1. Introduction

Up-to-date Liquefied Natural Gas (LNG) plants are highly electrified and based on high power electrical motors supplied by Variable Frequency Drives (VFDs). The interaction among the VFDs and the Turbine-Generator (TG) units may cause torsional vibrations known as Sub-Synchronous Torsional Interactions (SSTIs) [

1,

2,

3]. Over the last years some SSTI phenomena have been experienced on site in the LNG plants by the authors. One of the most significant occurred during the commissioning phase and the event is used as a case study for the present paper.

When SSTI phenomena occur, the torsional vibrations measured on the TG shaft-line generate electric disturbances such as voltage fluctuations in the power system. The voltage fluctuations in input to the VFDs imply current fluctuations at the VFD DC link and at the VFD output. Finally, high torsional vibrations can lead to torsional instability.

In the literature the first studies focused on the torsional instability risk assessment are related to the Sub Synchronous Resonance (SSR) phenomenon [

4,

5,

6,

7]. In [

4], the generator damping, measured at no load condition, is used as an index value to define the risk. In [

5] the compensation impact factor is used to detect SSR risks in the case of series compensated transmission lines. In [

6] the impact of the transmission expansion on the system damping is evaluated using the frequency-scan approach. In [

7] the SSR risk is detected comparing the electrical damping with the modal damping.

The most used risk assessment technique is based on the Unit Interaction Factor (UIF) calculation, originally introduced for HVDC applications [

8]. For oil and gas applications, the method implies high variations of the threshold value adopted to evaluate the risk, for this reason the UIF technique is not always feasible.

In this paper, the risk assessment for an LNG plant is based on the electrical damping evaluation. The torsional instability risk can be considered high when the electrical damping at the Torsional Natural Frequencies (TNFs) is negative. Hence the risk assessment relies on the electrical damping assessment.

In [

1] a connection between the power electronics analysis and the power systems analysis is established and a complete model of a LNG plant is provided combining the dynamic model of the power conversion stage and the TG electromechanical model. The sole theoretical model allows electrical damping assessment in the case of a basic LNG plant configuration with one TG unit and one VFD. However the analysis provided in [

1] lacks a deep investigation about the impact of the synchronization system design on the electrical damping estimation. In the same model the design of the TG controller is not considered.

Some previous studies such as [

9,

10] have shown that the synchronization system parameters affect the power system stability in the case of weak grids. Besides the impact of the Power System Stabilizer (PSS) on the SSR damping has been previously demonstrated in [

11,

12,

13,

14]. Aware of these considerations and starting from the combined electromechanical model developed in [

1], the same authors present in this paper a more accurate model providing the electrical damping assessment. Differently from the model presented in [

1], both the control systems of the VFD and of the TG unit are included in the overall model. It allows one to detect which control parameters have more impact on the generator units’ electrical damping. Moreover a classical tool such as the sensitivity analysis [

15,

16,

17] is adopted for this purpose. In particular the Finite Difference Method (FDM) [

18] is employed to achieve a local sensitivity study. The overall advanced model is the first original contribution of the paper compared to [

1].

Nevertheless, it has to pointed out that in the case of complex LNG plant configurations, with numerous TG units and several VFDs, the calculation of the electrical damping by the theoretical model can exhibit some practical limitations. Starting from this consideration, a complete simulation platform, which emulates the theoretical model, is developed and the results are shown in the paper. The complete simulation platform allows one to analyze also the complex LNG plant configurations and to extend the results of this study to different plants. The flexibility relies in the possibility to adapt the software to different power ranges and a different kind of loads, including also changes of the operational TG units’ number in real time. Finally, an extensive test campaign has been carried out on a real LNG plant in order to take into account also commissioning and potential grid contingencies. These products represent innovative contributions compared to [

1].

In conclusion, the theoretical outcomes are confirmed by the simulation and experimental results. The electrical damping assessment allows one to determine the risk of the LNG plant considering different configurations. It is also demonstrated that the proper tuning of the control parameters can modify the electrical damping and, as a consequence, can influence the LNG plant level of risk.

The rest of the paper is organized as follows: in

Section 2 the LNG plant configuration is presented; in

Section 3 and in

Section 4 there are proposed, respectively, the detailed TG unit and VFD models and a preliminary sensitivity analysis is performed;

Section 5 treats the LNG plant simulation platform; in

Section 6 the simulation and experimental results are shown; in

Section 7 a brief discussion about the future insights and possible applications is presented; finally

Section 8 is focused on final remarks.

2. LNG Plant Configuration

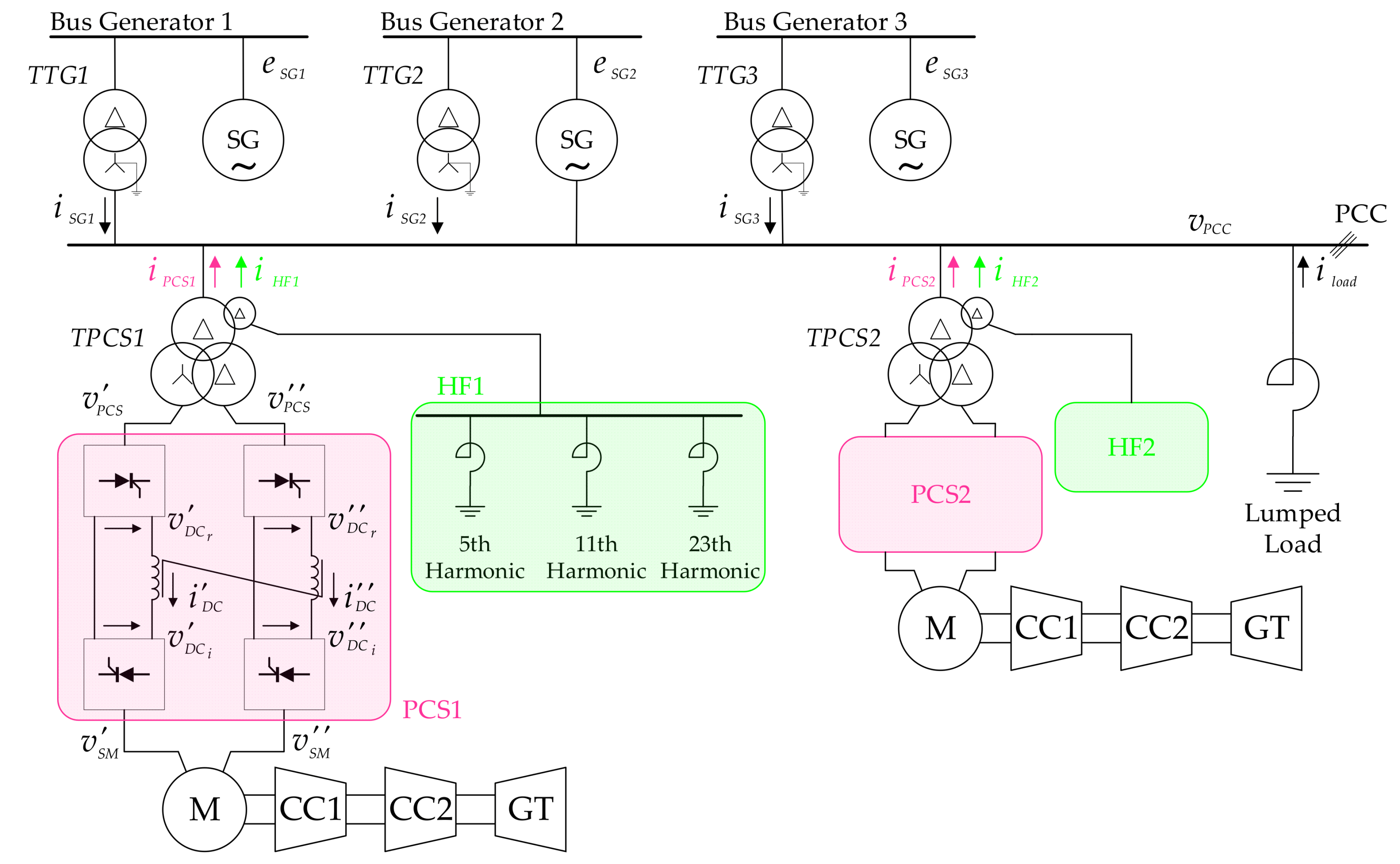

The LNG plant under analysis is shown in

Figure 1. The considered power system is composed of three identical Gas Turbines (GTs) connected to three identical Synchronous Generators (SGs). For the sake of simplicity,

Figure 1 represents only the SGs while the complete TG unit is depicted in

Figure 2. The SGs are connected to the Point of Common Coupling (PCC) through three step-up transformers, denoted as TTG1, TTG2 and TTG3. Two compression trains operate the natural gas liquefaction. Each compression train is composed of two centrifugal compressors (CC1 and CC2), a GT (the prime mover) and a synchronous Motor (M). M acts as starter and helper motor, which allows one to start-up the entire train and provides additional power when required. The motors are supplied by two power conversion stages denoted as PCS1 and PCS2. The power conversion stages are two Thyristor Variable frequency Drives (TVFDs). Each TVFD is connected to the PCC through a step-down transformer with two secondary windings. The two step-down transformers are indicated with TPCS1 and TPCS2 and adapt the voltage level in order to supply the TVFDs. Each TVFD consists of two Line-Commutated-Converters (LCCs). Each LCC is a double-stage converter since the first stage is a line-commutated-rectifier (LCR), while the second stage is a Line-Commutated-Inverter (LCI). The fundamental frequency of the LCRs is the grid frequency

fn. The LCIs supply the synchronous motor M, hence the LCIs fundamental frequency is the motor frequency denoted as

fm. Each TVFD is based on 6-pulse H-Bridges.

A Harmonic Filter (HF) is connected at the PCC. The HF consists of resonant circuits connected in parallel. The circuits are designed to cut harmonics at 5 fn, 11 fn and 23 fn.

In order to simplify the analysis, the overall loads connected to the power system are taken into account through a lumped load.

As in [

1] the TG unit and the TVFD can be described by the following equations:

where

is the vector of the current perturbations,

is the vector of the voltage perturbations,

is the state-space vector and the matrixes

Ai,

Bi,

Ci and

Di are referred to a generic state-space representation.

