Liquid-Liquid Flow Pattern Prediction Using Relevant Dimensionless Parameter Groups

Abstract

1. Introduction

1.1. Importance of Flow Patterns in the Industrial Sector

1.2. Liquid-Liquid Flow Patterns in Horizontal Pipes

2. Data Collection

2.1. Experimental Studies on Liquid-Liquid Flow in Horizontal Pipelines

| Author | Year | Diameter (mm) | Pipe Material | µo/µw | ρo/ρw | σ (mN/m) | Velocity Range (m/s) | Measurement Techniques | Observed Flow Patterns | Fluids Used | Temperature/Pressure | Mixing Device | L/D |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Russell et al. [6] | 1959 | 20.5 | Cellulose acetate butyrate | 20.13 | 0.834 | 40 | vso = 0.01–1.0, vsw = 0.04–1.08 | VO + P (4 × 5 in Linhoof press camera with a 90 mm lens) | Bb, ST, mixed | Mineral oil-Kremol 70/water | 25 °C/NP | 48° Y | 419 |

| Charles et al. [7] | 1961 | 26.4 | Cellulose acetate butyrate | 7.04, 18.79, 72.71 | 1 | 45, 45, 30 | vso = 0.02–0.9, vsw = 0.043–1.07, 0.043–1.08, 0.043–1.09 | VO + P | SL, AN, Bb, Dw/o, Do/w | Oil (Marcol CX)/water; Oil (Wyrol J)/water; Oil (Teresso 85)/water | 25 °C/NP | Oil via nozzle, water via annulus | 277 |

| Hasson et al. [33] | 1970 | 12.6 | Glass-pipe | 1.22 | ρm = 1020 kg/m3 | 17–17.5 | VO + P | D, SL, ST, AN and mixed flows | Kerosene-perchloroethylene/distilled water | 30 °C/NP | Inlet nozzle device for concentric flow | 214 | |

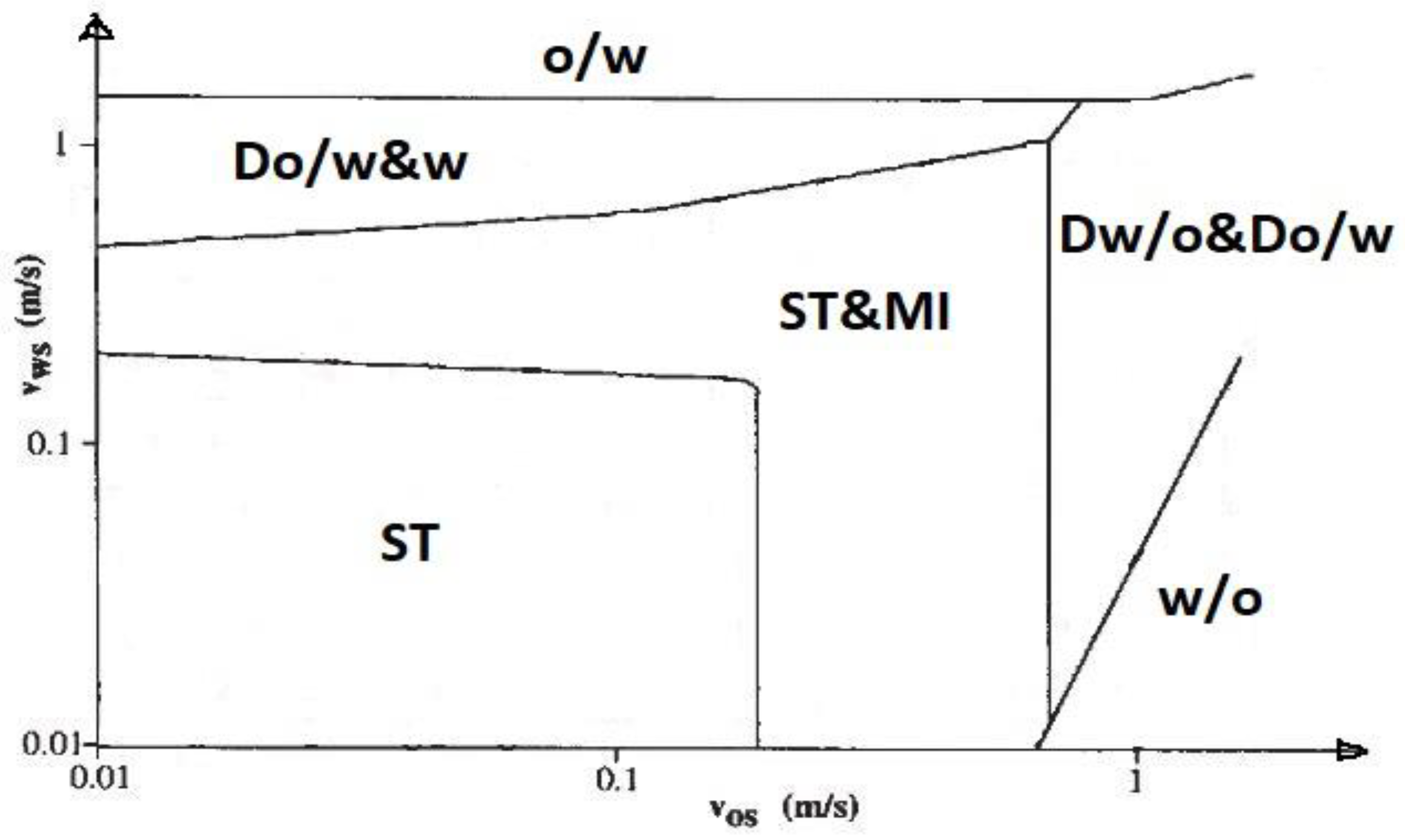

| Guzhov et al. [38] Source: [49,50] | 1973 | 39.4 | Steel | 21.8 | 0.896 | 44.8 | vm = 0.3–1.6 | VO | ST, ST & MI, Do/w, Dw/o, Do/w & w, Dw/o & o/w | NP | 21°C/NP | NP | NP |

| Oglesby [20] | 1979 | 41 | Steel | 167, 61, 32 | 0.87; 0.863; 0.859 | 35.4 | NP | VO | ST, ST & MI, Do/w & w, o/w, Dw/o & Do/w, w/o, SL, SLw, AN, AO | Oil (Sun Oil Co. solvent (250-SN)/water; Oil (diesel fuel)/water; Oil (blend of Sun Oil Co. solvent (250-SN and diesel fuel)/water | NP; 18.3 °C/NP; 21.1 °C/NP. | 90° angle 2 in T | 282 |

| Arirachakaran et al. [17] | 1989 | 41 | Steel | 27.9, 344, 498, 682 | 0.854, 0.868, 0.868, 0.868 | NP, 29, 30, 31 | vm = 0.457–3.66 | NP | ST, Do/w & w, o/w, o & Dw/o, w/o, SL, SLw, AN, AO | No. 2 Diesel fuel oil/tap water, Experimental oil No. 1/tap water, Experimental oil No. 2/tap water, Experimental oil No. 3/tap water | 21.1 °C/NP | NP | 312 |

| Arirachakaran et al. [17] | 1989 | 26.6 | Steel | 1405, 12550 | 0.869, 0.90 | 32, 32 | vm = 1.5−3.05 | NP | ST, Do/w & w, o/w, o & Dw/o, w/o, SL, SLw, AN, AO | Refined oil (SN-250)/tap water Refined oil (150-SB)/tap water | 21.1 °C/NP | NP | 229 |

| Kurban et al. [51] | 1995 | 24.3; 24 | Glass, Acrylic | 1.6 | 0.803 | NP | NP | P + conductivity probe | ST, ST & MI, Dw/o | NP | NP | NP | NP |

