1. Introduction

Active wake control (AWC) is a strategy for operating wind farms in such a way that wake effects are mitigated. This allows to increase the overall power yield of the wind farm and/or reduce the fatigue loading of the individual wind turbines. There are two main approaches to AWC: induction control and wake redirection. Induction control is based on reducing the axial induction of upstream turbines in order to let downstream turbines benefit from the increased wind velocity ([

1,

2,

3,

4]). This can be achieved, for instance, by increasing the pitch angle at below rated wind speeds. The second approach, wake redirection, relies on operating upstream wind turbines with yaw misalignment in order to generate a transverse force on the air flow and effectively steer the wake aside from downstream turbines ([

5,

6,

7,

8]). For most wind farms, wake redirection is the more beneficial strategy in terms of power production increase [

9]. In addition to optimizing the AWC strategy to maximize the power production gain, other benefits have also been studied by researchers such as layout optimization ([

8,

10]) and loads mitigation ([

9,

11]). Furthermore, there has been increasing interest into obtaining improved understanding of the behaviour of wakes due to oblique inflow ([

12,

13,

14,

15]). Recently, NREL published measurement results from two field campaigns with wake redirection: one offshore ([

16]) and one on land ([

17,

18]). Sandia National Laboratories has also performed recent field trials at their scaled wind farm facility with intentional yaw misalignment ([

19]).

In addition to being potentially more beneficial in terms of power production gain, the wake redirection AWC strategy has also a more pronounced impact on turbine loads, and the risk associated with it is usually higher. Clearly, loads need to be well understood before this farm control strategy can be commercialized. This has led to an increasing interest in the past years in assessing the impact of wake redirection on the loads. To begin with, it is important to understand the load implications for a standalone wind turbine operated with yaw misalignment. Does misaligned operation always imply loads increase? This turns out not to be the case, as some initial studies based on simulations and wind tunnel measurements with misaligned flow conditions ([

20,

21]) indicated that the fatigue loads increase for some yaw angles, but decrease for other yaw angles. This is primarily caused by vertical wind shear, that shifts the minimal loading towards a non-zero yaw angle. For this reason, in [

21] is argued that operation under misaligned inflow can be beneficial in terms of loading even for a stand-alone wind turbine. These findings are well aligned with later numerical studies ([

6,

22,

23,

24,

25]). Finally, these simulation results were recently confirmed by field measurements performed with intentionally misaligned turbines by NREL ([

26]) and Sandia ([

19,

27]).

These initial studies on the impact of AWC on the farm loads have been limited to one or two turbines. Furthermore, the focus has primarily been on the loads due to yaw misalignment on the most upstream wind turbine. In addition to that, there have also been some publications on modelling wake induced loading in offshore wind farms during normal operation without AWC ([

28,

29]). However, there is still insufficient understanding of the impact of wake redirection control on the fatigue loads of wind turbines within the whole wind farm, i.e., including loads induced by both misaligned flow and wake effects deeper downstream. Even more, as some fatigue loads are increasing for some yaw misalignment angles, it is important to be able to evaluate the fatigue loads during the complete lifetime of a wind farm. To this end, the whole spectrum of wind conditions expected at a given site needs to be considered, and including all wind turbines in the analysis. Such a detailed loads analysis will provide essential insights into the overall impact of AWC on lifetime fatigue loads, which is expected to represent a major step towards derisking the AWC technology and increasing its acceptance in the industry.

Within this paper, a detailed analysis is performed on the impacts of wake redirection control on the lifetime fatigue loads in an existing offshore wind farm. For each turbine in the wind farm, the loads are calculated at several key locations along the blades, shaft and tower. The load simulations are performed using Focus/Phatas, a commercial aeroelastic simulation tool used for the design and certification of commercial wind turbines. To enable prediction of the loads in all possible wind conditions and all locations in the farm, while at the same time keeping the calculation effort manageable, a loads database is constructed by simulating a single turbine operating in a wake under a wide range of realistic operating and environmental conditions. As a result, around 100,000 simulations have been performed to construct the database containing fatigue loads and statistics for different combinations of wind speeds, turbulence intensities, wake locations, wake deficit width, wake deficit depth, yaw misalignments and pitch angle offsets. Subsequently, farm simulations have been performed using ECN-TNO’s wake model FarmFlow [

30] for the whole spectrum of ambient wind conditions at the considered site. The calculated inflow conditions in front of each turbine are then used to interpolate the corresponding load levels from the database. The results from the analyses indicate that the lifetime fatigue loads tend to decrease under wake redirection control by yaw misalignment.

