Experimental Study of the Corona Performance of Aged Sand-Cast Substation Connectors

Abstract

1. Introduction

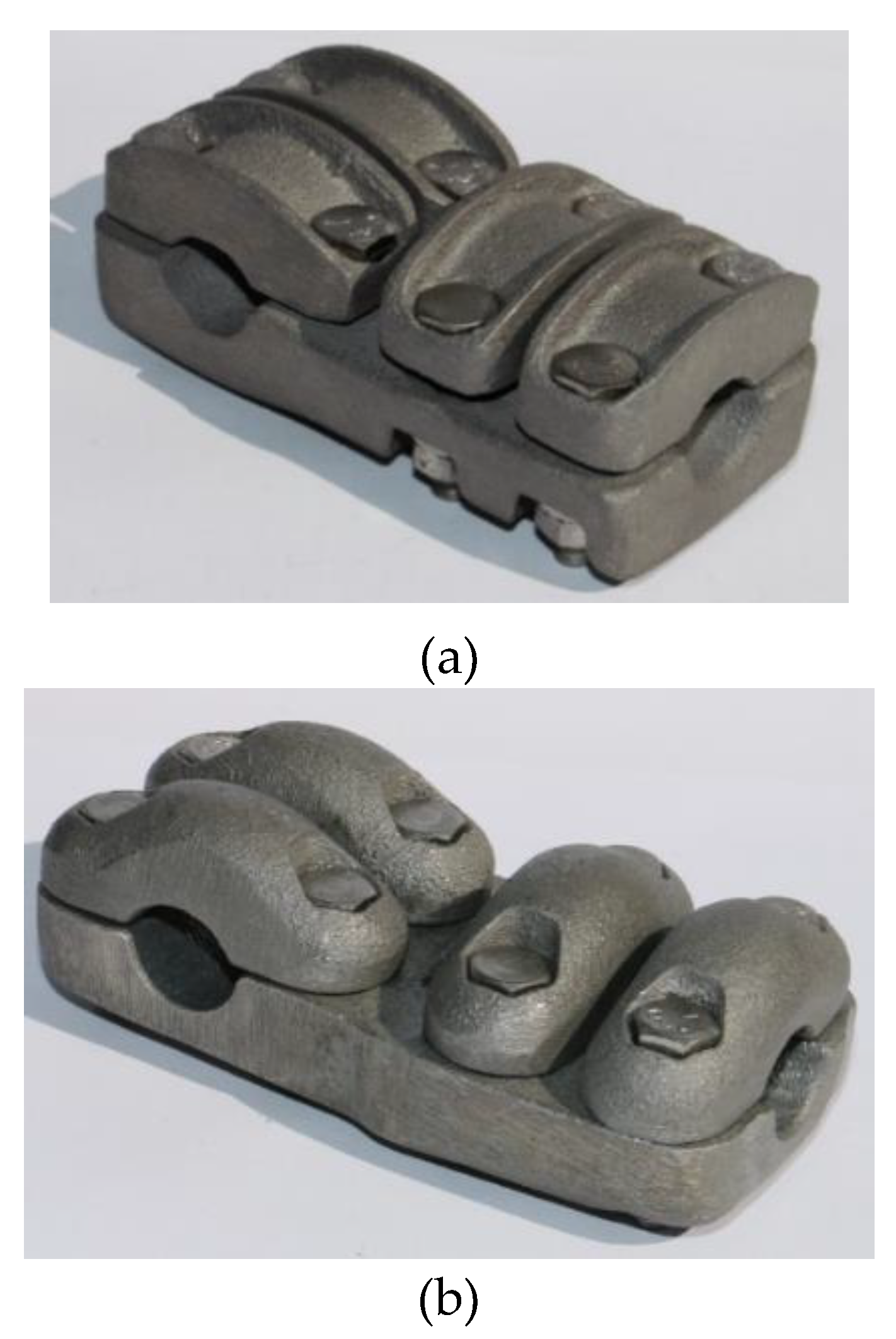

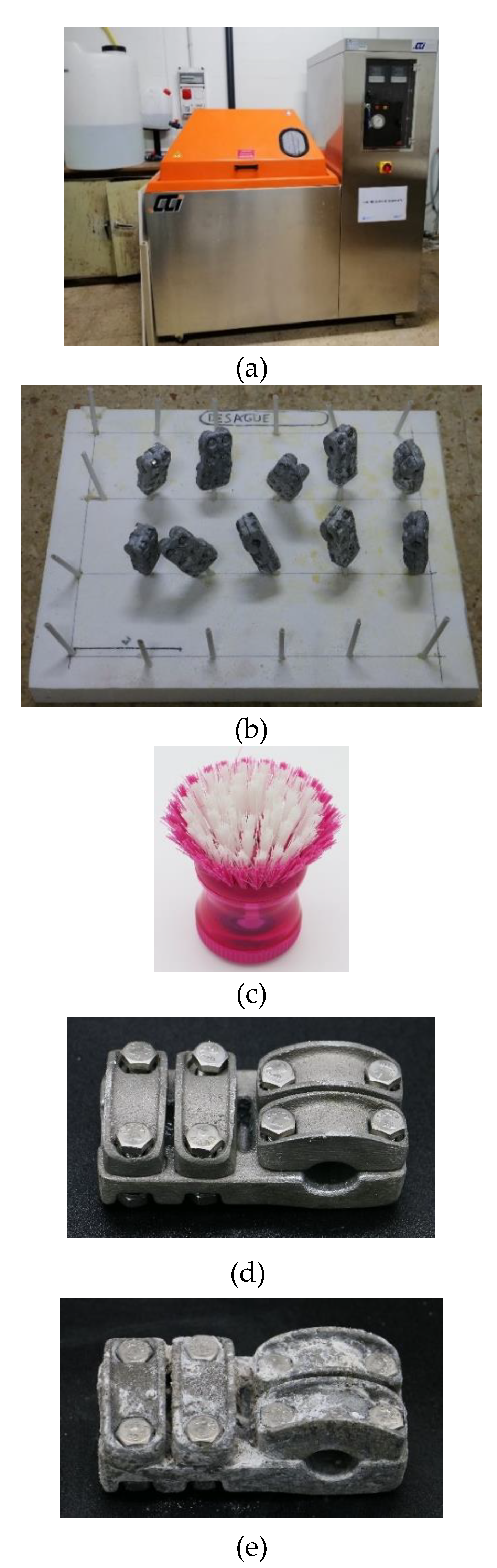

2. The Analyzed Substation