Modeling of Electric Energy Consumption during Dairy Wastewater Treatment Plant Operation

Abstract

:1. Introduction

2. Materials and Methods

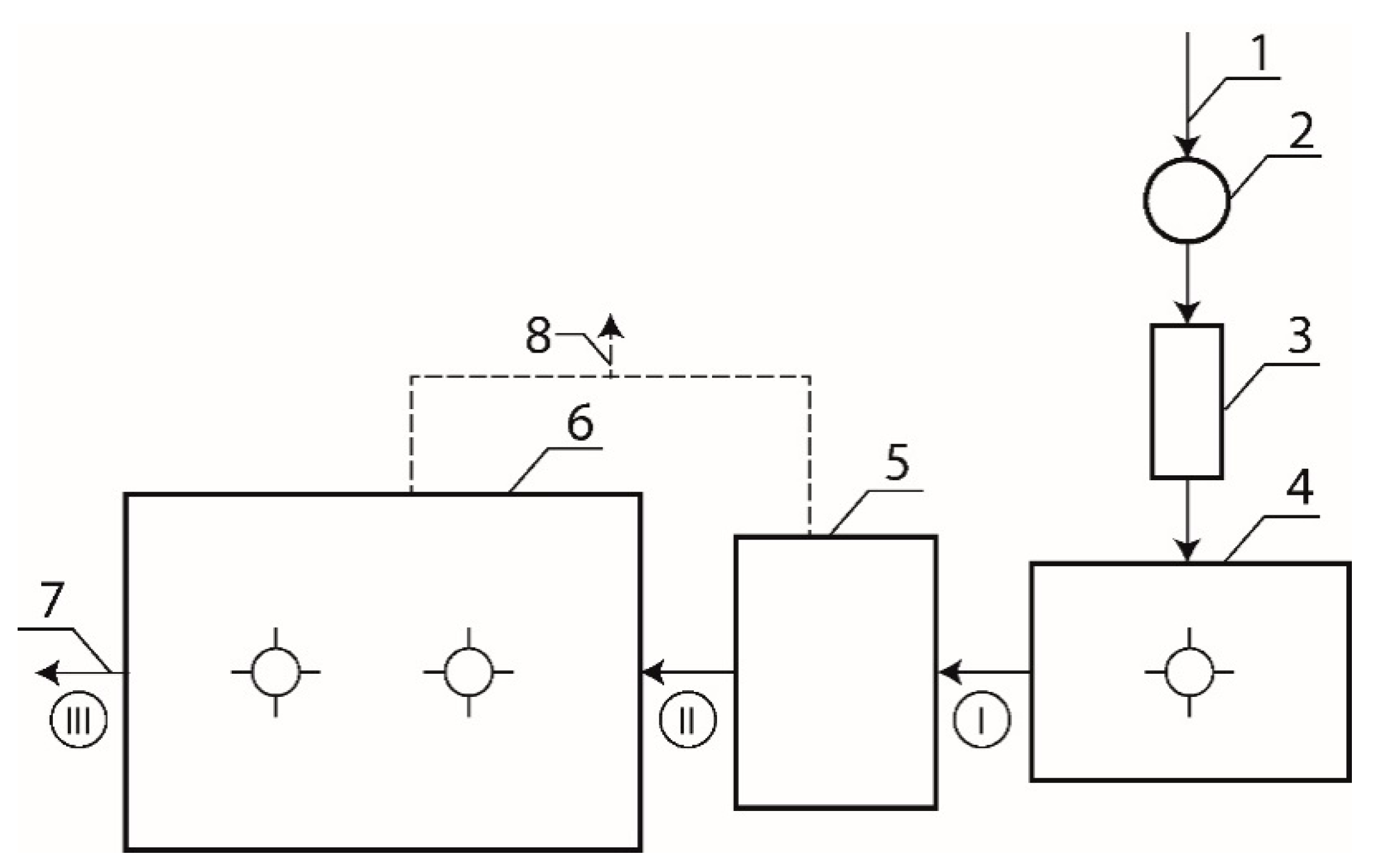

2.1. Study Site

2.2. Electric Energy Measuring Methods

2.3. Sampling of Sewage and Analytical Procedures

- —air temperature,

- , , , —pollutant (BOD5, COD, Ntot, and Ptot) loads after the averaging tank (point I),

- , , , —pollutant loads after DAF treatment (point II),

- , , , —pollutant loads after biological treatment in SBRs (point III).