| Trallero et al. [11] | 1997 | 50.1 | Acrylic resin | 29.7 | 0.852 | 36 | vso = 0.01–1.61, vsw = 0.01–1.83 | VO | ST, ST & MI, Do/w & w, o/w, Dw/o & Do/w, o/w | Mineral oil (Crystex AF-M)/tap water | 25.5 °C/NP | Y-type | 310 |

| Nädler and Mewes [21] | 1997 | 59 | Perspex | 22–35 | 0.848 | NP | vm = 0.3–1.61 | VO + conductance probe | ST, ST & MI, Do/w & w, o/w, Dw/o & Do/w & w, Dw/o & w, w/o. | Mineral white oil (Shell Ondina 17)/tap water | 30 °C, 25 °C, 18 °C/NP | Cone-shaped nozzle separated by baffle plates | 225, 680 |

| Vedapuri, et al. [36] | 1997 | 101.6 | Plexiglass | 2; 90 | NP | vm = 0.1–2.0 | VO (by video home system camera) | ST & MI, Dw/o & o/w | Oil (Standard ASTM salt-water)/water | 40 °C/0.13 MPa | T-junction | 177 | |

| Valle and Utvik [35] | 1997 | 77.9 | Steel | 1 | 0.741 | NP | vm = 1.17, 1.74, 2.33 | Conductivity needle probe | Do/w, Dw/o, S | Light crude oil/synthetic formation water | 70 °C/10.5 MPa | NP | 154 |

| Bannwart [43] | 1998 | 22.5 | Glass | 2700 | 0.989 | 40 | vso = 0.30–0.63, vsw = 0.03–0.28 | P (Kodak EktaPro EM high speed camera) | AN | Viscous oil/water | RT/NP | Nozzle (tube for oil, shell for water) | NP |

| Soleimani [52] | 1999 | 25.4 | Steel | 1.6 | 0.801 | 17 @ 22 °C | vm = 1.25–3.0 | VO, Impedance probe, Gamma densitometer | ST, SWD, SMW, SMO, 3L, Dw/o & Do/w | Kerosene/(Exxsol D80)/tap water | 25 °C/NP | Static mixer | 382 |

| Angeli and Hewitt [30] | 2000 | 24.3; 24 | Steel; Acrylic resin | 1.6 | 0.801 | 17 | vm = 0.2–3.9 | VO, high-speed video-camera, HFI probe | SW, SWD, SMO, 3L, SMW, Mixed | Kerosene (Exxsol D80)/tap water | 20 °C/NP | T-junction | 370; 375 |

| Simmons and Azzopardi [37] | 2001 | 63 | PVC | 1.125 | 0.684 | 10 | vm = 0.8–3.1 | Lasentec TM Par-Tec 300 C, Malvern 2600 | SM, Dw/o & w, Dw/o | Kerosene/Aqueous potassium carbonate solution | NP | Mixer with porous walls | 71 |

| Mu [53] Source: [54] | 2001 | 25.4 | Steel | 310 | 0.93 | NP | NP | High-speed P | ST, ST & MI, SLw, AO Do/w, Dw/o | NP | NP | NP | NP |

| Bannwart et al. [42] | 2004 | 28.4 | Glass | 488.0 | 0.926 | 29 | vso = 0.007–2.5; vsw = 0.04–0.5 | P (high speed camera (Olympus, 1000 frames/s) (at slow motion 30 frames/s)) | ST, Bb, AN | Heavy crude oil/water | 20 °C/NP | Injection nozzle (central tube for oil, shell for water) | 191 |

| Lovick and Angeli [55] | 2004 | 38 | Stainless steel | 6.0 | 0.828 | 39.6 | vm = 0.8–3.0 | VO, conductance probe and HFI probe | SW, Dw/o, Do/w, DC | Mineral oil (ExxsolD140)/tap water | NP | T (mixing reduction) | 210 |

| Chakrabarti et al. [56] | 2005 | 25.4 | Polymethyl-methacrylate | 0.7 | 0.787 | 45 | vso = 0.029–2.12; vsw = 0.04–1.46 | VO + P | ST, ST & MI, PL, Do/w & w, Dw/o & o | Kerosene/water | 25 °C/NP | Mixer (pipe inserted in another pipe) | 84 |

| Wegmann and Rudolf von Rohr [34] | 2006 | 5.6; 7 | Glass | 5.78–6.14 | 0.82–0.822 | 62.2 @ 20 °C | vso = 0.01–2.5, vsw = 0.01–2.0, vso = 0.01–1.6, vsw = 0.01–13. | P (digital camera (Minolta Dimage 7i with a resolution of 2560–1920 pixels) | ST, AN, I, Do/w, Dw/o | Paraffin-oil/water | 19.1–23.3 °C/NP | T-shaped (selected to prevent emulsion formation | 660; 528 |

| Vielma et al. [57] | 2007 | 50.8 | Acrylic resin | 18.8 | 0.859 | 16.4 | vso = 0.03–1.75, vsw = 0.03–1.75 | VO, P and conductance probe | ST, ST & MI, Do/w & w, o/w, Dw/o & Do/w, o/w | Refined mineral oil (Tulco Tech 80)/tap water | 40 °C–29 °C/NP | 30° Y | 440 |

| Grassi et al. [41] | 2008 | 21 | Polycarbonate | 615 | 0.886 | 50 | vso = 0.029–0.7, vsw = 0.14–2.5 | VO + P | ST, Do/w, AN, PL/SL, Do/w & w | Paraffin oil/water | 20 °C/NP | Injecting device (oil at the core and water annulus) | 429 |

| Dasari et al. [58] | 2013 | 25 | Perspex | 107 | 0.889 | 24 | vso = 0.015–1.22, vsw = 0.1–1.1 | VO + P (camera model no DSC-HX100 V, by sony) | SL, ST, ST & MI, Do/w, Dw/o, PL | Lube oil/water | 25 °C/NP | NP | 40 |

| Al-Wahaibi et al. [22] | 2014 | 19 | Acrylic | 12 | 0.877 | 20.1 | vso = 0.06–1.69,vsw = 0.12–1.69 | VO + High speed camera (Fastec Troubleshooter, records up to 1000 fps) | ST, Bb, AN, DC, Do/w, Dw/o | Mineral oil/water | NP | Y-junction | 421 |

| Voulgaropoulos et al. [59] | 2016 | 37 | Acrylic | 6.2 | 0.830 | 32.9 | vm = 0.31–0.73 | High-speed camera (with Tokina Macro lens) and a dual conductance probe | ST, SM, Do/w, Dw/o, Do/w & w, Dw/o & o/w | Kerosene (Exxsol D140)/fresh water | 20 °C/NP | Multi-nozzle inlet | 189 |

