1. Introduction

Power consumption increase and the never-ending industrial demand on electrical energy have resulted in a higher requirement of electrical energy generation worldwide and therefore, a depletion of conventional generation resources, such as fossil fuels. On the other hand, renewable energies are still facing issues for massive generation and supply due to its unpredictable nature. These challenges have allowed a development in efficient technologies for energy conversion. An alternative to cope this situation is the use of renewable energy sources; however, its’ massive introduction and sustainable production are still open challenges to be satisfied. One alternative to solve these issues is the distributed generation techniques sourced by renewable energy which require efficient and highly reliable power management schemes in microgrids [

1].

Among the investigations carried out on energy-management systems (EMSs) in microgrids (µGs) there are different approaches. In [

2] a theoretical reference is presented for the optimization and operation of µGs considering the impact of energy storage, the integration of renewable energy sources and the request for an answer for a case in Hong Kong. In [

3] a study of interconnected µGs is presented, focusing on energy commercialization and scheduling strategies considering the local energy consumption (individual µG), but also on the exchange of energy between µGs, demonstrating a reduction in operating cost up to 13%. In [

4] an effective EMS applied in integrated building systems and µGs is presented, demonstrating that the proposed system has the ability to preserve energy and reduce consumption costs. This EMS considers aspects such as distributed heat generation and characteristics of electrical generation. The results of this research focus on the behavior of the energy of the elements of the µG, the frequency and the voltage in response to their proposed master-slave control system, heat flow and temperature. All these studies present results using numeric simulation and focus on the analysis of energy levels between µGs and the elements that compose them.

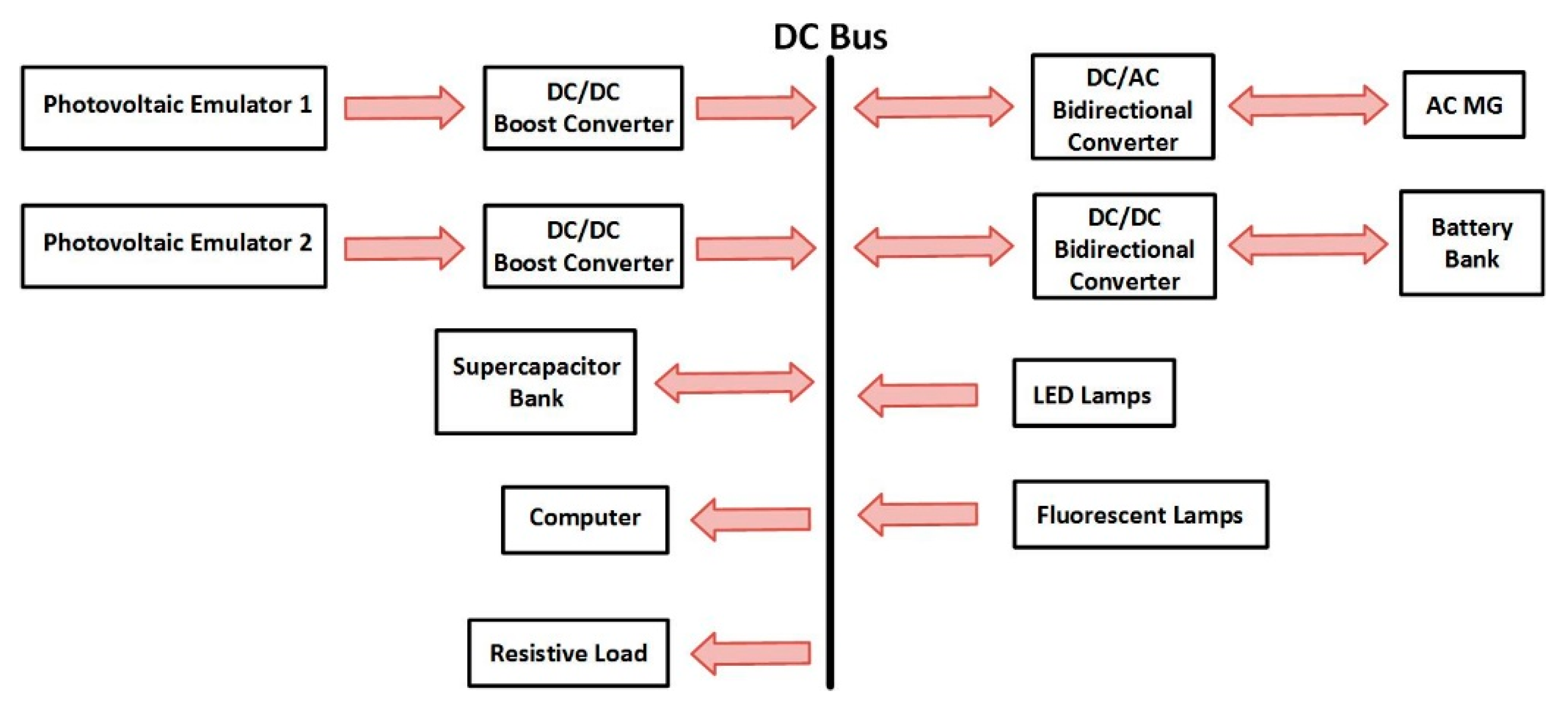

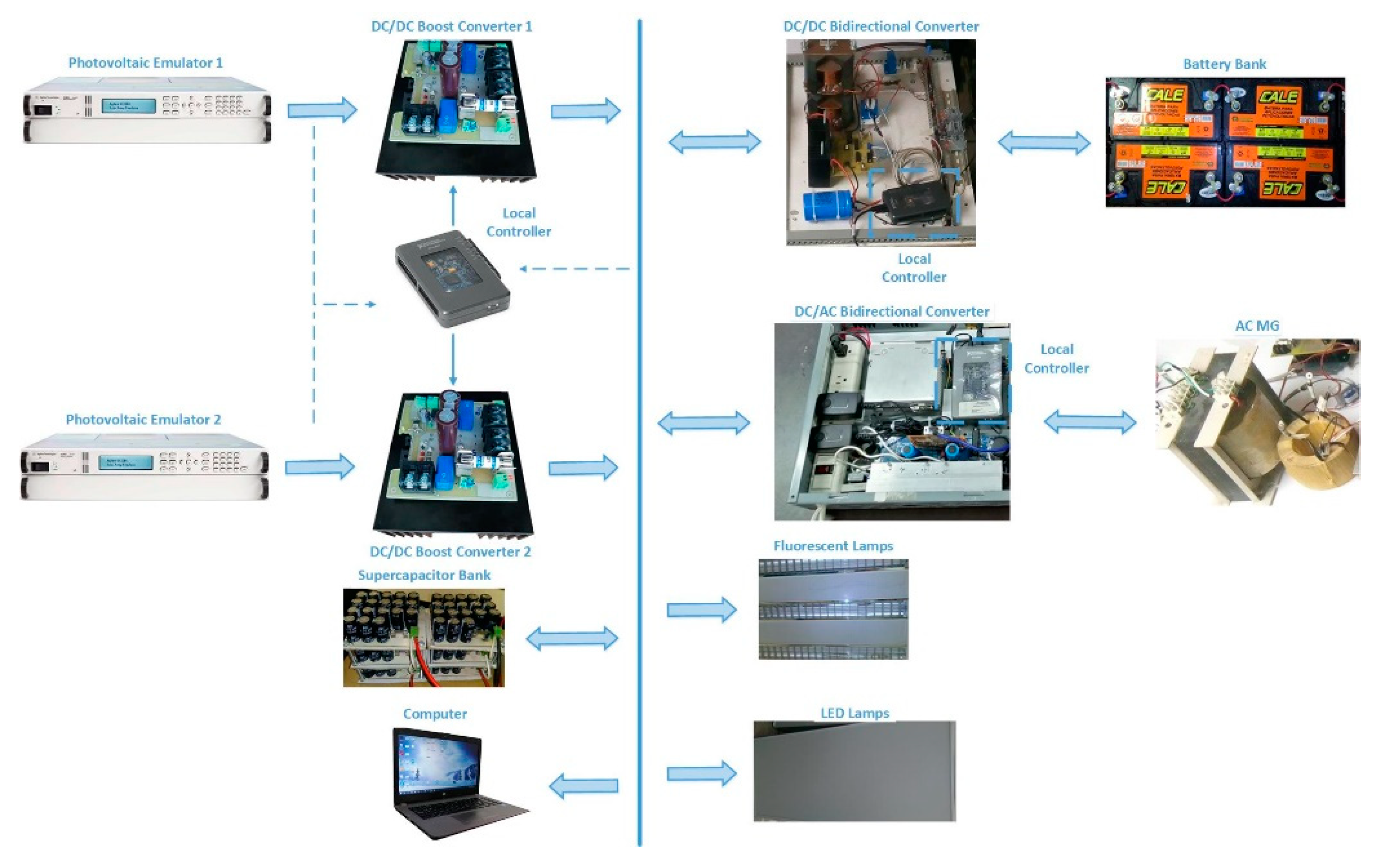

An example, of the configuration of a microgrid is a residential direct current microgrid (DC-µG) using photovoltaic solar panels as a main energy source. A conventional grid-connected DC-µG is constituted by different elements such as: generators, storage energy devices, loads and the interconnexion device linked to the alternating current (AC) main grid (MG). Usually, those elements are connected to the DC-link through power electronic converters (PECs). In this proposal, the efficiency of two optimization strategies of a DC-µG is evaluated: (1) a centralized EMS that manages the energy in the batteries in order to keep the bus voltage stable; (2) optimization of switching frequency of each converter to improve its efficiency. The authors conclude that both independent strategies increase the efficiency of DC-µG [

5].

In [

6], the authors carry out a scientific review about control strategies, stability analysis and stabilization techniques implemented in a DC-µG, one of their main conclusions is that the local control of the converters is relevant to the integration of a level of control higher than most used in the control techniques that are proportional-integral (PI), proportional-derivative (PD), proportional-integral-derivative (PID) and fuzzy control (FC). Regarding communication between the elements of a DC-µG, the authors conclude that three basic control strategies have been widely reported: (1) Decentralized control: the digital communications links are nulled and the electric lines are used as communication channels. Usually, the DC-link voltage demand is used as feedback; (2) Centralized control: the information is generated by different devices, and it is sent to a unique master. In this master, data are processed and sent it back by using different digital communication links; (3) Distributed control: The digital communication channels are implemented between systems and the coordinated control strategies are locally processed.

Lately, there have been reports of EMS applied in DC-µG with good simulation results, and a brief review following the report. Reference [

7] reported an isolated DC-µG with a DC-link of 24 V and connected to different loads (laptop (19 V, 65 W), lighting LED (240 V, 90 W), fan (48 V, 90 W)) by using appropriate PECs and one active filter. The proposed design facilitates standalone powering of a rural household which need less than 250 W provided by a PA. Reference [

8] proposed a hierarchical controller based on three operation modes, the controller guaranteed the DC-link bus stability for the different operation modes, only numeric results are reported. Considering three modes of operation under six operational situations in terms of load variations, an analysis of operation times is performed for each of the six operational situations under consideration.

Further DC-µG configurations are the ones reported in [

9,

10]. In these proposals, a supercapacitor bank is connected to the DC-link bus by using a bidirectional converter. Additionally, a virtual resistor and capacitor is used as an impedance control loop, between the DC-link and converter. The reported numeric results in MATLAB, showed a good dynamic response, which was more precise compared with previous topologies. However, it lacked practical or at least hardware in the loop (HIL) validation. On the other hand, a decentralized power management for an isolated DC-µG was reported in [

11]. In this investigation, numeric results were obtained by using SIMULINK the results showed an adaptive I/V characteristic as a decentralized control strategy of a hybrid DC-µG whose structure contains a PA and battery energy storage system and wind turbine generator that can keep the DC-link bus stable even when the energy demand exceeds the maximum power generation. Following this trend, a different isolated DC-µG with six operation modes was controlled by using an energy balance method [

12]. In this study, an interesting scheme to control the on-the-fly photovoltaic transitions between modes was reported, which reduced the DC-link bus oscillations. Restrictions of this scheme were the use of only linear loads and a maximum bus variation of 6%.