2.4. Modeling of Electric Energy Consumption

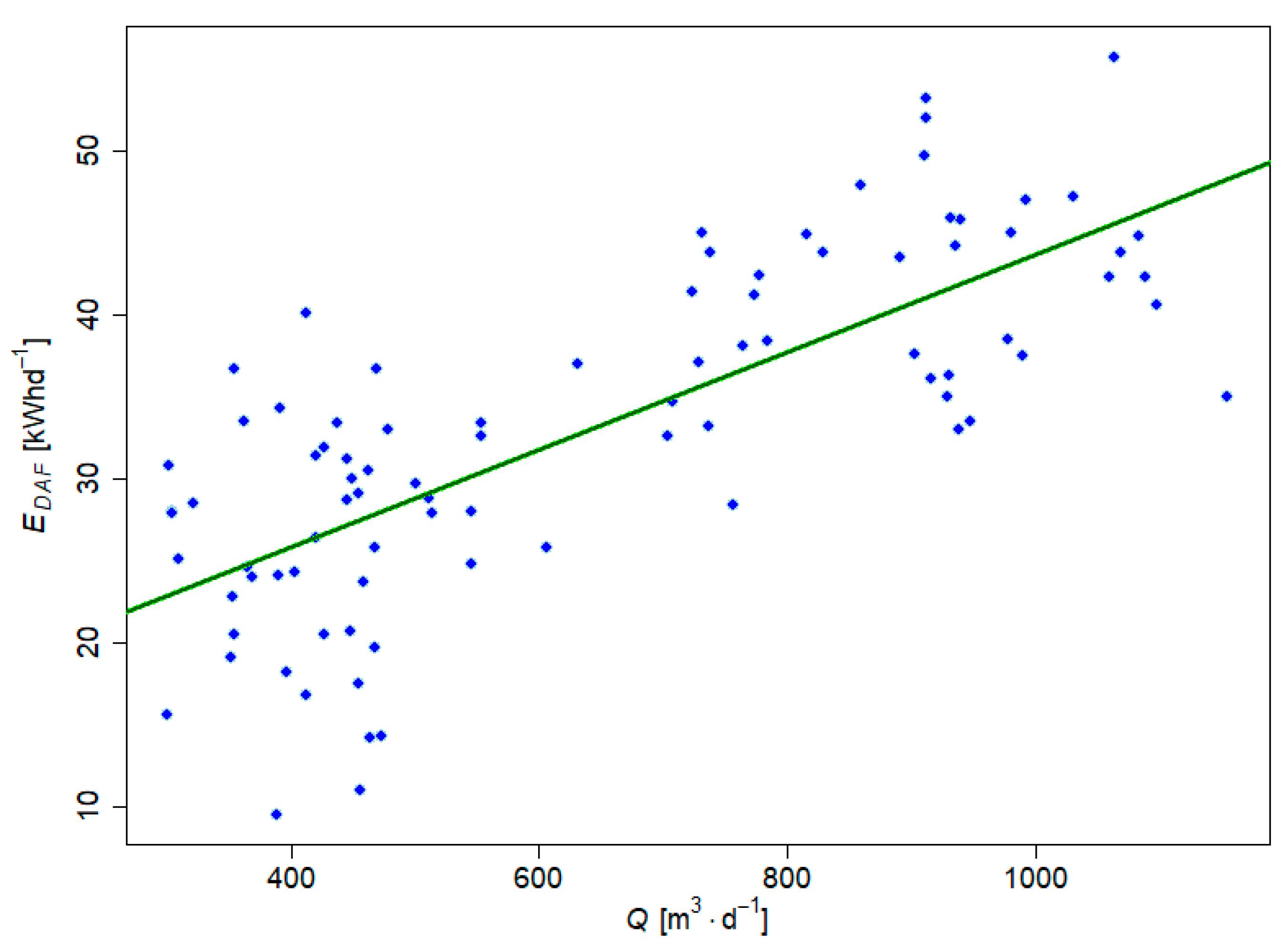

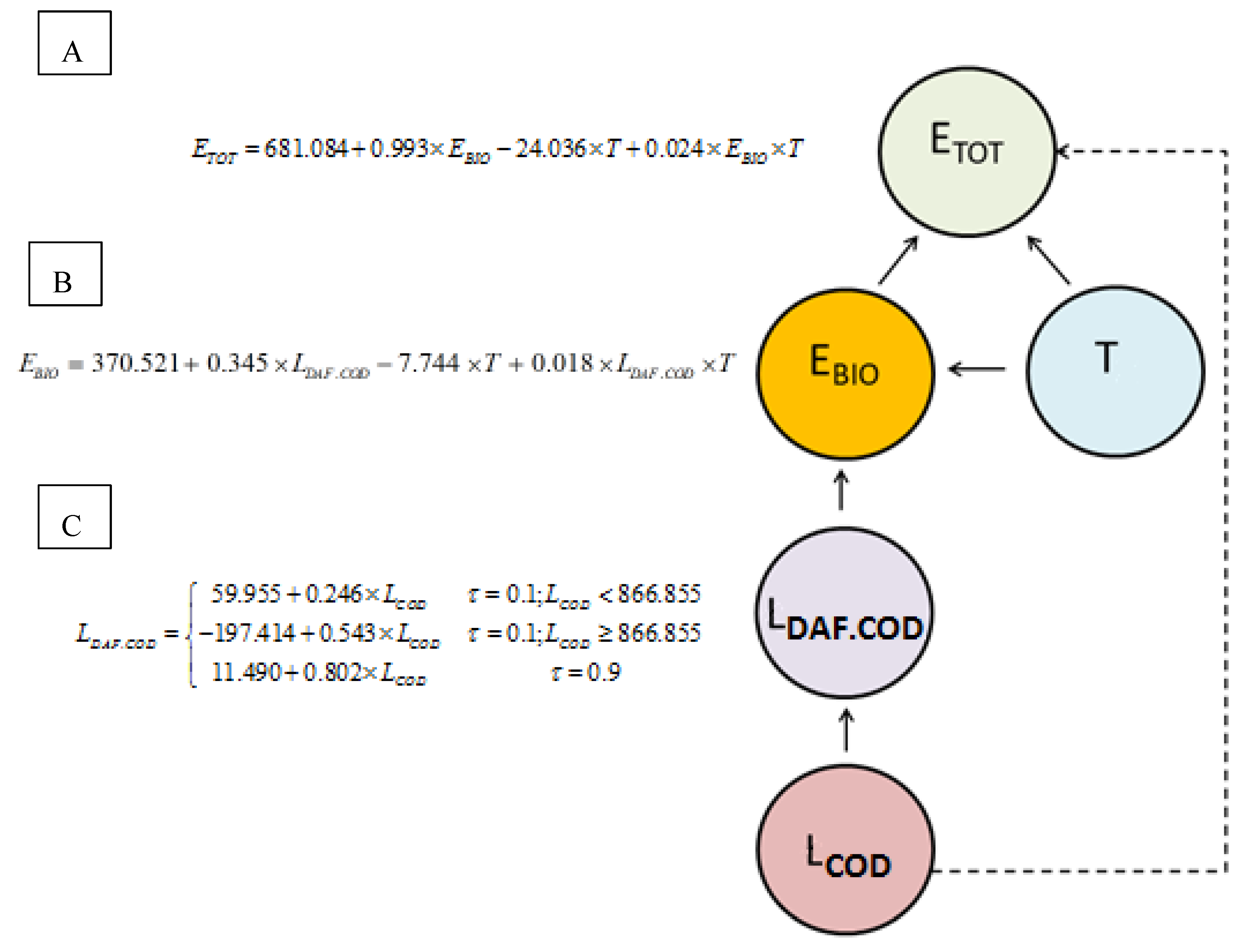

- modeling of was carried out based on and (the least squares linear regression);

