Design and Construction of a New Metering Hot Box for the In Situ Hygrothermal Measurement in Dynamic Conditions of Historic Masonries

Abstract

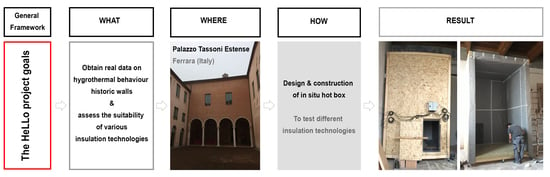

1. Introduction

2. Aims and Methodology

3. State of the Art

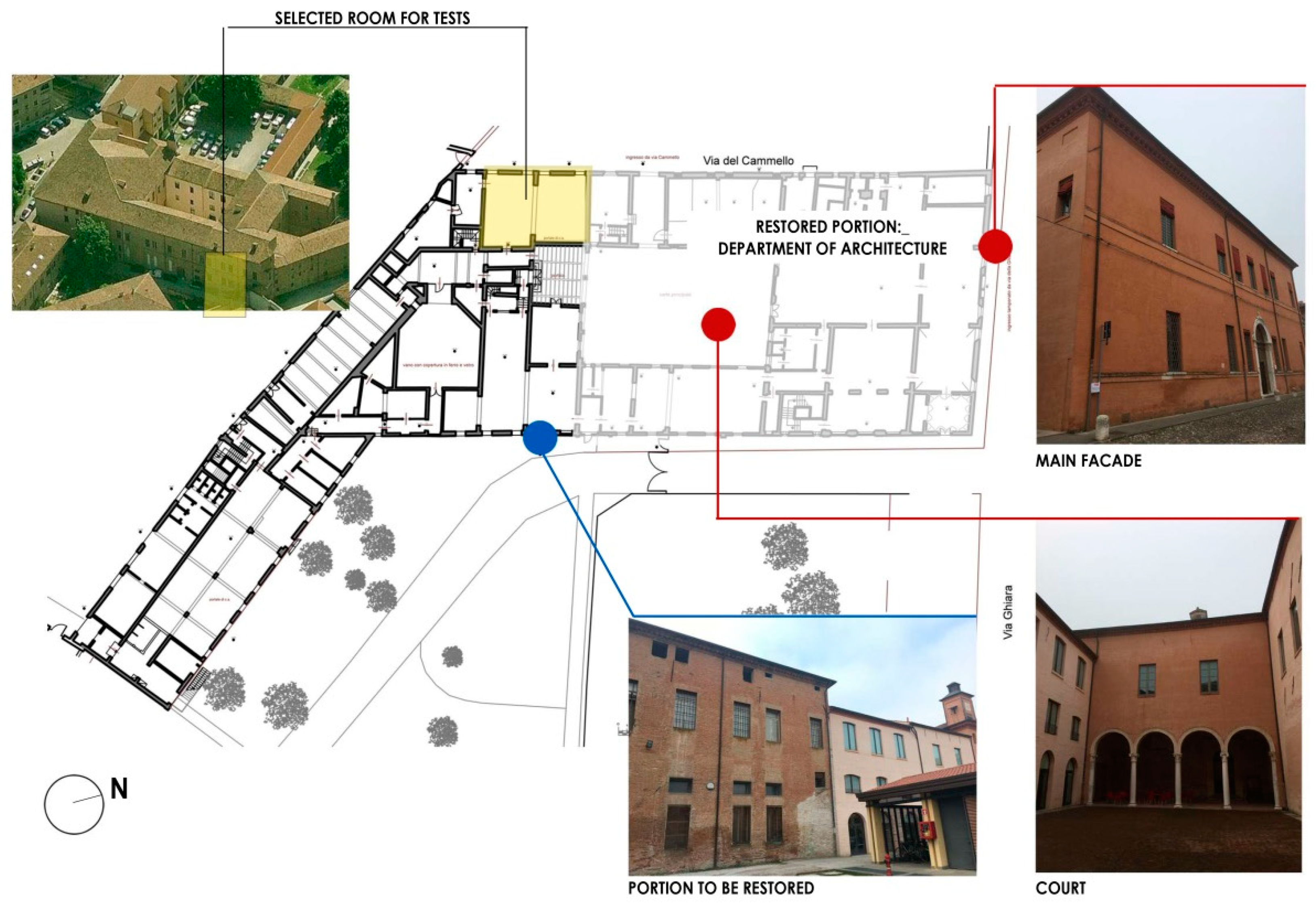

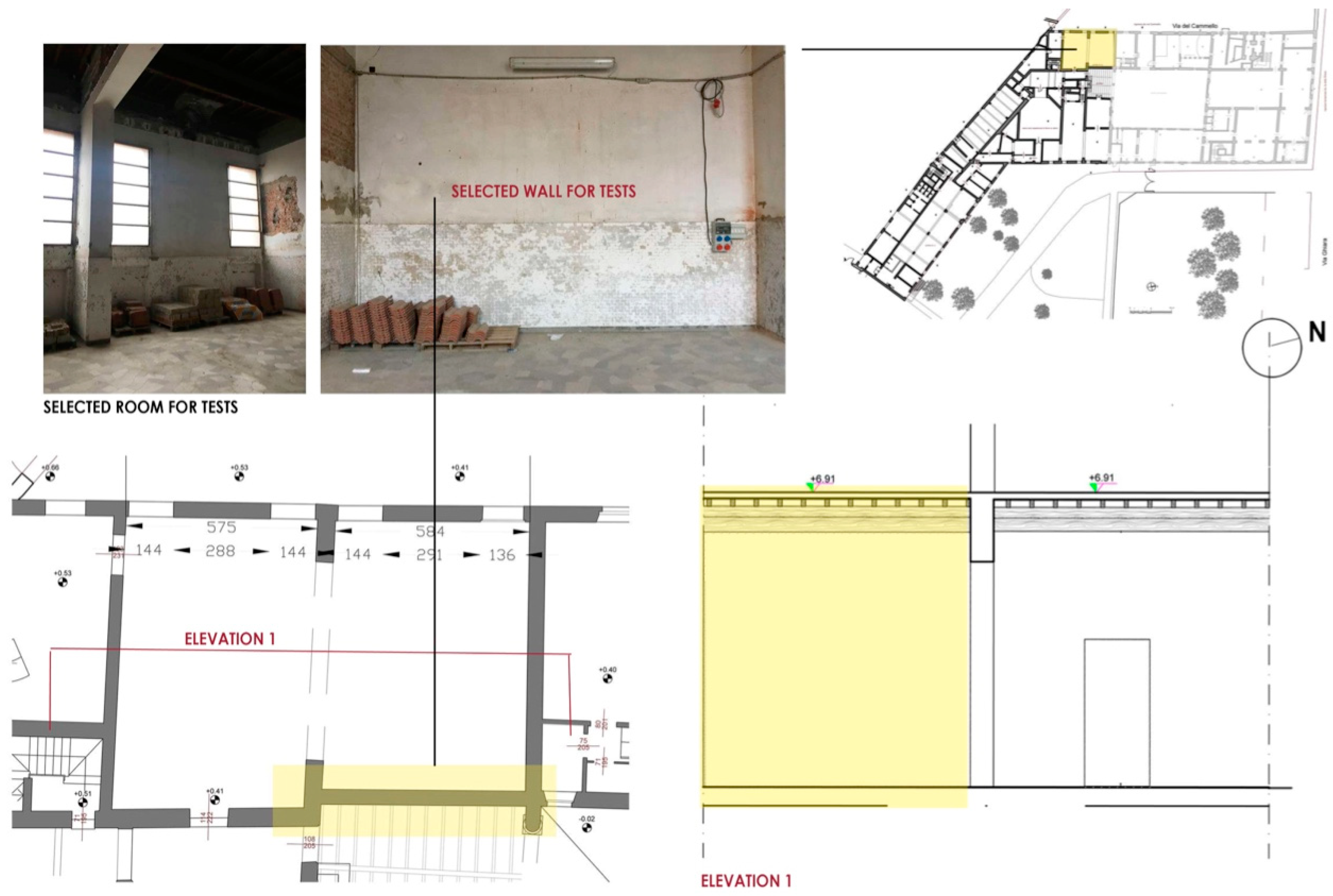

4. Case-Study Presentation and Experimental Methodology

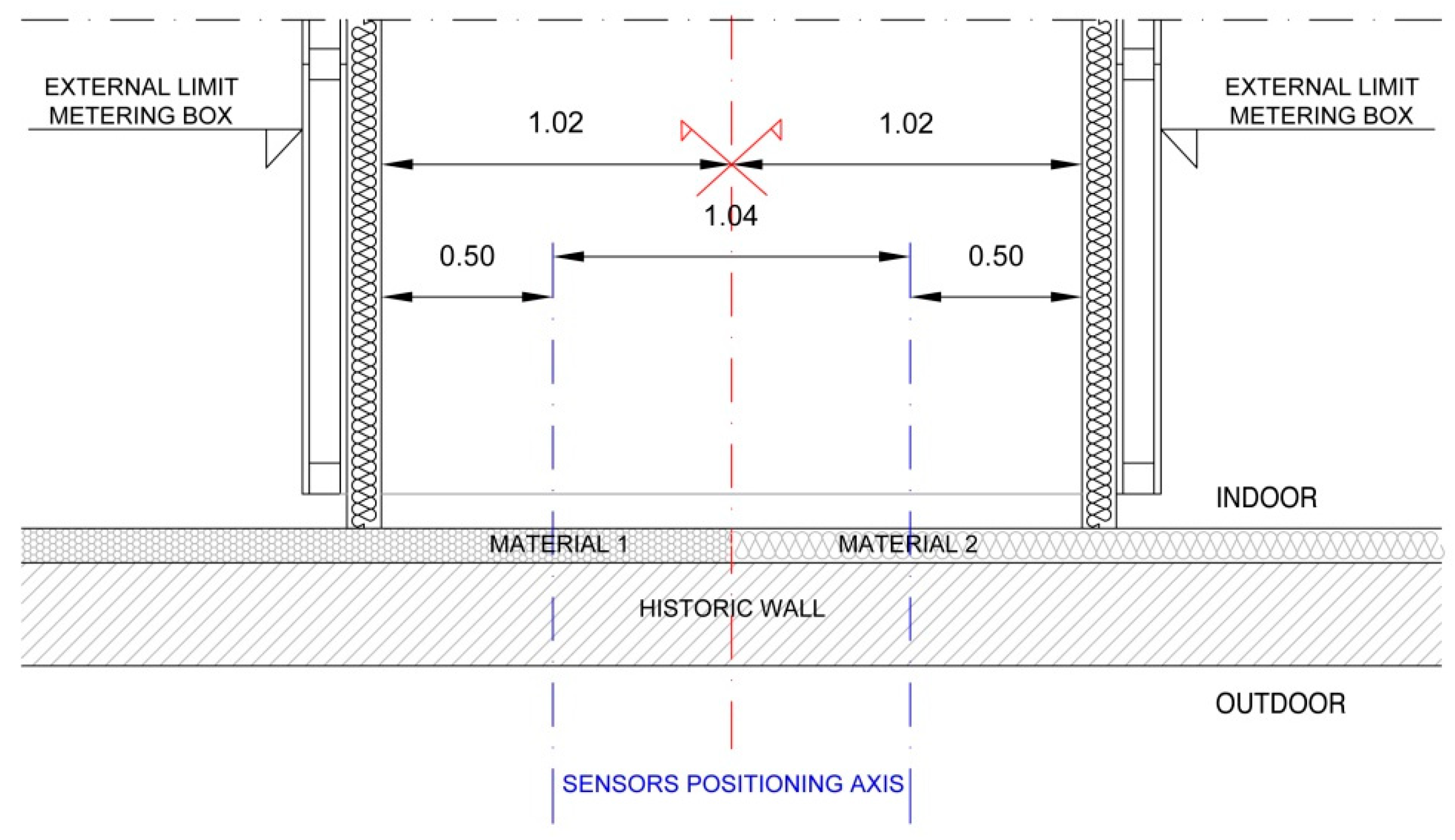

4.1. Contextualization and Configuration of the Tested Wall

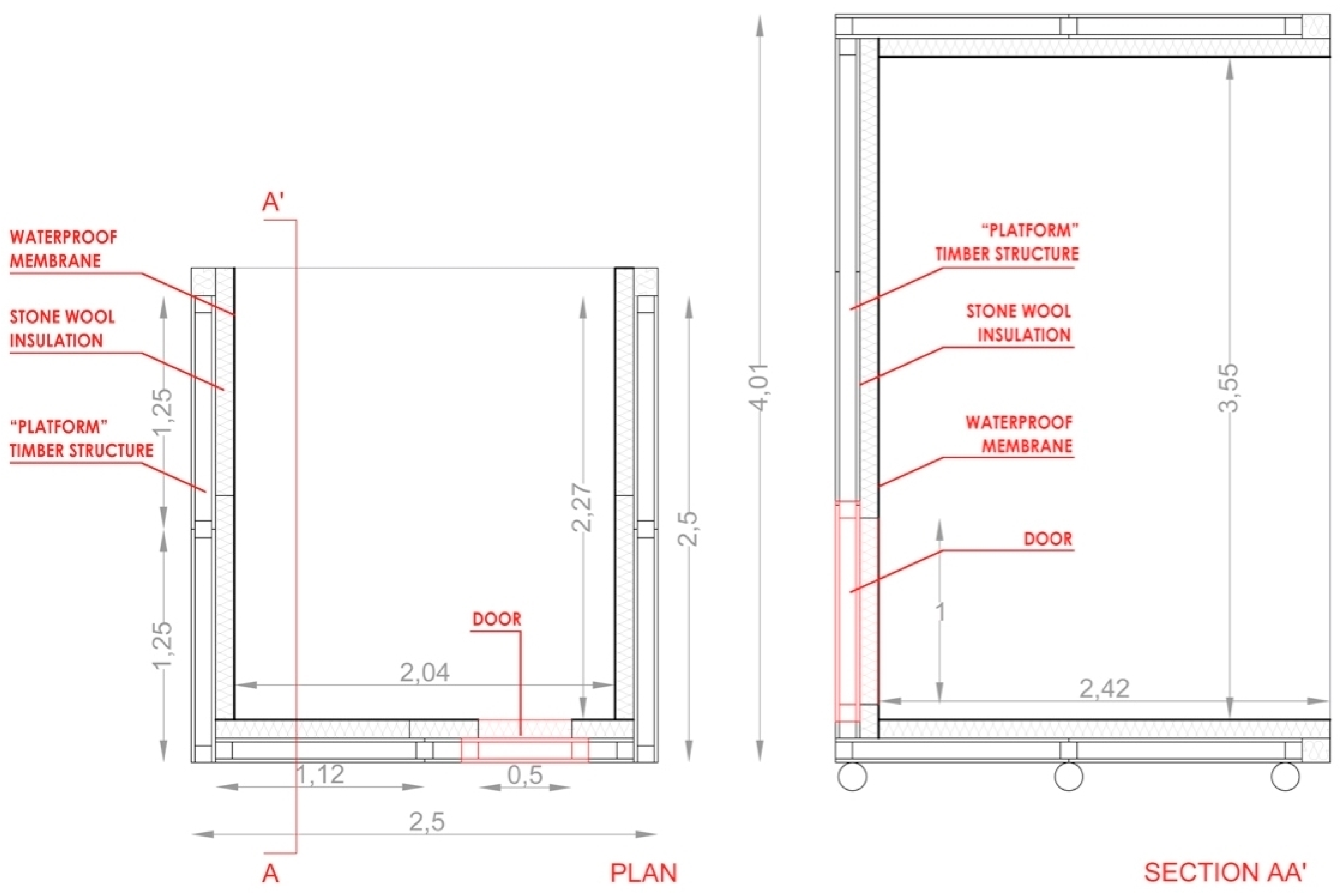

4.2. Design of the New Metering Hot Box

4.3. Construction of the Metering Box

4.4. Monitoring System of the Metering Box

- Email notification is sent hourly if everything works with a summary of all measurements, otherwise, every critical change in status is notified, with detailed information;

- An hourly backup copy of raw data is performed on a local drive;

- Daily processing of raw data is performed to produce more usable data files;

- Web pages with a summary of system and measurement details are updated every minute and synchronized with an online web server. This allows us to have a simple view of status available on every device connected to the internet, like a PC and mobile device;

- A protected local folder containing raw data backup and all pdf reports are synchronized with an external cloud.