Combining the state-space models of the TG and of the TVFD it is possible to obtain the overall model and to estimate the damping associated to each TG. Focusing on the LNG plant shown in

Figure 1, the overall damping

ξ(

fi) related to each TG unit is the sum of the electrical damping

ξe(

fi) and of the shaft-line inherent mechanical damping

ξm(

fi) [

19].

The mechanical damping is mainly determined by the lube oil bearing actions. For the torsional vibrations, it presents an estimated parameter whose value is normally low. The electrical damping is influenced by all the devices included in the electromechanical system (TG units, power conversion stages, HFs and lumped load) as described in [

1,

19].

The electrical damping assessment provides information about the torsional instability risk level of an LNG plant. Hence, in this paper, the value of ξe(fi) is chosen as the torsional instability risk index. In particular, if the electrical damping has negative value, high risk can be associated to the LNG plant configuration.

3. TG Units Complete Model

Considering the LNG plant shown in

Figure 1, each TG unit includes several inertial masses coupled together via steel shaft sections, special couplings and gears, as discussed in [

20]. In [

1] a three Degrees of Freedom (DOFs) model is adopted for the TG unit. The first DOF represents the whole gas turbine whose inertia moment is denoted as

J1, the second DOF represents the gearbox whose inertia moment is denoted as

J2 and the third DOF represents the SG whose inertia moment is denoted as

J3. The overall model is characterized by two stiffness coefficients

D1 and

D2 as shown in

Figure 2. In the LNG industry empirical damping assessment is commonly accepted [

3]. In the present analysis the mechanical damping for each TG is assumed to be null.

The SG model is developed in a d–q reference frame rotating at the grid pulsation

ωn as described in [

21]. The SG field voltage is assumed constant and the air-gap torque is calculated as function of currents and fluxes. For each TG unit the electromechanical model can be described by [

1]:

where Δ

TGT indicates the gas turbine driving torque; Δ

TAGT indicates the SG air-gap torque;

is the vector of the voltage perturbations and

is the vector of the current perturbations. All the coefficients in Equation (3) are derived in

Appendix A.

The state-space vector

is defined as:

where

δ1,

δ2 and

δ3 denote the DOFs angular positions and

ψfd,,

ψkd and

ψkq are the rotor fluxes.

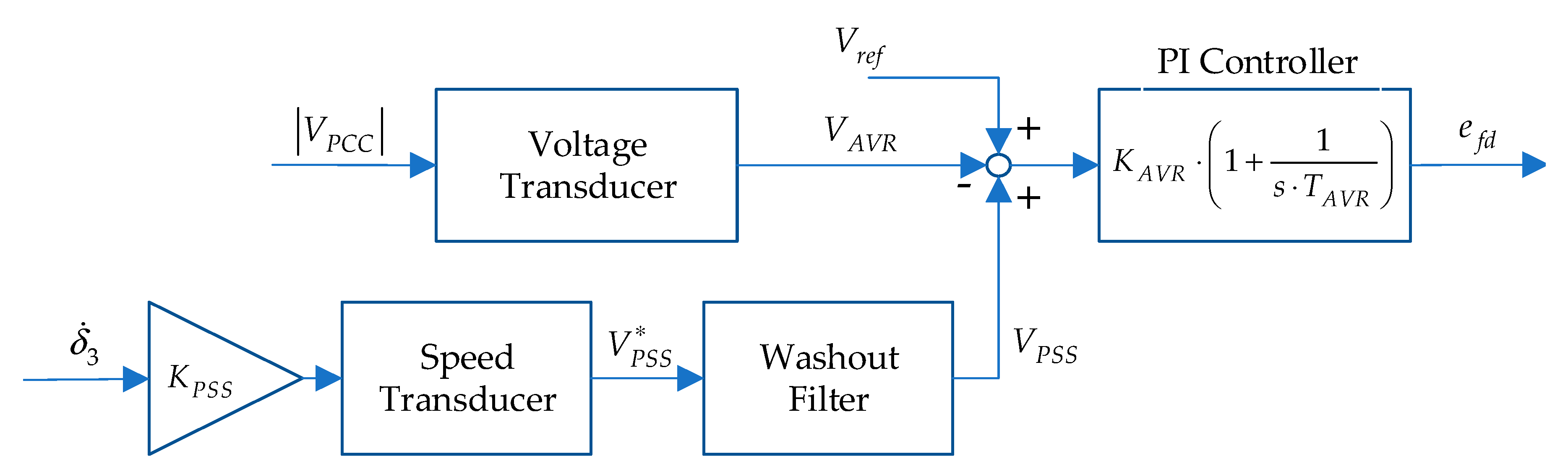

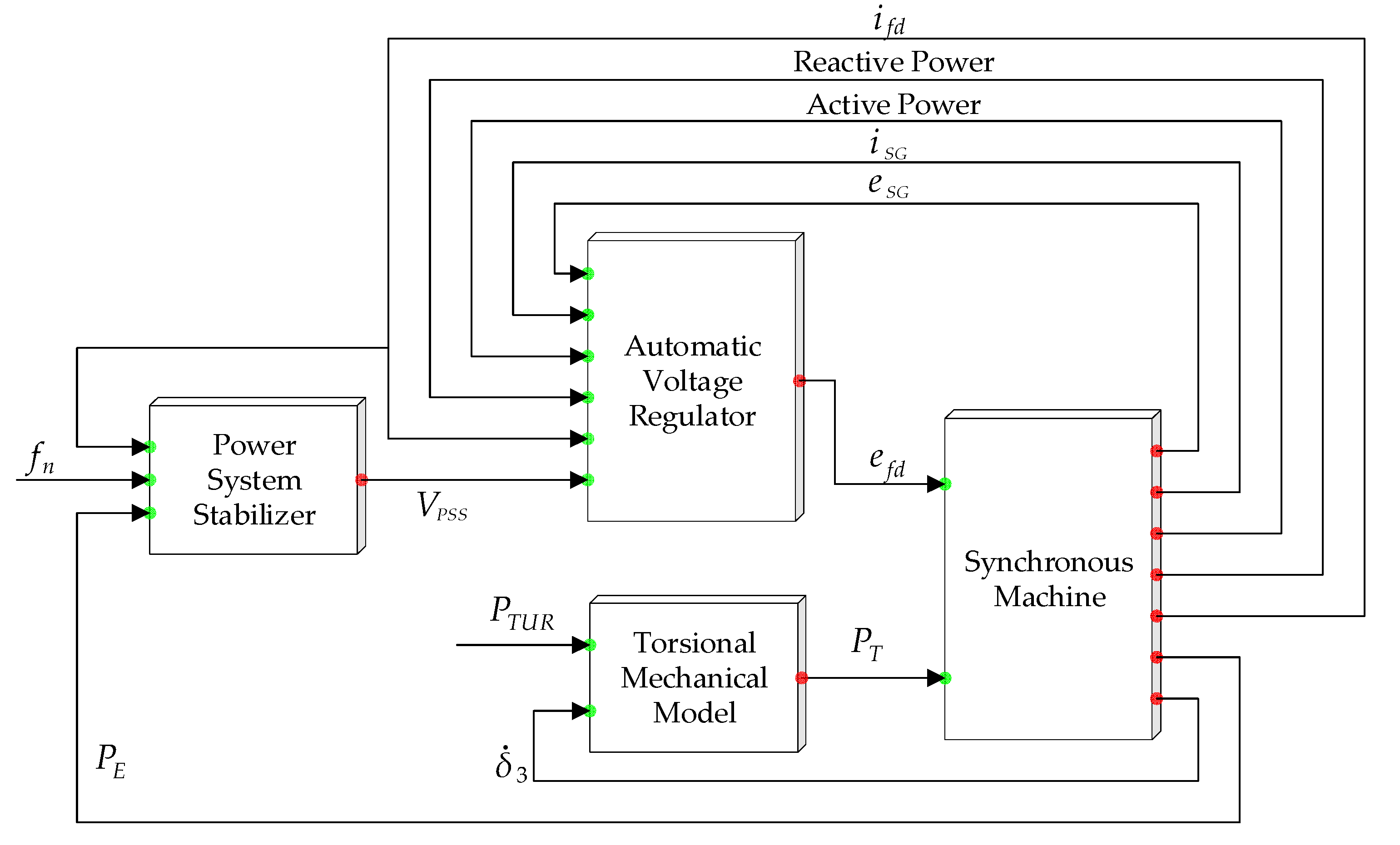

The model described by Equations (3) and (4) can be modified including the TG unit control loop. The SG excitation circuit is controlled by an Automatic Voltage Regulator (AVR) and a PSS in compliance with [

22]. The transfer functions of the AVR and the PSS controllers are shown in

Figure 3. The AVR regulates the SG field voltage

efd with a PI controller whose proportional gain and time constant are denoted respectively as

KAVR and

TAVR. Usually, the AVR gain

KAVR has high value in order to provide the required air-gap torque when the rotational speed of the rotor

ωR deviates from the synchronous value. At very low frequencies (0–2 Hz), the action of the AVR could introduce undamped oscillations, hence the PSS action allows to avoid this instability source. The proportional gain of the PSS is denoted as

KPSS.

denotes the signal provided in output by the voltage transducer.

denotes the signal provided in output by the speed transducer. Differently

denotes the output signal generated by the PSS.

Using the small-signal analysis, the grid voltage magnitude variation

can be expressed as:

where

and

are the direct and quadrature component of the grid voltage vector;

,

and

are respectively the steady-state value of the grid voltage magnitude and the steady-state value of the direct and quadrature components.

The derivatives of the voltage signals related to the TG controllers can be calculated as:

where

T1PSS and

T2PSS are, respectively, the time constant of the speed transducer and the time constant of the washout filter; the gain and the time constant of the voltage transducer are indicated as

KR and

TR. The AVR and PSS control actions provide in output the signal

calculated as:

As a consequence the system defined in Equation (4) can be rearranged as:

with

The state-space vector and the matrixes, which compose Equation (10), can be expressed as:

Independently of the causes, in the presence of SSTI phenomena the generator shaft is led to vibrate. The overall damping of the TG unit coincides with the electrical damping since, as previously declared, the shaft-line inherent mechanical damping is assumed to be null. The TG electrical damping evaluation is based on the matrix ÂTG eigenvalues calculation. Besides the torsional natural frequencies of the shaft-line can be identified. In particular, Equation (10) allows one to detect two modes of torsional vibration for each TG with TNFs equal to 9.2 and 31.5 Hz.

