Emerging Tools for Energy System Design Increasing Economic and Environmental Sustainability

Abstract

1. Introduction

- Heat Integration and heat transfer.

- Integrated and newly developed heat exchangers.

- Integration of renewables.

- Roles in economic and environmental sustainability.

2. Emerging Tools

3. Issues Developed and Extended in this Special Volume

3.1. Heat Integration and Heat Transfer

3.2. Integrated and Newly Developed Heat Exchangers

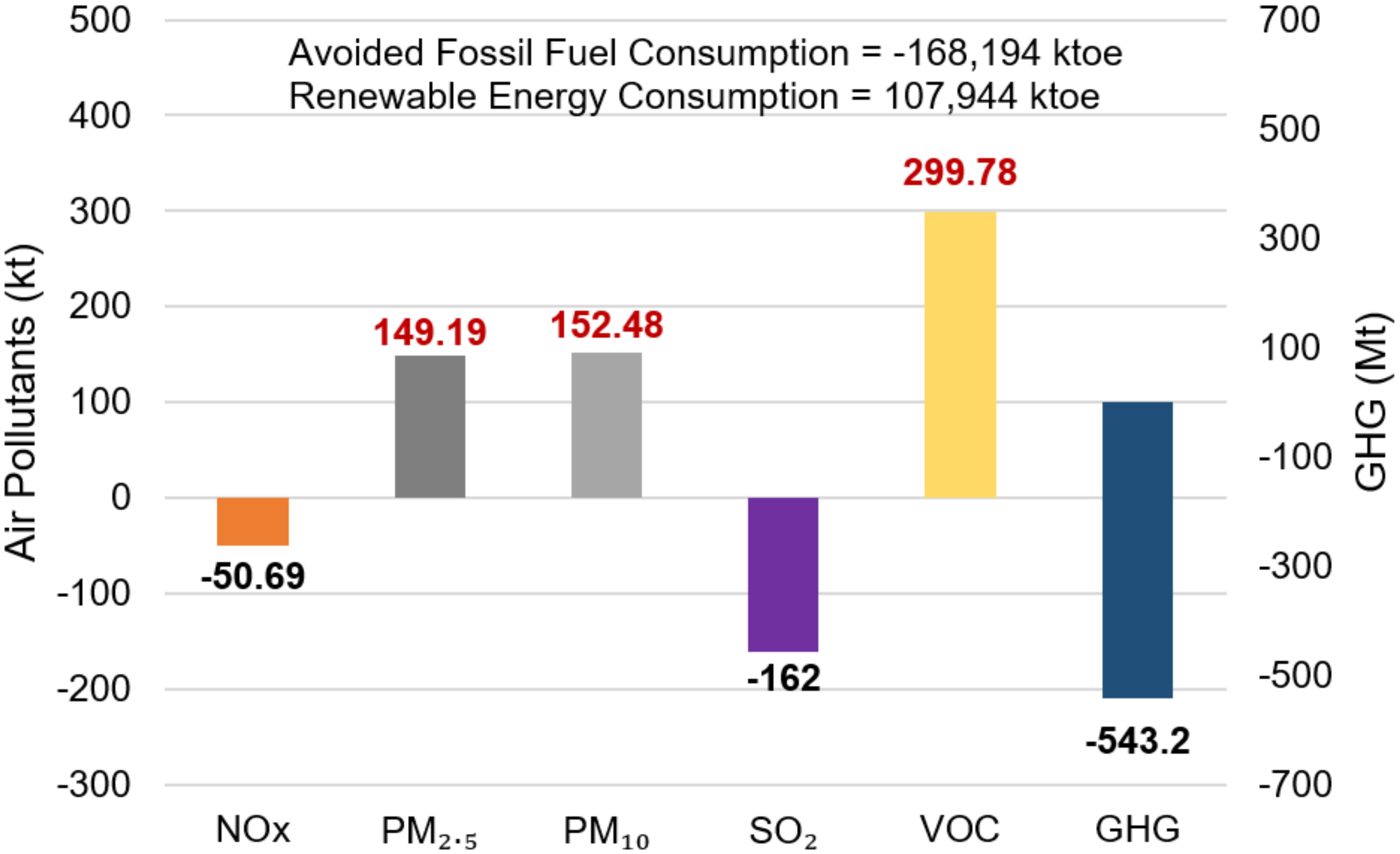

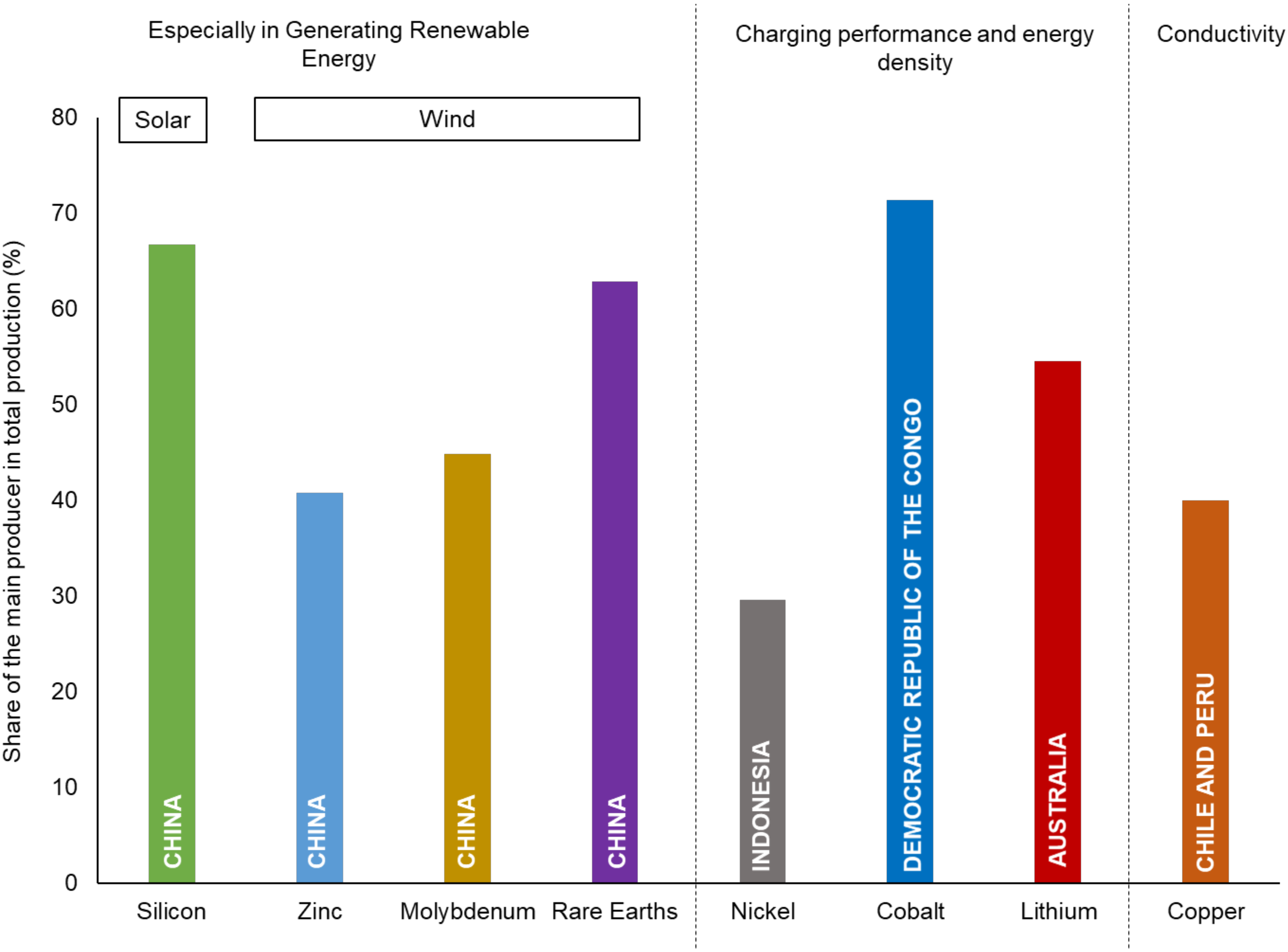

3.3. Integration of Renewables

3.4. Roles in Economic and Environmental Sustainability

4. Suggestions for Research Focus and Development

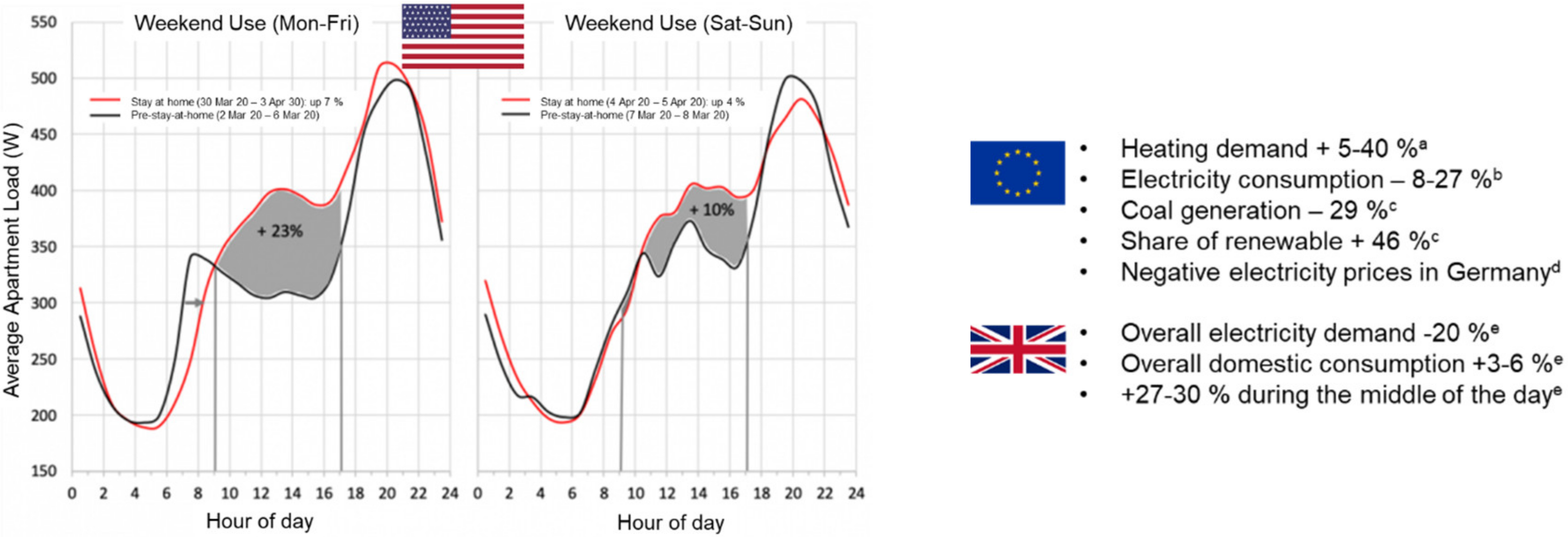

4.1. Social Impact of Novel and Fast-Developing Methodologies

4.2. Energy Storage

4.3. Implementation of IoT and Advanced Technologies

4.4. Non-Traditional Engineering Solutions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hong, J.H.; Kim, J.; Son, W.; Shin, H.; Kim, N.; Lee, W.K.; Kim, J. Long-term energy strategy scenarios for South Korea: Transition to a sustainable energy system. Energy Policy 2019, 127, 425–437. [Google Scholar] [CrossRef]

- Qin, J.; Liu, Y.; Grosvenor, R.; Lacan, F.; Jiang, Z. Deep learning-driven particle swarm optimisation for additive manufacturing energy optimisation. J. Clean. Prod. 2020, 245, 118702. [Google Scholar] [CrossRef]

- Liu, S.; Yuan, J.; Deng, W.; Luo, M.; Xie, Y.; Liang, Q.; Zou, Y.; He, Z.; Wu, H.; Cao, Y. High-efficiency organic solar cells with low non-radiative recombination loss and low energetic disorder. Nat. Photonics 2020, 14, 300–305. [Google Scholar] [CrossRef]

