Pattern Recognition of DC Partial Discharge on XLPE Cable Based on ADAM-DBN

Abstract

1. Introduction

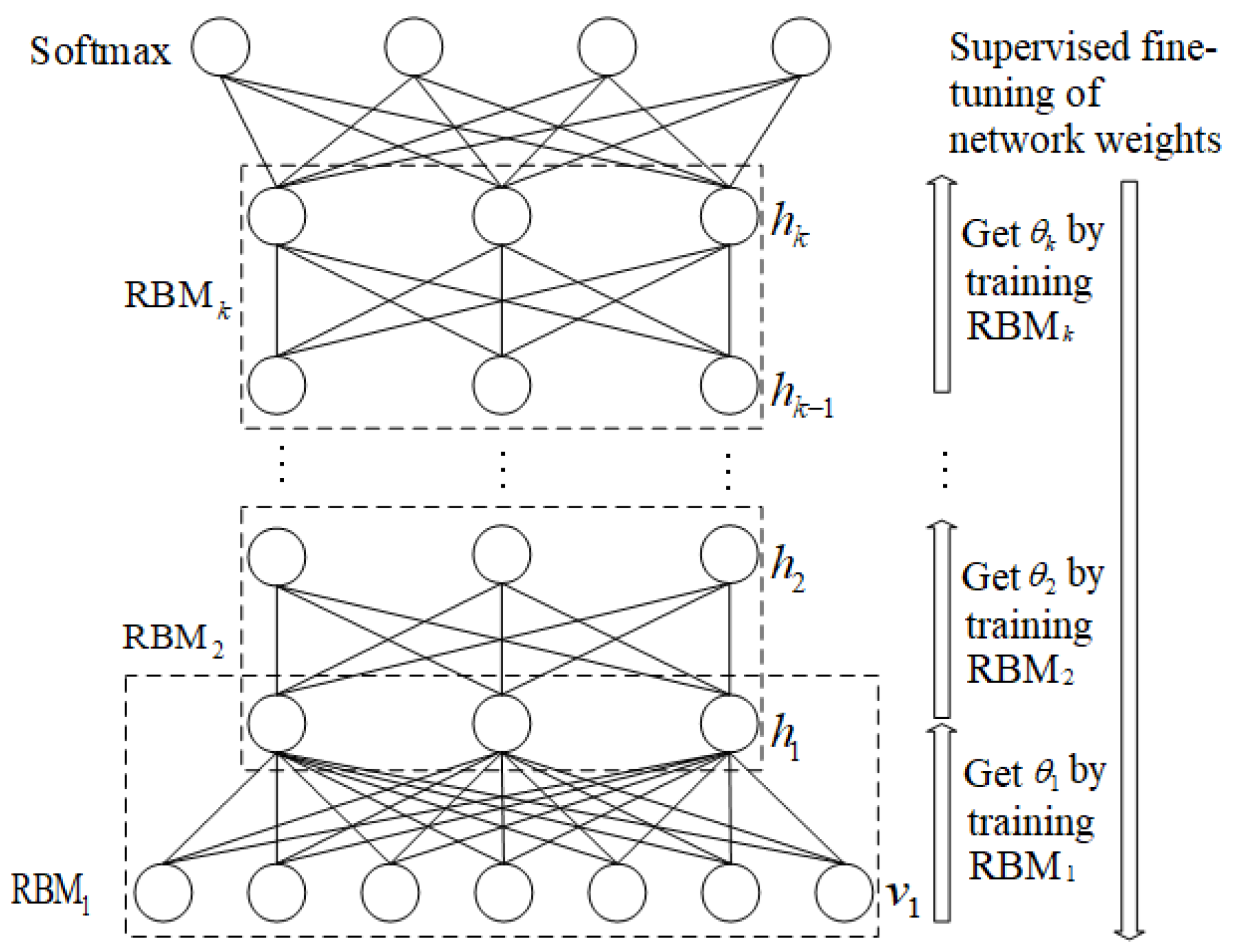

2. Deep Belief Networks

2.1. RBM

2.2. Pre-Training of DBN

2.3. Supervised Fine-Tuning Based on ADAM