The TG units rated electrical and torsional mechanical parameters are reported respectively in

Table 1 and

Table 2.

The sensitivity analysis can be applied to detect the TG control parameters, which impact the torsional stability of the electromechanical system. The Finite Difference Method (FDM) [

18] can be adopted to provide the sensitivity analysis of the system shown in

Figure 2. FDM implies simple implementation and computational burden proportional to the number of design variables.

Considering the objective function F(P) as a function of a design variable P, its sensitivity coefficient can be approximated from the exact displacement between the initial point P0 and the perturbated point P0 + ΔP, where ΔP is the perturbation of the design variable.

Accuracy can be improved using the central-difference approximation and the sensitivity coefficient

dF/dP can be defined as:

As discussed in [

23] the FDM approximation can lead to an accuracy error, which can be reduced by a proper choice of the perturbation Δ

P. In order to reduce the error source, the perturbation Δ

P can be assumed high, in particular 50% of the considered design variable.

Considering the data shown in

Table 1 and

Table 2, the sensitivity analysis can be applied to the state-space electromechanical model of the TG units. The analysis is performed assuming rated conditions of the TG unit and starting from the controller parameters provided by the Original Equipment Manufacturers (OEMs) and reported in

Table 3.

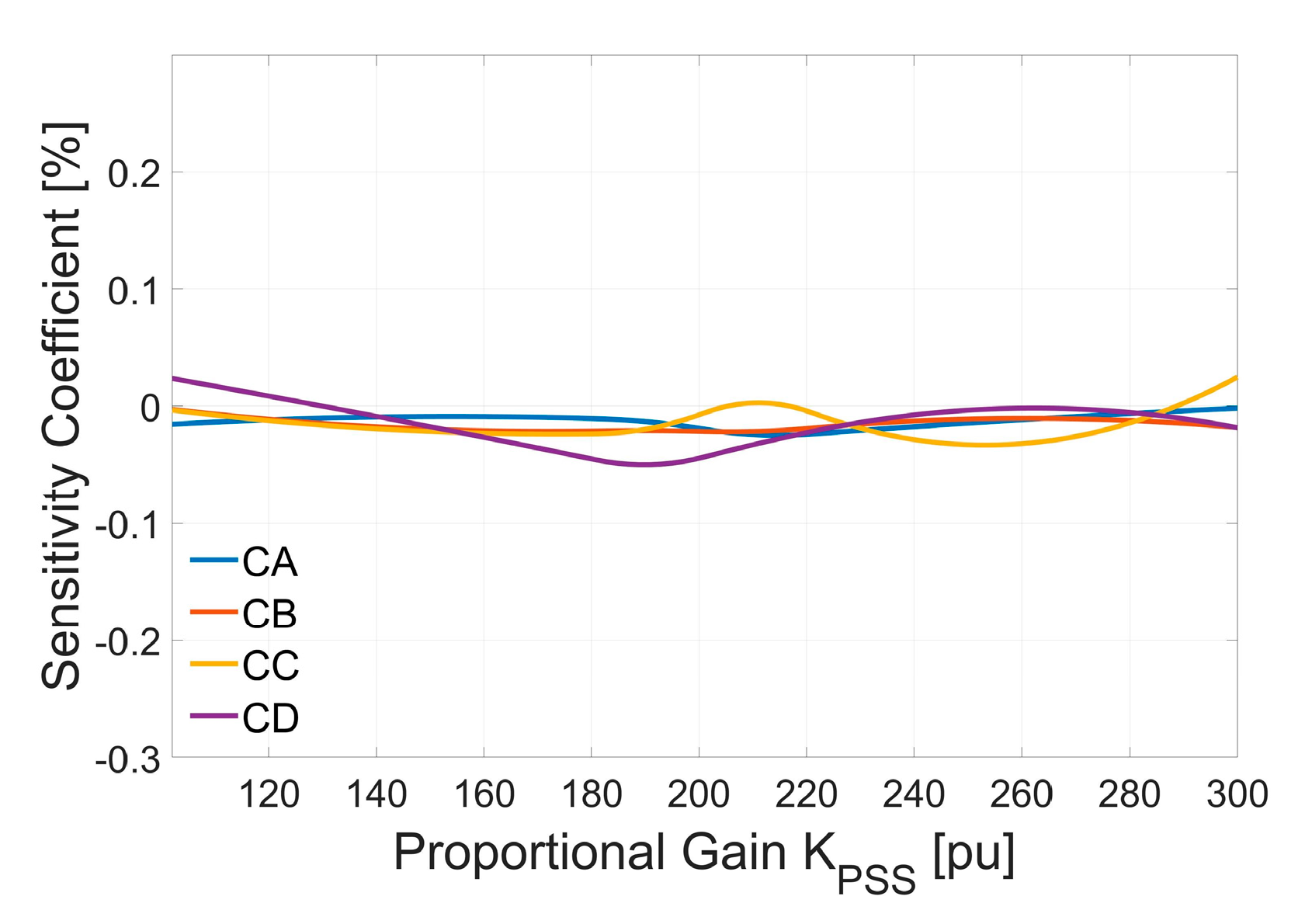

On the basis of Equation (17) the FDM analysis can be carried out regarding various frequencies. The sensitivity coefficients for the phase and the magnitude of the output current perturbations can be determined considering the action of the AVR and the PSS controllers. The magnitude sensitivity coefficients provide percent information about magnitude variation due to the controller’s parameters variation in respect of the steady-state conditions. The phase sensitivity coefficients provide information about phase variation expressed in degrees.