- Ochoa, G.V.; Rojas, J.P.; Forero, J.D. Advance Exergo-Economic Analysis of a Waste Heat Recovery System Using ORC for a Bottoming Natural Gas Engine. Energies 2020, 13, 267. [Google Scholar] [CrossRef]

- Marquant, J.F.; Mavromatidis, G.; Evins, R.; Carmeliet, J. Comparing different temporal dimension representations in distributed energy system design models. Energy Proc. 2017, 122, 907–912. [Google Scholar] [CrossRef]

- Weinand, J.M.; McKenna, R.; Mainzer, K. Spatial high-resolution socio-energetic data for municipal energy system analyses. Sci. Data 2019, 6, 1–6. [Google Scholar] [CrossRef]

- IEA. Renewables. 2020. Available online: www.iea.org/fuels-and-technologies/renewables (accessed on 4 June 2020).

- Larsen, M.A.D.; Drews, M. Water use in electricity generation for water-energy nexus analyses: The European case. Sci. Total Environ. 2019, 651, 2044–2058. [Google Scholar] [CrossRef]

- UCSUSA. Benefits of Renewable Energy Use. 2017. Available online: www.ucsusa.org/resources/benefits-renewable-energy-use (accessed on 2 June 2020).

- Fan, Y.V.; Klemeš, J.J.; Ko, C.H. Bioenergy carbon emissions footprint considering the biogenic carbon and secondary effects. Int. J. Energy Res. 2020. [Google Scholar] [CrossRef]

- Schmidt, O.; Melchior, S.; Hawkes, A.; Staffell, I. Projecting the future levelized cost of electricity storage technologies. Joule 2019, 3, 81–100. [Google Scholar] [CrossRef]

- Lazard. Levelized Cost of Energy and Levelized Cost Of Storage 2019. 2019. Available online: www.lazard.com/perspective/lcoe2019 (accessed on 1 June 2020).

