A Case Study of the Water Abundance Evaluation of Roof Aquifer Based on the Development Height of Water-Conducting Fracture Zone

Abstract

1. Introduction

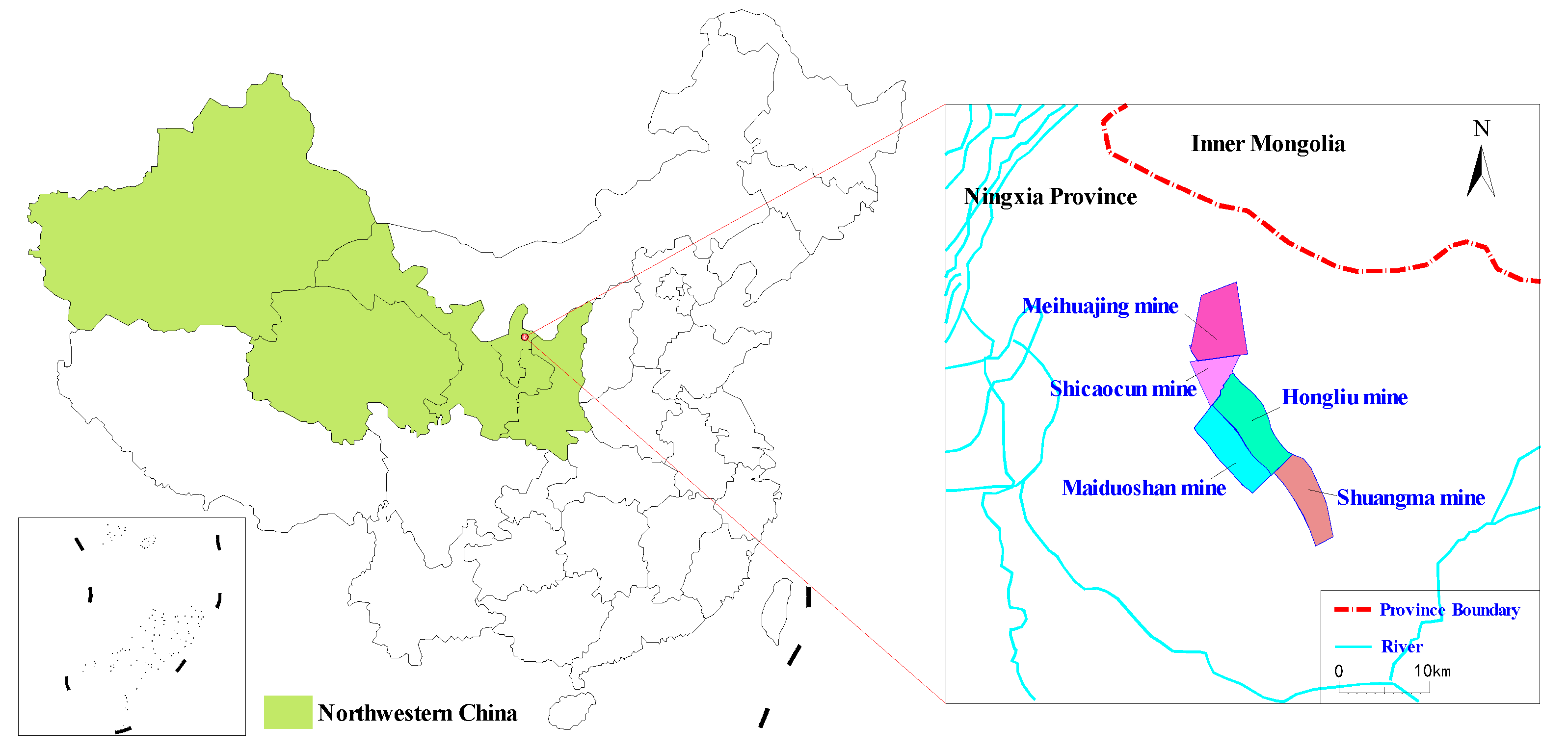

2. Overview of the Study Area

2.1. Geographical Location

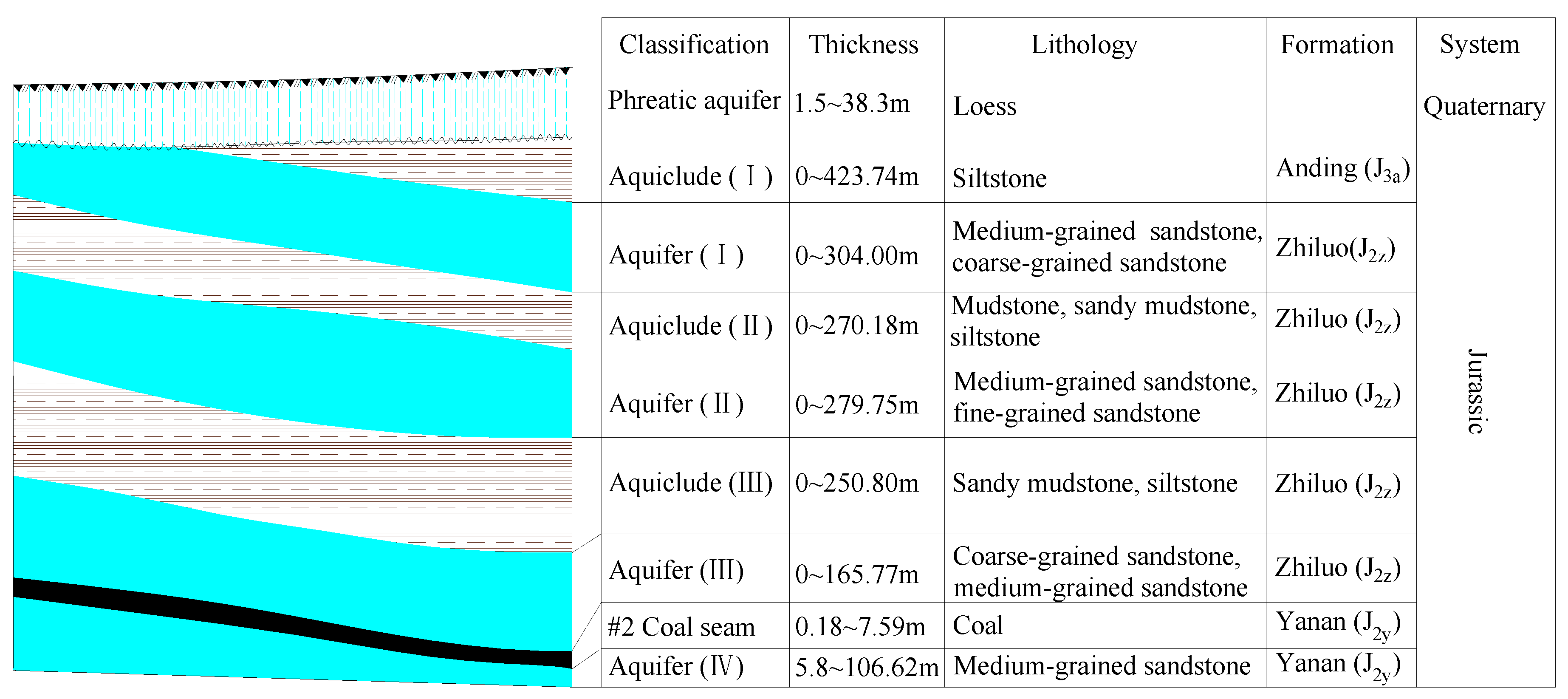

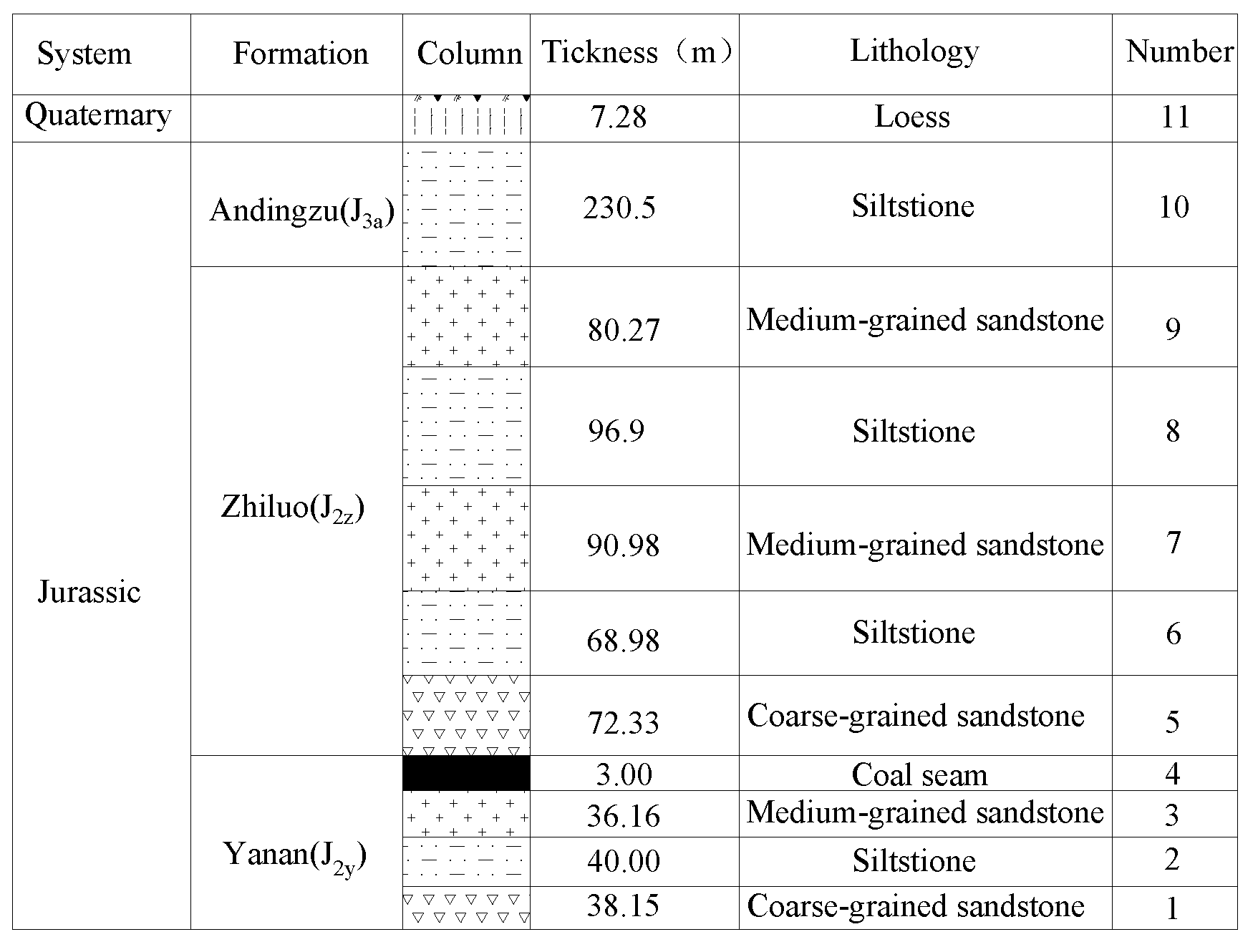

