Study of the Effect of Addition of Hydrogen to Natural Gas on Diaphragm Gas Meters

Abstract

1. Introduction

Introducing Hydrogen to the Network According to Applicable Legal Regulations

- Natural gas E is gas of group E of the second gas family, whose main component is methane.

- Natural gas Lw is gas of group Lw linked with the second gas family, whose main components are methane and nitrogen.

- Natural gas Ls is gas of group Ls linked with the second gas family, whose main components are methane and nitrogen.

- Wobbe index Ws is the ratio of the gross calorific value of a gas per unit volume and the square root of its relative density under the same reference conditions [30].

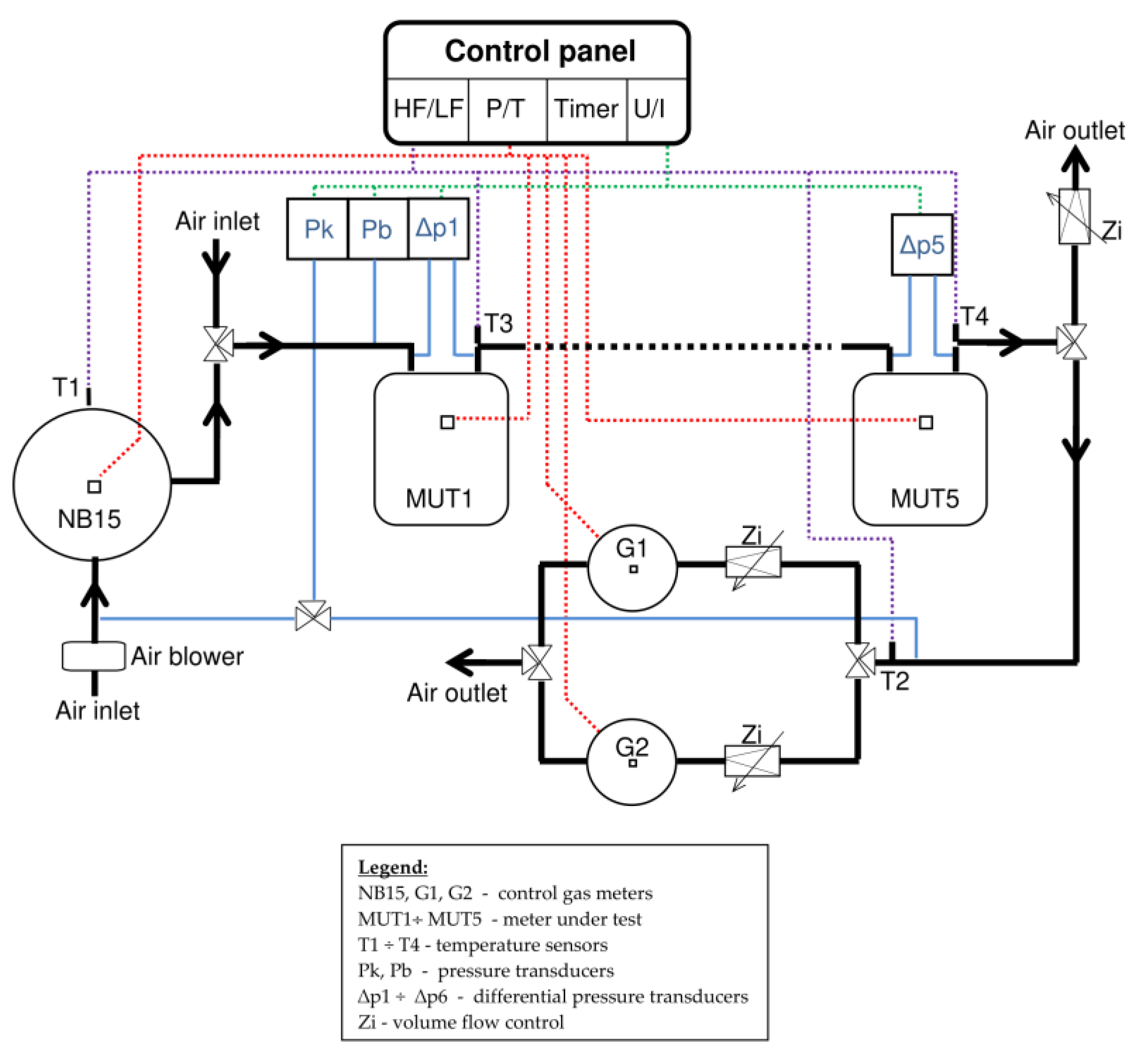

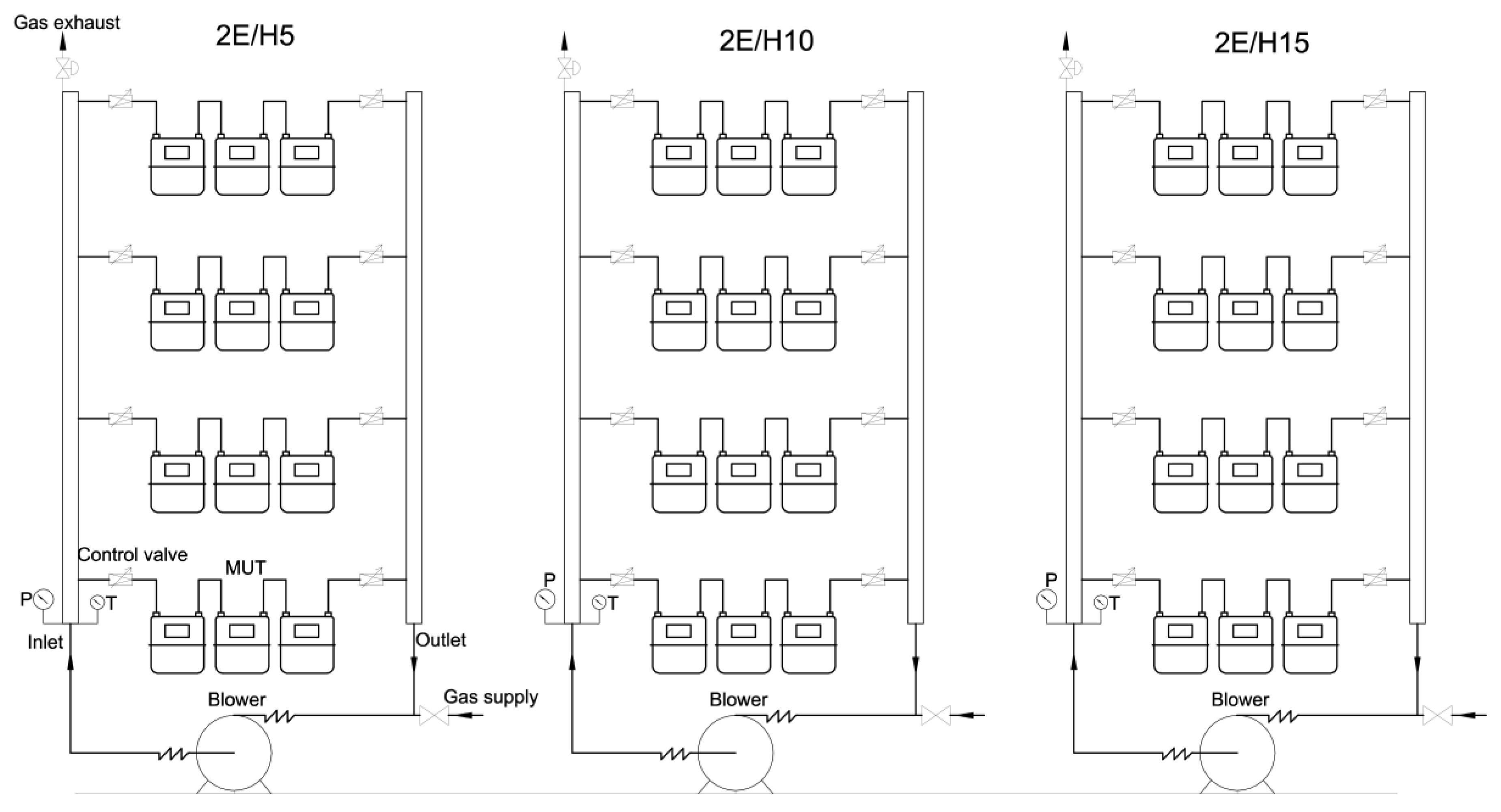

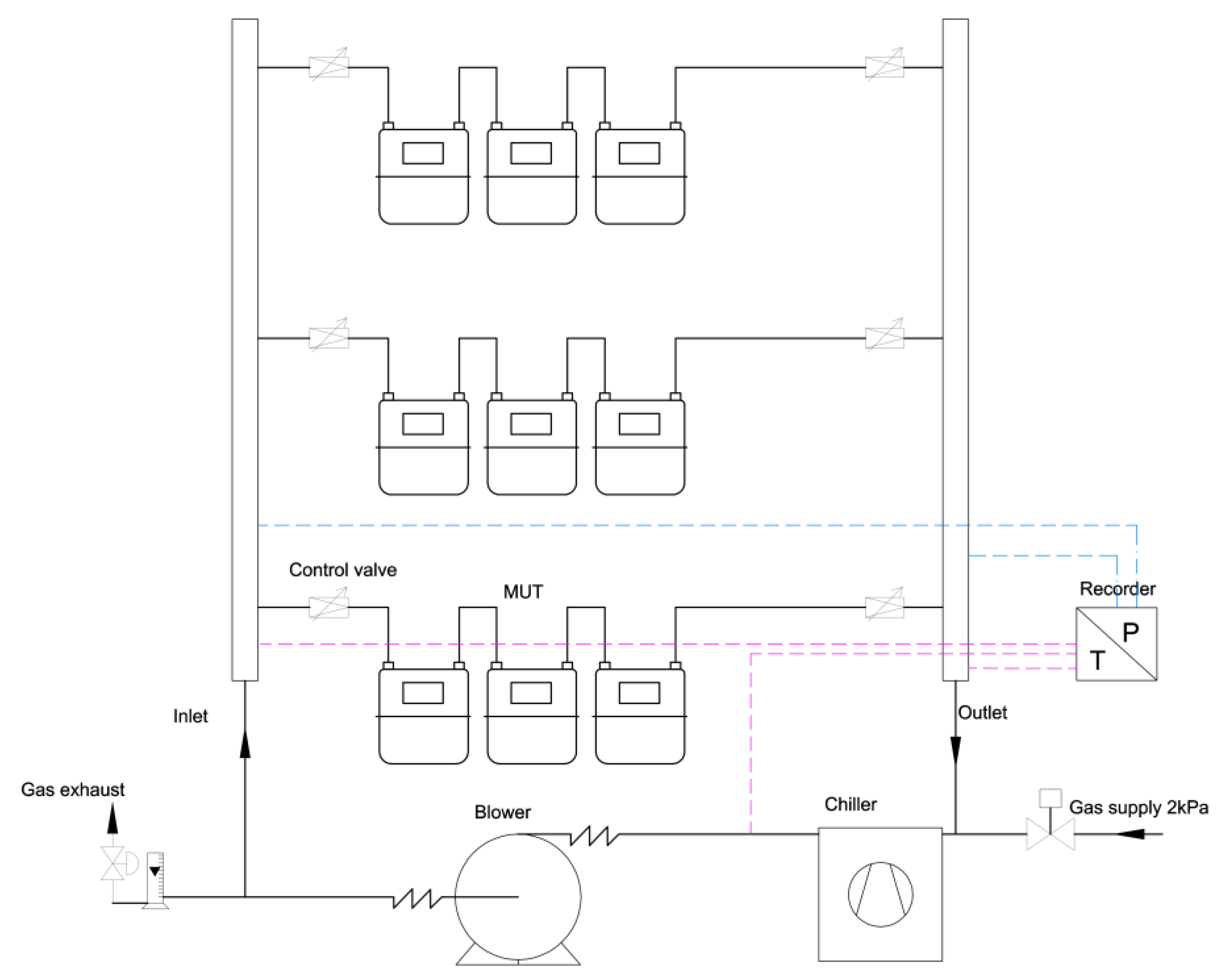

2. Materials and Methods

- 2/3 Qmax; for 5 s,

- 1/3 Qmax; for 3 s,

- 3/3 Qmax; for 5 s,

- No flow; for 3 s.

Assumptions for the Study

- 2E/H0–2E natural gas mixture without hydrogen addition;

- 2E/H5–2E natural gas mixture with 5% hydrogen content (V/V);

- 2E/H10–2E natural gas mixture with 10% hydrogen content (V/V);

- 2E/H15–natural gas mixture with 15% hydrogen content (V/V).