The paper is organized as follows. In the next

Section 2, the wake modelling implemented in the FarmFlow tool is described. In the

Section 3, the approach to modelling the fatigue loads on the individual wind turbines within the farm is discussed. Subsequently, in

Section 4 information is provided about the case study Reference wind farm. The approach to optimizing the yaw misalignment angles for this farm is outlined in

Section 5. Finally, the analysis of the effect of wake redirection on the lifetime fatigue loads at wind turbine level are presented in

Section 6.

Section 7 provides some final remarks.

2. Wake Modelling

In this study the FarmFlow [

30,

31] wake model is used, originally based on the UPMWAKE code [

32]. It is a 3D parabolised Navier–Stokes code, where the turbulence in the wake is modelled by a

turbulence model. The ambient wind is modelled as in [

33]. The ambient wind at different heights is computed for a prescribed ambient turbulence intensity and Monin–Obukhov length, taking into account the atmospheric stability. The

turbulence model parameters are tuned so that the turbulent kinetic energy in the free stream agrees with value from Panofsky and Dutton for neutral conditions.

Originally, the wake was divided in two regions: a near wake region up to 2.25 rotor diameters (D), and a far wake region. Moreover, the axial pressure gradients were also neglected. Since the axial pressure gradients force the expansion of the wake and the deceleration of the flow in the near wake, these effects had to be excluded from the original model. As a result of that, the turbulence model started at the far wake with an empirical initial wake velocity profile at 2.25D.

The wake model has undergone a significant improvement in 2006 by including the stream-wise pressure gradient into the model, by prescribing it as a source term in the flow equations [

34]. The parabolization, the resulting huge reduction in computational complexity, was retained. The pressure gradients stream wise are computed via an axisymmetric inviscid free vortex wake method. The rotor is modeled as an actuator disc under uniform loading. The blade element momentum (BEM) theory is used to compute the average axial induction given the thrust curve. The initial induced wake velocities are then calculated by the free vortex wake model to match the average axial wind deficit in the rotor plane. This way, the pressure gradients depend only on the axial force. For computational efficiency, the pressure gradients have been precomputed for a wide range of axial induction factors and stored in a database. This hybrid method of wake modelling results in high accuracy at an acceptable computational time. The code runs up to 20 calculations for different wind conditions in parallel using the available cores.

The computational domain of the wake model in FarmFlow has the dimension of a rectangular box, where the size of the grid cells is chosen to achieve a good compromise between accuracy and computational time. The size of the grid cells in direction perpendicular to the flow is chosen equal to D/9. In this way, the rotor area is covered by approximately 50 grid cells. In the flow direction the grid begins at the rotor area with an exponentially increasing step size because of the slower wake development at larger distance downstream of the rotor. At the rotor area the step size is 0.01D and after a distance of 15D, the maximum step size of 1.6D is reached. In the near wake, the parameters of the turbulence model have been adjusted in order to correct for overestimated turbulence production from shear.

The power production of wind turbines is based on the rotor average velocity calculated with FarmFlow and the power curve data. As a result of the curved velocity profile, the rotor averaged velocity is slightly lower than the velocity at hub height. For this reason, the calculated power production of undisturbed wind turbines may be around 99% of the true power curve. FarmFlow uses cubic splines with overshoot prevention to interpolate power and thrust values.

According to the description of the wake behaviour from [

35], the wake of a wind turbine can be separated in three regions: a near wake region, a far wake region and a transition region in-between.

