The Impact of Pitch-To-Stall and Pitch-To-Feather Control on the Structural Loads and the Pitch Mechanism of a Wind Turbine

Abstract

1. Introduction

2. Methodology

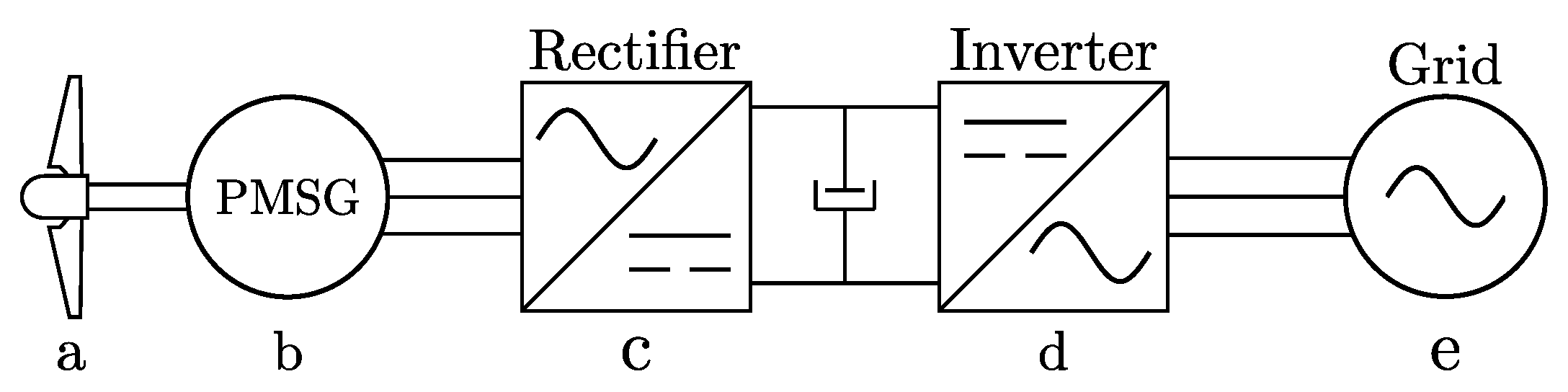

2.1. Wind Turbine Generation System

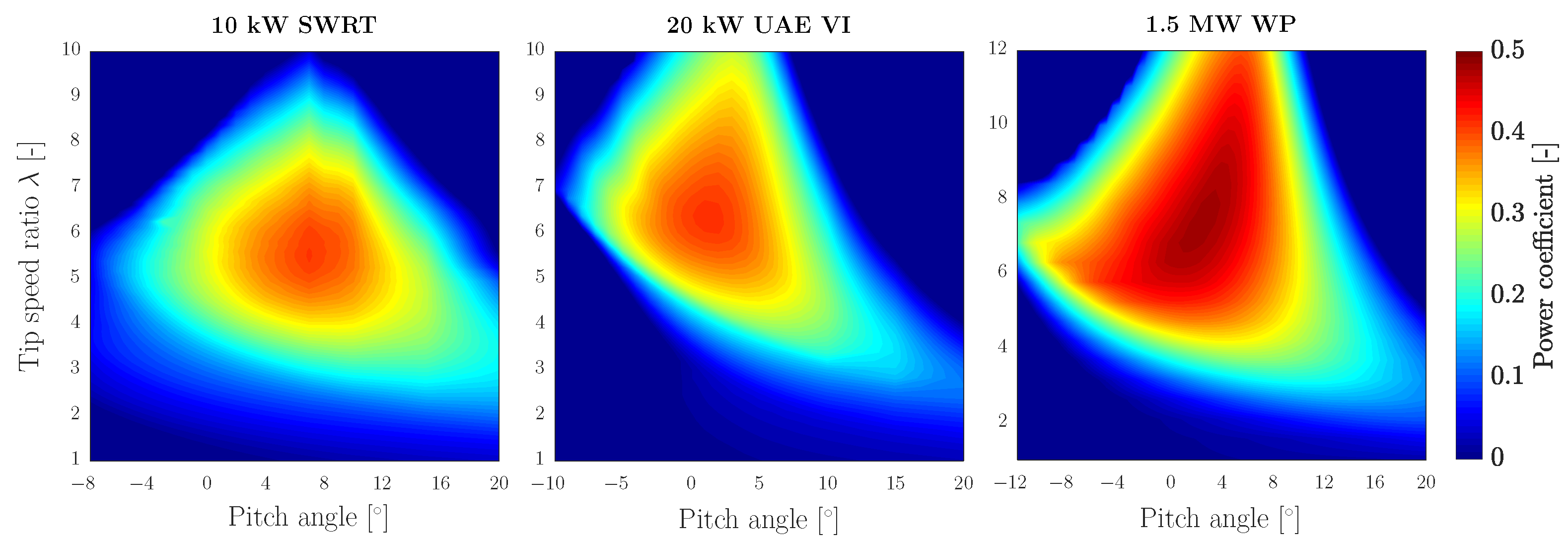

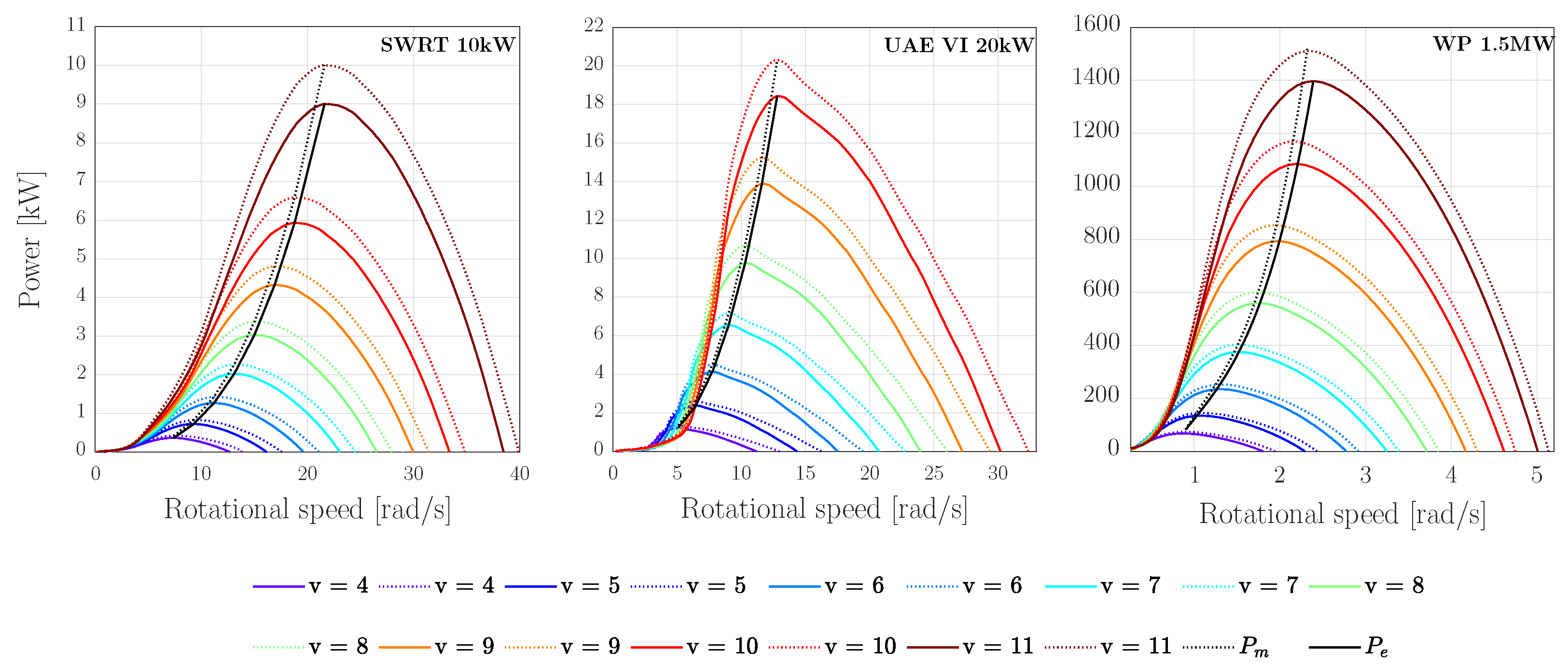

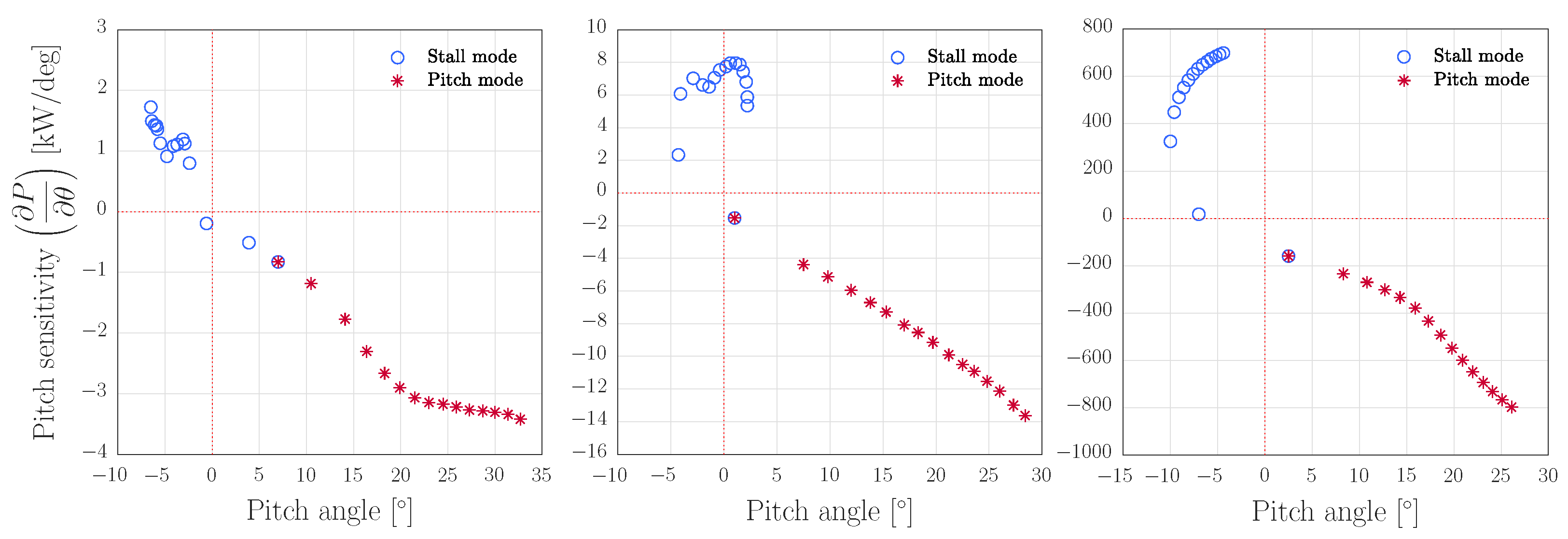

2.2. Control System

- Pitch-to-feather (pitch control): the rotational speed is limited to the rated value by pitching the blades to feather. By pitching the blades’ leading edge into the wind, the aerodynamic process of blade feathering occurs, which causes a reduction of the aerodynamic forces. Therefore, the speed controller increases the pitch angle, thus reducing the angle of attack, in order to limit