Gassing Tendency of Fresh and Aged Mineral Oil and Ester Fluids under Electrical and Thermal Fault Conditions

Abstract

1. Introduction

2. Experimental

2.1. Samples

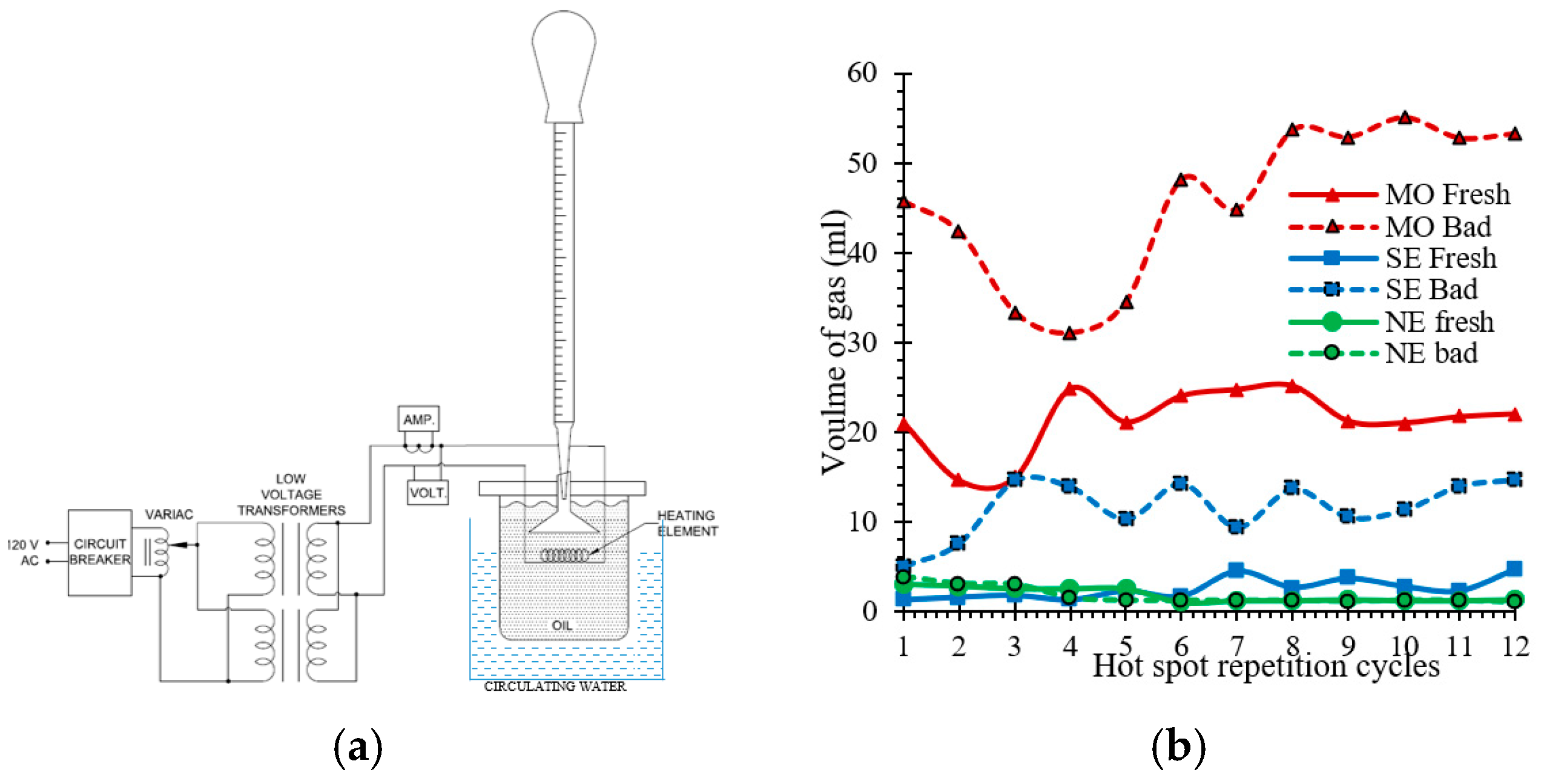

2.2. Laboratory Simulation of Electrical and Thermal Faults

2.2.1. High Energy Discharges (Arcing)

2.2.2. Low Energy Discharges (Partial Discharges)

2.2.3. Thermal Faults (Hotspot)

3. Results and Discussions

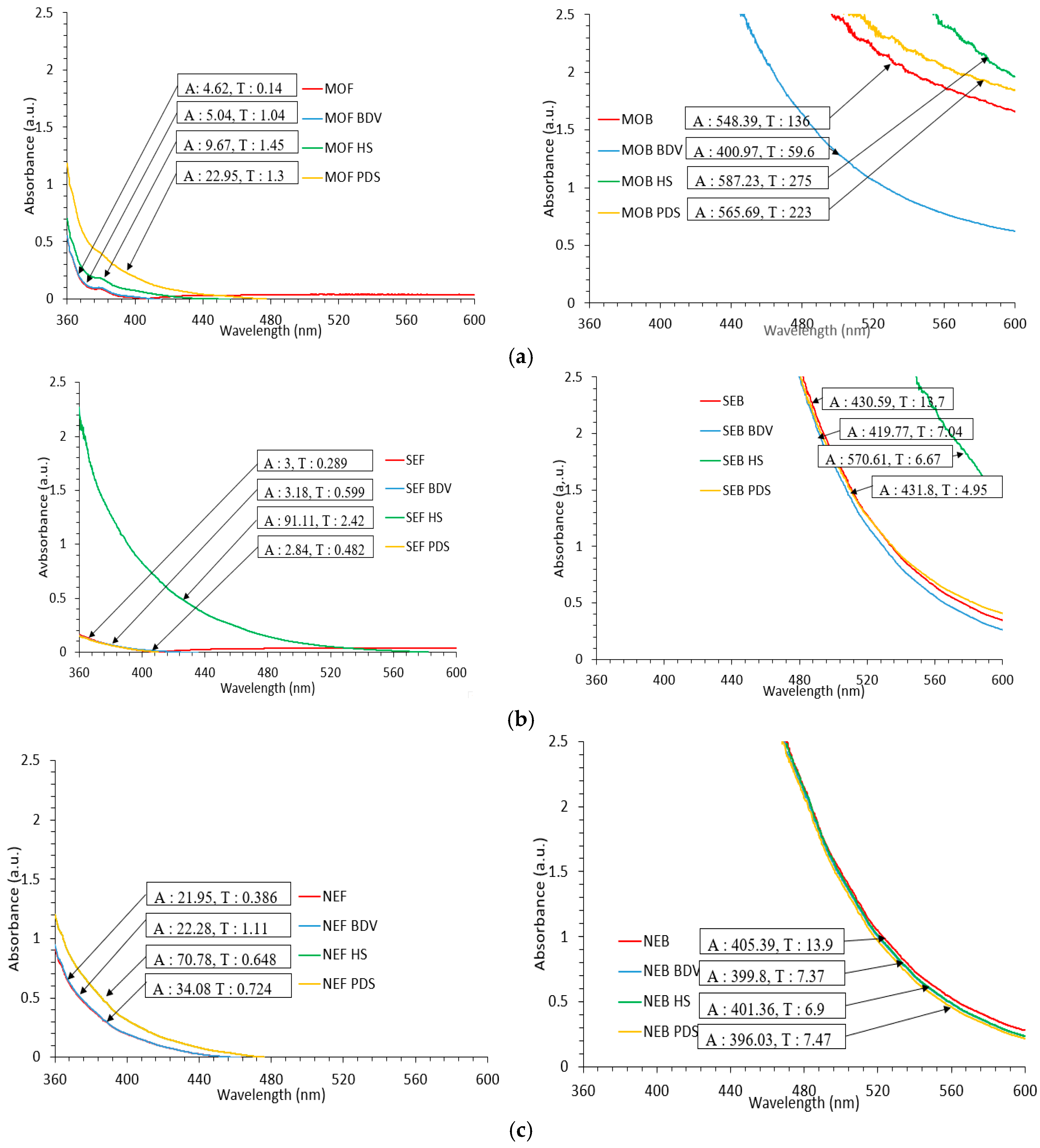

3.1. Degradation of Insulating Fluids

