Acoustic Emission Characteristics and Damage Evolution of Rock under Different Loading Modes

Abstract

1. Introduction

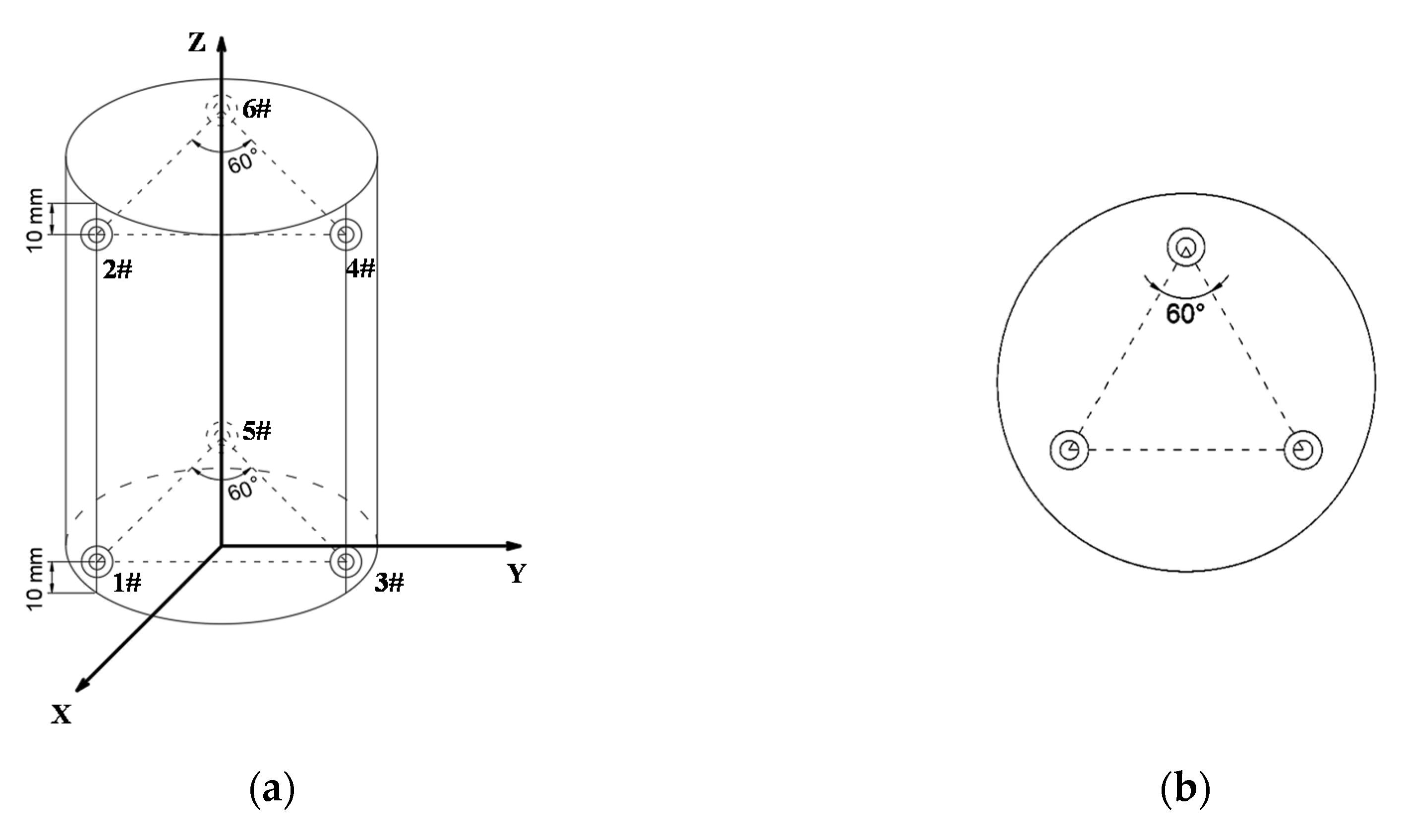

2. Experimental Methods and Techniques

2.1. Sample Preparation

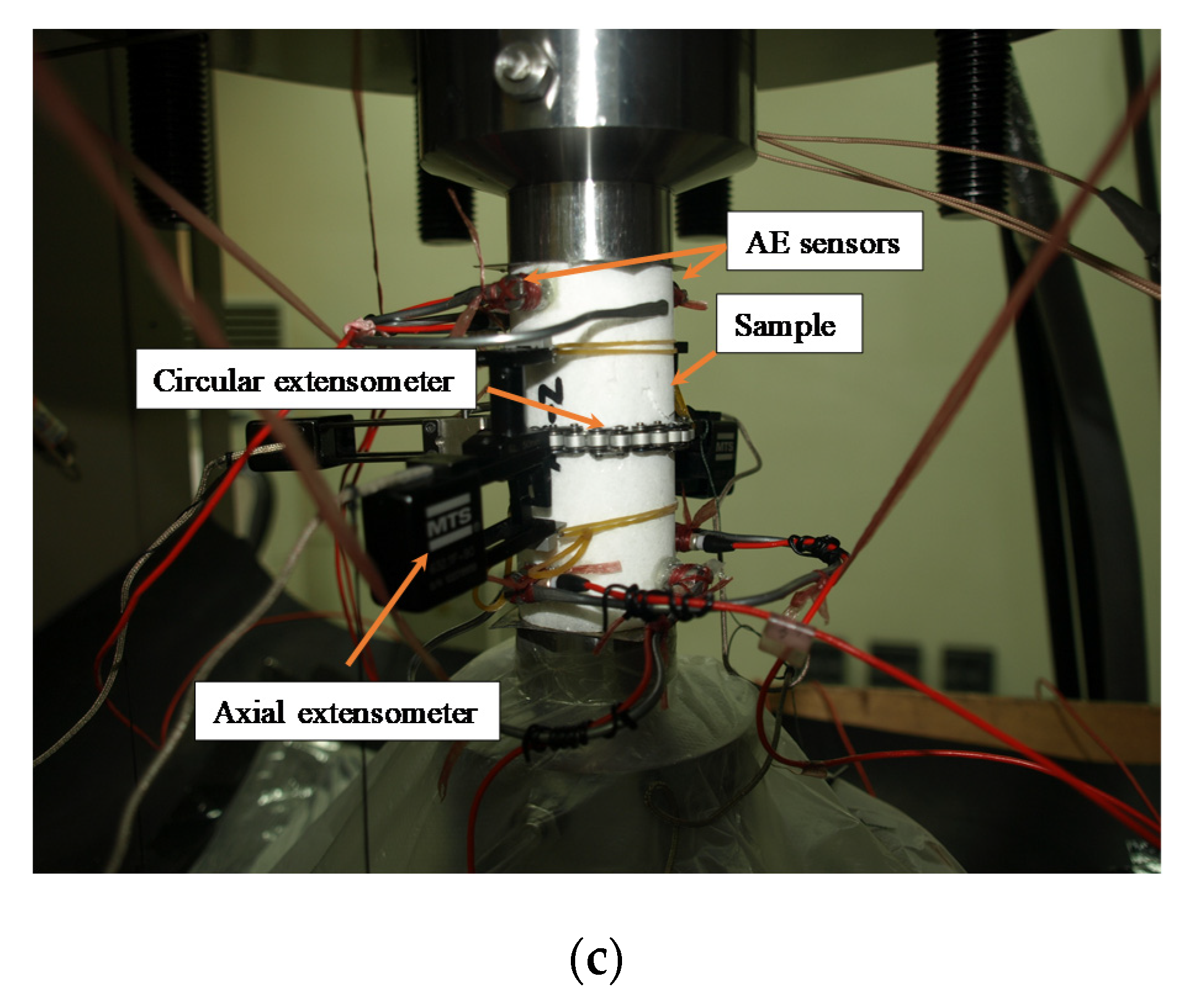

2.2. Testing Equipment

2.3. Testing Method

3. Temporal and Spatial Evolution of Acoustic Emission (AE) Parameters under Different Loading Modes

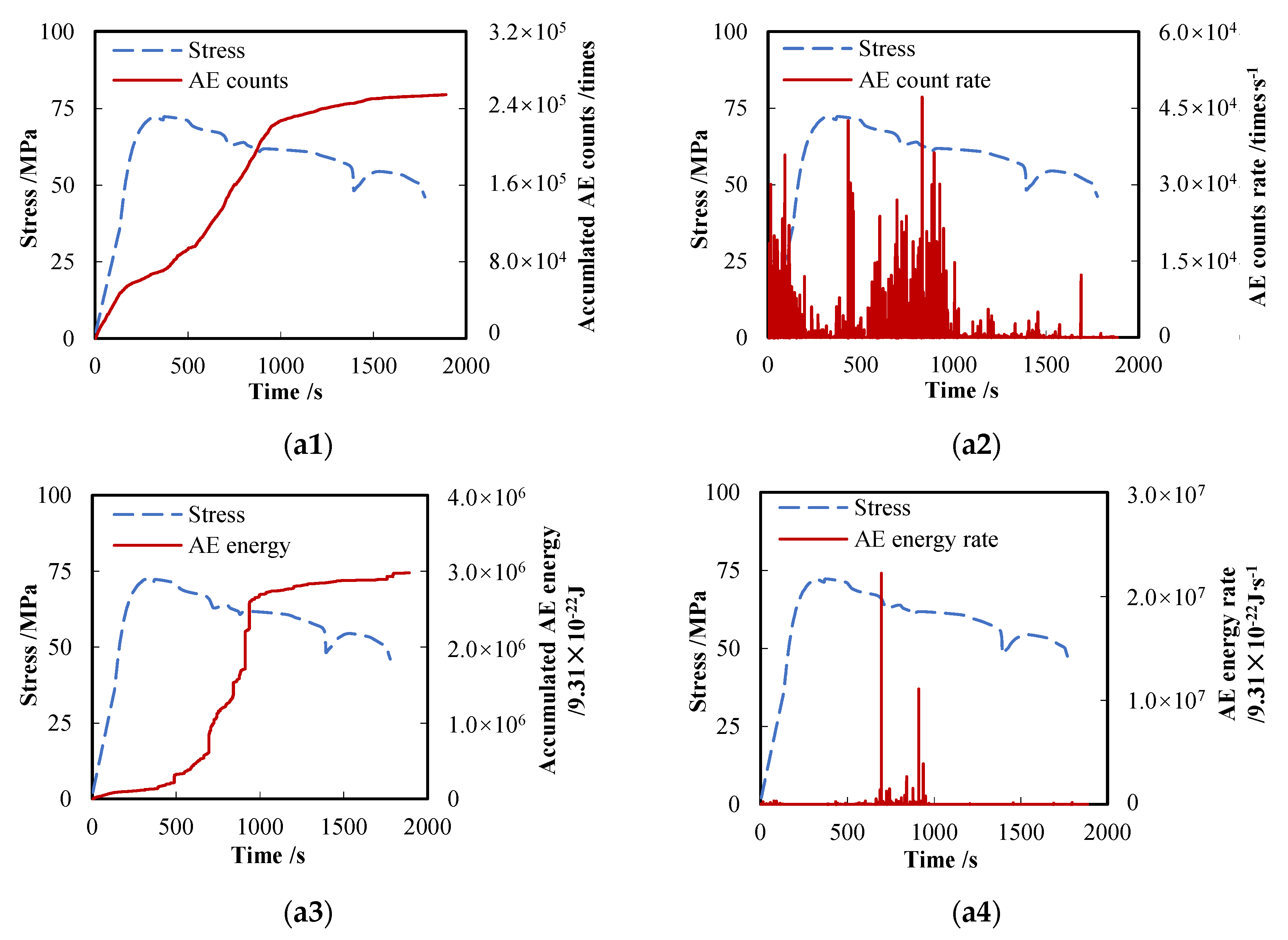

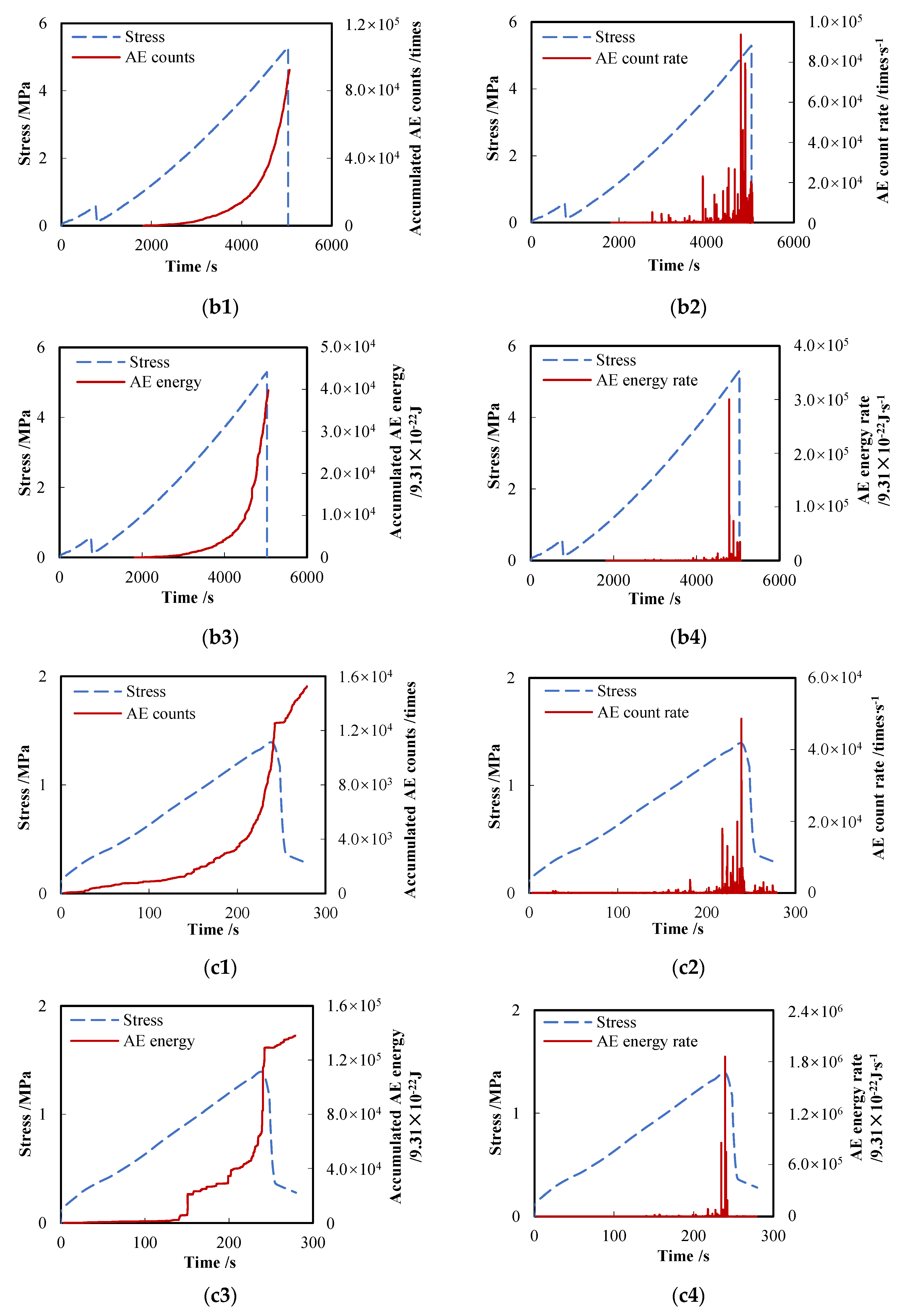

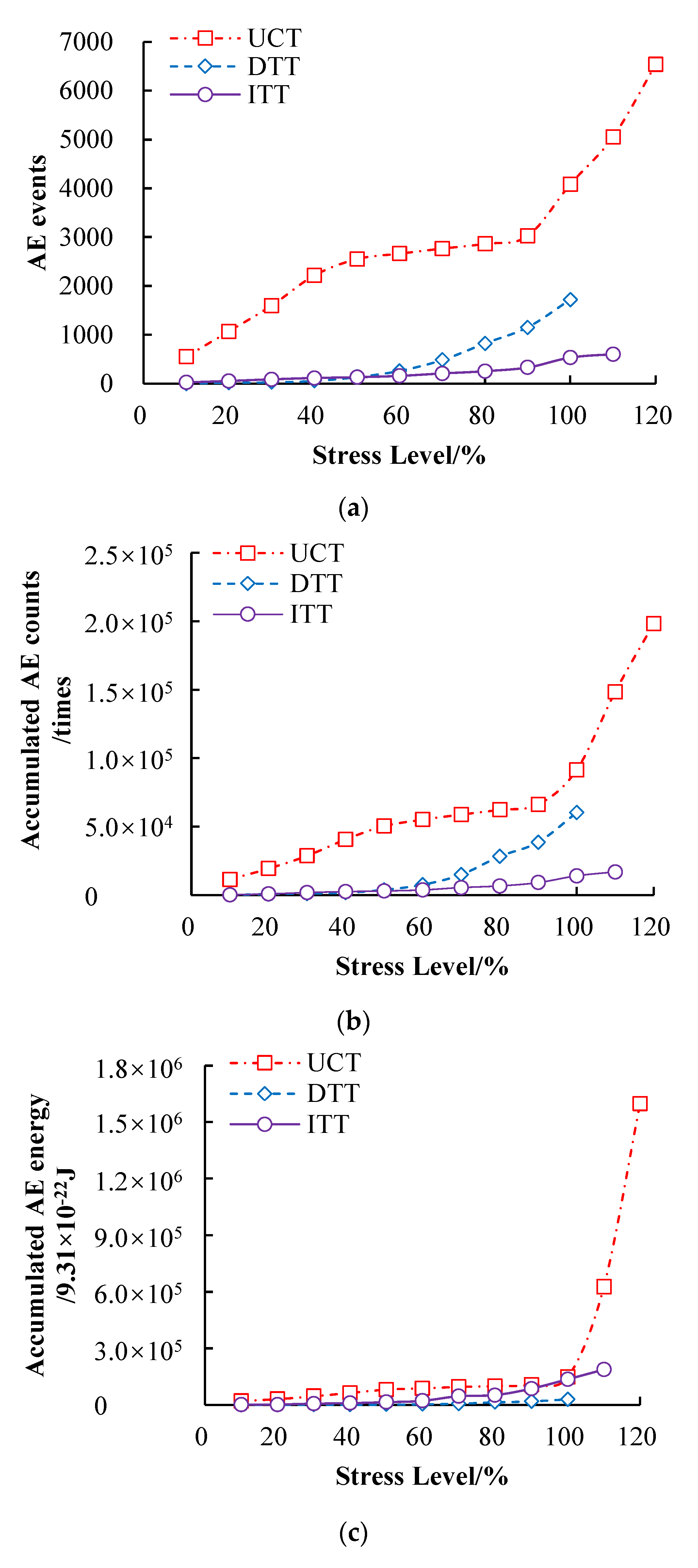

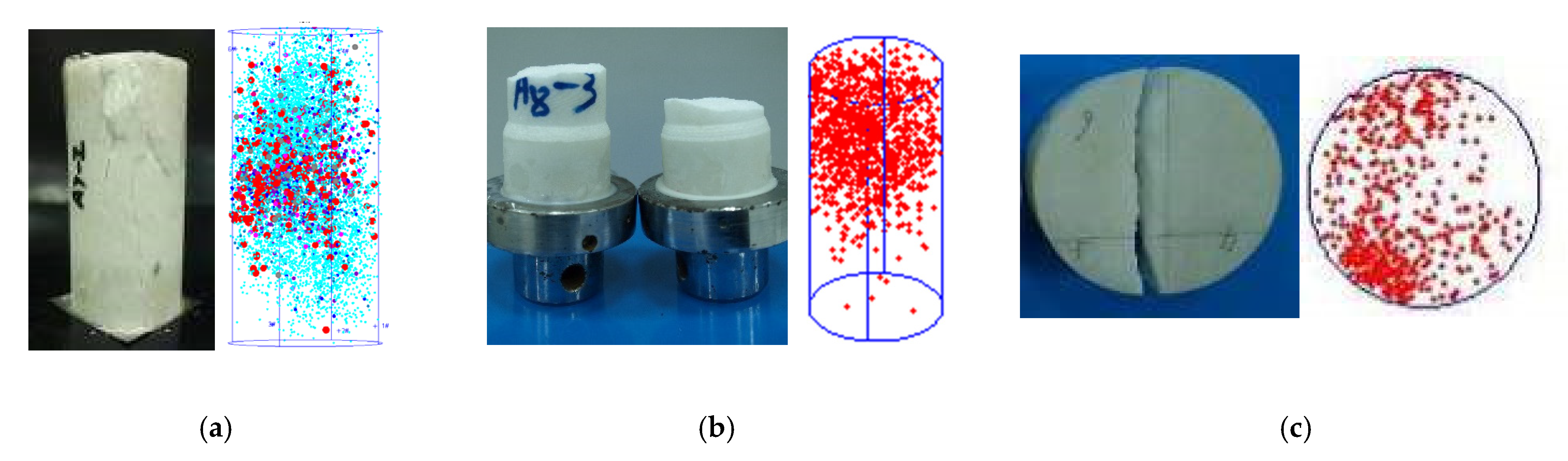

