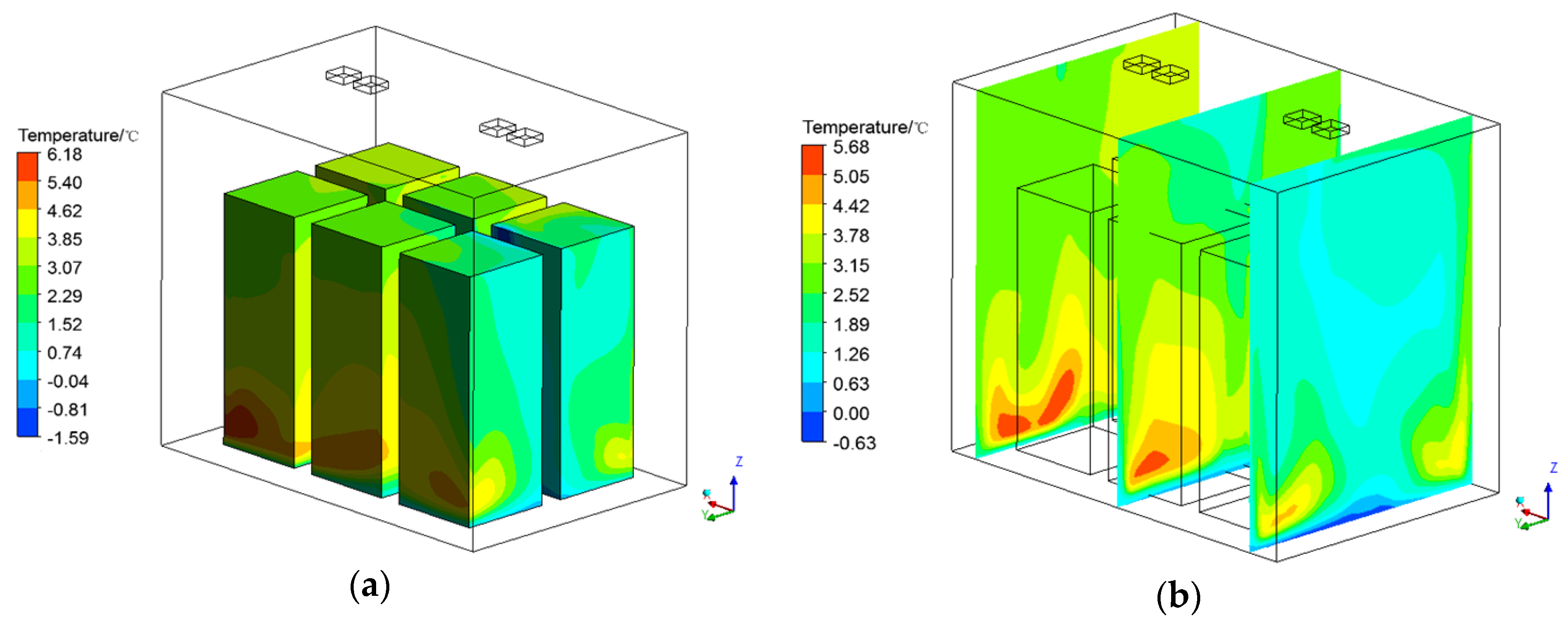

3.2. Air-Flow and Temperature Distribution

3.3. Inlet-Velocity Influence

3.4. Fan-Location Influence

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, M.; Saman, W.; Bruno, F. Computer simulation with TRNSYS for a mobile refrigeration system incorporating a phase change thermal storage unit. Appl. Energy 2014, 132, 226–235. [Google Scholar] [CrossRef]

- Mercier, S.; Villeneuve, S.; Mondor, M.; Uysal, I. Time-Temperature Management along the Food Cold Chain: A Review of Recent Developments. Compr. Rev. Food Sci. Food Saf. 2017, 16, 647–667. [Google Scholar] [CrossRef]