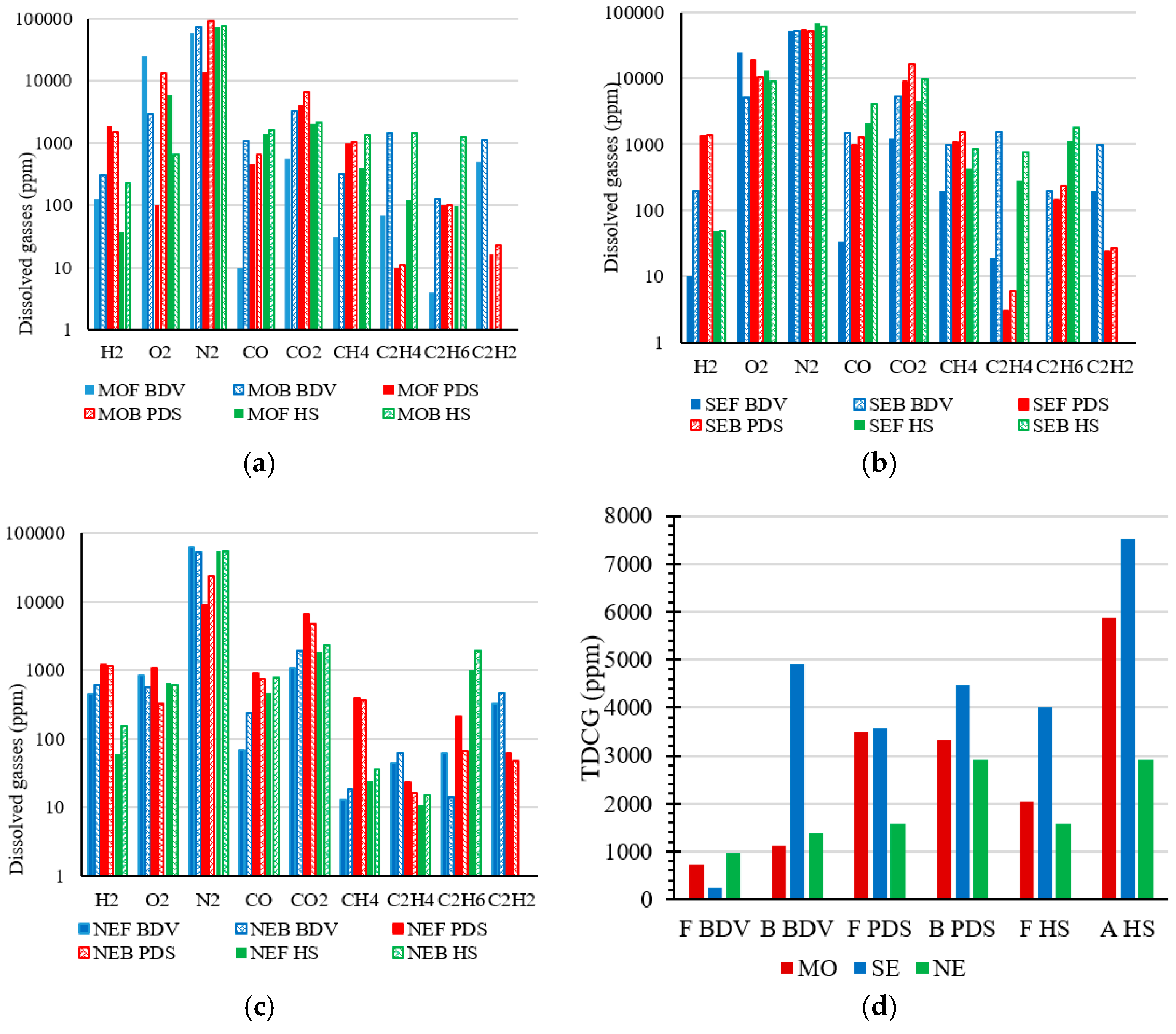

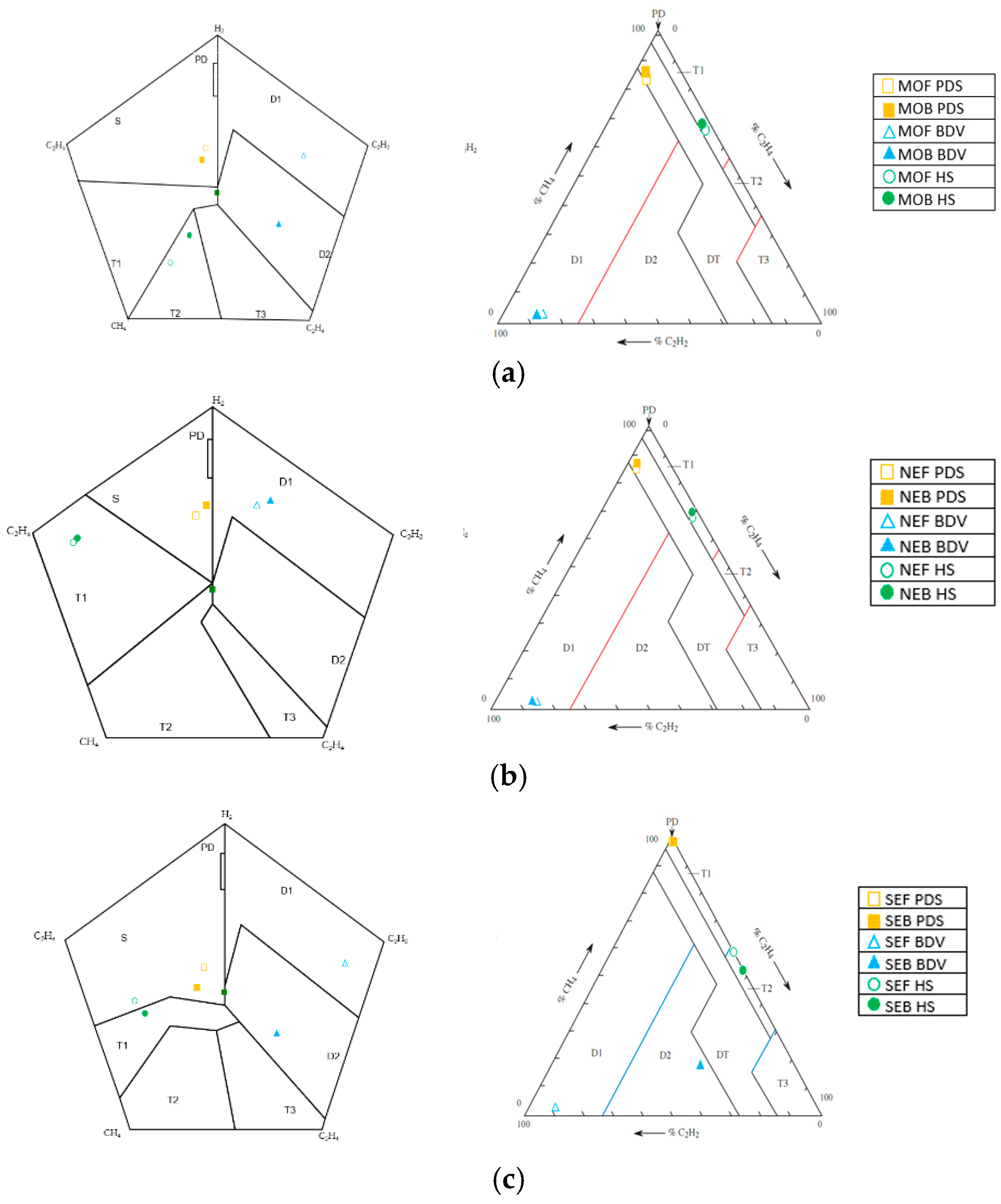

3.2. Gassing Tendency of Insulating Fluids

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mohan Rao, U.; Fofana, I.; Jaya, T.; Rodriguez-Celis, E.M.; Jalbert, J.; Picher, P. Alternative dielectric fluids for transformer insulation system: Progress, challenges, and future prospects. IEEE Access 2019, 7, 184552–184571. [Google Scholar] [CrossRef]

- Abdelmalik, A.A. Analysis of thermally aged insulation paper in a natural ester-based dielectric fluid. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2408–2414. [Google Scholar] [CrossRef]

- Rafiq, M.; Lv, Y.Z.; Zhou, Y.; Ma, K.B.; Wang, W.; Li, C.R.; Wang, Q. Use of vegetable oils as transformer oils—A review. Renew. Sustain. Energy Rev. 2015, 52, 308–324. [Google Scholar] [CrossRef]

- Ghani, S.A.; Muhamad, N.A.; Noorden, Z.A.; Zainuddin, H.; Bakar, N.A.; Talib, M.A. Methods for improving the workability of natural ester insulating oils in power transformer applications: A review. Electr. Power Syst. Res. 2018, 163, 655–667. [Google Scholar] [CrossRef]

- Martin, D.; Saha, T.K.; McPherson, L. Condition monitoring of vegetable oil insulation in in-service power transformers: Some data spanning 10 years. IEEE Electr. Insul. Mag. 2017, 33, 44–51. [Google Scholar] [CrossRef]

- Wilhelm, H.M.; Stocco, G.B.; Batista, S.G. Reclaiming of in-service natural ester-based insulating fluids. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 128–134. [Google Scholar] [CrossRef]