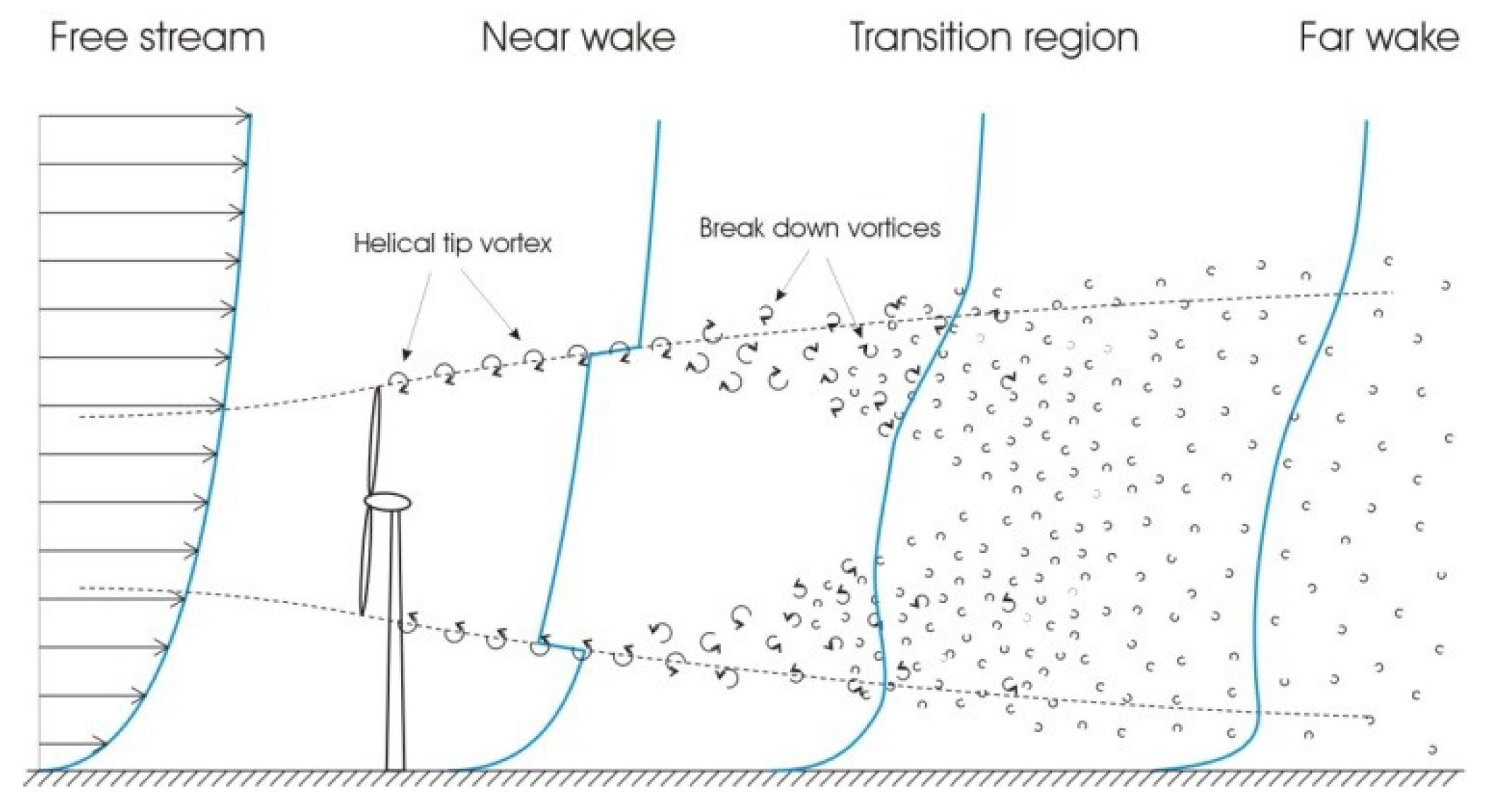

Figure 1 shows the development of the vertical velocity profile downstream a wind turbine. In the flow direction the area is divided into four regions: the (undisturbed) free stream region upstream of the rotor and the three wake regions. For each region a velocity profile is drawn in the figure. The near wake region ends approximately at two rotor diameters downstream of the rotor, and the far wake begins at approximately 4D–5D downstream.

The near wake region starts at the rotor surface where wind energy is extracted by means of a pressure drop over the rotor plane. The cylindrical shear layer separates the slow moving air inside the wake from the air outside the wake. Inside the shear layer tip vortices, which are shed from the turbine blades, are following a helical trajectory. The velocity deficit inside the wake increases as a result of increasing pressure inside the wake, until this pressure reaches the pressure of the external flow. The wake expands as a result of the increasing velocity deficit. The stable system of helical vortices inside the shear layer produce only a small amount of turbulence. As a result of limited turbulent diffusion inside the shear layer, the thickness of the shear layer grows slowly. Particle image velocimetry (PIV) measurements [

36] have shown that the effect of individual blades on axial velocity disappears beyond a distance of one rotor diameter, while the tip vortices stay present for a much longer time. At the end of the near wake region, the tip vortices start to break down and produce high levels of turbulence. As a result of the increased turbulent diffusion, the shear layer thickness increases faster. When the shear layer reaches the wake axis, the near wake ends and the transition region begins. The transition region ends where the wake is completely developed with self-similar distribution profiles of the velocity deficit and turbulence intensity. Here, in the far wake region, the wake meets the criteria for which the standard

model has been calibrated.

Applying the standard

model in the near wake region and the transition region results in large overestimated turbulence production from shear. [

37] also noted this, and added an extra term to the transport equation for the turbulence energy dissipation rate. FarmFlow uses recalibrated

model parameters for the near wake region and the transition region to correct the behaviour of the turbulence model. Only in the far wake region the standard

model parameters are applied.