3.1. Temporal Evolution of AE Parameters under Different Loading Modes

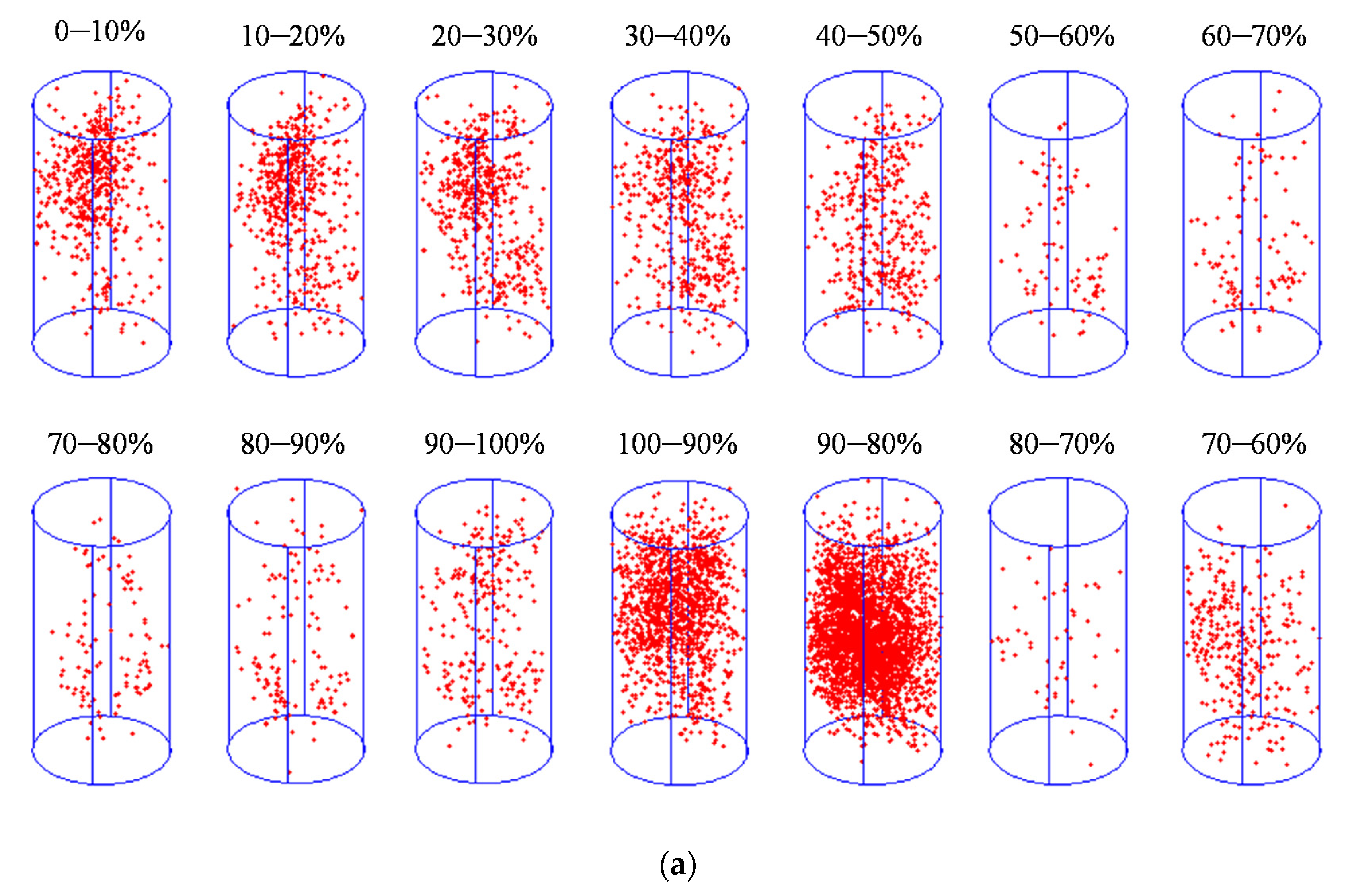

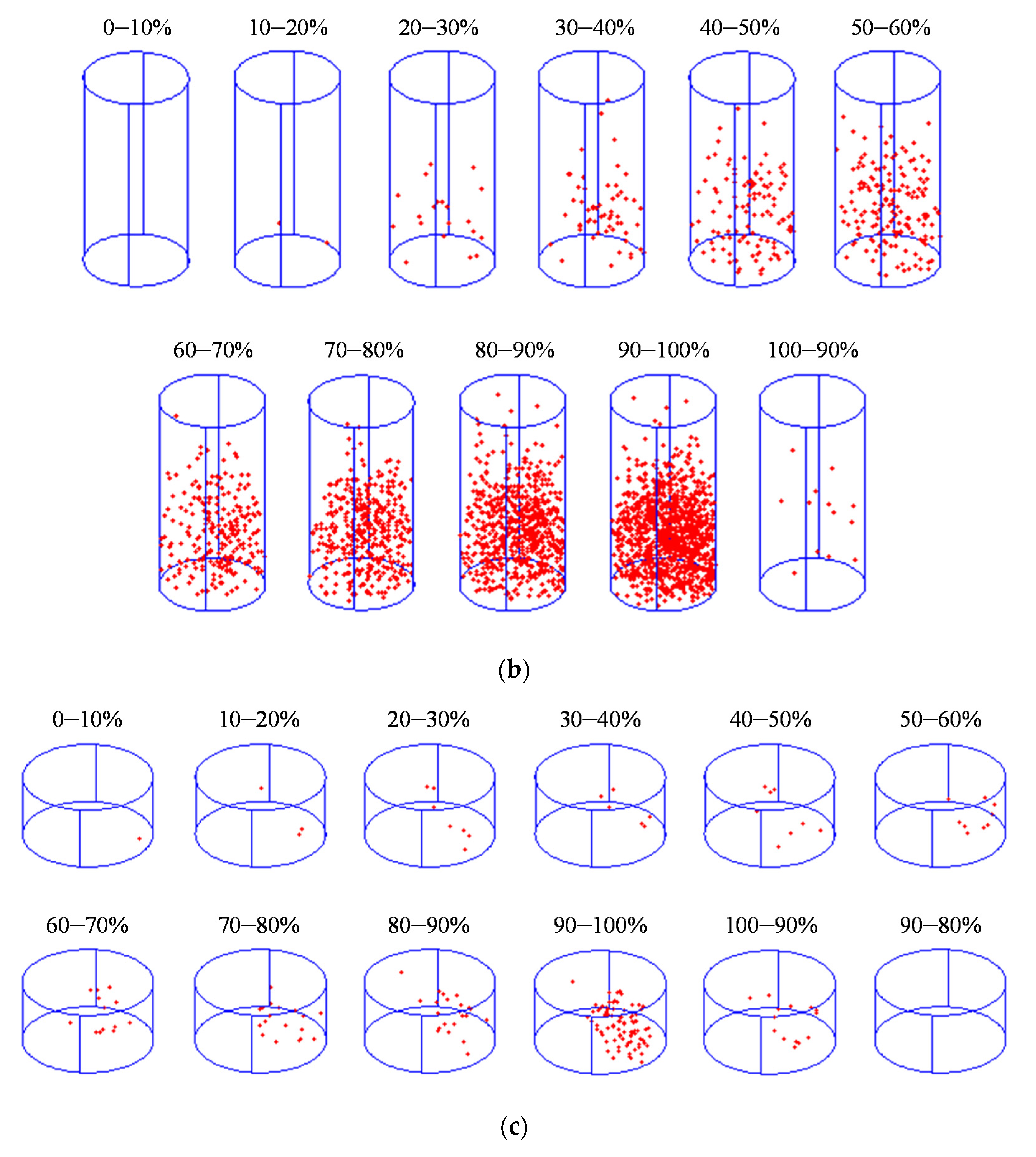

3.2. Differences in the Spatial Evolution of AE Events and Their Failure Patterns under Different Loading Modes

3.3. AE b-Value Analysis Based on AE Amplitude under Different Loading Modes

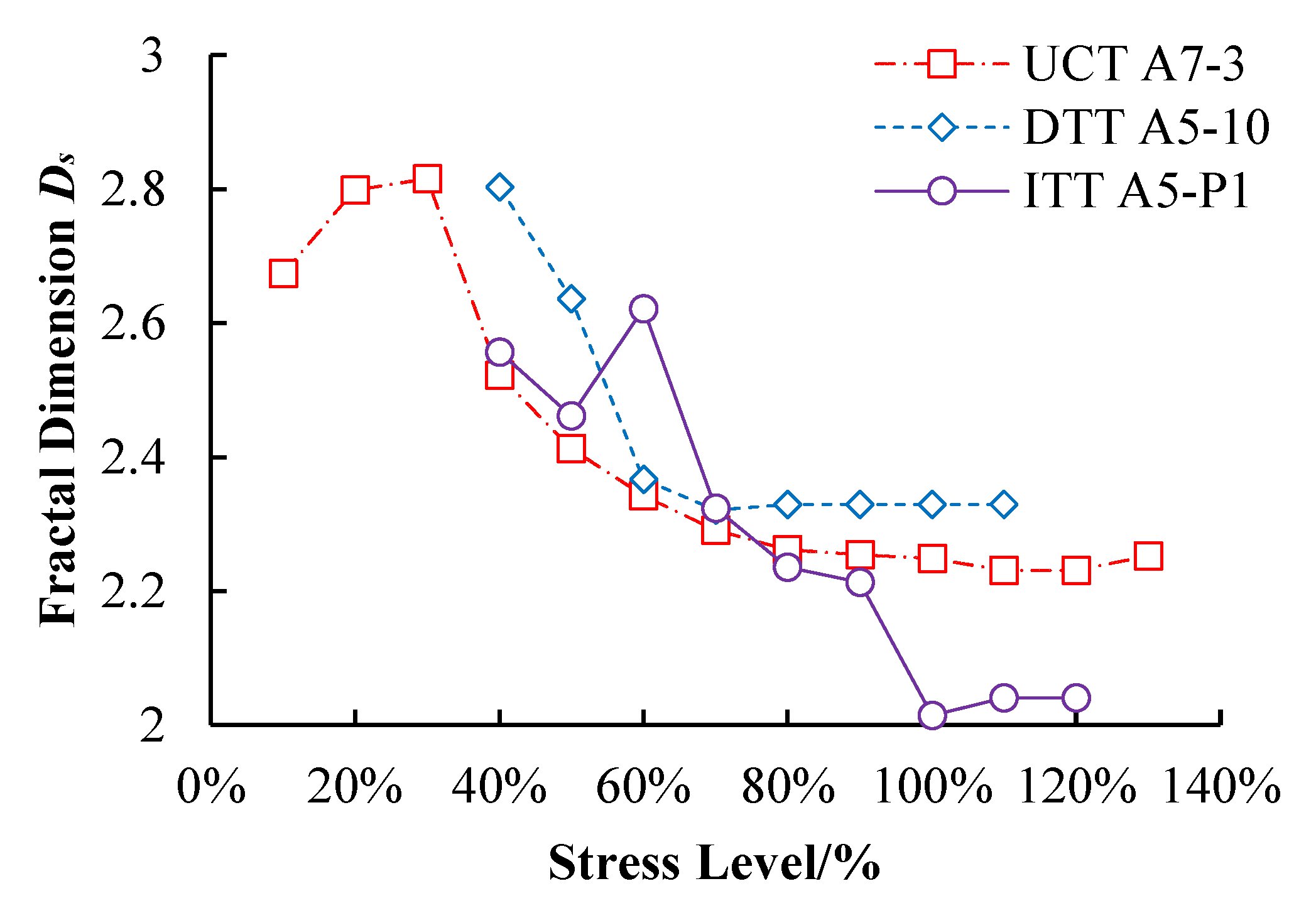

3.4. Spatial Fractal Dimension Ds of AE Events Based on The Column Covering Method under Different Loading Modes

4. Discussion and Precursor Information of Failure under Different Loading Modes

5. Conclusions

- (1)