5. Results and Discussion of the Conditions inside the Box

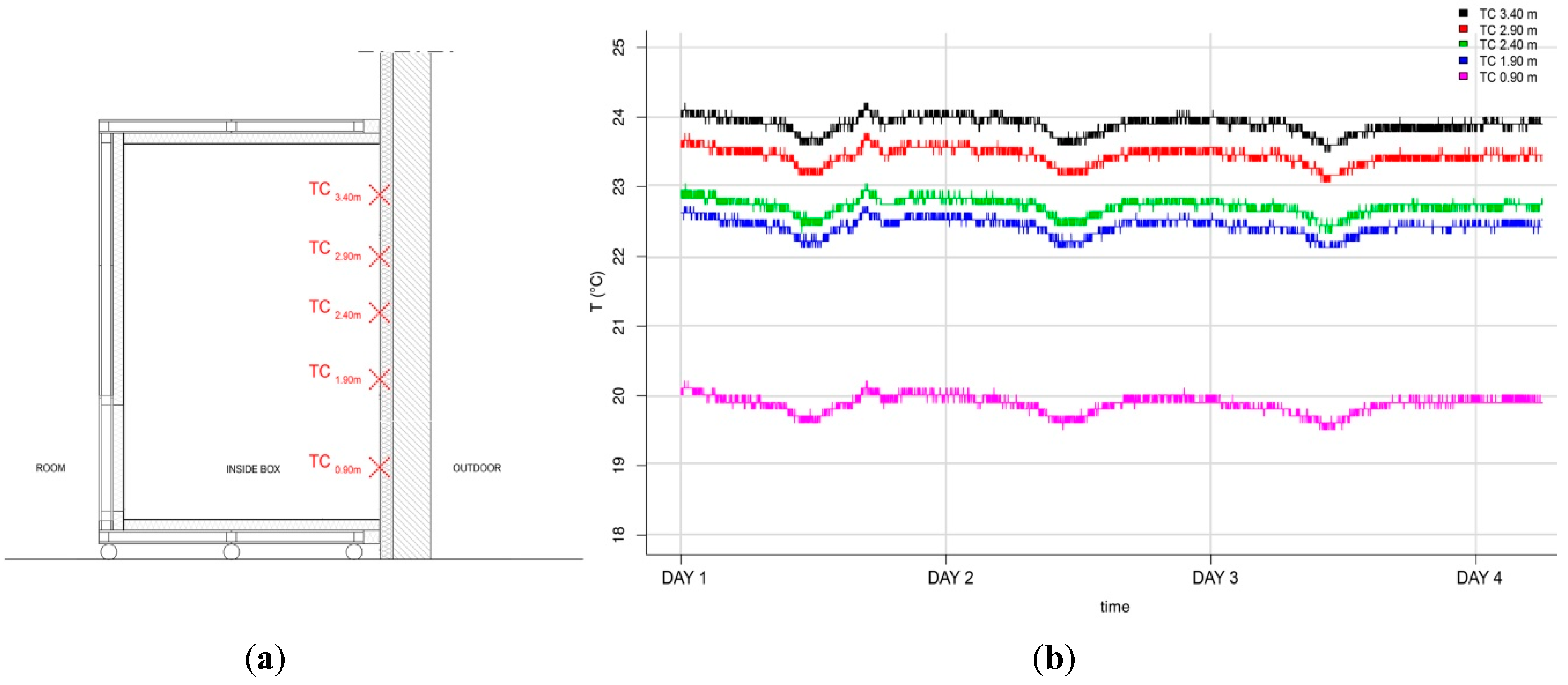

5.1. Preliminary Test for the Evaluation of Heat Stratifications

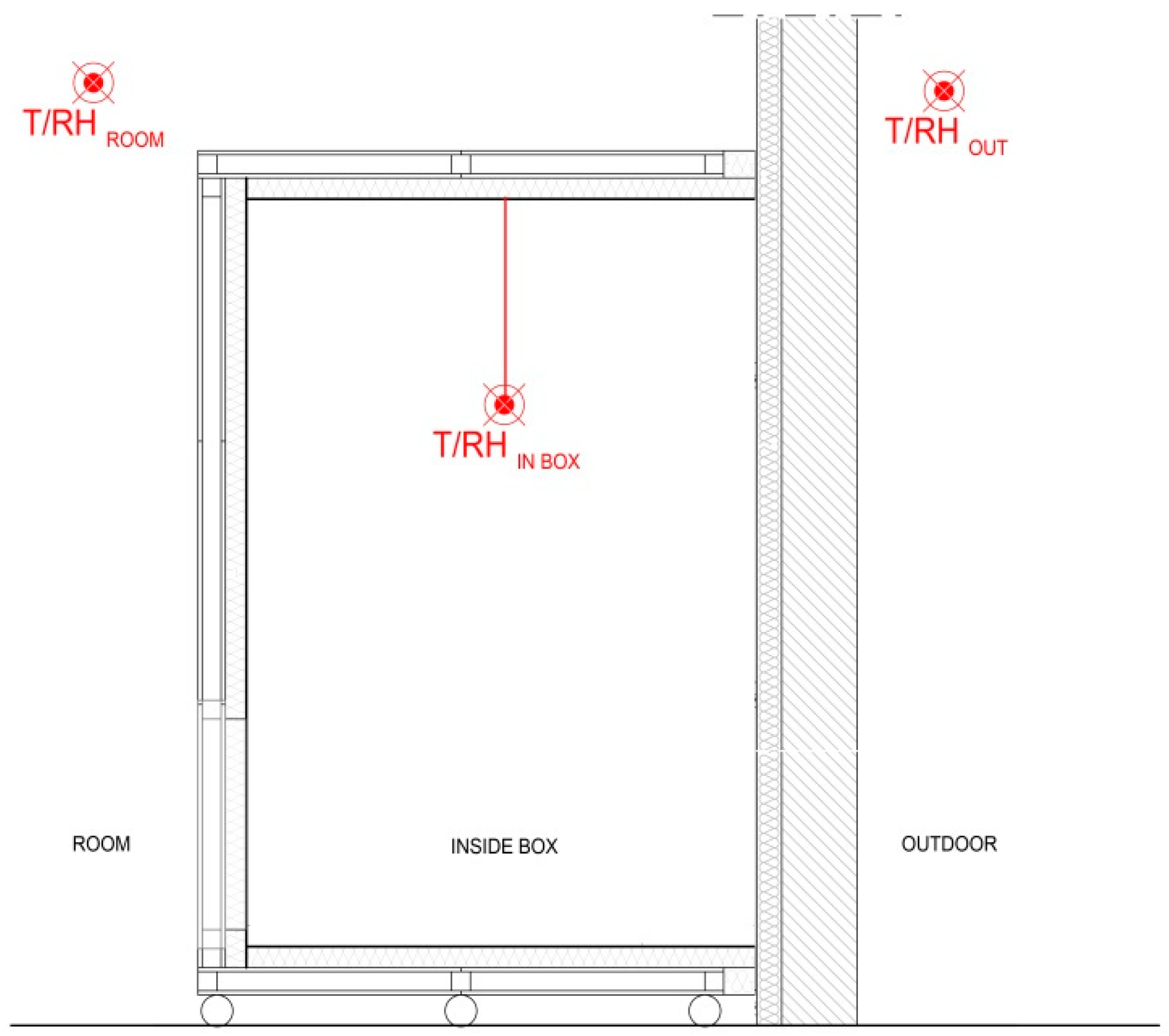

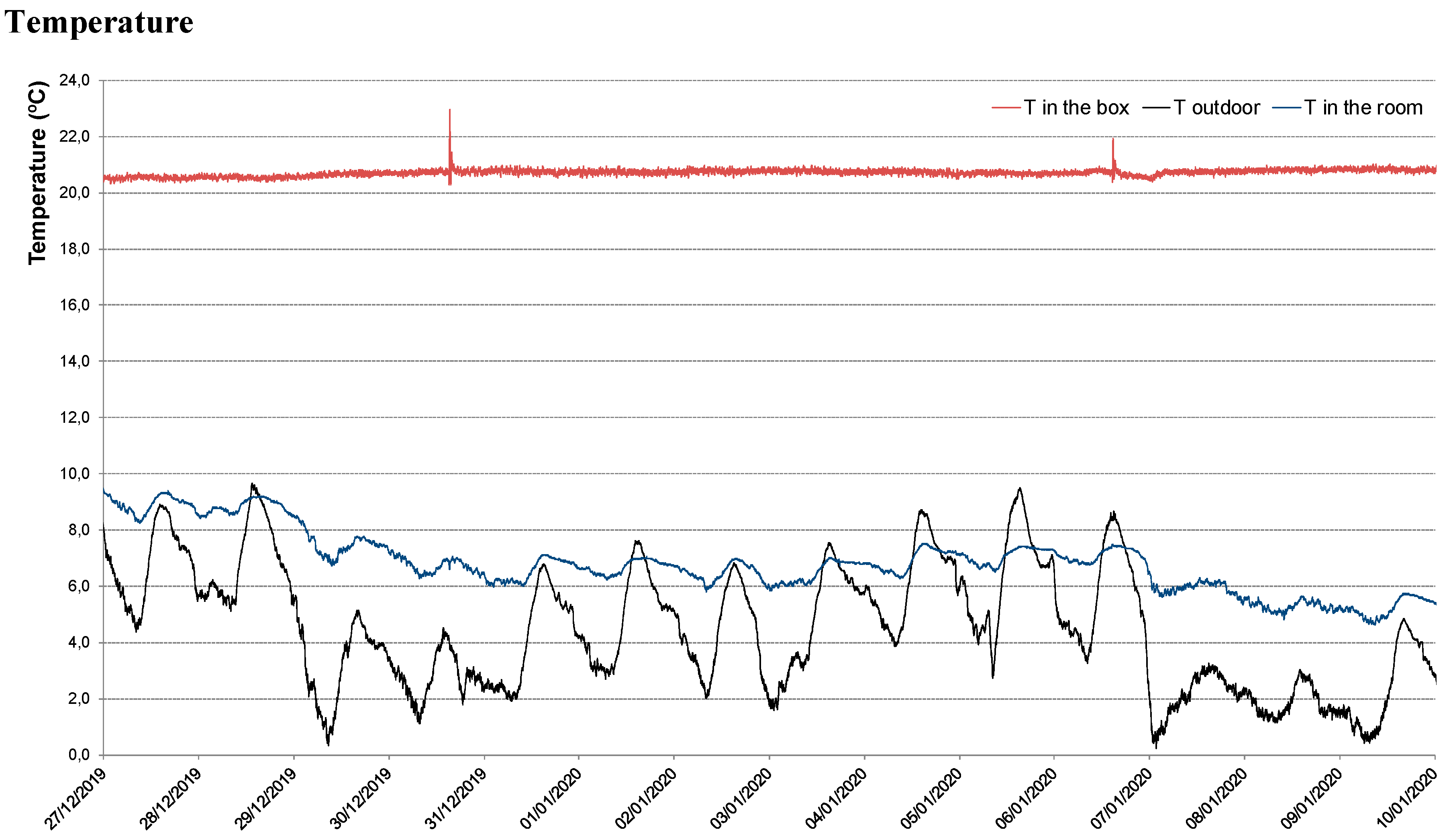

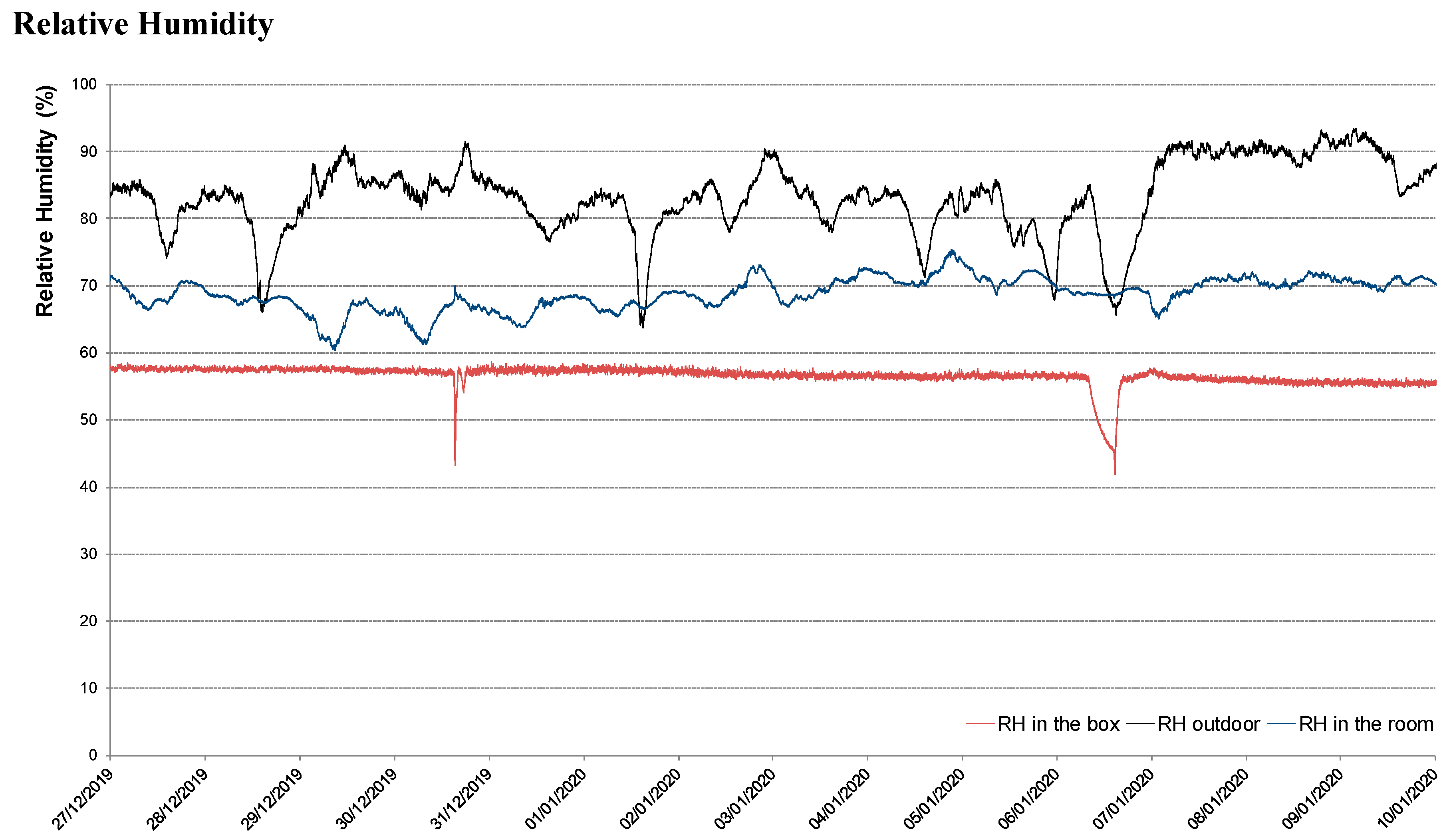

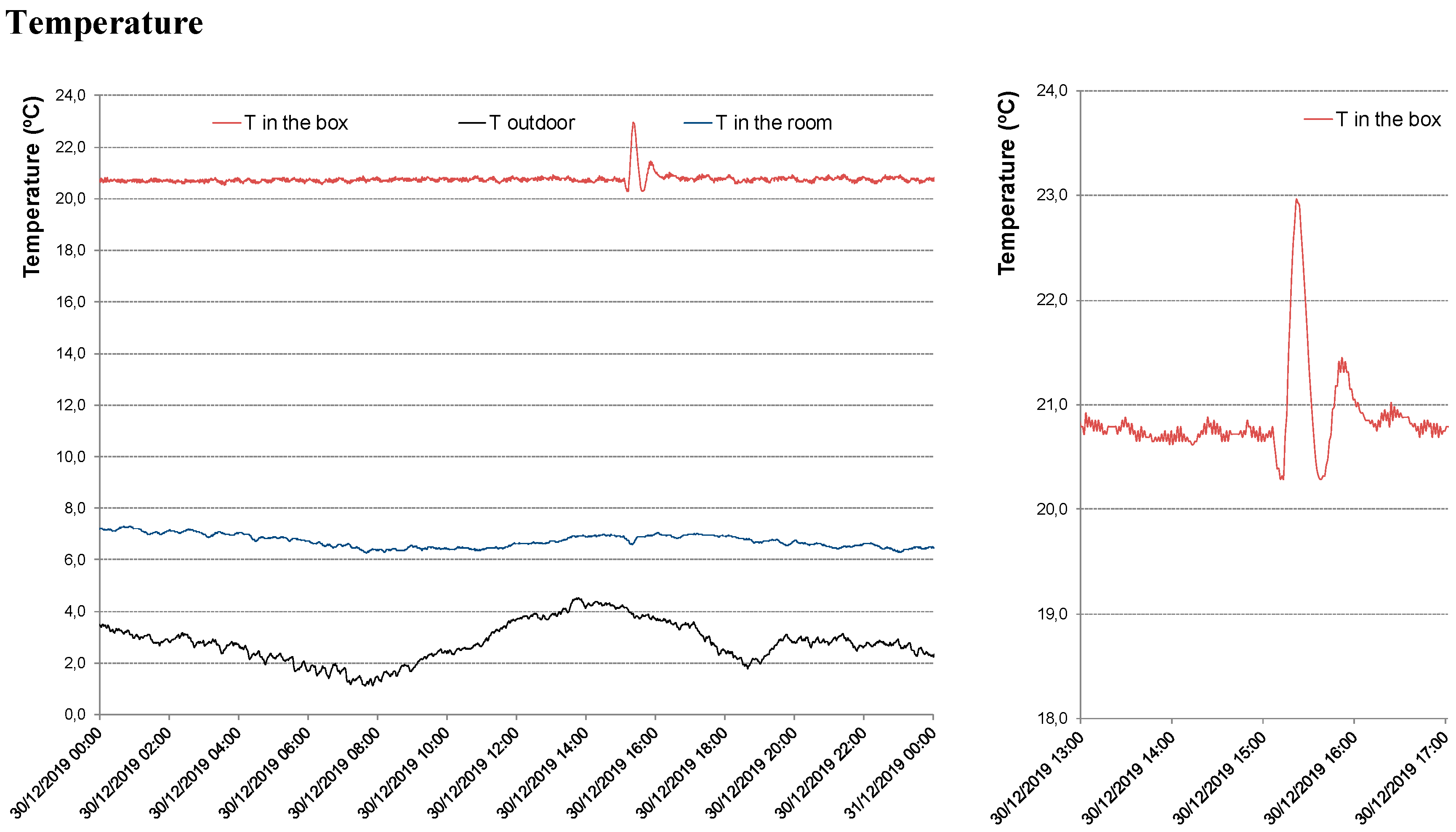

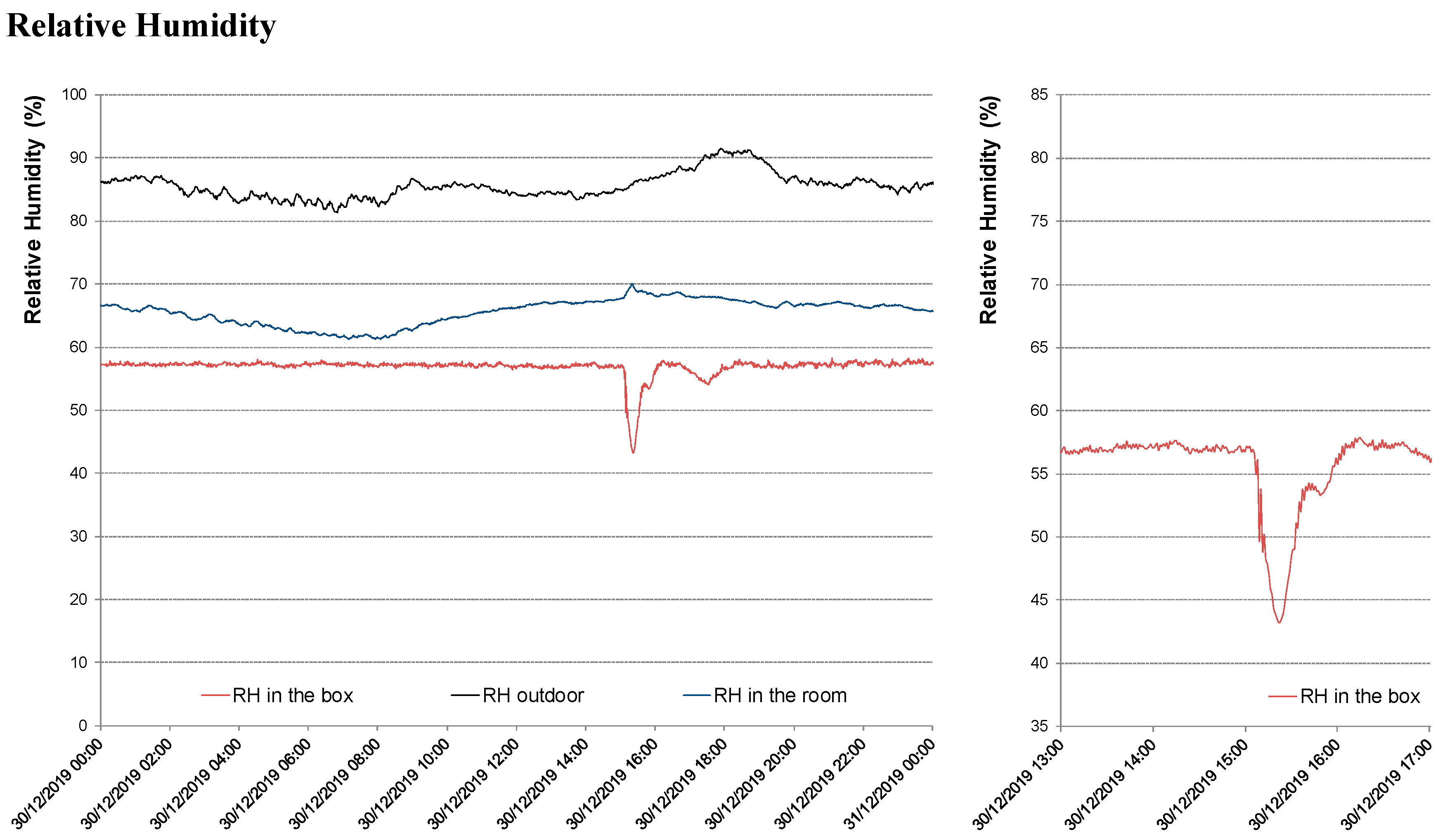

5.2. Validation of the Hygrothermal Set-Up

- Of the outdoor climate conditions (T/RH OUT);

- Of the non-refurbished and not heated room in which the box is located (T/RH ROOM);

- Inside the metering box (T/RH IN BOX), placed in the center at circa 1.0 m from the top of the box.

6. Conclusions and Outlook

- It allows long-term monitoring simulating a ‘real’ indoor environment (e.g., the study in [69] was proposed for short-time HFM measurements);

- It contributes to minimizing biased results since it addresses both the thermal and hygric phenomena of the walls (e.g., in [68] (p. 49) authors recalled that the measured thermal transmittance results obtained in [69] were “55% higher than the design thermal transmittance and that the measurement error was attributed to high moisture”);