The target for the recalibration process of the model parameters has been to produce the best agreement with measurements in large offshore wind farms. For those wind farms, the distance between wind turbines are generally between 5 and 10 rotor diameters. Therefore, the aim of the recalibration process has been to get the highest accuracy of power prediction for wind turbine arrays with a distance of 5 to 10 rotor diameters between the turbines.

The FarmFlow model enables AWC simulations. Induction control is implemented by specifying a modified power and thrust curve, and wake redirection is achieved by directly specifying the yaw misalignment angle. To realize that, the pressure gradients are prescribed with respect to the yaw angle instead of the flow direction. The effect of this on the wake deflection is validated using measurements from the wind tunnel and from a scaled wind farm. To optimize the deflection angle of the wake and its velocity deficit, two empirical correction factors have been utilized. Additionally, the wake width is decreased by a factor

, where

is the misalignment angle. A power reduction factor of

, adopted from recent field studies with wake redirection [

16]. Note that the parameter

in this expression has no relation with the loads on the yawed turbine or its wake, it is only used to determine the power loss due to yaw misalignment.

3. Loads Modelling

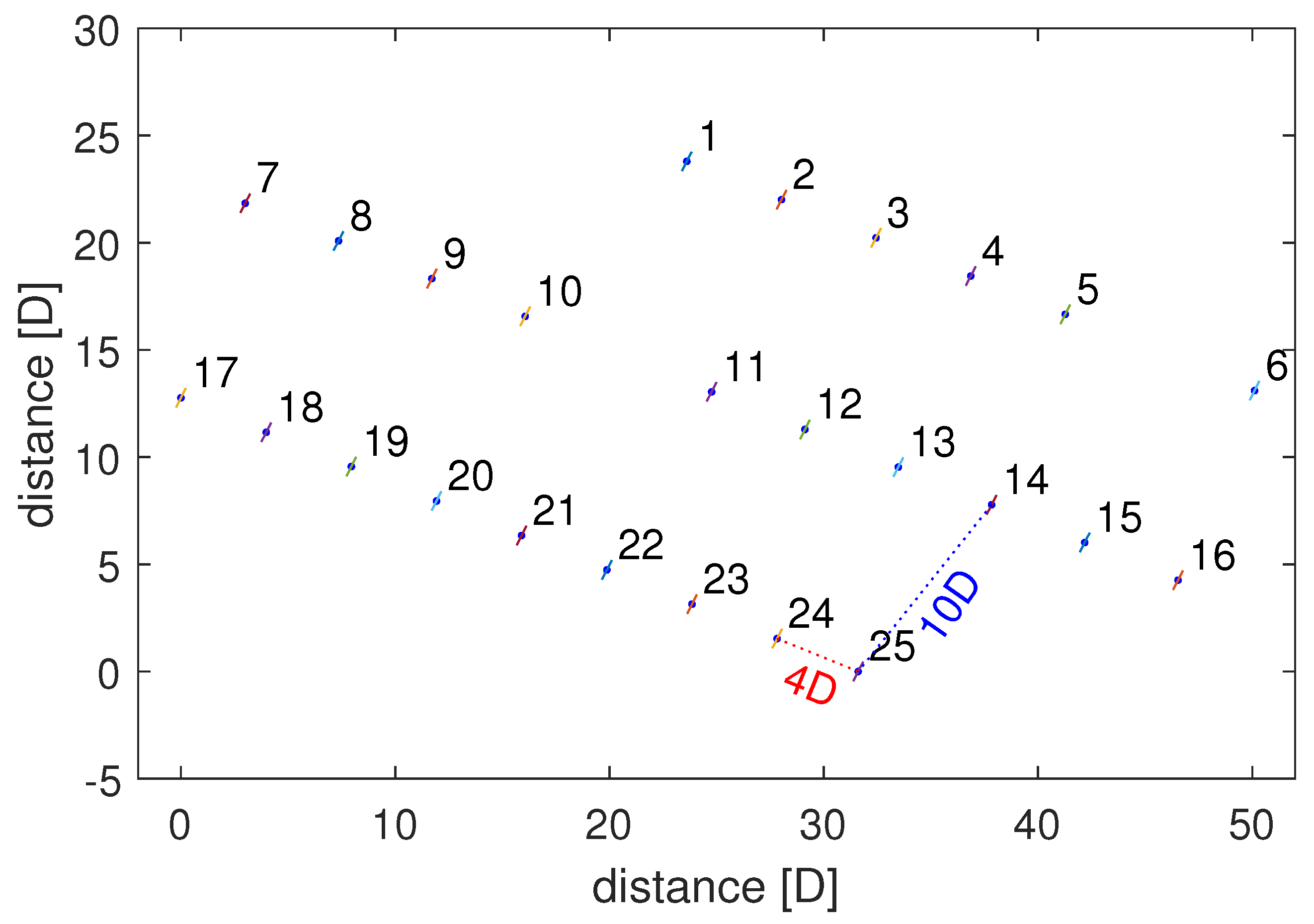

A loads module has been developed and coupled to FarmFlow to allow for estimating the loading at a number of locations on each wind turbine. This information is very relevant for AWC simulations as it enables evaluation of the impact of AWC on the turbine loads. Furthermore, it makes it possible to include the loads in the AWC optimization. The loads module comprises a pre-calculated database, created using aeroelastic simulations with software tool Focus/Phatas. The simulations are carried out on a single turbine that operates in a wake situation, under a wide variety of operating conditions, consisting of combinations of the following parameters (see

Figure 2):

By varying these parameters, normal production simulations are carried out, each for six different realizations of a 3D turbulent wind field. The loads database represents a lookup table containing the results from around 100,000 such simulations, i.e., the calculated fatigue loading and/or statistics (MIN, MAX, AVG, STD) at the selected locations (see

Table 1). It needs to be pointed out that, even though it is generally considered that BEM theory is inaccurate for oblique inflow, some recent studies show that the load trends are actually captured quite well [

38]. As the current study is focused on the impact of AWC on the

relative changes in the fatigue loading, BEM theory is considered sufficient for this purpose.In each farm simulation, FarmFlow computes the wake conditions (above-listed parameters) that best fit the actual wind field in front of each wind turbine. These wake parameters are provided as output for each turbine, which are used to interpolate from the loads database the corresponding loads at the locations listed in