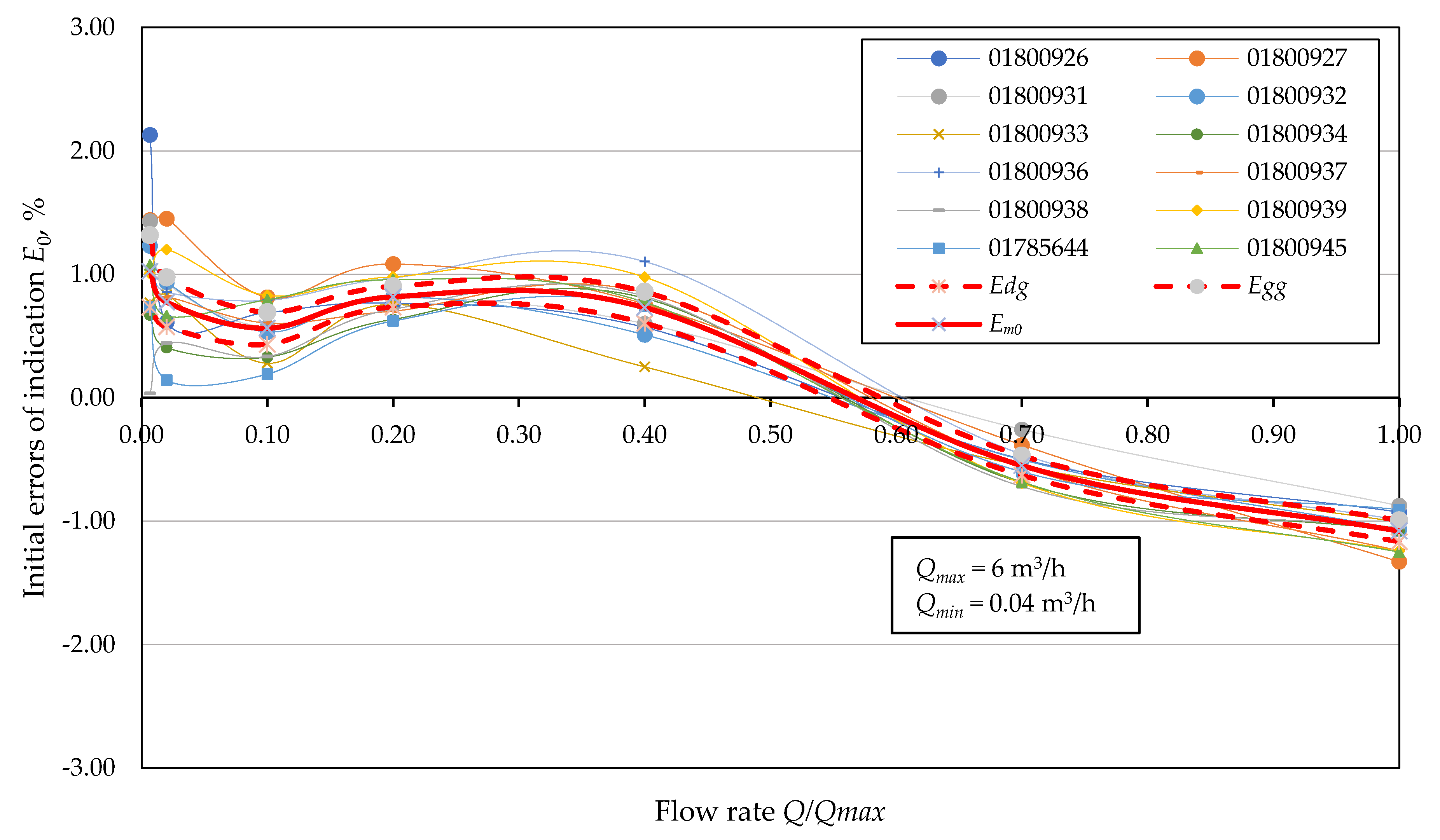

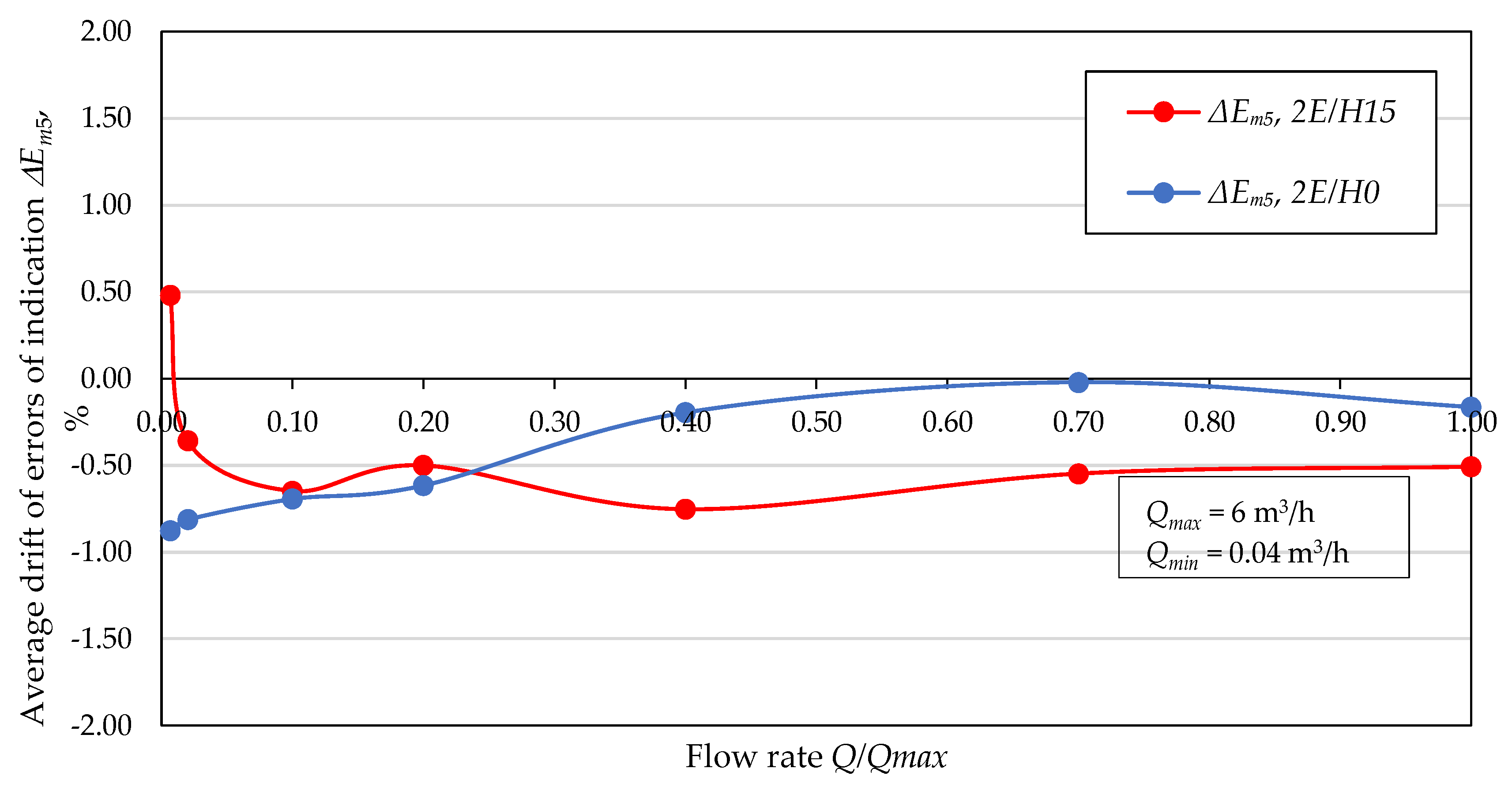

3. Results

4. Discussion

- Values of gas meter errors of indications determined during and after the durability test should be within the permissible maximum error limit (MPE) during the durability test;

- Values of gas meter errors of indications determined during and after the durability test, within the flow rate range from 0.1 Qmax to Qmax may not differ by more than 2% from the corresponding initial values;

- The maximum value of the pressure loss in a gas meter should not be greater than that given in the "after durability test" column (in the operating conditions); and

- After the durability test, all gas meters should maintain external tightness.

- U(ΔEmH-m2E) represents uncertainty in determining the difference in the average drift of errors of indications of the gas meters subjected to the durability test using a 2E/H5, 2E/H10, and 2E/H15 natural gas mixture with hydrogen and a 2E/H0 natural gas mixture without the addition of hydrogen [%];

- U(EmH) is uncertainty in determining the difference in the average drift of errors of indications of the gas meters subjected to the durability test using a 2E/H5, 2E/H10, and 2E/H15 natural gas mixture with hydrogen [%]; and

- U(Em2E) is uncertainty in determining the difference in the average drift of errors of indications of the gas meters subjected to the durability test using a 2E/H0 natural gas mixture without the addition of hydrogen [%].

5. Conclusions

- For the gas meters tested, no significant metrological difference was found between the obtained average drift of errors of indications after the durability test using natural gas mixtures with different hydrogen concentration(from 0% to 15%). However, there was a significant metrological impact of prolonged operation of the gas meters on their errors of indications, but it should not be considered as dependent on the hydrogen concentration in the gas but rather on the wear of the internal components of the gas meters during the durability test, which were indicated by the analysis of the results of the durability tests using a natural gas mixture without a hydrogen addition. The average drifts of errors of indications observed with the use of the 2E/H0 natural gas mixture were noticeable despite the lack of hydrogen addition in that mixture.

- During the durability tests, no damage was found that would compromise operational safety. All gas meters remained airtight after the durability tests.