2.2. Aquifer Division in the Study Area

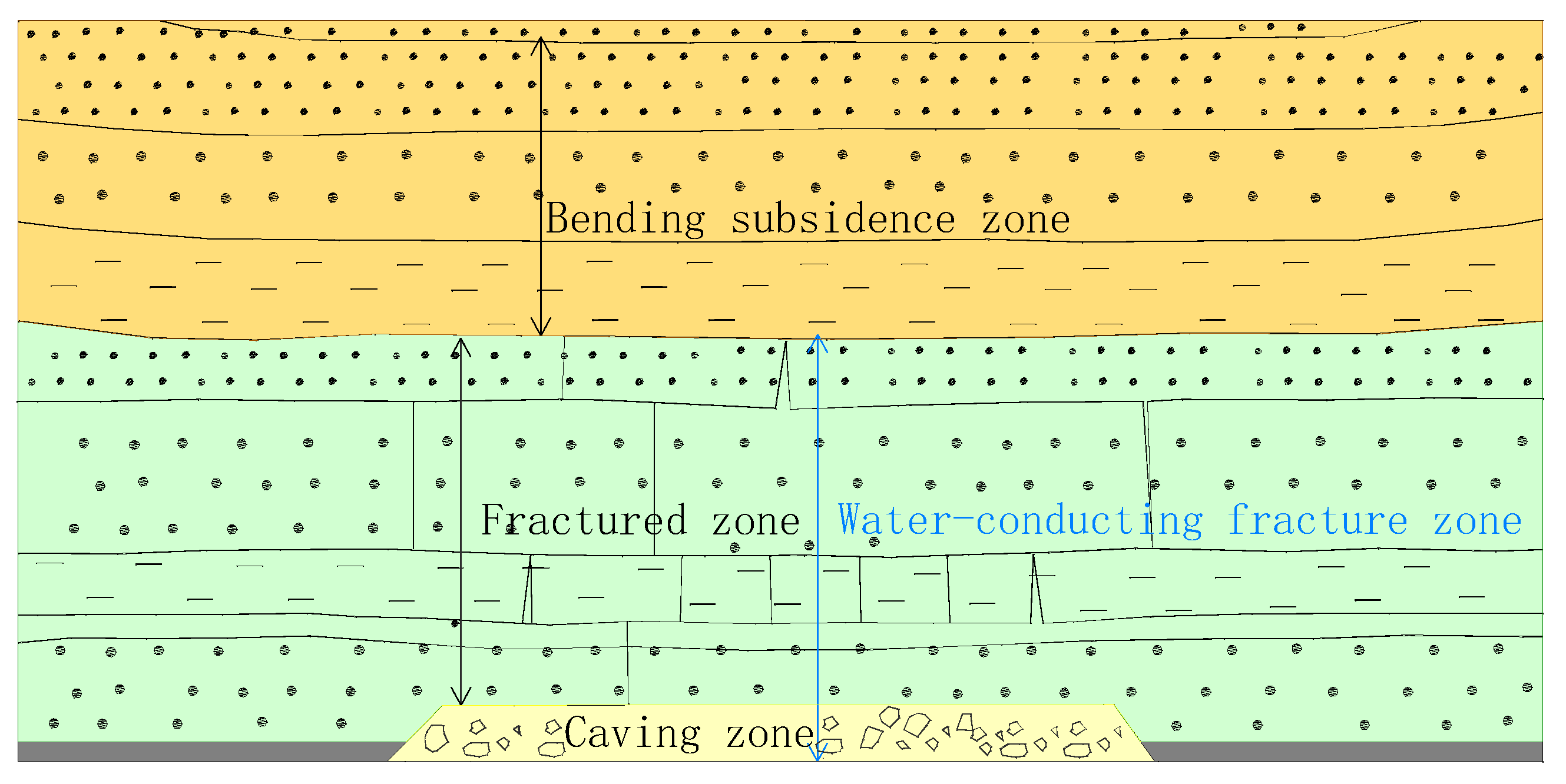

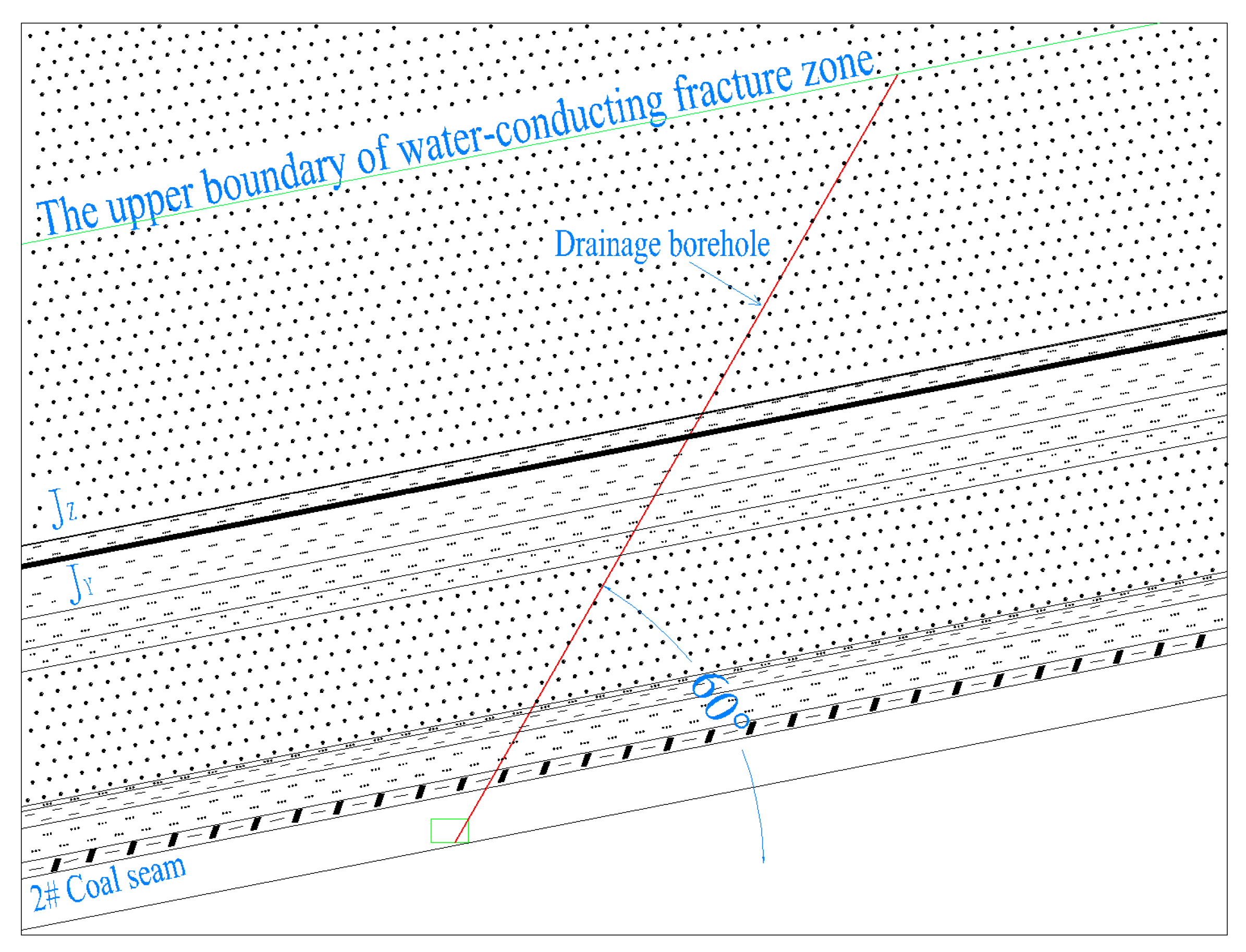

3. Estimation of Development Height of Water-Conducting Fracture Zone in Coal Seam Roof

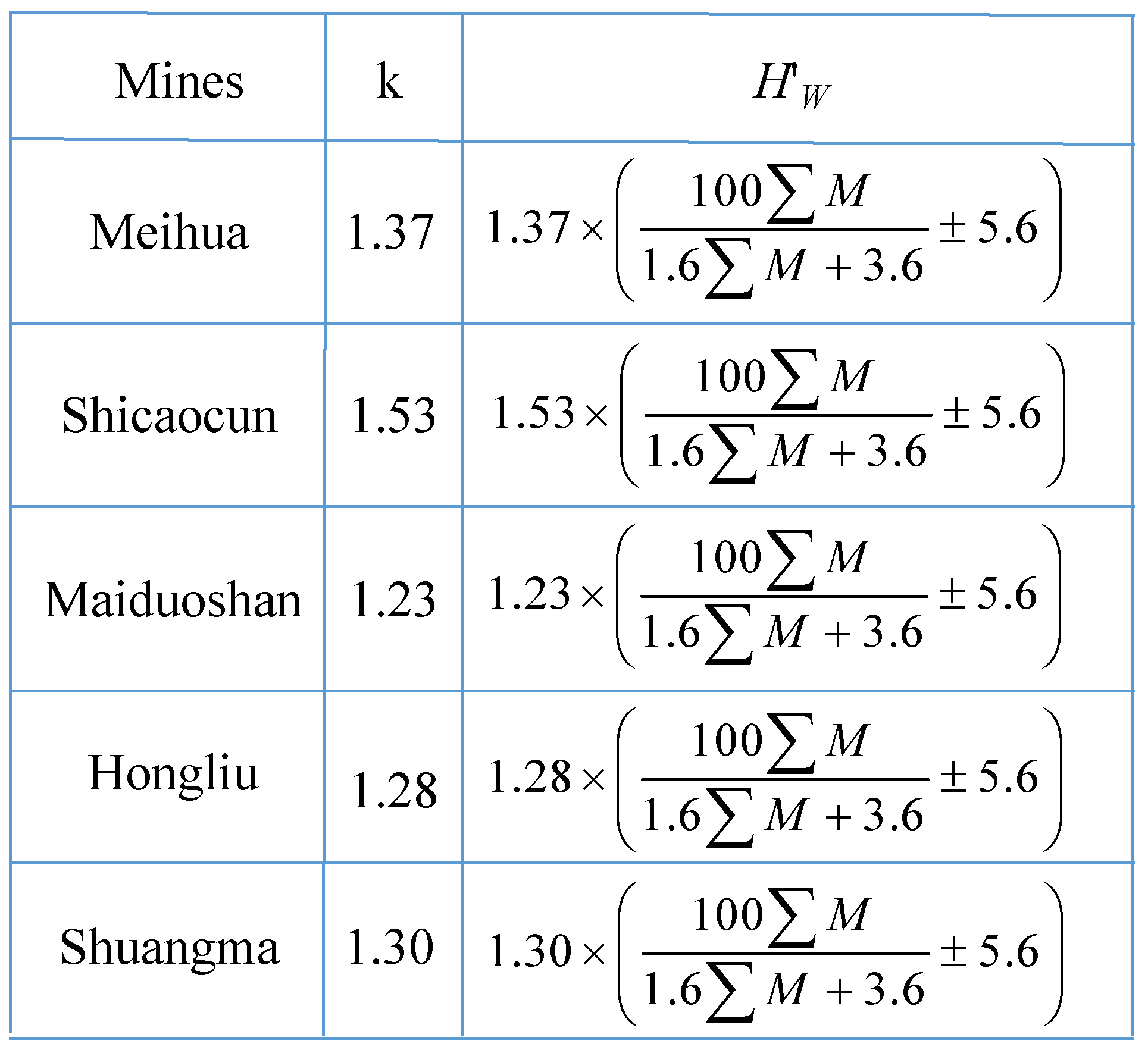

3.1. Empirical Calculation Method of Development Height of Water-Conducting Fracture Zone