2.2. Development of Flow Maps for Liquid-Liquid in a Horizontal Pipeline

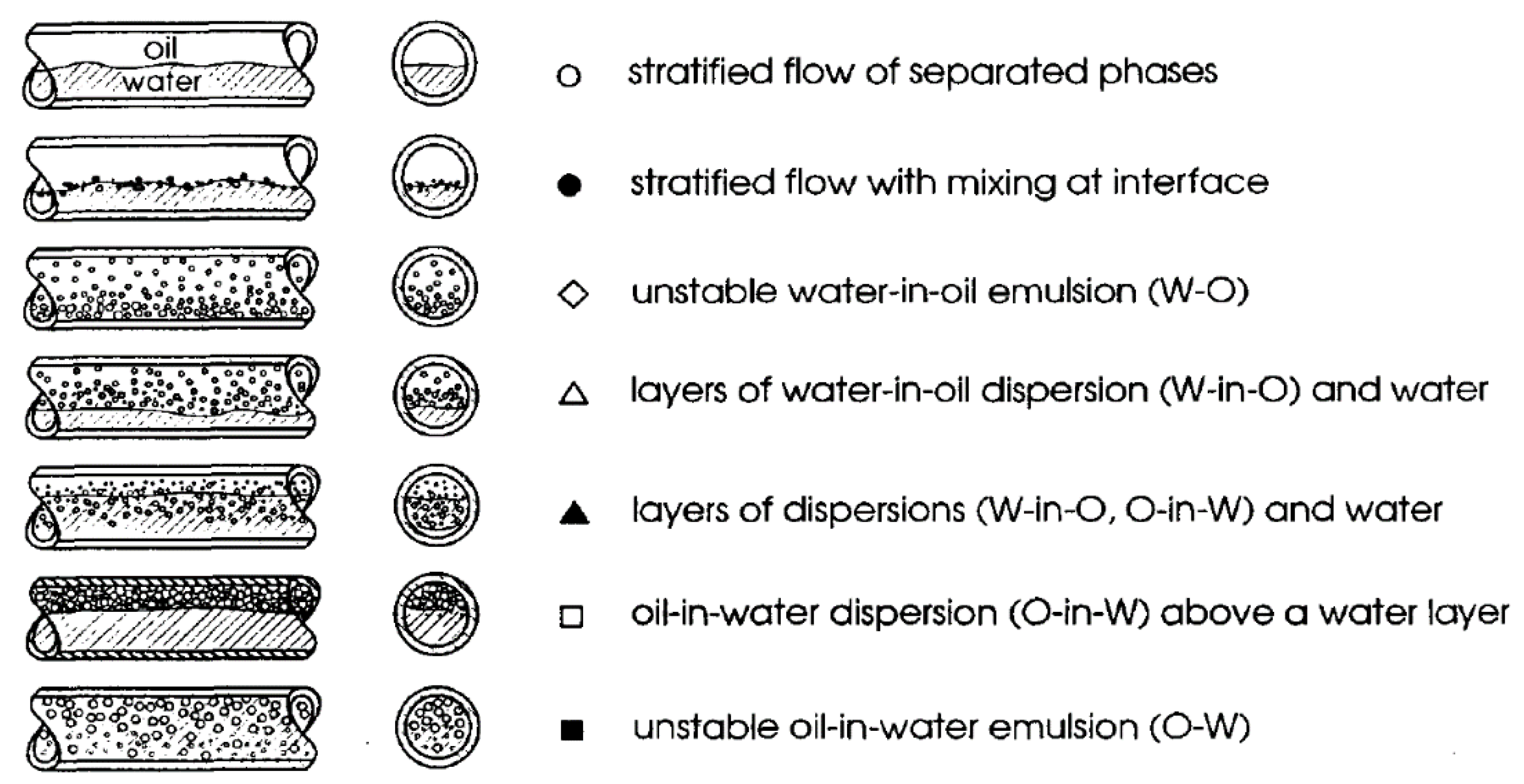

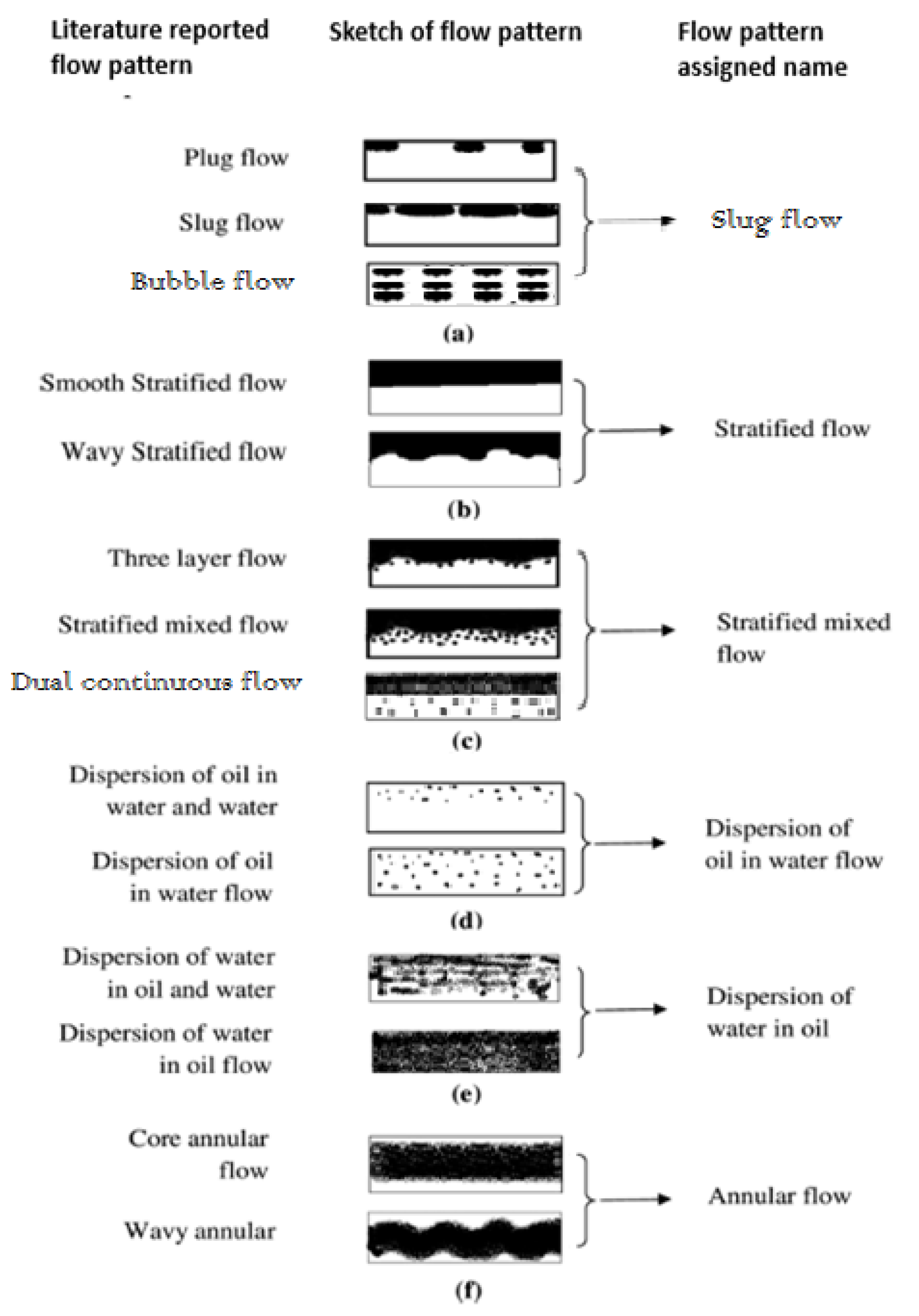

2.3. Harmonising the Major Flow Patterns in the Liquid-Liquid Horizontal Flow Literature

3. Dimensionless Parameter Definition

3.1. Mixture Reynolds Number to Eötvös number (Rem/Eo)

3.2. Weber Number to Eötvös Number (We/Eo)

3.3. Mixture Froude Number (Frm), Oil Froude Number (Fro) and Water Froude Number (Frw)

3.4. Gravity Force to Viscous Force (G/V)

4. Results

4.1. Data Sources

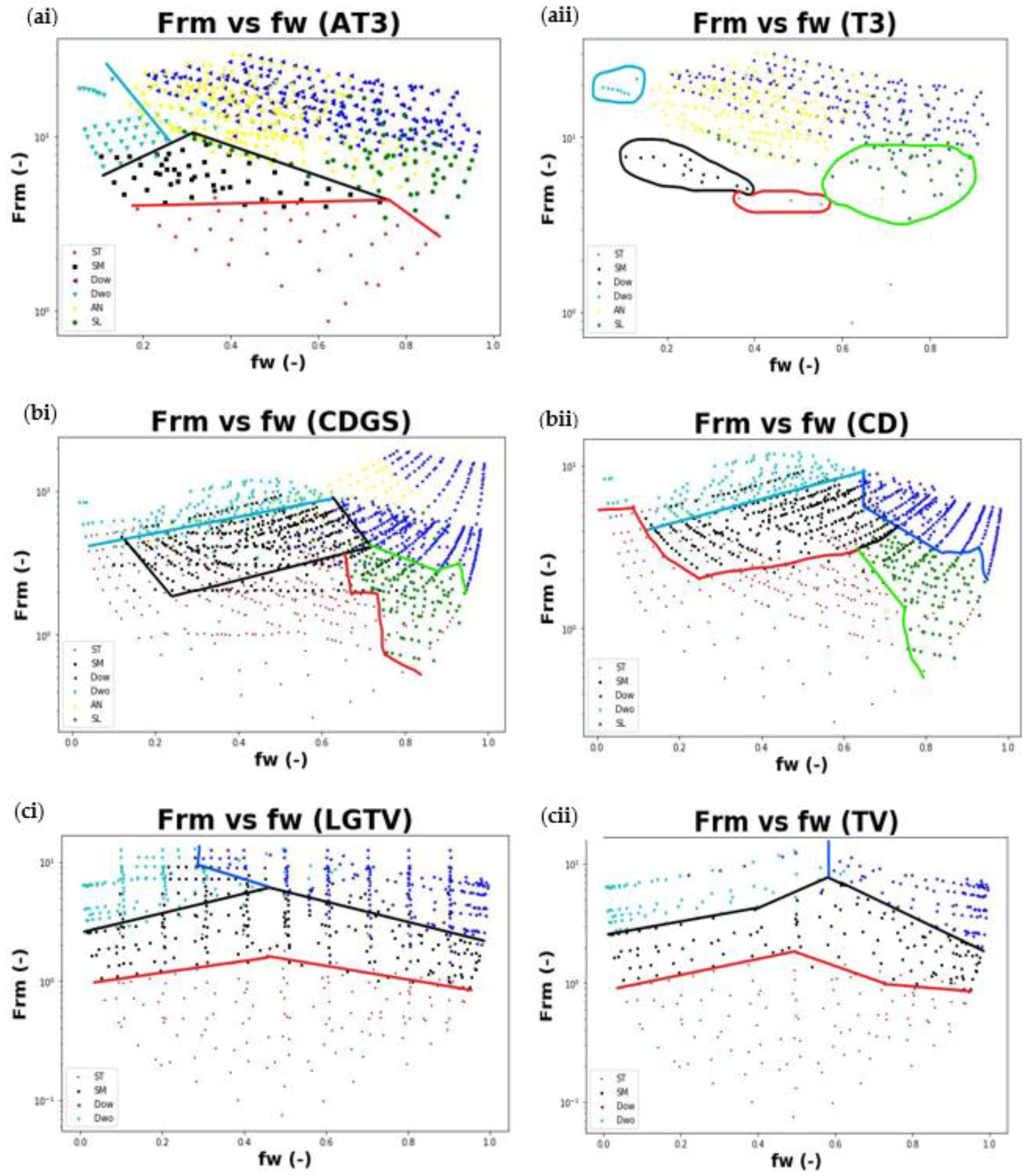

4.2. Flow Pattern Maps Construction

4.2.1. Flow Pattern Maps Based on Oil Viscosity

4.2.2. Flow Pattern Maps Based on the Pipe Diameter

5. Discussion

5.1. Data Analysis

5.1.1. Data Analysis Based on Oil Viscosity

5.1.2. Data Analysis Based on the Pipe Diameter

6. Conclusions

- Based on the analysis done in this project, it can be concluded that each flow pattern formed more than one trend on the flow map when data from the twelve sources were brought together, hence no particular region can be designated to a particular flow pattern in such a flow map. In exception of the combinations, (i) We/Eo versus fw and (ii) Frm versus fw, where ST, SM, SL and Dw/o were marked out.

- However, the flow patterns formed clearer trends on the flow map when the data points were regrouped, based on the oil-phase viscosity and pipe diameter used in the experimental studies.

- For regrouping based on oil viscosity, combinations of the ratio of mixture Reynold number to Eötvös number (Rem/Eo) versus water fraction (fw), and water Froude number (Frw) versus oil Froude number (Fro) dimensionless groups marked out regions for all the considered flow patterns under the medium-viscous oil (MVO) category, though slug and annular flow patterns had only a few data points as compared to the other flow patterns.

- Under low-viscous oil (LVO) <10 group, there is no occurrence of annular flow, and hence the combination of these dimensionless groups G/V versus fw, and Frw versus Fro were able to normalise all the data points so that each flow pattern formed on a distinct region on the flow map.

- Under heavy-viscous oil (HVO) group, the ratio of mixture Reynold number to Eötvös number (Rem/Eo) versus water fraction (fw) normalised all the data points except for the annular flow pattern. The ratio of gravity force to viscous force (G/V) versus water fraction (fw) normalised all the data points except for dispersed oil in water and slug flow patterns, while the and water Froude number (Frw) versus the oil Froude number (Fro) could not normalise dispersed oil in water, slug and annular flow patterns.

