1. Introduction

In general, one third of energy is consumed by the industrial sector. However, more than 50% of this energy is wasted as heat [

1]. Waste heat is hard to identify and evaluate in terms of quality and quantity, as it is not clearly visible like material waste. Due to global energy interests and responsibilities, as well as the opposition to the consumption of energy-rich fossil-based fuels, we must find ways to overcome this energy-saving issue. One of the most promising solutions is the waste heat recovery (WHR) method. Waste heat is defined as the unused heat developed throughout the chemical reaction or combustion process, which is instantaneously drained to the surroundings. There are several advantages in converting exhaust heat into useful power, for example it can help to reduce fuel consumptions, improve engine power density, and further decrease carbon dioxide (CO

2) and other harmful exhaust emissions. Among the available bottoming cycle methods, steam or Rankine cycles are undoubtedly the most reliable options, although they may be not the most efficient ones [

2,

3,

4,

5].

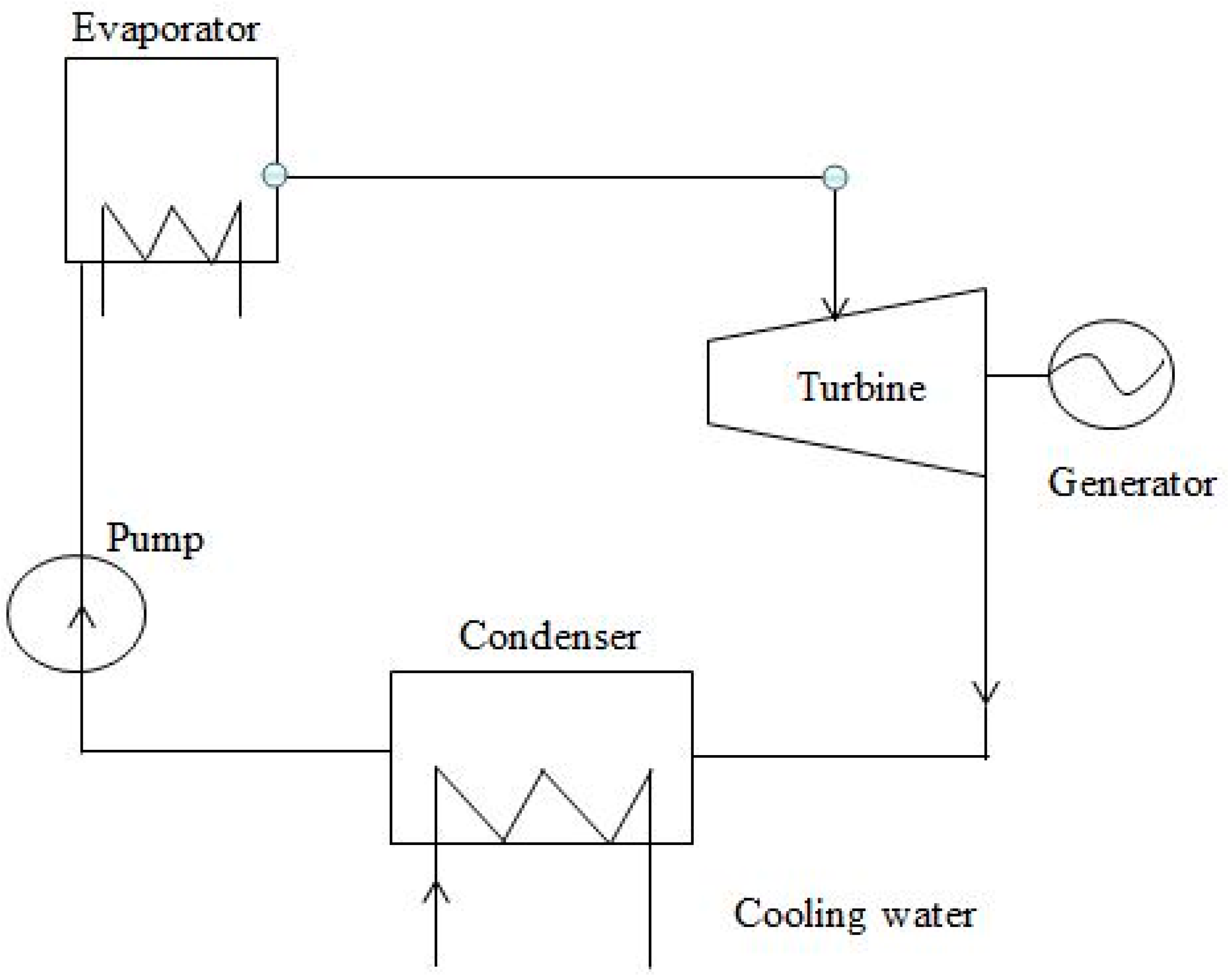

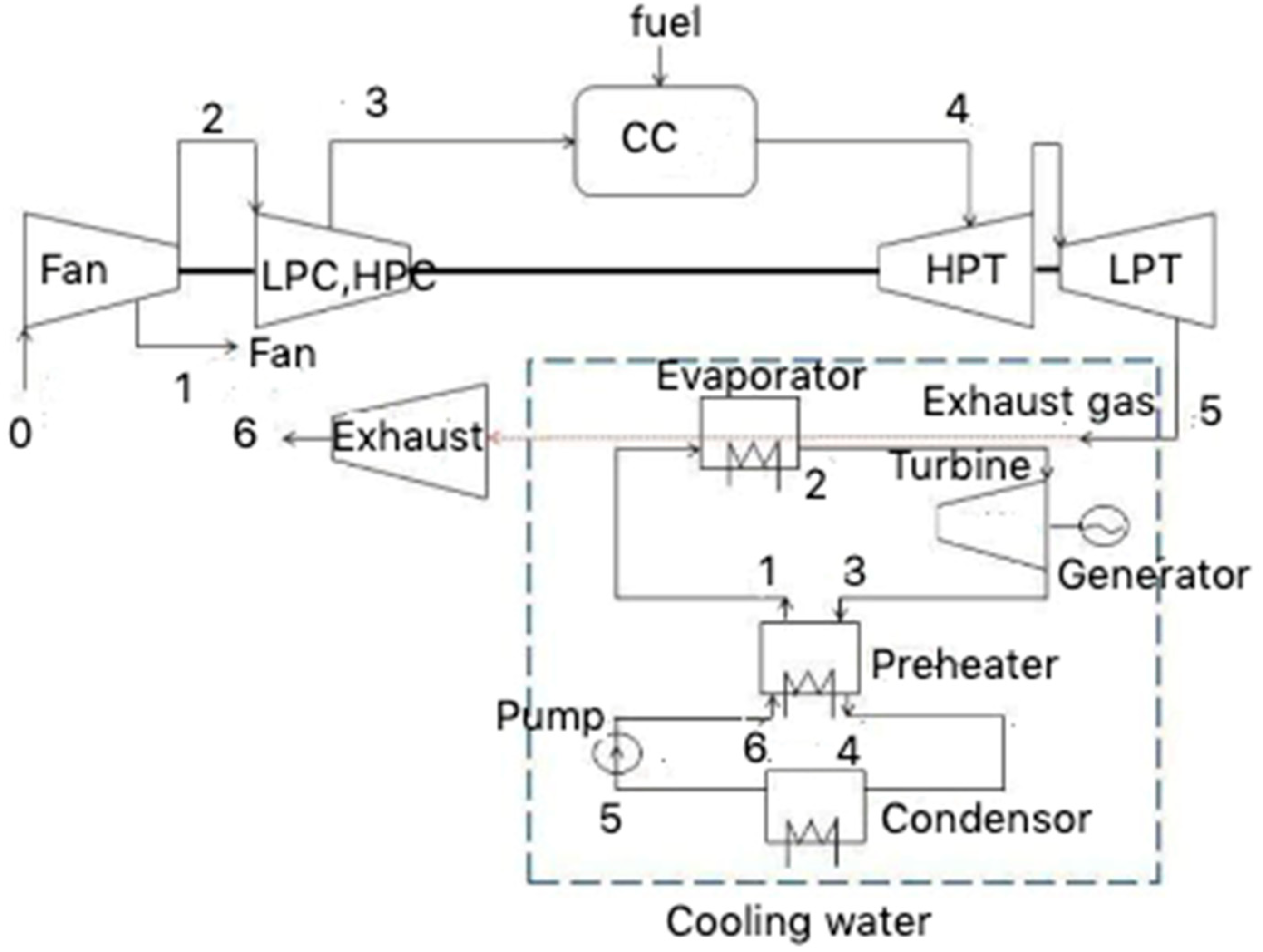

The Organic Rankine Cycle (ORC) is one type of WHR system, which works on the principle of the Rankine cycle, where a working fluid is transported through four basic components. This allows the waste heat to be converted to useful power. Although ORC has many disadvantages such as the fact that the fluids used in an ORC cycle are combustible and, if leakages occurred, an environmental hazard could result, and the fact that ORCs are more expensive than water, the selection of organic fluids over water brings a lot of advantages to the system compared to the steam cycle. The possibility of the transformation of low temperature heat into useful electrical energy is high and can be effective based on its thermophysical characteristics—for instance, a low boiling temperature, low critical point, and high molecular mass.

The analysis of supercritical fluid parameters is crucial. It is proven to perform higher efficiencies which are more attractive for waste heat applications [

6]. In supercritical ORC, the vapor is expanded in the turbine at slightly superheated conditions. Unlike the subcritical ORC, the heating process does not pass through the two-phase (liquid and vapor) regions. This leads to a lower difference in temperature in the evaporator between the hot and cold fluids with a lower irreversibility. In supercritical condition, the ORC thermal efficiency could be improved by 10–30% due to the increment of specific work output, since the heat is added to the working fluid at supercritical pressure [

7,

8,

9]. As a result, the loss in exergy will eventually become lower [

10]. However, the challenge lies in the unpredictable process of heat transfer in the evaporator since the properties of the fluid are variable to the temperature [

11].

Various design configurations have special benefits and constraints. They differ in their construction complexity and performance while operating under distinctive applications and thermal conditions. Daniel R.M. [

12] mentioned that more waste heat can be recovered when a superheater is attached. However, an extra weight is also added since, in order to transfer energy, and for the cooler to be able to condensate the organic fluid, a larger area is needed. Boz B. et al. [

13] performed a study to compare the performance of subcritical and supercritical ORC in exhaust heat recovery. There are two configurations presented, the Regenerative ORC (RORC) and Preheating-Regenerative ORC (PRORC). The greatest net power output by using R245fa was found to be 203.1 kW at around 36% of efficiency with the RORC system. This was due to the increase in turbine inlet temperature that led to the total net power output increasing. In subcritical cycles, the RORC and PRORC showed lower thermal efficiency and power output compared to supercritical cycles. Yagli H. et al. [

14] have done a study on the net power production, mass flow rate and system thermal efficiency of an ORC system with additional preheater and superheater, applied to a power plant using R245fa as working fluid. From the results, the supercritical ORC gives better net power and thermal efficiency at 81.52 kW and 15.93% compared to the subcritical ORC at 79.23 kW and 15.51%. Gao T et al. [