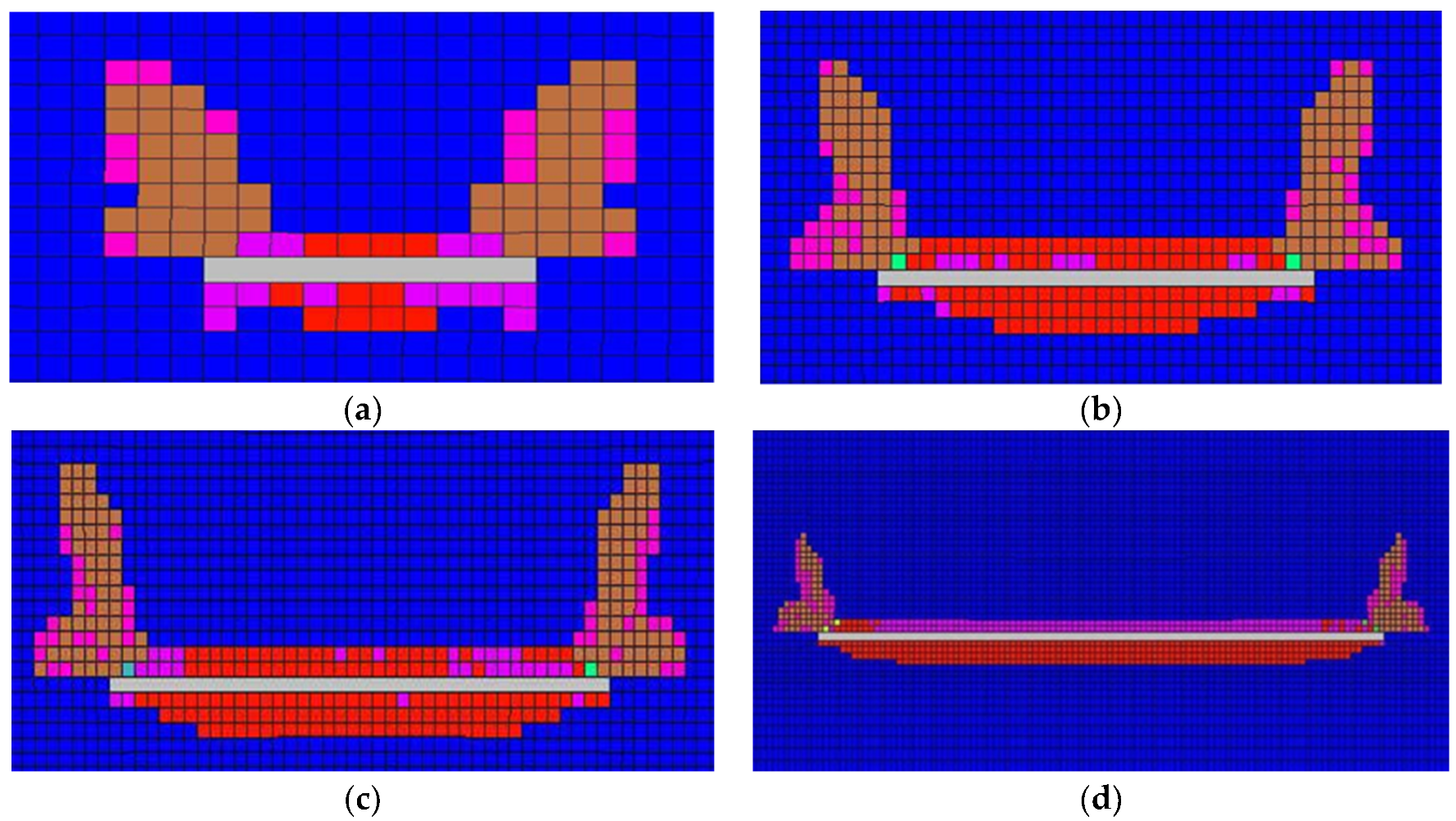

3.2. Numerical Simulation Analysis of Height of Water-Conducting Fracture Zone

3.3. Correction and Calculation of Development Height of Water-Conducting Fracture Zone

4. Evaluation of the Water Abundance of the Sandstone Aquifer of the Roof within the Development Height of the Water-Conducting Fracture Zone