- Oury, A.; Namy, P.; Youbi-Idrisi, M. Aero-thermal Simulation of a Refrigerated Truck under Open/Closed-Door Cycles. In Proceedings of the 2015 COMSOL Conference, Grenoble, France, 14 November 2015. [Google Scholar]

- Liu, M.; Saman, W.; Bruno, F. Development of a novel refrigeration system for refrigerated trucks incorporating phase change material. Appl. Energy 2012, 92, 336–342. [Google Scholar] [CrossRef]

- Ahmed, M.; Meade, O.; Medina, M.A. Reducing heat transfer across the insulated walls of refrigerated truck trailers by the application of phase change materials. Energy Convers. Manag. 2010, 51, 383–392. [Google Scholar] [CrossRef]

- Pielichowska, K.; Pielichowski, K. Phase change materials for thermal energy storage. Prog. Mater. Sci. 2014, 65, 67–123. [Google Scholar] [CrossRef]

- Zhou, D.; Zhao, C.Y.; Tian, Y. Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl. Energy 2012, 92, 593–605. [Google Scholar] [CrossRef]

- Oró, E.; Miró, L.; Farid, M.M.; Cabeza, L.F. Thermal analysis of a low temperature storage unit using phase change materials without refrigeration system. Int. J. Refrig. 2012, 35, 1709–1714. [Google Scholar] [CrossRef]

- Liu, L.; Su, D.; Tang, Y.; Fang, G. Thermal conductivity enhancement of phase change materials for thermal energy storage: A review. Renew. Sustain. Energy Rev. 2016, 62, 305–317. [Google Scholar] [CrossRef]

- Fioretti, R.; Principi, P.; Copertaro, B. A refrierated container envelope with a PCM (Phase Change Material) layer: Experimental and theoretical investigation in a representative town in Central Italy. Energy Convers. Manag. 2016, 122, 131–141. [Google Scholar] [CrossRef]

- Oró, E.; de Gracia, A.; Cabeza, L.F. Active phase change material package for thermal protection of ice cream containers. Int. J. Refrig. 2013, 36, 102–109. [Google Scholar] [CrossRef]

- Wang, C.; He, Z.; Li, H.; Wennerstern, R.; Sun, Q. Evaluation on Performance of a Phase Change Material Based Cold Storage House. Energy Procedia 2017, 105, 3947–3952. [Google Scholar] [CrossRef]

- Yusufoglu, Y.; Apaydin, T.; Yilmaz, S.; Paksoy, H.O. Improving performance of household refrigerators by incorporating phase change materials. Int. J. Refrig. 2015, 57, 173–185. [Google Scholar] [CrossRef]

- Huang, L.; Piontek, U. Improving Performance of Cold-Chain Insulated Container with Phase Change Material: An Experimental Investigation. Appl. Sci. 2017, 7, 1288. [Google Scholar] [CrossRef]

- Gin, B.; Farid, M.M. The use of PCM panels to improve storage condition of frozen food. J. Food Eng. 2010, 100, 372–376. [Google Scholar] [CrossRef]

- Liu, G.; Wu, J.; Alan, F.; Xie, R.; Tang, H.; Zou, Y.; Qu, R. Design and no-load performance test of GU-PCM2 temperature controlled phase change storage refrigerator. Trans. Chin. Soc. Agric. Eng. 2019, 35, 288–295. [Google Scholar]

- Xu, X.F.; Zhang, X.L.; Munyalo, J.M. Simulation Study on Temperature Field and Cold Plate Melting of Cold Storage Refrigerator Car. Energy Procedia 2017, 142, 3394–3400. [Google Scholar]

- Zhang, Z.; Guo, Y.G.; Tian, J.J.; Li, M. Numerical simulation and experiment of temperature field distribution in box of cold plate refrigerated truck. Trans. Chin. Soc. Agric. Eng. 2013, 29, 18–24. [Google Scholar]