- Analyzing the literature, it was found that for technologies other than diaphragm gas meters, e.g., thermal gas meters, since the addition of hydrogen to natural gas causes a change in the physicochemical properties of the gas mixture (including a change in density), this may result in exceeding the maximum permissible errors. Therefore, during the potential implementation of thermal gas meters in Poland, the above problem should be analyzed in detail and the gas meters’ suitability for measuring such gas mixtures should be verified with tests.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| E | error of indications of the gas meter, [%] |

| Em | average errors of indications of the gas meter, [%] |

| Edg | lower confidence interval limit of errors of indications of the gas meters, [%] |

| Egg | upper confidence interval limit of errors of indications of the gas meters, [%] |

| E0 | initial errors of indications of the gas meter, [%] |

| Em0 | average initial errors of indications of the gas meters, [%] |

| Em1 | average errors of indications of the gas meters after 250 hours of work |

| Em2 | average errors of indications of the gas meters after 1000 hours of work; [%] |

| Em3 | average errors of indications of the gas meters after 2000 hours of work; [%] |

| Em4 | average errors of indications of the gas meters after 3500 hours of work; [%] |

| Em5 | average errors of indications of the gas meters after 5000 hours of work; [%] |

| MPE | maximum permissible errors, [%] |

| ΔEm1 | average drift of errors of indications of the gas meters after 250 hours of work; [%] |

| ΔEm2 | average drift of errors of indications of the gas meters after 1000 hours of work; [%] |

| ΔEm3 | average drift of errors of indications of the gas meters after 2000 hours of work; [%] |

| ΔEm4 | average drift of errors of indications of the gas meters after 3500 hours of work; [%] |

| ΔEm5 | average drift of errors of indications of the gas meters after 5000 hours of work; [%] |

| ΔEmH-m2E | difference of the average drifts of errors of indications of the gas meters tested for durability using a 2E/H5, 2E/H10 and 2E/H15 natural gas mixture with hydrogen and a 2E/H0 natural gas mixture without the addition of hydrogen, [%] |

| Q | flow rate, [m3/h] |

| U(ΔmH-m2E) | uncertainty of determining the difference of the average drifts of errors of indications of the gas meters tested for durability using a 2E/H5, 2E/H10 and 2E/H15 natural gas mixture with hydrogen and a 2E/H0 natural gas mixture without the addition of hydrogen, [%], |

| U(EmH) | uncertainty of determining the average drifts of errors of indications of the gas meters tested for durability using a 2E/H5, 2E/H10 and 2E/H15 natural gas mixture with hydrogen, [%], |

| U(Em2E) | uncertainty of determining the average drifts of errors of indications of the gas meters tested for durability using a 2E/H0 natural gas mixture without the addition of hydrogen, [%]. |

Abbreviations

| INiG-PIB | Oil and Gas Institute–National Research Institute |

| PSG | Polska Spółka Gazownictwa Sp. z o.o. |

| PtG/P2G | Power to Gas |

| OZE | renewable energy sources |

| 2E | natural gas of group E of the second gas family (high-methane) described in EN 437 |

| 2E/H0 | 2E natural gas mixture without the addition of hydrogen |

| 2E/H5 | 2E natural gas mixture with 5% hydrogen content (V/V) |

| 2E/H10 | 2E natural gas mixture with 10% hydrogen content (V/V) |

| 2E/H15 | 2E natural gas mixture with 15% hydrogen content (V/V) |

| IRiESD | Distribution Network Operation and Maintenance Manual |

| EU | European Union |

| KE | European Commission |

| LNG | Liquefied natural gas |

| MID | Metering Instrument Directive |

References

- Ustawa z dnia 10 kwietnia 1997 r. Prawo energetyczne. (Dz.U. z 2017 r., poz. 220). Art. 4 ust. 2. Available online: http://prawo.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20170000220 (accessed on 8 December 2019).

- Polska Spółka Gazownictwa. Objectives. Available online: https://www.psgaz.pl (accessed on 8 December 2019).

- Energy Roadmap 2050, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; COM(2011) 885 final; European Commission, Brussels. 2011, p. 7. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2011:0885:FIN:EN:PDF (accessed on 8 December 2019).

- A Framework Strategy for a Resilient Energy Union with a Forward-Looking Climate Change Policy, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee, the Committee of the Regions and the European Investment Bank; COM(2015) 80 final; European Commission, Brussels. 2015, p. 11. Available online: http://eur-lex.europa.eu/resource.html?uri=cellar:1bd46c90-bdd4-11e4-bbe1-01aa75ed71a1.0001.03/DOC_1&format=PDF (accessed on 8 December 2019).

- Long Term Infrastructure Vision for Europe and Beyond, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; COM(2013) 711 final; European Commission, Brussels. 2013, p. 6. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2013:0711:FIN (accessed on 8 December 2019).

- Gruber, M.; Weinbrecht, P.; Biffar, L.; Harth, S.; Trimis, D.; Brabandt, J.; Posdziech, O.; Blumentritt, R. Power-to-Gas through thermal integration of high-temperature steam electrolysis and carbon dioxide methanation—Experimental results. Fuel Process. Technol. 2018, 181, 61–74. [Google Scholar] [CrossRef]

- McDonagh, S.; O’Sheaa, R.; Walla, D.M.; Deane, J.P.; Murphy, J.D. Modelling of a power-to-gas system to predict the levelised cost of energy of an advanced renewable gaseous transport fuel. Appl. Energy 2018, 444–456. [Google Scholar] [CrossRef]

- Salomone, F.; Giglio, E.; Ferrero, D.; Santarelli, M.; Pirone, R.; Bensaid, S. Techno-economic modelling of a Power-to-Gas system based on SOEC electrolysis and CO2 methanation in a RES-based electric grid. Chem. Eng. J. 2019, 377, 120233. [Google Scholar] [CrossRef]

- Becker, W.L.; Penev, M.; Braun, R.J. Production of Synthetic Natural Gas from Carbon Dioxide and Renewably Generated Hydrogen: A Techno-Economic Analysis of a Power-to-Gas Strategy. J. Energy Resour. Technol. 2019, 141. [Google Scholar] [CrossRef]

- EU Strategy for Liquefied Natural Gas and Gas Storage, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; COM(2016) 49 final; European Commission, Brussels. 2016. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52016DC0049 (accessed on 8 December 2019).