- The stress states and failure modes of rocks under different loading modes were different, resulting in substantial differences in the temporal evolution of the AE parameters. The AE experiment results showed that the sequence of total AE events and AE counts was UCT > DTT > ITT. The AE energy release in the DTT and ITT was concentrated at the peak stress, and the AE signal rapidly weakened after the peak. However, there were still a large number of AE signals generated after the peak in the UCT accompanied by violent AE energy release.

- (2)

- Due to different loading methods of the same rock, the microfracture mechanism and macroscopic failure mode of the rocks were different. For example, in the UCT, the multiple cleavage failure surfaces were mainly caused by compression-induced fracture. In the DTT, the fracture surface was subjected to tensile stress, whereas in the ITT, the fracture surface was in a compressive-tensile stress state. In the DTT and ITT, the spatial distribution of AE events coincided with the damage accumulation zone and the macroscopic failure surface, whereas in the UCT, the failure surface was composed of multiple compression-induced fractures parallel to the loading direction.

- (3)

- The stress level at which the b-value and the spatial fractal dimension Ds substantially decreased were consistent, and the sequence was UCT < DTT < ITT. These two AE parameters could reflect the development of microfractures and overall damage inside the rock.

- (4)

- In the UCT, the first precursor point of rock failure was defined as the stress level of the AE count rate peak (or energy rate peak) during prepeak loading, whereas in the DTT and ITT, the first precursor point was defined as the starting stress level of the active period of the AE count rate (or energy rate). This characteristic point can reflect the internal fracture growth from stable to unsteady expansion and had a corresponding relationship with the b-value and other AE parameters. In the UCT, the second precursor point of rock failure was defined as the starting stress level of the quiet period of the AE count rate (or energy rate), whereas in the DTT and ITT, the second precursor point was defined as the stress level of the AE count rate peak (or energy rate peak) during prepeak loading. This characteristic point can reflect the internal fracture growth from unsteady expansion to macroscopic failure.