the lift forces and driving torque. The pitching rate should be high enough to keep the generator speed at its nominal value and deal with the fluctuating nature of wind.

- Pitch-to-stall (stall control): the controller turns the blades in the opposite direction to the direction of pitch-to-feather, i.e., turning the blades’ leading edge out of the wind, thus increasing the blades’ angle of attack beyond the critical or stalling angle of attack. Therefore, the lift forces on the blades are reduced as the lift coefficient exceeds its maximum .

3. Verifications and Results

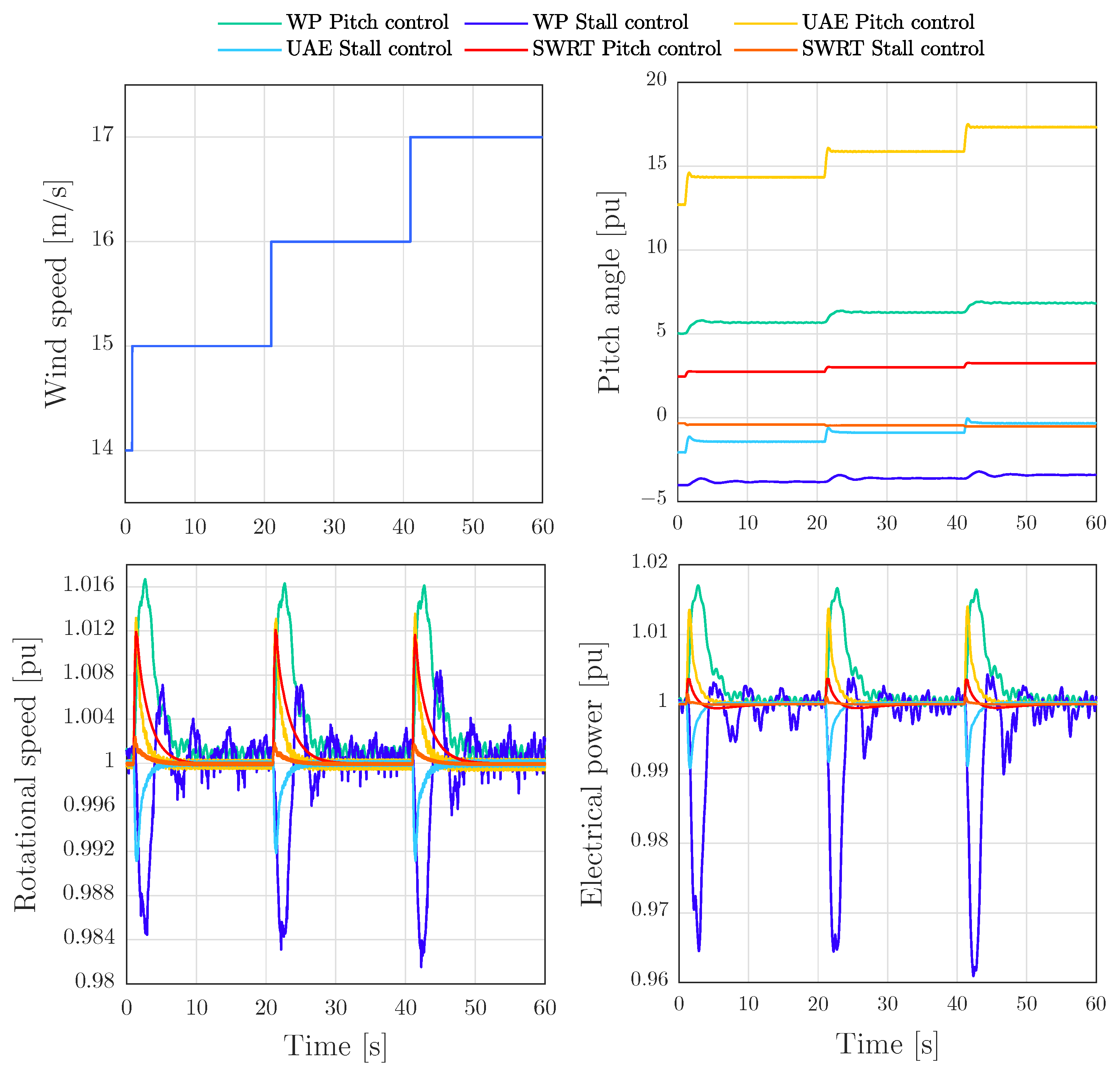

3.1. Validation of Control Performance

- To maximise the energy capture in the low-speed region by maximising the aerodynamic efficiency of the wind turbine.