- Energy Storage—The Role of Electricity, Commission Staff Working Document. SWD (2017) 61 final. European Commission, Brussels. 2017, p. 3. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/swd2017_61_document_travail_service_part1_v6.pdf (accessed on 8 December 2019).

- DVGW Forschung G 1/07/10, Management Summary. Entwicklung von modularen Konzepten zur Erzeugung, Speicherung und Einspeisung von Wasserstoff und Methan ins Erdgasnetz. 2013. Available online: https://www.dvgw.de/medien/dvgw/forschung/berichte/g1_07_10.pdf (accessed on 8 December 2019).

- Dolci, F.; Thomas, D.; Hilliard, S.; Guerra, C.F.; Hancke, R.; Ito, H.; Jegoux, M.; Kreeft, G.; Leaver, J.; Newborough, M.; et al. Incentives and legal barriers for power-to-hydrogen pathways: An international snapshot. Int. J. Hydrog. Energy 2019, 44, 11394–11401. [Google Scholar] [CrossRef]

- HyLAW project Online Database. Legal Framework: Permissions and Restrictions. Available online: https://www.hylaw.eu/database#/database/spain/gas-grid-issues/injection-of-hydrogen-at-transmission-level-for-energy-storage-and-enhancing-sustainabily/legal-framework-permissions-and-restrictions-and-ownership-constraints-unbundling (accessed on 20 May 2020).

- Jaworski, J.; Kukulska-Zając, E.; Kułaga, P. Wybrane zagadnienia dotyczące wpływu dodatku wodoru do gazu ziemnego na elementy systemu gazowniczego. Nafta-Gaz 2019, 10, 625–632. [Google Scholar] [CrossRef]

- An Energy Policy for Europe, Communication from the Commission to the European Council and The European Parliament; COM(2007) 1 final; European Commission, Brussels. 2007, p. 5. Available online: https://www.esmap.org/node/1112 (accessed on 8 December 2019).

- A European Strategic Energy Technology Plan (Set-Plan) ‘Towards a low carbon future’, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; COM(2007) 723 final; European Commission, Brussels. 2007, p. 13. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52008AE1199 (accessed on 8 December 2019).

- Towards a European Strategic Energy Technology Plan, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; COM(2006) 847 final; European Commission, Brussels. 2007, p. 13. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52006DC0847 (accessed on 8 December 2019).

- HyWays. The European Hydrogen Roadmap, European Commission. 2008. Available online: https://op.europa.eu/en/publication-detail/-/publication/66b2d3ee-f77c-4a5d-9c5d-1ed8c716911c/language-en (accessed on 8 December 2019).

- Council Regulation (EC). No 521/2008 of 30 May 2008 setting up the Fuel Cells and Hydrogen Joint Undertaking (OJ L 153, 12.6.2008); European Commission, Brussels. 2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32008R0521 (accessed on 8 December 2019).

- Energy Technologies and Innovation, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; COM(2013) 253 final; European Commission, Brussels. 2013. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A52013DC0253 (accessed on 8 December 2019).

- Council Regulation (EC). No 559/2014 of 6 May 2014 establishing the Fuel Cells and Hydrogen 2 Joint Undertaking (OJ L 169/211, 7.06.2014, p. 5); European Commission, Brussels. 2014. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32014R0559 (accessed on 8 December 2019).

- Fuel Cells and Hydrogen Joint Undertaking (FCH JU) Multi-Annual Work Plan 2014–2020. Available online: https://www.fch.europa.eu/sites/default/files/FCH%202%20JU%20MAWP-%20final%20%28ID%204221004%29.pdf (accessed on 8 December 2019).

- PN-C-04753 Polska Norma. Gaz Ziemny, Jakość Gazu Dostarczanego Odbiorcom z Sieci Dystrybucyjnej; Komitet Techniczny KT 277/PK 1; Polski Komitet Normalizacji: Polska, 2011. [Google Scholar]

- EN ISO 15403-1 European Standard. Natural gas. Natural Gas for Use as a Compressed Fuel for Vehicles. In Designation of the Quality; Technical Committee CEN/TC 238; European Committee for Standardization: Brussels, Belgium, 2008. [Google Scholar]

- EN 16723-1 European Standard. Natural Gas and Biomethane for Use in Transport and Biomethane for Injection in the Natural Gas Network. In Specifications for Biomethane for Injection in the Natural Gas Network; Technical Committee CEN/TC 408; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- EN 16726 European Standard. Gas infrastructure. In Quality of Gas. Group H; Technical Committee CEN/TC 408; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- Rozporządzenie Ministra Gospodarki z dnia 2 lipca 2010 r. w sprawie szczegółowych warunków funkcjonowania systemu gazowego (Dz.U. 2010 nr 133 poz. 891, wraz z późn. zm.). Available online: http://prawo.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20101330891 (accessed on 8 December 2019).

- Polska Spółka Gazownictwa. Instrukcja Ruchu i Eksploatacji Sieci Dystrybucyjnej, wersja 12, Warszawa lipiec 2016r. Available online: https://www.psgaz.pl (accessed on 8 December 2019).