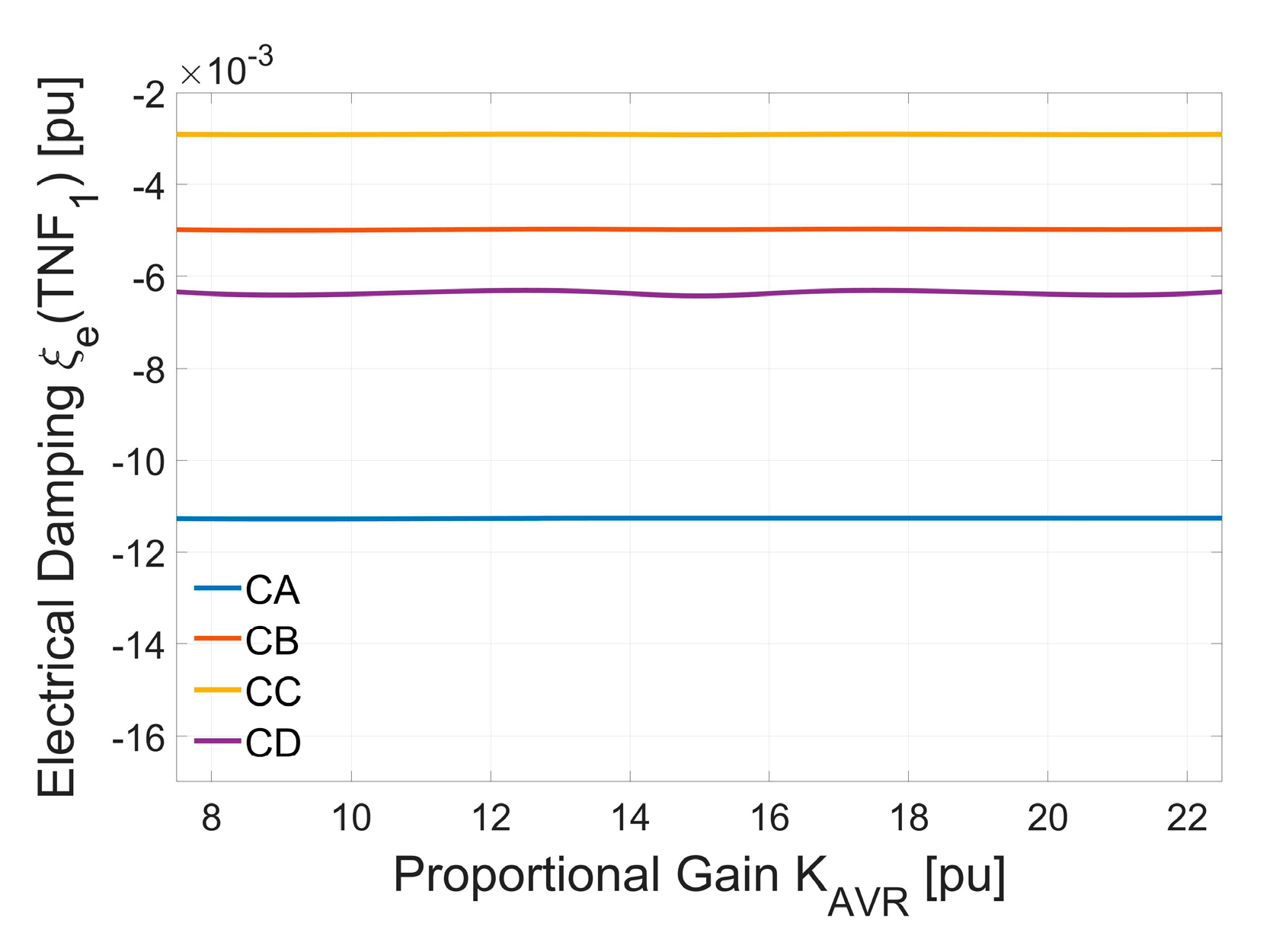

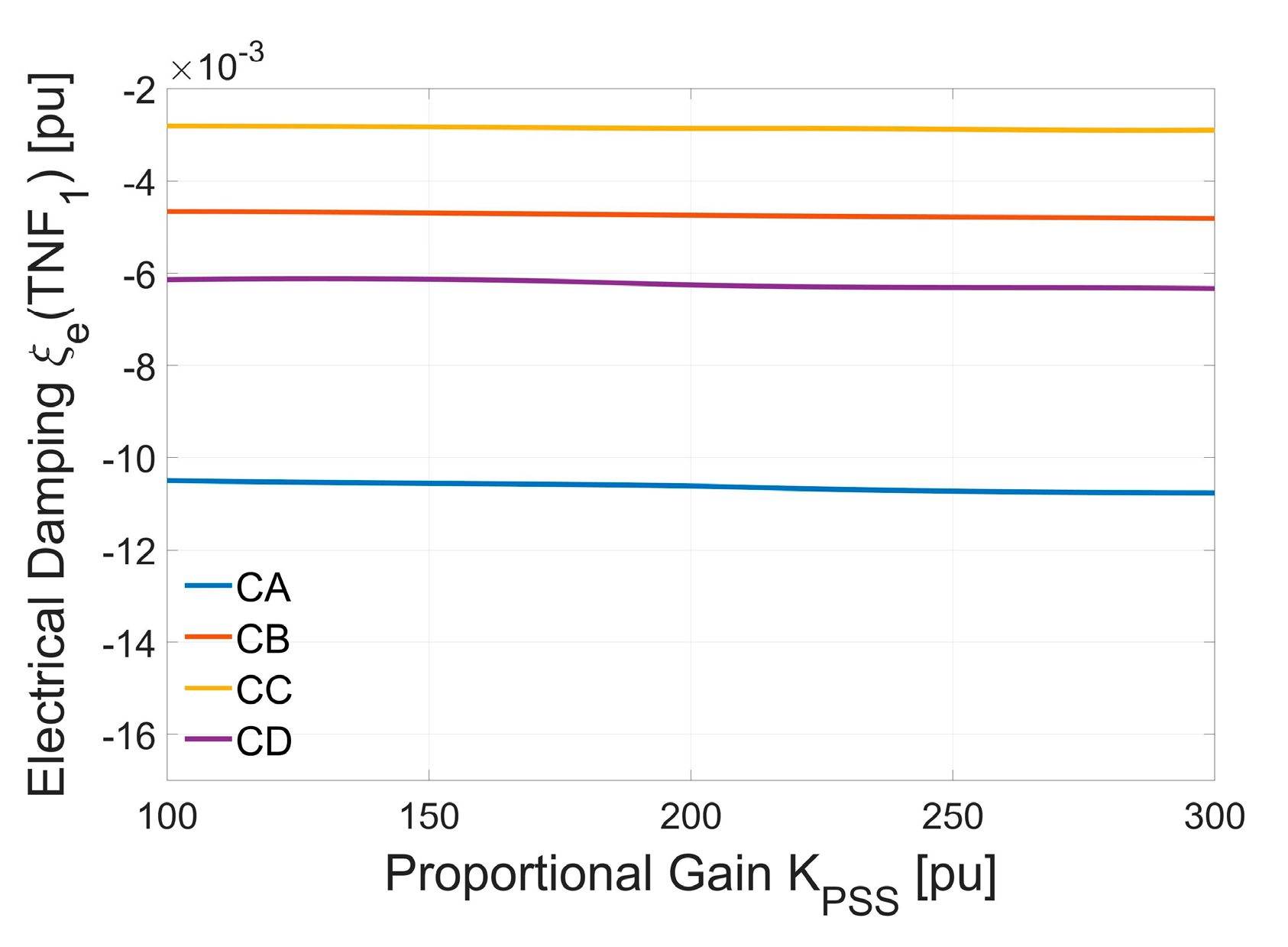

The sensitivity coefficients related to the AVR and PSS control parameters were calculated and the results point out that the AVR and PSS proportional gains (

KAVR and

KPSS) had more impact than the other design parameters (

TAVR,

T1PSS and

T2PSS). Nevertheless, also the sensitivity coefficients related to the AVR and PSS proportional gains variations were very low as shown in

Table 4. Considering the frequency range 5–50 Hz, the torsional stability seemed not influenced by the AVR and the PSS proportional gains variations since the phase of

did not vary with

KAVR or

KPSS and the magnitude of

was subjected to low value changes. Considering, for example, the data at 10 Hz, the increase of 50% of

KAVR or

KPSS led the current

to increase its magnitude about 10 percent or to decrease about 1 percent, respectively.

4. TVFD Complete Model

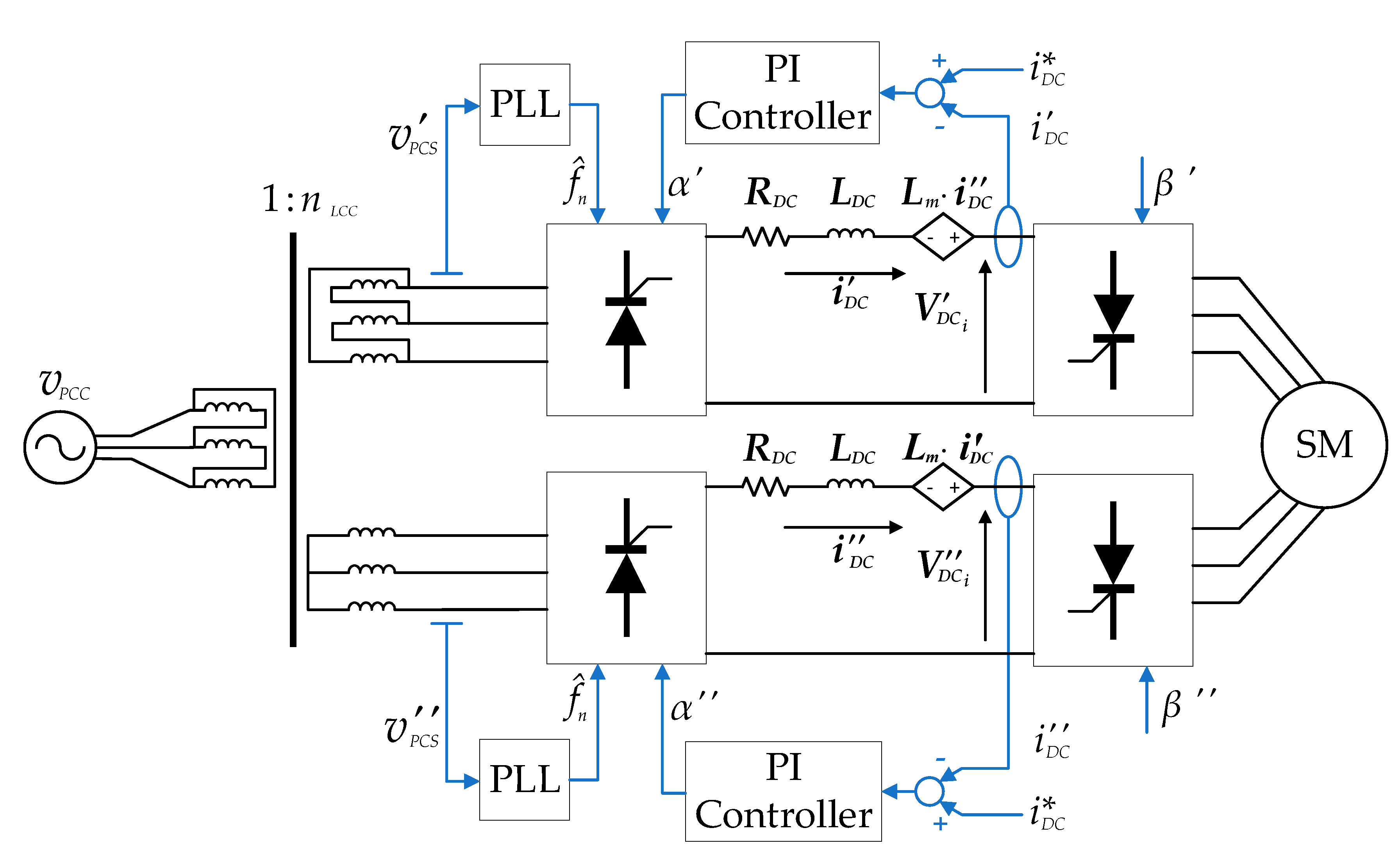

The detailed structure of the PCSs shown in

Figure 1 is represented in

Figure 4. Each TVFD consists of two branches whose DC-links are coupled by the mutual inductance

Lm. The control scheme of the TVFD first stage is depicted in the same figure where

and

denote the DC-links output voltages. The DC link currents are controlled by means of two PI controllers, which set the firing angles α′ and α″. Differently the TVFD second stage operates with constant firing angles denoted as

β′ and

β″. Two Phase Locked Loops (PLLs) provide synchronization with the voltages

and

and estimate the grid frequency

.

In [

1] the state-space model of the TVFD first power conversion stage has been presented and based on small-signal linearization. The operation of the power conversion stage can be defined by the following equation.

where the inputs are the PCC voltage fluctuations

, the variations of the DC-links voltages

and the variations of the firing angles

related to the two LCRs;

is the vector of the current perturbations and

is the vector of DC currents variations.

The coefficients of Equation (18) are defined as:

where Δ

T denotes the TVFD commutation period;

X5 is the state-space vector when the commutation process is assumed completed,

t0 denotes the initial time instant of the first commutation stage;

t1 denotes the end of the commutation period;

P(θ) is the Park transformation matrix and

θ is the Park angle. Further details can be found in [

1].