Table 1. Hence, by performing FarmFlow simulations for the complete range of ambient wind conditions at a site (wind velocities, directions and turbulence intensities), reading out the corresponding loads from the database and applying the wind distributions, the site-specific fatigue loads at the considered components are calculated for each turbine in the farm.

The FarmFlow software does not provide these load estimates, but provides sufficient output to characterize the operating conditions of each turbine. During the optimization process the loads on these components are interpolated using a lookup table of precomputed loads (loads database). The database is constructed using detailed aeroelastic simulations with the Focus/Phatas software under many different operating conditions, such as a range of wind speeds; turbulence intensities; wake deficit profiles; wake locations; and yaw misalignment. A result of each farm simulation, the FarmFlow software provides as output these operating conditions at each wind turbine, which are fed to the loads module for determination of the corresponding loads. The wind turbine used for the construction of the loads database is the Siemens SWT-3.6-107 wind turbine.

5. Wake Redirection Optimization

Conventionally, wind turbines are operated at below rated wind speed with the rotor orientation aligned with the wind direction to maximize their own individual power productions. The wake redirection strategy operates the wind turbines at yaw misalignment with respect to the incoming air flow in order to redirect their wakes aside from downstream turbines and increase the total power production of the wind farm. The optimization criterion used in this work is the wind farm annual energy production. To this end, the yaw misalignment angles are optimized for all turbines with a turbine in their wake. This optimization needs to be performed for all relevant wind velocities and directions. The relevant wind velocities are those for which the wind farm power production is below its rated value, while the relevant wind directions are those for which there are wake interactions. However, earlier (unpublished) studies have indicated that the sensitivity of the optimal yaw misalignments to variations in the wind speed is very low, in this study the yaw misalignments are optimized as function of the wind direction only (i.e., they are constrained to be constant over the considered below rated wind speed range). Notice that the optimization process still includes simulations for the whole range of relevant wind speeds, only the optimization variables (the yaw offsets) are constrained to not vary with the wind speed. The AWC optimization process results is a lookup table listing the optimized yaw misalignment angles for individual wind turbine and for each wind direction bin considered (direction bins of 1 degree are used in this study).

Since the focus of this paper is on load analysis, and due to confidentiality reasons, the upside in terms of power production increase by wake redirection is briefly discussed here for one single wind direction and one single row of wind turbines from the farm. The mentioned results, however, are well aligned with recent results presented by [

9] for similar offshore wind farms.