- EN 437 European Standard. Test Gases. Test Pressures. Appliance Categories; Technical Committee CEN/TC 238; European Committee for Standardization: Brussels, Belgium, 2018. [Google Scholar]

- Schuster, T.; Holewa-Rataj, J.; Kukulska-Zając, E. Ocena jakości paliw gazowych w kontekście wprowadzania wodoru do sieci gazu ziemnego. Gaz, Woda i Tech. Sanit. 2019, 2, 42–46. [Google Scholar] [CrossRef]

- Kuczyński, S.; Łaciak, M.; Olijnyk, A.; Szurlej, A.; Włodek, T. Thermodynamic and Technical Issues of Hydrogen and Methane-Hydrogen Mixtures Pipeline Transmission. Energies 2019, 12, 569. [Google Scholar] [CrossRef]

- Pluvinage, G.; Capelle, J.; Hadj Meliani, M. Pipe networks transporting hydrogen pure or blended with natural gas, design and maintenance. Eng. Fail. Anal. 2019, 106. [Google Scholar] [CrossRef]

- Ficco, G. Metrological performance of diaphragm gas meters in distribution networks. Flow Meas. Instrum. 2014, 37, 65–72. [Google Scholar] [CrossRef]

- Costello, K.W. Lost and unaccounted-for gas: Challenges for public utility regulators. Util. Policy 2014, 29, 17–24. [Google Scholar] [CrossRef]

- Cowgill, R.M. Methane Emissions—Leakage, Sources and Unaccounted—For Gas. In IGT Asian Natural Gas Conference III 1991; IGT: Singapore.

- Arpino, F.; Dell’Isola, M.; Ficco, G.; Vigo, P. Unaccounted for gas in natural gas transmission networks: Prediction model and analysis of the solutions. J. Nat. Gas Sci. Eng. 2014, 17, 58–70. [Google Scholar] [CrossRef]

- Union, E. Directive 2014/32/EC of The European Parliament and of The Council of 26 February 2014 on the harmonisation of the laws of the Member States relating to the making available on the market of measuring instruments. Off. J. Eur. Union 2014. [Google Scholar]

- EN 1359 European Standard. Gas Meters—Diaphragm Gas Meters; Technical Committee CEN/TC 237; European Committee for Standardization; CEN-CENELEC: Brussels, Belgium, 1998. [Google Scholar]

- EN 12261 European Standard. Gas Meters—Turbine Gas Meters; Technical Committee CEN/TC 237; European Committee for Standardization; CEN-CENELEC: Brussels, Belgium, 2002. [Google Scholar]

- EN 12480 European Standard. Gas Meters—Rotary Displacement Gas Meters; Technical Committee CEN/TC 237; European Committee for Standardization; CEN-CENELEC: Brussels, Belgium, 2002. [Google Scholar]

- Kułaga, P. Trwałość gazomierzy miechowych—różne metody badania. Nafta-Gaz 2015, 8, 565–571. [Google Scholar]

- Kułaga, P.; Jaworski, J. Wyniki badań trwałości gazomierzy miechowych uzyskiwane z zastosowaniem różnych metodyk—Analiza porównawcza. Nafta-Gaz 2016, 8, 645–650. [Google Scholar] [CrossRef]

- OIML R 137-1&2 International Recommendation Gas Meters; Part 1 and Part 2. International Organization of Legal Metrology OIML. 2012. Available online: https://www.oiml.org/en/files/pdf_r/r137-1-2-e12.pdf (accessed on 8 December 2019).

- Wojtowicz, R. An analysis of the effects of hydrogen addition to natural gas on the work of gas appliances. Nafta-Gaz 2019, 8, 465–473. [Google Scholar] [CrossRef]