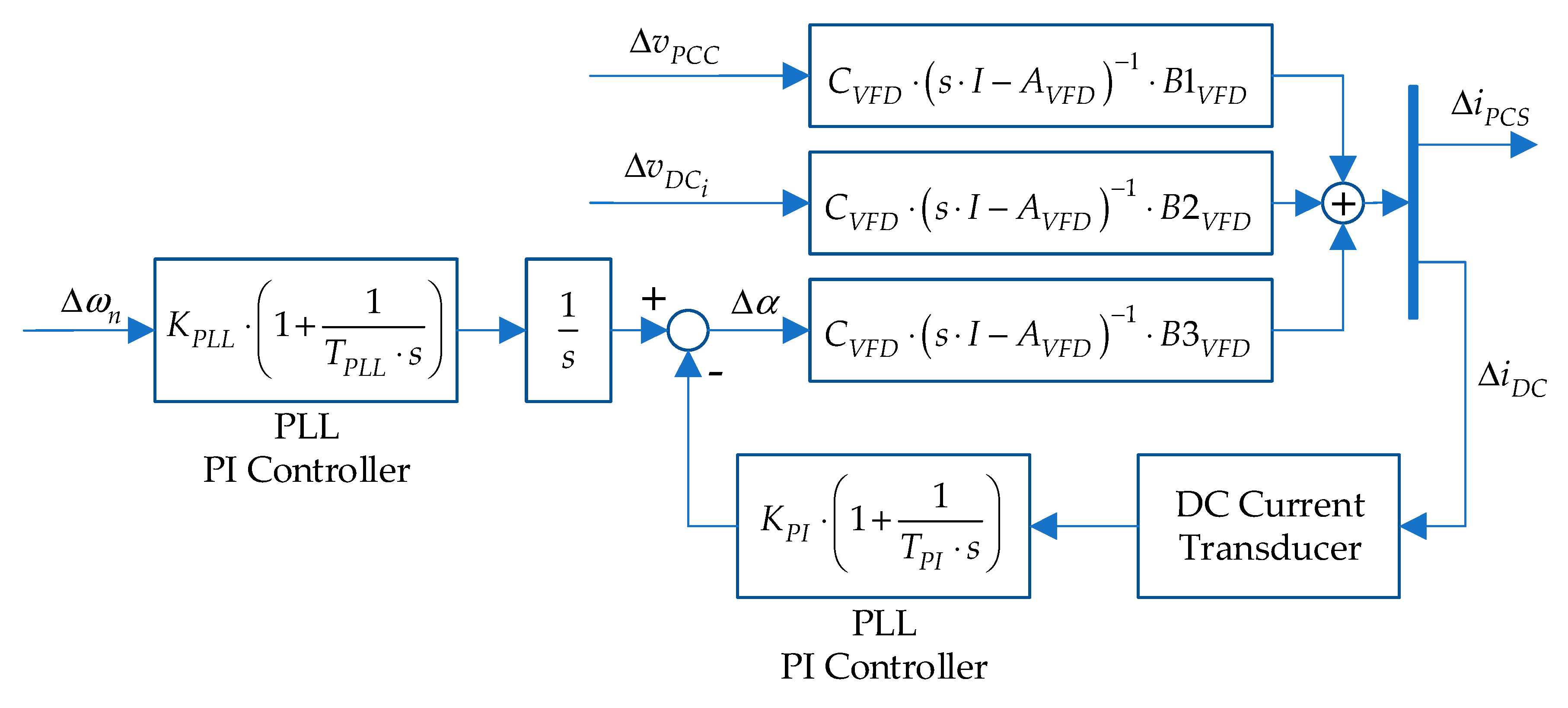

Since the SSTI phenomena are strongly influenced by the TVFD controller parameters [

2], a more detailed TVFD model can be developed where the current controllers and the PLLs dynamics can be included. The detailed control scheme of the TVFD and the PLL structure are shown respectively in

Figure 5 and

Figure 6 where

KPI and

TPI denote the proportional gain and the time constant of the DC current controllers while

KPLL and

TPLL denote the proportional gain and the time constant of the PLL PI.

The closed-loop state-space model is described by the following equations system:

where the state-space vector Δ

XPCS includes the vector of DC currents, the dynamics of the PLLs and the dynamics of the PI current controllers.

The inputs of the state-space (24) are the PCC voltage fluctuations , the DC-links voltages variations and the variations of grid pulsation .

The PCSs rated parameters and the control parameters provided by the OEMs are reported respectively in

Table 5 and

Table 6.

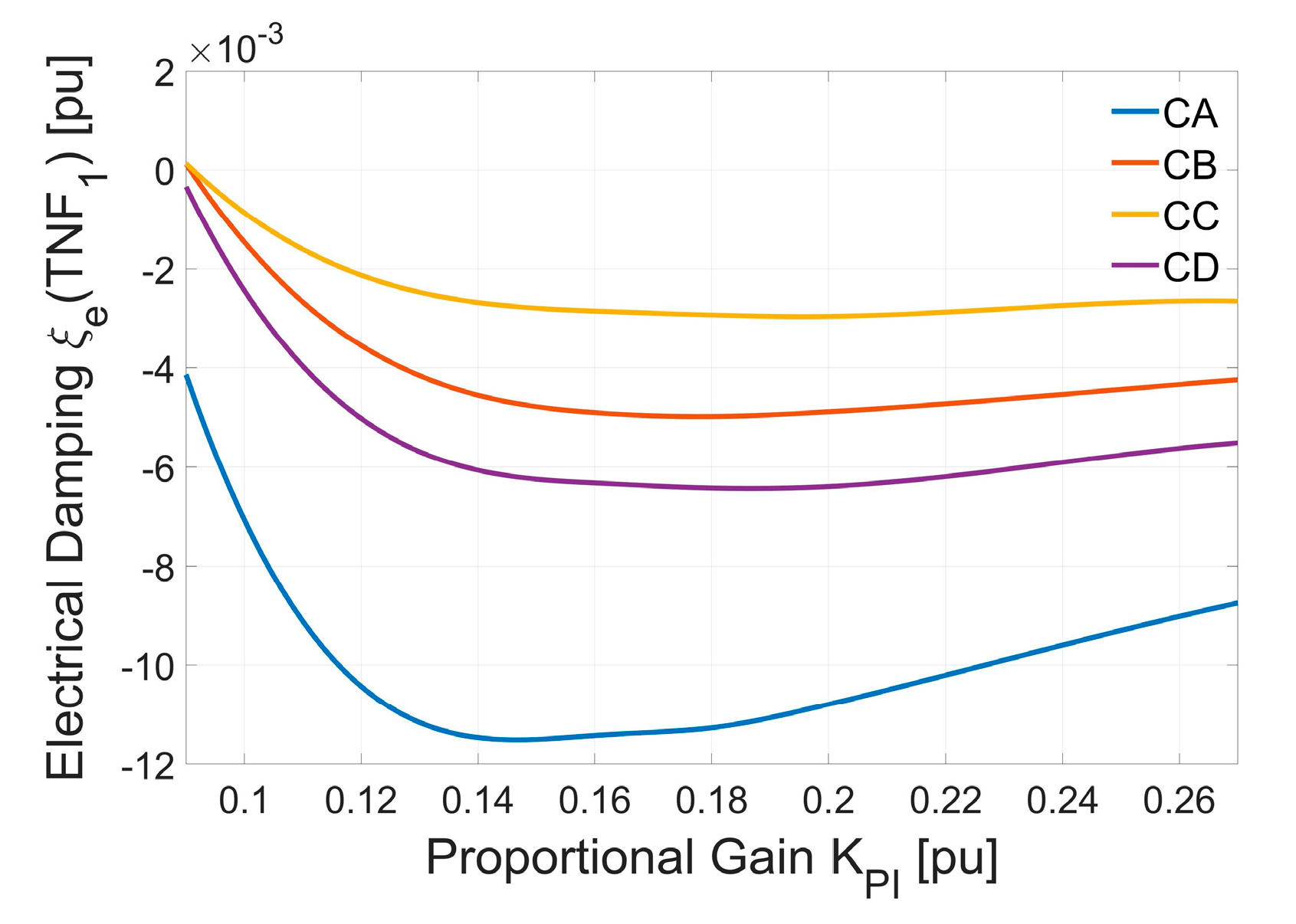

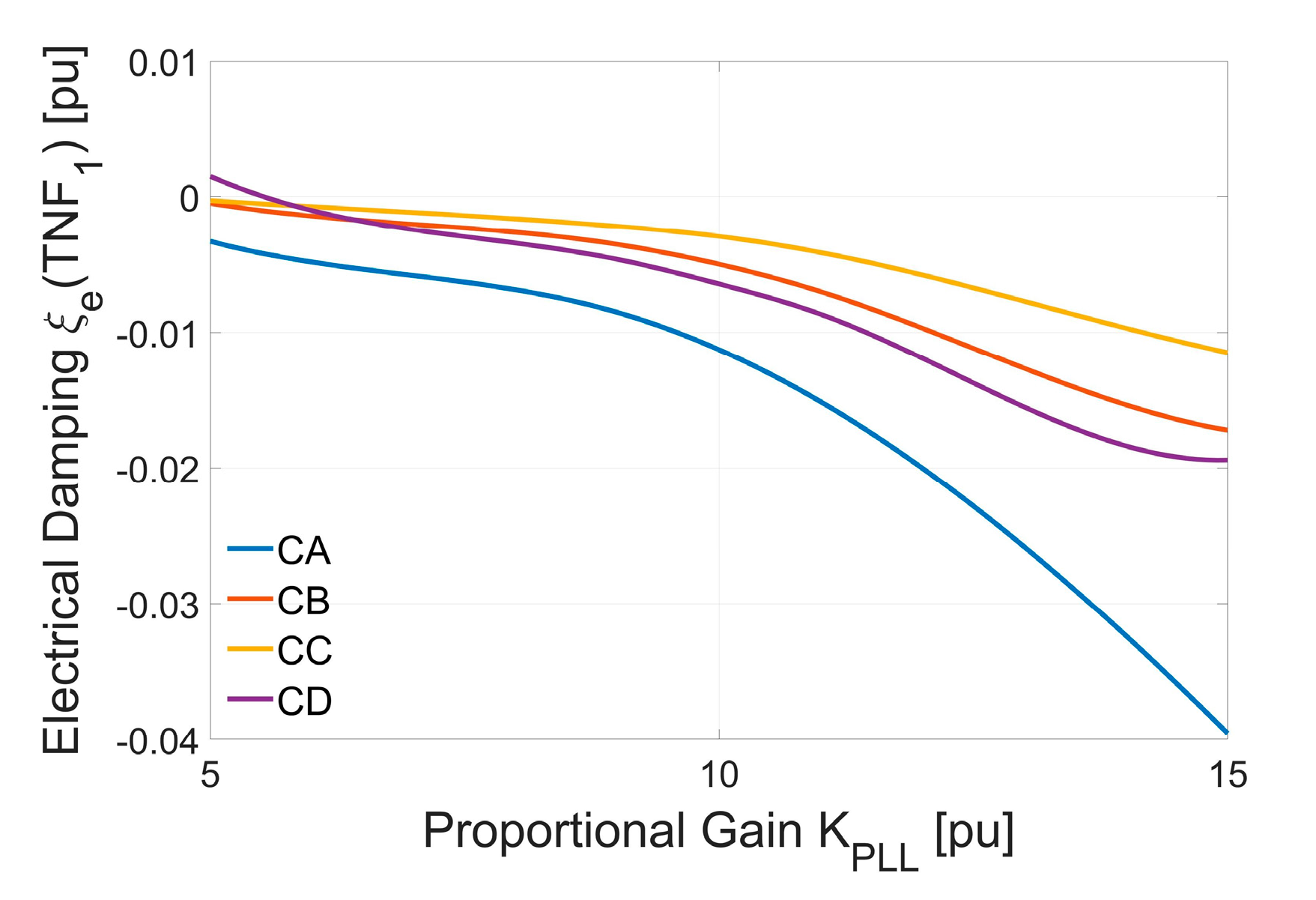

The FDM analysis can be applied to the model described by Equation (24) in order to assess the control parameters that influence the stability of the overall power system. On the basis of Equation (17) the FDM analysis is carried out regarding various frequencies. The sensitivity coefficients for the phase and the magnitude of the output current perturbations can be determined considering the action of the PI current controllers and of the PLLs. The parameters KPI and KPLL are detected as elements with high sensitivity coefficients.