- For the regrouping based on pipe diameters, as the range of considered pipe diameters narrows, the cluster of data points for each flow pattern forms a more distinct region on the flow map.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Flow Pattern/ Abbreviation | Interpretation | Symbol/ Abbreviation | Unit | Interpretation |

| 3L | Three layers flow | ∆ρ | - | Change in density |

| AN | Annular/oil in water concentric flow | A | m2 | Pipe cross-sectional area |

| AO | Annular/oil annulus flow | d | m | Diameter |

| Bb | Oil bubbles in water flow | DPG | - | Dimensionless parameter groups |

| CAF | Core-annular flow | Eo | - | Eötvös number |

| D | Dispersed flow | Eo’ | - | Modified Eötvös number |

| DC | Dual continuous flow | EOR | - | Enhanced oil recovery |

| Do/w or Dow | Dispersed oil in water flow | ff | - | Friction factor |

| Do/w & w | Dispersed oil in water with water layer flow | f | - | Volume fraction |

| Dw/o or Dwo | Dispersed water in oil flow | FPM | - | Flow pattern maps |

| Dw/o & Do/w & w | Dispersed water in oil and dispersed oil in water, and water layer flow | Fr | - | Froude number |

| Dw/o & o | Dispersed water in oil with oil layer flow | g | m/s2 | Acceleration due to gravity |

| Dw/o & o/w | Dispersed water in oil and dispersed oil in water flow | G/V | - | Ratio of the gravitational force to viscous force |

| I | Intermediate flow | HFI | - | High-frequency impedance |

| M | Mixed flow | HVO | - | Heavy-viscous oil |

| O & W/O | Oil layer and dispersed water in oil flow | LVO | - | Low-viscous oil |

| o/w | Oil-in-water emulsion flow | MVO | - | Medium-viscous oil |

| PL | Plug flow | N | - | No, flow pattern not marked out |

| SL | Oil slugs in water flow | N/A | - | Not applicable |

| SLw | Water slugs in oil flow | NP | - | Not provided |

| SM | Stratified mixed flow | OV | - | Visual observation |

| SMO | Stratified mixed/oil flow | P | - | Photography |

| SMW | Stratified mixed/water flow | Q | m3/s | Volumetric flow rate |

| ST | Stratified flow | Rem/Eo | - | Ratio of mixture Reynolds number to Eötvös number |

| ST & MI | Stratified with mixing at interface flow | RT | - | Room temperature |

| SW | Stratified wavy | Subscript m | - | Mixture |

| SWD | Stratified wavy with droplets at the interface (Stratified wavy/drops) flow | Subscript o | - | Oil phase |

| w/o | Water-in-oil emulsion flow | Subscript or | - | Organic phase |

| Subscript w | - | Water phase | ||

| vm | m/s | Mixture velocity | ||

| vso | m/s | Superficial oil velocity | ||

| vsw | m/s | Superficial water velocity | ||

| We/Eo | - | Weber number to Eötvös number | ||

| Y | - | Yes, flow pattern marked out | ||

| α | - | Wettability | ||

| ϴ | ° | Inclination angle | ||

| μ | mPa s | Oil viscosity | ||

| ρ | Kg/m3 | Density | ||

| σ | N/m | Interfacial tension |

References

- Angeli, P.; Hewitt, G.F. Pressure Gradient in Horizontal Liquid-Liquid Flows. Int. J. Multiph. Flow 1999, 24, 1183–1203. [Google Scholar] [CrossRef]