Another branch of EMS is the development and application of intelligent algorithms. For instance, reference [

13] proposed an isolated residential DC-µG controlled by a fuzzy logic EMS. In this work, only SIMULINK numeric results were achieved and the FC is evaluated under two scenarios of a DC-µG consisting of PAs, wind turbine, battery bank (BB), fuel cell and diesel generator supplying a typical residential load, the EMS is controlled by a low complexity FC with only 25 fuzzy rules that combine two input variables, the state of battery charge and the power difference between generated power from renewables and load demand ΔP represent the power difference between generated power from renewables and load power during day hours. The authors consider their proposal as an economic dispatch problem. A further centralized fuzzy logic proposal was reported in [

14]. In this study, an accurate DC-link voltage and current regulation was achieved for a DC-µG. As a result, authors claimed a cost reduction compared with centralized controllers. Unfortunately, only resistive loads and numeric results were stated. In [

15], a low voltage (200 V) grid-connected DC-µG with PA and storage unit was reported. In this proposal, a neuronal controller was implemented and behavior in the DC-link was given. Once again, HIL or practical results were missed.

On the other hand, investigations that present experimental tests, [

16] proposes a flexible control mechanism to change the operation mode of photovoltaic systems in a DC-µG, although experimental results were presented, the stability of the DC-link bus was not presented. Study [

17] present a multi-condition strategy based on energy management for an isolated DC-µG consisting of a PA, a fuel cell and a BB. This proposal distributes the energy and keeps the DC-link bus voltage stable in different operating conditions that depend on the state of charge (S°C) of the batteries, the loads and the power of the PA. To verify the operation of the proposed administration system, an experimental prototype was implemented considering that the results obtained were good.

In [

18] the authors proposed a centralized control technique for EMS in an experimental prototype of a DC-µG with a 380 V bus, this µG is interconnected to the MG through a PEC, which is in charge of EMS, regulating the DC-link bus. LabVIEW software is used to monitor the power of the DC-µG. Case studies are presented considering irradiation changes, resistive load, S°C and power limits. In the quest to improve energy management in a DC-µG with a BB, [

19] proposed the use of a fuzzy controller to improve the life cycle of a BB, stabilizing the DC-link bus in a range of 380 V ± 20 V; this system uses LabVIEW software to implement the EMS. LabVIEW is an alternative in EMS design, this is because it has boards for monitoring and control. [

20] used the PCI-MIO16-E-4 board to control a three-phase converter which is used to control an induction motor connected in a DC-µG with a 600 V bus, the experimental tests presented used resistive loads. In [

21] the authors proposed a power control approach to provide energy management and stabilization of a hybrid DC-µG for transportation applications, the control system was implemented on dSPACE real-time boards. The simulation results shown the effectiveness of the control system to manage the power flows between the supercapacitor, the rectifier and the load; furthermore, the authors found that the experimental results are consistent with the simulations. In [

22] a fault-tolerant supervisory controller (FTSC) is proposed, and its effectiveness is evaluated using a hybrid AC/DC µG simulated in MATLAB considering the effects of maximum power derived from possible failures in solar and wind systems, the proposed FTSC considers a procedure to determine the maximum power available under fault conditions and increases the tolerance of the supervisory controller. These faults in solar and wind systems represent an unknown dynamic that can be modeled using fuzzy controllers. Consequently, in [

23] a control strategy for a hybrid renewable energy sources (HRES) system is proposed using FC systems that contain adaptive rules to obtain better performance from an HRES system evaluated under different load conditions and failures in renewable energy sources.

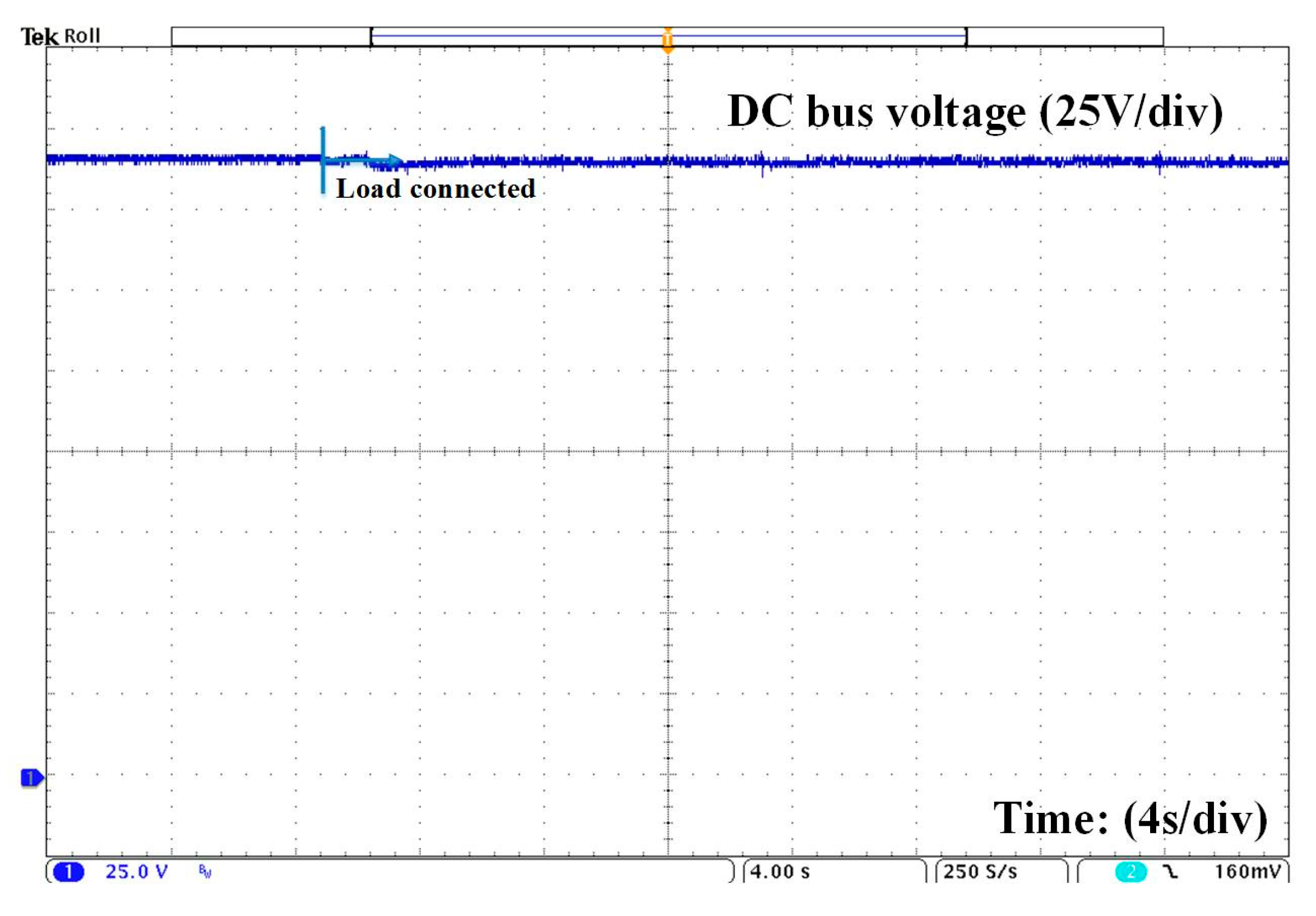

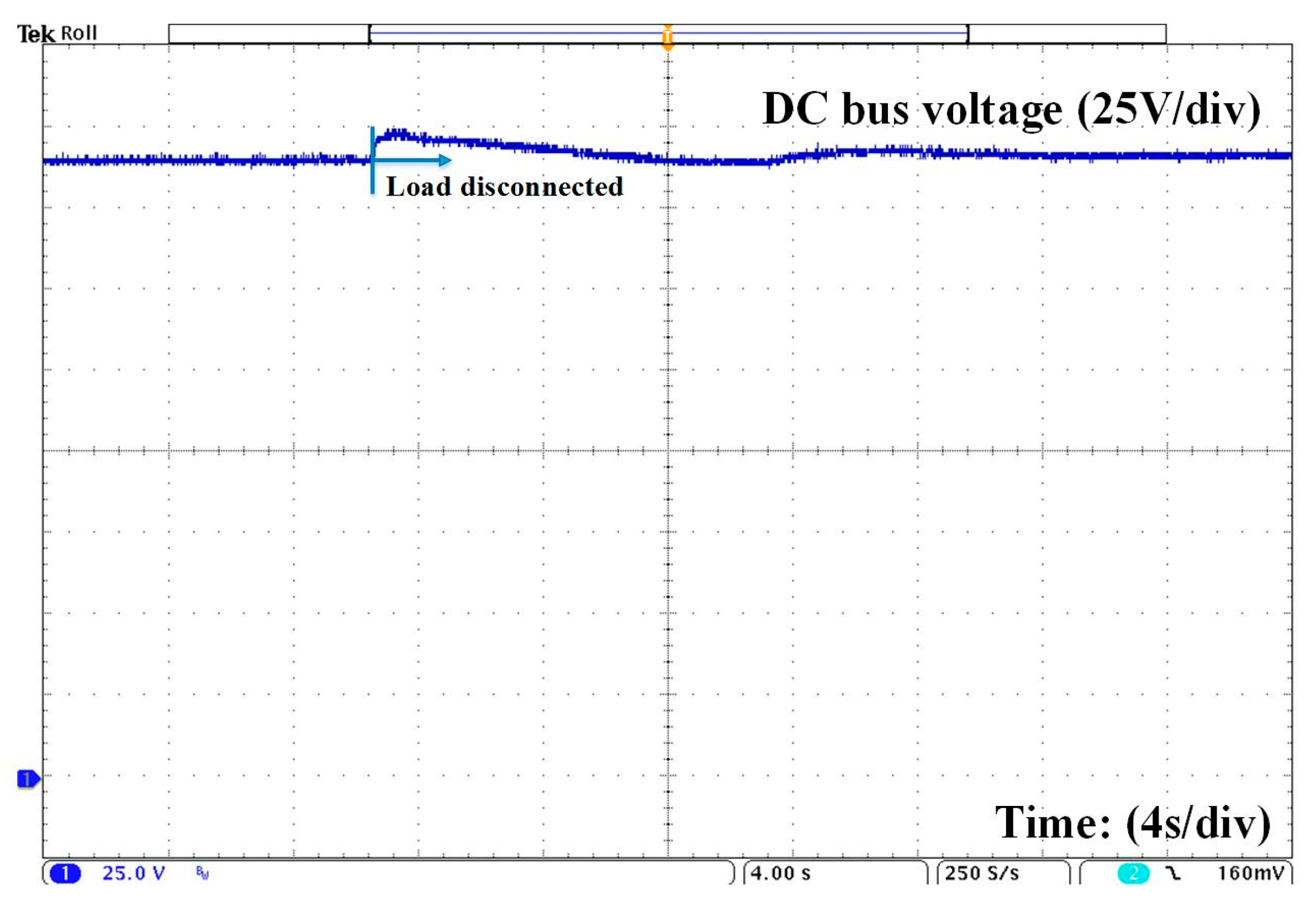

The previously described state of the art shows that several architectures implemented in hardware have been reported with satisfactory results. However, in author’s opinion, some of them are oversimplified and other considers ideal conditions, which are not satisfied in real-life situations. Therefore, this study proposes a methodology for the design and implementation of a EMS that has a global administrator, which defines the operation mode each PEC’s controllers inside the DC-µG. Both controllers use National Instruments technology; indeed, the embedded EMS was used in an experimental DC-µG prototype that has two PAs, a BB and a bidirectional DC–AC converter to interconnect it. Experimental tests on DC-µG’s behavior with the EMS were performed using electronic loads such as computer equipment, LED lamps and fluorescent lamps focusing on the behavior of the DC-link bus when connecting and disconnecting sources and loads which generate changes in the operating modes of each of the local controllers in charge of manipulating the PECs that make up the DC-µG.