- Perera, A.T.D.; Nik, V.M.; Wickramasinghe, P.U.; Scartezzini, J.L. Redefining energy system flexibility for distributed energy system design. Appl. Energy 2019, 253, 113572. [Google Scholar] [CrossRef]

- WNA (World Nuclear Association). Comparison of Lifecycle Greenhouse Gas Emissions of Various Electricity Generation Sources. 2011. Available online: www.world-nuclear.org/uploadedFiles/org/WNA/Publications/Working_Group_Reports/comparison_of_lifecycle.pdf (accessed on 4 June 2020).

- Jin, Y.; Behrens, P.; Tukker, A.; Scherer, L. Water use of electricity technologies: A global meta-analysis. Renew. Sustain. Energy Rev. 2019, 115, 109391. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Gerbens-Leenes, P.W.; Hoekstra, A.Y. The consumptive water footprint of electricity and heat: A global assessment. Environ. Sci. Water Res. Technol. 2015, 1, 285–297. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldinelli, G.; D’Alessandro, F.; Scrucca, F. Life cycle assessment of electricity production from renewable energies: Review and results harmonisation. Renew. Sustain. Energy Rev. 2015, 42, 1113–1122. [Google Scholar] [CrossRef]

- Amponsah, N.Y.; Troldborg, M.; Kington, B.; Aalders, I.; Hough, R.L. Greenhouse gas emissions from renewable energy sources: A review of lifecycle considerations. Renew. Sustain. Energy Rev. 2014, 39, 461–475. [Google Scholar] [CrossRef]

- EEA. Renewable Energy Impacts Dashboard. 2019. Available online: www.eea.europa.eu/themes/energy/renewable-energy/renewables-crucial-for-eu-decarbonisation (accessed on 4 June 2020).

- Lazard. Lazard’s Levelised Cost of Energy Analysis—Version 11.0. 2019. Available online: www.lazard.com/media/450337/lazard-levelized-cost-of-energy-version-110.pdf (accessed on 2 June 2020).

- Lazard. Lazard’s Levelised Cost of Energy Analysis—Version 12.0. 2019. Available online: www.lazard.com/media/450784/lazards-levelized-cost-of-energy-version-120-vfinal.pdf (accessed on 2 June 2020).

- Taylor, M. Cheaper than coal: IRENA’s Comprehensive Report on Cost Declines all Renewables Categories. 2019. Available online: energypost.eu/cheaper-than-coal-irenas-comprehensive-report-on-cost-declines-all-renewables-categories/ (accessed on 2 June 2020).

- Fiksel, J. Designing resilient, sustainable systems. Environ. Sci. Technol. 2003, 37, 5330–5339. [Google Scholar] [CrossRef] [PubMed]

- Kambhampati, U.S. The Whole Idea of Global Value Chains will be Reconsidered After Coronavirus. 2020. Available online: theconversation.com/the-whole-idea-of-global-value-chains-will-be-reconsidered-after-coronavirus-137132 (accessed on 4 June 2020).

- IEA. Clean Energy Progress after the Covid-19 Crisis will need Reliable Supplies of Critical Minerals. 2020. Available online: www.iea.org/articles/clean-energy-progress-after-the-covid-19-crisis-will-need-reliable-supplies-of-critical-minerals#reference-4 (accessed on 4 June 2020).

- Statista. Major Countries in Worldwide Zinc Mine Production from 2010–2019. 2020. Available online: www.statista.com/statistics/264634/zinc-production-by-country/ (accessed on 4 June 2020).

- Statista. Major Countries Silicon Production from 2014–2019. 2020. Available online: www.statista.com/statistics/268108/world-silicon-production-by-country// (accessed on 4 June 2020).

- IEA. Reductions of Electricity Demand after Implementing Lockdown Measures in Selected Countries, Weather Corrected, 0 to 68 Days. 2020. Available online: www.iea.org/data-and-statistics/charts/reductions-of-electricity-demand-after-implementing-lockdown-measures-in-selected-countries-weather-corrected-0-to-68-days/ (accessed on 4 June 2020).

- IEA. Energy Investment is Set to Fall by One Fifty in 2020 due to the Covid-19 Pandemic. 2020. Available online: www.iea.org/reports/world-energy-investment-2020/key-findings#abstract (accessed on 4 June 2020).

- Amelang, S. Negative Electricity Prices: Lockdown’s Demand Slump Exposes Inflexibility of German Power. 2020. Available online: energypost.eu/negative-electricity-prices-lockdowns-demand-slump-exposes-inflexibility-of-german-power/ (accessed on 4 June 2020).

- Meinrenken, C.; Modi, V.; Mckeown, K.; Culligan, P. New data suggest COVID-19 is shifting the burden of energy cost to households. 2020. Available online: blogs.ei.columbia.edu/2020/04/21/covid-19-energy-costs-households// (accessed on 4 June 2020).

- Amelang, S. Coronavirus Lockdown Pushes Up Heating Demand Across Europe—Report. 2020. Available online: www.cleanenergywire.org/news/coronavirus-lockdown-pushes-heating-demand-across-europe-report/ (accessed on 4 June 2020).

- Kortenhorst, J. Here’s What we Know and Don’t Know about the Energy Transition. 2020. Available online: www.weforum.org/agenda/2020/04/heres-what-the-pandemic-means-for-the-energy-transition// (accessed on 4 June 2020.).

- WARTSILA. European Responses to Covid-19 Accelerate the Electricity System Transition by a Decade. 2020. Available online: news.cision.com/wartsila-corporation/r/european-responses-to-covid-19-accelerate-the-electricity-system-transition-by-a-decade--according-t,c3090780/ (accessed on 4 June 2020).

- BBC. Coronavirus: Domestic Electricity use up During Day as Nation Works From Home. 2020. Available online: www.bbc.com/news/technology-52331534/ (accessed on 4 June 2020).

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualising the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Mayer, A.; Haas, W.; Wiedenhofer, D.; Krausmann, F.; Nuss, P.; Blengini, G.A. Measuring Progress towards a Circular Economy: A Monitoring Framework for Economy-wide Material Loop Closing in the EU28. J. Ind. Ecol. 2019, 23, 62–76. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; de Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Loucks, D.P.; van Beek, E. Models for Identifying and Evaluating Alternatives. In Water Resource Systems Planning and Management; Springer: Cham, Switzerland, 2017; pp. 73–91. [Google Scholar]

- LLNL (Lawrence Livermore National Laboratory). Energy Flow Chart. Available online: flowcharts.llnl.gov/ (accessed on 4 June 2020).