- Brauner, N. Liquid-Liquid Two-Phase Flow Systems. In Modelling and Control of Two-Phase Phenomena; Bertola, V., Ed.; Springer: Vienna, Austria, 2003; pp. 221–279. [Google Scholar] [CrossRef]

- Tan, J.; Jing, J.; Hu, H.; You, X. Experimental Study of the Factors Affecting the Flow Pattern Transition in Horizontal Oil–Water Flow. Exp. Therm. Fluid Sci. 2018, 98, 534–545. [Google Scholar] [CrossRef]

- Brennen, C.E. Fundamentals of Multiphase Flow; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Ibarra, R.; Zadrazil, I.; Markides, C.N.; Matar, O.K. Towards a Universal Dimensionless Map of Flow Regime. In Proceedings of the 11th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Skukuza, South Africa, 20–23 July 2015. [Google Scholar]

- Russell, T.W.F.; Hodgson, G.W.; Govier, G.W. Horizontal Pipeline Flow of Mixtures of Oil and Water. Can. J. Chem. Eng. 1959, 37, 9–17. [Google Scholar] [CrossRef]

- Charles, M.E.; Govier, G.W.; Hodgson, G.W. The Horizontal Pipeline Flow of Equal Density Oil-water Mixtures. Can. J. Chem. Eng. 1961, 39, 27–36. [Google Scholar] [CrossRef]

- Charles, M.E.; Lilleleht, L.V. Correlation of Pressure Gradients for the Stratified Laminar-turbulent Pipeline Flow of Two Immiscible Liquids. Can. J. Chem. Eng. 1966, 44, 47–49. [Google Scholar] [CrossRef]

- Valle, A. Multiphase Pipeline Flows in Hydrocarbon Recovery. Multiph. Sci. Technol. 1998, 10, 1–139. [Google Scholar] [CrossRef]

- Ahmed, S.A.; John, B. Liquid-Liquid Horizontal Pipe Flow—A Review. J. Pet. Sci. Eng. 2018, 168, 426–447. [Google Scholar] [CrossRef]

- Trallero, J.L.; Sarica, C.; Brill, J.P. A Study of Oil/Water Flow Patterns in Horizontal Pipes. In SPE Annual Technical Conference and Exhibition; Society of Petroleum Engineers: Dallas, TX, USA, 1997; pp. 165–172. [Google Scholar] [CrossRef]

- Al-Sarkhi, A.; Pereyra, E.; Mantilla, I.; Avila, C. Dimensionless Oil-Water Stratified to Non-Stratified Flow Pattern Transition. J. Pet. Sci. Eng. 2017, 151, 284–291. [Google Scholar] [CrossRef]

- Paolinelli, L.D.; Rashedi, A.; Yao, J.; Singer, M. Study of Water Wetting and Water Layer Thickness in Oil-Water Flow in Horizontal Pipes with Different Wettability. Chem. Eng. Sci. 2018, 183, 200–214. [Google Scholar] [CrossRef]

- Efird, K.D.; Jasinski, R.J. Effect of the Crude Oil on Corrosion of Steel in Crude Oil/Brine Production. Corrosion 1989, 45, 165–171. [Google Scholar] [CrossRef]

- Cai, J.; Li, C.; Tang, X.; Ayello, F.; Richter, S.; Nesic, S. Experimental Study of Water Wetting in Oil-Water Two Phase Flow-Horizontal Flow of Model Oil. Chem. Eng. Sci. 2012, 73, 334–344. [Google Scholar] [CrossRef]

- Shi, J.; Lao, L.; Yeung, H. Water-Lubricated Transport of High-Viscosity Oil in Horizontal Pipes: The Water Holdup and Pressure Gradient. Int. J. Multiph. Flow 2017, 96, 70–85. [Google Scholar] [CrossRef]

- Arirachakaran, S.; Oglesby, K.D.; Malinowsky, M.S.; Shoham, O.; Brill, J.P. An Analysis of Oil/Water Flow Phenomena in Horizontal Pipes. In SPE Production & Facilities; Society of Petroleum Engineers: Dallas, TX, USA, 1989. [Google Scholar]

- Mukhaimer, A.; Al-sarkhi, A.; El Nakla, M.; Ahmed, W.H.; Al-hadhrami, L. Effect of Water Salinity on Flow Pattern and Pressure Drop in Oil-Water Flow. J. Pet. Sci. Eng. 2015, 128, 145–149. [Google Scholar] [CrossRef]

- Piroozian, A.; Hemmati, M.; Ismail, I.; Manan, M.A.; Rashidi, M.M.; Mohsin, R. An Experimental Study of Flow Patterns Pertinent to Waxy Crude Oil-Water Two-Phase Flows. Chem. Eng. Sci. 2017, 164, 313–332. [Google Scholar] [CrossRef]

- Oglesby, K.D. An Experimental Study on the Effect of Oil Viscosity, Mixture Velocity and Water Fraction on Horizontal Oil-Water Flow. Master’s Thesis, The University of Tulsa, Tulsa, OK, USA, 1979. [Google Scholar]

- Nädler, M.; Mewes, D. Flow Induced Emulsification in the Flow of Two Immiscible Liquids in Horizontal Pipes. Int. J. Multiph. Flow 1997, 23, 55–68. [Google Scholar] [CrossRef]

- Al-Wahaibi, T.; Al-Wahaibi, Y.; Al-Ajmi, A.; Al-Hajri, R.; Yusuf, N.; Olawale, A.S.; Mohammed, I.A. Experimental Investigation on Flow Patterns and Pressure Gradient through Two Pipe Diameters in Horizontal Oil-Water Flows. J. Pet. Sci. Eng. 2014, 122, 266–273. [Google Scholar] [CrossRef]

- Almutairi, Z.; Al-Alweet, F.M.; Alghamdi, Y.A.; Almisned, O.A.; Alothman, O.Y. Investigating the Characteristics of Two-Phase Flow Using Electrical Capacitance Tomography (ECT) for Three Pipe Orientations. Processes 2020, 8, 51. [Google Scholar] [CrossRef]

- Cheng, L.; Ribatski, G.; Thome, J.R. Two-Phase Flow Patterns and Flow-Pattern Maps: Fundamentals and Applications. Appl. Mech. Rev. 2008, 61, 0508021–05080228. [Google Scholar] [CrossRef]

- Torres, C.F.; Mohan, R.S.; Gomez, L.E.; Shoham, O. Oil-Water Flow Pattern Transition Prediction in Horizontal Pipes. J. Energy Resour. Technol. 2016, 138, 1–11. [Google Scholar] [CrossRef]