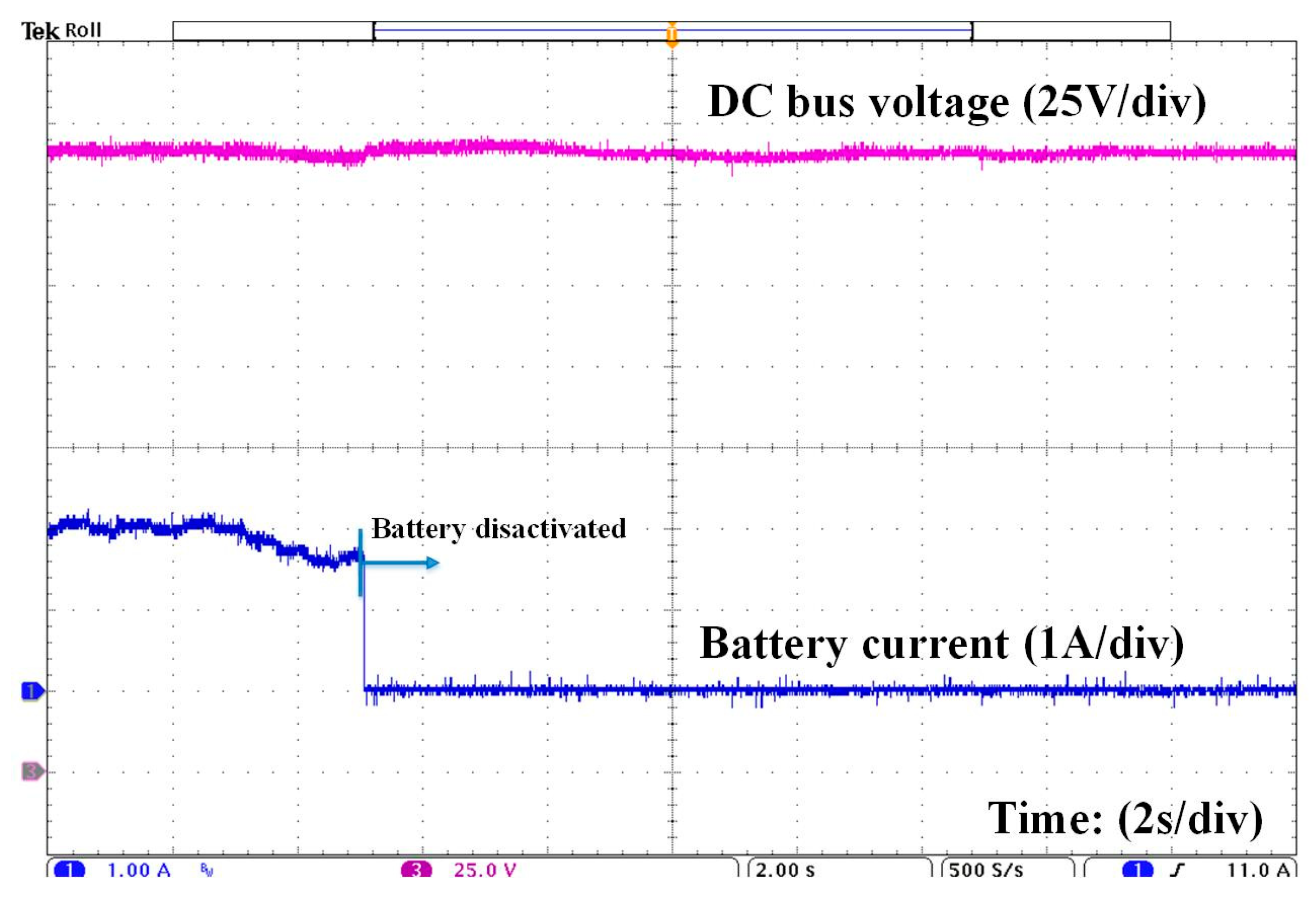

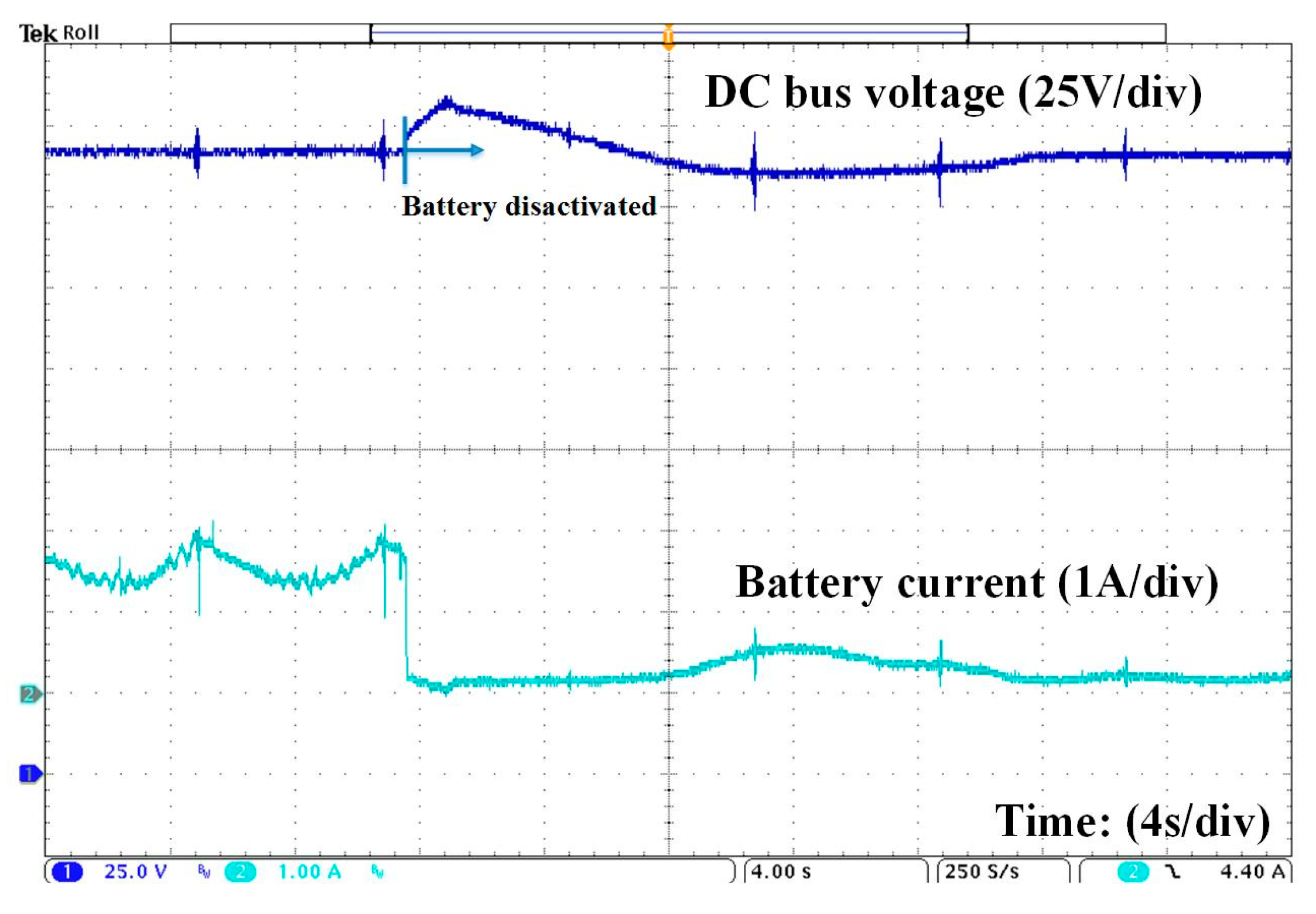

The obtained results show stability in the DC-link bus due to the generated disturbances and to changes in the operating modes of the DC-µG components, advantages of this proposed system compared with reported literature is listed to follow. First, results obtained show that it is not necessary to include electrical components to the network for the connection and disconnection of energy sources and real loads. Second, the DC-µG state machine that controls the global manager considers six operating scenarios to stability of the DC bus, taking advantage of the maximum power of the PAs, balancing the energy generated and demanded by the elements that make up the DC -µG, and take care of the charging and discharging processes of the battery bank, thus increasing their useful life. Third, results presented focus on the behavior of the DC bus when connecting and disconnecting electronic sources and loads used daily, which shows robustness and stability, presenting transitory response times between 4 and 20 s with variations in voltage on the bus less than 5%. Finally, using the LabVIEW virtual instrumentation software (2015, National Instruments, USA) and the NI myRIO-1900 for the implementation of the global administrator and local controllers has virtues such as the generation of a user-friendly interface, which allows monitoring relevant variables of the DC- µG and modify parameters of the controllers in real time. Additionally, it has flexibility for the quick reconfiguration of the generated controllers, which enables the generation of more complex systems in a short time, adapting embedded systems to new experiments.

This work is organized as follows: In

Section 2, the structure of the DC-µG used to evaluate the EMS under different scenarios is described. In

Section 3, the control and management system (CMS) is described which establishes the mode of operation for each element of the DC-µG in order to extract the maximum energy from the PVEs. In

Section 4, the results obtained are described to verify the behavior of the CMS embedded with the experimental prototype of the DC-μG, each of the PVEs was configured with the following parameters: V

mpp = 120 V, V

oc = 130 V, I

mpp = 2 A and I

sc = 3 A.

Section 5, finally, presents a brief summary and conclusions of the obtained results.

3. Control and Management System

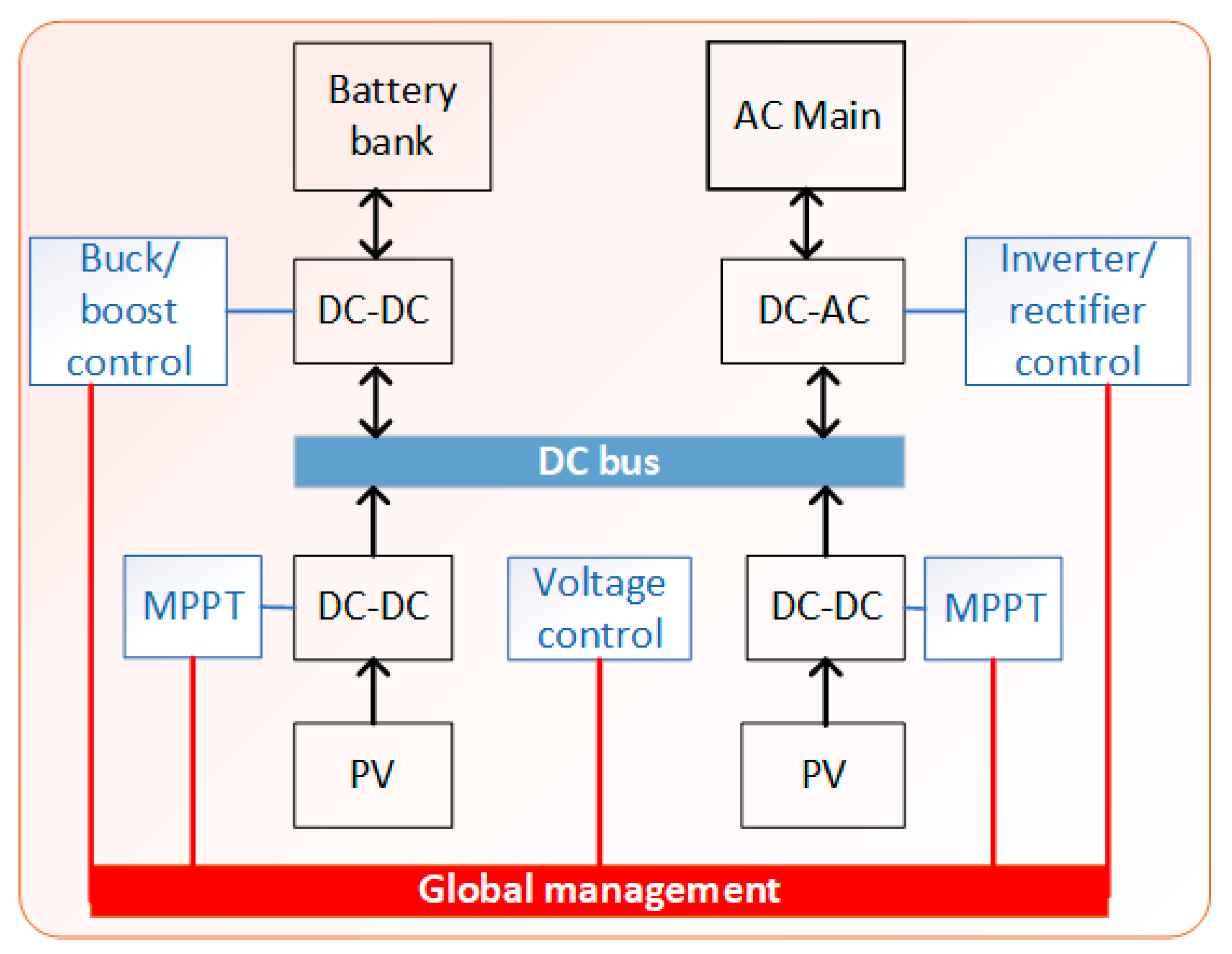

The proposed CMS consist of a general administrator and independent controllers, which operates different µG’s systems. The general block system of the µG is shown in

Figure 6. The black color represents the µG’s systems and the blue color the different local controllers. Additionally, the global controller is shown in red color. More details about the different working modes and operation of the DC-µG are given in the following sections.