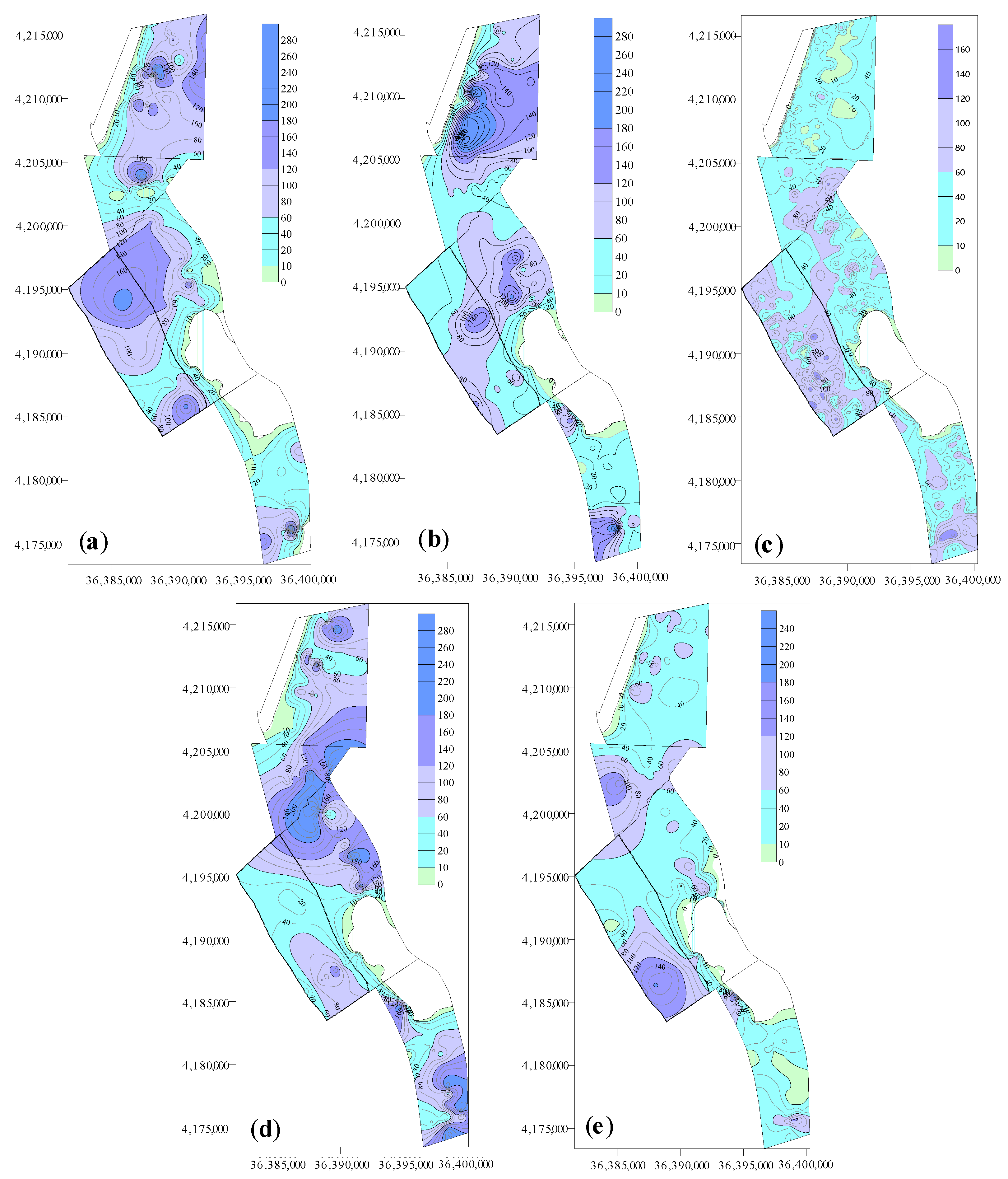

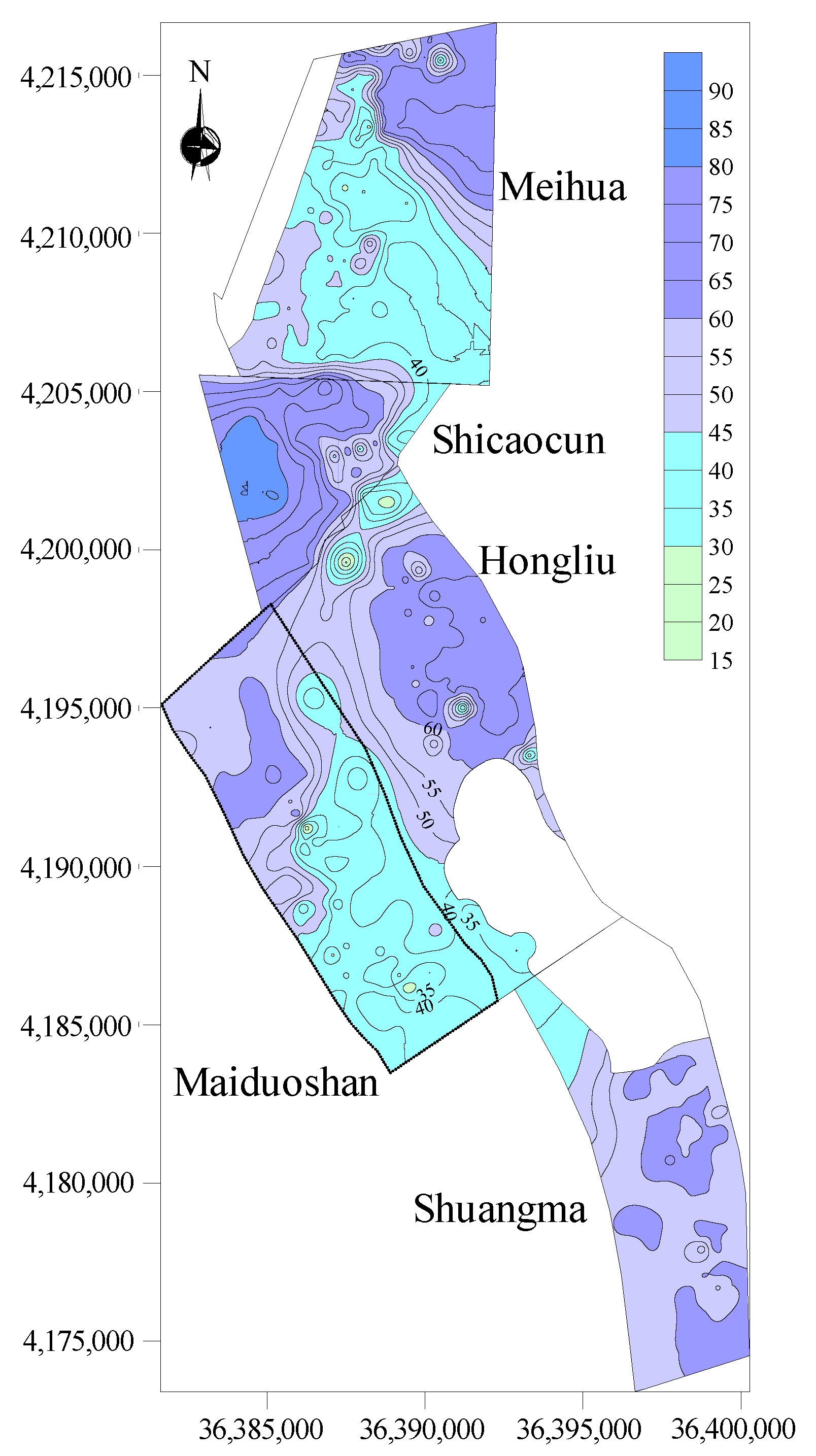

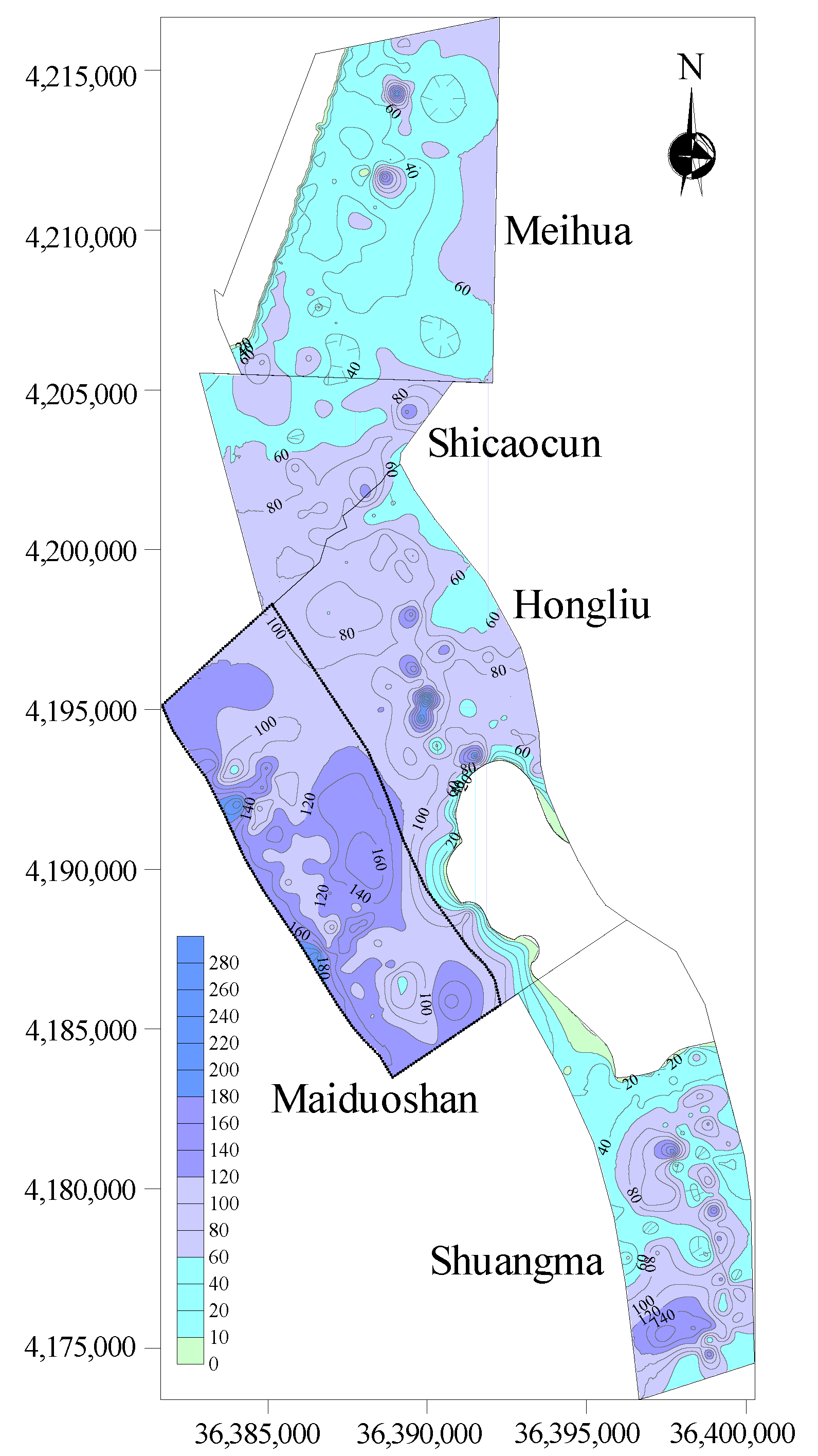

4.1. Variation Characteristics of Sandstone Aquifer Thickness within the Development Height of Water-Conducting Fracture

4.2. Establishment of Lithology Influencing Index for the Roof

4.2.1. Equivalent Thickness of Lithology

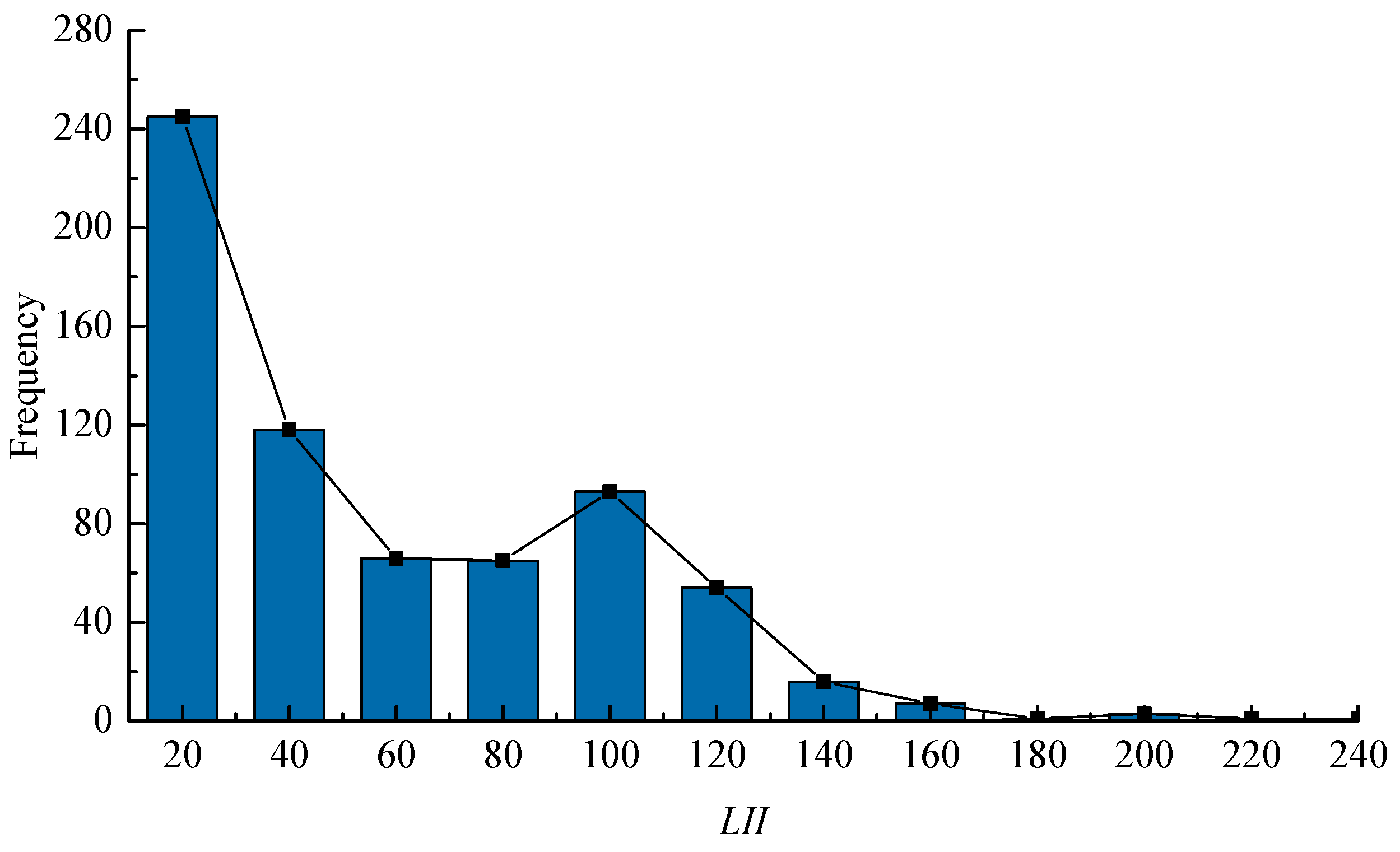

4.2.2. Establishment of LII

4.3. Water Abundance Analysis

5. Engineering Practice

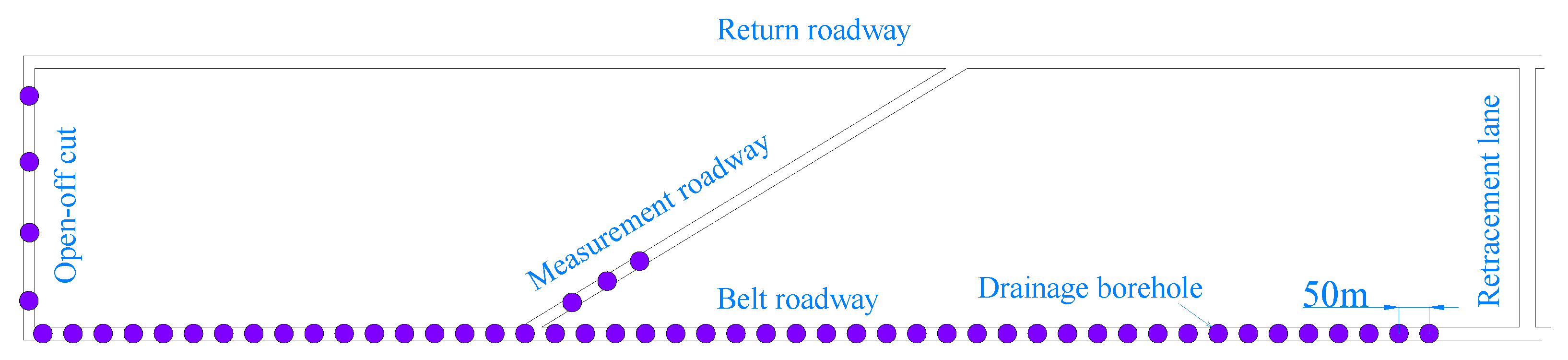

5.1. Arrangement of Drainage Borehole

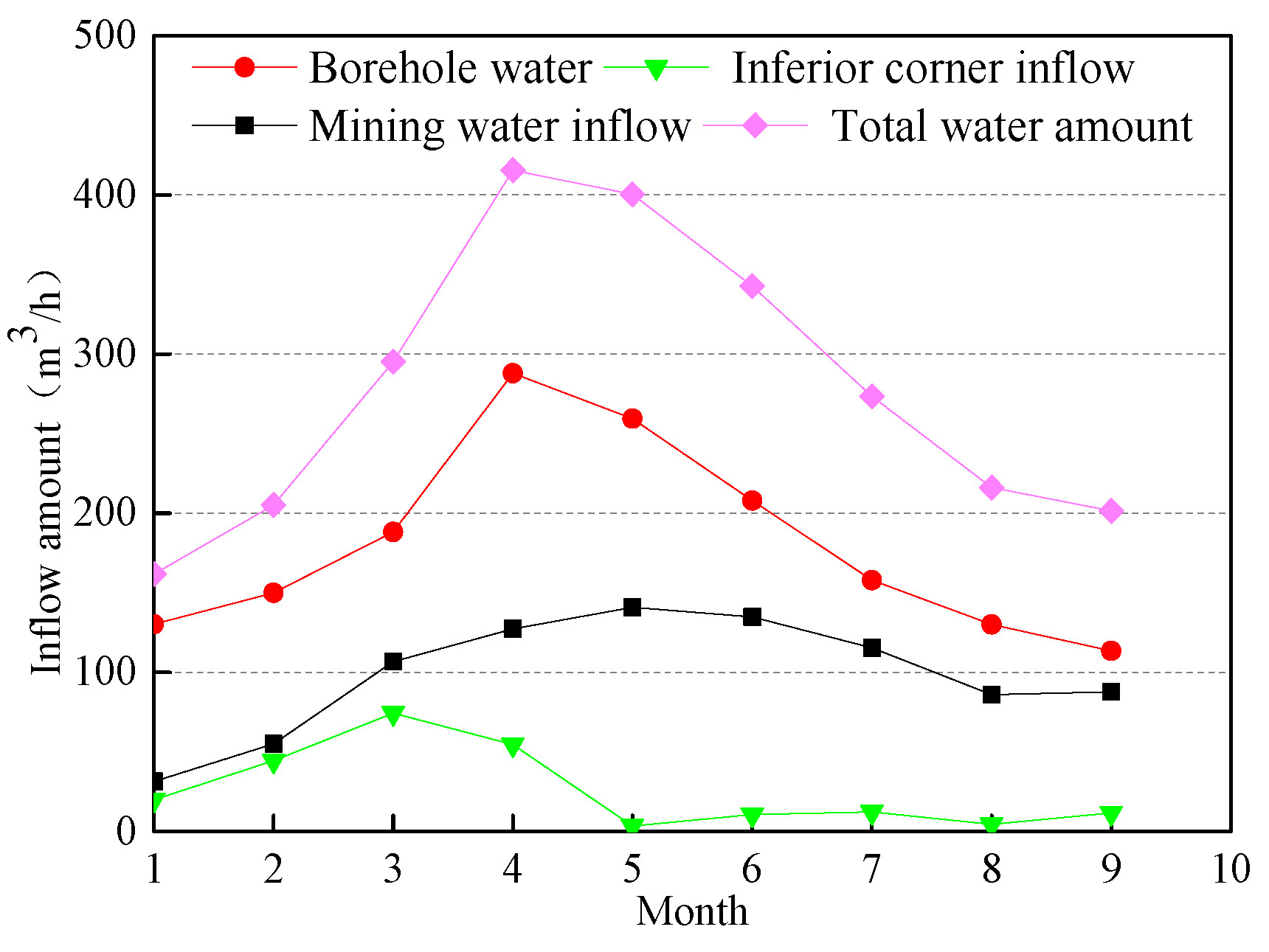

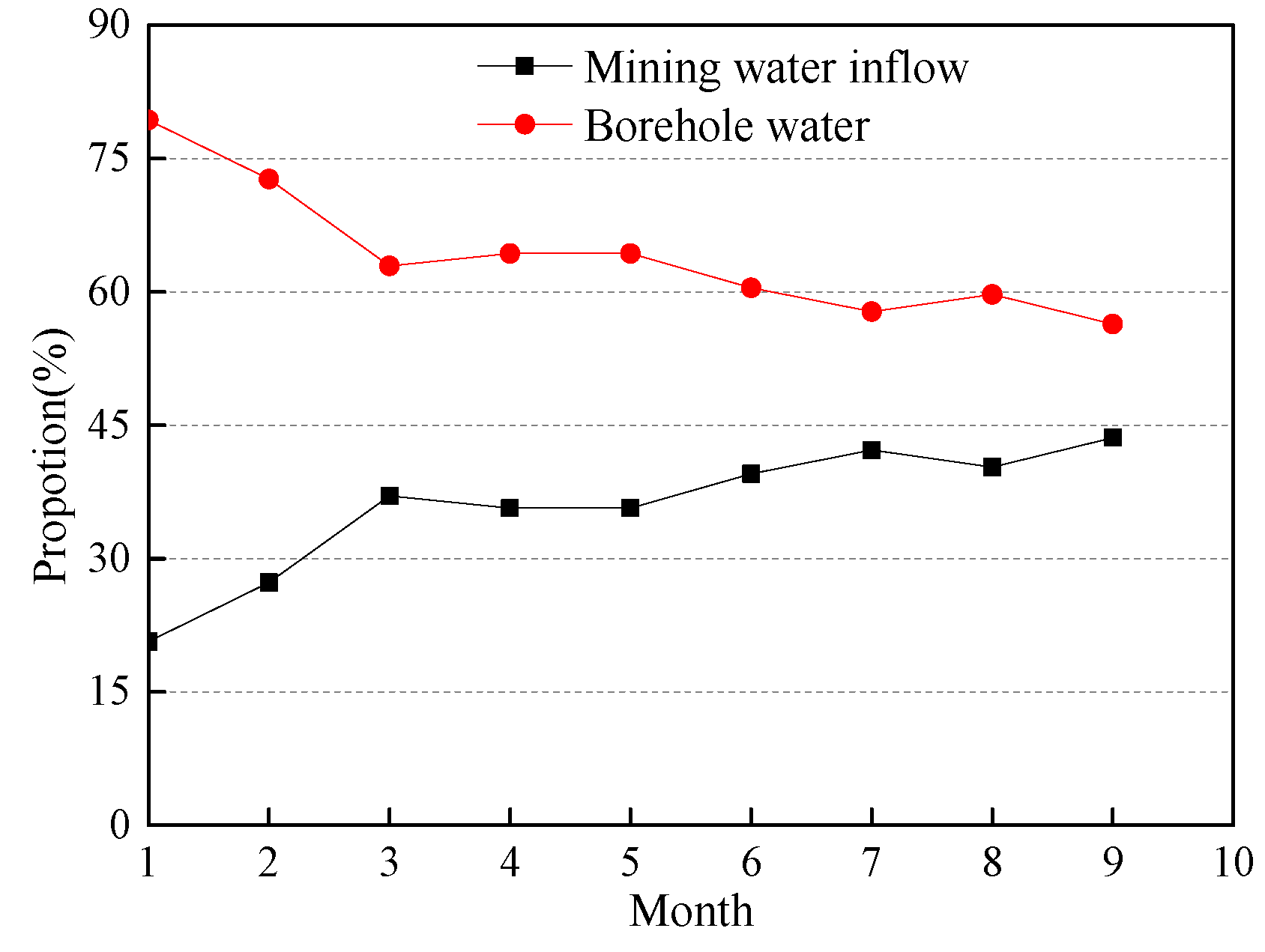

5.2. Pre-Drainage Effect of the Drilling

6. Conclusions

- The the development heights of the roof water-conducting fracture zone are beyond the total thickness of aquifer III and aquiclude III, except in the southern part of Maduoshan mine. Aquifer III in the lower part of Zhiluo formation is mainly the direct water-source aquifer of coal seam #2, while the aquifer II and aquifer I in Zhiluo formation are indirect water-source aquifers.