15] studied the performance of subcritical and supercritical ORC in Geothermal Power Systems. The results from this study indicate that ORC at a supercritical condition has better output power with 480 kW compared to subcritical ORC with only 450 kW. Yang M.H. et al. [

16] evaluated on the performance of an ORC system with the addition of both a superheater and a preheater applied to a marine engine. By using R245fa as the working fluid, a net power output of 87.05 kW and a thermal efficiency of 10.08% are achieved.

The energy consumption and environmental impacts have increased with the growth of the aviation industry. Many researchers have attempted to increase the power and decrease the consumption of fuel and the noise of engines in aircraft [

17]. Actions have been taken by the aircraft designers and engineers to enhance the fuel efficiency by changing the aircraft system and fuel types. In order to enhance an aircraft engine’s thrust, it is possible to recover the engine core’s exhaust heat and reuse it to produce useful power. The ORC system applied to a CFM56 turbofan engine’s system demonstrated a 0.9% (by considering additional weight of WHR) to 2.5% (without additional weight) benefit in relation to the vehicle’s fuel burn [

18]. However, due to concerns about resources and time, some assumptions for the modeling are made. A fixed heat transfer coefficient was used, pressure loss was only assumed within the turbine and they estimated the fixed core exhaust flow to the evaporator as 30%, although the fluid was changed while the engine was running. De Servi et al. [

19] have also investigated the possibility of recovering waste heat using supercritical carbon dioxide (sCO

2) as the working fluid. They found that the reduction in Specific Fuel Consumption (SFC) with respect to the SFC of the GE90-94B turbofan engine is about 2.8%, which is nearly one of order of magnitude lower than the value predicted by the sole thermodynamic cycle analysis. Moreover, the model does not take into account the additional fuel consumption due to the weight of sCO

2 WHR unit. Another approach to reduce the SFC was outlined by O. Petit et al. [

20] on an intercooled turbofan engine by recovering the waste heat from the intercooler and reusing it to generate useful power. They achieved a maximum SFC improvement of 3% by using this method.

In order to account for the sustainability of an aircraft engine, exergy plays an important role. According to Sohret Y. et al. [

21], the number of studies covering the aspect of exergy for aircraft engines has increased in the past six years. The exergy efficiency increases at high altitudes due to the decrease in temperature and pressure. However, the exergy efficiency is decreased when the flight is taking off, then starts to climb and during landing [

22]. Turgut et al. [

23] performed an analysis of a turbofan engine based on exergy with an afterburner at sea level and 11000 m altitude. They concluded that, in the exhaust section, a major portion of the exergy is lost due to a higher temperature and velocity in the exhaust of the stream. Meanwhile, Tona C. et al. [

24] presented an analysis of a turbofan engine for commercial flights based on exergy. According to the results, the maximum exergy efficiency was achieved while the flight was cruising, with a value of 26.5%. Their analysis also showed that 50.66% of the total destroyed exergy occurred within the combustion chamber and the exhaust. Turan O. et al. [

25] focused on a detailed exergetic analysis of a high bypass turbofan engine and revealed that the exergy efficiency of the engine was 29.6%. In addition, 1.48 and 0.675 were achieved, respectively, for the exergetic sustainability index and environmental effect factor of the engine. Later on, they proceeded with their investigation on a low bypass turbofan engine and found the exergy efficiency to be 11%, while 3.163 and 0.316, respectively, were achieved for the environmental effect factor and sustainability index based on exergy with zero recoverable exergy [

26]. A study conducted by Aydin H. et al. [

27] on a turbofan engine based on exergetic sustainability shows that the values of environmental impact, sustainability index, waste exergy ratio and exergy efficiency are 2.174, 0.460, 0.685 and 0.315, respectively. Another quite similar study with a mixed exhaust turbofan engine, carried out by S. Saadon et al. [

28], found that the environmental impact factor was higher, at 2.72, and the sustainability index was around 0.37.