- Zou, Q.; Opara, L.U.; McKibbin, R. A CFD modeling system for airflow and heat transfer in ventilated packaging for fresh foods: I. Initial analysis and development of mathematical models. J. Food Eng. 2006, 77, 1037–1047. [Google Scholar] [CrossRef]

- Jiang, T.; Xu, N.; Luo, B.; Deng, L.; Wang, S.; Gao, Q.; Zhang, Y. Analysis of an internal structure for refrigerated container: Improving distribution of cooling capacity. Int. J. Refrig. 2020, 113, 228–238. [Google Scholar] [CrossRef]

- Jedermann, R.; Geyer, M.; Praeger, U.; Lang, W. Sea transport of bananas in containers–Parameter identification for a temperature model. J. Food Eng. 2013, 115, 330–338. [Google Scholar] [CrossRef]

- Delele, M.A.; Ngcobo, M.E.K.; Getahun, S.T.; Chen, L.; Mellmann, J.; Opara, U.L. Studying airflow and heat transfer characteristics of a horticultural produce packaging system using a 3-D CFD model. Part II: Effect of package design. Postharvest Biol. Technol. 2013, 86, 546–555. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, L.; Tian, J.; Guo, Y.; Li, Y. Effects of refrigerated truck temperature field uniformity on preservation of vegetables. Trans. Chin. Soc. Agric. Eng. 2014, 30, 309–316. [Google Scholar]

- Defraeye, T.; Nicolai, B.; Kirkman, W.; Moore, S.; Niekerk, S.V.; Verboven, P.; Cronjé, P. Integral performance evaluation of the fresh-produce cold chain: A case study for ambient loading of citrus in refrigerated containers. Postharvest Biol. Technol. 2016, 112, 1–13. [Google Scholar] [CrossRef]

- Trias, F.X.; Oliet, C.; Rigola, J.; Pérez-Segarra, C.D. A simple optimization approach for the insulation thickness distribution in household refrigerators. Int. J. Refrig. 2018, 93, 169–175. [Google Scholar] [CrossRef]

- Thiessen, S.; Knabben, F.T.; Melo, C.; Gonçalves, J.M. A study on the effectiveness of applying vacuum insulation panels in domestic refrigerators. Int. J. Refrig. 2018, 96, 10–16. [Google Scholar] [CrossRef]

- Hammond, E.C.; Evans, J.A. Application of Vacuum Insulation Panels in the cold chain–Analysis of viability. Int. J. Refrig. 2014, 47, 58–65. [Google Scholar] [CrossRef]

- Smale, N.J.; Moureh, J.; Cortella, G. A review of numerical models of airflow in refrigerated food applications. Int. J. Refrig. 2006, 29, 911–930. [Google Scholar] [CrossRef]

- Sajadiye, S.M.; Zolfaghari, M. Simulation of in-line versus staggered arrays of vented pallet boxes for assessing cooling performance of orange in cool storage. Appl. Therm. Eng. 2017, 115, 337–349. [Google Scholar] [CrossRef]

- Moureh, J.; Flick, D. Airflow pattern and temperature distribution in a typical refrigerated truck configuration loaded with pallets. Int. J. Refrig. 2004, 27, 464–474. [Google Scholar] [CrossRef]

- Kayansayan, N.; Alptekin, E.; Ezan, M.A. Thermal analysis of airflow inside a refrigerated container. Int. J. Refrig. 2017, 84, 76–91. [Google Scholar] [CrossRef]

- Jara, P.B.T.; Rivera, J.J.A.; Merino, C.E.B.; Silva, E.V.; Farfán, G.A. Thermal behavior of a refrigerated vehicle: Process simulation. Int. J. Refrig. 2019, 100, 124–130. [Google Scholar] [CrossRef]

- Han, J.; Zhu, W.; Ji, Z. Comparison of veracity and application of different CFD turbulence models for refrigerated transport. Artif. Intell. Agric. 2019, 3, 11–17. [Google Scholar]