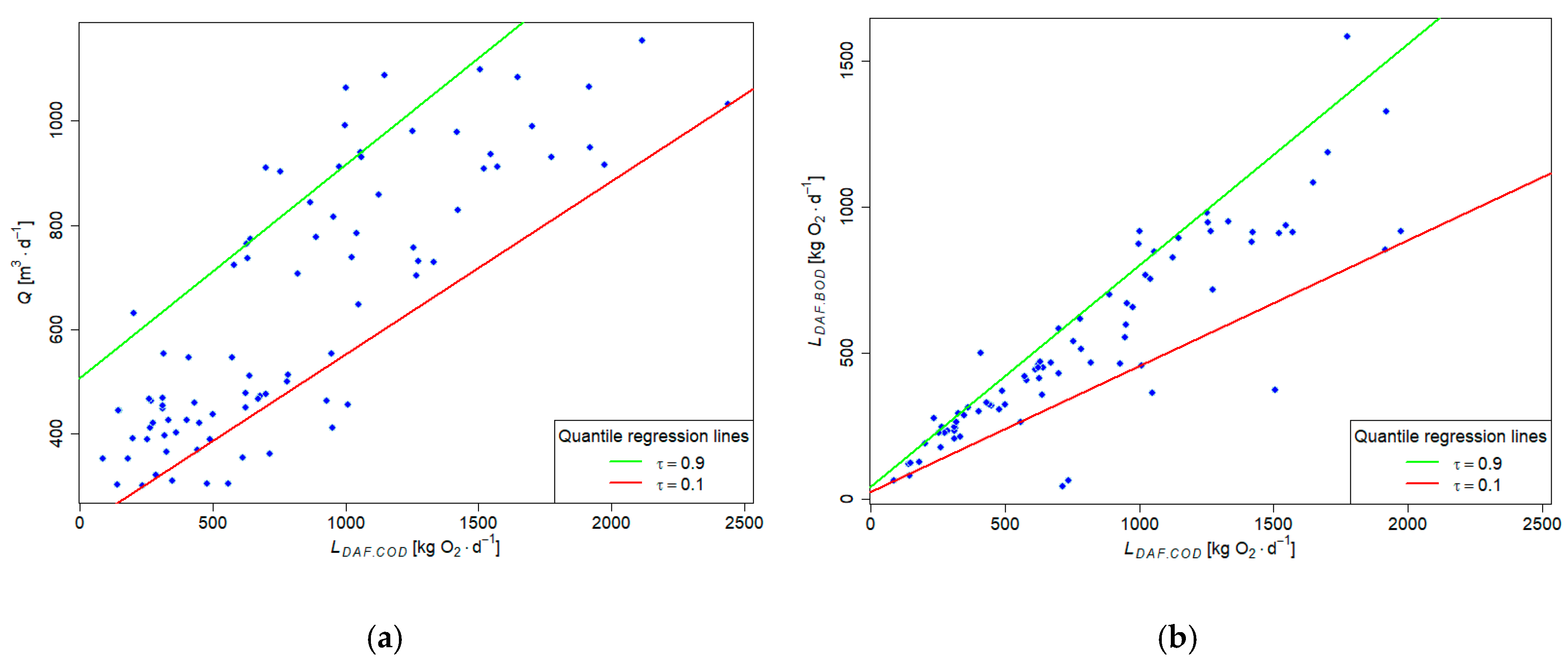

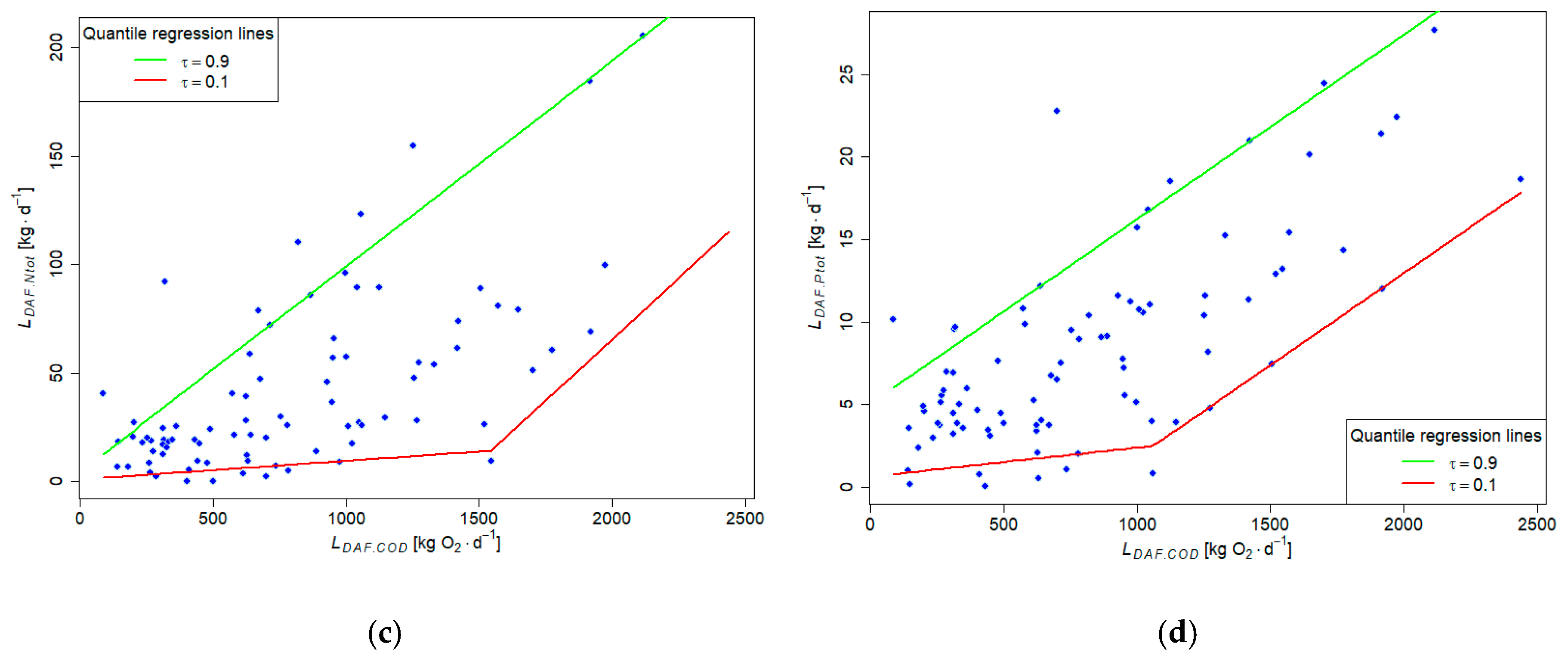

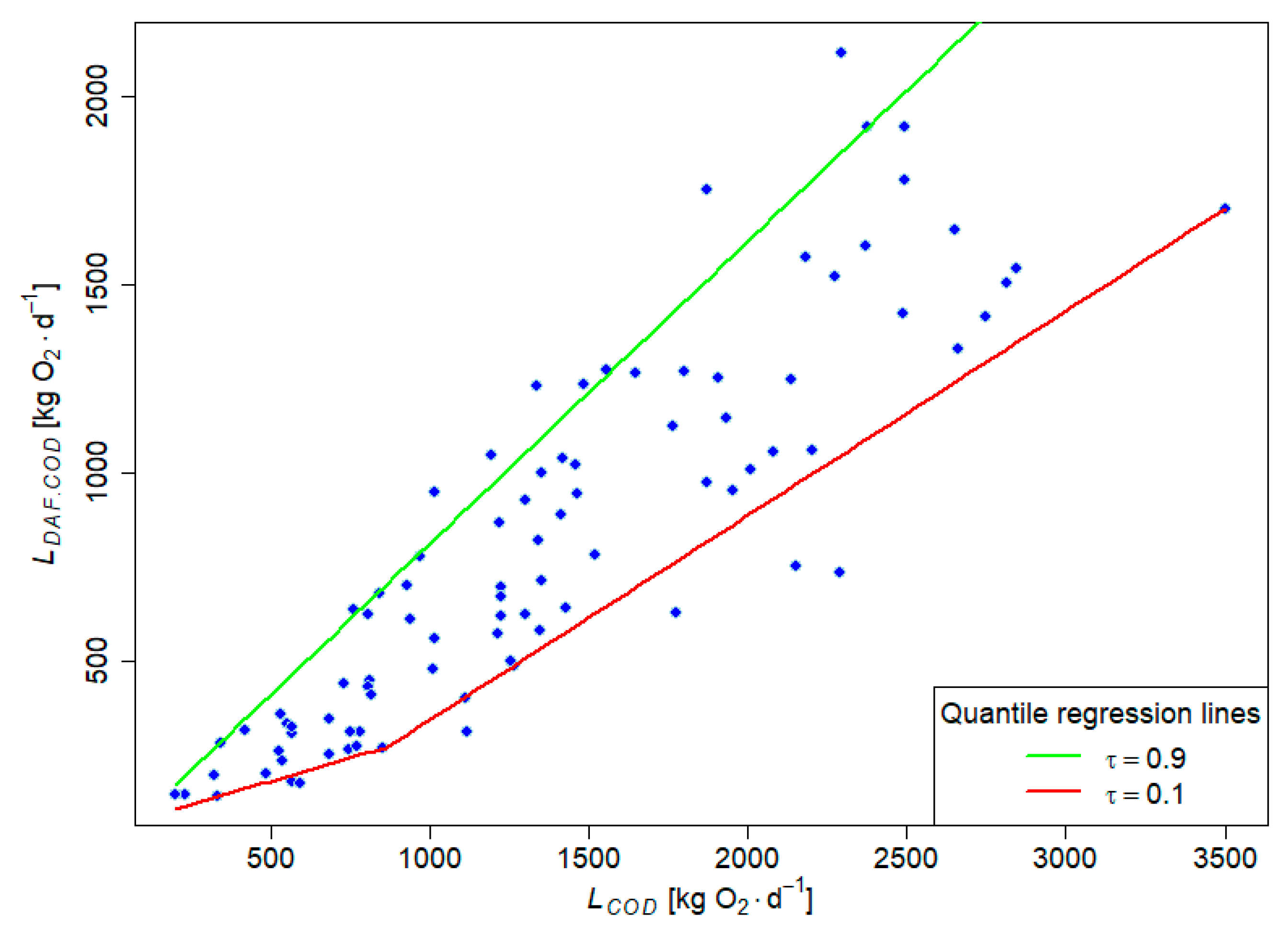

- a qualitative analysis of , , , and was carried out. was used as an independent variable (quantile and quantile segmented regression methods);