For this farm, wind direction

has been found to be the most beneficial one in terms of power gain. For the row of turbines T16-T7,

Figure 5 gives the power productions, the turbulence intensity and yaw misalignment setting per wind turbine for a wind speed of 11 m/s, both in the reference case (blue bars) and with wake redirection (red bars). It is clear from the figure that wake redirection results in the leading turbine producing less power due to the introduced yaw misalignment, while the remaining wind turbines all achieve an increase in power production due to the higher wind velocity. As a result, wake redirection increases the total power production for row T16-T7 with 19.54% for the considered wind direction (

) and wind speed (11 m/s). As a side comment, notice the decreasing pattern of the optimized yaw misalignments. This pattern is imposed by the optimization, which uses the misalignment angles of the first two turbines of the row as the only free optimization variables. The misalignments of the remaining turbines are linearly decreasing from the second turbine downstream towards zero at the last turbine. Previous studies of the authors, such as [

9], have shown that this pattern often delivers close to optimal results, which are confirmed by similar results reported in [

39].

Looking at the whole park, the effect of wake redirection reduces to 16.48% increase in power production (still for one single wind direction and wind speed). Considering that wake redirection has effect only at below rated wind speeds, and since the wake redirection setting is chosen to be independent of the wind speed, using the wind speed distribution it is established that the yearly increase of the power production for the whole wind farm for this particular wind direction drops to 8.29%. These results are also visible in

Table 2 that gives an overview of the results for yearly power optimization.

Considering the wind speed distribution on site, the power gain as a function of the wind direction is given in

Figure 6. Including the wind direction distribution, the yearly wind farm power production increase due to wake redirection becomes around 1.11%.

6. Fatigue Loads Analysis and Discussion

In this section, the fatigue loads under operation with wake redirection are analysed and compared to the loads in the reference case under normal operation. These site-specific loads are also compared to the design loads according to IEC Class 1A. As the Siemens SWT-3.6-107 is designed for Class 1A conditions (with 18% turbulence intensity at 15 m/s) and placed inside a wind farm, it is particularly interesting to compare the actual site-specific loading to that the turbine is designed to withstand. Within the wind farm, the turbulence intensity at a given location depends on the wind direction due to the wake effects, and is around 6% at 15 m/s in free stream.

The fatigue loads are evaluated for each individual wind turbine, and for the complete range of wind conditions. To this end, the farm is simulated using FarmFlow for each combination of ambient wind speed and direction (wind speeds binned at 1 m/s, and wind directions at 1deg), and the wake conditions in front of each turbine are determined. These wake conditions, in combination with the corresponding pitch or yaw misalignment settings, are used to interpolate the fatigue loads from the loads database.

Furthermore, the fatigue loads are also computed for a single turbine in free stream conditions with turbulence according to the turbine wind Class 1A (according to IEC 61400-1 ed.2), and the corresponding 1A-class load levels are compared to the site-specific loads calculated. This comparison is done to provide understanding of the available fatigue loads margin for the specific site situation.

A summary of the results is provided in

Table 3. For each considered component (first column), the table lists:

column 2 (Reference case): the ID number of the most loaded turbine for the reference case (no wake redirection),

column 3 (wake redirection case): the ID number of the most loaded turbine for the wake redirection case,

column 4 (Load ratio): the relative difference between the highest loads in the wake redirection case compared to the reference case,

column 5 (Load ratio): the relative difference between the highest loads in the wake redirection case compared to the Class 1A loads.

In the columns “Load ratio”, a value lower than 1 indicates that wake redirection achieves a reduction of the loads, while a value larger than 1 indicates load increase. The reported loads are lifetime loads (including the complete ranges of wind speeds and directions, and their distributions), but loads are normalized to the loads that occur at the site for a wind speed of 8 m/s and wind direction of 275 deg at turbine 16 (operating in free stream).

The most important observation from

Table 3 is that the lifetime fatigue loads at all considered components decrease under wake redirection, with the exception of the side-to-side load at tower location 5.5 m and at the tower top, which increase by 7% and 10%, respectively with respect to the reference case. However, the tower load is dominated by the fore-aft loading, where there are very pronounced load reductions observed (factor 0.906 for location 5.5 m and 0.933 for the tower top in the table). As a result, the resultant load on the tower decreases.

Another important observation from

Table 3 is that the load levels from the Class 1A simulations are much higher than the site-specific loads at all locations. The loads ratios reported in the table are computed using the lifetime load levels, with the site-specific wind speed and direction distributions included. This implies that there is quite some margin available with respect to the loading level under wake redirection (see last column in the table).