- Papapetrou, M.; Kosmadakis, G.; Cipollina, A.; La Commare, U.; Micale, G. Industrial waste heat: Estimation of the technically available resource in the EU per industrial sector, temperature level and country. Appl. Therm. Eng. 2018, 138, 207–216. [Google Scholar] [CrossRef]

- Bianchi, G.; Panayiotou, G.P.; Aresti, L.; Kalogirou, S.A.; Florides, G.A.; Tsamos, K.; Christodoulides, P. Estimating the waste heat recovery in the European Union Industry. Energy Ecol. Environ. 2019, 4, 211–221. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Varbanov, P.V.; Walmsley, T.G.; Jia, X.X. New directions in the implementation of Pinch Methodology (PM). Renew. Sustain. Energy Rev. 2018, 98, 439–468. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Varbanov, P.S. Process Intensification and Integration: An assessment. Clean Technol. Environ. Policy 2013, 15, 417–422. [Google Scholar] [CrossRef]

- Klemeš, J.J. (Ed.) Assessing and Measuring Environmental Impact and Sustainability; Elsevier/Butterworth-Heinemann: Oxford, UK, 2015; 559p, ISBN 978-0-12-799968-5. [Google Scholar]

- Čuček, L.; Klemeš, J.J.; Kravanja, Z. A Review of Footprint Analysis Tools for Monitoring Impacts on Sustainability. J. Clean. Prod. 2012, 34, 9–20. [Google Scholar] [CrossRef]

- Mann, M.E. Greenhouse Gas. 2019. Available online: www.britannica.com/science/greenhouse-gas#ref280534 (accessed on 1 June 2020).

- Klemeš, J.J.; Wang, Q.W.; Varbanov, P.S.; Zeng, M.; Chin, H.H.; Lal, N.S.; Li, N.Q.; Wang, B.; Wang, X.C.; Walmsley, T.G. Heat transfer enhancement, intensification and optimisation in heat exchanger network retrofit and operation. Renew. Sustain. Energy Rev. 2020, 120, 109644. [Google Scholar] [CrossRef]

- Forsberg, C.H. Heat Transfer Principles and Applications; Academic Press/Elsevier: Cambridge, MA, USA, 2020. [Google Scholar] [CrossRef]

- Luo, A.; Fang, H.; Xia, J.; Lin, B.; Yiang, Y. Mapping potentials of low-grade industrial waste heat in Northern China. Resour. Conserv. Recycl. 2017, 125, 335–348. [Google Scholar] [CrossRef]

- Tovazhnyanskyy, L.; Klemeš, J.J.; Kapustenko, P.; Arsenyeva, O.; Perevertaylenk, O.; Arsenyev, P. Optimal Design of Welded Plate Heat Exchanger for Ammonia Synthesis Column: An Experimental Study with Mathematical Optimisation. Energies 2020, 13, 2847. [Google Scholar] [CrossRef]

- Vergara-Dietrich, J.D.; Morato, M.M.; Mendes, P.R.; Cani, A.A.; Normey-Rico, J.E.; Bordons, C. Advanced chance-constrained predictive control for the efficient energy management of renewable power systems. J. Process Control 2019, 74, 120–132. [Google Scholar] [CrossRef]

- Alavi, S.A.; Ahmadian, A.; Aliakbar-Golkar, M. Optimal probabilistic energy management in a typical micro-grid based-on robust optimisation and point estimate method. Energy Convers. Manag. 2015, 95, 314–325. [Google Scholar] [CrossRef]

- Mehrjerdi, H.; Rakhshani, E. Correlation of multiple time-scale and uncertainty modelling for renewable energy-load profiles in wind powered system. J. Clean. Prod. 2019, 236, 117644. [Google Scholar] [CrossRef]

- Talaat, M.; Farahat, M.A.; Elkholy, M.H. Renewable power integration: Experimental and simulation study to investigate the ability of integrating wave, solar and wind energies. Energy 2019, 170, 668–682. [Google Scholar] [CrossRef]

- Baum, Z.; Palatnik, R.R.; Ayalon, O.; Elmakis, D.; Frant, S. Harnessing households to mitigate renewables intermittency in the smart grid. Renew. Energy 2019, 132, 1216–1229. [Google Scholar] [CrossRef]

- Fiedler, T. Simulation of a power system with large renewable penetration. Renew. Energy 2019, 130, 319–328. [Google Scholar] [CrossRef]

- Draycott, S.; Sellar, B.; Davey, T.; Noble, D.R.; Venugopal, V.; Ingram, D.M. Capture and simulation of the ocean environment for offshore renewable energy. Renew. Sustain. Energy Rev. 2019, 104, 15–29. [Google Scholar] [CrossRef]

- Wagh, M.M.; Kulkarni, V.V. Modeling and optimisation of integration of Renewable Energy Resources (RER) for minimum energy cost, minimum CO2 Emissions and sustainable development, in recent years: A review. Mater. Today Proc. 2018, 5, 11–21. [Google Scholar] [CrossRef]

- Al Nouss, A.; McKay, G.; Al-Ansari, T. Production of syngas via gasification using optimum blends of biomass. J. Clean. Prod. 2020, 242, 118499. [Google Scholar] [CrossRef]

- Peng, Z.; Herfatmanesh, M.R.; Liu, Y. Cooled solar PV panels for output energy efficiency optimisation. Energy Convers. Manag. 2017, 150, 949–955. [Google Scholar] [CrossRef]

- Bravo, R.; Ortiz, C.; Chacartegui, R.; Friedrich, D. Hybrid solar power plant with thermochemical energy storage: A multi-objective operational optimisation. Energy Convers. Manag. 2020, 205, 112421. [Google Scholar] [CrossRef]

- Zheng, Y.; Jenkins, B.M.; Kornbluth, K.; Kendall, A.; Træholt, C. Optimisation of a biomass-integrated renewable energy microgrid with demand side management under uncertainty. Appl. Energy 2018, 230, 836–844. [Google Scholar] [CrossRef]

- Nowdeh, S.A.; Davoudkhani, I.F.; Moghaddam, M.H.; Najmi, E.S.; Abdelaziz, A.Y.; Ahmadi, A.; Gandoman, F.H. Fuzzy multi-objective placement of renewable energy sources in distribution system with objective of loss reduction and reliability improvement using a novel hybrid method. Appl. Soft Comput. 2019, 77, 761–779. [Google Scholar] [CrossRef]

- Jafari, A.; Khalili, T.; Ganjehlou, H.G.; Bidram, A. Optimal integration of renewable energy sources, diesel generators, and demand response program from pollution, financial, and reliability viewpoints: A multi-objective approach. J. Clean. Prod. 2020, 247, 119100. [Google Scholar] [CrossRef]

- Rinaldi, A.; Soini, M.C.; Patel, M.K.; Parra, D. Optimised allocation of PV and storage capacity among different consumer types and urban settings: A prospective analysis for Switzerland. J. Clean. Prod. 2020, 259, 120762. [Google Scholar] [CrossRef]

- Santibañez-Aguilar, J.E.; Castellanos, S.; Flores-Tlacuahuac, A.; Shapiro, B.B.; Powell, D.M.; Buonassisi, T.; Kammen, D.M. Design of domestic photovoltaics manufacturing systems under global constraints and uncertainty. Renew. Energy 2020, 148, 1174–1189. [Google Scholar] [CrossRef]

- Zakaria, A.; Ismail, F.B.; Lipu, M.H.; Hannan, M.A. Uncertainty models for stochastic optimisation in renewable energy applications. Renew. Energy 2020, 145, 1543–1571. [Google Scholar] [CrossRef]