3. Cable PD Pattern Recognition Based on ADAM-DBN

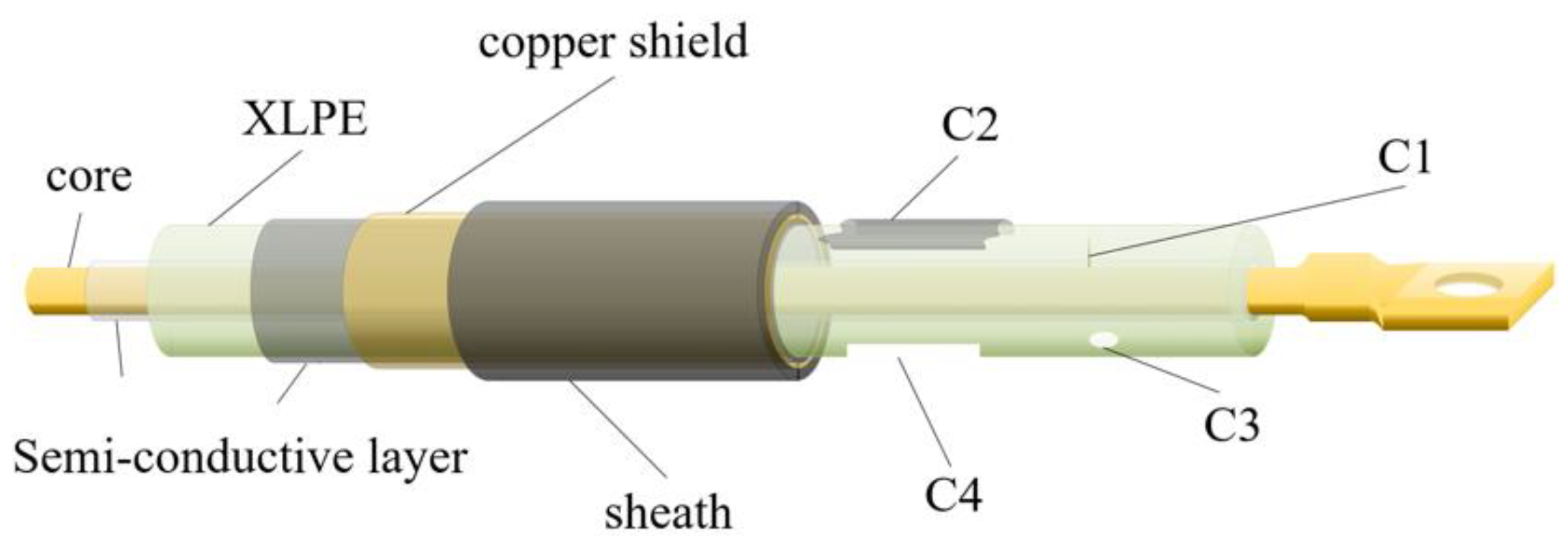

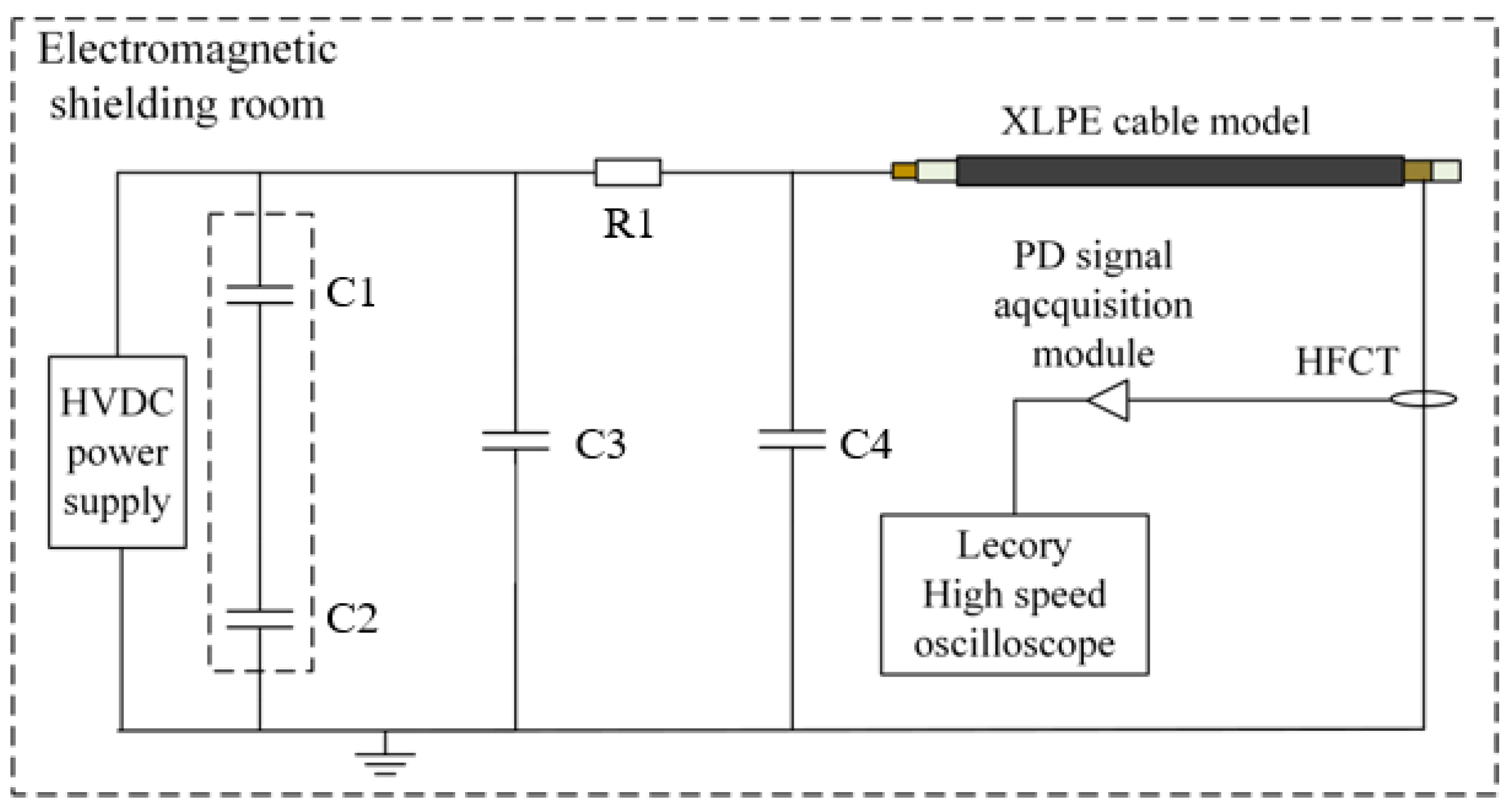

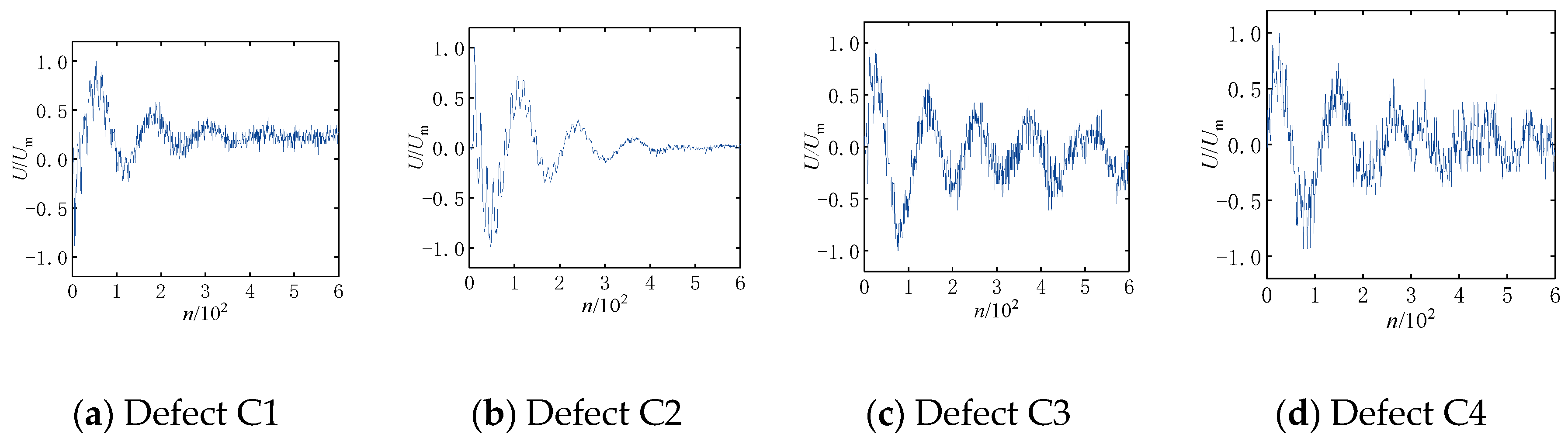

3.1. Insulation Defect Design and Test System Construction

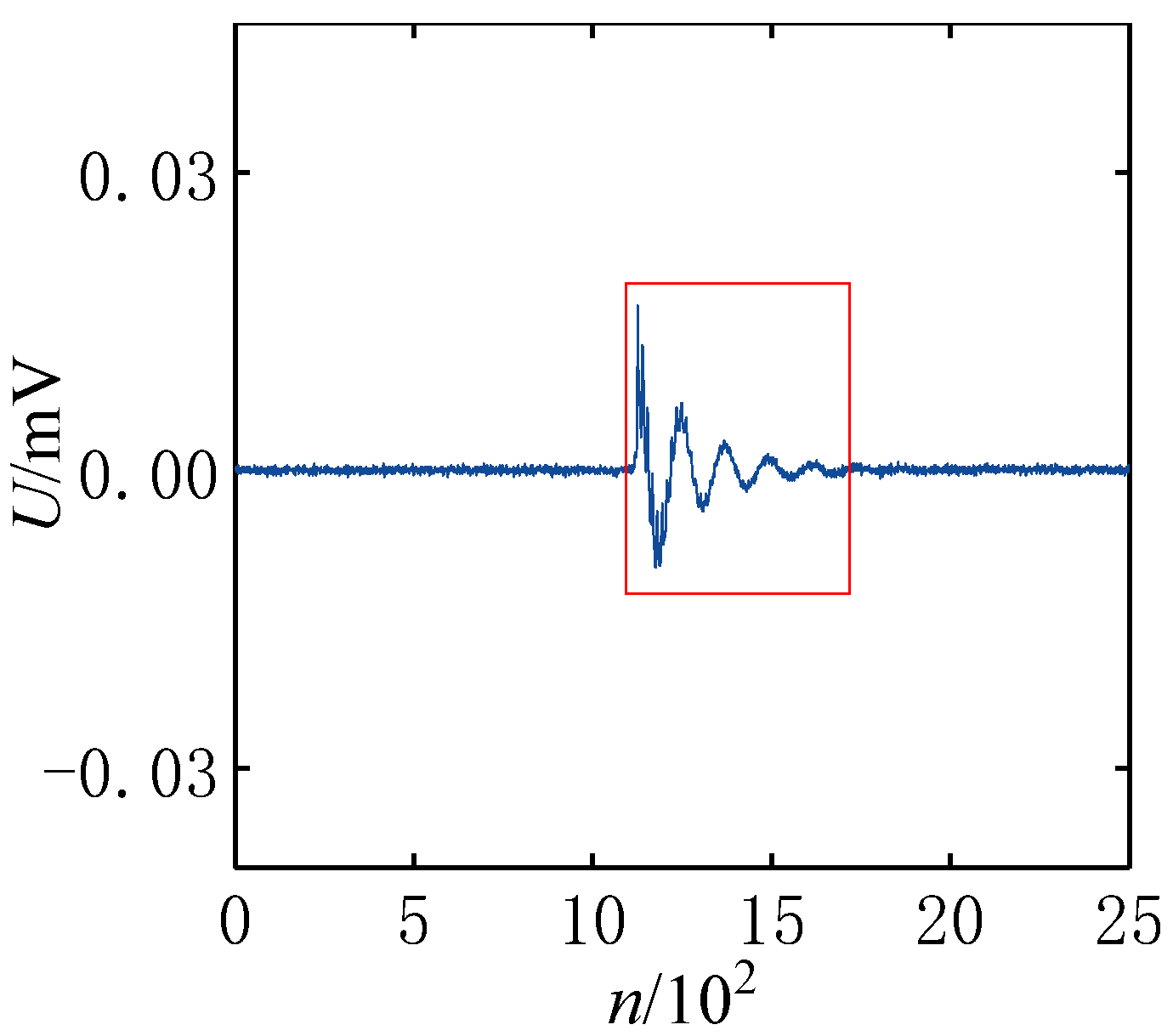

3.2. Sample Collection

3.3. Pattern Recognition Step Based on ADAM-DBN

- (1)

- The original data are pre-processed and divided proportionally into training sets and sample sets.

- (2)

- Construct the DBN recognition model, pre-train it with CD algorithm, and get the pre-trained network parameters of the identification model.

- (3)

- Using the ADAM algorithm, the DBN model is supervised trained by training sample label, fine-tuning the network parameters to make the model optimized.

- (4)

- Use the test data set as input to inspect the trained DBN model.