3.1. Global Management Controller

The global management controller (GMC) operates with the following six hierarchical scenarios: (1) to maintain the DC-link bus voltage in an operation range of 190 V ± 5%, (2) to consume the maximum energy from the PVE (to reduce the energy coming from the MG), (3) in the case of low load energy consumption and over generated energy from the PVE, the remained energy is stored in the BB, (4) in the case of full charge of the BB or BB discharge, the generated energy is send to the MG, (5) in the case that the load’s consumption is bigger than the generated energy from the PVE, the energy difference will be provided by the MG and (6) energy from BB will be used only when the MG is not available or in the case that the generated energy from the PVE and the MG are not enough to cope the demanded load energy.

These scenarios were considered for the design of the GMC in order to keep the DC bus stable, if the bus destabilizes or goes out of the established range, the connected loads could be damaged. On the other hand, it is of utmost importance to make the most of the renewable energy source that MG has. In addition, to defining the energy exchange between the BB and the MG loads, the cost of electrical energy was considered. It is more expensive to transfer energy to the BB than to the MG. Reason why, if there is a surplus of photovoltaic energy, this energy will be stored in the BB and not in the MG. Otherwise, if the loads connected to the DC bus demand more energy than that generated by the PVEs, the missing energy will be taken from the MG and not from the BB. Finally, for the BB charging and discharging process, it is considered that the processes must be completed to take care of the BB’s useful life.

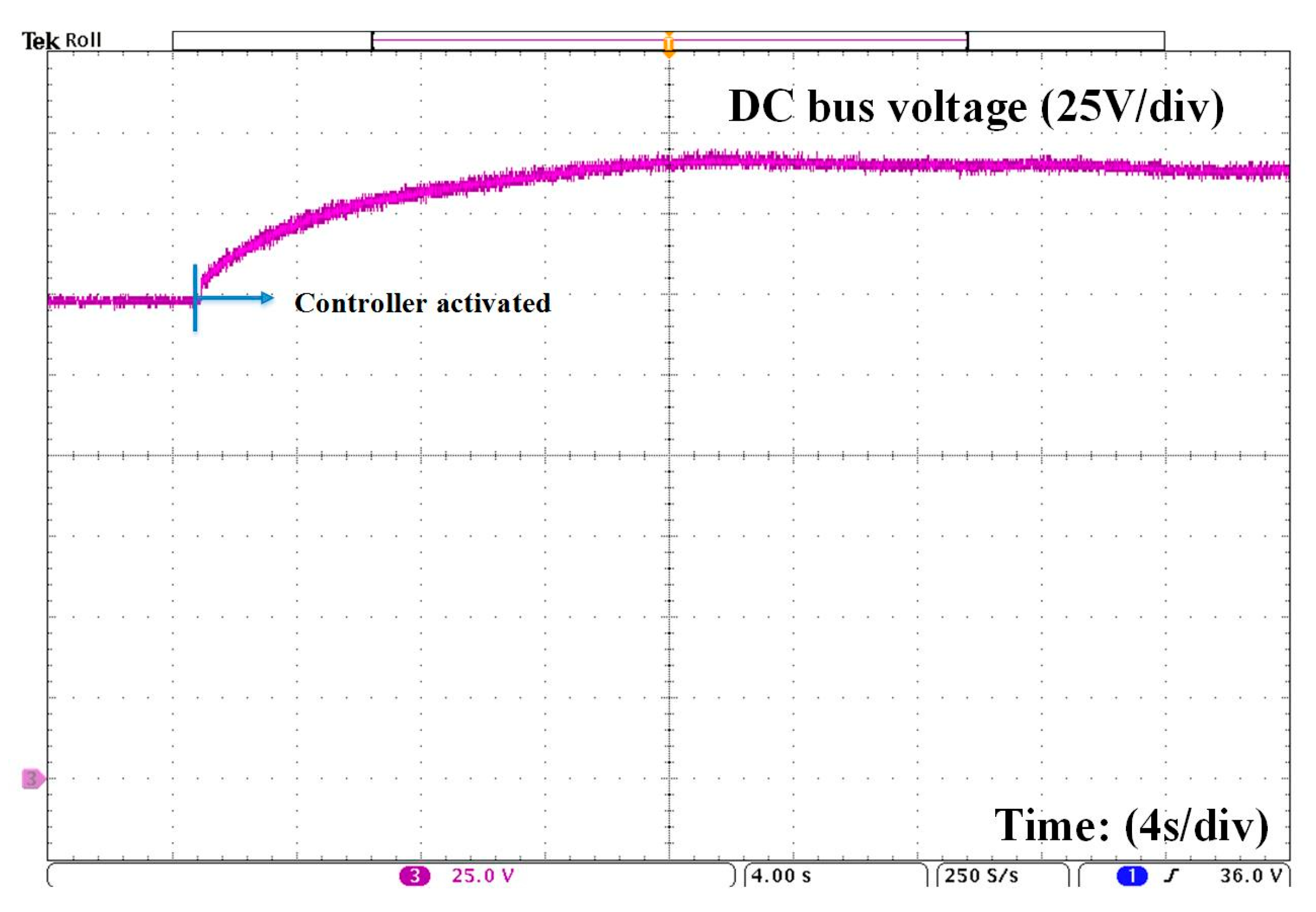

It can be noticed that the GMC works as a function of the DC-link bus voltage and the working operation mode of each µG section. During the startup, the PVEs are turned on and those work in the voltage control (VC) mode, in this period, the BB and the MG are turned off. Once the system reaches the steady state, the different loads are connected.

If the demanded load energy is greater than the generated by the PVEs, the DC-link voltage will decrease, in this situation if the voltage reaches a minimum of 183 V (2 V before the critical value of 180.5 V), the GMC changes the PVEs controller to a maximum power point tracking (MPPT), and it obtains the energy difference from the DC–AC rectifier. As a result, the DC-link voltage is stabilized and the load energy demand is handled. This operation mode is also used if the energy generated by the PVEs is not enough to supply the energy demanded by the loads connected to the bus. However, this operation mode can be changed if the BB is chosen to cope the energy difference or during lack of solar or MG energy.

On the other hand, if the µG is in steady state, with the PVEs working in VC mode, and the demanded power by loads in less than 80% of the DC-link maximum capacity, the GMC monitors the S°C of the BB and the MG with the main aim to change the PVE’s operation mode to MPPT and send energy to the BB or the MG. In other words, the energy sent to the BB or the MG is the difference energy generated from the PVEs and the one demanded by loads.

If the BB is depleted or in charging mode, with a light load and the PVE energy is not available, the energy to charge the BB is obtained from the bidirectional DC–DC converter. On the contrary, if the BB is charged, with a light load and the PVE energy is available, the energy is sent to the MG by using the bidirectional DC–DC converter.

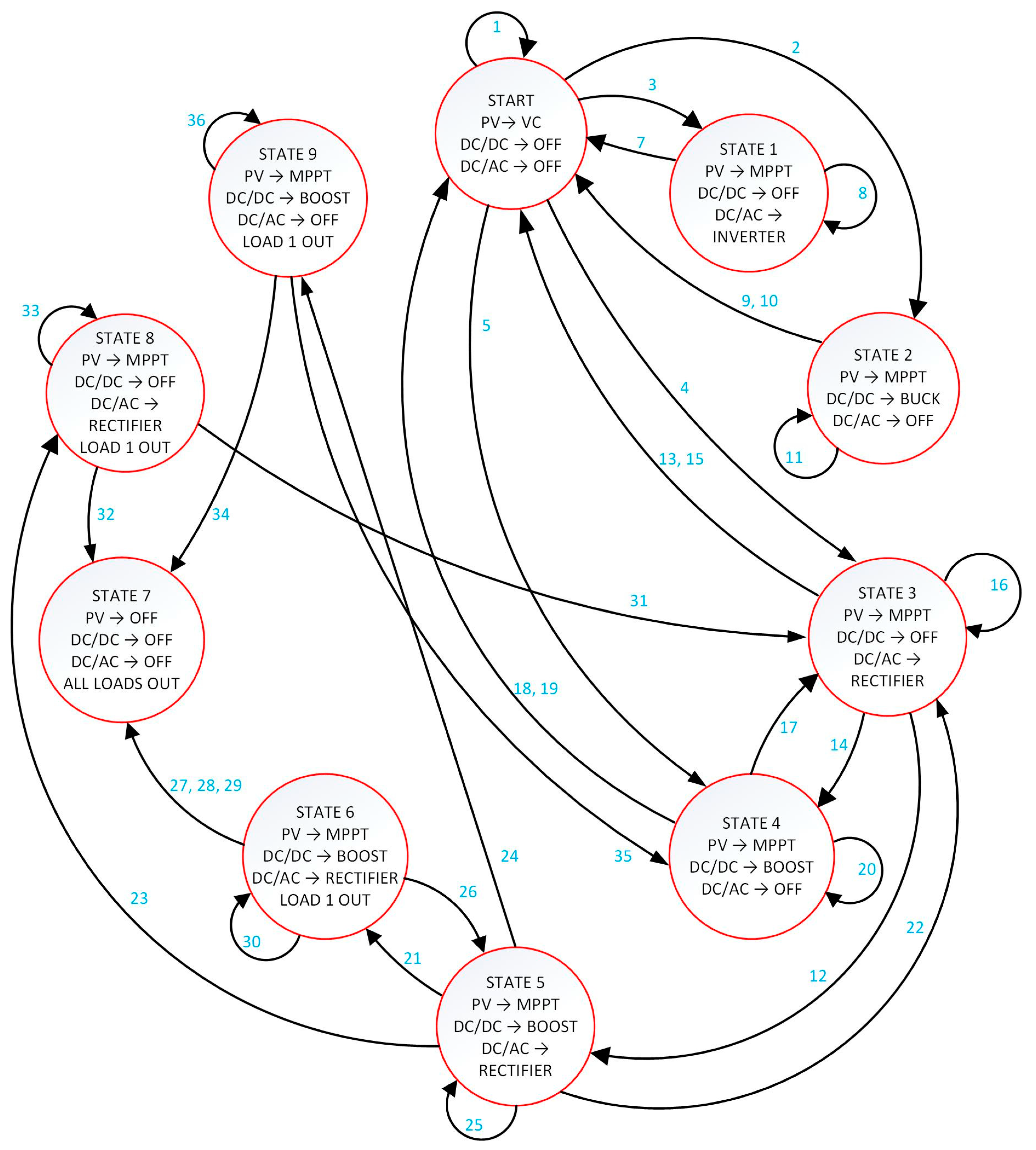

Figure 7 shows the state machine diagram used in the GMC and

Table 3,

Table 4,

Table 5,

Table 6 and

Table 7 show the transitions defined between states.