- To obtain an identical response for all wind turbines in the whole wind speed range of region IV, i.e., coping with the different sensitivity of the aerodynamic power to the blade pitch angle for each wind speed.

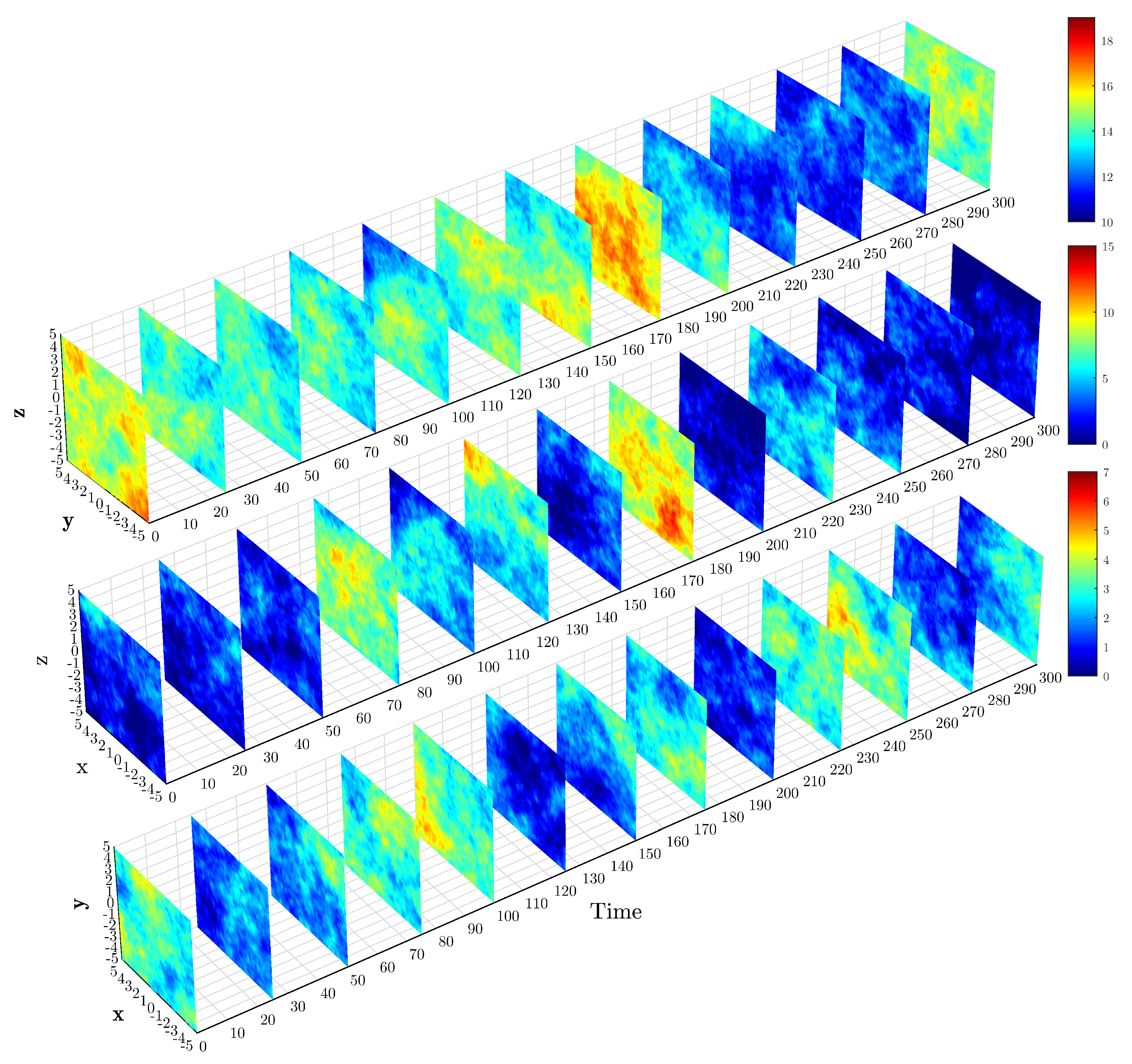

3.2. Turbulent Wind Field Simulation

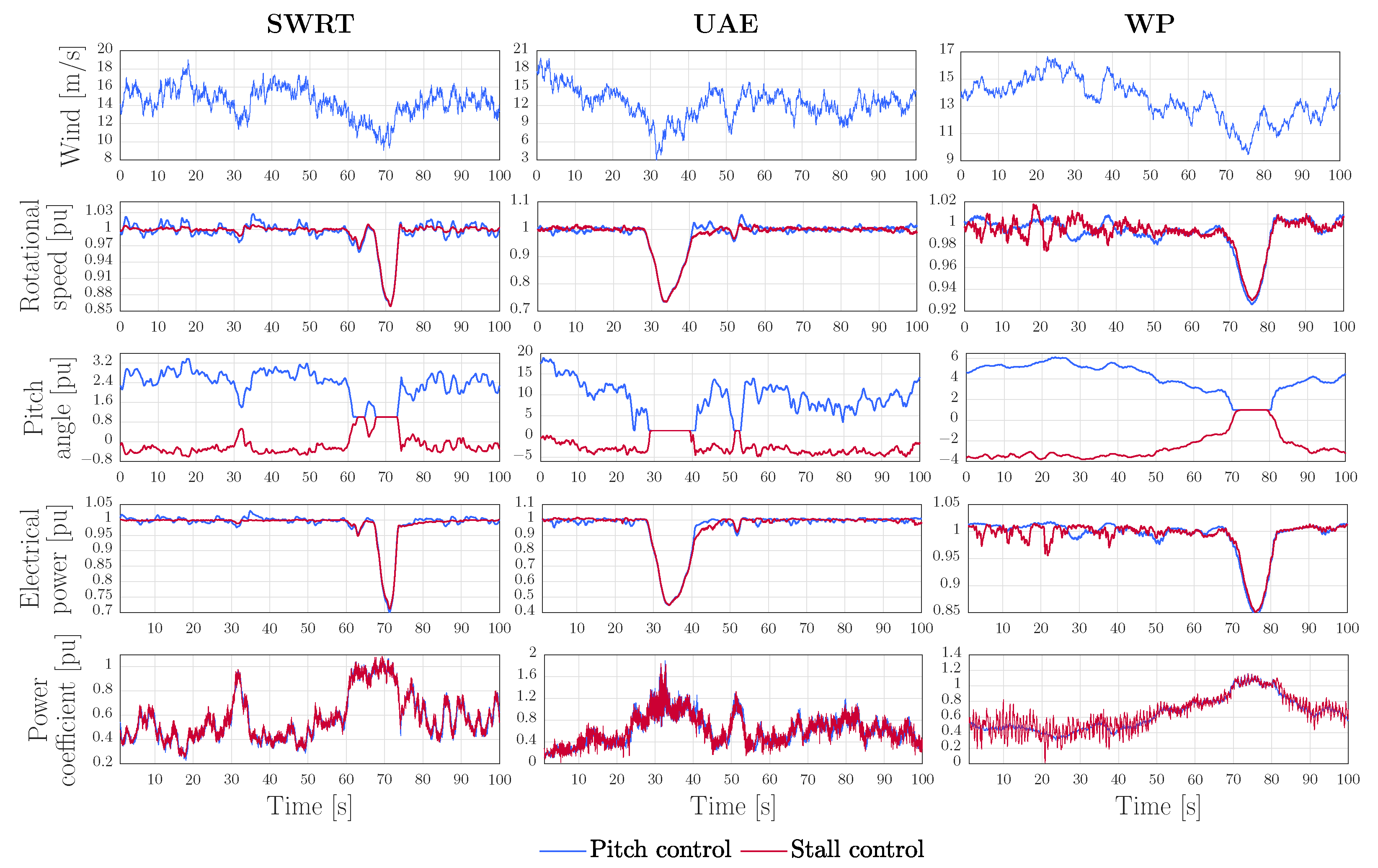

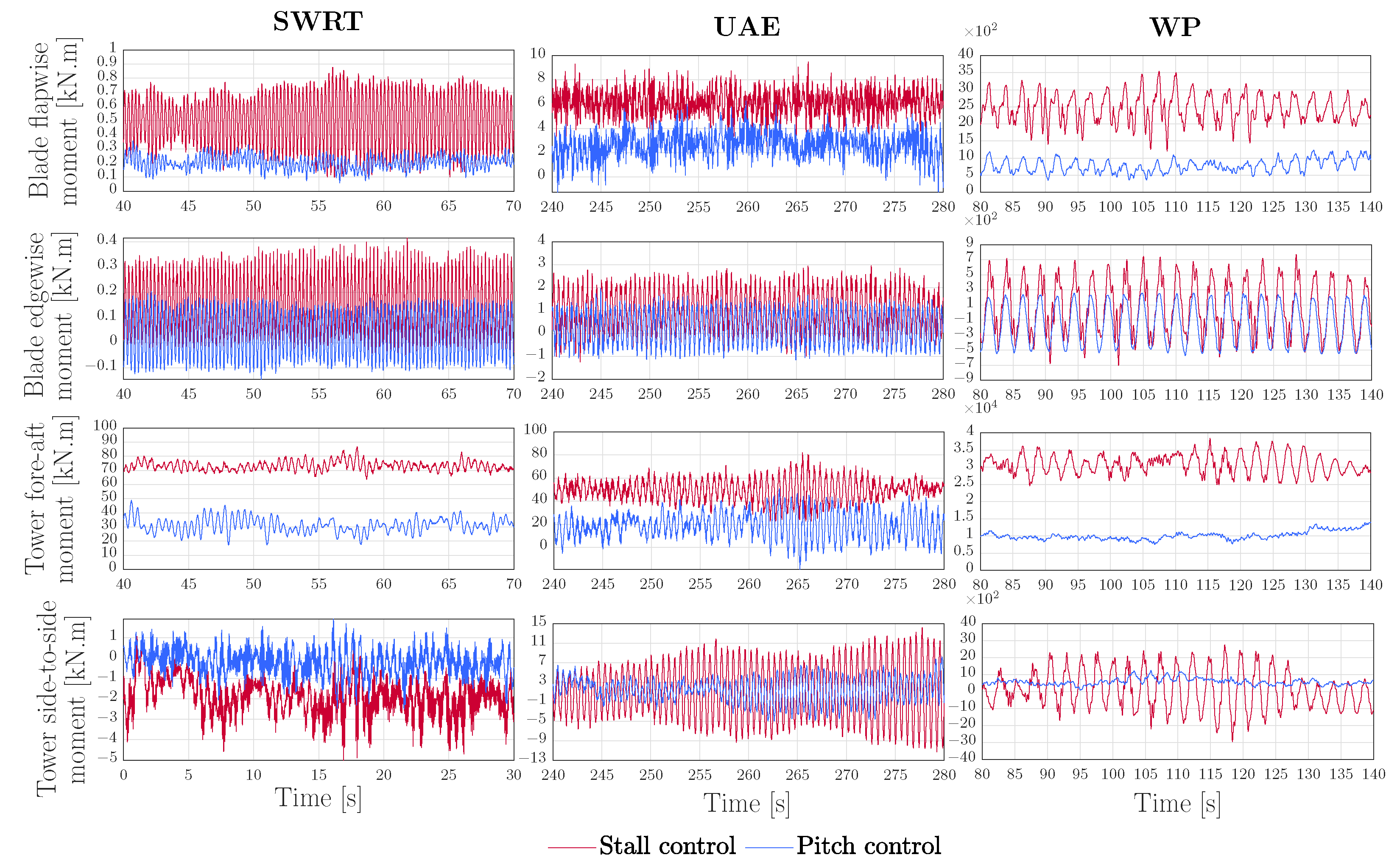

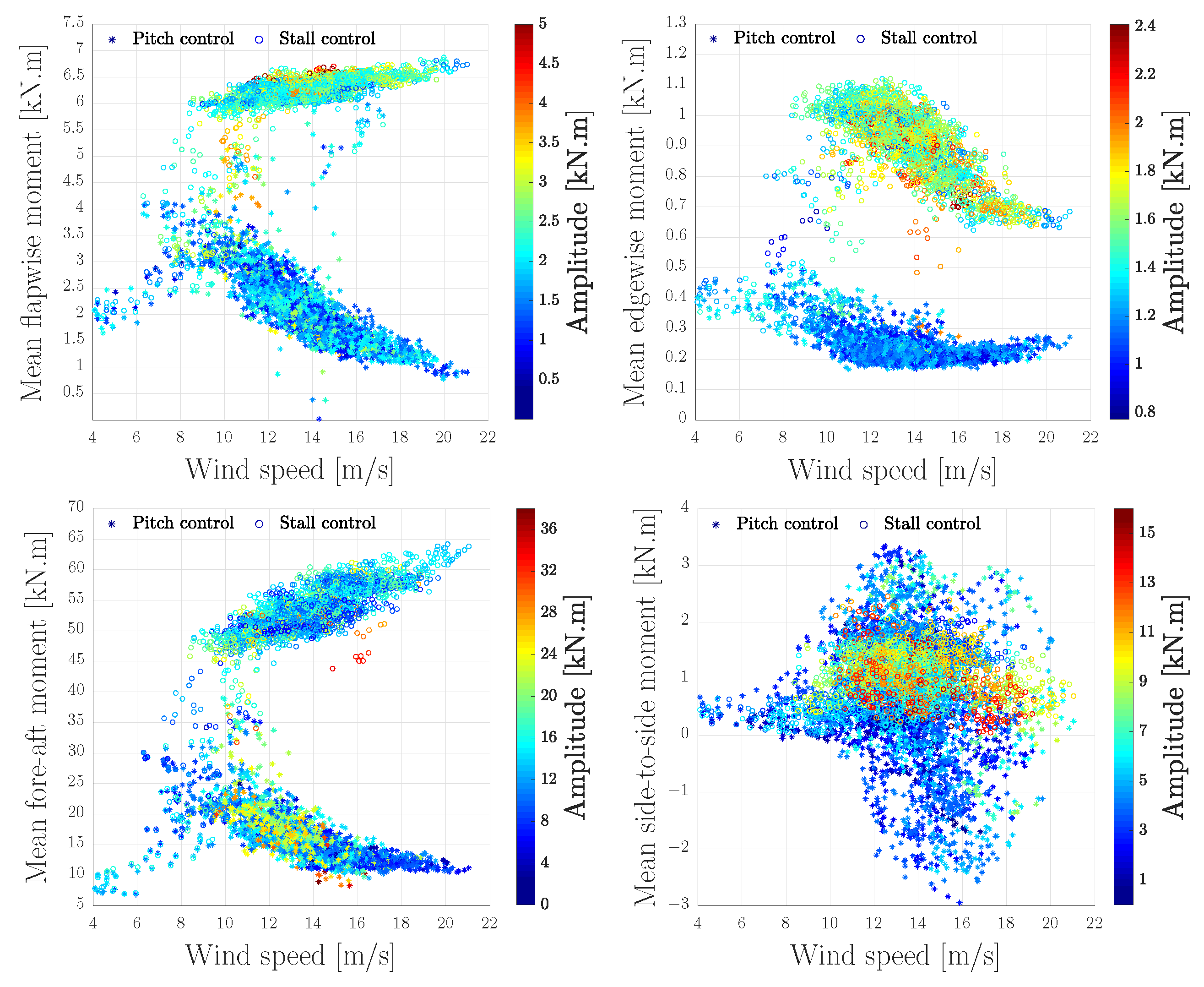

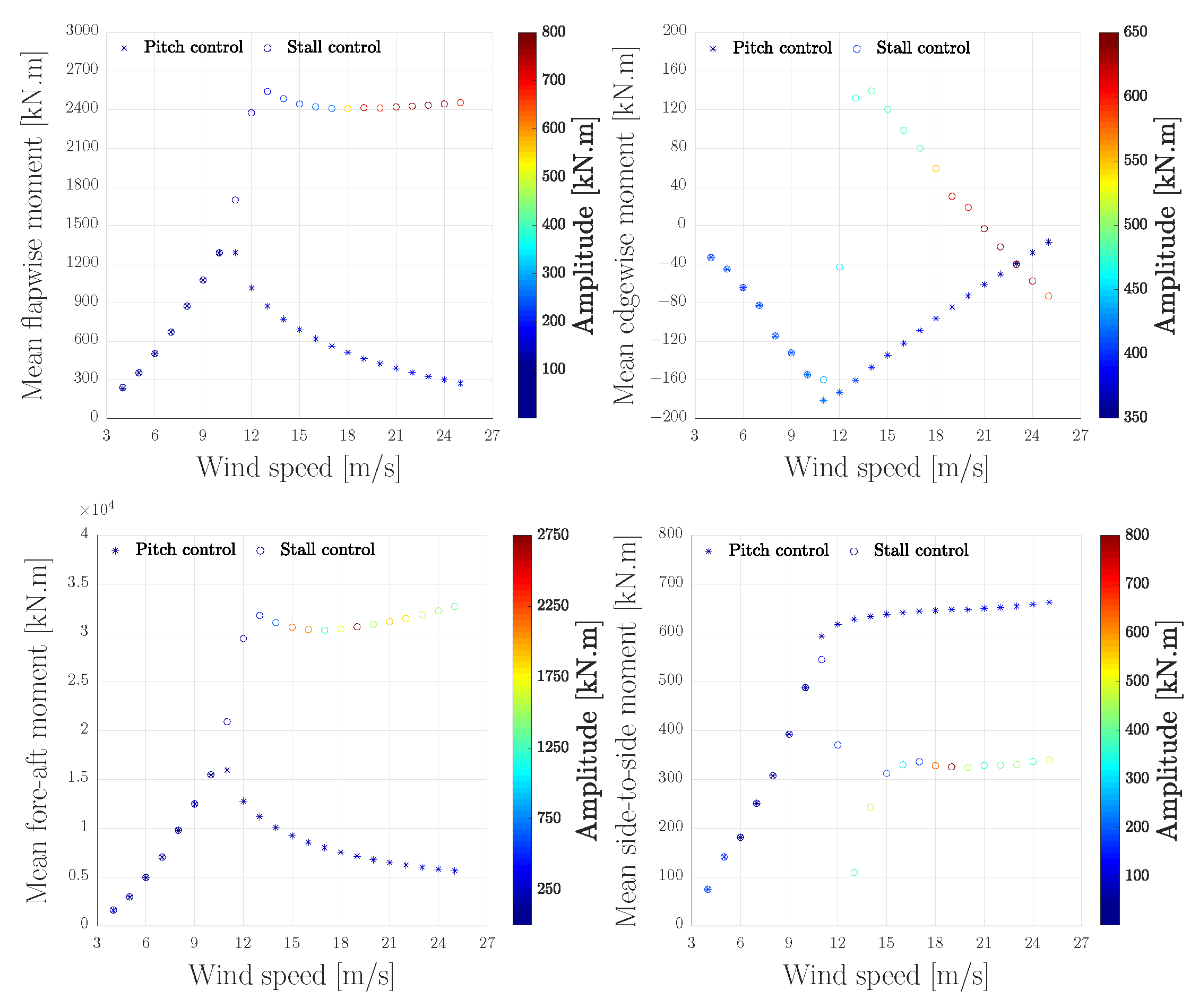

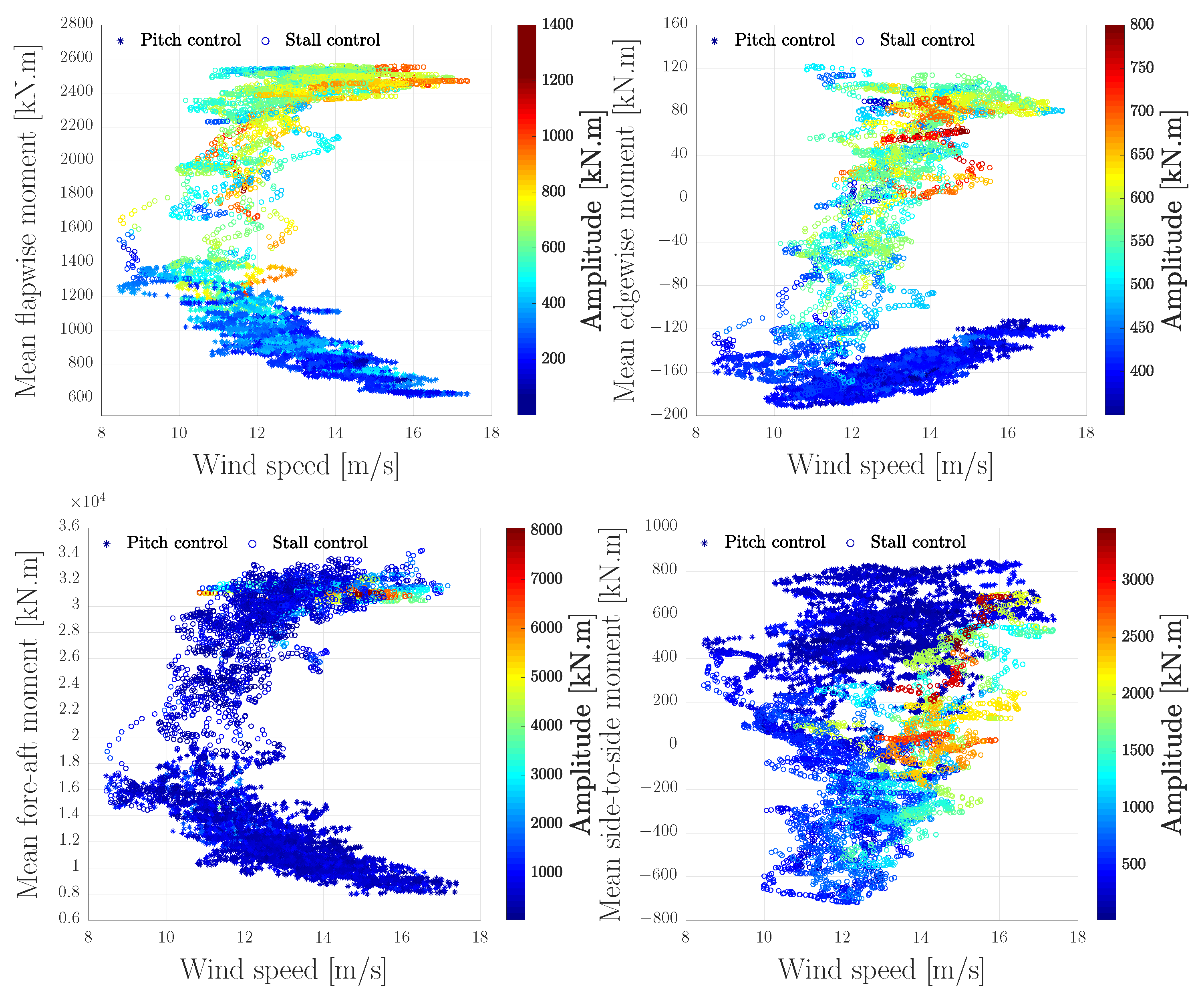

3.3. Performance in Turbulent Wind

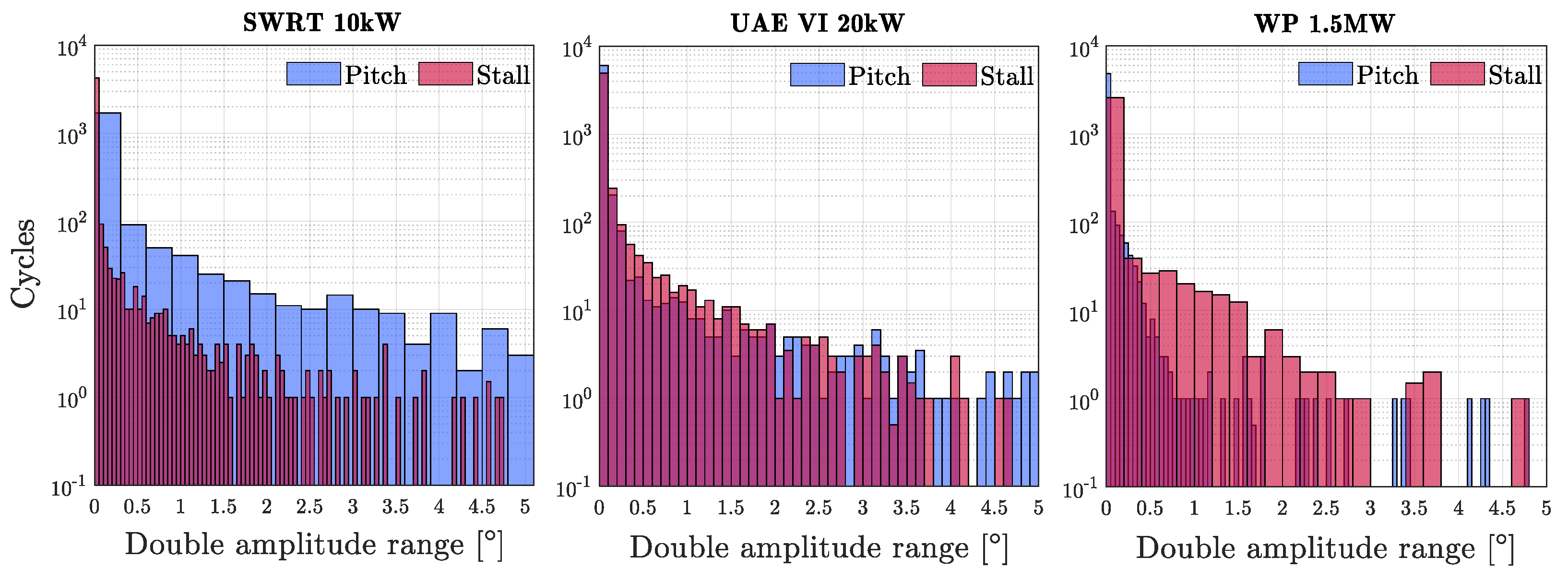

3.4. Control Impact on the Pitch Mechanism

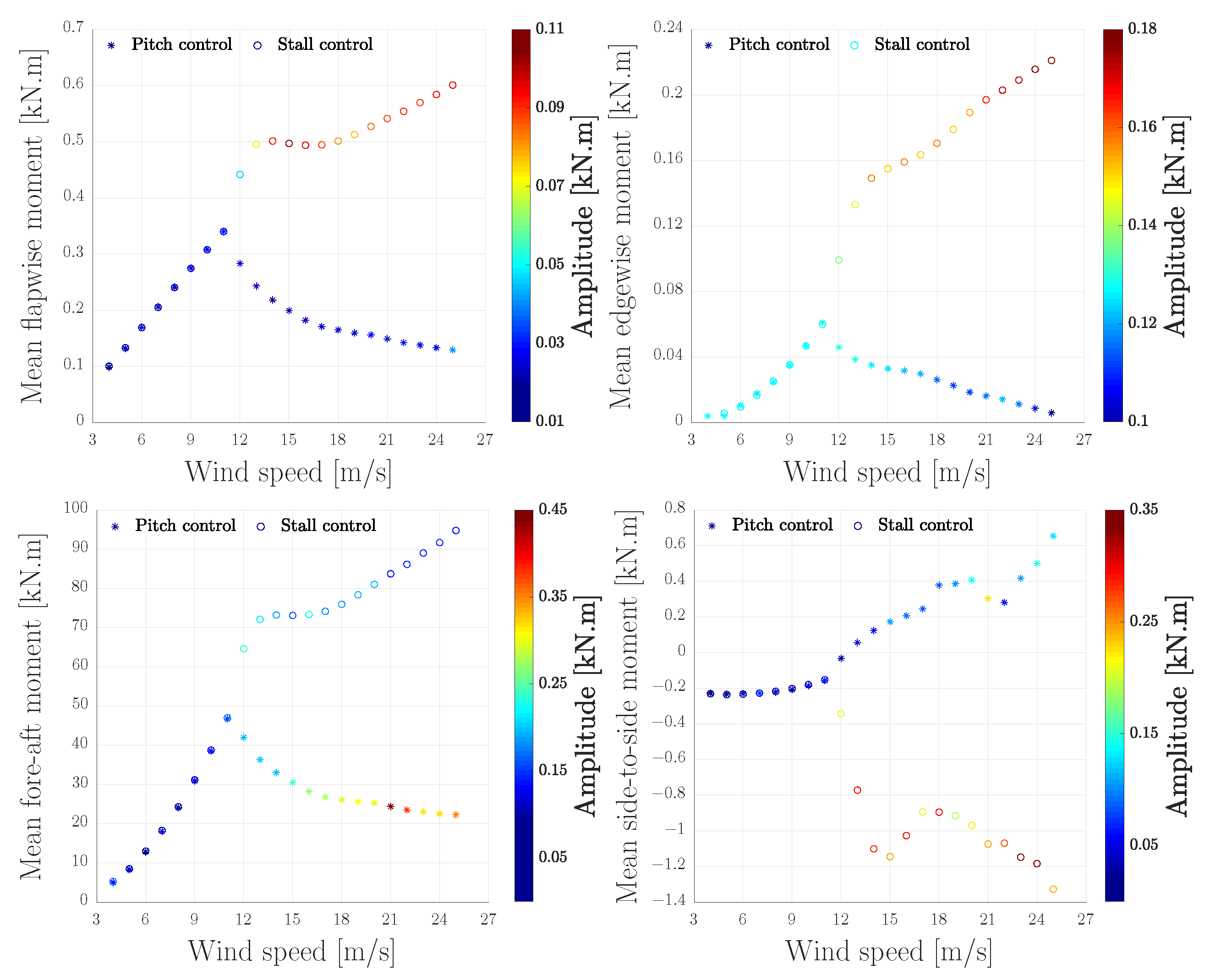

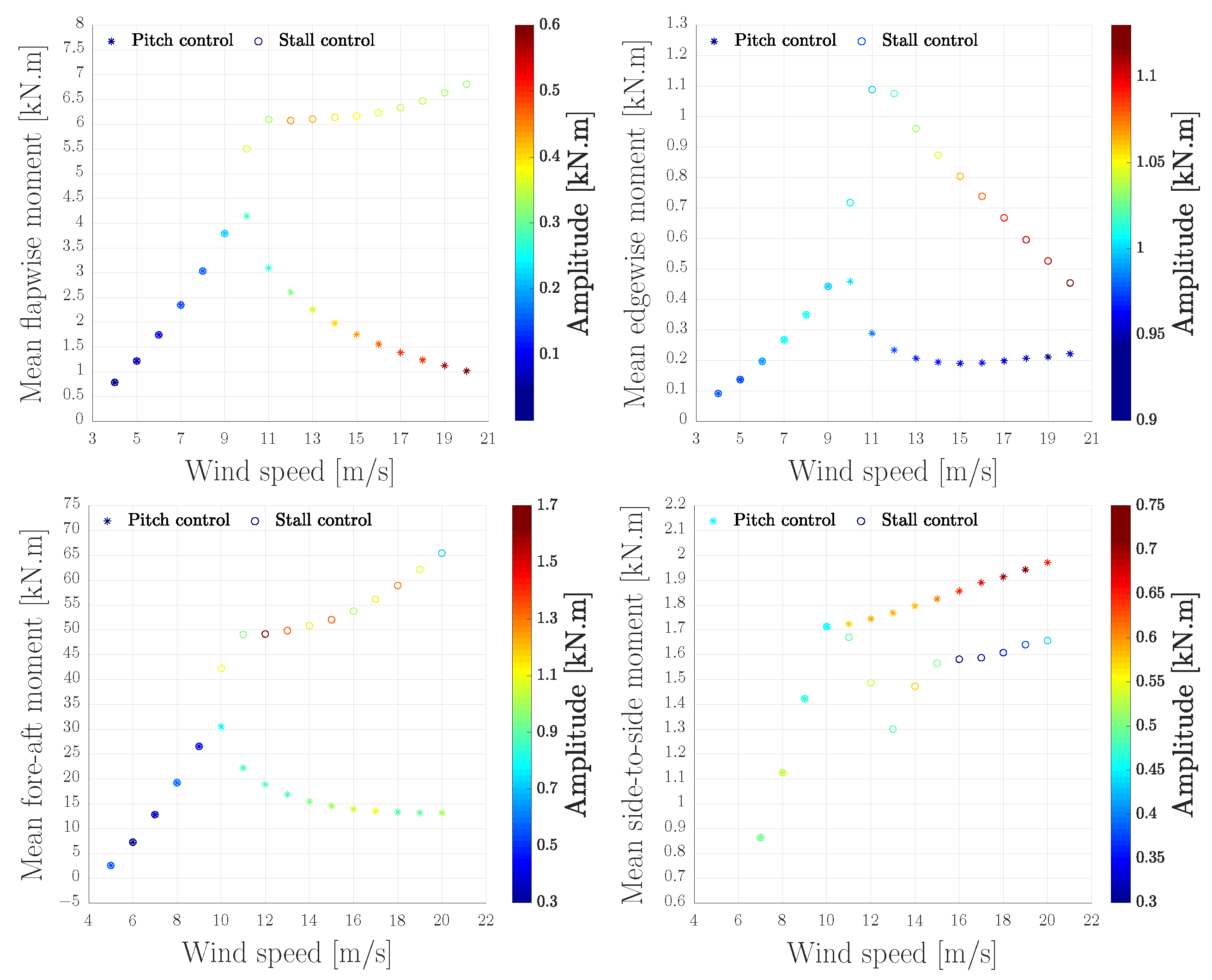

3.5. Control Impact on Structural Loads

4. Conclusions and Discussions

- Pitch-to-stall control reduces the rotor speed oscillations and power transients, as compared to pitch-to-feather, for the SWRT and UAE wind turbines with untwisted and stall-regulated blade designs, respectively.

- Pitch-to-stall control reduces the fore-aft fatigue load on the tower, as compared to pitch-to-feather, of the wind turbines with untwisted and stall-regulated blade designs.

- For SWRT and UAE wind turbines, pitch-to-stall control decreases the flapwise moment on the blades in uniform wind, and stabilises it in turbulent wind. However, the amplitude of the cycling component increases in turbulent wind.