4. Experimental Analysis

4.1. Experimental Evaluation Indicators

4.2. Structure and Parameter Settings

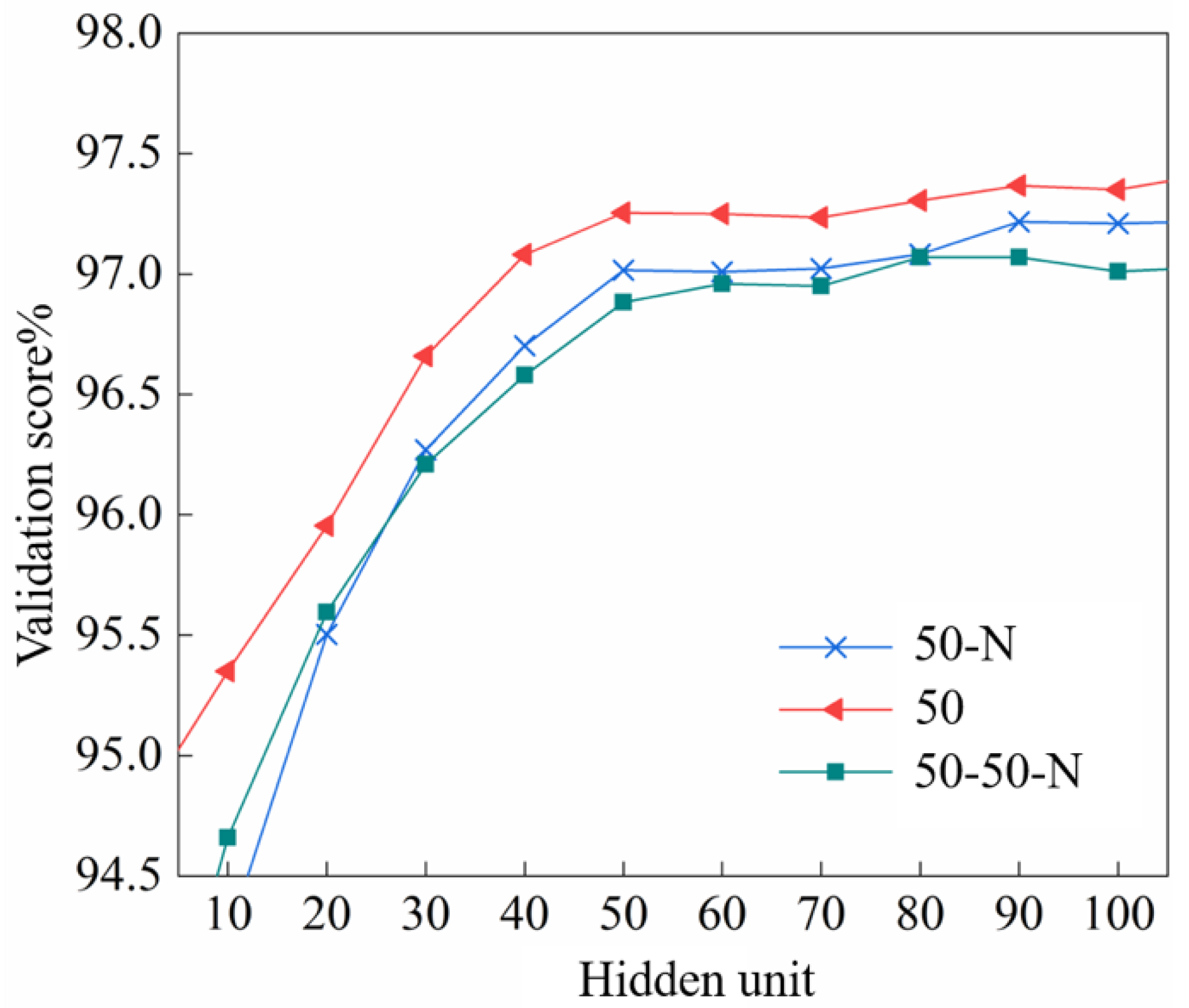

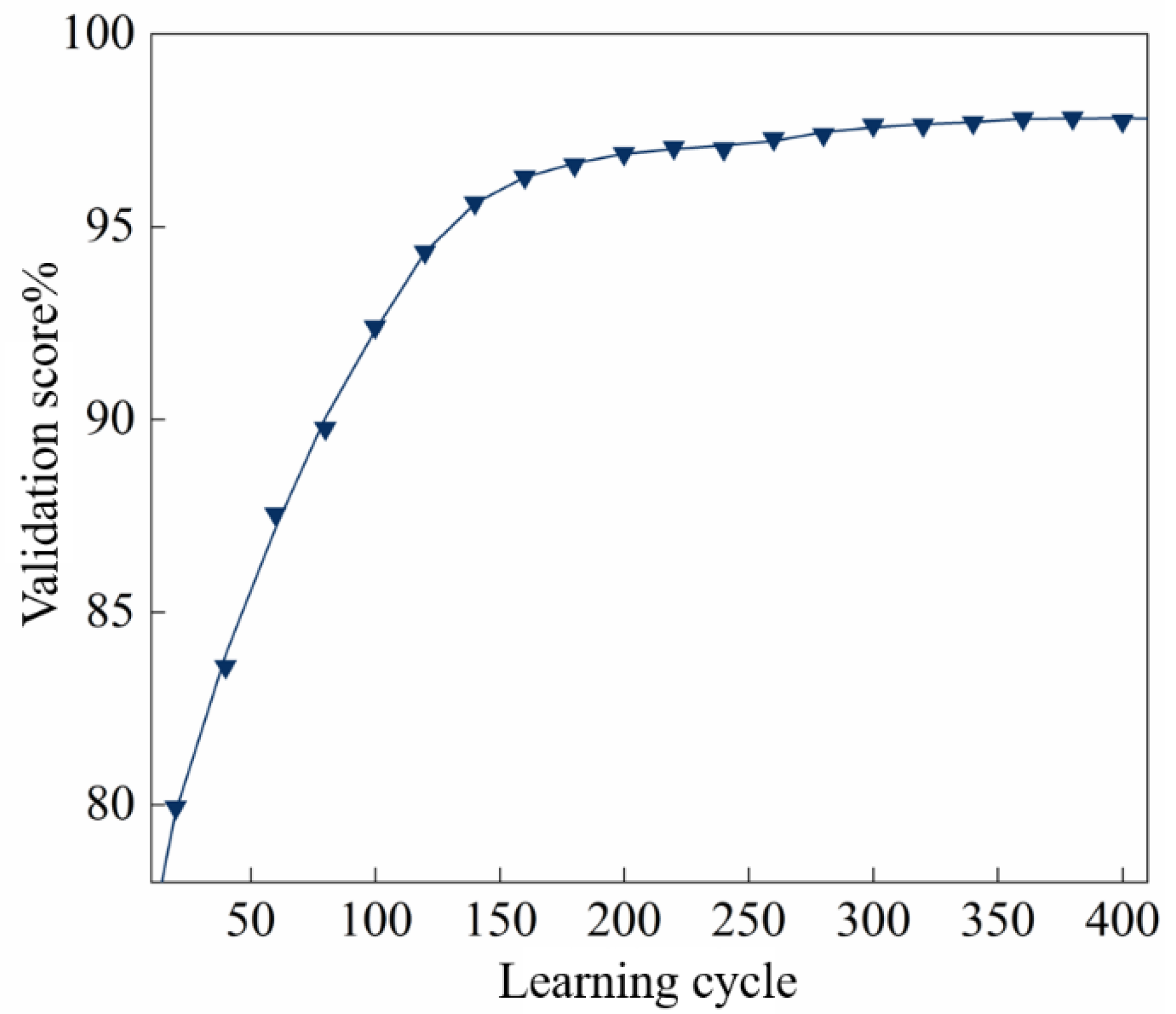

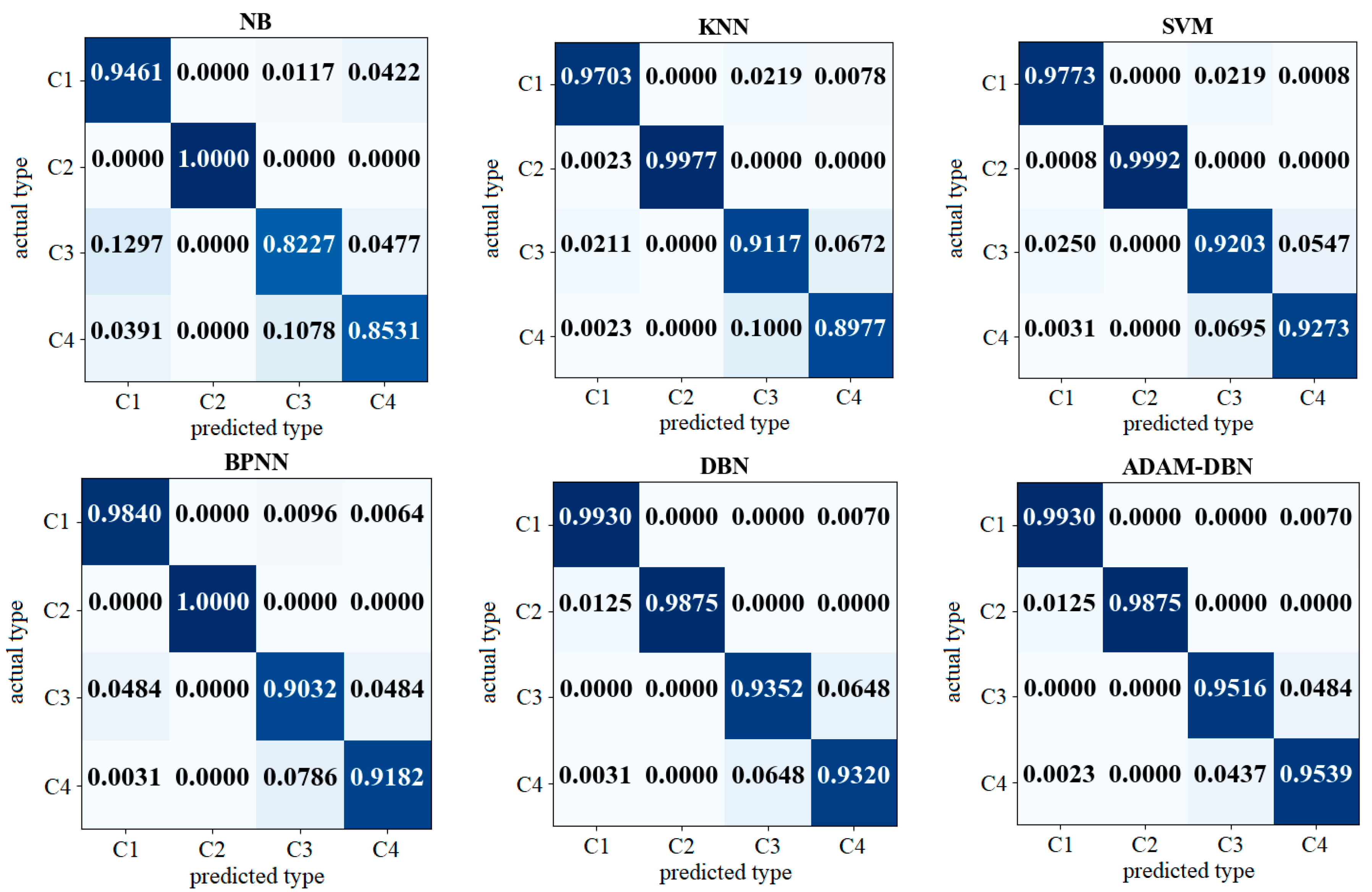

4.3. Results Analysis

5. Conclusions

- The Canny operator is used to pre-process the PD pulse waveform of the XLPE cable. The modified DBN model supervised fine-tuned by the ADAM algorithm is trained to get the pattern recognition result.

- Compared with the NB, KNN, SVM, and BPNN algorithms, ADAM-DBN can unsupervised extract the characteristic information contained in the PD pulse waveforms. And the recognition accuracy of the typical insulation defects in DC XLPE cables is higher than other methods.

- In the experiment, it is found that the traditional classification method based on statistical characteristics performs not so well in the identification of air gap and scratch defects. However, the pattern recognition method based on DBN can effectively characterize the intrinsic relationship between the insulation defect and the PD pulse current waveforms, and have a better recognition effect on all kinds of defects.