Connectors and the Artificial Ageing Tests

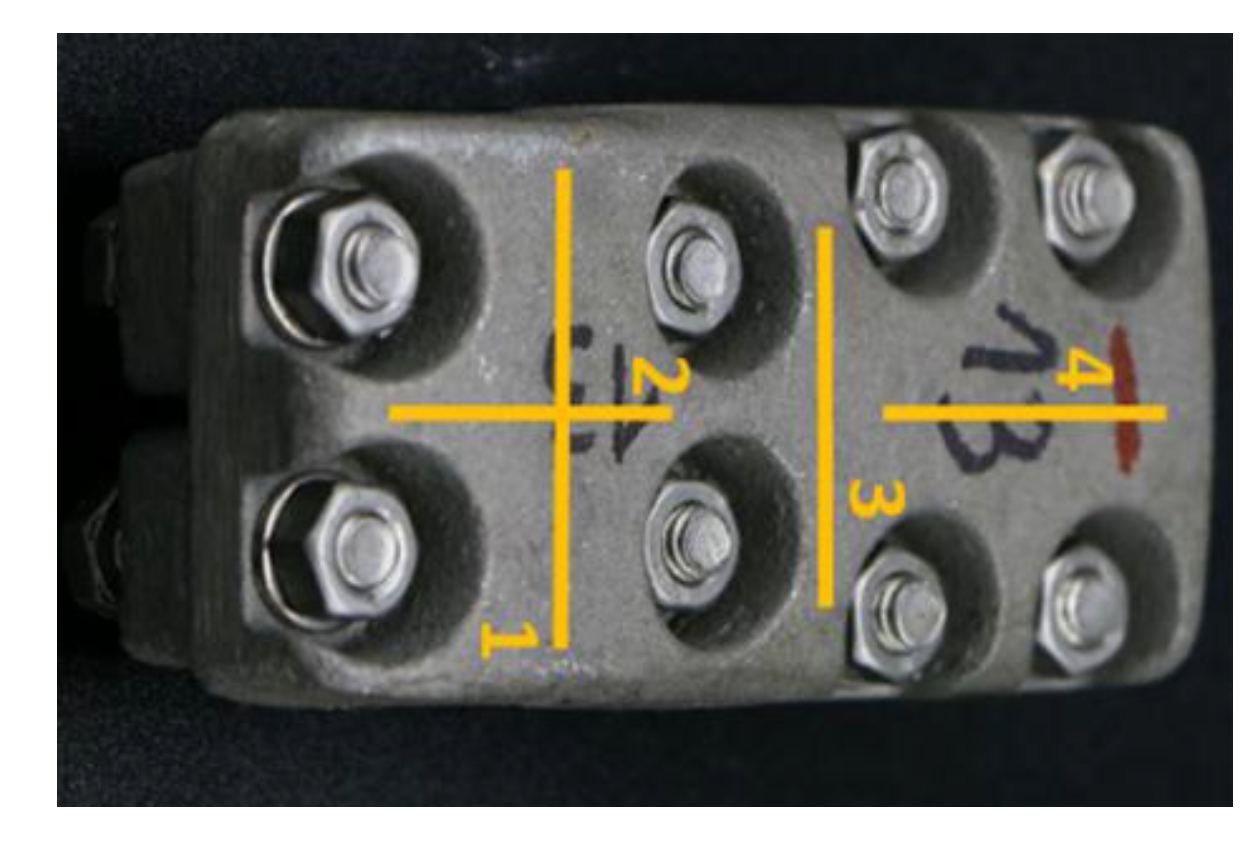

3. The Surface Roughness