Author Contributions

Funding

Conflicts of Interest

References

- Nazarchuk, Z.; Serhiyenko, O.; Skalskyi, V. Acoustic Emission: Methodology and Application; Springer: New York, NY, USA, 2017. [Google Scholar]

- Lockner, D.A.; Byerlee, J.D.; Kuksenko, V.; Ponomarev, A.; Sidorin, A. Quasi-static fault growth and shear fracture energy in granite. Nature 1991, 350, 39–42. [Google Scholar] [CrossRef]

- Lockner, D.A. The role of acoustic emission in the study of rock fracture. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 883–899. [Google Scholar] [CrossRef]

- Meng, Q.B.; Zhang, M.W.; Han, L.J.; Pu, H.; Nie, T.Y. Effects of acoustic emission and energy evolution of rock specimens under the uniaxial cyclic loading and unloading compression. Rock Mech. Rock Eng. 2016, 49, 3873–3886. [Google Scholar] [CrossRef]

- Yang, S.Q.; Wang, S.Y. Experimental investigation on the strength, deformability, failure behavior and acoustic emission locations of red sandstone under triaxial compression. Rock Mech. Rock Eng. 2012, 45, 583–606. [Google Scholar] [CrossRef]

- Li, L.R.; Deng, J.H.; Zheng, L.; Liu, J.F. Dominant frequency characteristics of acoustic emissions in white marble during direct tensile tests. Rock Mech. Rock Eng. 2017, 50, 1337–1346. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.K.; Morioka, H.; Minami, M.; Maejima, T.; Tasaka, Y.; Kurose, H. FLAC/PFC coupled numerical simulation of AE in large-scale underground excavations. Int. J. Rock Mech. Min. Sci. 2007, 44, 550–564. [Google Scholar] [CrossRef]

- Lisjak, A.; Liu, Q.; Zhao, Q.; Mahabadi, O.K.; Grasselli, G. Numerical simulation of acoustic emission in brittle rocks by two-dimensional finite-discrete element analysis. Geophys. J. Int. 2013, 195, 423–443. [Google Scholar] [CrossRef]

- Zhu, W.C.; Zhao, X.D.; Kang, Y.M.; Wei, C.H.; Tian, J. Numerical simulation on the acoustic emission activities of concrete. Mater. Struct. 2010, 43, 633–650. [Google Scholar] [CrossRef]

- Liu, J.F.; Chen, L.; Wang, C.P.; Man, K.; Wang, L.; Wang, J.; Su, R. Characterizing the mechanical tensile behavior of Beishan granite with different experimental methods. Int. J. Rock Mech. Min. Sci. 2014, 69, 50–58. [Google Scholar] [CrossRef]

- Wang, Q.S.; Chen, J.X.; Guo, J.Q.; Luo, Y.B.; Wang, H.Y.; Liu, Q. Acoustic emission characteristics and energy mechanism in karst limestone failure under uniaxial and triaxial compression. Bull. Eng. Geol. Environ. 2017, 78, 1427–1442. [Google Scholar] [CrossRef]

- Zhang, R.; Dai, F.; Gao, M.Z.; Xu, N.W.; Zhang, C.P. Fractal analysis of acoustic emission during uniaxial and triaxial loading of rock. Int. J. Rock Mech. Min. Sci. 2015, 79, 241–249. [Google Scholar] [CrossRef]

- Chmel, A.; Shcherbakov, I. A comparative acoustic emission study of compression and impact fracture in granite. Int. J. Rock Mech. Min. Sci. 2013, 64, 56–59. [Google Scholar] [CrossRef]

- Chen, Z.H.; Tang, C.A.; Fu, Y.F. Effect of stiffness load on rock samples in AE test. J. China Coal Soc. 1996, 21, 364–369. [Google Scholar]

- Ohtsu, M. Acoustic emission characteristics in concrete and diagnostic applications. J. Acoust. Emiss. 1987, 6, 99–108. [Google Scholar]

- Dai, S.T.; Labuz, J.F. Damage and failure analysis of brittle materials by acoustic emission. J. Mater. Civ. Eng. 1997, 9, 200–205. [Google Scholar] [CrossRef]

- Zhao, X.G.; Cai, M.; Wang, J.; Ma, L.K. Damage stress and acoustic emission characteristics of the Beishan granite. Int. J. Rock Mech. Min. Sci. 2013, 64, 258–269. [Google Scholar] [CrossRef]

- Tang, C.A.; Xu, X.H. Evolution and propagation of material defects and Kaiser Effect Function. J. Seismol. Res. 1990, 13, 203–213. [Google Scholar]

- Ji, M. Damage evolution law based on acoustic emission and weibull distribution of granite under uniaxial stress. Acta Geodyn. Geomater. 2014, 175, 269–274. [Google Scholar] [CrossRef]

- Ai, T.; Zhang, R.; Liu, J.F.; Ren, L. Space-time evolution rules of acoustic emission location of unloaded coal sample at different loading rates. Int. J. Min. Sci. Technol. 2012, 22, 847–854. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Zhang, R.; Xie, H.P.; Liu, J.F.; Patrick, W. Differences in the acoustic emission characteristics of rock salt compared with granite and marble during the damage evolution process. Environ. Earth Sci. 2015, 73, 6987–6999. [Google Scholar] [CrossRef]

- Zhang, R. Research on AE Properties of Rock Damage Evolution Process and Rockburst Integrated Prediction. Ph.D. Thesis, Sichuan University, Chengdu, China, 2010. [Google Scholar]

- Carpinteri, A.; Lacidogna, G.; Corrado, M.; di Battista, E. Cracking and crackling in concrete-like materials: A dynamic energy balance. Eng. Fract. Mech. 2016, 155, 130–144. [Google Scholar] [CrossRef]