- Pitch-to-stall control magnifies the side-to-side tower fatigue loading and the blades flapwise and edgewise fatigue loads in turbulent winds. However, the difference with pith-to-feather control is minimised for the UAE wind turbines due to its stall-regulated blade design.

- Although the pitch-to-stall control reduces the summed blade pitch movements of SWRT and UAE wind turbines, the pitch movements with small amplitude oscillation increases, which increases the risk of wear in the rolling contacts of the blade bearings.

- Pitch-to-stall control has a negative impact on the WP wind turbine (with pitch-regulated blade design) in terms of dynamic performance and structural loading.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Pitch angle | |

| Sensitivity of the aerodynamic power to the pitch angle | |

| Pitch angle at the rated operating point | |

| Pitch angle at which the blade sensitivity has increased by a factor of 2, compared to its value at the rated operating point | |

| Gain correction factor | |

| Horizontal wind speed (vectorial u + v) | |

| Wind direction | |

| Vertical wind speed (w component) | |

| Vertical linear wind-shear parameters | |

| Horizontal linear wind-shear parameters | |

| Horizontal gust speed | |

| Vertical power-law wind-shear exponent | |

| Reference height | |

| Reference length for linear horizontal and vertical sheer | |

| Power law exponent | |

| Spectrum scaling factor | |

| Spectrum scaling factor | |

| f | Cyclic frequency |

| Friction velocity | |

| Mean wind speed at height z |

Appendix A. Blade Characteristic of Wind Turbine Models

| SWRT 10 kW | UAE 20 kW | WP 1.5 MW | ||||||

|---|---|---|---|---|---|---|---|---|

| Blade Radius (m) | Twist Angle (°) | Aerofoils | Blade Radius (m) | Twist Angle (°) | Aerofoils | Blade Radius (m) | Twist Angle (°) | Aerofoils |

| 0 | 2 | SH3052 | 0 | 0 | cylinder | 0 | 11.1 | cylinder |

| 0.0865 | 0 | SH3052 | 0.136 | 0 | cylinder | 1.108 | 11.1 | cylinder |

| 0.432 | 0 | SH3052 | 0.448 | −0.098 | cylinder | 3.325 | 11.1 | S818 |

| 0.605 | 0 | SH3052 | 0.8 | 19.423 | S809 | 5.541 | 11.1 | S818 |

| 0.779 | 0 | SH3052 | 1.076 | 14.318 | S809 | 7.758 | 11.1 | S818 |

| 0.952 | 0 | SH3052 | 1.277 | 10.971 | S809 | 9.975 | 8.38 | S818 |

| 1.125 | 0 | SH3052 | 1.495 | 8.244 | S809 | 12.191 | 6.35 | S818 |

| 1.298 | 0 | SH3052 | 1.713 | 6.164 | S809 | 14.408 | 4.33 | S818 |

| 1.471 | 0 | SH3052 | 1.914 | 4.689 | S809 | 16.625 | 2.85 | S825 |

| 1.644 | 0 | SH3052 | 2.116 | 3.499 | S809 | 18.841 | 2.22 | S825 |

| 1.817 | 0 | SH3052 | 2.334 | 2.478 | S809 | 21.058 | 1.58 | S825 |