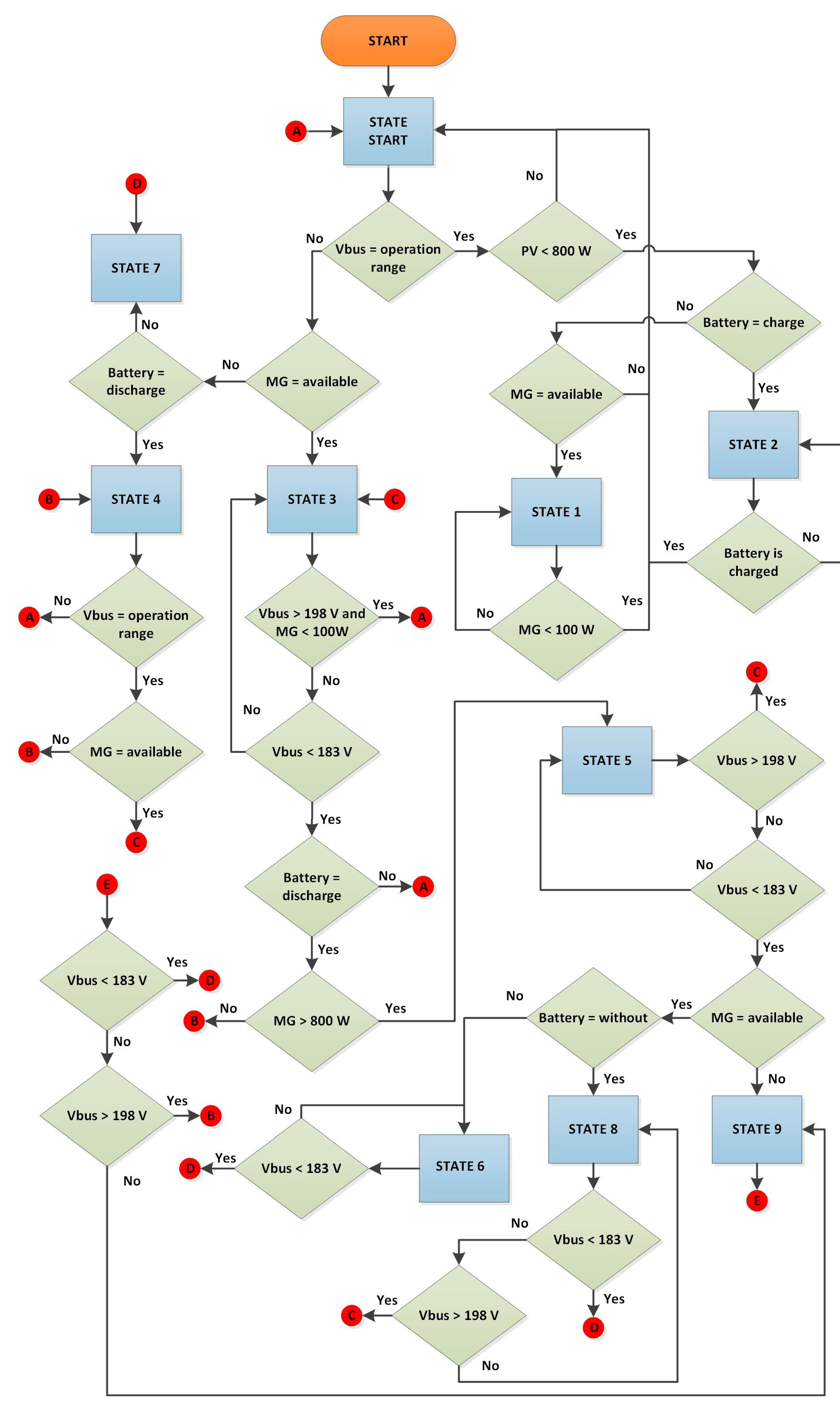

Figure 8 presents the flow diagram of the behavior of the GMC. This diagram illustrates the priorities of the GMC. These priorities are based on the six hierarchical scenarios described at the beginning of this section. The priority of the GMC algorithm is to keep the DC bus voltage level within the established range, to extract the maximum power from the PVEs, if the energy demanded by the loads is greater than that generated by the PVEs, the missing energy is taken from the MG, if the MG is not available the energy is drawn from the BB. In the event that the energy demanded by the loads is less than that generated by the PVEs, the excess energy will be transferred to the BB, if the BB is charged or in the process of discharge, this energy will be transferred to the MG.

The state machine diagram used in µG has ten states, which are listed to follow: START, STATE 1, STATE 2, STATE 3, STATE 4, STATE 5, STATE 6, STATE 7, STATE 8 and STATE 9. For the overall states, there are defined three main systems: the PVE (PV), the BB DC–DC converter (DC–DC) and the bidirectional converter connected to the MG (DC–AC). For instance, if the GMC is in the START mode, the PV works in voltage control mode (VC), the DC–DC is turned off (OFF) and the DC–AC is also turned off (OFF). Another example is STATE 6, the PV works in the MPPT, the DC–DC as BOOST and the DC–AC as RECTIFIER.

Table 3,

Table 4,

Table 5,

Table 6 and

Table 7 show the states transition tables; these have a section of entries that define the conditions for changing from the current state to the next. These inputs are the following signals that were monitored in the µG: the bus voltage level (Vbus), the power generated by the PVE (PV Power), the condition of the MG (MG) and the condition of the BB (Battery). Tables have an output section that defines the operation mode of the PECs and the condition of the local loads connected to the DC bus, these operation modes are the same as those defined in the state machine of

Figure 7. For example, when the current state is START, if condition 1 is met, the next state will be START. In this condition Vbus must be greater than 185 V and less than 195 V, the PV Power must be greater than 800 W, here the MG and Battery status are not considered. In condition 12, Vbus must be less than 183 V, the PV Power must be greater than 800 W, just like the power extracted from the MG (MG), in addition Battery must be in the discharge process.

3.2. Local Controllers

The GMC defines the operation mode of each of the local controllers. While these are responsible for generating the control signals that are used in each of the PECs that make up the µG. The following describes the embedded control systems designed to keep the system stable.

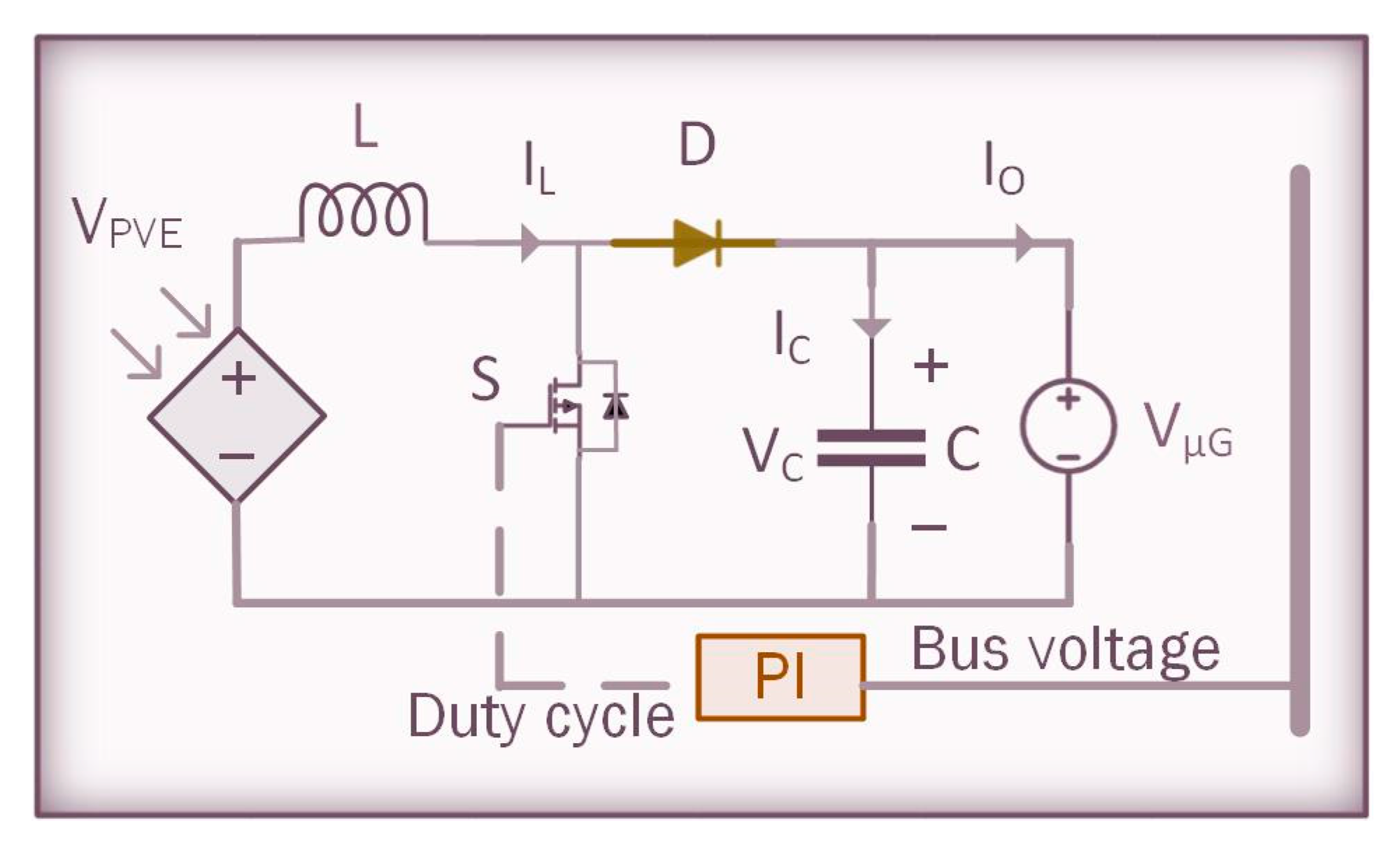

The DC–DC boost converters connected to the PVEs have two operation modes: (1) the VC mode, and (2) the MPPT mode. In VC mode, a classic PI controller is responsible for maintaining the output voltage of the DC–DC converter (DC bus voltage) at a level of 190 V. This control mode only works when the BB and MG do not supply or extract power to the DC bus.

Figure 9 illustrates the converter diagram with the PI controller; this controller monitors the converter output voltage level (V

μG) by performing corrective actions to eliminate the effects generated by system disturbances (connection and disconnection of loads to the bus of DC).

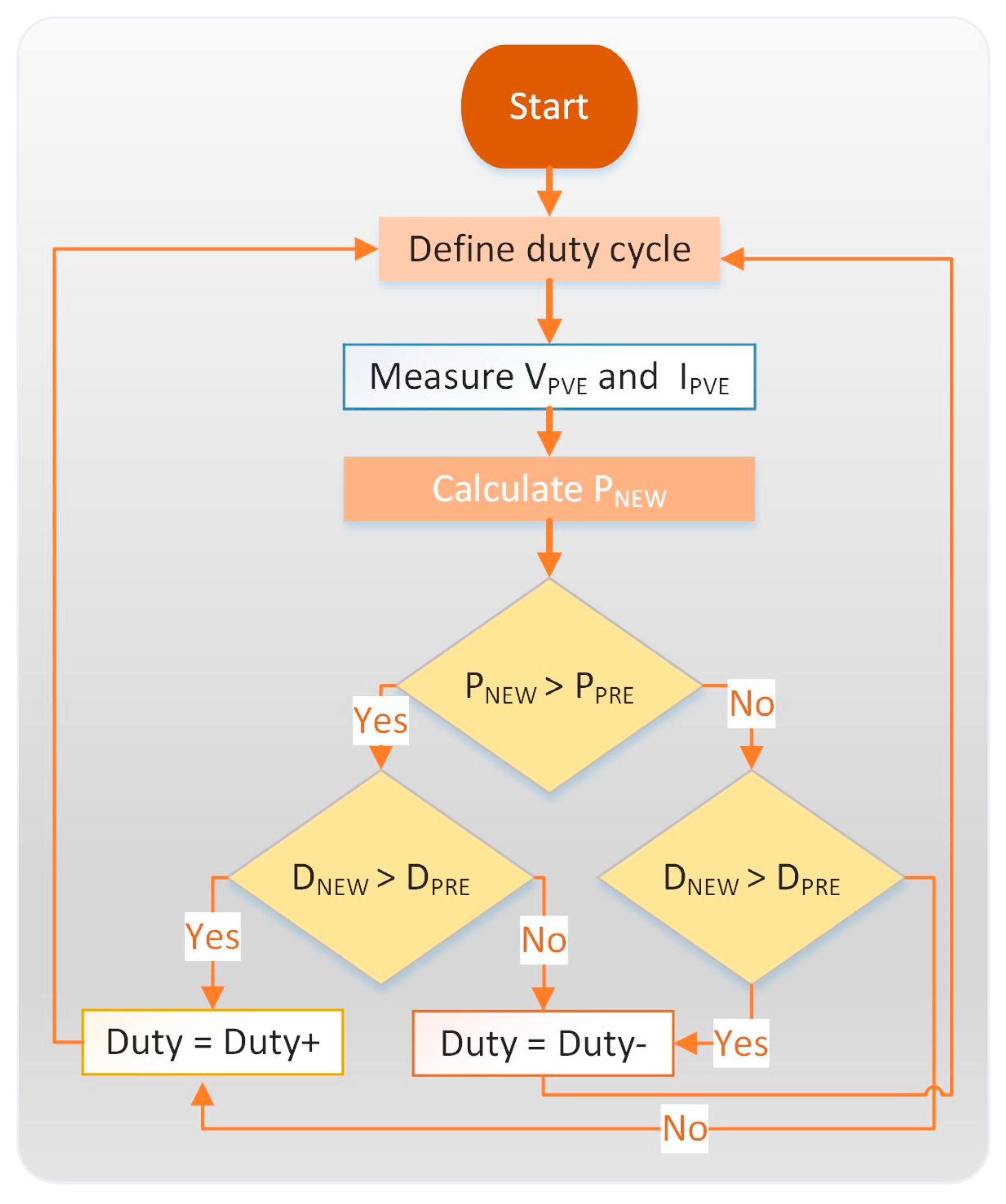

The operating point on the characteristics of the PVE module primarily depends on the impedance matching of the PVE module regarding the connected load. A DC–DC converter between the PVE module and the DC bus acts as an interface to operate at MPP by changing the duty cycle of the converter generated by the MPPT controller. In the MPPT operation mode, the boost converters extract the maximum power of the PVEs using the perturb and observe (P&O) control algorithm illustrated in

Figure 10. The conventional P&O MPPT algorithm is developed based on the slope (d

P/d

V) variation on the P–V characteristics of the PVE module [

29]. In this algorithm, an initial value of the duty cycle is first defined, then the voltage and current of the PVE (V

PVE and I

PVE) are measured to calculate its supplied power, once the value of the current power (P

NEW) is known, it is compared with the power obtained in the past iteration (P

PRE), the current value of the duty cycle (D

NEW) is also compared and is compared with the previous value of the same (D

PRE), based on these comparisons an increase is defined (Duty +) or a decrease (Duty-) in the duty cycle; with this new value of the duty cycle the process is repeated, always seeking to increase the value of the power supplied by the PVE.