It needs to be pointed out that the turbine that experiences the highest load at a given component in the reference case often differs from the one with highest load under wake redirection operation. The relative loads differences, listed in the fourth column, can happen to relate to the loading at the same turbine (see the second row in the table, indicating that turbine 12 receives highest fore-aft loading at tower location 5.5 m for both the reference and wake redirection cases), but often relate to different turbines (see the first row, giving the side-to-side loading at tower location 5.5 m, which under wake redirection is highest at a different turbine). Therefore, based on this table it cannot be concluded if the mentioned load reduction at farm level under wake redirection also occurs at turbine level. More detailed analysis at farm level indicated that the loads decrease also at each individual turbine and on all components with the exception of the side-to-side loading at the tower. Again, this is of no concern because the more dominant fore-aft component of the tower loading achieves reduction of load, giving a decrease in the resultant load (combined fore-aft and side-to-side).

These results may seem counter-intuitive as one may expect the loads to increase due to the introduced yaw misalignment. Indeed, by itself, yaw misalignment may increase or decrease the fatigue loads ([

20,

22]). However, the wake effects (and mainly the turbulence in the wake) appear to have a much more pronounced impact on the fatigue loads. This is confirmed in

Figure 7, which gives the normalized fatigue load on the tower versus the turbulence intensity (left plot) and the yaw misalignment (right plot) for different wind speeds below rated. Clearly, the sensitivity of the loads with respect to turbulence intensity is much higher than with respect to yaw misalignment. In a row of turbines, the misalignment may induce increased loading but will also result in the wakes being diverted from the turbines downstream. Therefore, downstream turbines will get a larger proportion of the free (low-turbulence) air flow. The lower turbulence will result in reduction of the fatigue loads that outweighs the increase due to misalignment and the higher wind velocity. The most upstream wind turbine will, of course, not benefit from a lower turbulence airflow, so it might end up with higher loads for that particular wind direction, but when the wind comes from the opposite direction the loads on that turbine will decrease further.