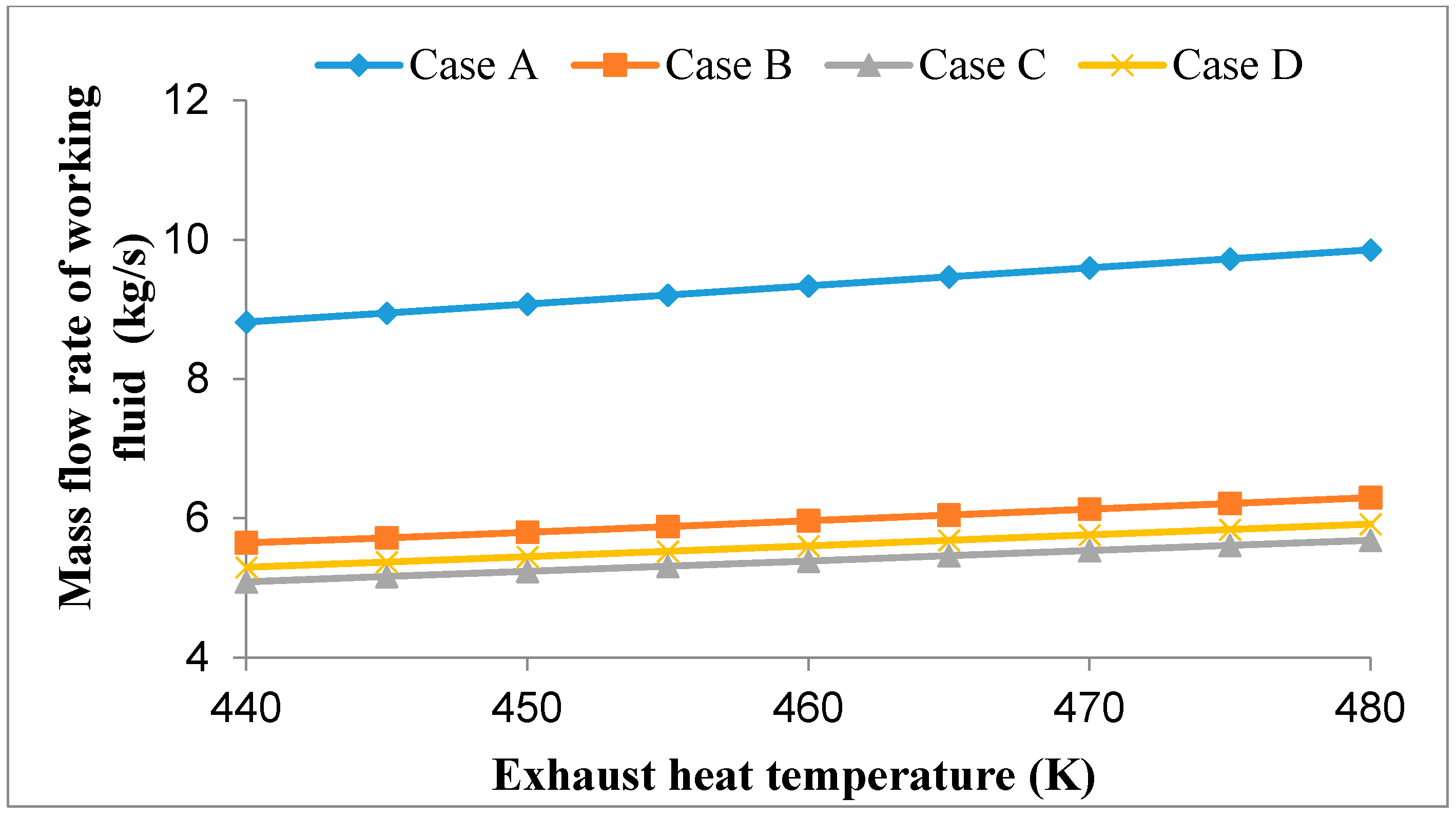

Notably, as represented in the literature review above, the consciousness of reusing low and medium temperature heat sources has captivated many research around the globe and ORC seems to be the most promising option to reuse this waste heat. Our previous works [

29,

30] have attempted to explore this application. However, these works only considered an evaporator as the heat exchanger; therefore, the output power produced was quite inadequate. Moreover, the performance of ORC has to be further improved to allow more waste heat to be extracted. Therefore, research must be done to increase the output power produced by the ORC. One of the ways to improve this power and eventually the engine’s fuel consumption is to include an additional heat exchanger device and to find the most capable design configuration for this heat exchanger in the ORC system. Another issue that may need to be overcome is the fact that the organic fluid mass flow rate used is generally greater than the mass flow rate of water or steam in the Rankine cycle. This will create the need for a bigger feed pump for the ORC. Therefore, this study plans to explore the design of an ORC system by using additional heat exchangers in a superheating condition to obtain a better output power and also to examine the effect of applying dry fluid as refrigerant at supercritical conditions. This research will be accomplished on the basis of these parameters. Many investigators have done extensive research to boost the performance of the ORC. Nevertheless, the areas related to ORC design with additional heat exchangers and the use of organic fluids at supercritical condition have not yet been explored and these are crucial elements to enhance the power output of a waste heat recovery system.

On the other hand, based on previous studies, we can see that the main problem that causes a loss of exergy in an aircraft engine is found within the combustion chamber and exhaust nozzle. However, the areas related to the improvement of the exhaust component and the evaluation of aircraft engine’s sustainability based on exergy are still very lacking. Therefore, this study will try to explore the possibility of reducing the irreversibility problem in aircraft engines and eventually increase the engine’s sustainability. Additionally, this paper also adds a modified formula to the exergy equations to satisfy the effect of integrating Organic Rankine Cycle (ORC) systems.

5. Sustainability Analysis

In this section, we focus on the exergy analysis for each of the aircraft components and the exergetic sustainability of the whole engine with ORC. Within each component, the exergies that will be considered are physical and chemical exergies, except at the exhaust, since high velocity occurs in this part. For most of the cases, the working fluid consists of a mixture of ideal gases and combustion products. The specific physical and chemical exergy is defined as follows [

42]:

Table 5 shows the composition of chemicals in the fuel used in this study.

The exergy efficiency of the engine’s component,

i, can be expressed as the ratio of output exergy to the input exergy or the product exergy to the fuel exergy, where the exergy symbol

Ɛi is denoted as [

43]

Exergy destruction is the rate of irreversibility in the gas turbine. In a steady state cycle, the exergy destruction rate is the difference in exergy input and exergy output, denoted as

, where the equation is [

44,

45,

46]

Finally, the improvement in the potential rate in terms of exergy is defined. This term will assist us to identify the components that require modification or improvement [

47,

48].

In this particular study, the main component of the turbofan engine, which is different from the other previous studies reviewed here, is the exhaust. The exergy inlet, outlet and efficiency equations for the exhaust are calculated as

To calculate the exergy efficiency of the overall turbofan engine, it is required that the thrust power is calculated first, then the fuel and chemical exergy of the inlet air. These are the useful products of an engine.

Thrust power is defined as

Therefore, the overall exergy efficiency is

The most crucial part of this exergy analysis is how to define the recoverable exergy since most of the exergy is lost throughout the engine’s running process. Generally, all the waste heat exergy is unused due to the non-recoverable exhaust emission. Therefore, the recoverable exergy is considered to be null. However, in this study, the recoverable exergy will not be null because the exhaust heat was reused for waste heat recovery [

27,

44,

49,

50,

51,

52,

53].

In the meantime, the environmental effect factor can be defined as [

27,

44,

49,

50,

51,

52,

53]

The heat and exergy at the evaporator are crucial in order to assess sustainability performances. The original Equations (31) and (33)–(35), are actually without the heat and exergy of the evaporator to begin with. By integrating the ORC system, these equations need to be modified with regard to the ORC system.

For the purpose of this evaluation, the exergy efficiency, improvement potential rate and exergy destruction for each component are calculated using sea level data. The thrust power produced at sea level during take-off is 32 MW.

Table 6 (below) shows the design parameters used for this type of turbofan engine at sea level [

23].