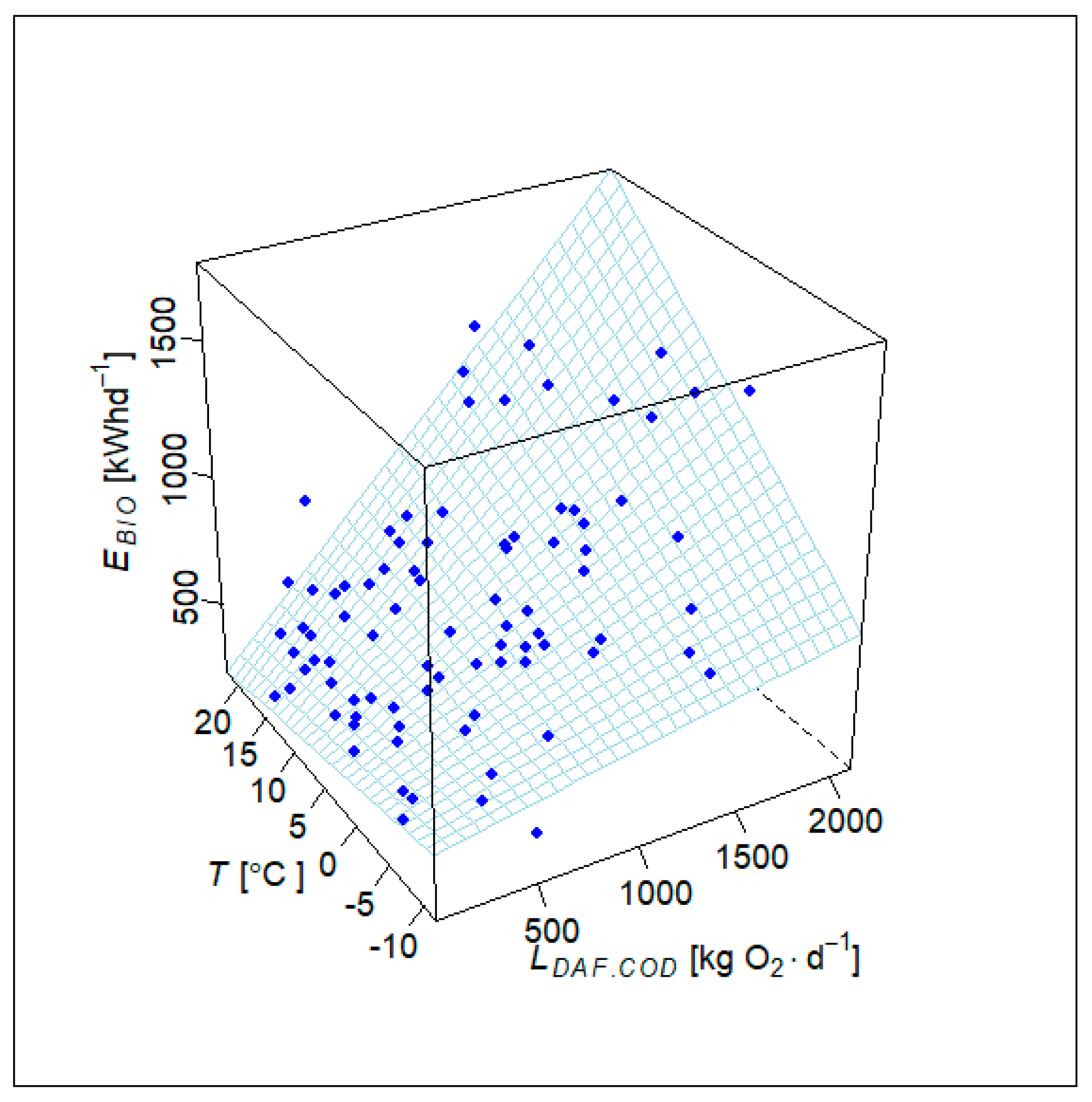

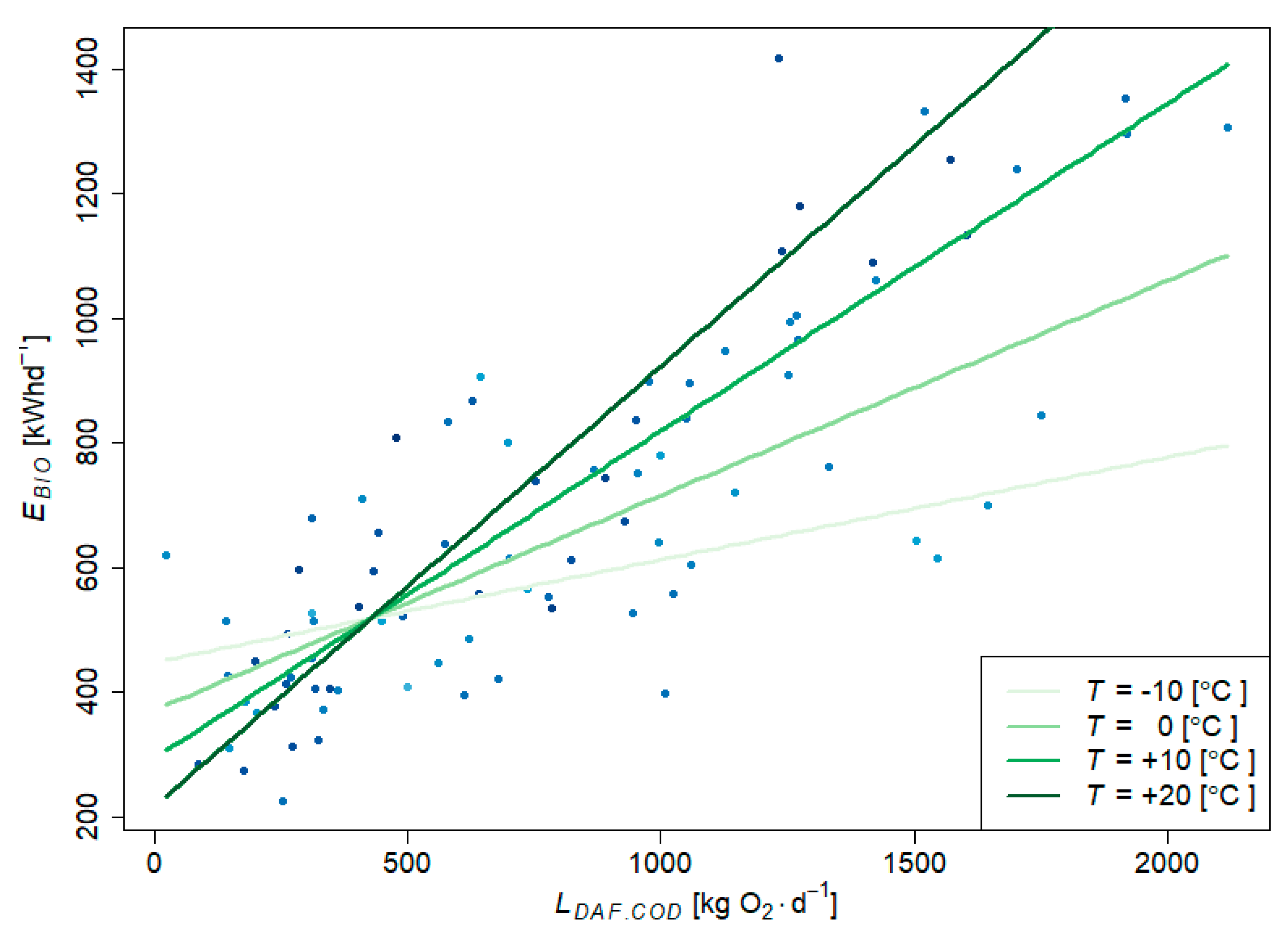

- modeling of was carried out based on the and (the least squares linear regression method);

- a qualitative analysis of was carried out based on (quantile regression and segmented quantile regression methods);

- modeling of was carried out based on (the least squares linear regression method).