- Yang, T.; Wang, C.; Sun, Q.; Wennersten, R. Study on the application of latent heat cold storage in a refrigerated warehouse. Energy Procedia 2017, 142, 3546–3552. [Google Scholar] [CrossRef]

- Xie, R.; Tang, H.; Tao, W.; Liu, G.; Liu, J.; Wu, J. Optimization of cold-plate location in refrigerated vehicles based on simulation and test of no-load temperature field. Trans. Chin. Soc. Agric. Eng. 2017, 33, 290–298. [Google Scholar]

- Guo, J.; Fang, S.; Zeng, Z.; Lu, H.; Lü, E. Numerical simulation and experimental verification on humidity field for pipeline humidifying device. Trans. Chin. Soc. Agric. Eng. 2015, 31, 57–64. [Google Scholar]

- Cheng, W.; Yuan, X. Numerical analysis of a novel household refrigerator with shape-stabilized PCM (phase change material) heat storage condensers. Energy 2013, 59, 265–276. [Google Scholar] [CrossRef]

- Chourasia, M.K.; Goswami, T.K. Simulation of Effect of Stack Dimensions and Stacking Arrangement on Cool-down Characteristics of Potato in a Cold Store by Computational Fluid Dynamics. Bioprocess Eng. 2007, 96, 503–515. [Google Scholar] [CrossRef]

- Clarke, H.; Martinez-Herasme, A.; Crookes, R.; Wen, D.S. Experimental study of jet structure and pressurisation upon liquid nitrogen injection into water. Int. J. Multiph. Flow 2010, 36, 940–949. [Google Scholar] [CrossRef]

- Ho, S.H.; Rosario, L.; Rahman, M.M. Numerical simulation of temperature and velocity in a refrigerated warehouse. Int. J. Refrig. 2010, 33, 1015–1025. [Google Scholar] [CrossRef]

- Choi, S.; Burgess, G. Practical mathematical model to predict the performance of insulating packages. Packag. Technol. Sci. 2007, 20, 369–380. [Google Scholar] [CrossRef]

- Fang, G.Y.; LI, H. Automobile Air Conditioning Technology, 1st ed.; China Machine Press: Beijing, China, 2002; pp. 88–89. [Google Scholar]

- Wang, D.B.; Song, Q.W. Optimum design insulated body of refrigerated van. J. Jiangsu Ins. Technol. 1993, 14, 13–18. [Google Scholar]

- Guo, J.; Lü, E.; Lu, H.; Wang, Y.; Zhao, J. Numerical Simulation of Gas Exchange in Fresh-keeping Transportation Containers with a Controlled Atmosphere. Food Sci. Technol. Res. 2016, 22, 429–441. [Google Scholar] [CrossRef][Green Version]

- Hahn, M.; Drikakis, D. Large-eddy simulation of compressible turbulence using high-resolution methods. Int. J. Numer. Methods Fluids 2005, 47, 971–977. [Google Scholar] [CrossRef]

- Tsoutsanis, P.; Antoniadis, A.F.; Drikakis, D. WENO schemes on arbitrary unstructured meshes for laminar, transitional and turbulent flow. J. Comput. Phys. 2014, 256, 254–276. [Google Scholar] [CrossRef]

- Thornber, B.J.R.; Drikakis, D. Numerical dissipation of upwind schemes in low Mach flow. Int. J. Numer. Methods Fluids 2008, 56, 1535–1541. [Google Scholar] [CrossRef]

- Söylemez, E.; Alpman, E.; Onat, A.; Yükselentürk, Y.; Hartomacıoğlu, S. Numerical (CFD) and experimental analysis of hybrid household refrigerator including thermoelectric and vapour compression cooling systems. Int. J. Refrig. 2019, 99, 300–315. [Google Scholar] [CrossRef]

- Aslam Bhutta, M.M.; Hayat, N.; Bashir, M.H.; Khan, A.R.; Ahmad, K.N.; Khan, S. CFD applications in various heat exchangers design: A review. Appl. Therm. Eng. 2012, 32, 1–12. [Google Scholar] [CrossRef]