| 1.990 | 0 | SH3052 | 2.552 | 1.686 | S809 | 23.275 | 0.95 | S825 |

| 2.164 | 0 | SH3052 | 2.753 | 1.115 | S809 | 25.491 | 0.53 | S825 |

| 2.337 | 1.6 | SH3052 | 2.954 | 0.666 | S809 | 27.708 | 0.38 | S825 |

| 2.510 | 3.2 | SH3052 | 3.172 | 0.267 | S809 | 29.925 | 0.23 | S826 |

| 2.596 | 3.2 | SH3052 | 3.390 | −0.079 | S809 | 32.141 | 0.08 | S826 |

| 3.591 | −0.381 | S809 | 33.25 | 0.08 | S826 | |||

| 3.792 | −0.679 | S809 | ||||||

| 3.968 | −0.933 | S809 | ||||||

| 4.144 | −1.184 | S809 | ||||||

| 4.345 | −1.466 | S809 | ||||||

| 4.521 | −1.711 | S809 | ||||||

| 4.597 | −1.815 | S809 | ||||||

References

- Council, G.W.E. Global Wind Report 2019; Global Wind Energy Council: Brussels, Belgium, 2020. [Google Scholar]

- Bossanyi, E.A. Individual blade pitch control for load reduction. Wind Energy 2003, 6, 119–128. [Google Scholar] [CrossRef]

- Park, S.; Nam, Y. Two LQRI based blade pitch controls for wind turbines. Energies 2012, 5, 1998–2016. [Google Scholar] [CrossRef]

- Macquart, T.; Maheri, A.; Busawon, K. Microtab dynamic modelling for wind turbine blade load rejection. Renew. Energy 2014, 64, 144–152. [Google Scholar] [CrossRef]

- He, K.; Qi, L.; Zheng, L.; Chen, Y. Combined pitch and trailing edge flap control for load mitigation of wind turbines. Energies 2018, 11, 2519. [Google Scholar] [CrossRef]