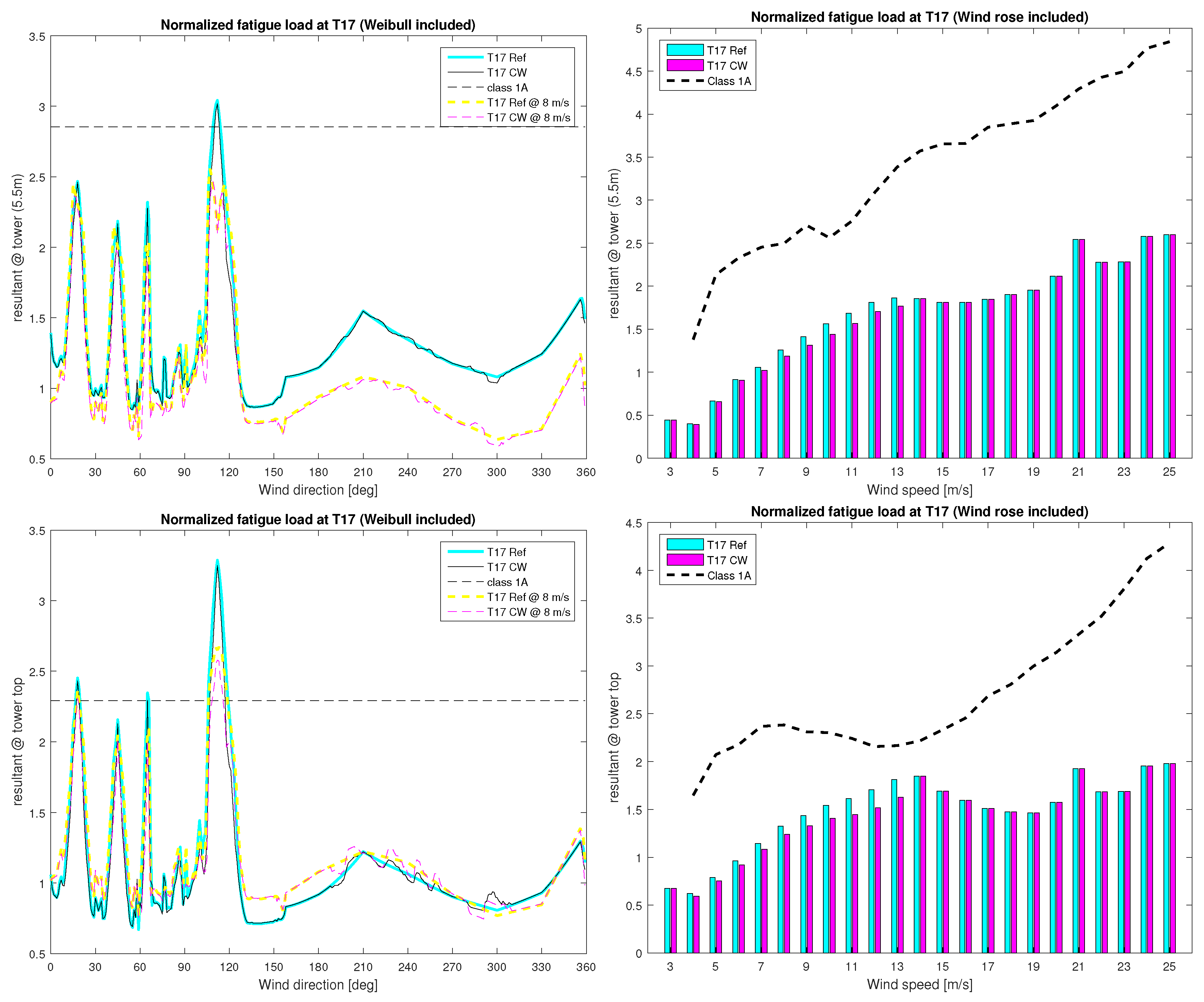

To provide further understanding of these effects,

Figure 8 is included and depicts the normalized loads at a wind turbine at the Western edge of the wind farm, namely T17 (see

Figure 3). The figure provides plots of the loads at different locations as function of the wind direction (left plots) and wind speed (right plots). The solid curves in the left-hand side plots represent the loads averaged over all wind velocities (Weibull distribution included), while the dashed curves give the loads for one specific wind velocity (8 m/s). The loads for both the reference case and wake redirection are provided. The Class 1A load levels are also given (horizontal dashed lines). The effects of the wakes on the loads are obviously very pronounced at all plotted locations (the peaks in the plots). For wind directions from the West, T17 is not in the wake of other turbines, and its load levels are much lower. The reduction of fatigue load at T17 in wake conditions (around the high peaks) is observable by careful inspection of the lines. Notice that, for some wind directions, loads raise above the Class 1A norm level (dashed line). This should not be seen as excessive loading because it occurs only for a short period of time. Taking the wind direction distribution into account (right-hand side plots in

Figure 8), the fatigue loads remain well below the Class 1A limit.

Additionally interesting is to observe the effect of yaw misalignment on the loads of T17. For wind directions around 290 deg, T17 is a leading turbine and operates at large yaw misalignment of up to 30–35 deg. As discussed above, this situation could result in an increased loading at T17, which is indeed conformed by the left-hand side plots in

Figure 8 (observe the small deviations of the loads for wake redirection (CW) from the reference loads at these directions). However, the load increase there is obviously orders of magnitude lower than those induced by wake effects.

The right-hand side plots in

Figure 8 depict the normalized loads versus the wind velocity, averaged over all wind directions (distribution included). The following observations can be made. Firstly, the fatigue loads for wake redirection are lower than in the reference case for all below-rated wind speeds. Secondly, above rated loads are the same because wake redirection is only applied at below rated wind speeds. Finally, the Class 1A load levels are much higher than the site-specific loads, as already mentioned, which suggest a decent margin in the loading.

7. Conclusions

This paper presents a detailed study on the impacts from wake redirection control on the fatigue loads within a real-life offshore wind farm. To this end, farm simulations have been performed using the FarmFlow wake model for the complete spectrum of ambient wind conditions at the site. The computed inflow conditions in front of each turbine are then used to interpolate the corresponding fatigue loads from a loads database, containing fatigue loads and statistics at critical locations (including blades, shaft and tower). The database has been constructed using a large number of simulations with the aeroelastic turbine model Focus/Phatas. These simulations are done for a wide range of representative operational and environmental conditions, including different combinations of wind speeds, turbulence intensities, wake locations, wake deficit width, wake deficit depth, yaw misalignments and pitch angle offsets.

The obtained results confirm the earlier findings in the literature that yaw misalignment, by itself, could increase or decrease the fatigue loading on a wind turbine by up to a few tens of percentage points. This is due to wind shear. Furthermore, it is argued that wake induced loads significantly outweigh the loads incurred due to misalignment. The main reason for that is considered to be the higher turbulence levels in the wake. As a result of that, the load reduction achieved at a given downstream turbine, due to the wake in front of it having been moved aside by wake redirection control, is more pronounced than the loads impact due to misaligning the rotor of that turbine. As a result of that, it is shown that when the loads on a given turbine in the farm are combined for all wind speeds and directions, the resulting lifetime fatigue loads tend to decrease under wake redirection control by yaw misalignment.