- It is the first one of its kind addressing historic buildings—probably the type of buildings where data collection in situ is more urgent to be collected, considering that often the characteristics of the materials and their real performance are unknown;

- The singularity of addressing historic buildings justifies the box height. Its width was determined to allow future studies on the hygrothermal performances of internal thermal insulation (two materials can be tested in parallel);

- Similar to a traditional hot box, it was provided with wheels to be more easily moved. In order to minimize the impact on the monitoring, for maintenance purposes, the box was provided with a back door (located on the opposite side where main parameters are being collected);

- The box was built during an educational activity, involving students from a perspective of learning through practice, making the entire scientific process more inclusive.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| BES | Building Energy Simulation | NDT&E | Non-Destructive Testing and Evaluation |

| CH | Cultural Heritage | OSB | Oriented strand board |

| CHB | Calibrated Hot Box | PID | Proportional, Integrative, Derivative |

| EU | European Union | φ | Heat flux (W⋅m−2) |

| GHB | Guarded Hot Box | SHO | Simple Hot Box |

| GHP | Guarded Hot Plate | T | Temperature (°C) |

| HVAC | Heating, ventilation and Air conditioning | Ta | Air Temperature (°C) |

| HeLLo | Heritage energy Living Lab onsite | TC | Thermocouples |

| HFM | Heat Flow Meter | TCB | Temperature Control Box |

| IRT | Infrared Thermography | Ts | Surface temperature |

| ITT | Infrared Thermography Testing | RH | Relative Humidity (%) |

| NDT | Non-Destructive Testing | RHa | Air Relative Humidity (%) |

| NDE | Non-Destructive Evaluation | U-value | Thermal transmittance (W/m2K) |

Appendix A

References

- European Commission. Directive 2012/27/Eu of the European Parliament and of the Council; 2012; 56p, Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32012L0027&from=PT (accessed on 28 May 2020).