Figure 11 shows the diagram of the converter with the MPPT controller. The controller modifies the duty cycle of the power switch and monitors the changes in the voltage and current of the PVEs, always looking for an increase in the power extracted from the PVEs.

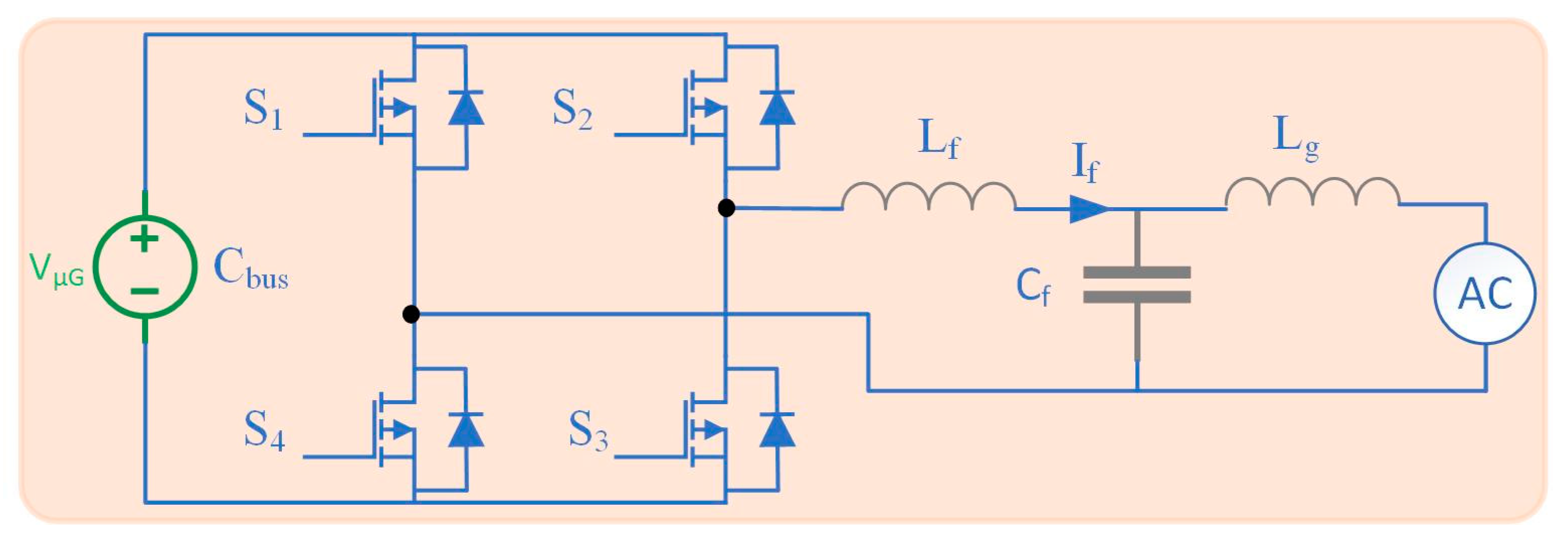

The bidirectional DC–AC converter used to interconnect the DC-µG with the MG can operate as a rectifier (transferring energy from the MG to the loads connected to the DC bus) or as an inverter (transferring energy from the DC bus to the MG). The block diagram of the control system implemented for the converter when operating as an inverter is presented in

Figure 12. This controller has a PI control action in charge of defining the amplitude of the high frequency triangular signal based on the voltage level of the DC bus, thereby modifying the amount of energy that is transferred to the MG. If the DC bus suffers a voltage drop, a reduction in the amplitude of the triangular signal is generated causing a decrease in the energy transferred to the MG and thus causing an increase in the bus voltage level. In case the bus suffers a voltage overcharge, the amplitude of the triangular signal is increased generating a surge in the energy that is transferred to the MG, thereby lessening the voltage level of the DC bus.

The converter diagram with the controller is shown in

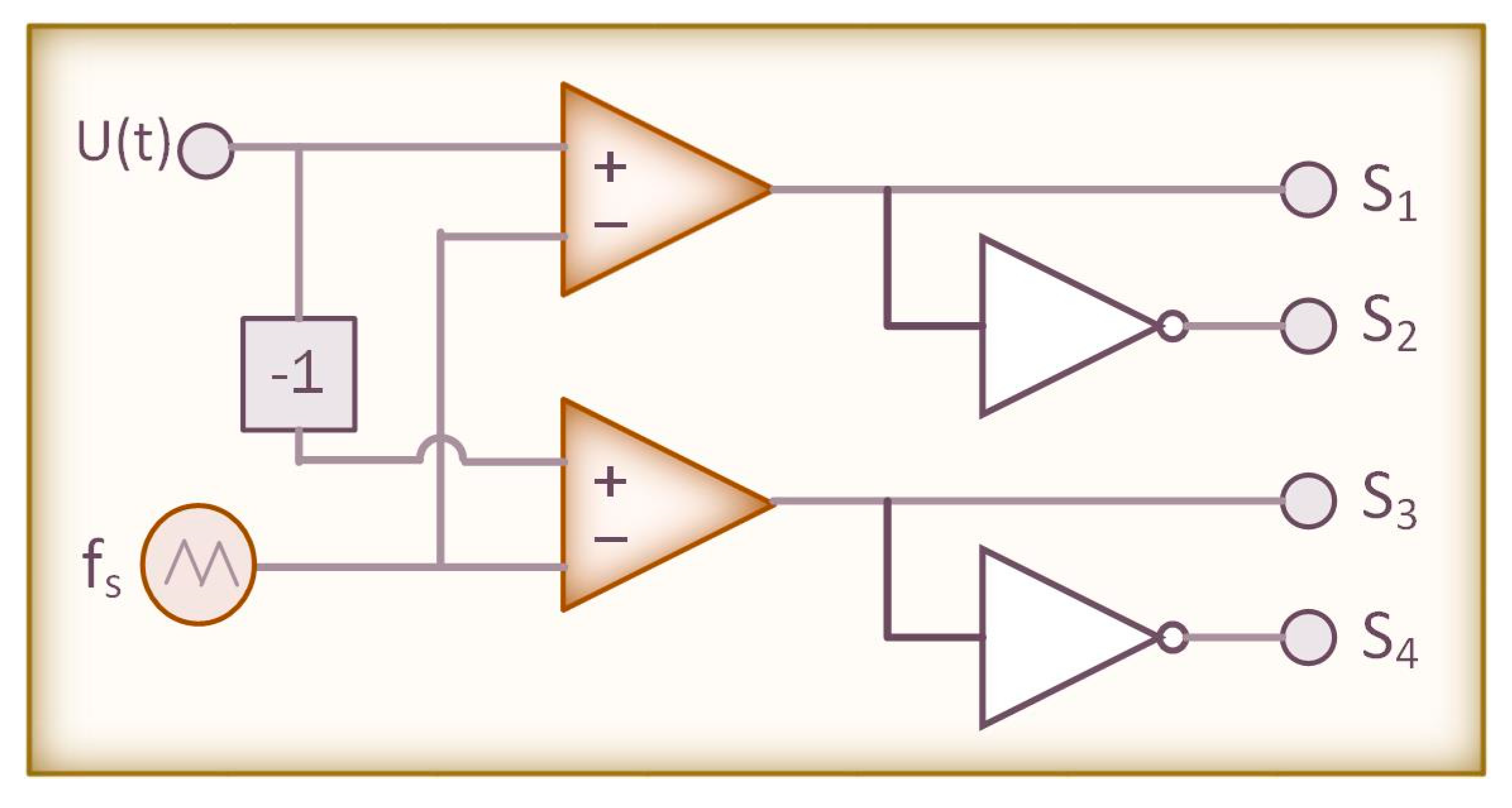

Figure 13. The synchronization between the signal generated by the inverter and the MG is performed by the zero crossing detection modules and the second-order generalized integrators with frequency-locked loop (SOGI-FLL) algorithm, this when determined by the GMC. The control signals of the four switches of the complete bridge inverter are generated by comparing the output signal of the SOGI-FLL block with the triangular signal of 25 kHz frequency.

When the DC–AC bidirectional converter works as a rectifier, the control system is carried out with a classic PI controller, which is responsible for stabilizing the bus voltage level at 190 V by increasing or decreasing the amplitude of the high frequency triangular signal f

s which is compared with the low frequency sine wave signal u(t) as illustrated in

Figure 14.

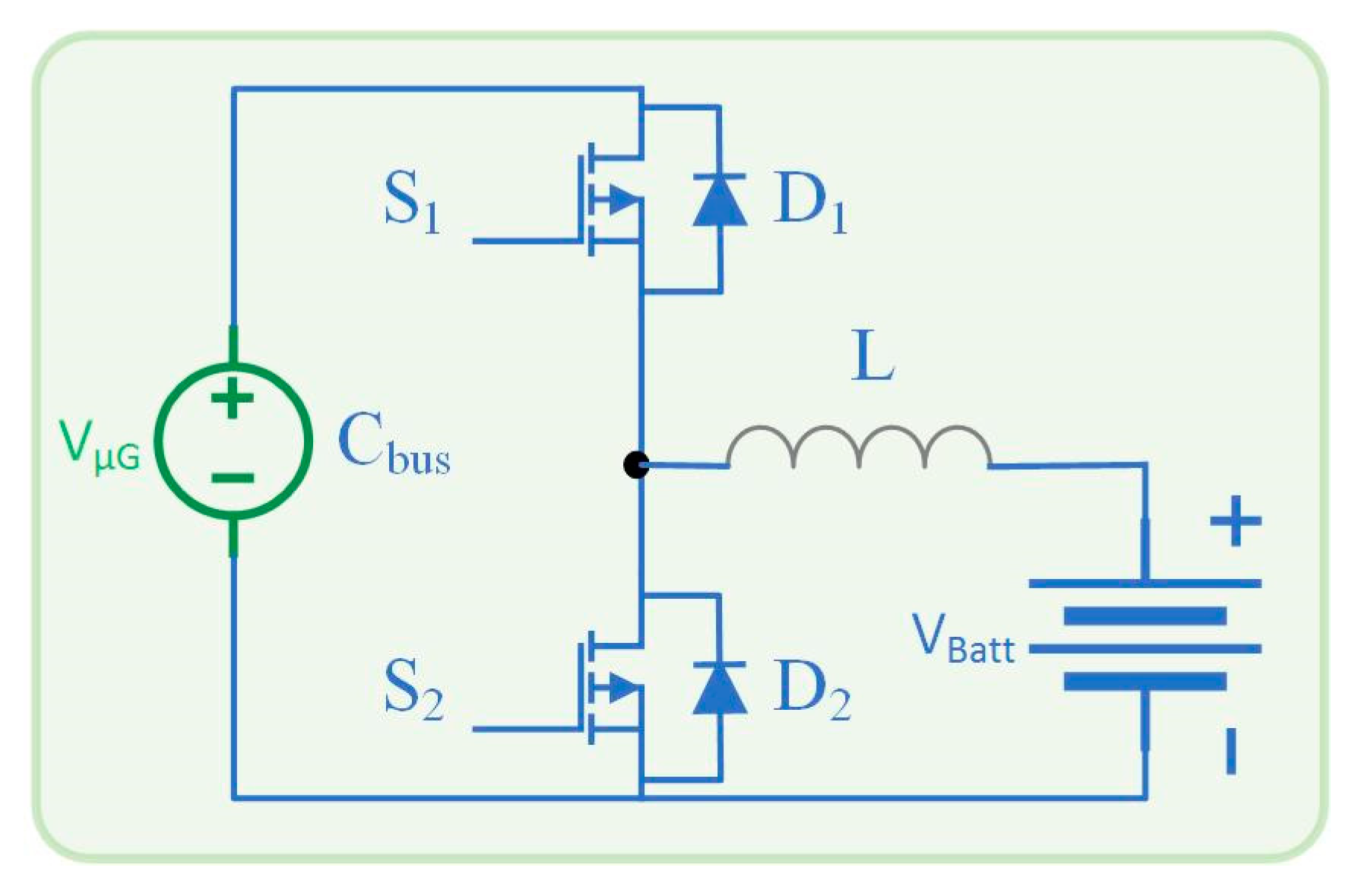

The bidirectional DC–DC converter used to interconnect the DC bus with the BB is controlled by a PI controller similar to that used for VC in the PVE converter (

Figure 9). This control system has three modes of operation defined by the GMC based on the status of the PVEs, the MG, the electronic loads connected to the DC bus and the electrical charge status of the BB.