- Aviso, K.B.; Marfori, I.A.V.; Tan, R.R.; Ubando, A.T. Optimising abnormal operations of off-grid community utility systems with fuzzy P-graph. Energy 2020, 202, 117725. [Google Scholar] [CrossRef]

- Cuesta, M.A.; Castillo-Calzadilla, T.; Borges, C.E. A critical analysis on hybrid renewable energy modeling tools: An emerging opportunity to include social indicators to optimise systems in small communities. Renew. Sustain. Energy Rev. 2020, 122, 109691. [Google Scholar] [CrossRef]

- Akhtari, M.R.; Shayegh, I.; Karimi, N. Techno-economic assessment and optimisation of a hybrid renewable earth-air heat exchanger coupled with electric boiler, hydrogen, wind and PV configurations. Renew. Energy 2020, 148, 839–851. [Google Scholar] [CrossRef]

- Armin Razmjoo, A.; Sumper, A.; Davarpanah, A. Energy sustainability analysis based on SDGs for developing countries. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 1041–1056. [Google Scholar] [CrossRef]

- Baldasso, E.; Mondejar, M.E.; Larsen, U.; Haglind, F. Regression Models for the Evaluation of the Techno-Economic Potential of Organic Rankine Cycle-Based Waste Heat Recovery Systems on Board Ships Using Low Sulfur Fuels. Energies 2020, 13, 1378. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Tabatabaei, M.; Tsapekos, P.; Rafiee, S.; Aghbashlo, M.; Lindeneg, S.; Angelidaki, I. Environmental life cycle assessment of different biorefinery platforms valorising municipal solid waste to bioenergy, microbial protein, lactic and succinic acid. Renew. Sustain. Energy Rev. 2020, 117, 109493. [Google Scholar] [CrossRef]

- Ramírez-Islas, M.E.; Güereca, L.P.; Sosa-Rodriguez, F.S.; Cobos-Peralta, M.A. Environmental assessment of energy production from anaerobic digestion of pig manure at medium-scale using life cycle assessment. Waste Manag. 2020, 102, 85–96. [Google Scholar] [CrossRef] [PubMed]

- Longo, S.; Beccali, M.; Cellura, M.; Guarino, F. Energy and environmental life-cycle impacts of solar-assisted systems: The application of the tool “ELISA”. Renew. Energy 2020, 145, 29–40. [Google Scholar] [CrossRef]

- Stamford, L. Life cycle sustainability assessment in the energy sector. In Biofuels for a More Sustainable Future; Elsevier: Amsterdam, The Netherlands; Oxford, UK; Cambridge, MA, USA, 2020; pp. 115–163. [Google Scholar]

- Duan, C.; Chen, B. Driving factors of water-energy nexus in China. Appl. Energy 2020, 257, 113984. [Google Scholar] [CrossRef]

- Fan, Y.V.; Tan, R.R.; Klemeš, J.J. A system analysis tool for sustainable biomass utilisation considering the Emissions-Cost Nexus. Energy Convers. Manag. 2020, 210, 112701. [Google Scholar] [CrossRef]

- Razmjoo, A.A.; Sumper, A.; Davarpanah, A. Development of sustainable energy indexes by the utilisation of new indicators: A comparative study. Energy Rep. 2019, 5, 375–383. [Google Scholar] [CrossRef]

- Liu, G. Development of a general sustainability indicator for renewable energy systems: A review. Renew. Sustain. Energy Rev. 2014, 31, 611–621. [Google Scholar] [CrossRef]

- Jóźwiak, P.; Hercog, J.; Kiedrzyńska, A.; Badyda, K.; Olevano, D. Thermal Effects of Natural Gas and Syngas Co-Firing System on Heat Treatment Process in the Preheating Furnace. Energies 2020, 13, 1698. [Google Scholar] [CrossRef]

- Echi, S.; Bouabidi, A.; Driss, Z.; Abid, M.S. CFD simulation and optimisation of industrial boiler. Energy 2019, 169, 105–114. [Google Scholar] [CrossRef]

- Silva, J.; Teixeira, J.; Teixeira, S.; Preziati, S.; Cassiano, J. CFD Modeling of Combustion in Biomass Furnace. Energy Proc. 2017, 120, 665–672. [Google Scholar] [CrossRef]

- You, S.; Ok, Y.S.; Tsang, D.C.W.; Kwon, E.; Wang, C.-H. Towards practical application of gasification: A critical review from syngas and biochar perspectives. Crit. Rev. Environ. Sci. Technol. 2018, 48, 1165–1213. [Google Scholar] [CrossRef]

- Hancsók, J.; Kasza, T.; Visnyei, O. Isomerisation of n-C5/C6 Bioparaffins to Gasoline Components with High Octane Number. Energies 2020, 13, 1672. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Q.; Ding, M.; Wang, C.; Li, Y.; Zhang, Q.; Ma, L. Bio-gasoline production by coupling of biomass catalytic pyrolysis and oligomerisation. Energy Proc. 2017, 105, 858–863. [Google Scholar] [CrossRef]

- Sauciuc, A.; Abosteif, Z.; Weber, G.; Potetz, A.; Rauch, R.; Hofbauer, H.; Schaub, G.; Dumitrescu, L. Influence of operating conditions on the performance of biomass-based Fischer-Tropsch synthesis. Biomass Convers. Biorefin. 2012, 2, 253–263. [Google Scholar] [CrossRef]

- Kwon, E.E.; Kim, Y.T.; Kim, H.J.; Lin, K.Y.L.; Kim, K.H.; Lee, J.; Huber, G.W. Production of high-octane gasoline via hydrodeoxygenation of sorbitol over palladium-based bimetallic catalysts. J. Environ. Manag. 2018, 227, 329–334. [Google Scholar] [CrossRef]

- Huber, G.W.; Chedda, J.N.; Barre, C.J.; Dumestic, J.A. Production of liquid alkanes by aqueous-phase processing of biomass-derived carbohydrates. Science 2005, 308, 1446–1450. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Yang, J.; Guo, Z.; Wang, Q.; Sunden, B. Numerical Study of Heat Transfer in Gravity-Driven Particle Flow around Tubes with Different Shapes. Energies 2020, 13, 1961. [Google Scholar] [CrossRef]

- Bartsch, P.; Zunft, S. Granular flow around the horizontal tubes of a particle heat exchanger: DEM-simulation and experimental validation. Solar Energy 2019, 182, 48–56. [Google Scholar] [CrossRef]

- Liu, J.; Yu, Q.; Peng, J.; Hu, X.; Duan, W. Thermal energy recovery from high-temperature blast furnace slag particles. Int. Commun. Heat Mass Transfer 2015, 69, 23–28. [Google Scholar] [CrossRef]

- Létal, T.; Turek, V.; Babička Fialová, D.; Jegla, Z. Nonlinear Finite Element Analysis-Based Flow Distribution and Heat Transfer Model. Energies 2020, 13, 1664. [Google Scholar] [CrossRef]