- Filippi, M. Remarks on the green retrofitting of historic buildings in Italy. Energy Build. 2015, 95, 15–22. [Google Scholar] [CrossRef]

- European Commission. European Commission > Energy > Topics > Energy Efficiency > Buildings. Available online: https://ec.europa.eu/energy/en/topics/energy-efficiency/energy-performance-of-buildings/energy-performance-buildings-directive (accessed on 8 June 2016).

- Buildingradar.com. Europe Construction Market Forecast from 2015 to 2020. Available online: https://buildingradar.com/construction-blog/european-construction-market-forecast/ (accessed on 26 June 2016).

- Phoenix, T. Lessons learned: ASHRAE’s approach in the refurbishment of historic and existing buildings. Energy Build. 2015, 95, 13–14. [Google Scholar] [CrossRef]

- Edinburgh World Heritage. Old and New Towns of Edinburgh World Heritage Site Management Plan 2017–2022; Edinburgh, UK, 2017; Available online: https://ewh.org.uk/plan/assets/Management-Plan-2018.pdf (accessed on 28 May 2020).

- Litti, G.; Khoshdel, S.; Audenaert, A.; Braet, J. Hygrothermal performance evaluation of traditional brick masonry in historic buildings. Energy Build. 2015, 105, 393–411. [Google Scholar] [CrossRef]

- Historic England. Energy Efficiency and Historic Buildings: Insulating Solid Walls; Historic England: London, UK, 2012; pp. 1–61. [Google Scholar] [CrossRef]

- Lucchi, E. Thermal transmittance of historical stone masonries: A comparison among standard, calculated and measured data. Energy Build. 2017, 151, 393–405. [Google Scholar] [CrossRef]

- Lucchi, E. Thermal transmittance of historical brick masonries: A comparison among standard data, analytical calculation procedures, and in situ heat flow meter measurements. Energy Build. 2017, 134, 171–184. [Google Scholar] [CrossRef]

- Peak District National Park. Conserving Your Historic Building. Sustainability and Historic Buildings: A Guide for Owners and Occupiers. Available online: http://www.special-eu.org/assets/uploads/Sustainability_and_Historicbuildings_by_Peak_District.pdf (accessed on 28 May 2020).

- Raftery, C. Energy Performance in Protected Structures: Planning implications and grants. In Energy Efficiency in Historic Houses; Irish Georgian Society: Dublin, Ireland, 2013; pp. 7–18. ISBN 978-0-9545691-4-3. Available online: https://www.igs.ie/uploads/Energy_Efficiency_in_Historic_Houses.pdf (accessed on 28 May 2020).

- Khoury, J.; Alameddine, Z.; Hollmuller, P. Understanding and bridging the energy performance gap in building retrofit. Energy Procedia 2017, 122, 217–222. [Google Scholar] [CrossRef]

- Zou, P.X.W.; Xu, X.; Sanjayan, J.; Wang, J. Review of 10 years research on building energy performance gap: Life-cycle and stakeholder perspectives. Energy Build. 2018, 178, 165–181. [Google Scholar] [CrossRef]

- Bortoluzzi, D.; Costa, A.; Casciati, S. Reducing Energy Performance Gap in Buildings—Built2Spec Project Solution. Proceedings 2017, 1, 640. [Google Scholar] [CrossRef]

- Bourdeau, M.; Guo, X.; Nefzaoui, E. Buildings energy consumption generation gap: A post-occupancy assessment in a case study of three higher education buildings. Energy Build. 2018, 159, 600–611. [Google Scholar] [CrossRef]

- Built2Spec. D1.2 Performance Gap and Its Assessment Methodology in Built2Spec Project. 2015. Available online: http://built2spec-project.eu/wp-content/uploads/2016/06/Built2Spec_Performance_gap_assessment_methodology_part_1.pdf (accessed on 28 May 2020).

- Barthelmes, V.M.; Becchio, C.; Fabi, V.; Corgnati, S.P. Occupant behaviour lifestyles and effects on building energy use: Investigation on high and low performing building features. Energy Procedia 2017, 140, 93–101. [Google Scholar] [CrossRef]

- Soares, N.; Bastos, J.; Pereira, L.D.; Soares, A.; Amaral, A.R.; Asadi, E.; Rodrigues, E.; Lamas, F.B.; Monteiro, H.; Lopes, M.A.R.; et al. A review on current advances in the energy and environmental performance of buildings towards a more sustainable built environment. Renew. Sustain. Energy Rev. 2017, 77, 845–860. [Google Scholar] [CrossRef]

- van Dronkelaar, C.; Dowson, M.; Spataru, C.; Mumovic, D. A Review of the Regulatory Energy Performance Gap and Its Underlying Causes in Non-domestic Buildings. Front. Mech. Eng. 2016, 1, 1–14. [Google Scholar] [CrossRef]

- Calzolari, M.; Davoli, P. Instruments for the calculation of energy performance in historical buildings. Limits of applicability and tuning proposal. SMC Sustain. Mediterr. Constr. L. Cult. Res. Technol. Mag. 2018, 1, 108–114. [Google Scholar]

- Adhikari, R.S.; Lucchi, E.; Pracchi, V. Energy modelling of historic buildings: Applicability, problems and compared results. In Proceedings of the 3rd European Workshop on Cultural Heritage Protection (EWCHP): Taking Care of Our Treasures, Bolzano, Italy, 16–17 September 2013; pp. 119–125. [Google Scholar]

- Evangelisti, L.; Battista, G.; Guattari, C.; Basilicata, C.; de Lieto Vollaro, R. Analysis of two models for evaluating the energy performance of different buildings. Sustainability 2014, 6, 5311–5321. [Google Scholar] [CrossRef]

- Rye, C. A Short Paper on the Conventions and Standards that Govern the Understanding of Heat Loss in Traditional Buildings. 2012. Available online: http://www.sdfoundation.org.uk/downloads/STBA-Short-Paper-on-heat-loss-FINAL.pdf (accessed on 28 May 2020).

- Akkurt, G.G.; Aste, N.; Borderon, J.; Buda, A.; Calzolari, M.; Chung, D.; Costanzo, V.; Del Pero, C.; Evola, G.; Huerto-Cardenas, H.E.; et al. Dynamic thermal and hygrometric simulation of historical buildings: Critical factors and possible solutions. Renew. Sustain. Energy Rev. 2020, 118, 109509. [Google Scholar] [CrossRef]

- Calzolari, M. Prestazione Energetica Delle Architetture Storiche: Sfide e Soluzioni. Analisi dei Metodi di Calcolo per la Definizione del Comportamento Energetico; Franco Angelli: Milano, Italy, 2016; ISBN 9788891740885. [Google Scholar]

- Belpoliti, V.; Bizzarri, G.; Boarin, P.; Calzolari, M.; Davoli, P. A parametric method to assess the energy performance of historical urban settlements. Evaluation of the current energy performance and simulation of retrofit strategies for an Italian case study. J. Cult. Herit. 2018, 30, 155–167. [Google Scholar] [CrossRef]

- Mantesi, E.; Hopfe, C.J.; Cook, M.J.; Glass, J.; Strachan, P. The modelling gap: Quantifying the discrepancy in the representation of thermal mass in building simulation. Build. Environ. 2018, 131, 74–98. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Coronel, J.F.; Maestre, I.R. A review of HVAC systems requirements in building energy regulations. Energy Build. 2011, 43, 255–268. [Google Scholar] [CrossRef]

- Dias Pereira, L.; Bispo Lamas, F.; Gameiro da Silva, M. Improving energy use in schools: From IEQ towards energy-efficient planning—method and in-field application to two case studies. Energy Effic. 2019, 12, 1253–1277. [Google Scholar] [CrossRef]

- Rhodes, J.D.; Stephens, B.; Webber, M.E. Using energy audits to investigate the impacts of common air-conditioning design and installation issues on peak power demand and energy consumption in Austin, Texas. Energy Build. 2011, 43, 3271–3278. [Google Scholar] [CrossRef]

- HeLLo EU H2020 MSCA-IF-ES HeLLo Project. 2019. Available online: https://cordis.europa.eu/project/rcn/215475/factsheet/en (accessed on 7 April 2019).