- According to the partition thresholds of LII, 10, 40, and 100, the water abundance of areas can be classified as four classes; that is, extremely strong water abundance, strong water abundance, medium water abundance, and weak water abundance. The south of Maiduoshan, Hongliu, Shicaocun, the southeast and southwest of Meihuajing, and the middle and south of Shuangma mining areas are areas with extremely strong and strong water abundance; the north of Shicaocun, the north of Shuangma, and most of Meihuajing mining areas are areas with medium water abundance; while the south of Meihuajing, the south of Hongliu, and the north of Shuangma mining areas are areas with weak water abundance. Maduoshan mine can be classified as a mine of extremely strong and strong water abundance, Hongliu as a mine of strong water abundance, Shicaocun and Shuangma as mines of strong and medium water abundance, and Meihua as a mine of medium water abundance.

- There were 54 drainage holes with an elevation angle of 60° arranged to drain the roof aquifer, most of which were arranged in the belt roadway with a relatively lower altitude. When the borehole depth reaches the development height of the water-conducting fracture zone, the pre-drainage of the roof water before mining can effectively reduce the mining inrush water.

Author Contributions

Funding

Conflicts of Interest

References

- Li, W.; Wang, Q.; Liu, S.; Wang, S. Grade types of water-preserved coal mining coalmines in ecologically fragile area. J. China Coal Soc. 2019, 44, 718–726. (In Chinese) [Google Scholar]

- Gu, D.; Zhang, Y.; Cao, Z. Technical progress of water resource protection and utilization by coal mining in China. Coal Sci. Technol. 2016, 44, 1–7. (In Chinese) [Google Scholar]

- Zhao, C.; Jin, D.; Geng, J.; Sun, Q. Numerical Simulation of the Groundwater System for Mining Shallow Buried Coal Seams in the Ecologically Fragile Areas of Western China. Mine Water Environ. 2018, 38, 158–165. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Zhang, C.; Canbulat, I.; Sepasgozar, S.; Saydam, S. A Novel Damage Model for Strata Layers and Coal Mass. Energies 2020, 13, 1928. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, J.; Yin, W.; Sun, Q. Analysis of Overlying Strata Movement and Behaviors in Caving and Solid Backfilling Mixed Coal Mining. Energies 2017, 10, 1057. [Google Scholar] [CrossRef]

- Ning, J.; Wang, J.; Tan, Y.; Xu, Q. Mechanical mechanism of overlying strata breaking and development of fractured zone during close-distance coal seam group mining. Int. J. Min. Sci. Technol. 2020, 30, 207–215. [Google Scholar] [CrossRef]

- Hou, E.; Che, X.; Feng, J.; Duan, Z.; Gao, L.; Li, J. Abundance of aquifers in Yushenfu coal field and the measures for water-preserved coal mining. J. China Coal Soc. 2019, 44, 812–819. (In Chinese) [Google Scholar]

- Ma, L.; Du, X.; Wang, F.; Liang, J. Water-preserved Mining Technology for Shallow Buried Coal Seam in Ecologically-vulnerable Coal field: A case study in the Shendong Coal field of China. Disaster Adv. 2013, 6, 268–278. [Google Scholar]