- With the increase of training sample size, the recognition accuracy of DC cable based on ADAM-DBN is increased, and the recognition effect is better than that of traditional DBN and other classification methods.

Author Contributions

Funding

Conflicts of Interest

References

- Du, B.X.; Li, Z.L.; Yang, Z.R.; Li, J. Application and Research Progress of HVDC XLPE Cables. High Volt. Eng. 2017, 43, 344–354. [Google Scholar]

- Thue, W.A. Electrical Power Cable Engineering, 3rd ed.; Taylor and Francis: Abingdon, UK, 2012. [Google Scholar]

- Gregory, B. Cable technology and applications in the 21st century. IEEE Power Eng. Rev. 2000, 20, 6–7. [Google Scholar] [CrossRef]

- Kaminaga, K.; Ichihara, M.; Jinno, M.; Fujii, O.; Fukunaga, S.; Kobayashi, M.; Watanabe, K. Development of 500-kV XLPE cables and accessories for long-distance underground transmission lines. V. Long-term performance for 500-kV XLPE cables and joints. IEEE Trans. Power Deliv. 1996, 11, 1185–1194. [Google Scholar] [CrossRef]

- Xu, Y.; Gu, X.; Liu, B.; Hui, B.; Ren, Z.; Meng, S. Special requirements of high frequency current transformers in the on-line detection of partial discharges in power cables. IEEE Electr. Insul. Mag. 2016, 32, 8–19. [Google Scholar] [CrossRef]

- He, W.; Wang, Q.; Huang, C.; Li, H.; Liang, D. A Cost-Effective Technique for PD Testing of MV Cables Under Combined AC and Damped AC Voltage. IEEE Trans. Power Deliv. 2018, 33, 2039–2040. [Google Scholar]

- Oyegoke, B.; Birtwhistle, D.; Lyall, J. Condition assessment of XLPE cable insulation using short-time polarisation and depolarisation current measurements. IET Sci. Meas. Technol. 2008, 2, 25–31. [Google Scholar] [CrossRef]

- Fromm, U. Interpretation of partial discharges at dc voltages. IEEE Trans. Dielectr. Electr. Insul. 1995, 2, 761–770. [Google Scholar] [CrossRef]

- Yang, F.; Sheng, G.; Xu, Y.; Hou, H.; Qian, Y.; Jiang, X. Partial discharge pattern recognition of XLPE cables at DC voltage based on the compressed sensing theory. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2977–2985. [Google Scholar] [CrossRef]

- Mazroua, A.A.; Salama, M.M.A.; Bartnikas, R. PD pattern recognition with neural networks using the multilayer perceptron technique. IEEE Trans. Electr. Insul. 1993, 28, 1082–1089. [Google Scholar] [CrossRef]