- Maldonado, V. Active Flow Control of Wind Turbine Blades. In Wind Turbines—Design, Control and Applications; In-Tech: Rijeka, Croatia, 2016; pp. 303–324. [Google Scholar]

- Dinwoodie, I.; McMillan, D.; Revie, M.; Lazakis, I.; Dalgic, Y. Development of a combined operational and strategic decision support model for offshore wind. Energy Procedia 2013, 35, 157–166. [Google Scholar] [CrossRef]

- Dao, C.; Kazemtabrizi, B.; Crabtree, C. Wind turbine reliability data review and impacts on levelised cost of energy. Wind Energy 2019, 22, 1848–1871. [Google Scholar] [CrossRef]

- Harris, T.A.; Kotzalas, M.N. Advanced Concepts of Bearing Technology: Rolling Bearing Analysis; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Stammler, M.; Thomas, P.; Reuter, A.; Schwack, F.; Poll, G. Effect of load reduction mechanisms on loads and blade bearing movements of wind turbines. Wind Energy 2019, 23, 274–290. [Google Scholar] [CrossRef]

- Larsen, T.J.; Hanson, T.D. A method to avoid negative damped low frequent tower vibrations for a floating, pitch controlled wind turbine. J. Phys. Conf. Ser. IOP Publ. 2007, 75, 012073. [Google Scholar] [CrossRef]

- Jonkman, J.M. Dynamics Modeling and Loads Analysis of an Offshore Floating Wind Turbine; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2007.