- Institute of Electrical and Electronics Engineers. IEEE Draft Guide for Acceptance and Maintenance of Natural Ester Insulating Liquid in Transformers; IEEE PC57.147/D5; Institute of Electrical and Electronics Engineers: New York, NY, USA, 21 November 2017. [Google Scholar]

- Institute of Electrical and Electronics Engineers. IEEE Draft Guide for Interpretation of Gases Generated in Natural Ester and Synthetic Ester Immersed Transformers; IEEE PC57.155/D6; Institute of Electrical and Electronics Engineers: New York, NY, USA, 15 August 2014. [Google Scholar]

- Wang, Z.D.; Liu, Q.; Wang, X.; Yi, X.; Jarman, P.; Wilson, G.; Dyer, P.; Perrot, F.; Perrier, C.; Walker, D.; et al. Ester Insulating Liquids for Power Transformers; International Council on Large Electric Systems: Paris, France, 2012; p. A2-209. [Google Scholar]

- Fofana, I.; Wasserberg, V.; Borsi, H.; Gockenbach, E. Challenge of mixed insulating liquids for use in high-voltage transformers. 1. Investigation of mixed liquids. IEEE Electr. Insul. Mag. 2002, 18, 18–31. [Google Scholar] [CrossRef]

- Fofana, I.; Wasserberg, V.; Borsi, H.; Gockenbach, E. Challenge of mixed insulating liquids for use in high-voltage transformers. II. Investigations of mixed liquid impregnated paper insulation. IEEE Electr. Insul. Mag. 2002, 18, 5–16. [Google Scholar] [CrossRef]

- Mohan Rao, U.; Sood, Y.R.; Jarial, R.K. Physiometric and Fourier transform infrared spectroscopy analysis of cellulose insulation in blend of mineral and synthetic ester oils for transformers. IET Sci. Meas. Technol. 2017, 11, 297–304. [Google Scholar]

- Mohan Rao, U.; Kumar, Y.N.; Jarial, R.K. Understanding the ageing behaviour of transformer oil-paper insulation with ester and mixed dielectric fluids. IET Sci. Meas. Technol. 2018, 12, 851–857. [Google Scholar]

- Meira, M.; Álvarez, R.E.; Catalano, L.J.; Ruschetti, C.; Verruchi, C. Comparación de aceites dieléctricos minerales y vegetales en relación a la producción de gases. In Proceedings of the Congreso Bienal de IEEE Argentina, Tucumán, Argentina, 6–8 June 2018. [Google Scholar]

- Meira, M.; Ruschetti, C.; Álvarez, R.; Catalano, L.; Verucchi, C. Dissolved gas analysis differences between natural esters and mineral oils used in power transformers: A review. IET Gen. Trans. Distr. 2019, 13, 5441–5448. [Google Scholar] [CrossRef]

- Perrier, C.; Marugan, M.; Beroual, A. DGA comparison between ester and mineral oils. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1609–1614. [Google Scholar] [CrossRef]

- Hamid, M.; Ishak, M.; Ariffin, M.; Katim, N.; Amin, N.; Azis, N. Dissolved gas analysis (DGA) of vegetable oils under electrical stress. In Proceedings of the International Conference on High Voltage Engineering and Power Systems, Denpasar, Indonesia, 2–5 October 2017; pp. 29–34. [Google Scholar]

- Xiang, C.; Zhou, Q.; Li, J.; Huang, Q.; Song, H.; Zhang, Z. Comparison of dissolved gases in mineral and vegetable insulating oils under typical electrical and thermal faults. Energies 2016, 9, 321. [Google Scholar] [CrossRef]

- Dongjin, K.; Kyosun, K. The criteria of dissolved gas analysis in natural Ester fluid. In Proceedings of the IEEE International Conference on Condition Monitoring and Diagnosis, Bali, Indonesia, 23–27 September 2012; pp. 901–904. [Google Scholar]

- Liu, Y.; Li, J.; Zhang, Z. Fault gases dissolved in vegetable insulating oil under electrical faults. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013; pp. 198–201. [Google Scholar]

- Przybylek, P.; Gielniak, J. Analysis of gas generated in mineral oil, synthetic ester, and natural ester as a consequence of thermal faults. IEEE Access 2019, 7, 65040–65051. [Google Scholar] [CrossRef]

- Cong, H.; Du, S.; Li, Q.; Liu, J. Electro-thermal fault diagnosis method of rapo vegetable oil transformer based on characteristic gas and ratio criterion. IEEE Access 2019, 7, 101147–101159. [Google Scholar] [CrossRef]

- Loiselle, L.; Mohan Rao, U.; Fofana, I. Influence of aging on oil degradation and gassing tendency for mineral oil and synthetic ester under low energy discharge electrical faults. Energies 2020, 13, 595. [Google Scholar] [CrossRef]

- Gray, I.A.R. A Guide to Transformer Oil Analysis; Transformer Chemistry Service. Available online: https://www.satcs.co.za/Transformer_Oil_Analysis.pdf (accessed on 13 June 2020).