- Soares, N.; Martins, C.; Gonçalves, M.; Santos, P.; Simões da Silva, L.; Costa, J.J. Laboratory and in-situ non-destructive methods to evaluate the thermal transmittance and behaviour of walls, windows, and construction elements with innovative materials: A review. Energy Build. 2019, 182, 88–110. [Google Scholar] [CrossRef]

- Lucchi, E.; Dias Pereira, L.; Andreotti, M.; Malaguti, R.; Cennamo, D.; Calzolari, M.; Frighi, V. Development of a Compatible, Low Cost and High Accurate Conservation Remote Sensing Technology for the Hygrothermal Assessment of Historic Walls. Electronics 2019, 8, 1–20. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 7345:2018. In Thermal Performance of Buildings and Building Components—Physical Quantities and Definitions; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- International Organization for Standardization (ISO). ISO 8301:1991. In Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus; ISO: Geneva, Switzerland, 1991. [Google Scholar]

- International Organization for Standardization (ISO). ISO 9869-1:2014. In Thermal Insulation. Building Elements. In Situ Measurement of Thermal Resistance and Thermal Transmittance—Part 1: Heat Flow Meter Method; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- Santos, P.; Gonçalves, M.; Martins, C.; Soares, N.; Costa, J.J. Thermal transmittance of lightweight steel framed walls: Experimental versus numerical and analytical approaches. J. Build. Eng. 2019, 25, 100776. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 10880:2017. In Non-Destructive Testing—Infrared Thermography Testing—General Principles; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- International Organization for Standardization (ISO). ISO 6781:1983. In Thermal Insulation—Qualitative Detection of Thermal Irregularities in Building Envelopes—Infrared Method; ISO: Geneva, Switzerland, 1983. [Google Scholar]

- International Organization for Standardization (ISO). ISO 8990:1994. In Thermal Insulation—Determination of Steady-State Thermal Transmission Properties—Calibrated and Guarded Hot Box; ISO: Geneva, Switzerland, 1994. [Google Scholar]

- Asdrubali, F.; Baldinelli, G. Thermal transmittance measurements with the hot box method: Calibration, experimental procedures, and uncertainty analyses of three different approaches. Energy Build. 2011, 43, 1618–1626. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Moyano, J.; Marín, D.; Fresco-Contreras, R. Review of in situ methods for assessing the thermal transmittance of walls. Renew. Sustain. Energy Rev. 2019, 102, 356–371. [Google Scholar] [CrossRef]

- Sala, J.M.; Urresti, A.; Martín, K.; Flores, I.; Apaolaza, A. Static and dynamic thermal characterisation of a hollow brick wall: Tests and numerical analysis. Energy Build. 2008, 40, 1513–1520. [Google Scholar] [CrossRef]

- Giorgio, P.; De Carli, M. A measuring campaign of thermal conductance in situ and possible impacts on net energy demand in buildings. Energy Build. 2013, 59, 29–36. [Google Scholar] [CrossRef]

- Nardi, I.; Lucchi, E.; de Rubeis, T.; Ambrosini, D. Quantification of heat energy losses through the building envelope: A state-of-the-art analysis with critical and comprehensive review on infrared thermography. Build. Environ. 2018, 146, 190–205. [Google Scholar] [CrossRef]

- Lucchi, E. Applications of the infrared thermography in the energy audit of buildings: A review. Renew. Sustain. Energy Rev. 2018, 82, 3077–3090. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 8302:1991. In Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Guarded Hot Plate Apparatus; ISO: Geneva, Switzerland, 1991. [Google Scholar]

- ASTM International (American Society for Testing and Materials). ASTM C177—19. In Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus; ASTM: West Conshohhocken, PA, USA, 2019. [Google Scholar]

- Reddy, K.S.; Jayachandran, S. Investigations on design and construction of a square guarded hot plate (SGHP) apparatus for thermal conductivity measurement of insulation materials. Int. J. Therm. Sci. 2017, 120, 136–147. [Google Scholar] [CrossRef]

- Kobari, T.; Okajima, J.; Komiya, A.; Maruyama, S. Development of guarded hot plate apparatus utilizing Peltier module for precise thermal conductivity measurement of insulation materials. Int. J. Heat Mass Transf. 2015, 91, 1157–1166. [Google Scholar] [CrossRef]

- Sanjaya, C.S.; Wee, T.-H.; Tamilselvan, T. Regression analysis estimation of thermal conductivity using guarded-hot-plate apparatus. Appl. Therm. Eng. 2011, 31, 1566–1575. [Google Scholar] [CrossRef]

- ASTM International (American Society for Testing and Materials). ASTM C1363-19. In Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus; ASTM: West Conshohhocken, PA, USA, 2019. [Google Scholar]

- European Committee for Standardization (CEN). EN 1934:1998 Thermal Performance of Buildings—Determination of Thermal Resistance by Hot Box Method Using Heat Flow Meter—Masonry; CEN: Brussels, Belgium, 1998. [Google Scholar]

- Interstate Standard of Russian Federation (ISRF). Standard GOST 26602.1-99. In Windows and Doors. Methods of Determination of Resistance of Thermal Transmission; ISFR: Moscow, Russia, 1999. [Google Scholar]

- Vereecken, E.; Roels, S. A comparison of the hygric performance of interior insulation systems: A hot box-cold box experiment. Energy Build. 2014, 80, 37–44. [Google Scholar] [CrossRef]

- Byrne, A.; Byrne, G.; Robinson, A. Compact facility for testing steady and transient thermal performance of building walls. Energy Build. 2017, 152, 602–614. [Google Scholar] [CrossRef]

- Cucumo, M.; De Rosa, A.; Ferraro, V.; Kaliakatsos, D.; Marinelli, V. A method for the experimental evaluation in situ of the wall conductance. Energy Build. 2006, 38, 238–244. [Google Scholar] [CrossRef]

- Han, J.; Lu, L.; Peng, J.; Yang, H. Performance of ventilated double-sided PV façade compared with conventional clear glass façade. Energy Build. 2013, 56, 204–209. [Google Scholar] [CrossRef]

- Cattarin, G.; Causone, F.; Kindinis, A.; Pagliano, L. Outdoor test cells for building envelope experimental characterisation—A literature review. Renew. Sustain. Energy Rev. 2016, 54, 606–625. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Rodrigues, F.; Samagaio, A.; Cardoso, C. Development of a window shutter with phase change materials: Full scale outdoor experimental approach. Energy Build. 2015, 88, 110–121. [Google Scholar] [CrossRef]

- Young, C.-H.; Chen, Y.-L.; Chen, P.-C. Heat insulation solar glass and application on energy efficiency buildings. Energy Build. 2014, 78, 66–78. [Google Scholar] [CrossRef]

- Qahtan, A.; Keumala, N.; Rao, S.P.; Abdul-Samad, Z. Experimental determination of thermal performance of glazed façades with water film, under direct solar radiation in the tropics. Build. Environ. 2011, 46, 2238–2246. [Google Scholar] [CrossRef]

- Gao, Y.; Roux, J.J.; Teodosiu, C.; Zhao, L.H. Reduced linear state model of hollow blocks walls, validation using hot box measurements. Energy Build. 2004, 36, 1107–1115. [Google Scholar] [CrossRef]

- Kus, H.; Özkan, E.; Göcer, Ö.; Edis, E. Hot box measurements of pumice aggregate concrete hollow block walls. Constr. Build. Mater. 2013, 38, 837–845. [Google Scholar] [CrossRef]

- Baldwin, C.; Cruickshank, C.A.; Schiedel, M.; Conley, B. Comparison of steady-state and in-situ testing of high thermal resistance walls incorporating vacuum insulation panels. Energy Procedia 2015, 78, 3246–3251. [Google Scholar] [CrossRef]

- Peng, C.; Wu, Z. In situ measuring and evaluating the thermal resistance of building construction. Energy Build. 2008, 40, 2076–2082. [Google Scholar] [CrossRef]

- Meng, X.; Gao, Y.; Wang, Y.; Yan, B.; Zhang, W.; Long, E. Feasibility experiment on the simple hot box-heat flow meter method and the optimization based on simulation reproduction. Appl. Therm. Eng. 2015, 83, 48–56. [Google Scholar] [CrossRef]

- Zhu, X.F.; Li, L.P.; Yin, X.B.; Zhang, S.H.; Wang, Y.; Liu, W.; Zheng, L. An in-situ test apparatus of heat transfer coefficient for building envelope. Build. Energy Effic. 2012, 256, 57–60. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-FCYY201206018.htm (accessed on 28 May 2020).