- Vidya, S.R.; Raghu, P.B.K. Damage limit states of reinforced concrete beams subjected to incremental cyclic loading using relaxation ratio analysis of AE parameters. Constr. Build. Mater. 2012, 35, 139–148. [Google Scholar] [CrossRef]

- Liu, J.F.; Xu, J.; Yang, C.H.; Hou, Z.M.M. Mechanical characteristics of tensile failure of salt rock. Chin. J. Geotech. Eng. 2011, 33, 580–586. [Google Scholar]

- Gutenberg, B.; Richter, C.F. Frequency of earthquakes in California. Bull. Seismol. Soc. Am. 1944, 34, 185–188. [Google Scholar]

- Xue, Y.; Dang, F.N.; Cao, Z.Z.; Du, F.; Ren, J.; Chang, X.; Gao, F. Deformation, permeability and acoustic emission characteristics of coal masses under mining-induced stress paths. Energies 2018, 11, 2233. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Wang, H.Q.; Cai, X.; Chen, L.; Yude, E.; Cheng, R.S. Damage evolution and failure behavior of post-mainshock damaged rocks under aftershock effects. Energies 2019, 12, 4429. [Google Scholar] [CrossRef]

- Carnì, D.L.; Scuro, C.; Lamonaca, F.; Olivito, R.S.; Grimaldi, D. Damage analysis of concrete structures by means of acoustic emissions technique. Compos. Part B Eng. 2017, 115, 79–86. [Google Scholar] [CrossRef]

- Zeng, Z.W.; Ma, J.; Liu, L.Q.; Liu, T.C. AE b-value dynamic features during rockmass fracturing and their significances. Seismol. Geol. 1995, 17, 7–12. [Google Scholar]

- Lei, X.L.; Kusunose, K.; Rao, M.V.M.S.; Nishizawa, O.; Satoh, T. Quasi-static fault growth and cracking in homogeneous brittle rock under triaxial compression using acoustic emission monitoring. J. Geophys. Res. Atmos. 2000, 105, 6127–6139. [Google Scholar] [CrossRef]

| Sample Number | Height (mm) | Diameter (mm) | Compressive or Tensile Strength (MPa) | Test Method |

|---|---|---|---|---|

| A7-2 | 100.06 | 49.31 | 72.28 | UCT |

| A7-3 | 100.21 | 49.53 | 86.01 | |

| A5-9 | 102.80 | 49.15 | 5.29 | DTT |

| A5-10 | 105.46 | 49.26 | 5.72 | |

| A5-P1 | 24.68 | 49.14 | 1.39 | ITT |

| A5-P2 | 25.12 | 49.14 | 1.63 |

| Sample Number | Test Type | Stress Level of AE Count Rate Peak | Stress Level of AE Energy Rate Peak | Stress Level of Volumetric Dilatation | Starting Stress Level of Active Period in AE Count Rate | Starting Stress Level of Active Period in AE Energy Rate |

|---|---|---|---|---|---|---|

| A7-2 | UCT | 34.45% | 29.66% | 56.54% | - | - |

| A7-3 | 34.08% | 34.08% | 48.34% | - | - | |

| A5-9 | DTT | - | - | - | 68.10% | 68.10% |

| A5-10 | - | - | - | 42.26% | 45.06% | |

| A5-P1 | ITT | - | - | - | 68.75% | 62.17% |

| A5-P2 | - | - | - | 56.94% | 56.94% |

| Sample Number | Test Type | Stress Level where b-Value Decreases Dramatically | Stress Level where Ds Decreases Dramatically |

|---|---|---|---|

| A7-2 | UCT | 20–30% | 10–30% |

| A7-3 | 30–50% | 30–60% | |

| A5-9 | DTT | 60–90% | 50–80% |

| A5-10 | 40–60%, 70–80% | 40–60% | |

| A5-P1 | ITT | 50–70% | 60–70%, 90–100% |

| A5-P2 | 40–70% | 20–60%, 90–100% |

| Sample Number | Test Type | Stress Level of AE Count Rate Peak | Stress Level of AE Energy Rate Peak | Starting Stress Level of Quiet Period in AE Count Rate | Starting Stress Level Range of Quiet Period in AE Energy Rate |

|---|---|---|---|---|---|

| A7-2 | UCT | - | - | 97.27% | 99.79% |

| A7-3 | - | - | 99.92% | 99.92% | |

| A5-9 | DTT | 93.00% | 93.00% | - | - |

| A5-10 | 63.67% | 63.67% | - | - | |

| A5-P1 | ITT | 99.70% | 99.70% | - | - |

| A5-P2 | 97.96% | 99.00% | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zha, E.; Zhang, R.; Zhang, Z.; Ai, T.; Ren, L.; Zhang, Z.; Liu, Y.; Lou, C. Acoustic Emission Characteristics and Damage Evolution of Rock under Different Loading Modes. Energies 2020, 13, 3649. https://doi.org/10.3390/en13143649

Zha E, Zhang R, Zhang Z, Ai T, Ren L, Zhang Z, Liu Y, Lou C. Acoustic Emission Characteristics and Damage Evolution of Rock under Different Loading Modes. Energies. 2020; 13(14):3649. https://doi.org/10.3390/en13143649

Chicago/Turabian StyleZha, Ersheng, Ru Zhang, Zetian Zhang, Ting Ai, Li Ren, Zhaopeng Zhang, Yang Liu, and Chendi Lou. 2020. "Acoustic Emission Characteristics and Damage Evolution of Rock under Different Loading Modes" Energies 13, no. 14: 3649. https://doi.org/10.3390/en13143649

APA StyleZha, E., Zhang, R., Zhang, Z., Ai, T., Ren, L., Zhang, Z., Liu, Y., & Lou, C. (2020). Acoustic Emission Characteristics and Damage Evolution of Rock under Different Loading Modes. Energies, 13(14), 3649. https://doi.org/10.3390/en13143649