Measurements

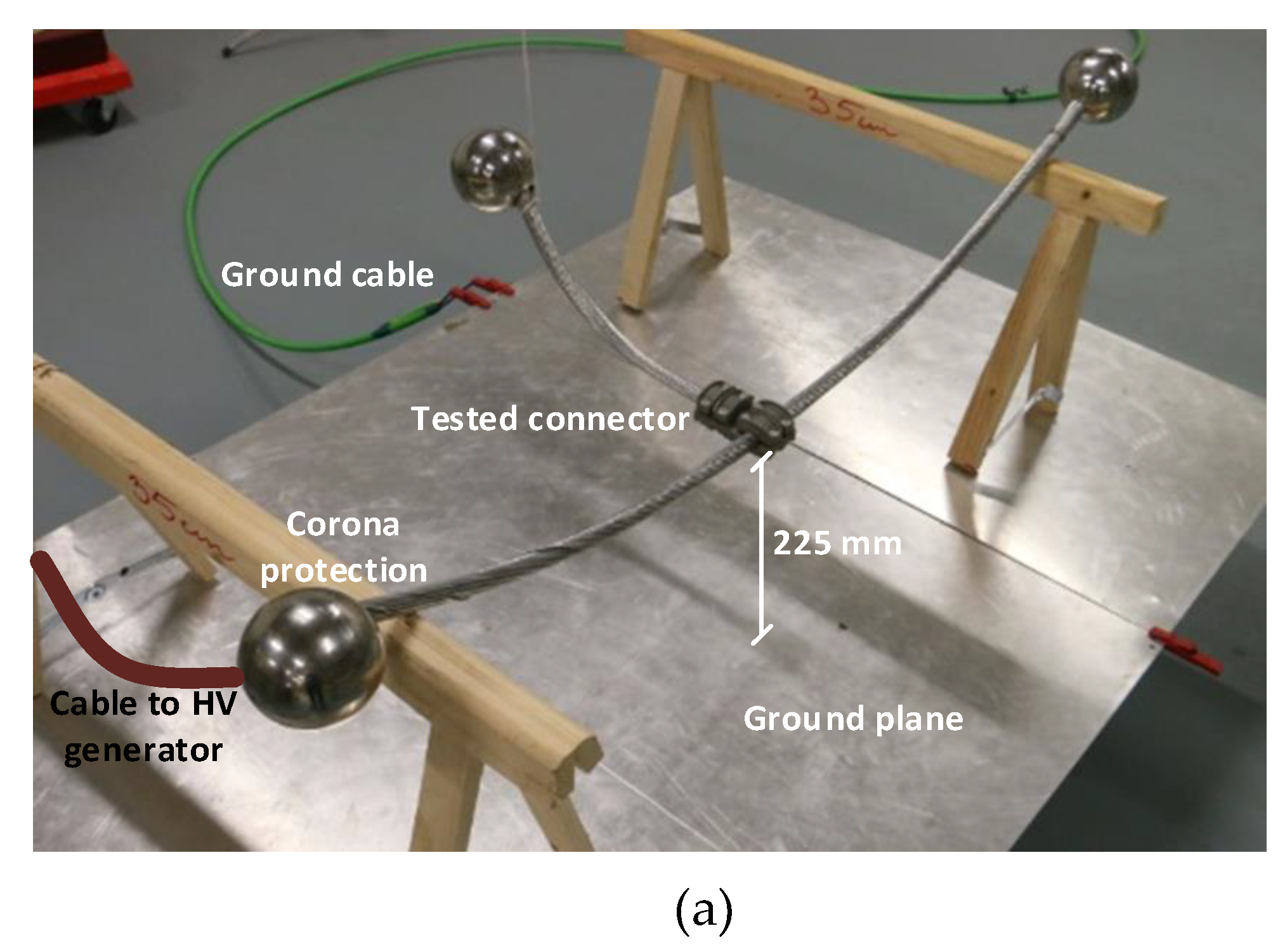

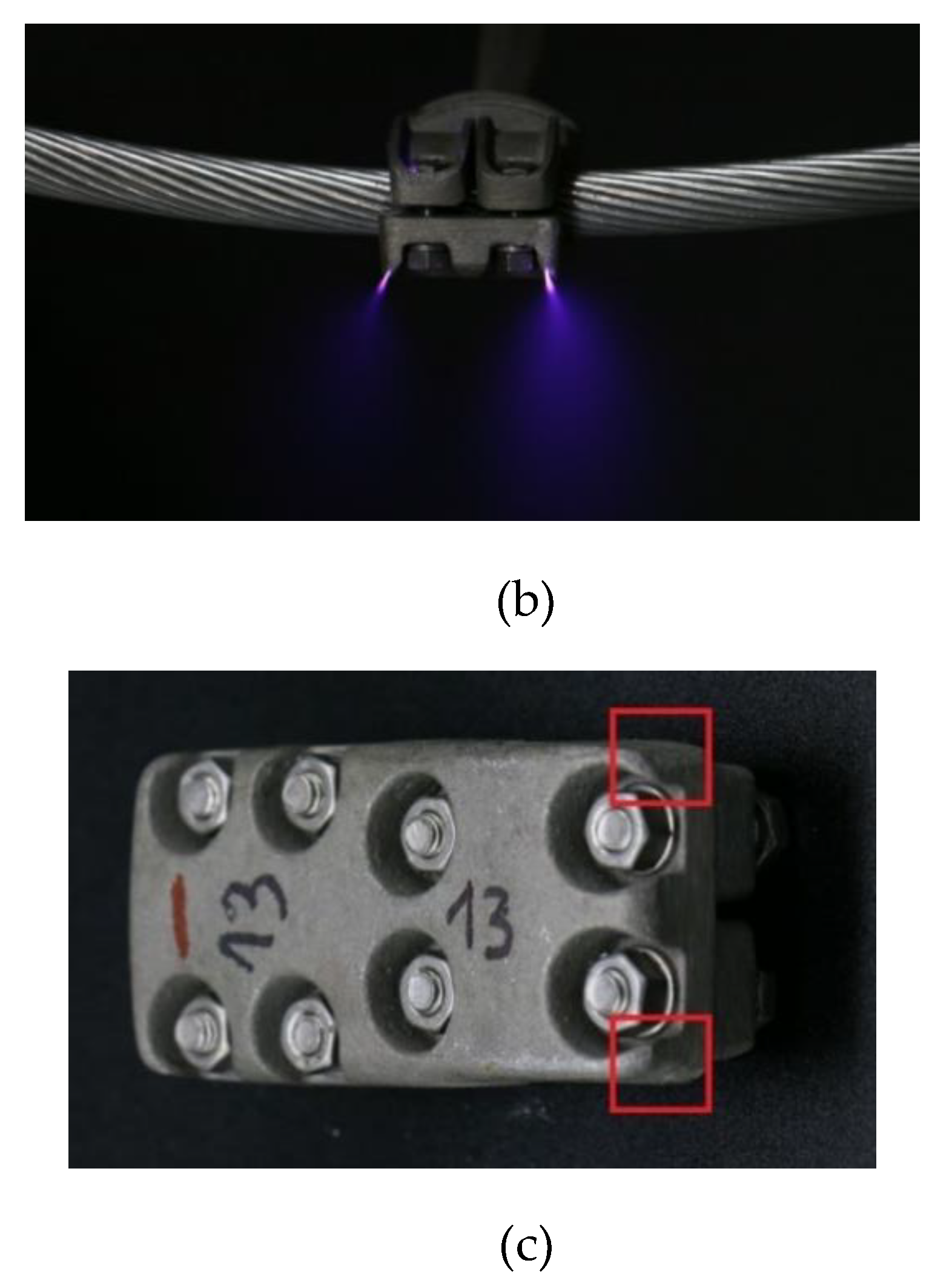