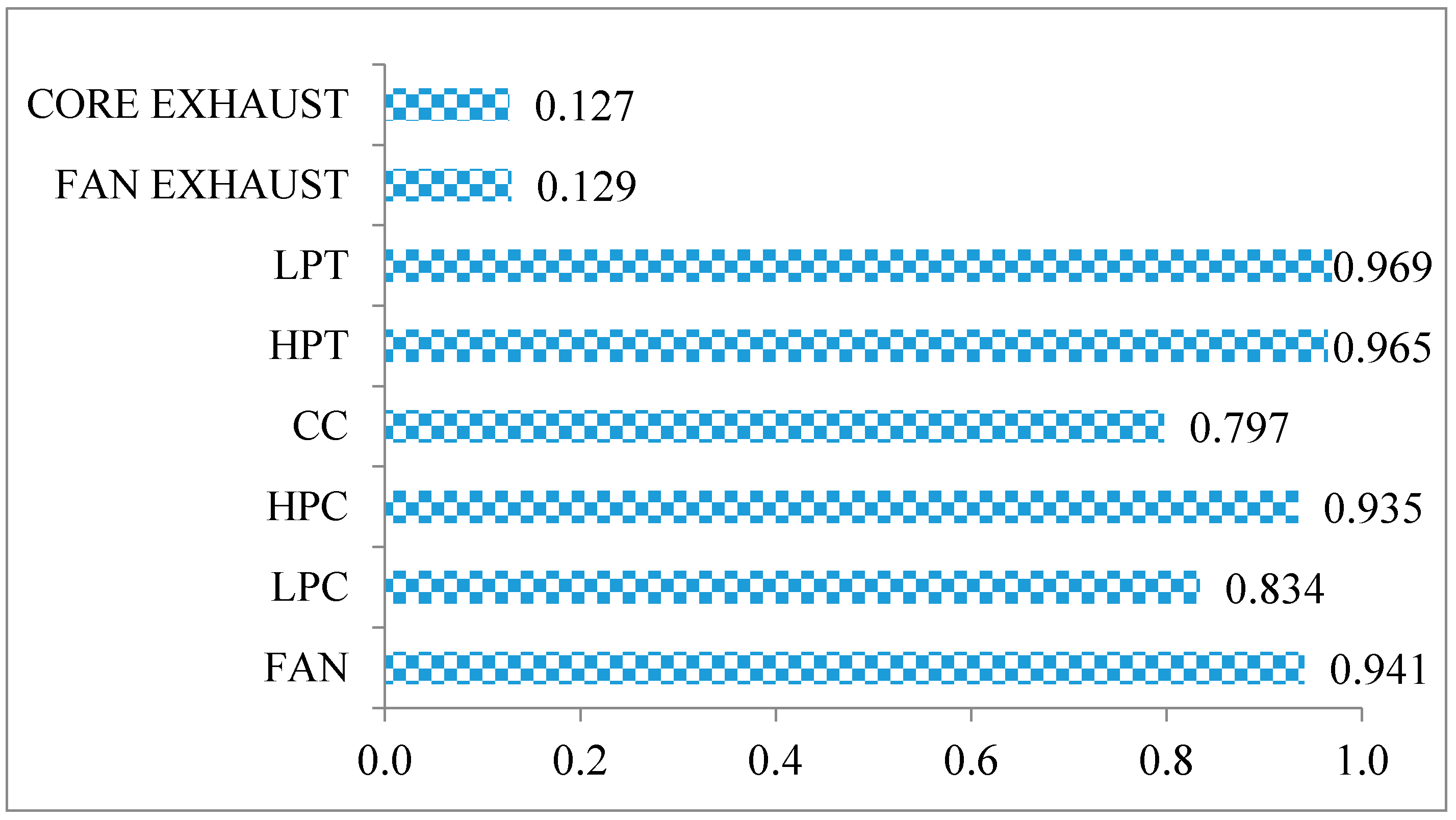

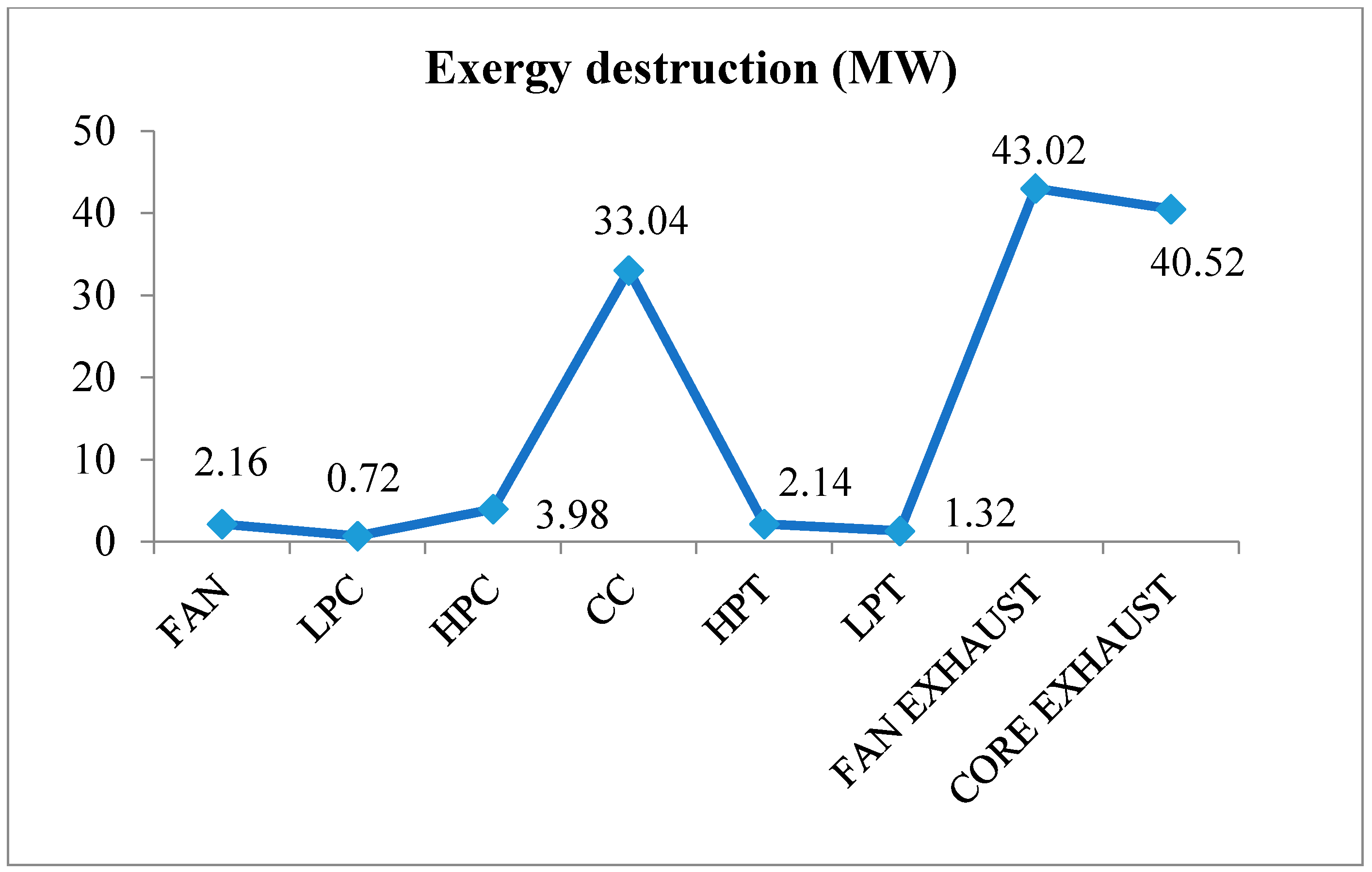

The exergy efficiency and the exergy loss of each component are inter-related. If a component has a low exergy efficiency, it will eventually lead to high exergy destruction. This is shown in

Figure 14 and

Figure 15, where the component with the lowest exergy efficiency are the fan and core engine exhaust, while the highest exergy destruction is found to occur at the fan exhaust with the value of 43.02 MW, followed by the core engine exhaust at 40.52 MW. On the other hand, the exergy destruction of compressors and turbines is shown to be quite low.