| Group | Wobbe Index Ws, MJ/m3 | Gross Calorific Value, MJ/m3 |

|---|---|---|

| Regulation [28] | ||

| Natural gas E | 45.0–56.9 | >34.0 |

| Natural gas Lw | 37.5–45.0 | >30.0 |

| Natural gas Ls | 32.5–37.5 | >26.0 |

| IRiESD [29] | ||

| Natural gas E | 45.0–56.9 | >38.0 |

| Natural gas Lw | 37.5–45.0 | >30.0 |

| Natural gas Ls | 32.5–37.5 | >26.0 |

| Flow Rate Q | |||||||

|---|---|---|---|---|---|---|---|

| Qmin | 3 Qmin | 0.1 Qmax | 0.2 Qmax | 0.4 Qmax | 0.7 Qmax | Qmax | |

| Em0 | 0.60 | 0.70 | 0.58 | 0.80 | 0.93 | −0.58 | −1.10 |

| Em1 | 0.50 | 0.28 | 0.07 | 0.26 | 0.40 | 0.98 | −1.29 |

| Em2 | 0.93 | 0.35 | 0.03 | 0.10 | 0.30 | −0.57 | −1.15 |

| Em3 | 0.70 | −0.32 | −0.22 | 0.15 | 0.09 | −1.03 | −1.18 |

| Em4 | 0.40 | 0.00 | −0.12 | −0.03 | −0.04 | −0.92 | −1.32 |

| Em5 | 1.08 | 0.34 | −0.07 | 0.30 | 0.17 | −1.13 | −1.60 |

| ΔEm1 | −0.10 | −0.42 | −0.50 | −0.53 | −0.52 | −0.40 | −0.20 |

| ΔEm2 | 0.33 | −0.36 | −0.55 | −0.70 | −0.63 | 0.01 | −0.05 |

| ΔEm3 | 0.10 | −1.03 | −0.80 | −0.64 | −0.84 | −0.45 | −0.09 |

| ΔEm4 | −0.20 | −0.70 | −0.69 | −0.83 | −0.97 | −0.34 | −0.22 |

| ΔEm5 | 0.48 | −0.36 | −0.65 | −0.50 | −0.75 | −0.55 | −0.51 |

| Flow Rate Q | |||||||

|---|---|---|---|---|---|---|---|

| Qmin | 3 Qmin | 0.1 Qmax | 0.2 Qmax | 0.4 Qmax | 0.7 Qmax | Qmax | |

| E0 | 0.94 | 0.67 | 0.60 | 0.85 | 0.83 | −0.66 | −1.13 |

| E1 | 0.88 | 0.23 | 0.20 | 0.44 | 0.14 | −1.03 | −1.32 |

| E2 | 0.61 | 0.17 | −0.14 | −0.12 | 0.44 | −0.57 | −1.15 |

| E3 | 0.24 | −0.06 | −1.48 | 0.12 | 0.56 | −0.68 | −1.18 |

| E4 | −0.36 | −0.34 | −0.30 | −0.17 | −0.09 | −0.83 | −1.33 |

| E5 | 0.06 | −0.14 | −0.09 | 0.24 | 0.63 | −0.68 | −1.30 |

| ΔE1 | −0.06 | −0.44 | −0.41 | −0.41 | −0.69 | −0.38 | −0.18 |

| ΔE2 | −0.33 | −0.49 | −0.74 | −0.97 | −0.39 | 0.09 | −0.01 |

| ΔE3 | −0.70 | −0.73 | −2.09 | −0.73 | −0.27 | −0.02 | −0.05 |

| ΔE4 | −1.30 | −1.01 | −0.91 | −1.02 | −0.92 | −0.17 | −0.20 |

| ΔE5 | −0.88 | −0.81 | −0.69 | −0.62 | −0.20 | −0.02 | −0.17 |

| Volume Flow Q | Average Drift of Errors of Indications after the 5000 h Test for Mixtures [%] | Differences in Average Drift of Errors [%] | Uncertainty in Average Drift of Errors [%] | Permitted Difference in Drift [%] | Metrological Assessment | ||

|---|---|---|---|---|---|---|---|

| ΔEm5 2E/H15 | ΔEm52E/H0 | ΔEmH-m2E | U(Em) | U(ΔEmH-m2E) | |||

| 2E/H15 | 2E/H0 | ||||||

| Qmax | −0.51 | −0.17 | −0.34 | ±0.20 | ±0.32 | ±0.76 | insignificant |

| 0.7 Qmax | −0.55 | −0.02 | −0.53 | ±0.19 | ±0.27 | ±0.66 | insignificant |

| 0.4 Qmax | −0.75 | −0.20 | −0.56 | ±0.17 | ±0.24 | ±0.59 | insignificant |

| 0.2 Qmax | −0.50 | −0.62 | 0.12 | ±0.21 | ±0.26 | ±0.67 | insignificant |

| 0.1 Qmax | −0.65 | −0.69 | 0.05 | ±0.15 | ±0.21 | ±0.52 | insignificant |

| 3 Qmin | −0.36 | −0.81 | 0.45 | ±0.32 | ±0.26 | ±0.83 | insignificant |

| Qmin | 0.48 | −0.88 | 1.36 | ±0.30 | ±0.57 | ±1.29 | significant |

| Volume Flow Q | Brown-Forsythe Variance Homogeneity Test | Fisher-Snedecor Variance Equality Test | Tukey Post-Hoc Test | ||

|---|---|---|---|---|---|

| Statistics | Significance Level | Statistics | Significance Level | ||

| Qmin | 0.880521 | 0.490863 | 3.070469 | 0.090881 | X |

| 3 Qmin | 1.230547 | 0.360374 | 0.564573 | 0.653490 | X |

| 0.1 Qmax | 0.917415 | 0.474862 | 0.054262 | 0.982173 | X |

| 0.2 Qmax | 0.470874 | 0.710909 | 0.048505 | 0.984828 | X |

| 0.4 Qmax | 1.029391 | 0.429739 | 1.422513 | 0.306041 | X |

| 0.7 Qmax | 0.267006 | 0.847455 | 4.083597 | 0.049516 | X |

| Qmax | 0.960493 | 0.456905 | 2.770344 | 0.110779 | X |

| Gas Meter Serial Number | WME before Durability Test [%] | WME after Durability Test [%] | ||

|---|---|---|---|---|

| 2E/H15 | 2E/H0 | 2E/H15 | 2E/H0 | |

| 01800936 | 0.01 | - | −0.47 | - |

| 01800937 | −0.18 | - | −0.91 | - |

| 01800938 | −0.22 | - | −0.75 | - |

| 01800939 | - | −0.15 | - | −0.76 |

| 01785644 | - | −0.18 | - | 0.06 |

| 01800945 | - | −0.21 | - | −0.47 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaworski, J.; Kułaga, P.; Blacharski, T. Study of the Effect of Addition of Hydrogen to Natural Gas on Diaphragm Gas Meters. Energies 2020, 13, 3006. https://doi.org/10.3390/en13113006

Jaworski J, Kułaga P, Blacharski T. Study of the Effect of Addition of Hydrogen to Natural Gas on Diaphragm Gas Meters. Energies. 2020; 13(11):3006. https://doi.org/10.3390/en13113006

Chicago/Turabian StyleJaworski, Jacek, Paweł Kułaga, and Tomasz Blacharski. 2020. "Study of the Effect of Addition of Hydrogen to Natural Gas on Diaphragm Gas Meters" Energies 13, no. 11: 3006. https://doi.org/10.3390/en13113006

APA StyleJaworski, J., Kułaga, P., & Blacharski, T. (2020). Study of the Effect of Addition of Hydrogen to Natural Gas on Diaphragm Gas Meters. Energies, 13(11), 3006. https://doi.org/10.3390/en13113006