- Hanafizadeh, P.; Hojati, A.; Karimi, A. Experimental Investigation of Oil-Water Two Phase Flow Regime in an Inclined Pipe. J. Pet. Sci. Eng. 2015, 136, 12–22. [Google Scholar] [CrossRef]

- Cheng, H.; Hills, J.H.; Azzorpardi, B.J. A Study of the Bubble-to-Slug Transition in Vertical Gas-Liquid Flow in Columns of Different Diameter. Int. J. Multiph. Flow 1998, 24, 431–452. [Google Scholar] [CrossRef]

- Al-Wahaibi, T.; Yusuf, N.; Al-Wahaibi, Y.; Al-Ajmi, A. Experimental Study on the Transition between Stratified and Non-Stratified Horizontal Oil-Water Flow. Int. J. Multiph. Flow 2012, 38, 126–135. [Google Scholar] [CrossRef]

- Yusuf, N.; Al-Wahaibi, Y.; Al-Wahaibi, T.; Al-Ajmi, A.; Olawale, A.S.; Mohammed, I.A. Effect of Oil Viscosity on the Flow Structure and Pressure Gradient in Horizontal Oil-Water Flow. Chem. Eng. Res. Des. 2012, 90, 1019–1030. [Google Scholar] [CrossRef]

- Angeli, P.; Hewitt, G.F. Flow Structure in Horizontal Oil-Water Flow. Int. J. Multiph. Flow 2000, 26, 1117–1140. [Google Scholar] [CrossRef]

- Huang, Z.; Lee, H.S.; Senra, M.; Scott Fogler, H. A Fundamental Model of Wax Deposition in Subsea Oil Pipelines. AIChE J. 2011, 57, 2955–2964. [Google Scholar] [CrossRef]

- Tritton, D.J. Physical Fluid Dynamics; Springer: Dordrecht, The Netherlands, 1977. [Google Scholar] [CrossRef]

- Hasson, D.; Mann, V.; Nir, A. Annular Flow of Two Immiscible Liquids I. Mechanisms. Can. J. Chem. Eng. 1970, 48, 514–520. [Google Scholar] [CrossRef]

- Wegmann, A.; von Rohr, P.R. Two Phase Liquid-Liquid Flows in Pipes of Small Diameters. Int. J. Multiph. Flow 2006, 32, 1017–1028. [Google Scholar] [CrossRef]

- Valle, A.; Utvik, O.H. Pressure Drop, Flow Pattern and Slip for Two-Phase Crude Oil/Water Flow: Experiments and Model Predictions. In International Symposium on Liquid-Liquid Two-Phase Flow and Transport Phenomena; Begellhouse: Danbury, CT, USA, 1997; pp. 1–12. [Google Scholar] [CrossRef]

- Vedapuri, D.; Bessette, D.; Jepson, W.P. A Segregated Flow Model to Predict Water Layer Thickness in Oil-Water Flows in Horizontal and Slightly Inclined Pipelines. In Proceedings of the 8th International Conference Multiphase ’97, Cannes, France, 18–20 June 1997; BHR Group, Ed.; Mechanical Engineering Publications: London, UK, 1997; pp. 75–106. [Google Scholar]

- Simmons, M.J.H.; Azzopardi, B.J. Drop Size Distributions in Dispersed Liquid-Liquid Pipe Flow. Int. J. Multiph. Flow 2001, 27, 843–859. [Google Scholar] [CrossRef]

- Guzhov, A.I.; Grishin, A.D.; Medredev, V.F.; Medredeva, O.P. Emulsion Formation during the Flow of Two Immiscible Liquids. Neft. Choz. 1973, 8, 58–61. (In Russian) [Google Scholar]

- Brauner, N.; Moalem Maron, D. Flow Pattern Transitions in Two-Phase Liquid-Liquid Flow in Horizontal Tubes. Int. J. Multiph. Flow 1992, 18, 123–140. [Google Scholar] [CrossRef]

- Ismail, A.S.I.; Ismail, I.; Zoveidavianpoor, M.; Mohsin, R.; Piroozian, A.; Sariman, M.Z.; Misnan, M.S. Review of Oil-Water through Pipes. Flow Meas. Instrum. J. 2015, 45, 357–374. [Google Scholar] [CrossRef]

- Grassi, B.; Strazza, D.; Poesio, P. Experimental Validation of Theoretical Models in Two-Phase High-Viscosity Ratio Liquid-Liquid Flows in Horizontal and Slightly Inclined Pipes. Int. J. Multiph. Flow 2008, 34, 950–965. [Google Scholar] [CrossRef]

- Bannwart, A.C.; Rodriguez, O.M.H.; de Carvalho, C.H.M.; Wang, I.S.; Vara, R.M.O. Flow Patterns in Heavy Crude Oil-Water Flow. J. Energy Resour. Technol. 2004, 126, 184. [Google Scholar] [CrossRef]

- Bannwart, A.C. Wavespeed and Volumetric Fraction in Core Annular Flow. Int. J. Multiph. Flow 1998, 24, 961–974. [Google Scholar] [CrossRef]

- Bordalo, S.N.; Oliveira, R.C. Experimental Study of Oil/ Water Flow With Paraffin Precipitation in Subsea Pipelines. In SPE Annual Technical Conference and Exhibition; Society of Petroleum Engineers: Dallas, TX, USA, 2007; pp. 1–8. [Google Scholar] [CrossRef]

- Abubakar, A.; Al-Wahaibi, Y.; Al-Wahaibi, T.; Al-Hashmi, A.; Al-Ajmi, A.; Eshrati, M. Effect of Low Interfacial Tension on Flow Patterns, Pressure Gradients and Holdups of Medium-Viscosity Oil/Water Flow in Horizontal Pipe. Exp. Therm. Fluid Sci. 2015, 68, 58–67. [Google Scholar] [CrossRef]

- Al-wahaibi, T.; Angeli, P. Experimental Study on Interfacial Waves in Stratified Horizontal Oil-Water Flow. Int. J. Multiph. Flow 2011, 37, 930–940. [Google Scholar] [CrossRef]

- Wang, W.; Gong, J. Flow Regimes and Transition Characters of the High Viscosity Oil-Water Two Phase Flow. In Proceedings of the CPS/SPE International Oil & Gas Conference and Exhibition, Beijing, China, 8–10 June 2010; pp. 1–8. [Google Scholar] [CrossRef]

- Gafonova, O.V.; Yarranton, H.W. The Stabilization of Water-in-Hydrocarbon Emulsions by Asphaltenes and Resins. J. Colloid Interface Sci. 2001, 241, 469–478. [Google Scholar] [CrossRef]

- Angeli, P. Liquid-Liquid Dispersed Flows in Horizontal Pipes. Ph.D. Thesis, Imperial College London, London, UK, 1996. [Google Scholar]

- Trallero, J.L. Oil-Water Flow Patterns in Horizontal Pipes. Ph.D. Thesis, The University of Tulsa, Tulsa, OK, USA, 1995. [Google Scholar]

- Kurban, A.P.A.; Angeli, P.A.; Mendestatsis, M.A.; Hewitt, G.F. Stratified and Dispersed Oil-Water Flows in Horizontal Pipes. In Proceedings of the Multiphase 95, 7th International Conference, Cannes, France, 7–9 June 1995; pp. 277–291. [Google Scholar]

- Soleimani, A. Phase Distribution and Associated Phenomena in Oil-Water Flows in Horizontal Tubes. Ph.D. Thesis, University of London, London, UK, 1999. [Google Scholar]

- Mu, H. Experimental Research on Oil–Water Horizontal Pipe Flow. Master’s Thesis, University of Petroleum, Beijing, China, 2001. [Google Scholar]