- (1)

Battery charging: The PVEs work with the algorithm for the MPPT and the bidirectional DC–DC converter as a buck transferring power to the BB, while the MG is disabled. The controller operates based on the voltage level of the DC bus. If the voltage level increases, the energy transferred to the BB increases; otherwise, if the voltage level decreases, the energy transferred to the BB decreases;

- (2)

Battery charging: The PVEs work with the MPPT algorithm, the bidirectional DC–AC converter operates as a rectifier by transferring power from the MG to the loads connected to the DC bus. In this operation mode, it is possible to transfer power from the MG to the BB, the bidirectional DC–DC converter works as a buck. For the control of the energy that is transferred to the BB, the controller operates with the electric current that is transferred to the BB. This electric current is defined by the power demanded from the DC–AC converter before transferring power to the BB, caring not to exceed the maximum capacity of the DC–AC converter designed to work at 1 kW;

- (3)

Battery discharge: The PVEs work with the algorithm for the MPPT, the bidirectional DC–DC converter functions as a boost transferring power from the BB to the loads connected to the bus, while the MG is disabled. The controller operates based on the voltage level of the DC bus. If the voltage level decreases, the energy transferred from the BB to the DC bus increases; otherwise, if the voltage level increases, the energy transferred decreases.

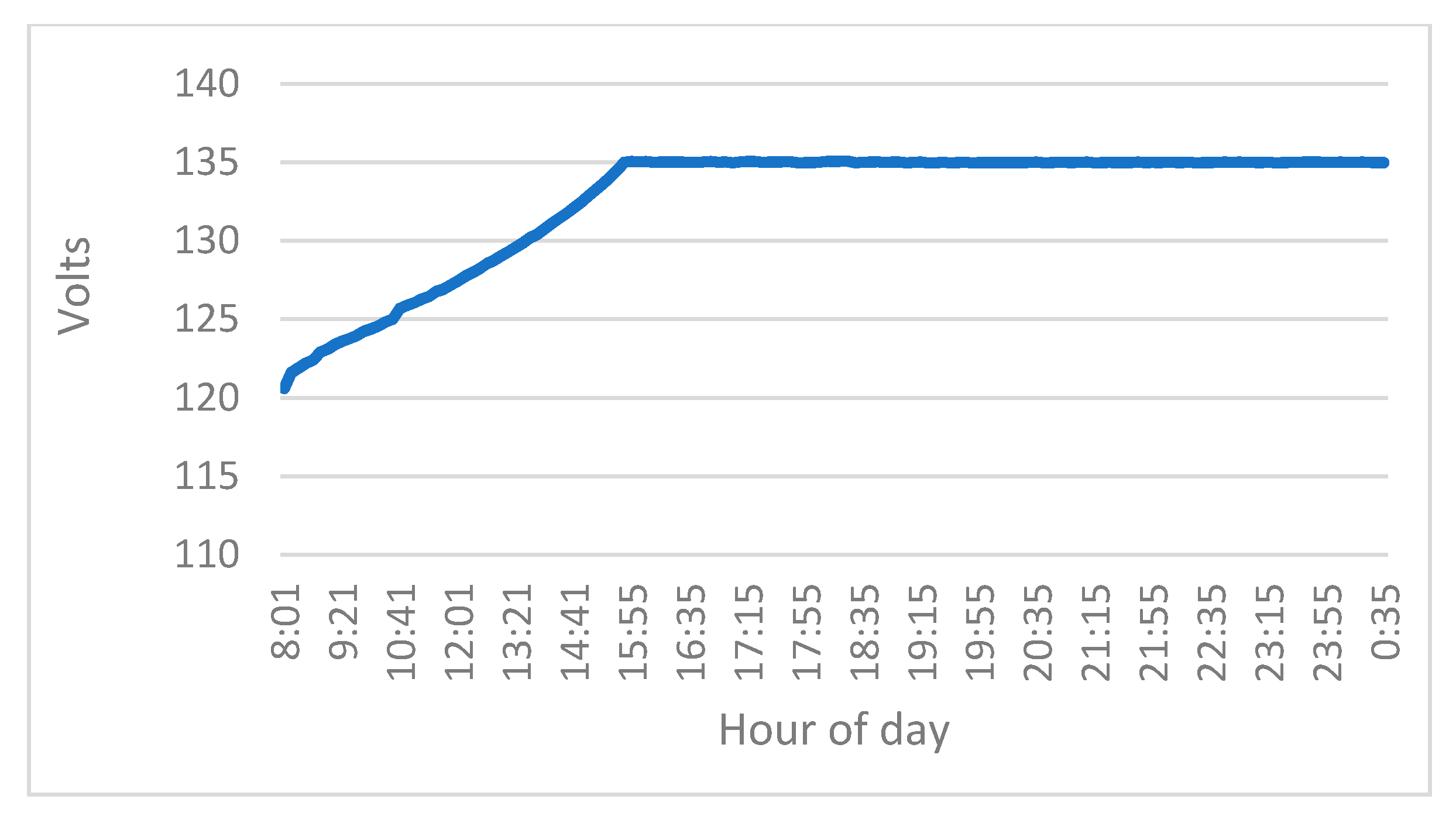

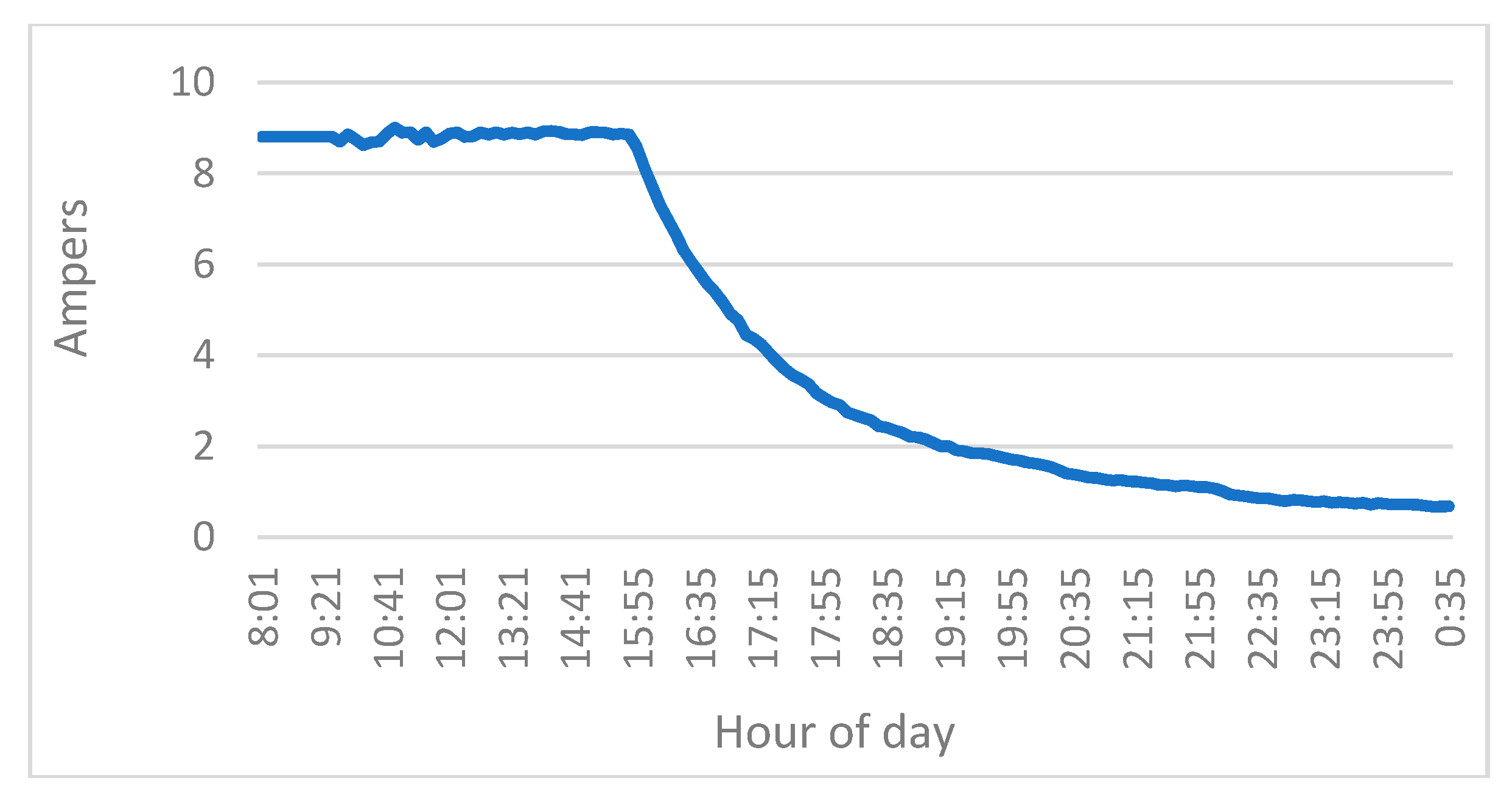

The previously described cases were defined based on the following BB operating criteria: (1) the BB charging and discharging process must always be completed, (2) the constant current charging process ends until the BB takes a value of maximum voltage of 135 V (if the energy generated is not enough to transfer energy to the BB at constant current the available energy is transferred to the BB), (3) the constant voltage charging process ends when the current that is injected into the BB is less than 0.5 A and (4) the discharge process ends when the battery voltage is 100 V. It is important to mention that the bidirectional power converter used in the BB has a maximum capacity of 1 kW, for this reason, the maximum current that can be extracted or transferred to the bank is 10 A.

5. Conclusions

This study shows the design and implementation of a management and control system applied to an experimental prototype of a DC-µG for a maximum power of 1 kW with a DC bus with a voltage level 190 V, which can operate isolated or interconnected with the MG. The proposed DC-µG is made up of two photovoltaic systems, a complete bridge inverter, a BB and electronic loads (LED-type, fluorescent and computer equipment). For the administration and control of energy in the DC-µG, an EMS was implemented on the NI myRIO-1900 platform using the LabVIEW virtual programming software for the design of the EMS.