- Mladenov, E.S.; Staykov, G.; Cholakov, G. Water saturation limit of transformer oils. IEEE Electr. Insul. Mag. 2009, 25, 23–30. [Google Scholar] [CrossRef]

- Krins, M.; Reuter, M.; Borsi, H.; Gockenbach, E. Breakdown and flashover phenomena related to the presence of high absolute water contents in clean and carbonized transformer oil. In Proceedings of the IEEE Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Cancun, Mexico, 20–24 October 2002; pp. 1–5. [Google Scholar]

- Betie, A.; Mohan Rao, U.; Fofana, I.; Fethi, M.; Yeo, Z. Influence of cellulose paper on gassing tendency of transformer oil under electrical discharge. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1729–1737. [Google Scholar] [CrossRef]

- Duval, M.; Lamarre, L. The new Duval Pentagons available for DGA diagnosis in transformers filled with mineral and ester oils. In Proceedings of the IEEE Electrical Insulation Conference, Baltimore, MD, USA, 11–14 June 2017; pp. 279–281. [Google Scholar]

| Parameters | MO | NE | SE |

|---|---|---|---|

| Power Factor 50 Hz 90 °C, IEC 60247 | <0.001 | − | <0.008 |

| Water content (ppm), IEC 60814 | <20 | <50 | <50 |

| Viscosity (cSt @ 40 °C), ISO 3104 | 9.2 | 32 | 29 |

| Fire point (°C), ISO 2592 | − | >350 | 316 |

| Flash point (°C), ISO 2719 | 148 | >260 | 260 |

| Pour Point (°C), ISO 3016 | −54 | −18 | −56 |

| Acidity, (mg KOH/g), IEC 62021 | <0.01 | <0.04 | <0.03 |

| Density at 20 °C (kg/dm3) | 0.869 | 0.92 | 0.97 |

| Sample | Acidity Test 1 mg KOH/g | Acidity Test 2 mg KOH/g | Average | Std. Deviation | Ratio of Degraded Solution to Fresh Oil * |

|---|---|---|---|---|---|

| MO Bad Class | 0.2757 | 0.2675 | 0.2716 | 0.0058 | 1:26.6 |

| SE Bad Class | 0.2314 | 0.2573 | 0.24435 | 0.0183 | 1:20 |

| NE Bad Class | 0.3016 | 0.2801 | 0.29085 | 0.0152 | 1:40 |

| Sample | MO Fresh | MO Bad | SE Fresh | SE Bad | NE Fresh | NE Bad |

|---|---|---|---|---|---|---|

| Average energy used for 100 BDV’s (Joules) | 4.53 × 10−1 | 5.53 × 10−1 | 4.40 × 10−1 | 7.11 × 10−1 | 3.50 × 10−1 | 2.97 × 10−1 |

| Abbreviation | Details |

|---|---|

| MOF | Mineral Oil Fresh |

| MOB | Mineral Ester Bad |

| SEF | Synthetic Ester Fresh |

| SEB | Synthetic Ester Bad |

| NEF | Natural Ester Fresh |

| NEB | Natural Ester Bad |

| BDV | High energy discharge (arcing) |

| PDS | Low energy discharge (Partial discharge) |

| HS | Hot spot (Thermal fault) |

| A | Dissolved decay products |

| T | Turbidity |

| TDCG | Total dissolved combustible gasses |

| Sample | Fault Diagnosis by Duval’s Pentagon | Fault Diagnosis by Duval’s Triangle | Fault Matching | ||

|---|---|---|---|---|---|

| Code | Fault | Code | Fault | ||

| MOF BDV | D1 | Electrical discharges of low energy | D1 | Electrical discharges of low energy | Matched |

| MOA BDV | D2 | Electrical discharges of high energy | D1 | Electrical discharges of low energy | Partially matched (electrical discharges) |

| MOF PDS | S | Stray gassing | DT | Mixture of electrical and thermal faults | Not matched |