- Ma, H.; Saha, T.K.; Ekanayake, C. Statistical learning techniques and their applications for condition assessment of power transformer. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 481–489. [Google Scholar] [CrossRef]

- Morette, N.; Ditchi, T. Oussar, Feature Extraction and Ageing State Recognition using Partial Discharges in Cables under HVDC. Electr. Power Syst. Res. 2020, 178, 106053. [Google Scholar] [CrossRef]

- Morette, N.; Heredia, L.C.; Ditchi, T.; Mor, A.R.; Oussar, Y. Partial discharges and noise classification under HVDC using unsupervised T and semi-supervised learning. Int. J. Electr. Power Energy Syst. 2020, 121, 106129. [Google Scholar] [CrossRef]

- Liu, F.; Jiao, L.; Hou, B.; Yang, S. POL-SAR Image Classification Based on Wishart DBN and Local Spatial Information. IEEE Trans. Geosci. Remote Sens. 2016, 54, 3292–3308. [Google Scholar] [CrossRef]

- Zhang, X.; Pan, X.; Wang, S. Fuzzy DBN with rule-based knowledge representation and high interpretability. In Proceedings of the 2017 12th International Conference on Intelligent Systems and Knowledge Engineering (ISKE), Nanjing, China, 24–26 November 2017; pp. 1–7. [Google Scholar]

- Bengio, Y. Learning deep architectures for AI. Found. Trends Mach. Learn. 2009, 2, 1–127. [Google Scholar] [CrossRef]

- Wang, T.; He, Y.; Shi, T.; Li, B. Transformer Incipient Hybrid Fault Diagnosis Based on Solar-Powered RFID Sensor and Optimized DBN Approach. IEEE Access 2019, 7, 74103–74110. [Google Scholar] [CrossRef]

- Zhang, C.; He, Y.; Yuan, L.; Xiang, S. Analog Circuit Incipient Fault Diagnosis Method Using DBN Based Features Extraction. IEEE Access 2018, 6, 23053–23064. [Google Scholar] [CrossRef]

- Hinton, G.E. A practical guide to training restricted Boltzmann machines. Momentum 2012, 9, 599–619. [Google Scholar]

- Hinton, G.; Deng, L.; Yu, D.; Dahl, G. Deep neural networks for acoustic modeling in speech recognition: The shared views of four research groups. IEEE Signal Process. Mag. 2012, 29, 82–97. [Google Scholar] [CrossRef]

- Hinton, G.E. Training products of experts by minimizing contrastive divergence. Neural Comput. 2002, 14, 1771–1800. [Google Scholar] [CrossRef]

- Kingma, D.; Ba, J. Adam: A Method for Stochastic Optimization. Comput. Sci. 2014, arXiv:1412.6980. [Google Scholar]

- Canny, J. A computational approach to edge detection. Read. Comput. Vis. 1987, 6, 184–203. [Google Scholar]

| Training Set | Recognition Accuracy% | |||||

|---|---|---|---|---|---|---|

| NB | KNN | SVM | BPNN | DBN | ADAM-DBN | |

| 400 | 90.4 | 93.8 | 94.6 | 93.9 | 92.8 | 93.8 |

| 800 | 90.1 | 94.3 | 95.3 | 94.5 | 95.1 | 95.9 |

| 1200 | 90.4 | 94.7 | 95.9 | 95.2 | 96.1 | 96.8 |

| 1600 | 90.5 | 94.8 | 96.0 | 95.3 | 97.0 | 98.0 |

| 2000 | 90.6 | 95.0 | 96.1 | 95.4 | 97.2 | 98.2 |

| 2400 | 90.5 | 95.1 | 96.1 | 95.6 | 97.3 | 98.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Xu, Y.; Jiang, X. Pattern Recognition of DC Partial Discharge on XLPE Cable Based on ADAM-DBN. Energies 2020, 13, 4566. https://doi.org/10.3390/en13174566

Li Z, Xu Y, Jiang X. Pattern Recognition of DC Partial Discharge on XLPE Cable Based on ADAM-DBN. Energies. 2020; 13(17):4566. https://doi.org/10.3390/en13174566

Chicago/Turabian StyleLi, Zhe, Yongpeng Xu, and Xiuchen Jiang. 2020. "Pattern Recognition of DC Partial Discharge on XLPE Cable Based on ADAM-DBN" Energies 13, no. 17: 4566. https://doi.org/10.3390/en13174566

APA StyleLi, Z., Xu, Y., & Jiang, X. (2020). Pattern Recognition of DC Partial Discharge on XLPE Cable Based on ADAM-DBN. Energies, 13(17), 4566. https://doi.org/10.3390/en13174566