3. Results

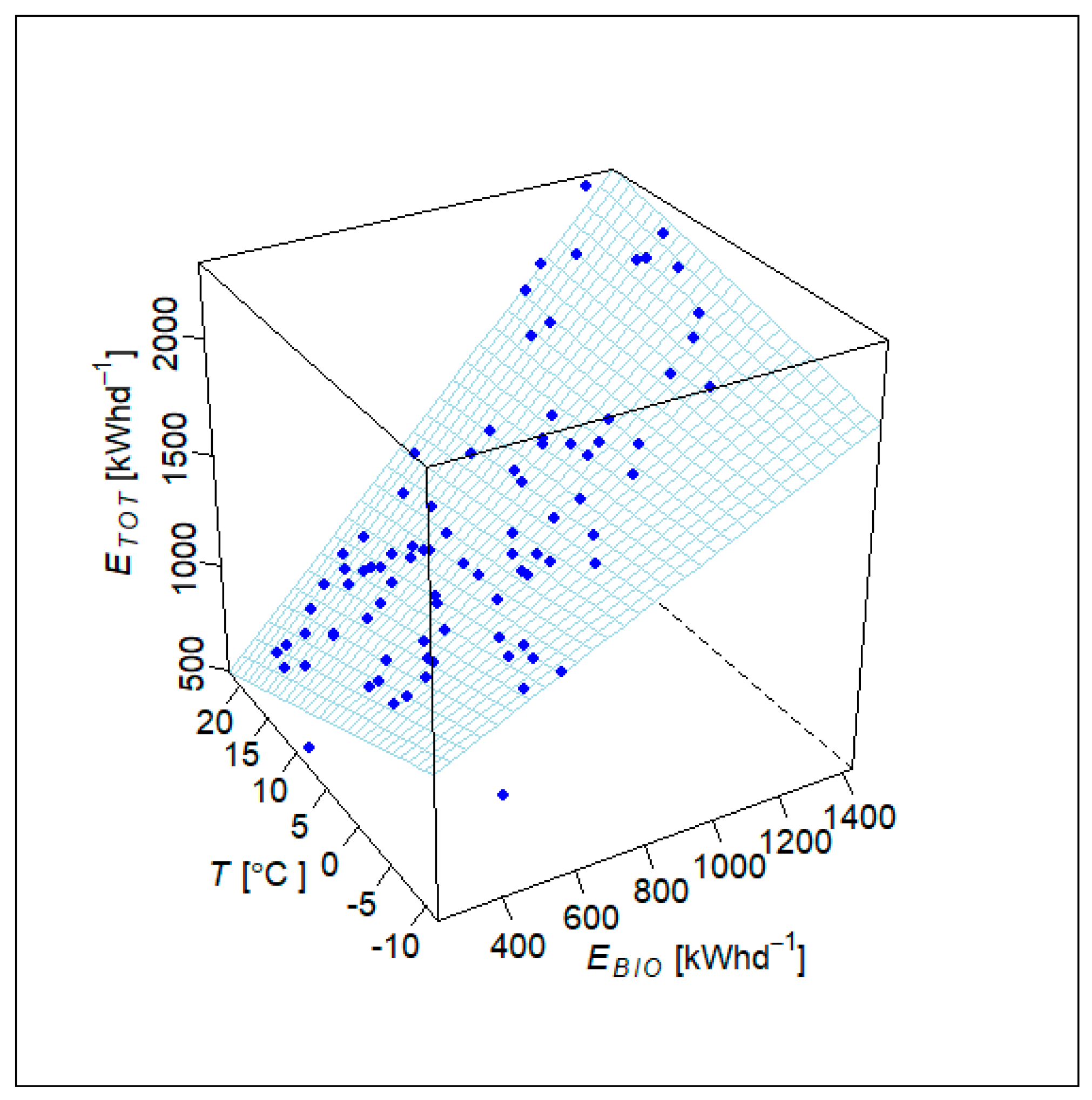

3.1. Total Electric Energy Consumption

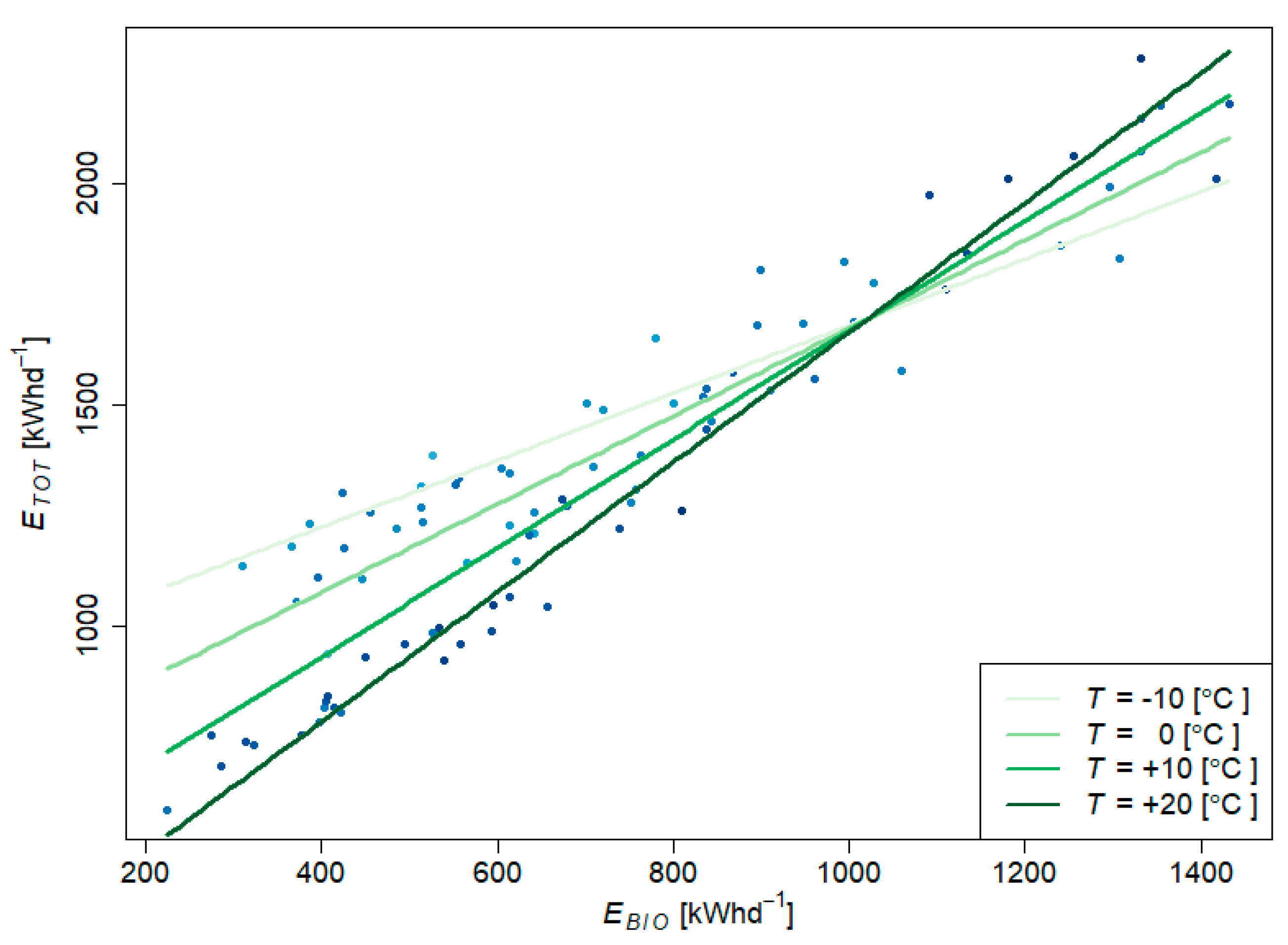

3.2. Electric Energy Consumption during Biological Treatment

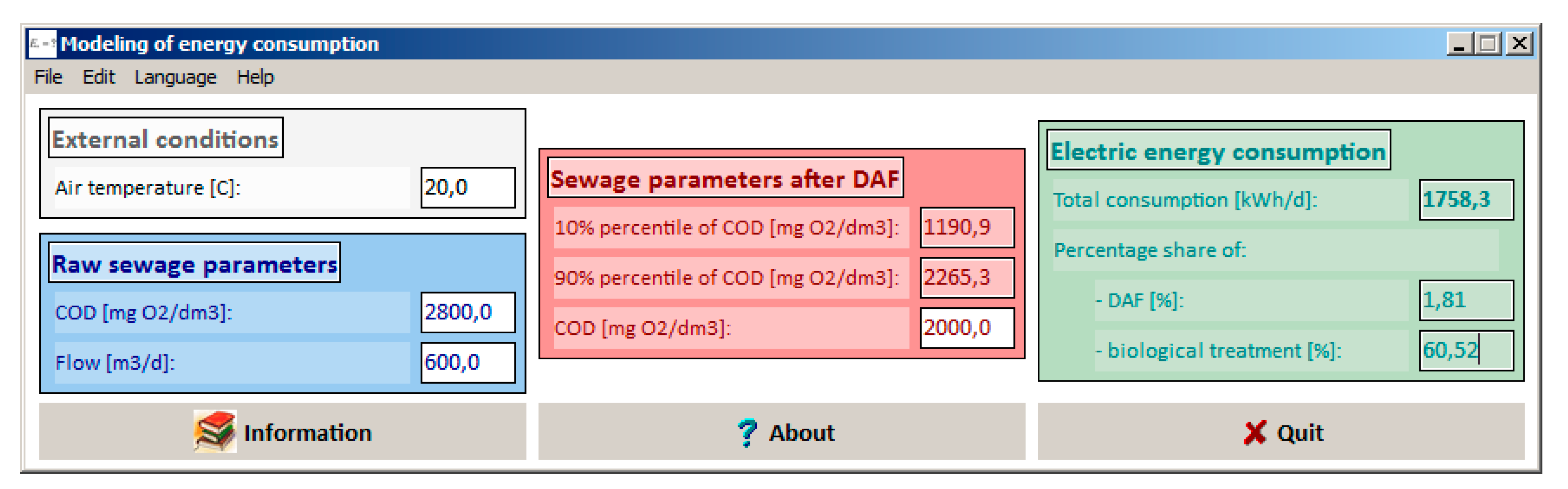

4. Final Modeling Scheme and Discussion

- The increased electric energy consumption in the biological treatment process causes a decrease in the temperature dependence of the total electric energy consumption. After exceeding the value of , the reverse dependence can be observed, i.e., with increasing temperature, total energy consumption grows. Mamais et al. [19] have also reported an increase in the electric energy consumption during summer periods. This is due to an increase of endogenous respiration when the temperature rises.

- Quantile regression models confirm the interdependence of wastewater parameters after the DAF process. Due to the ease of measurement, can be used to qualitatively describe other wastewater parameters. Along with the increase in , the influence of on electric energy consumption during biological treatment increases. When exceeding the load , the relationship between and with respect to temperature reverses. Lowering the air temperature increases energy consumption for smaller loads, and decreases electric energy consumption for larger pollutant loads. According to Niu et. al. [20], in order to reduce electric energy consumption, the pollutant load in the wastewater discharged into biological treatment should be increased. The authors point out that a properly loaded WWTP is characterized by lower energy consumption than an underloaded one. Therefore, it is important to control the pollutant load discharged into the biological treatment, depending on the air temperature. This can be realized by controlling the flotation efficiency.

- The results of the qualitative analysis make it possible to predict the range of variability of the by measuring the COD parameter in the wastewater before the DAF process. Parameters such as and can be easily monitored during all of the treatment processes. The COD parameter in raw sewage was also mentioned by Huang et al. [21] as being important to the modeling of electric energy consumption. It is used to predict not only the electric energy consumption but also the parameters of treated wastewater.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Central Statistical Office. Statistical Yearbook of Agriculture; Statistical Publishing Establishment: Warsaw, Poland, 2017. [Google Scholar]