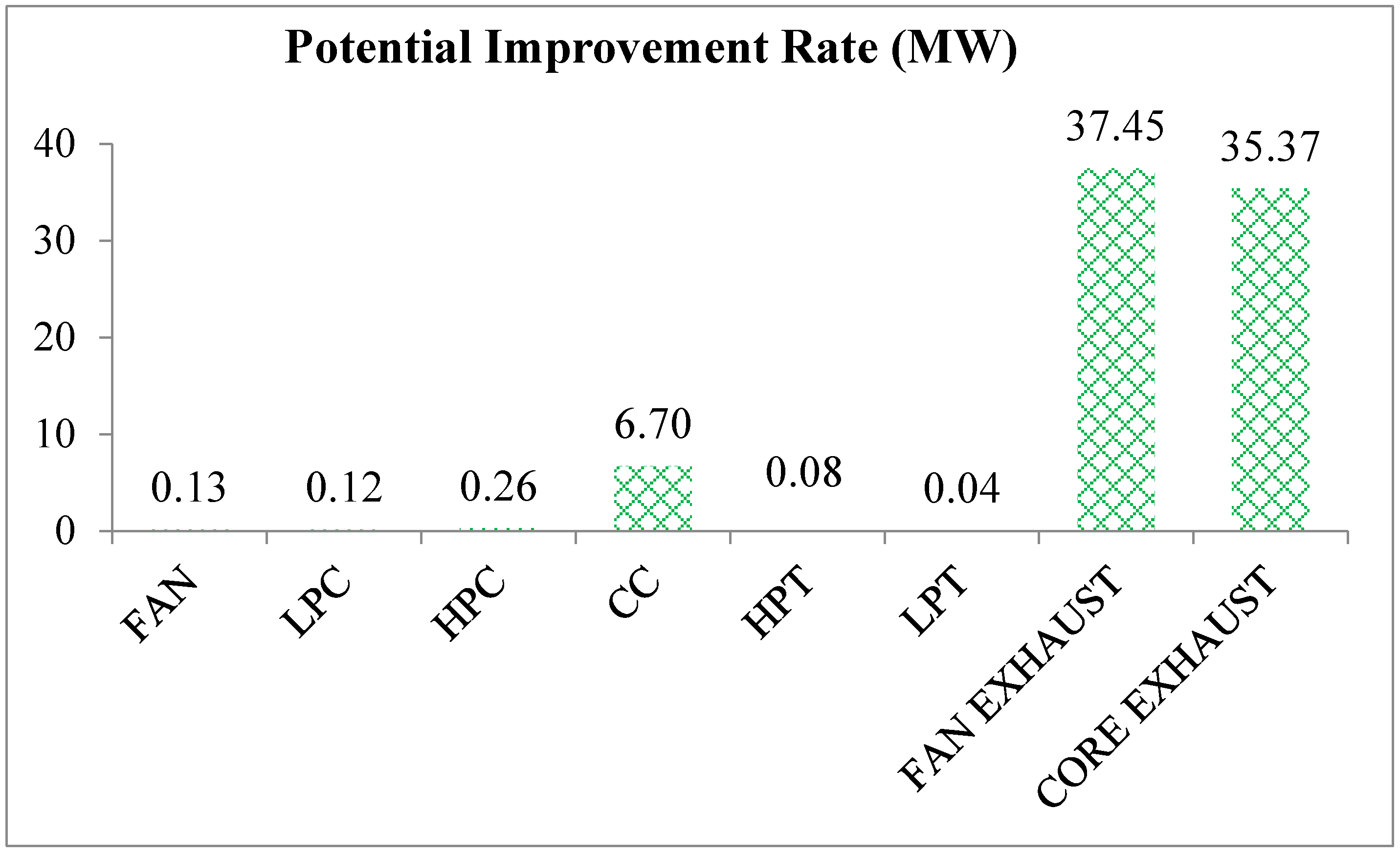

Figure 16 shows the potential improvement rate of the turbofan engine components. The highest exergetic improvement potential rate is within the exhaust. The fan and core engine exhaust, as well as the combustion chamber, still have some potential that can be improved in the turbofan engine. This is why this section focuses on the improvement of the exhaust system by integrating it with the ORC system.