- Meng, X.; Luo, T.; Gao, Y.; Zhang, L.; Shen, Q.; Long, E. A new simple method to measure wall thermal transmittance in situ and its adaptability analysis. Appl. Therm. Eng. 2017, 122, 747–757. [Google Scholar] [CrossRef]

- EN 15758:2010. Conservation Of Cultural Property—Procedures and Instruments for Measuring Temperatures of the Air and the Surfaces of Objects; CEN: Brussels, Belgium, 2010. [Google Scholar]

- EN 16242. EN 16242 Conservation of Cultural Heritage—Procedures and Instruments for Measuring Humidity in the Air and Moisture Exchanges between Air and Cultural Property; CEN: Brussels, Belgium, 2012. [Google Scholar]

- Ente Italiano di Normazione (UNI). UNI 10829. In Beni di Interesse Storico e Artistico—Condizioni Ambientali di Conservazione—Misurazione ed Analisi; UNI: Milano, Italy, 1999. [Google Scholar]

- European Committee for Standardization (CEN). Standard CEN/TC 346—Conservation of Cultural Heritage; CEN: Brussels, Belgium, 2009. [Google Scholar]

- European Committee for Standardization (CEN). EN 15757:2010 Conservation of Cultural Property—Specifications for Temperature and Relative Humidity to Limit Climate-Induced Mechanical Damage in Organic Hygroscopic Materials; 2010; Available online: http://shop.bsigroup.com/ProductDetail?pid=000000000030173518 (accessed on 28 May 2020).

- European Committee for Standardization (CEN). CEN UNI EN 15759-1 (2012) (English). In Conservation of Cultural Property—Indoor Climate—Part 1: Guidelines for Heating Churches, Chapels and Other Places of Worship; CEN: Brussels, Belgium, 2012. [Google Scholar]

- Ente Nazionale Italiano di Unificazione (UNI). UNI 10969. In Beni Culturali. Principi Generali per la Scelta e il Controllo del Microclima per la Conservazione; UNI: Milano, Italy, 2002. [Google Scholar]

- Ente Nazionale Italiano di Unificazione (UNI). UNI 10586. In Condizioni Climatiche per Ambienti di Conservazione di Documenti Grafici e Caratteristiche Degli Alloggiamenti; UNI: Milano, Italy, 1999. [Google Scholar]

- Camuffo, D. Microclimate for Cultural Heritage: Conservation, Restoration, and Maintenance of Indoor and Outdoor Monuments, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014; ISBN 9780444632968. [Google Scholar] [CrossRef]

- Walker, R.; Pavía, S.; Dalton, M. Measurement of moisture content in solid brick walls using timber dowel. Mater. Struct. 2016, 49, 2549–2561. [Google Scholar] [CrossRef]

- European Committee for Standardization (CEN). Standard prEN 16682. In Conservation of Cultural Heritage. Guide to the Measurements of Moisture Content in Materials Constituting Movable and Immovable Cultural Heritage; CEN: Brussels, Belgium, 2013. [Google Scholar]

- Ente Nazionale Italiano di Unificazione (UNI). UNI 11085. In Beni Culturali—Materiali Lapidei Naturali ed Artificiali—Determinazione del Contenuto D’acqua: Metodo Ponderale; UNI: Milano, Italy, 2003. [Google Scholar]

- Odgaard, T.; Bjarløv, S.P.; Rode, C. Interior insulation—Experimental investigation of hygrothermal conditions and damage evaluation of solid masonry façades in a listed building. Build. Environ. 2018, 129, 1–14. [Google Scholar] [CrossRef]

- Walker, R.; Pavía, S. Thermal and moisture monitoring of an internally insulated historic brick wall. Build. Environ. 2018, 133, 178–186. [Google Scholar] [CrossRef]

- Hansen, T.K.; Bjarløv, S.P.; Peuhkuri, R.H.; Harrestrup, M. Long term in situ measurements of hygrothermal conditions at critical points in four cases of internally insulated historic solid masonry walls. Energy Build. 2018, 172, 235–248. [Google Scholar] [CrossRef]

- UNESCO. Ferrara, City of the Renaissance, and its Po Delta. 1995. Available online: http://whc.unesco.org/en/list/733 (accessed on 9 January 2019).

- Davoli, P. Complexity, information surplus and interdisciplinarity management. The Rehabilitation of Tassoni Estense Palace in Ferrara. In Conserving Architecture; Jain, K., Ed.; AADI CENTRE: Ahmedabad, Indian, 2017; pp. 124–145. ISBN 978-81-908528-2-1. [Google Scholar]

- International Organization for Standardization (ISO). ISO 7730: 2005. In Ergonomics of the Thermal Environment. Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria; UNI: Geneva, Switzerland, 2005. [Google Scholar]

- Ente Italiano di Normazione (UNI). UNI EN ISO 13788. In Prestazione Igrotermica dei Componenti e Degli Elementi per Edilizia—Temperatura Superficiale Interna per Evitare L’umidita’ Superficiale Critica e la Condensazione Interstiziale. Metodi di Calcolo; UNI: Milano, Italy, 2013. [Google Scholar]

- International Organization for Standardization (ISO). ISO 17772-1: 2017. In Energy Performance of Buildings—Indoor Environmental Quality—Part 1: Indoor Environmental Input Parameters for the Design and Assessment of Energy Performance of Buildings; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- Rasooli, A.; Itard, L.; Ferreira, C.I. A response factor-based method for the rapid in-situ determination of wall’s thermal resistance in existing buildings. Energy Build. 2016, 119, 51–61. [Google Scholar] [CrossRef]

- Nardi, I.; Paoletti, D.; Ambrosini, D.; De Rubeis, T.; Sfarra, S. Validation of quantitative IR thermography for estimating the U-value by a hot box apparatus. J. Phys. Conf. Ser. 2015, 655, 012006. [Google Scholar] [CrossRef]

- Kloseiko, P.; Arumagi, E.; Kalamees, T. Hygrothermal performance of internally insulated brick wall in cold climate: A case study in a historical school building. J. Build. Phys. 2015, 38, 444–464. [Google Scholar] [CrossRef]

- Raffler, S.; Bichlmair, S.; Kilian, R. Mounting of sensors on surfaces in historic buildings. Energy Build. 2015, 95, 92–97. [Google Scholar] [CrossRef]

- Council of Europe. Guidelines on Cultural Heritage: Technical Tools for Heritage Conservation and Management. 2012. Available online: https://rm.coe.int/16806ae4a9 (accessed on 28 May 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andreotti, M.; Calzolari, M.; Davoli, P.; Dias Pereira, L.; Lucchi, E.; Malaguti, R. Design and Construction of a New Metering Hot Box for the In Situ Hygrothermal Measurement in Dynamic Conditions of Historic Masonries. Energies 2020, 13, 2950. https://doi.org/10.3390/en13112950

Andreotti M, Calzolari M, Davoli P, Dias Pereira L, Lucchi E, Malaguti R. Design and Construction of a New Metering Hot Box for the In Situ Hygrothermal Measurement in Dynamic Conditions of Historic Masonries. Energies. 2020; 13(11):2950. https://doi.org/10.3390/en13112950

Chicago/Turabian StyleAndreotti, Mirco, Marta Calzolari, Pietromaria Davoli, Luisa Dias Pereira, Elena Lucchi, and Roberto Malaguti. 2020. "Design and Construction of a New Metering Hot Box for the In Situ Hygrothermal Measurement in Dynamic Conditions of Historic Masonries" Energies 13, no. 11: 2950. https://doi.org/10.3390/en13112950

APA StyleAndreotti, M., Calzolari, M., Davoli, P., Dias Pereira, L., Lucchi, E., & Malaguti, R. (2020). Design and Construction of a New Metering Hot Box for the In Situ Hygrothermal Measurement in Dynamic Conditions of Historic Masonries. Energies, 13(11), 2950. https://doi.org/10.3390/en13112950