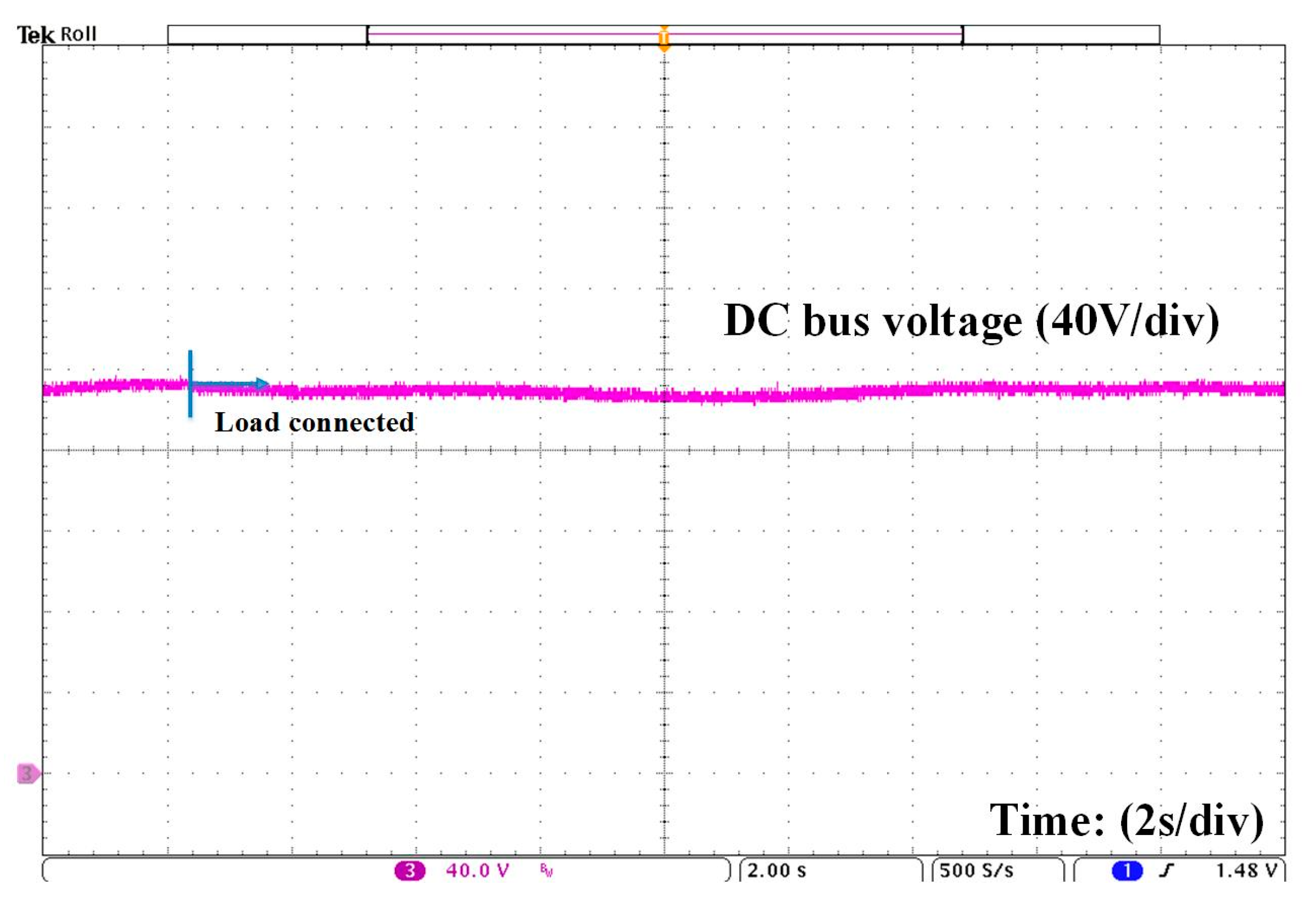

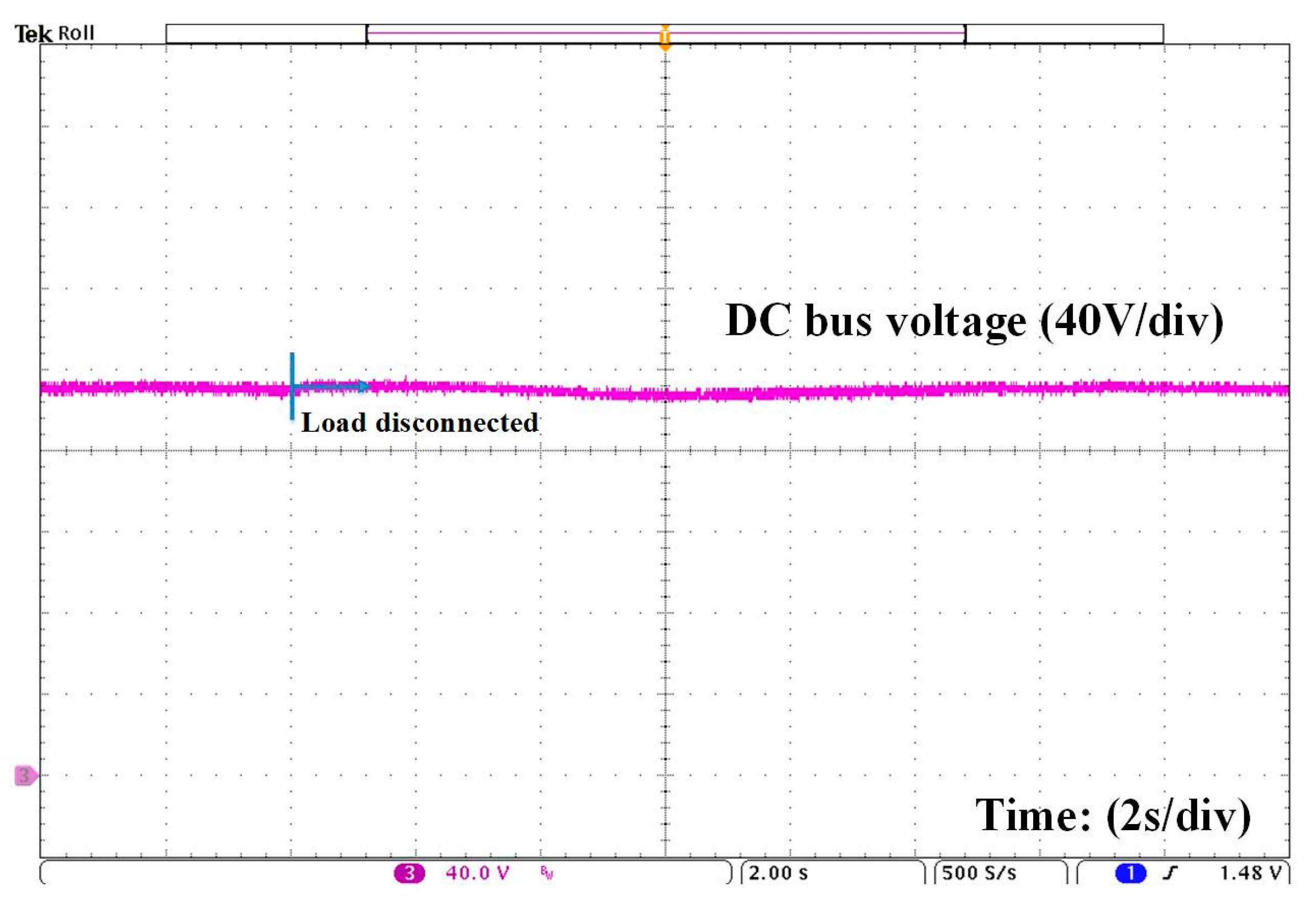

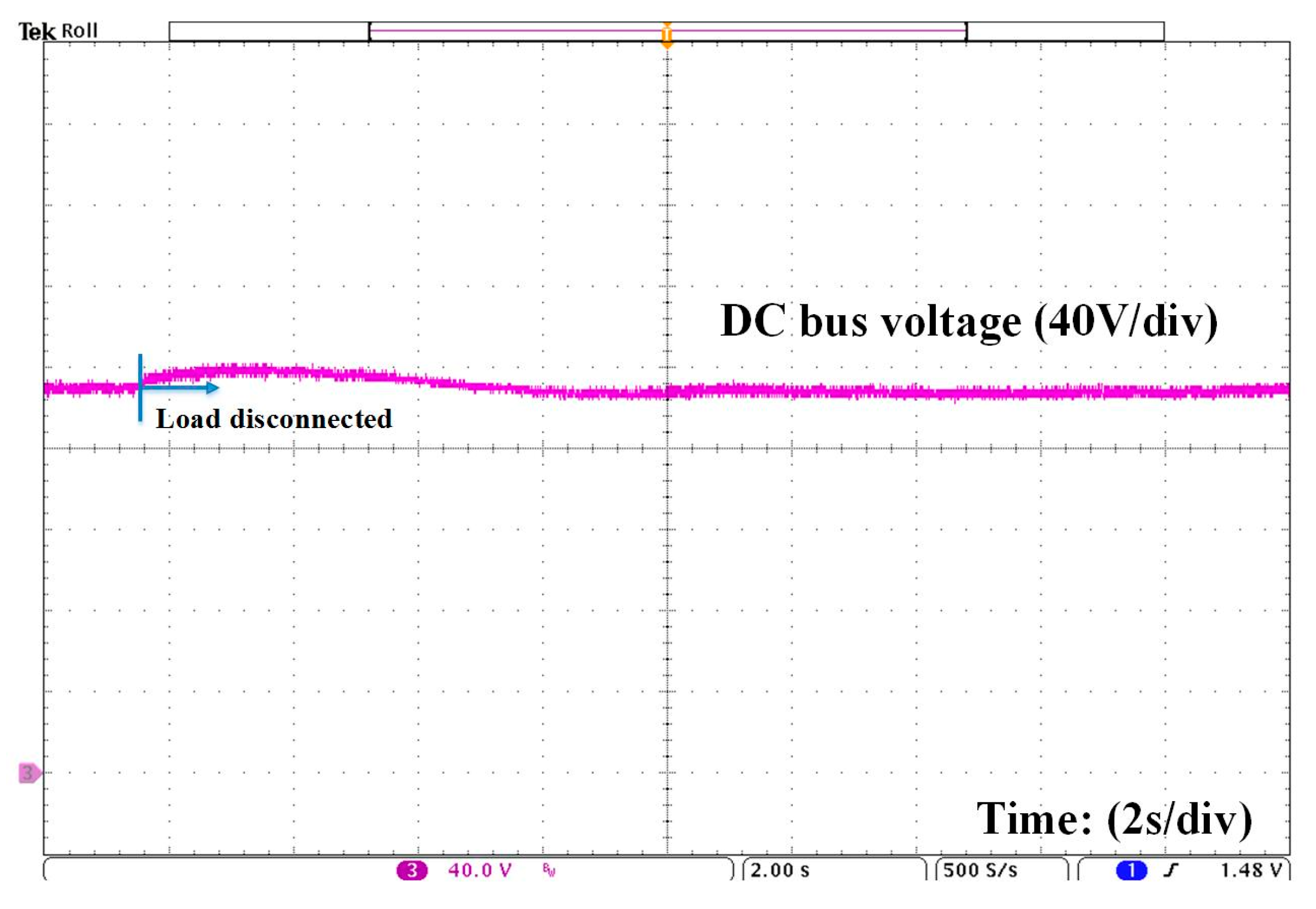

In the experimental results, the operation of the DC-µG is presented under principle operating conditions, all of them with the objective of evaluating the response of the DC bus to disturbances caused by the connection and disconnection of energy sources and real electronic loads. Throughout the different tests carried out, it was observed that the voltage bus of the proposed DC-µG remains within the operating range established in the design, and in each case the transitory response time ranged between 4 and 20 s. These periods are suitable for the design of the DC-µG because the voltage peaks and drops in the DC bus do not exceed 5% of the nominal value of the bus, this period is defined by the capacitance that the bus presents, that increased with the use of the bank of supercapacitors. This can result in the proposed bus voltage of the DC-µG being able to achieve short-term stability after being exposed to different disturbances. In addition, in the experiments performed, no inconvenience was observed in the operation of the power converters, so it is suggested that it is possible to extrapolate the design of the proposed DC-µG to a higher power.

Our proposal for administration and energy control of a DC-µG based on a state machine that presents response times similar to those shown in [

30]. The authors obtained times between 4 and 37 s in 15 different operation modes using a supervisory control based on a state machine to satisfy the energy demand of an AC/DC µG and a FC to maintain the S°C of a BB. The effectiveness of the proposed was evaluated through extensive numeric simulations.

During the experiments that were carried out in this research, problems related to system instability caused by the dynamic interaction of the converters and/or impedances were not observed. For the design of the PECs, design techniques such as the one reported by [

31] were used, taking into account whether the PEC commutes at a frequency at least ten times greater than the dynamics of the output voltage (or current), the switching noise is not mixed. The control technique used in parallel converters, in addition to the ratio of the impedances of the input/output sources contributed to the dynamics [

32]. However, for future studies, a stability study, under conditions of higher power and a greater number of distributed generations (DGs) and loads, is necessary to ensure stability in certain interaction scenarios in the MG. If the noise is present in the complete system, a stability analysis can be done using the impedance of the source output filter and the input filter of the loads to find the loop with the lowest gain and evaluate it against criteria such as phase gain- phase margin or others [

33,

34,

35].

Finally, for further study, the dimensioning of the components of the DC-µG proposed in order to make it economically viable will be considered. The methodology proposed by [

36] is viable for this purpose because it demonstrates the effectiveness of a sizing method based on genetic algorithms applied to EMS similar to that proposed in this article. From the point of view of power electronics, the increase in the number of DGs represents a greater number of switched power converters. Dynamics under voltage drop conditions could present a problem in the stability of the DC bus.