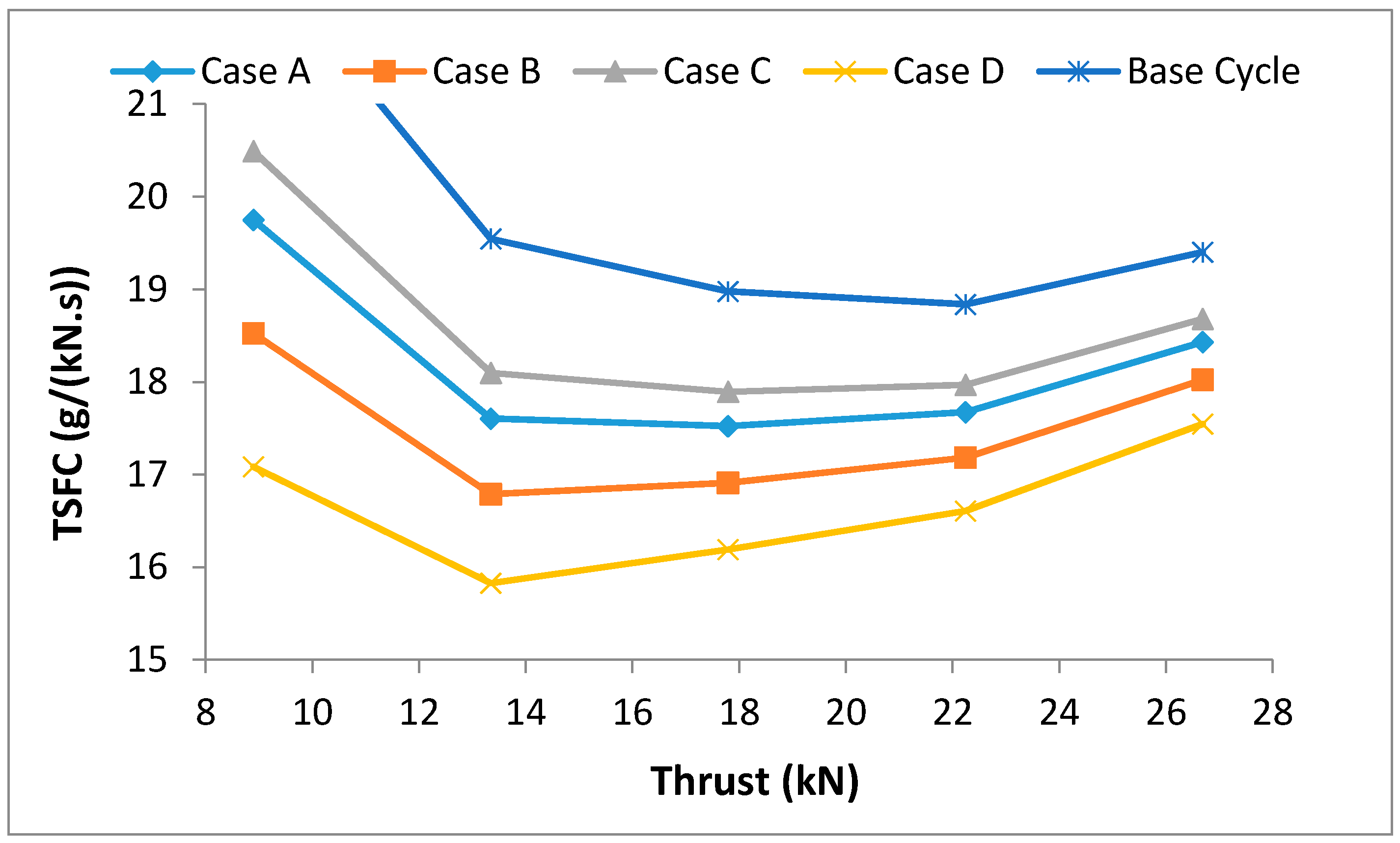

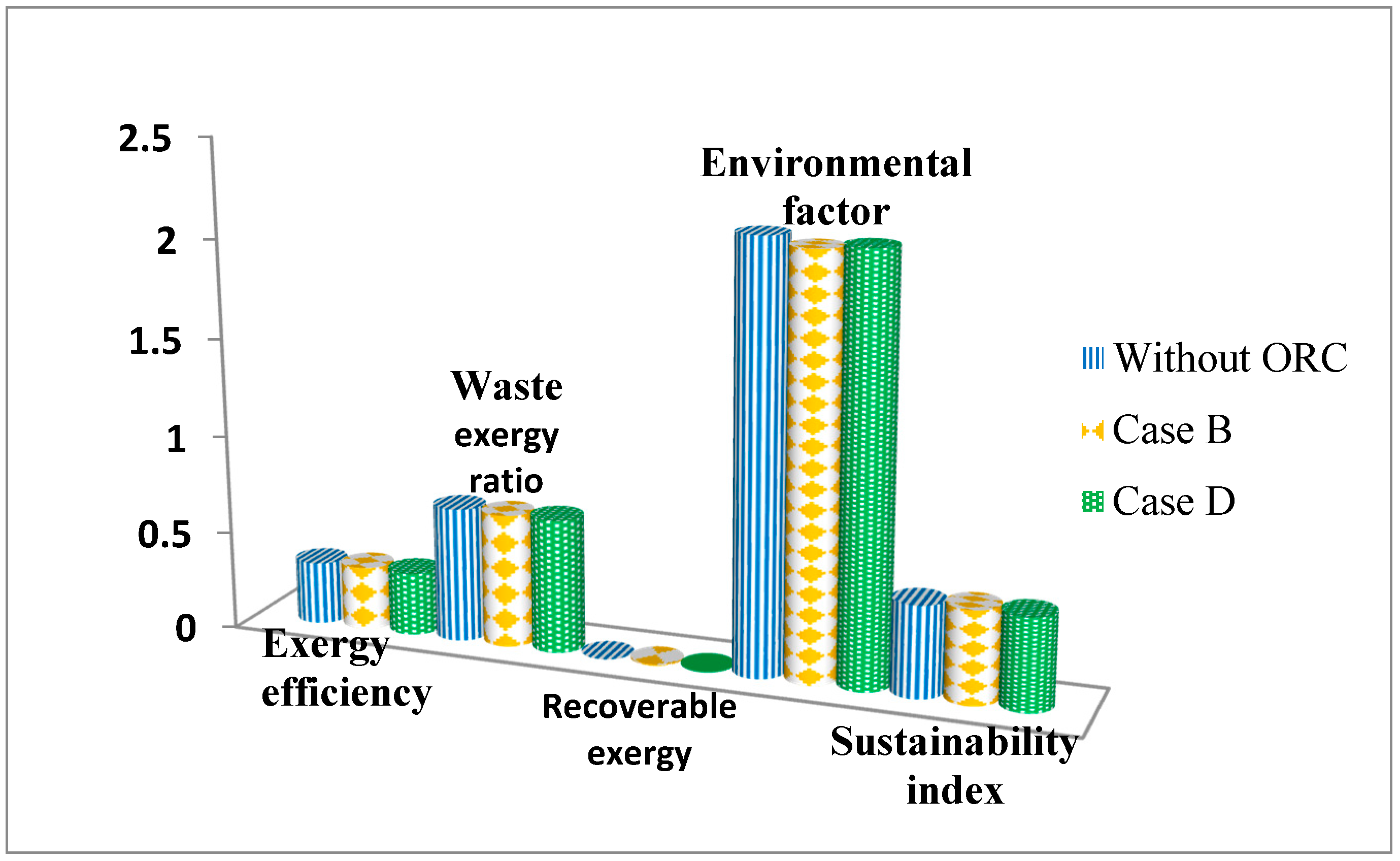

The sustainability analysis of the engine based on exergy is the most important part of this study, and it is shown in two conditions in

Table 7 and

Figure 17: with and without the integration of the ORC system. This analysis will only focus on case B and case D, as both of the designs show good potential in reducing the TSFC of the turbofan engine. From the numerical model of the ORC system integrated with a turbofan engine created previously, it was found that the total heat power that can be extracted from exhaust heat using ORC for cases B and D is 0.471 MW and 0.266 MW, respectively.

The exergetic sustainability index of the turbofan engine with ORC is 0.474 for case B and 0.470 for case D, which shows slight improvements of 2.16% and 1.29%, respectively, compared to the turbofan engine alone, without the integration of ORC for waste heat recovery.

Here, one can observe that, by applying an ORC system to the turbofan engine, the overall engine’s exergy efficiency is increased due to the higher thrust power produced by the engine. As a result, the exergy wasted to the environment is reduced. Compared to the turbofan engine alone, the ORC system provides an opportunity for the energy of the engine to be recovered and reused for other power needs. With this type of engine, the recoverable exergy is quite low but is still able to have a positive impact on the engine. Finally, by integrating ORC, we can reduce the engine’s environmental factor and consequently increase its index of sustainability. Here, we note that, for better practical applications, a higher value of the index of sustainability is preferable.