| MOB PDS | S | Stray gassing | DT | Mixture of electrical and thermal faults | Not matched |

| MOF HS | T2 | Thermal faults between 300 and 700 °C | T1 | Thermal fault of less than 300 °C | Partially matched (Thermal) |

| MOB HS | T2 | Thermal faults between 300 and 700 °C | T1 | Thermal fault of less than 300 °C | Partially matched (Thermal) |

| NEF BDV | D1 | Electrical discharges of low energy | D1 | Electrical discharges of low energy | Matched |

| NEB BDV | D1 | Electrical discharges of low energy | D1 | Electrical discharges of low energy | Matched |

| NEF PDS | S | Stray gassing | DT | Mixture of electrical and thermal faults | Not matched |

| NEB PDS | S | Stray gassing | DT | Mixture of electrical and thermal faults | Not matched |

| NEF HS | T1 | Thermal fault of less than 300 °C | T1 | Thermal fault of less than 300 °C | Matched |

| NEB HS | T1 | Thermal fault of less than 300 °C | T1 | Thermal fault of less than 300 °C | Matched |

| SEF BDV | D1 | Electrical discharges of low energy | D1 | Electrical discharges of low energy | Matched |

| SEB BDV | D2 | Electrical discharges of high energy | D2 | Electrical discharges of high energy | Matched |

| SEF PDS | S | Stray gassing | T1 | Thermal fault of less than 300 °C | Not matched |

| SEB PDS | S | Stray gassing | T1 | Thermal fault of less than 300 °C | Not matched |

| SEF HS | S | Stray gassing | T2 | Thermal faults between 300 and 700 °C | Not matched |

| SEB HS | T1 | Thermal fault of less than 300 °C | T2 | Thermal faults between 300 and 700 °C | Partially matched (Thermal) |

| Dissolved Gas in Liquid Phase (ppm) | Dissolved Gas in Gas Phase (ppm) | Total Gas Generated (ppm) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | MOF | MOB | SEF | SEB | NEF | NEB | MOF | MOB | SEF | SEB | NEF | NEB | MOF | MOB | SEF | SEB | NEF | NEB | ||

| H2 | BDV | 0.0429 | 125 | 299 | 10 | 195 | 1220 | 1140 | 2914 | 6970 | 233 | 4545 | 28438 | 26573 | 3039 | 7269 | 243 | 4740 | 29658 | 27713 |

| CO | 0.9 | 10 | 1083 | 34 | 1490 | 907 | 760 | 11 | 1203 | 38 | 1656 | 1008 | 844 | 21 | 2286 | 72 | 3146 | 1915 | 1604 | |

| CO2 | 0.102 | 558 | 3176 | 1243 | 5320 | 6660 | 4810 | 5471 | 31137 | 12186 | 52157 | 65294 | 47157 | 6029 | 34313 | 13429 | 57477 | 71954 | 51967 | |

| CH4 | 0.337 | 31 | 319 | 192 | 983 | 397 | 359 | 92 | 947 | 570 | 2917 | 1178 | 1065 | 123 | 1266 | 762 | 3900 | 1575 | 1424 | |

| C2H4 | 1.35 | 68 | 1446 | 19 | 1540 | 23 | 16 | 50 | 1071 | 14 | 1141 | 17 | 12 | 118 | 2517 | 33 | 2681 | 40 | 28 | |

| C2H6 | 1.99 | 4 | 125 | 1 | 198 | 215 | 67 | 2 | 63 | 1 | 99 | 108 | 34 | 6 | 188 | 2 | 297 | 323 | 101 | |

| C2H2 | 0.938 | 492 | 1113 | 192 | 983 | 61 | 48 | 525 | 1187 | 205 | 1048 | 65 | 51 | 1017 | 2300 | 397 | 2031 | 126 | 99 | |

| H2 | PDS | 0.0429 | 1910 | 1527 | 1330 | 1390 | 1220 | 1140 | 44522 | 35594 | 31002 | 32401 | 28438 | 26573 | 46432 | 37121 | 32332 | 33791 | 29658 | 27713 |

| CO | 0.9 | 459 | 649 | 992 | 1280 | 907 | 760 | 510 | 721 | 1102 | 1422 | 1008 | 844 | 969 | 1370 | 2094 | 2702 | 1915 | 1604 | |

| CO2 | 0.102 | 4114 | 6724 | 8840 | 16100 | 6660 | 4810 | 40333 | 65922 | 86667 | 157843 | 65294 | 47157 | 44447 | 72646 | 95507 | 173943 | 71954 | 51967 | |