The magnitude sensitivity coefficients provide percent information about magnitude variation due to the controller’s parameters variation in respect to the steady-state conditions. The phase sensitivity coefficients provide information about phase variation expressed in degrees.

The data reported in

Table 7 point out that the sensitivity coefficients decrease when the frequency increases. At high frequencies the variations of

KPI and

KPLL are not able to influence the magnitude or the phase of

. At frequencies close to the TG first TNF (9.2 Hz) the sensitivity coefficients are indicative. Differently from the results reported in

Table 4, the phase coefficients are significant about the TVFD controller’s parameters. Considering, for example, the data at 10 Hz, a 50% variation of

KPI or

KPLL leads to a phase shift of the current perturbations

equal to 20 degree or 10 degree, respectively.

5. LNG Plant Simulation Platform

The theoretical model described in

Section 3 and

Section 4 allows one to obtain electrical damping assessment and stability considerations in case of a basic LNG plant, which consists of a TG unit and a TVFD. In order to manage complex plant configurations, a complete simulation platform has been developed using the software DigSILENT PowerFactory, which allows one to provide detailed simulation results in the time domain. The overall power system shown in

Figure 1 has been emulated. In

Figure 7 there is represented the scheme of the TG unit integrated model used for the implementation in DigSILENT environment while the TVFD implementation is based on

Figure 4.

The TG unit was emulated considering the torsional mechanical model and the control system discussed in

Section 3. The SG was modeled through a classic d–q representation provided by the Power Factory software. In

Figure 7 the powers related to the TG shaft torque, the air-gap-torque and the driving torque of the TG were indicated respectively with

PT,

PE and

PTUR.

The PCSs and their control system were implemented on the basis of the model discussed in

Section 4. The motor M of each compression train was represented as an ideal voltage source connected to the subsynchronous reactance

LM and the stator resistance

RM.

The TVFDs models and the TG units models were connected in order to obtain a combined electromechanical model. The action of the filter HF was taken into account since it modifies the operative condition of the TG units, changing the amount of active and reactive power supplied by the SGs. The MV transformers were modeled on the basis of their short circuit voltages and the Joule losses. The step-up transformers related to the TG units (

TTG1,

TTG2 and

TTG3) were assumed identical such as the step-down transformers related to the TVFDs (

TPCS1 and

TPCS2). The transformers parameters are reported in

Table 8.