- Zhou, J.; Ding, M.; Bian, H.; Zhang, Y.; Sun, Z. Characteristics of flow distribution in central-type compact parallel-flow heat exchangers with modified inlet and header. Appl. Therm. Eng. 2020, 166, 114636. [Google Scholar] [CrossRef]

- Łopata, S.; Ocłoń, P.; Stelmach, T. Investigation of flow non-uniformities in the cross-flow heat exchanger with elliptical tubes. E3S Web Conf. 2019, 108, 01009. [Google Scholar] [CrossRef]

- Karvounis, P.; Koubogiannis, D.; Hontzopoulos, E.; Hatziapostolou, A. Numerical and experimental study of flow characteristics in solar collector manifolds. Energies 2019, 12, 1431. [Google Scholar] [CrossRef]

- Pismennyi, E.; Polupan, G.; Carvajal-Mariscal, I.; Sanchez-Silva, F.; Pioro, I. Examples of calculations. In Handbook for Transversely Finned Tube Heat Exchanger Design; Academic Press: Cambridge, MA, USA, 2016; Chapter 7; pp. 83–106. [Google Scholar]

- ANSYS, Inc. ANSYS Fluent User’s Guide, Version 2019 R3; ANSYS, Inc.: Canonsburgh, PA, USA, 2019. [Google Scholar]

- Tang, W.; Kukulka, D.; Li, W.; Smith, R. Comparison of the Evaporation and Condensation Heat Transfer Coefficients on the External Surface of Tubes in the Annulus of a Tube-in-Tube Heat Exchanger. Energies 2020, 13, 952. [Google Scholar] [CrossRef]

- Shafaee, M.; Mashouf, H.; Sarmadian, A.; Mohseni, S.G. Evaporation heat transfer and pressure drop characteristics of R-600a in horizontal smooth and helically dimpled tubes. Appl. Eng. 2016, 107, 28–36. [Google Scholar] [CrossRef]

- Li, W.; Chen, X.; Chen, J.-X.; Sun, Z.-C.; Simon, T.W. Shell-Side Flow Condensation of R410A on Horizontal Tubes at Low-Mass Fluxes. J. Heat Transf. 2016, 139, 011501. [Google Scholar] [CrossRef]

- Gai, L.; Varbanov, P.; Walmsley, T.; Klemeš, J. Critical Analysis of Process Integration Options for Joule-Cycle and Conventional Heat Pumps. Energies 2020, 13, 635. [Google Scholar] [CrossRef]

- Radermacher, R.; Hwang, Y. Vapor Compression Heat Pumps with Refrigerant Mixes; Taylor & Francis: Boca Raton, FL, USA, 2005. [Google Scholar]

- Lorentzen, G. Trans-Critical Vapour Compression Cycle. Device. Patent Application No. WO1990007683A1, 12 July 1990. [Google Scholar]

- Fu, C.; Gundersen, T. A Novel Sensible Heat Pump Scheme for Industrial Heat Recovery. Ind. Eng. Chem. Res. 2016, 55, 967–977. [Google Scholar] [CrossRef]

- Wang, B.; Klemeš, J.; Varbanov, P.; Zeng, M. An Extended Grid Diagram for Heat Exchanger Network Retrofit Considering Heat Exchanger Types. Energies 2020, 13, 2656. [Google Scholar] [CrossRef]

- Yong, J.Y.; Varbanov, P.S.; Klemeš, J.J. Heat exchanger network retrofit supported by extended Grid Diagram and heat path development. Appl. Therm. Eng. 2015, 89, 1033–1045. [Google Scholar] [CrossRef]

- Soršak, A.; Kravanja, Z. Simultaneous MINLP synthesis of heat exchanger networks comprising different exchanger types. Comput. Chem. Eng. 2002, 26, 599–615. [Google Scholar] [CrossRef]

- Yong, J.Y.; Varbanov, P.S.; Klemeš, J.J. Shifted retrofit thermodynamic diagram: A modified tool for retrofitting heat exchanger networks. Chem. Eng. Trans. 2014, 39, 97–102. [Google Scholar]

- Langner, C.; Svensson, E.; Harvey, S.A. Framework for Flexible and Cost-Efficient Retrofit Measures of Heat Exchanger Networks. Energies 2020, 13, 1472. [Google Scholar] [CrossRef]

- Short, M.; Isafiade, A.J.; Fraser, D.M.; Kravanja, Z. Two-step hybrid approach for the synthesis of multi-period heat exchanger networks with detailed exchanger design. Appl. Therm. Eng. 2016, 105, 807–821. [Google Scholar] [CrossRef]

- Pintarič, Z.N.; Kravanja, Z.A. Methodology for the synthesis of heat exchanger networks having large numbers of uncertain parameters. Energy 2015, 92, 373–382. [Google Scholar] [CrossRef]

- Sheng, Y.; Liu, L.; Zhuang, Y.; Zhang, L.; Du, J. Simultaneous Synthesis of Heat Exchanger Networks Considering Steam Supply and Various Steam Heater Locations. Energies 2020, 13, 1467. [Google Scholar] [CrossRef]

- Elsido, C.; Martelli, E.; Grossmann, I.E. A Bilevel Decomposition Method for the Simultaneous Synthesis of Utility Systems, Rankine Cycles and Heat Exchanger Networks. Comp. Aided Process Eng. 2018, 43, 373–378. [Google Scholar]

- Wang, Q.; Guo, J.; Chen, P. Recent progress towards mild-condition ammonia synthesis. J. Energy Chem. 2019, 36, 25–36. [Google Scholar] [CrossRef]

- Khademi, M.H.; Sabbaghi, R.S. Comparison between three types of ammonia synthesis reactor configurations in terms of cooling methods. Chem. Eng. Res. Des. 2017, 128, 306–317. [Google Scholar] [CrossRef]

- Arsenyev, P.Y.; Tovazhnyansky, L.; Klemeš, J.J.; Arsenyeva, O.P.; Perevertaylenko, O.Y.; Kapustenko, P.O. The Optimal Design of Welded Plate Heat Exchanger with Intensified Heat Transfer for Ammonia Synthesis Column. Chem. Eng. Trans. 2019, 76, 61–66. [Google Scholar]

- Klemeš, J.J.; Arsenyeva, O.; Kapustenko, P.; Tovazhnyanskyy, L. Compact Heat Exchangers for Energy Transfer Intensification; CRC Press/Taylor & Francis Company: New York, NY, USA, 2015; Volume 372, pp. 54–65, ISBN-13: 978-1482232592. [Google Scholar]

- Walmsley, M.R.; Walmsley, T.G.; Atkins, M.J.; Neale, J.R. Sustainable Milk Powder Production using Enhanced Process Integration and 100% Renewable Energy. Chem. Eng. Trans. 2016, 2016, 559–564. [Google Scholar]

- Hechelmann, R.; Seevers, J.; Otte, A.; Sponer, J.; Stark, M. Renewable Energy Integration for Steam Supply of Industrial Processes—A Food Processing Case Study. Energies 2020, 13, 253. [Google Scholar] [CrossRef]