| CH4 | 0.337 | 1004 | 1018 | 1080 | 1520 | 397 | 359 | 2979 | 3021 | 3205 | 4510 | 1178 | 1065 | 3983 | 4039 | 4285 | 6030 | 1575 | 1424 | |

| C2H4 | 1.35 | 10 | 11 | 3 | 6 | 23 | 16 | 7 | 8 | 2 | 4 | 17 | 12 | 17 | 19 | 5 | 10 | 40 | 28 | |

| C2H6 | 1.99 | 100 | 100 | 145 | 235 | 215 | 67 | 50 | 50 | 73 | 118 | 108 | 34 | 150 | 150 | 218 | 353 | 323 | 101 | |

| C2H2 | 0.938 | 16 | 23 | 24 | 27 | 61 | 48 | 17 | 25 | 26 | 29 | 65 | 51 | 33 | 48 | 50 | 56 | 126 | 99 | |

| H2 | HS | 0.0429 | 37 | 225 | 49 | 48 | 60 | 150 | 862 | 5245 | 1142 | 1119 | 1399 | 3497 | 899 | 5470 | 1191 | 1167 | 1459 | 3647 |

| CO | 0.9 | 1375 | 1600 | 2100 | 4112 | 465 | 783 | 1528 | 1778 | 2333 | 4569 | 517 | 870 | 2903 | 3378 | 4433 | 8681 | 982 | 1653 | |

| CO2 | 0.102 | 2053 | 2141 | 4601 | 9566 | 1870 | 2340 | 20127 | 20990 | 45108 | 93784 | 18333 | 22941 | 22180 | 23131 | 49709 | 103350 | 20203 | 25281 | |

| CH4 | 0.337 | 404 | 1333 | 424 | 851 | 24 | 36 | 1199 | 3955 | 1258 | 2525 | 71 | 107 | 1603 | 5288 | 1682 | 3376 | 95 | 143 | |

| C2H4 | 1.35 | 120 | 1471 | 284 | 755 | 11 | 15 | 89 | 1090 | 210 | 559 | 8 | 11 | 209 | 2561 | 494 | 1314 | 19 | 26 | |

| C2H6 | 1.99 | 97 | 1259 | 1154 | 1773 | 1020 | 1930 | 49 | 633 | 580 | 891 | 513 | 970 | 146 | 1892 | 1734 | 2664 | 1533 | 2900 | |

| C2H2 | 0.938 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Gas | Accuracy | Repeatability |

|---|---|---|

| H2 | ±0.5 ppm or ±5% | ±0.5 ppm or ±3% |

| O2 | ±500 ppm or ±15% | ±500 ppm or ±10% |

| N2 | ±2.000 ppm or ±15% | ±2.000 ppm or ±10% |

| CO | ±10 ppm or ±5% | ±10 ppm or ±3% |

| CO2 | ±15 ppm or ±5% | ±15 ppm or ±3% |

| CH4 | ±0.2 ppm or ±5% | ±0.5 ppm or ±3% |

| C2H2 | ±0.2 ppm or ±5% | ±0.5 ppm or ±3% |

| C2H4 | ±0.2 ppm or ±5% | ±0.5 ppm or ±3% |

| C2H6 | ±0.2 ppm or ±6% | ±0.5 ppm or ±4% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loiselle, L.; Mohan Rao, U.; Fofana, I. Gassing Tendency of Fresh and Aged Mineral Oil and Ester Fluids under Electrical and Thermal Fault Conditions. Energies 2020, 13, 3472. https://doi.org/10.3390/en13133472

Loiselle L, Mohan Rao U, Fofana I. Gassing Tendency of Fresh and Aged Mineral Oil and Ester Fluids under Electrical and Thermal Fault Conditions. Energies. 2020; 13(13):3472. https://doi.org/10.3390/en13133472

Chicago/Turabian StyleLoiselle, Luc, U. Mohan Rao, and Issouf Fofana. 2020. "Gassing Tendency of Fresh and Aged Mineral Oil and Ester Fluids under Electrical and Thermal Fault Conditions" Energies 13, no. 13: 3472. https://doi.org/10.3390/en13133472

APA StyleLoiselle, L., Mohan Rao, U., & Fofana, I. (2020). Gassing Tendency of Fresh and Aged Mineral Oil and Ester Fluids under Electrical and Thermal Fault Conditions. Energies, 13(13), 3472. https://doi.org/10.3390/en13133472