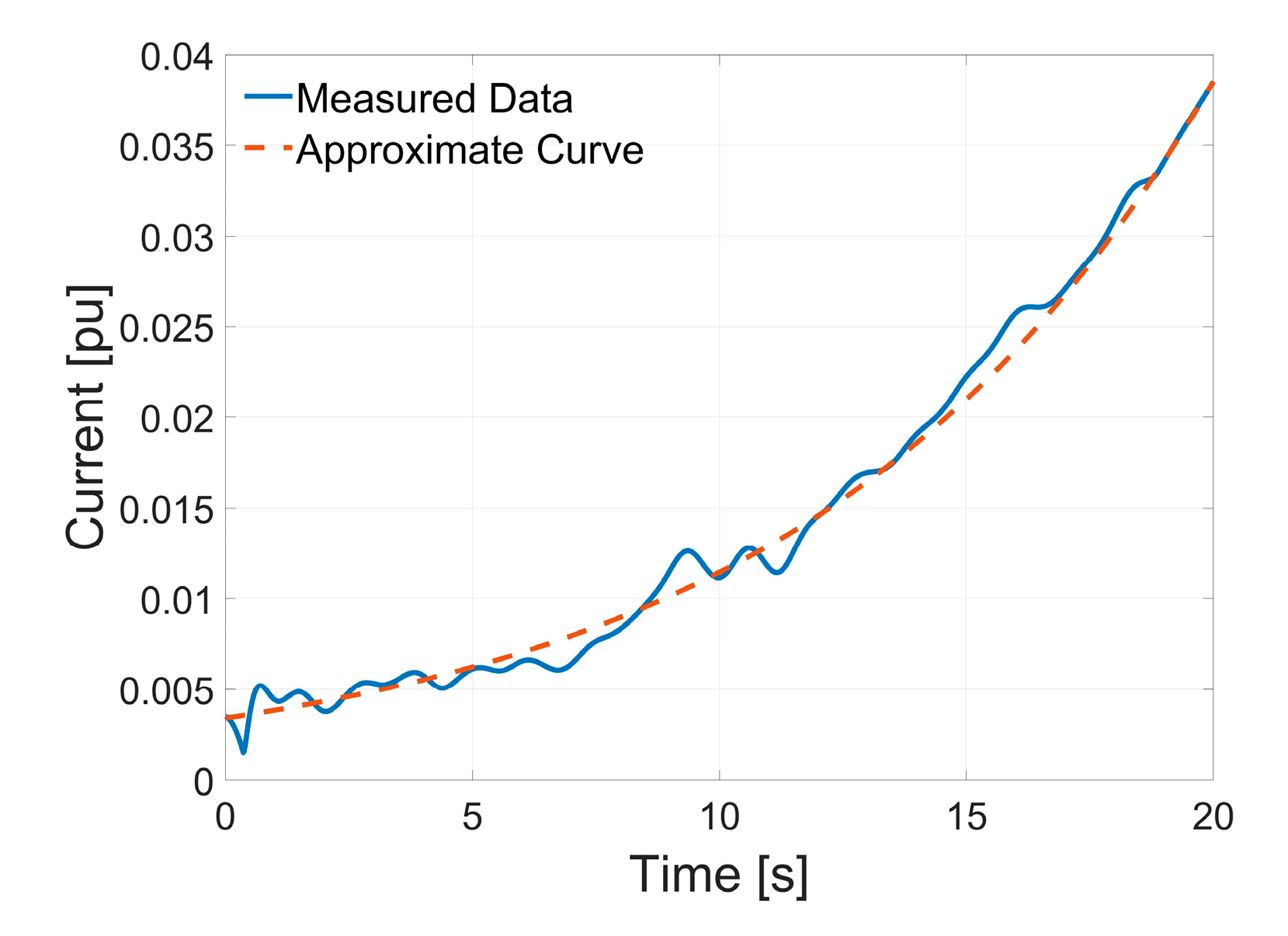

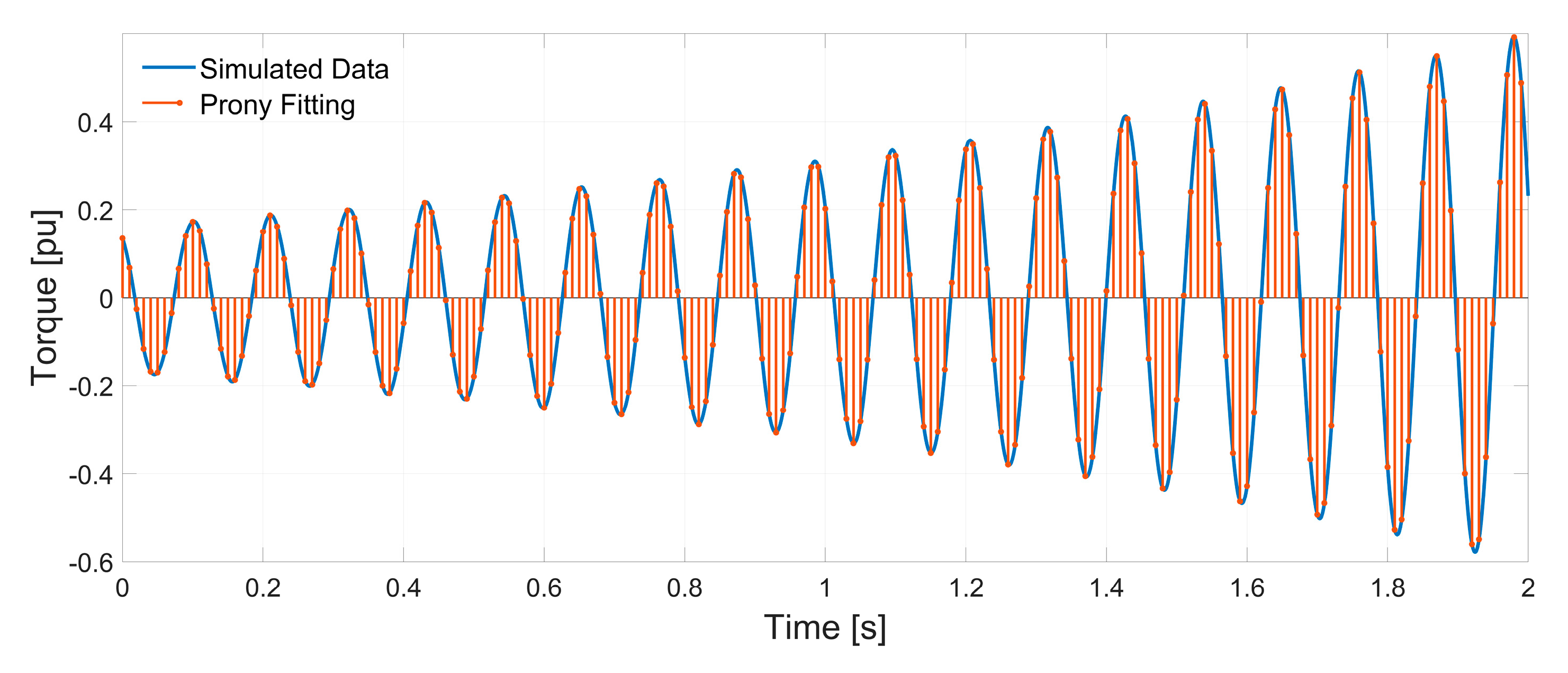

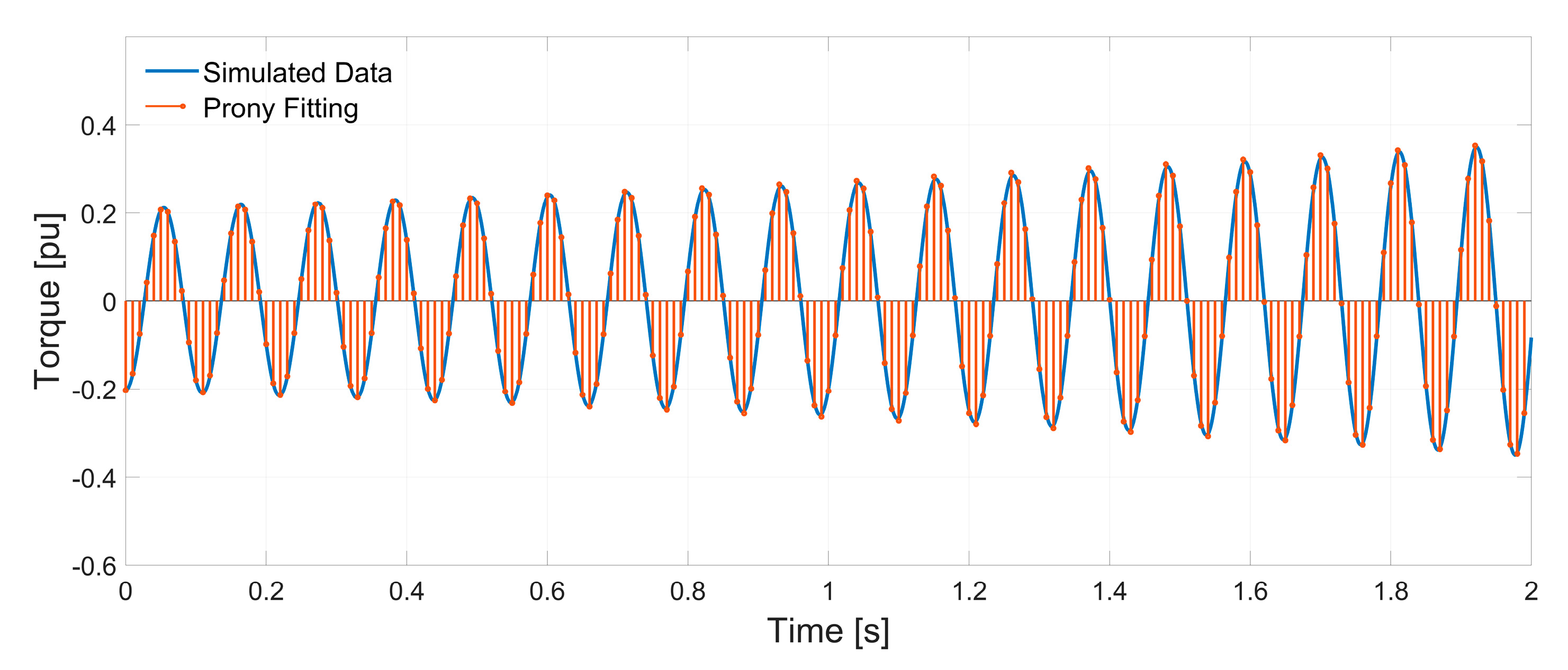

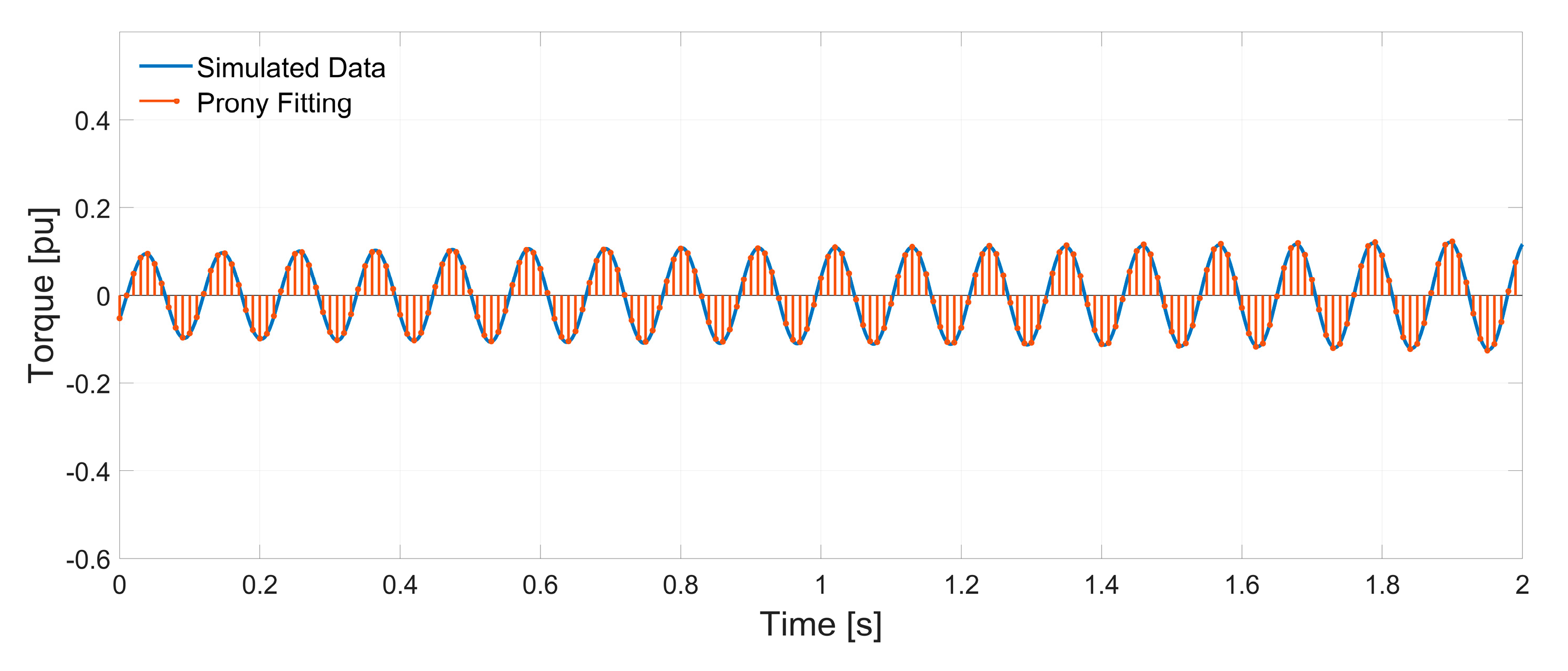

The TG shaft-line torque signals provided by the simulation platform are typically affected by time varying components in transient conditions. For this reason the torque signals can be post-processed through the Prony analysis as already discussed in [

1]. In particular, the Prony analysis allows one to identify growing or decaying components of a generic signal

f(t) on the basis of the following equation:

where

Kg is the magnitude,

ξg is the damping factor,

ωg is the pulsation and

g is an integer.