- Ahmad, T.; Aadil, M.R.; Ahmed, H.; Rahmasn, U.; Soares, B.; Souza, S.; Pimentel, T.; Scudino, H.; Guimares, J.; Esmerino, E.A.; et al. Treatment and utilization of dairy industrial waste: A review. Trends Food Sci. Technol. 2019, 88, 361–372. [Google Scholar] [CrossRef]

- Struk-Sokołowska, J.; Mielcarek, A.; Wiater, J.; Rodziewicz, J. Impacts of dairy wastewater and pre-aeration on the performance of SBR treating municipal sewage. Desalin. Water Treat. 2018, 105, 41–50. [Google Scholar] [CrossRef]

- Kushwaha, J.P.; Srivastava, V.C.; Mall, I.D. Sequential batch reactor for dairy wastewater treatment: Parametric optimization; kinetics and waste sludge disposal. J. Environ. Chem. Eng. 2013, 1, 1036–1043. [Google Scholar] [CrossRef]

- Martín-Rilo, S.; Coimbra, R.N.; Martín-Villacorta, J.; Otero, M. Treatment of dairy industry wastewater by oxygen injection: Performance and outlay parameters from the full scale implementation. J. Clean. Prod. 2015, 86, 15–23. [Google Scholar] [CrossRef]

- Struk-Sokołowska, J.; Rodziewicz, J.; Mielcarek, A. Effect of dairy wastewater on changes in COD fractions in technical-scale SBR type reactors. Wat. Sci. Technol. 2017, 1, 156–169. [Google Scholar] [CrossRef] [PubMed]

- Memisi, N.; Moracanin, S.V.; Milijasevic, M.; Babic, J.; Djukic, D. CIP cleaning processes in the dairy industry. Procedia. Food Sci. 2015, 5, 184–186. [Google Scholar] [CrossRef] [Green Version]

- Umiejewska, K. Biological Anaerobic-Aerobic Treatment of Dairy Wastewater. In Proceedings of the 15th International Conference on Environmental Science and Technology, Rhodes, Greece, 31 August–2 September 2017. [Google Scholar]

- Dębowski, M.; Zieliński, M.; Kisielewska, M.; Kazimierowicz, J. Evaluation of Anaerobic Digestion of Dairy Wastewater in an Innovative Multi-Section Horizontal Flow Reactor. Energies 2020, 13, 2392. [Google Scholar] [CrossRef]

- Dąbrowski, W.; Żyłka, R.; Rynkiewicz, M. Evaluation of energy consumption in agro-industrial wastewater treatment plant. J. Ecol. Eng. 2016, 17, 73–78. [Google Scholar] [CrossRef] [Green Version]

- Dąbrowski, W.; Żyłka, R.; Malinowski, P. Evaluation of energy consumption during aerobic sewage sludge treatment in dairy wastewater treatment plant. Environ. Res 2017, 153, 135–139. [Google Scholar] [CrossRef]

- Longo, S.; D’Antoni, B.M.; Bongards, M.; Chaparro, A.; Cronrath, A.; Fatone, F.; Lema, J.M.; Mauricio-Iglesias, M.; Soares, A.; Hospido, A. Monitoring and diagnosis of energy consumption in wastewater treatment plants. A state of the art and proposals for improvement. Appl. Energy 2016, 179, 1251–1268. [Google Scholar] [CrossRef]