- Hoo, P.Y.; Phun Chien, C.; Fan, Y.V. Operational Management Implemented in Biofuel Upstream Supply Chain and Downstream International Trading: Current Issues in Southeast Asia. Energies 2020, 13, 1799. [Google Scholar]

- Čuček, L.; Martín, M.; Grossmann, I.E.; Kravanja, Z. Multi-Period Synthesis of Optimally Integrated Biomass and Bioenergy Supply Network. Comput. Chem. Eng. 2014, 66, 57–70. [Google Scholar] [CrossRef]

- Asadi, E.; Habibi, F.; Nickel, S.; Sahebi, H.A. Bi-Objective Stochastic Location-Inventory-Routing Model for Microalgae-Based Biofuel Supply Chain. Appl. Energy 2018, 228, 2235–2261. [Google Scholar] [CrossRef]

- How, B.S.; Lam, H.L. Integrated Palm Biomass Supply Chain toward Sustainable Management. Chem. Prod. Process Model. 2017, 12, 1–19. [Google Scholar] [CrossRef]

- Hren, R.; Petrovič, A.; Čuček, L.; Simonič, M. Determination of Various Parameters during Thermal and Biological Pretreatment of Waste Materials. Energies 2020, 13, 2262. [Google Scholar] [CrossRef]

- Seidl, P.R.; Goulart, A.K. Pretreatment processes for lignocellulosic biomass conversion to biofuels and bioproducts. Curr. Opin. Green Sustain. Chem. 2016, 2, 48–53. [Google Scholar] [CrossRef]

- Pavlas, M.; Dvořáček, J.; Pitschke, T.; Peche, R. Biowaste Treatment and Waste-To-Energy—Environmental Benefits. Energies 2020, 13, 1994. [Google Scholar] [CrossRef]

- Reyes-Torres, M.; Oviedo-Ocaña, E.R.; Dominguez, I.; Komilis, D.; Sánchez, A.A. Systematic review on the composting of green waste: Feedstock quality and optimisation strategies. Waste Manag. 2018, 77, 486–499. [Google Scholar] [CrossRef]

- Fan, Y.V.; Klemeš, J.J.; Lee, C.T.; Perry, S. Anaerobic digestion of municipal solid waste: Energy and carbon emission footprint. J. Environ. Manag. 2018, 223, 888–897. [Google Scholar] [CrossRef]

- Ferdan, T.; Pavlas, M.; Nevrlý, V.; Šomplák, R. Greenhouse Gas Emissions from Thermal Treatment of Non-Recyclable Municipal Waste. Front. Chem. Sci. Eng. 2018, 12, 815–831. [Google Scholar] [CrossRef]

- Jensen, M.B.; Møller, J.; Scheutz, C. Comparison of the organic waste management systems in the Danish-German border region using life cycle assessment (LCA). Waste Manag. 2016, 49, 491–504. [Google Scholar] [CrossRef] [PubMed]

- Cormos, A.; Dragan, S.; Petrescu, L.; Sandu, V.; Cormos, C. Techno-Economic and Environmental Evaluations of Decarbonized Fossil-Intensive Industrial Processes by Reactive Absorption CO2 Capture Systems. Energies 2020, 13, 1268. [Google Scholar] [CrossRef]

- Fang, M.; Yi, N.; Di, W.; Wang, T.; Wang, Q. Emission and control of flue gas pollutants in CO2 chemical absorption system—A review. Int. J. Greenh. Gas Control 2020, 93, 102904. [Google Scholar] [CrossRef]

- Fan, L.S. Chemical Looping Systems for Fossil Energy Conversions; Wiley-AIChE: Hoboken, NJ, USA, 2010. [Google Scholar]

- Castro, M.; Alcanzare, M.; Esparcia, E.; Ocon, J.A. Comparative Techno-Economic Analysis of Different Desalination Technologies in Off-Grid Islands. Energies 2020, 13, 2261. [Google Scholar] [CrossRef]

- Tafech, A.; Milani, D.; Abbas, A. Water storage instead of energy storage for desalination powered by renewable energy—King Island case study. Energies 2016, 9, 839. [Google Scholar] [CrossRef]

- Haraldsson, J.; Johansson, M.T. Energy efficiency in the supply chains of the aluminium industry: The cases of five products made in Sweden. Energies 2019, 12, 245. [Google Scholar] [CrossRef]

- Gomilšek, R.; Čuček, L.; Homšak, M.; Tan, R.; Kravanja, Z. Carbon Emissions Constrained Energy Planning for Aluminum Products. Energies 2020, 13, 2753. [Google Scholar] [CrossRef]

- Tan, R.R.; Foo, D.C. Pinch analysis approach to carbon-constrained energy sector planning. Energy 2007, 562, 1422–1429. [Google Scholar] [CrossRef]

- Foo, D.C.; Tan, R.R.; Ng, D.K. Carbon and footprint-constrained energy planning using cascade analysis technique. Energy 2008, 33, 1480–1488. [Google Scholar] [CrossRef]

- Manan, Z.A.; Tan, Y.L.; Foo, D.C.Y. Targeting the minimum water flow rate using water cascade analysis technique. AIChE J. 2004, 50, 3169–3183. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Varbanov, P.S.; Kravanja, Z. Recent Developments in Process Integration. Chem. Eng. Res. Des. 2013, 91, 2037–2053. [Google Scholar] [CrossRef]

- Yang, H.; Ma, L.; Li, Z.A. Method for Analysing Energy-Related Carbon Emissions and the Structural Changes: A Case Study of China from 2005 to 2015. Energies 2020, 13, 2076. [Google Scholar] [CrossRef]

- Ma, L.; Allwood, J.M.; Cullen, J.M.; Li, Z. The use of energy in China: Tracing the flow of energy from a primary source to demand drivers. Energy 2012, 40, 174–188. [Google Scholar] [CrossRef]

- Premlall, K.; Lokhat, D. Reducing Energy Requirements in the Production of Acrylic Acid: Simulation and Design of a Multitubular Reactor Train. Energies 2020, 13, 1971. [Google Scholar] [CrossRef]

- Redlingshofer, H.; Fischer, A.; Weckbecker, K.H.; Emig, G. Kinetic modelling of the heterogeneously catalysed oxidation of propene to acrolein in a catalytic wall reactor. Ind. Eng. Chem. Res. 2003, 42, 5482–5488. [Google Scholar] [CrossRef]

- Estenfelder, M.; Lintz, H.G. Simultaneous determination of reaction kinetics and oxygen activity in single-phase oxidic catalysts and their mixture during partial oxidations. J. Catal. 2002, 209, 177–185. [Google Scholar] [CrossRef]

- Snyder, T.P.; Hill, C.G. The mechanism for the partial oxidation of propylene over bismuth molybdate catalysts. Catal. Rev. 1989, 31, 43–95. [Google Scholar] [CrossRef]

- Varbanov, P.S.; Chin, H.H.; Popescu, A.-E.P.; Boldyryev, S. Thermodynamics-Based Process Sustainability Evaluation. Energies 2020, 13, 2132. [Google Scholar] [CrossRef]