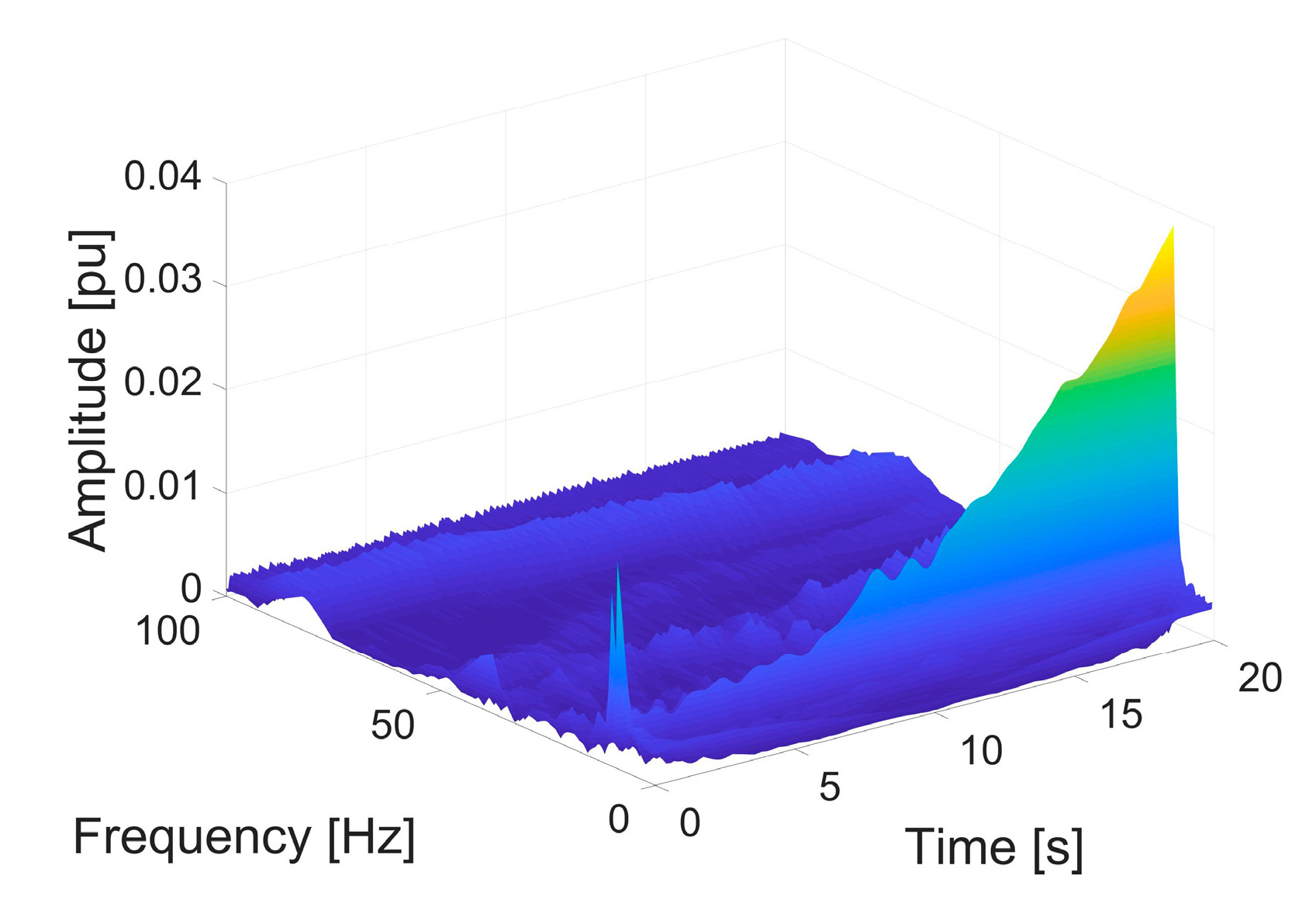

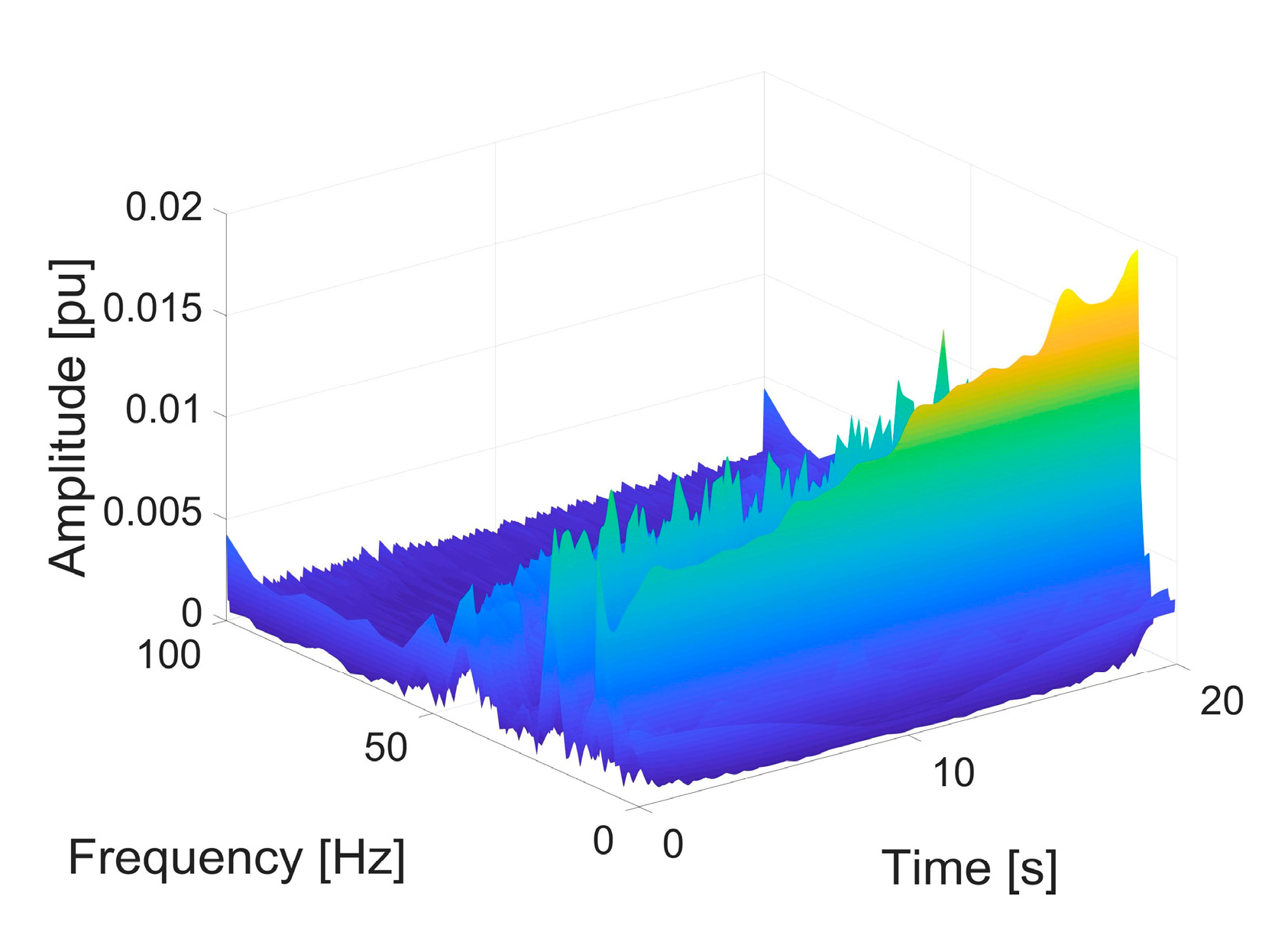

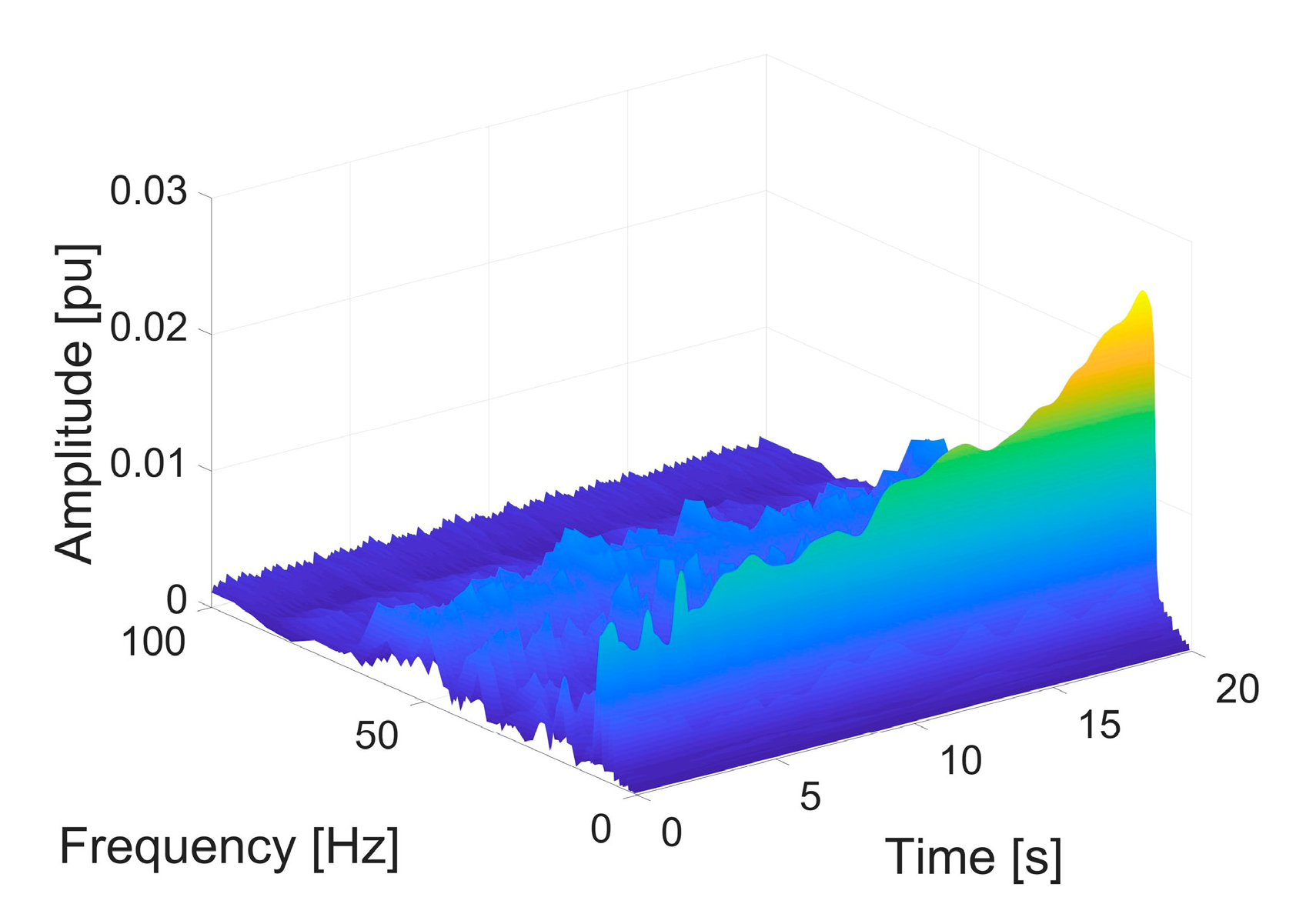

Considering the case study shown in

Figure 1, the results provided by the developed LNG plant simulation platform were post-processed through the Prony analysis and successively a proper estimation of the damping factor

ξ(fi) was achieved for each TG unit. The stability assessment of the LNG plant and the sensitivity analysis are direct consequences.

8. Conclusions

Due to the complexity and the numerous devices that compose an LNG plant, torsional instability phenomena can occur also in the case that the plant is operated considering rated electrical, mechanical and control parameters provided by the Original Equipment Manufacturers (OEMs). For this reason a comprehensive approach to the LNG plant stability analysis is required.

In the paper an improved theoretical model was presented to estimate accurately the electrical damping of an LNG plant and sensitivity analysis was performed to assess the impact of the control systems parameters on the risk of torsional instability. On the basis of the theoretical model, a complete simulation platform was developed in order to manage complex LNG plant configurations with numerous TG units and drives. Finally, an extensive tests campaign was carried out on a real LNG plant.

Both the theoretical model and the simulation platform provide proper evaluation of the real electrical damping and, as a consequence, of the risk of torsional instability. The results of the sensitivity analysis demonstrated how the tuning of the control systems parameters affected the electrical damping of the LNG plant. Hence fine tuning of the control parameters should be adopted in the LNG plants practice to operate the power systems avoiding conditions with high risk of torsional instability or reducing the risk of torsional instability.

The developed simulation platform represents a valuable and flexible tool to extend the results of this study to different plants. The platform can be arranged to manage other LNG plants with different power ranges, a different kind of loads and a variable number of TG units considering also the occurrence of contingencies and real time variations.