6. Conclusions

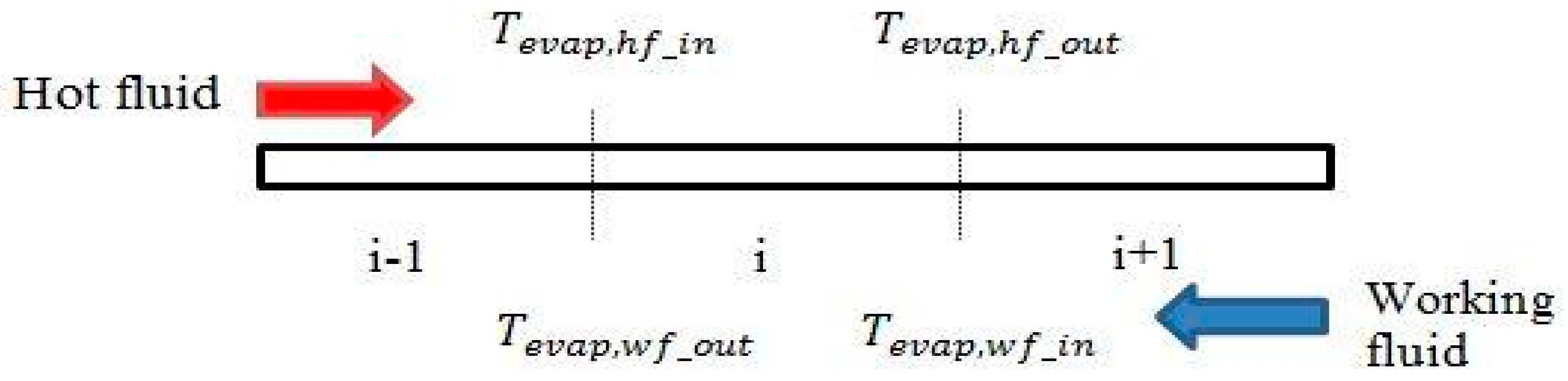

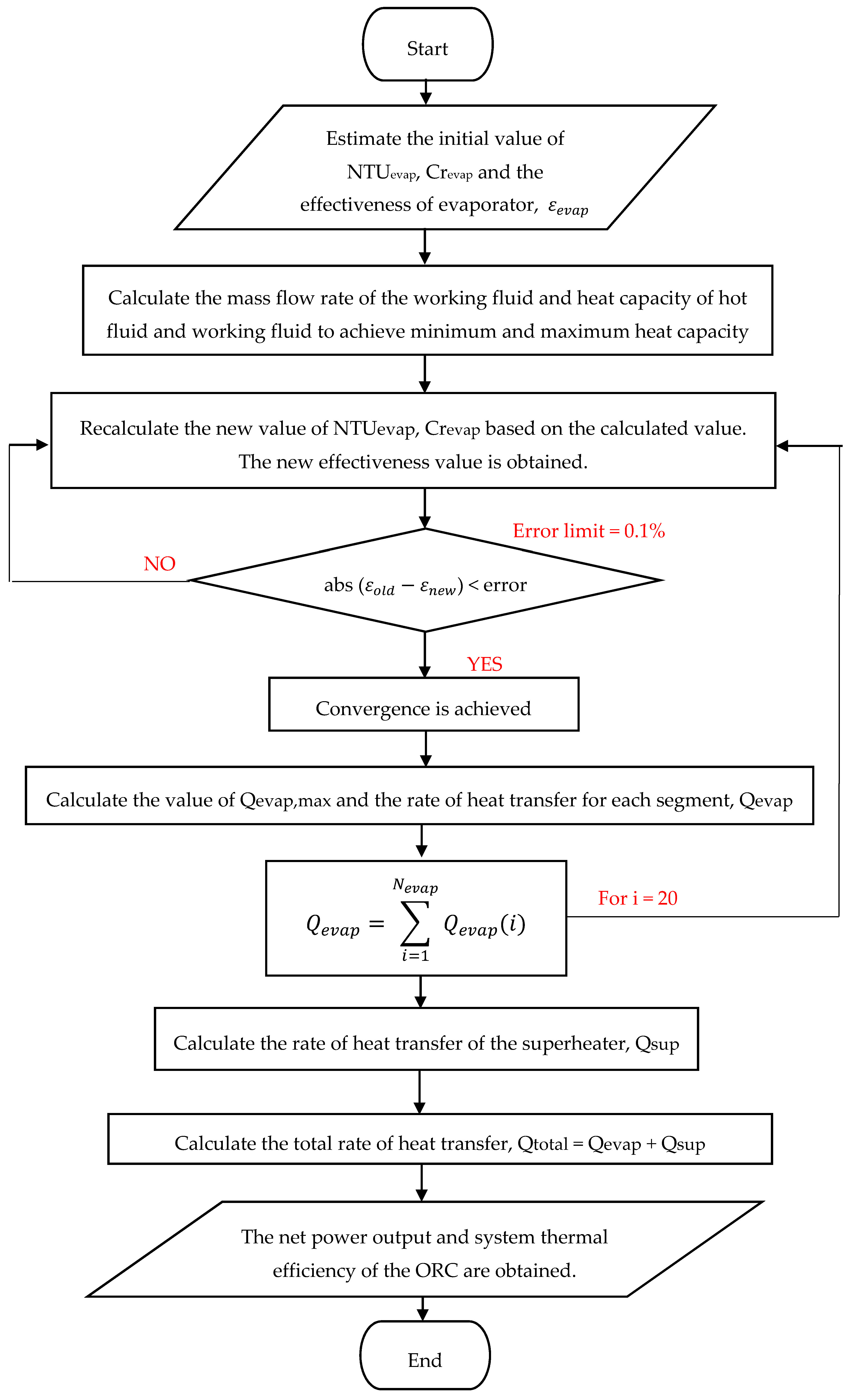

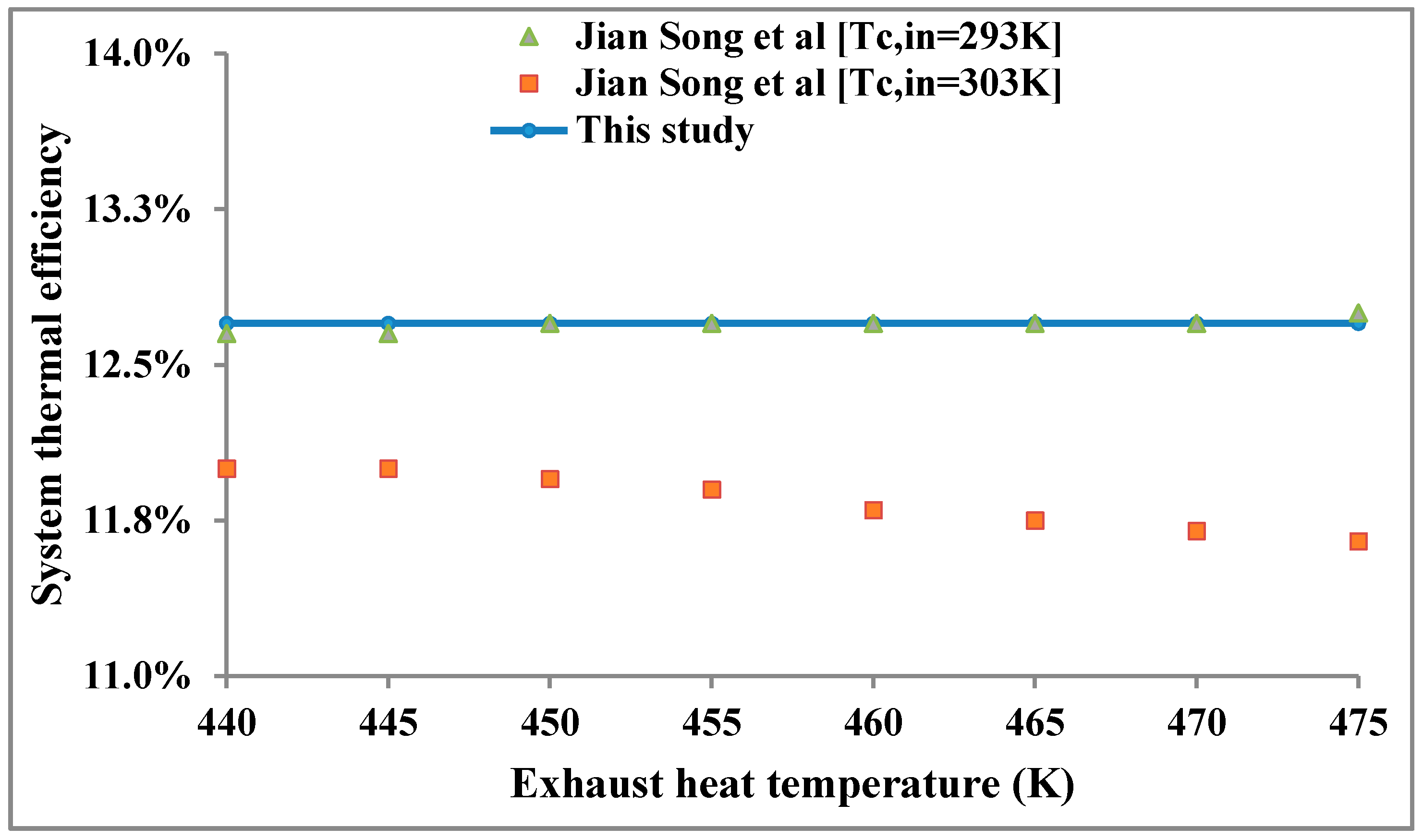

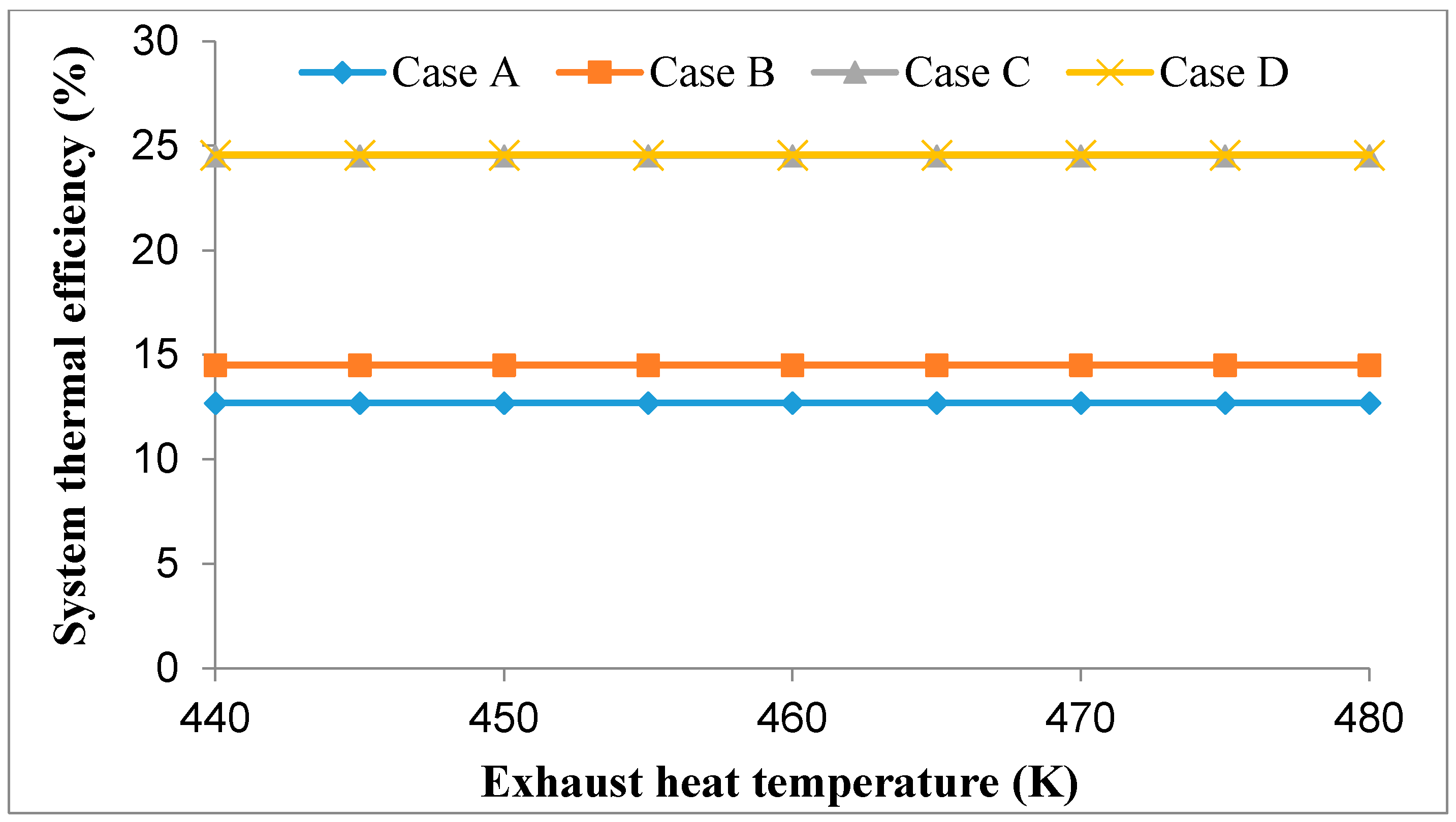

This work presented a detailed study of the modeling and design of an ORC system implemented in a high-bypass turbofan engine for civil aircraft. This idea came as a result of the high exergy destruction produced by the exhaust component of the engine. A model for a waste heat recovery system using ORC has been developed. The model considers the distributed modeling of the heat exchanger and a calculation of its effectiveness. Validations with previous authors’ ORC systems for industrial waste heat recovery are in good accordance with the thermal efficiency and net power output, although some deviations are identified at higher exhaust waste heat temperatures. These deviations could be, to some extent, due to the unchanged value of the inlet temperature of the working fluid assumed in our calculation.

From the four case studies of the design of this ORC system, it can be concluded that the additional heat exchanger gives advantages to the system at supercritical condition, with higher thermal efficiency and a higher net power output. Nonetheless, some precautions must be taken for supercritical cycles. These cycles must be operated at a higher operating pressure, and hence more material resistance is needed.

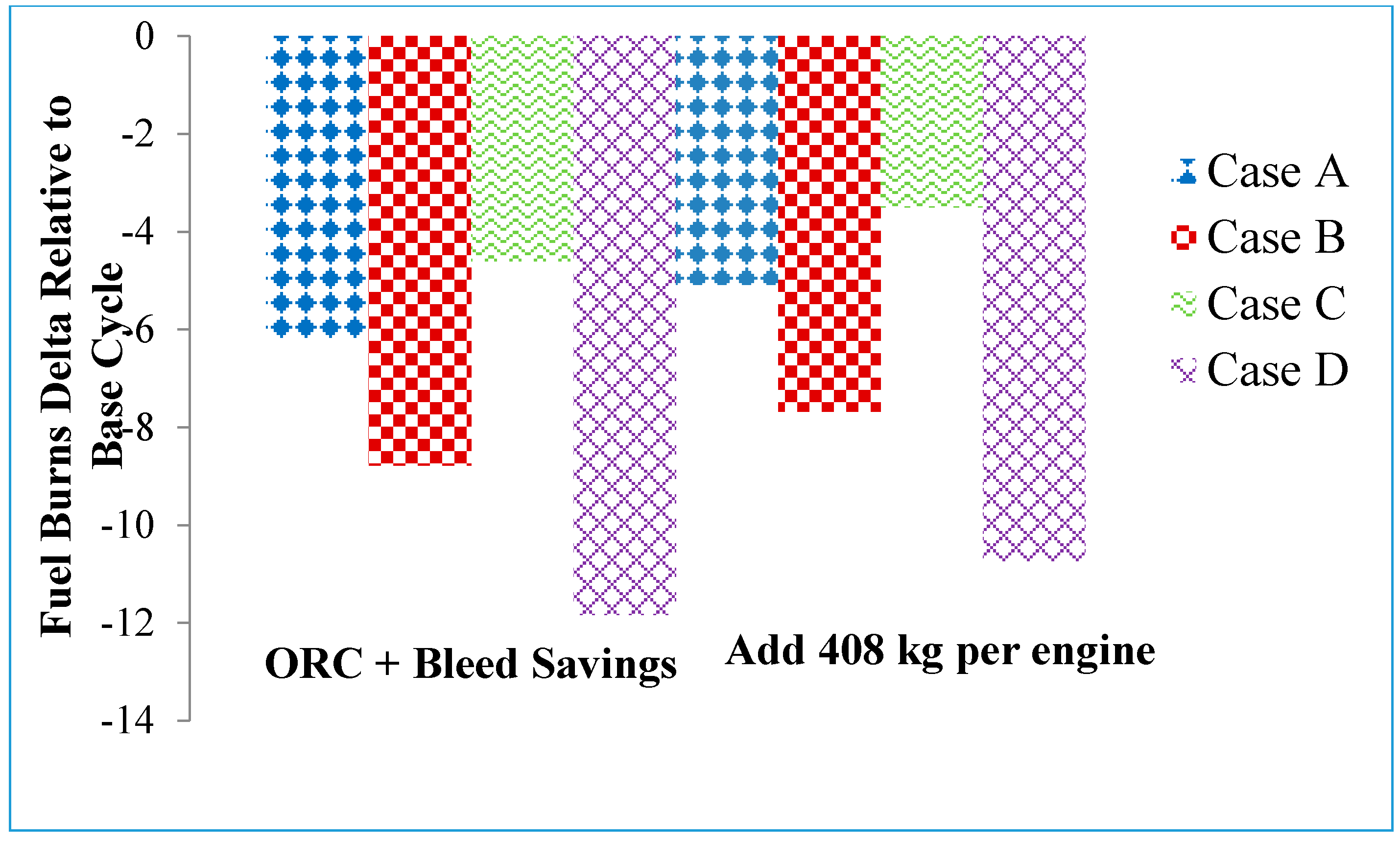