- Xu, X.X. Study on Oil-Water Two-Phase Flow in Horizontal Pipelines. J. Pet. Sci. Eng. 2007, 59, 43–58. [Google Scholar] [CrossRef]

- Lovick, J.; Angeli, P. Experimental Studies on the Dual Continuous Flow Pattern in Oil-Water Flows. Int. J. Multiph. Flow 2004, 30, 139–157. [Google Scholar] [CrossRef]

- Chakrabarti, D.P.; Das, G.; Ray, S. Pressure Drop in Liquid-Liquid Two Phase Horizontal Flow: Experiment and Prediction. Chem. Eng. Technol. 2005, 28, 1003–1009. [Google Scholar] [CrossRef]

- Vielma, M.; Atmaca, S.; Sarica, C.; Zhang, H.Q. Characterization of Oil/Water Flows in Horizontal Pipes. In SPE Annual Technical Conference and Exhibition; Society of Petroleum Engineers: Dallas, TX, USA, 2007. [Google Scholar] [CrossRef]

- Dasari, A.; Desamala, A.B.; Dasmahapatra, A.K.; Mandal, T.K. Experimental Studies and Probabilistic Neural Network Prediction on Flow Pattern of Viscous Oil-Water Flow through a Circular Horizontal Pipe. Ind. Eng. Chem. Res. 2013, 52, 7975–7985. [Google Scholar] [CrossRef]

- Voulgaropoulos, V.; Zhai, L.; Loannou, K.; Angeli, P. Evolution of Unstable Liquid-Liquid Dispersions in Horizontal Pipes. In Proceedings of the BHR Group-10th North American Conference on Multiphase Technology 2016, Banff, AB, Canada, 8–10 June 2016; pp. 305–318. [Google Scholar]

- Hapanowicz, J. Phase Inversion in Liquid-Liquid Pipe Flow. Flow Meas. Instrum. 2010, 21, 284–291. [Google Scholar] [CrossRef]

- Shi, J.; Yeung, H. Characterization of Liquid-Liquid Flows in Horizontal Pipes. AIChE J. 2017, 63, 1132–1143. [Google Scholar] [CrossRef]

- Joseph, D.D.; Nguyen, K.; Beavers, G.S. Non-Uniqueness and Stability of the Configuration of Flow of Immiscible Fluids with Different Viscosities. J. Fluid Mech. 1984, 141, 319–345. [Google Scholar] [CrossRef]

- Ibarra, R.; Markides, C.N.; Matar, O.K. A Review of Liquid-Liquid Flow Patterns in Horizontal and Slightly Inclined Pipes. Multiph. Sci. Technol. 2014, 26, 171–198. [Google Scholar] [CrossRef]

- Mandal, T.K.; Chakrabarti, D.P.; Das, G. Oil Water Flow through Different Diameter Pipes: Similarities and Differences. Chem. Eng. Res. Des. 2007, 85, 1123–1128. [Google Scholar] [CrossRef]

- Shoham, O. Mechanistic Modeling of Gas Liquid Two Phase Flow in Pipes; The Society of Petroleum Engineers (SPE): Tulsa, OK, USA, 2005. [Google Scholar]

- Langhaar, H.L. Dimensional Analysis and Theory of Model; John Wiley & Sons, Inc.: New York, NY, USA, 1951. [Google Scholar]

- Morales-Ruiz, S.; Rigola, J.; Rodriguez, I.; Oliva, A. Numerical Resolution of the Liquid-Vapour Two-Phase Flow by Means of the Two-Fluid Model and a Pressure Based Method. Int. J. Multiph. Flow 2012, 43, 118–130. [Google Scholar] [CrossRef]

- Levy, S. Two-Phase Flow in Complex Systems; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Dukler, A.E.; Wicks, M.; Cleveland, R.G. Frictional Pressure Drop in Two-phase Flow: B. An Approach through Similarity Analysis. AIChE J. 1964, 10, 44–51. [Google Scholar] [CrossRef]

| Group of Factors | Factor | Criterion | Reasons |

|---|---|---|---|

| Pipe Geometry | Pipe inclination | Horizontal (0°) |

|

| Pipe internal diameter | 10–100 mm |

| |

| Fluid Properties | Density | Water (~1000 kg/m3), oil (750–900 kg/m3) | |

| Viscosity | Water (0.8–1.0 mPa s), oil (<700 mPa s) |

| |

| Interfacial tension | 0.01–0.06 N/m |

| |

| Flow Conditions | Temperature | ~25 °C |

|

| Pressure | ~1 atm |

|

| Author | Year | Mapping Parameters | Identified Flow Pattern |

|---|---|---|---|

| Russell et al. [6] | 1959 | Friction factor (ff) versus superficial water velocity (vsw) | Bb, ST, mixed |

| Charles et al. [7] | 1961 | Superficial oil velocity (vso) versus superficial water velocity (vsw) | w/o, AN, SL, Bb, and o/w |

| Hasson et al. [33] | 1970 | The organic phase flow rate (Qor) versus the water phase flow rate (Qw) | D, SL, ST, AN and mixed flows |

| Guzhov et al. [38] Source: [49,50] | 1973 | Mixture velocity (vm) versus input water fraction (fw) | ST, ST & MI, Do/w, Dw/o, Do/w & w, Dw/o & o/w |

| Oglesby [20] | 1979 | Mixture velocity (vm) versus input water fraction (fw) | ST, ST & MI, Do/w & w, o/w, Dw/o & Do/w, w/o, SL, SLw, AN, AO |

| Arirachakaran et al. [17] | 1989 | Mixture velocity (vm) versus input water fraction (fw) | ST, Do/w & w, o/w, o & Dw/o, w/o, SL, SLw, AN, AO |

| Vedapuri et al. [36] | 1997 | The thickness of the water layer to the diameter of the pipe, h/D against the percentage of water (input water fraction fw) | Semi-segregated, semi-mixed and semi-dispersed |

| Trallero et al. [11] | 1997 |

| ST, ST & MI, Do/w & w, o/w, Dw/o & Do/w, o/w |

| Nädler and Mewes [21] | 1997 |

| ST, ST & MI, Do/w & w, o/w, Dw/o & Do/w & w, Dw/o & w, w/o |

| Angeli and Hewitt [30] | 2000 | Mixture velocity (vm) against input water volume fraction (fw) | SW, SWD, SMO, 3L, SMW, Mixed |

| Brauner [2] | 2003 | (No map proposed) Eotvös number | Gravity force dominated or interfacial force dominated |

| Lovick and Angeli [55] | 2004 | Mixture velocity (vm) against input oil volume fraction (fo) | Dw/o, Do/w, DC, SW |

| Chakrabarti et al. [56] | 2005 | Superficial water velocity (vsw) versus superficial oil velocity (vso) | ST, SW, 3L, Do/w & w, D, PL, O & W/O |

| Wegmann and Rudolf von Rohr [34] | 2006 | Mixture velocity (vm) against input water volume fraction (fw) | ST, AN, I, Do/w, Dw/o |

| Vielma et al. [57] | 2007 | Superficial water velocity (vsw) versus superficial oil velocity (vso) | ST, ST & MI, Do/w & w, o/w, Dw/o & Do/w, o/w |

| Grassi et al. [41] | Superficial water velocity (vsw) versus superficial oil velocity (vso) | ST, Do/w, AN, PL/SL, Do/w & w | |

| Hapanowic [60] | 2010 | Superficial mass fluxes for oil (gol,o) [kg/m2.s] versus Superficial mass fluxes for water (gw,o) [kg/m2.s] | Dr-drops, DrP-drops and plugs, D-dispersion, S-stratification AD-annular and dispersion; -W-for water, -O-for oil |