- Bukowski, P. Evaluation of water hazard in hard coal mines in changing conditions of functioning of mining industry in upper silesian coal basin—USCB (POLAND). Arch. Min. Sci. 2015, 60, 445–475. [Google Scholar] [CrossRef]

- Zha, H.; Liu, W.; Liu, Q. Physical Simulation of the Water-Conducting Fracture Zone of Weak Roofs in Shallow Seam Mining Based on a Self-Designed Hydromechanical Coupling Experiment System. Geofluids 2020, 2020, 2586349. [Google Scholar] [CrossRef]

- Cui, F.; Dong, S.; Lai, X.; Chen, J.; Cao, J.; Shan, P. Study on Rule of Overburden Failure and Rock Burst Hazard under Repeated Mining in Fully Mechanized Top-Coal Caving Face with Hard Roof. Energies 2019, 12, 4780. [Google Scholar] [CrossRef]

- Bai, E.; Guo, W.; Zhang, D.; Tan, Y.; Guo, M.; Zhao, G. Using the Magnetotelluric Method for Detecting Aquifer Failure Characteristics under High-Intensity Mining of Thick Coal Seams. Energies 2019, 12, 4397. [Google Scholar] [CrossRef]

- Zhang, S.; Shen, B.; Li, Y.; Zhou, S. Modeling Rock Fracture Propagation and Water Inrush Mechanisms in Underground Coal Mine. Geofluids 2019, 2019, 1796965. [Google Scholar] [CrossRef]

- Qu, S.; Wang, G.; Shi, Z.; Zhou, P.; Xu, Q.; Zhu, Z. Temporal changes of hydraulic properties of overburden aquifer induced by longwall mining in Ningtiaota coalfield, northwest China. J. Hydrol. 2020, 528, 124525. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.; Zhang, W.; Li, A.; Yin, W. Experimental Investigation of Water-Inrush Risk Based on Permeability Evolution in Coal Mine and Backfill Prevention Discussion. Geofluids 2019, 2019, 3920414. [Google Scholar] [CrossRef]

- Ju, J.; Li, Q.; Xu, J.; Wang, X.; Lou, J. Self-healing effect of water-conducting fractures due to water-rock interactions in undermined rock strata and its mechanisms. Bull. Eng. Geol. Environ. 2019, 79, 287–297. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, Y.; Shi, H.; Zhang, Z.; Chen, J. Impacts of Aquitard Properties on an Overlying Unconsolidated Aquifer in a Mining Area of the Loess Plateau: Case Study of the Changcun Colliery, Shanxi. Mine Water Environ. 2020, 39, 121–134. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, G.; Chen, X.; Mabaire, A.; Zhou, J.; Zhang, Y.; Zhang, G.; Zhu, L. Groundwater Hydrogeochemical Processes and the Connectivity of Multilayer Aquifers in a Coal Mine with Karst Collapse Columns. Mine Water Environ. 2020, 39, 356–368. [Google Scholar] [CrossRef]

- Younas, A.; Nisbah, M.; Khattak, J.A.; Javed, T.; Rehman, H.; Farooqi, A. High levels of fluoride contamination in groundwater of the semi-arid alluvial aquifers, Pakistan: Evaluating the recharge sources and geochemical identification via stable isotopes and other major elemental data. Environ. Sci. Pollut. Res. 2019, 26, 35728–35741. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, L.; Chen, Y.; Ge, R.; Ma, L.; Zhou, K.; Shi, X. Discrimination of water-inrush source and evolution analysis of hydrochemical environment under mining in Renlou coal mine, Anhui Province, China. Environ. Earth Sci. 2020, 79, 61. [Google Scholar] [CrossRef]

- Wu, G.; Bai, H.; Du, B.; Wu, L.; He, S.; Li, H. Study on the failure mechanism of clay layer overlying thin bedrock in coal seam mining. Environ. Earth Sci. 2019, 78, 315. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Q.; Li, W.; Li, T.; He, J. Height of water-conducting fractured zone in coal mining in the soil-rock composite structure overburdens. Environ. Earth Sci. 2019, 78, 242. [Google Scholar] [CrossRef]

- Xu, J. Green Mining of Coal Mine; China University of Mining and Technology Press: Xuzhou, China, 2011; pp. 133–134. (In Chinese) [Google Scholar]

- Wang, S.; Feng, J.; Hou, E.; Huang, K.; Xue, W.; Duan, H. Microscopic pore structure types of sandstone and its effects on aquifer water abundance in Ningtiaota coal mine. J. China Coal Soc. 2020, 09032020. Available online: http://www.mtxb.com.cn/CN/abstract/abstract24811.shtml (accessed on 5 August 2020). (In Chinese).

- Huang, Y.; Li, J.; Song, T.; Kong, G.; Li, M. Analysis on Filling Ratio and Shield Supporting Pressure for Overburden Movement Control in Coal Mining with Compacted Backfilling. Energies 2017, 10, 31. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, L.; Zhang, D. Characteristics of Roof Ground Subsidence While Applying a Continuous Excavation Continuous Backfill Method in Longwall Mining. Energies 2020, 13, 95. [Google Scholar] [CrossRef]

| Number | Bulk Modulus/MPa | Shear Modulus/MPa | Cohesion/MPa | Internal Friction Angle/° | Tensile Strength/MPa | Density/kg/m3 | Lithology Description |

|---|---|---|---|---|---|---|---|

| 10 | 1770 | 1800 | 2.95 | 36.13 | 2.2 | 2570 | Siltstone |

| 9 | 2280 | 2230 | 4.7 | 39.71 | 2.7 | 2440 | Medium-grained sandstone |

| 8 | 1770 | 1800 | 2.95 | 36.13 | 2.2 | 2570 | Siltstone |

| 7 | 2280 | 2230 | 4.7 | 39.44 | 2.8 | 2440 | Medium-grained sandstone |

| 6 | 1770 | 1800 | 2.95 | 36.13 | 2.2 | 2570 | Siltstone |

| 5 | 2170 | 2250 | 1.95 | 32.81 | 1.8 | 2380 | Coarse-grained sandstone |

| 4 | 350 | 260 | 3.2 | 28.0 | 0.8 | 1290 | #2 coal seam |

| 3 | 2280 | 2230 | 4.7 | 39.44 | 1.9 | 2320 | Medium-grained sandstone |

| 2 | 1770 | 1800 | 2.95 | 36.13 | 2.2 | 2680 | Siltstone |

| 1 | 2750 | 2375 | 2.03 | 34.94 | 1.8 | 2410 | Coarse-grained sandstone |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, W.; Li, W.; Huang, Y.; Ouyang, S.; Ma, K.; Li, J.; Gao, H.; Zhang, P. A Case Study of the Water Abundance Evaluation of Roof Aquifer Based on the Development Height of Water-Conducting Fracture Zone. Energies 2020, 13, 4095. https://doi.org/10.3390/en13164095

Zhai W, Li W, Huang Y, Ouyang S, Ma K, Li J, Gao H, Zhang P. A Case Study of the Water Abundance Evaluation of Roof Aquifer Based on the Development Height of Water-Conducting Fracture Zone. Energies. 2020; 13(16):4095. https://doi.org/10.3390/en13164095

Chicago/Turabian StyleZhai, Wen, Wei Li, Yanli Huang, Shenyang Ouyang, Kun Ma, Junmeng Li, Huadong Gao, and Peng Zhang. 2020. "A Case Study of the Water Abundance Evaluation of Roof Aquifer Based on the Development Height of Water-Conducting Fracture Zone" Energies 13, no. 16: 4095. https://doi.org/10.3390/en13164095

APA StyleZhai, W., Li, W., Huang, Y., Ouyang, S., Ma, K., Li, J., Gao, H., & Zhang, P. (2020). A Case Study of the Water Abundance Evaluation of Roof Aquifer Based on the Development Height of Water-Conducting Fracture Zone. Energies, 13(16), 4095. https://doi.org/10.3390/en13164095