The effects of this ORC system concept on the engine’s fuel consumption—specifically, the effect of bleed savings—are given through the initial results of this study. For the turbofan engine considered here, the reduction in TSFC may not be too predominant. Nevertheless, it is noted that a better fuel burn value can be achieved by integrating the ORC system in a turbofan engine with the aid of a superheater at both subcritical and supercritical conditions. By considering the additional weight that may be applied to the engine, it can still reduce the fuel burn to below 7.68% for subcritical and 10.74% for supercritical conditions relative to the base cycle data.

Exergy analysis can help us to assist the rate of the improvement potential of the system and evaluate the irreversibility of the process. Meanwhile, the exergetic sustainability index has proven to be an essential method to evaluate the sustainability of a system. From this analysis, the two best cases, case B and case D, show good sustainability indices at 0.474 and 0.470, respectively. By evaluating the exergetic sustainability performance of the engine, this study shows that this type of waste heat recovery system is a relevant component and can provide significant potential to the engine, as it can increase the engine’s power and the overall engine performance. As a recommendation, it is advisable to add an ORC system to a turbofan engine as it can reduce the engine’s impact on the environment, making the engine more sustainable in future.

This study will be continued with an experimental approach in order to better evaluate the thermodynamic behavior and the performance of this new waste heat recovery system for future practical applications.