- Ehyaei, M.A.; Ahmadi, A.; Rosen, M.A. Energy, exergy, economic and advanced and extended exergy analyses of a wind turbine. Energy Convers. Manag. 2019, 183, 369–381. [Google Scholar] [CrossRef]

- Quiroz-Ramírez, J.J.; Sánchez-Ramírez, E.; Segovia-Hernández, J.G. Energy, exergy and techno-economic analysis for biobutanol production: A multi-objective optimisation approach based on economic and environmental criteria. Clean Technol. Environ. Policy 2018, 20, 1663–1684. [Google Scholar] [CrossRef]

- Balest, J.; Secco, L.; Pisani, E.; Garegnani, G. Municipal transitions: The social, energy, and spatial dynamics of sociotechnical change in South Tyrol, Italy. Energy Res. Soc. Sci. 2019, 54, 211–223. [Google Scholar] [CrossRef]

- Garcia-Casals, X.; Ferroukhi, R.; Parajuli, B. Measuring the socioeconomic footprint of the energy transition. Energy Transit. 2019, 3, 105–118. [Google Scholar] [CrossRef]

- Chandler, D.L. Battery Reuse Systems Could Be Profitable for Electric Vehicle Companies and Grid Scale Solar Operations. 2020. Available online: techxplore.com/news/2020-05-battery-reuse-profitable-electric-vehicle.html (accessed on 2 June 2020).

- Hanley, S. Nanotech Energy Claims its Graphene Lithium Battery Will Charge 18 Times Faster than Conventional Li-Ion Battery. Clean Technica. 2020. Available online: cleantechnica.com/2020/05/25/nanotech-energy-claims-its-graphene-lithium-battery-will-charge-18-times-faster-than-conventional-li-ion-battery/ (accessed on 2 June 2020).

- EDF Environmental Defence Fund. Why Are Natural Gas Leaks a Problem. 2020. Available online: www.edf.org/climate/methanemaps/leaks-problem (accessed on 2 June 2020).

- Exxon Mobil Corporation. Using New Technologies to Reduce Methane Emissions. 2020. Available online: energyfactor.exxonmobil.com/news/tech-reducing-methane-emissions/ (accessed on 2 June 2020).

- Georgiou, M. The Role of AI Technology in Improving the Renewable Energy Sector. 2019. Available online: primary%20goal%20of%20AI,current%20energy%20consumption%20and%20demands (accessed on 4 June 2020).

- Kosovic, B.; Haupt, S.E.; Adriaansen, D.; Alessandrini, S.; Wiener, G.; Delle Monache, L.; Liu, Y.; Linden, S.; Jensen, T.; Cheng, W.; et al. Comprehensive Wind Power Forecasting System Integrating Artificial Intelligence and Numerical Weather Prediction. Energies 2020, 13, 1372. [Google Scholar] [CrossRef]

- Ho, L.T.T.; Dubus, L.; De Felice, M.; Troccoli, A. Reconstruction of Multidecadal Country-Aggregated Hydro Power Generation in Europe Based on a Random Forest Model. Energies 2020, 13, 1786. [Google Scholar] [CrossRef]

- Bandyk, M. Landfills Emerge as Promising Battery Storage Sites to Back Up Renewable Energy. 2020. Available online: www.utilitydive.com/news/landfills-promising-sites-battery-storage-solar-renewable-energy/578582/ (accessed on 2 June 2020).

| Energy Sources | GHG Footprint (kg/MWh) [14] | Water Footprint (L/MWh) [15] | Share of Water Footprint [16] |

|---|---|---|---|

| Biomass | 45 | 85,100 | 0.26% Operation; negligible Construction; 99.73% Fuel supply |

| Hydropower | 26 | 4961 | 100% Operation; negligible Construction; 0% Fuel supply |

| PV | 85 | 330 | 35.71% Operation; 64.29% Construction; 0% Fuel supply c |

| Wind | 26 | 43 | 15.38% Operation; 84.62% Construction; 0% Fuel supply |

| CSP | 108.6 a [17] | 1250 | 35.71% Operation; 64.29% Construction; 0% Fuel supply c |

| Geothermal | 53 b [18] | 1022 | 99.39% Operation; 0.61% Construction; 0% Fuel supply |

| Oil | 735 | 3220 | 88.70% Operation; negligible Construction; 11.1% Fuel supply |

| Nuclear | 28 | 2290 | 89.93% Operation; negligible Construction; 10.03% Fuel supply |

| Coal | 888 | 2220 | 89.93% Operation; negligible Construction; 10.03% Fuel supply |

| Natural Gas | 500 | 598 | 97.13% Operation; 0.45% Construction; 2.43% Fuel supply |

| Energy Sources | Levelized Energy Cost (USD/MWh) [21] | Without Subsidies (USD/MWh) [21] | Changes in Cost (%) [22] Global Weighted-Average LCOE |

|---|---|---|---|

| Solar PV | 32–245 | 36–267 | −77% (0.085 USD/kWh) |

| CSP | 96–169 | 98–181 | −45.75% (0.185 USD/kWh) |

| Geothermal | 67–110 | 71–111 | +50% (0.072 USD/kWh) |

| Wind | 14–47 | 29–56 | −20–34% (0.127 a–0.045 USD/kWh) |

| Biomass | 40–112 b | 55–114 b | −17.33% (0.062 USD/kWh) |

| Nuclear | 112–189 | NA | NA |

| Coal | 60–143 | NA | NA |

| Circular Strategies | Example | Indicators |

|---|---|---|

| Refuse, Rethink, Reduce | |

| Reuse, Refurbish, Remanufacture | eDiM, TRP, Longevity, MCI, EVR, PLCM, SCI |

| Reuse, Repurpose | eDiM, TRP, PLCM |

| Recycle, downcycle | CR, RR, EOL-RR, RIR, OSR, NTUM, Longevity, MCI, CIRC, LMA, PLCM, SCI, GRI, CEI, CPI, VRE |

| Energy Recovery | MCI, CPI, SCI |

| Compare to the linear economy | MCI, Longevity, SCI |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Y.V.; Pintarič, Z.N.; Klemeš, J.J. Emerging Tools for Energy System Design Increasing Economic and Environmental Sustainability. Energies 2020, 13, 4062. https://doi.org/10.3390/en13164062

Fan YV, Pintarič ZN, Klemeš JJ. Emerging Tools for Energy System Design Increasing Economic and Environmental Sustainability. Energies. 2020; 13(16):4062. https://doi.org/10.3390/en13164062

Chicago/Turabian StyleFan, Yee Van, Zorka Novak Pintarič, and Jiří Jaromír Klemeš. 2020. "Emerging Tools for Energy System Design Increasing Economic and Environmental Sustainability" Energies 13, no. 16: 4062. https://doi.org/10.3390/en13164062

APA StyleFan, Y. V., Pintarič, Z. N., & Klemeš, J. J. (2020). Emerging Tools for Energy System Design Increasing Economic and Environmental Sustainability. Energies, 13(16), 4062. https://doi.org/10.3390/en13164062