- Jaramillo, J.E.; Pérez-Segarra, C.; Oliva, A.; Claramunt, K. Analysis of different RANS models applied to turbulent forced convection. Int. J. Heat Mass Transfer. 2007, 50, 3749–3766. [Google Scholar] [CrossRef]

- Ambaw, A.; Bessemans, N.; Gruyters, W.; Gwanpua, S.G.; Schenk, A.; De Roeck, A.; Delele, M.A.; Verboven, P.; Nicolai, B.M. Analysis of the spatiotemporal temperature fluctuations inside an apple cool store in response to energy use concerns. Int. J. Refrig. 2016, 66, 156–168. [Google Scholar] [CrossRef]

- Alzuwaid, F.A.; Ge, Y.T.; Tassou, S.A.; Sun, J. The novel use of phase change materials in an open type refrigerated display cabinet: A theoretical investigation. Appl. Energy 2016, 180, 76–85. [Google Scholar] [CrossRef]

| Materials | Density (kg/m3) | Thermal Conductivity (W/(m·K)) |

|---|---|---|

| VIP | 280 | 0.0048 |

| PU | 45 | 0.0244 |

| GFRP | 1800 | 0.4651 |

| Name | Inlet | Outlet | Products | Wall |

|---|---|---|---|---|

| Boundary condition | Velocity inlet | Pressure outlet | Porous zone | Convection |

| Velocity (m/s) | 16 | - | - | - |

| Temperature (K) | UDF | 281.15 | - | 308.15 |

| Pressure (Pa) | - | 0 | - | - |

| Viscous resistance (1/m2) | - | - | 19,441 | - |

| Inertial resistance (1/m) | - | - | 0.06 | - |

| Heat transfer coefficient (W/m2K) | - | - | - | 0.13734 |

| Items | 4 m/s | 8 m/s | 12 m/s | 16 m/s |

|---|---|---|---|---|

| Average temperature (AT; °C) | 6.29 | 5.27 | 4.25 | 3.95 |

| Standard deviation (STEDV) | 1.63 | 1.89 | 1.86 | 1.44 |

| Coefficient of inhomogeneity (COI) | 2.74 | 3.96 | 4.32 | 5.35 |

| Items | L0 | L1 | L2 | L3 |

|---|---|---|---|---|

| Average temperature (AT; °C) | 4.25 | 4.13 | 4.62 | 4.95 |

| Standard deviation (STEDV) | 1.86 | 0.87 | 1.51 | 1.49 |

| Coefficient of inhomogeneity (COI) | 4.32 | 2.10 | 3.3 | 2.68 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Guo, J.; Xia, J.; Wei, X.; Shen, H.; Cao, Y.; Lu, H.; Lü, E. Temperature Distribution in Insulated Temperature-Controlled Container by Numerical Simulation. Energies 2020, 13, 4765. https://doi.org/10.3390/en13184765

Li B, Guo J, Xia J, Wei X, Shen H, Cao Y, Lu H, Lü E. Temperature Distribution in Insulated Temperature-Controlled Container by Numerical Simulation. Energies. 2020; 13(18):4765. https://doi.org/10.3390/en13184765

Chicago/Turabian StyleLi, Bin, Jiaming Guo, Jingjing Xia, Xinyu Wei, Hao Shen, Yongfeng Cao, Huazhong Lu, and Enli Lü. 2020. "Temperature Distribution in Insulated Temperature-Controlled Container by Numerical Simulation" Energies 13, no. 18: 4765. https://doi.org/10.3390/en13184765

APA StyleLi, B., Guo, J., Xia, J., Wei, X., Shen, H., Cao, Y., Lu, H., & Lü, E. (2020). Temperature Distribution in Insulated Temperature-Controlled Container by Numerical Simulation. Energies, 13(18), 4765. https://doi.org/10.3390/en13184765