- Macquart, T.; Maheri, A. A stall-regulated wind turbine design to reduce fatigue. Renew. Energy 2019, 133, 964–970. [Google Scholar] [CrossRef]

- Ward, D.; Collu, M.; Sumner, J. Reducing Tower Fatigue through Blade Back Twist and Active Pitch-to-Stall Control Strategy for a Semi-Submersible Floating Offshore Wind Turbine. Energies 2019, 12, 1897. [Google Scholar] [CrossRef]

- Loza, B.; Pacheco-Chérrez, J.; Cárdenas, D.; Minchala, L.I.; Probst, O. Comparative Fatigue Life Assessment of Wind Turbine Blades Operating with Different Regulation Schemes. Appl. Sci. 2019, 9, 4632. [Google Scholar] [CrossRef]

- De Kooning, J.D.M.; Van de Vyver, J.; Meersman, B.; Vandevelde, L. Maximum efficiency current waveforms for a PMSM including iron losses and armature reaction. IEEE Trans. Ind. Appl. 2017, 53, 3336–3344. [Google Scholar] [CrossRef]

- De Kooning, J.D.M.; Vandoorn, T.L.; Van de Vyver, J.; Meersman, B.; Vandevelde, L. Displacement of the maximum power point caused by losses in wind turbine systems. Renew. Energy 2016, 85, 273–280. [Google Scholar] [CrossRef]

- Cui, Z.; Song, L. Improvement of maximum power point tracking for a new wind power system. In Proceedings of the 2018 13th IEEE Conference on Industrial Electronics and Applications (ICIEA), Wuhan, China, 31 May–2 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1665–1670. [Google Scholar]

- Kazmi, S.M.R.; Goto, H.; Guo, H.J.; Ichinokura, O. A novel algorithm for fast and efficient speed-sensorless maximum power point tracking in wind energy conversion systems. IEEE Trans. Ind. Electron. 2010, 58, 29–36. [Google Scholar] [CrossRef]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2009.

- Hansen, M.H.; Hansen, A.D.; Larsen, T.J.; ∅ye, S.; Sørensen, P.; Fuglsang, P. Control design for a pitch-regulated, variable speed wind turbine. Moment 2005, 2, 3. [Google Scholar]

- Bossanyi, E.A. The design of closed loop controllers for wind turbines. Wind Energy 2000, 3, 149–163. [Google Scholar] [CrossRef]

- Singh, M.; Muljadi, E.; Jonkman, J.; Gevorgian, V.; Girsang, I.; Dhupia, J. Simulation for Wind Turbine Generators–with FAST and MATLAB-Simulink Modules; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2014.

- Platt, A.; Jonkman, B.; Jonkman, J. InflowWind Users Guide; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2016.

- Muljadi, E.; Butterfield, C.P. Pitch-controlled variable-speed wind turbine generation. IEEE Trans. Ind. Appl. 2001, 37, 240–246. [Google Scholar] [CrossRef]

- Hammerum, K.; Brath, P.; Poulsen, N.K. A fatigue approach to wind turbine control. J. Phys. Conf. Ser. 2007, 75, 012081. [Google Scholar] [CrossRef]

- Jonkman, B. TurbSim User’s Guide v2.00.00; NREL: Golden, CO, USA, 2016.

- Veers, P.S. Three-Dimensional Wind Simulation; Technical Report; Sandia National Labs.: Albuquerque, NM, USA, 1988.

- Kelley, N.; Hand, M.; Larwood, S.; McKenna, E. The NREL large-scale turbine inflow and response experiment: Preliminary results. In Proceedings of the Wind Energy Symposium, Reno, NV, USA, 14–17 January 2002; Volume 7476, pp. 412–426. [Google Scholar]

- Stammler, M.; Poll, G.; Reuter, A. The influence of oscillation sequences on rolling bearing wear. Bear. World J. 2019, 4, 19–25. [Google Scholar]

- Veers, P.S.; Ashwill, T.D.; Sutherland, H.J.; Laird, D.L.; Lobitz, D.W.; Griffin, D.A.; Mandell, J.F.; Musial, W.D.; Jackson, K.; Zuteck, M.; et al. Trends in the design, manufacture and evaluation of wind turbine blades. Wind Energy 2003, 6, 245–259. [Google Scholar] [CrossRef]

- Riziotis, V.; Madsen, H.A. Aeroelasticity and structural dynamics of wind turbines. In Wind Energy Systems; Elsevier: Amsterdam, The Netherlands, 2011; pp. 46–111. [Google Scholar]

| Turbine Name | Number of Blades | Rotor Diameter (m) | Rated Power (kW) | (-) | (-) | (°) | Rated Wind Speed (m/s) | Rated RPM |

|---|---|---|---|---|---|---|---|---|

| SWRT | 3 | 5.8 | 10 | 0.42 | 5.5 | 7 | 11.5 | 210 |

| UAE | 2 | 10 | 20 | 0.42 | 6.4 | 1 | 10 | 122 |

| WP | 3 | 70 | 1500 | 0.50 | 7.3 | 2.5 | 11 | 22 |

| Time step | 0.050 (s) |

| Mean wind speed at hub height | 14 (m/s) |

| Turbulent Intensity (TI) | 13 (%) |

| Vertical grid-point matrix dimension | 40 |

| Horizontal grid-point matrix dimension | 40 |

| Surface roughness length | 0.021 (m) |

| Hub height | 34.6 (m) |

| Assumed rotor diameter | 10 (m) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samani, A.E.; De Kooning, J.D.M.; Kayedpour, N.; Singh, N.; Vandevelde, L. The Impact of Pitch-To-Stall and Pitch-To-Feather Control on the Structural Loads and the Pitch Mechanism of a Wind Turbine. Energies 2020, 13, 4503. https://doi.org/10.3390/en13174503

Samani AE, De Kooning JDM, Kayedpour N, Singh N, Vandevelde L. The Impact of Pitch-To-Stall and Pitch-To-Feather Control on the Structural Loads and the Pitch Mechanism of a Wind Turbine. Energies. 2020; 13(17):4503. https://doi.org/10.3390/en13174503

Chicago/Turabian StyleSamani, Arash E., Jeroen D. M. De Kooning, Nezmin Kayedpour, Narender Singh, and Lieven Vandevelde. 2020. "The Impact of Pitch-To-Stall and Pitch-To-Feather Control on the Structural Loads and the Pitch Mechanism of a Wind Turbine" Energies 13, no. 17: 4503. https://doi.org/10.3390/en13174503

APA StyleSamani, A. E., De Kooning, J. D. M., Kayedpour, N., Singh, N., & Vandevelde, L. (2020). The Impact of Pitch-To-Stall and Pitch-To-Feather Control on the Structural Loads and the Pitch Mechanism of a Wind Turbine. Energies, 13(17), 4503. https://doi.org/10.3390/en13174503