- De Gussem, K.; Fenu, A.; Wambecq, T.; Weemaes, M. Energy saving on wastewater treatment plants through improved online control: Case study wastewater treatment plant Antwerp-South. Water Sci. Technol. 2014, 69, 1074–1079. [Google Scholar] [CrossRef] [PubMed]

- Mizuta, K.; Shimada, M. Benchmarking energy consumption in municipal wastewater treatment plant. Water Sci. Technol. 2010, 62, 2256–2262. [Google Scholar] [CrossRef] [PubMed]

- Venkatesh, G.; Brattebo, H. Energy consumption, costs and environmental impacts for urban water cycle services: Case study of Oslo (Norway). Energy 2011, 36, 792–800. [Google Scholar] [CrossRef]

- Singh, P.; Carliell-Marquet, C.; Kansal, A. Energy pattern analysis of a wastewater treatment plant. Appl. Water Sci. 2012, 2, 221–226. [Google Scholar] [CrossRef] [Green Version]

- Di Fraia, S.; Massarottia, N.; Vanolia, L. A novel energy assessment of urban wastewater treatment plants. Energy Convers. Manag. 2018, 163, 304–313. [Google Scholar] [CrossRef]

- Yu, Y.; Zou, Z.; Wang, S. Statistical regression modeling for energy consumption in wastewater treatment. J. Environ. Sci. (China) 2019, 17, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Mamais, D.; Noutsopoulos, C.; Dimopoulou, A.; Stasinakis, A.; Lekkas, T.D. Wastewater treatment process impact on energy savings and greenhouse gas emissions. Water Sci. Technol. 2015, 71, 303–308. [Google Scholar] [CrossRef] [PubMed]

- Niu, K.; Wu, J.; Qi, L.; Niu, Q. Energy intensity of wastewater treatment plants and influencing factors in China. Sci. Total. Environ. 2019, 670, 961–970. [Google Scholar] [CrossRef]

- Huang, X.; Han, H.; Qiao, J. Energy consumption model for wastewater treatment process control. Water Sci. Technol. 2013, 67, 667–674. [Google Scholar] [CrossRef] [Green Version]

- Fenu, A.; Roles, J.; Wambecq, T.; De Gussem, K.; Thoeye, C.; De Gueldre, G.; Van De Steene, B. Energy audit of a full scale MBR system. Desalination 2010, 262, 121–128. [Google Scholar] [CrossRef]

- Journal of Laws of the Republic of Poland. Regulations of the Maritime Economy and Inland Navigation Minister from 12nd of July 2019 on Substances that are Particularly Harmful to the Aquatic Environment and Conditions to be Met When Introducing Sewage into Water or Soil and When Discharging Rainwater or Snowmelt to Water or to Aquatic Facilities—item 1311; Journal of Laws of the Republic of Poland: Warsaw, Poland, 2019. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20190001311 (accessed on 10 May 2020). (In Polish)

- American Public Health Association (APHA). Standard Methods for Examination of Water and Wastewater, 21st ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Koenker, R. Quantile Regression; Cambridge University Press: Cambrige, UK, 2005; ISBN 978-0-521-60827-5. [Google Scholar]

- Cade, B.S.; Noon, B.R. A gentle introduction to quantile regression for ecologists. Front. Ecol. Environ. 2003, 1, 412–420. [Google Scholar] [CrossRef]

- Koenker, R.; Park, B.J. An Interior Point Algorithm for Nonlinear Quantile Regression. J. Econ. 1994, 71, 265–283. [Google Scholar] [CrossRef] [Green Version]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2018; Available online: https://www.R-project.org/ (accessed on 4 December 2018).

- Koenker, R. Quantreg: Quantile Regression; R package version 5.38: London, UK, 2018; Available online: https://CRAN.R-project.org/package=quantreg (accessed on 14 December 2018).

- Neuwirth, E. RColorBrewer: ColorBrewer Palettes; R package version 1.1.2: Vienna, Austria, 2014; Available online: https://CRAN.R-project.org/package=RColorBrewer (accessed on 17 December 2018).

- Deepayan, S. Lattice: Multivariate Data Visualization; Springer: New York, NY, USA, 2008; ISBN 978-0-387-75968-5. [Google Scholar]

- Bisak, A.; Cyganecka-Wilkoszewska, A.; Raszkiewicz, D. Efektywność energetyczna warszawskich oczyszczalni ścieków, Gaz. Woda i Tech. Sanit. 2017, 9, 372–381. (In Polish) [Google Scholar]

- Panaitescu, I.; Panaitescu, F.; Panaitescu, M. Solutions to optimize energy consumption of airblowers by monitoring oxygen levels in the bioreactor. In Proceedings of the 16th International Conference on Harmonics and Quality of Power (ICHQP), Bucharest, Romania, 25–28 May 2014; pp. 895–898. [Google Scholar]

- Silva, C.; Saldanha-Matos, J.; Rosa, M.J. A comprehensive approach for diagnosing opportunities for improving the performance of a WWTP. Wat. Sci. Technol. 2016, 74, 2935–2945. [Google Scholar] [CrossRef] [Green Version]

- Amerlinck, Y.; De Keyser, W.; Urchegui, G.; Nopens, I. A realistic dynamic blower energy consumption model for wastewater applications. Wat. Sci. Technol. 2016, 74, 1561–1576. [Google Scholar] [CrossRef]

| Parameter | Equations | Conditions |

|---|---|---|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żyłka, R.; Dąbrowski, W.; Malinowski, P.; Karolinczak, B. Modeling of Electric Energy Consumption during Dairy Wastewater Treatment Plant Operation. Energies 2020, 13, 3769. https://doi.org/10.3390/en13153769

Żyłka R, Dąbrowski W, Malinowski P, Karolinczak B. Modeling of Electric Energy Consumption during Dairy Wastewater Treatment Plant Operation. Energies. 2020; 13(15):3769. https://doi.org/10.3390/en13153769

Chicago/Turabian StyleŻyłka, Radosław, Wojciech Dąbrowski, Paweł Malinowski, and Beata Karolinczak. 2020. "Modeling of Electric Energy Consumption during Dairy Wastewater Treatment Plant Operation" Energies 13, no. 15: 3769. https://doi.org/10.3390/en13153769

APA StyleŻyłka, R., Dąbrowski, W., Malinowski, P., & Karolinczak, B. (2020). Modeling of Electric Energy Consumption during Dairy Wastewater Treatment Plant Operation. Energies, 13(15), 3769. https://doi.org/10.3390/en13153769