| Yusuf et al. [29] | 2012 | Superficial water velocity (vsw) versus superficial oil velocity (vso) | ST, Bb, AN, DC, Do/w, Dw/o |

| Dasari et al. [58] | 2013 | Superficial water velocity (vsw) versus superficial oil velocity (vso) | SL, ST, ST & MI, Do/w, Dw/o, PL |

| Al-Wahaibi et al. [22] | 2014 | Superficial water velocity (vsw) versus superficial oil velocity vso | ST, Bb, AN, DC, Do/w, Dw/o |

| Ibarra et al. [5] | 2015 | (Rem/Eo) versus(fw) | ST, SWD, Do/w & w, DC, D |

| Shi and Yeung [61] | 2017 | The gravitation to viscous force ratio (G/V) versus input water volume fraction (fw) | ST, D, I, CAF |

| Trallero et al. [11] | Soleimani [52] | ||

| Tap water density (kg/m3) | 997 * | Tap water density (kg/m3) | 998 |

| White oil density (kg/m3) | 884 | Exxsol 80 density (kg/m3) | 801 |

| Tap water viscosity (Pa s) | 0.00097 | Tap water viscosity (Pa s) | 0.001 |

| White oil viscosity (Pa s) | 0.0288 | Exxsol 80 viscosity (Pa s) | 0.0016 |

| Interfacial tension (N/m) | 0.036 | Interfacial tension (N/m) | 0.017 @ 22 °C |

| Diameter (m) | 0.0501 | Diameter (m) | 0.0243 |

| Temperature (°C) | 25.5 | Temperature (°C) | 25 |

| Al-Wahaibi et al. [22] | Vielma et al. [57] | ||

| Water density (kg/m3) | 998 | Tap water density (kg/m3) | 998 |

| Mineral oil density (kg/m3) | 875 | Mineral oil density (kg/m3) | 860 ** |

| Water viscosity (Pa s) | 0.001 | Tap water viscosity (Pa s) | 0.001 |

| Mineral oil viscosity (Pa s) | 0.012 | Mineral oil viscosity (Pa s) | 0.0188 ** |

| Interfacial tension (N/m) | 0.0201 | Interfacial tension (N/m) | 0.0285 ** |

| Diameter (m) | 0.019 | Diameter (m) | 0.0508 |

| Temperature (°C) | N/A | Temperature (°C) | 25.5 |

| Dasari et al. [58] | Guzhov et al. [38] | ||

| Water density (kg/m3) | 997 | Tap water density (kg/m3) | 998 |

| Lube oil density (kg/m3) | 889 | Mineral oil density (kg/m3) | 896 |

| Water viscosity (Pa s) | 0.001 | Tap water viscosity (Pa s) | 0.001 |

| Lube oil viscosity (Pa s) | 0.107 | Mineral oil viscosity (Pa s) | 0.0218 |

| Interfacial tension (N/m) | 0.024 | Interfacial tension (N/m) | 0.0448 |

| Diameter (m) | 0.025 | Diameter (m) | 0.0394 |

| Temperature (°C) | 25 | Temperature (°C) | 21 |

| Grassi et al. [41] | Tan et al. [3] 20# | ||

| Water density (kg/m3) | 997 | Tap water density (kg/m3) | 998 |

| Oil density (kg/m3) | 886 | Mineral oil density (kg/m3) | 888 |

| Water viscosity (Pa s) | 0.0013 | Tap water viscosity (Pa s) | 0.001 |

| Oil viscosity (Pa s) | 0.653 | Mineral oil viscosity (Pa s) | 0.02 |

| Interfacial tension (N/m) | 0.05 | Interfacial tension (N/m) | 0.01897 |

| Diameter (m) | 0.021 | Diameter (m) | 0.0145 |

| Temperature (°C) | 25 | Temperature (°C) | 25 |

| Chakrabarti et al. [56] | Tan et al. [3] 200# | ||

| Water density (kg/m3) | 997 | Tap water density (kg/m3) | 998 |

| Kerosine (kg/m3) | 787 | Mineral oil density (kg/m3) | 869 |

| Water viscosity (Pa s) | 0.00084 | Tap water viscosity (Pa s) | 0.001 |

| Kerosine (Pa s) | 0.0012 | Mineral oil viscosity (Pa s) | 0.237 |

| Interfacial tension (N/m) | 0.045 | Interfacial tension (N/m) | 0.04583 |

| Diameter (m) | 0.0254 | Diameter (m) | 0.0145 |

| Temperature (°C) | 25 | Temperature (°C) | 25 |

| Lovick and Angeli [55] | Tan et al. [3] 400# | ||

| Tap water density (kg/m3) | 998 | Tap water density (kg/m3) | 998 |

| Exxsol140 density (kg/m3) | 828 | Mineral oil density (kg/m3) | 896 |

| Tap water viscosity (Pa s) | 0.001 | Tap water viscosity (Pa s) | 0.001 |

| Exxsol140 viscosity (Pa s) | 0.006 | Mineral oil viscosity (Pa s) | 0.456 |

| Interfacial tension (N/m) | 0.0396 | Interfacial tension (N/m) | 0.05149 |

| Diameter (m) | 0.038 | Diameter (m) | 0.0145 |

| Temperature (°C) | 25 | Temperature (°C) | 25 |

| ST | SM | Do/w | Dw/o | SL | AN | |

|---|---|---|---|---|---|---|

| Rem/Eo versus fw | N | N | N | N | N | N |

| Rem/Eo versus fw (LVO <10) | N | N | N | N | Y | N/A |

| Rem/Eo versus fw (LVO <20) | N | N | N | N | Y | N |

| Rem/Eo versus fw (MVO) | Y | Y | Y | Y | Y * | Y * |

| Rem/Eo versus fw (HVO) | Y | Y | Y | Y | Y | N |

| We/Eo versus fw | Y | Y | N | Y | Y | N |

| Frm versus fw | Y | Y | N | Y | Y | N |

| G/V versus fw | N | N | N | N | N | N |

| G/V versus fw (LVO <10) | Y | Y | Y | Y | Y | N/A |

| G/V versus fw (LVO <20) | N | N | N | Y | N | Y |

| G/V versus fw (MVO) | Y | N | N | N | Y | Y |

| G/V versus fw (HVO) | Y | Y | N | Y | N | Y |

| Frw versus Fro | N | N | N | N | N | N |

| Frw versus Fro (LVO <10) | Y | Y | Y | Y | Y | N/A |

| Frw versus Fro (LVO <20) | N | N | N | N | N | N |

| Frw versus Fro (MVO) | Y | Y | Y | Y | Y * | Y * |

| Frw versus Fro (HVO) | Y | Y | N | Y | N | N |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osundare, O.S.; Falcone, G.; Lao, L.; Elliott, A. Liquid-Liquid Flow Pattern Prediction Using Relevant Dimensionless Parameter Groups. Energies 2020, 13, 4355. https://doi.org/10.3390/en13174355

Osundare OS, Falcone G, Lao L, Elliott A. Liquid-Liquid Flow Pattern Prediction Using Relevant Dimensionless Parameter Groups. Energies. 2020; 13(17):4355. https://doi.org/10.3390/en13174355

Chicago/Turabian StyleOsundare, Olusegun Samson, Gioia Falcone, Liyun Lao, and Alexander Elliott. 2020. "Liquid-Liquid Flow Pattern Prediction Using Relevant Dimensionless Parameter Groups" Energies 13, no. 17: 4355. https://doi.org/10.3390/en13174355

APA StyleOsundare, O. S., Falcone, G., Lao, L., & Elliott, A. (2020). Liquid-Liquid Flow Pattern Prediction Using Relevant Dimensionless Parameter Groups. Energies, 13(17), 4355. https://doi.org/10.3390/en13174355