4. The Corona Tests in the High-Voltage Laboratory

5. Experimental Results

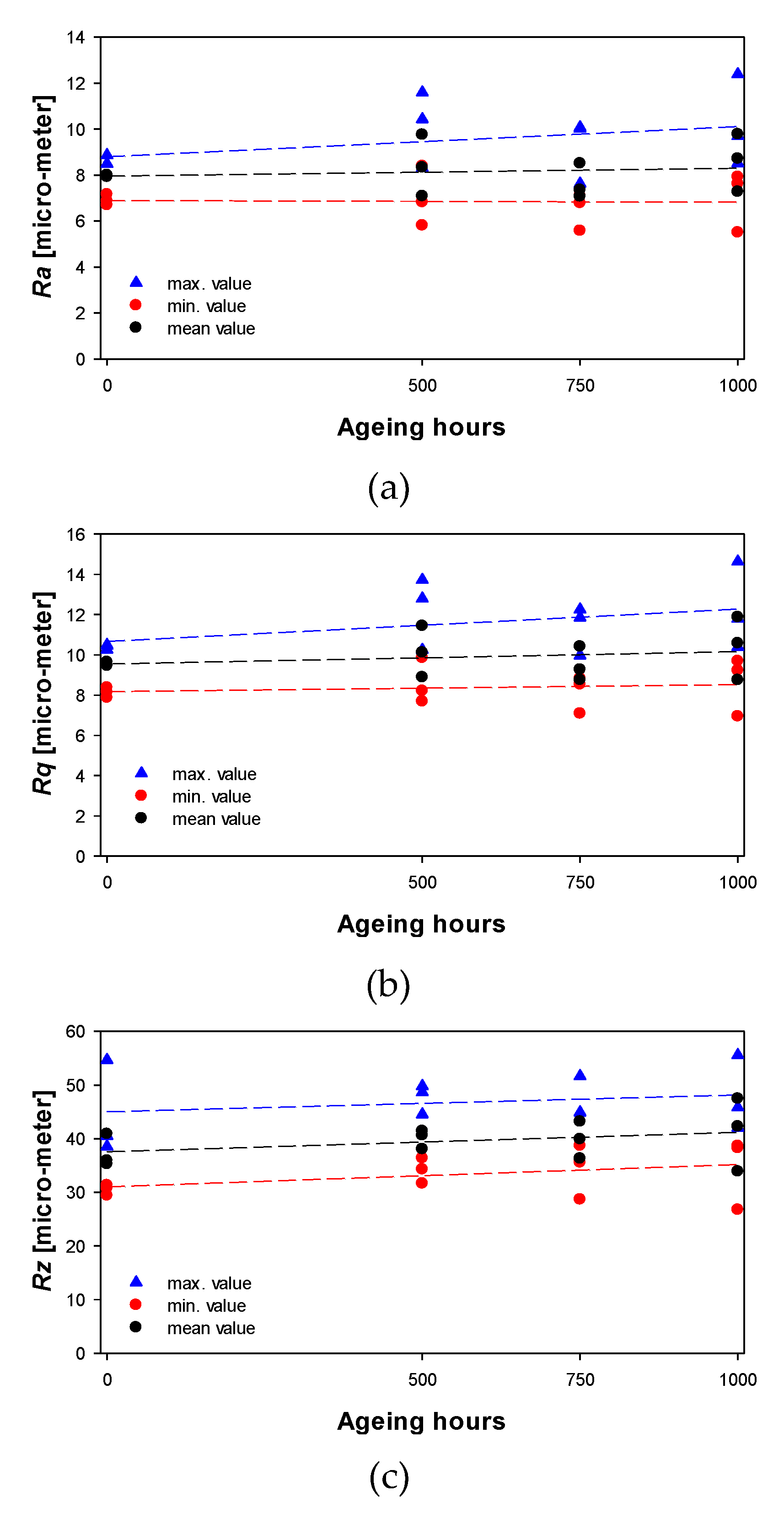

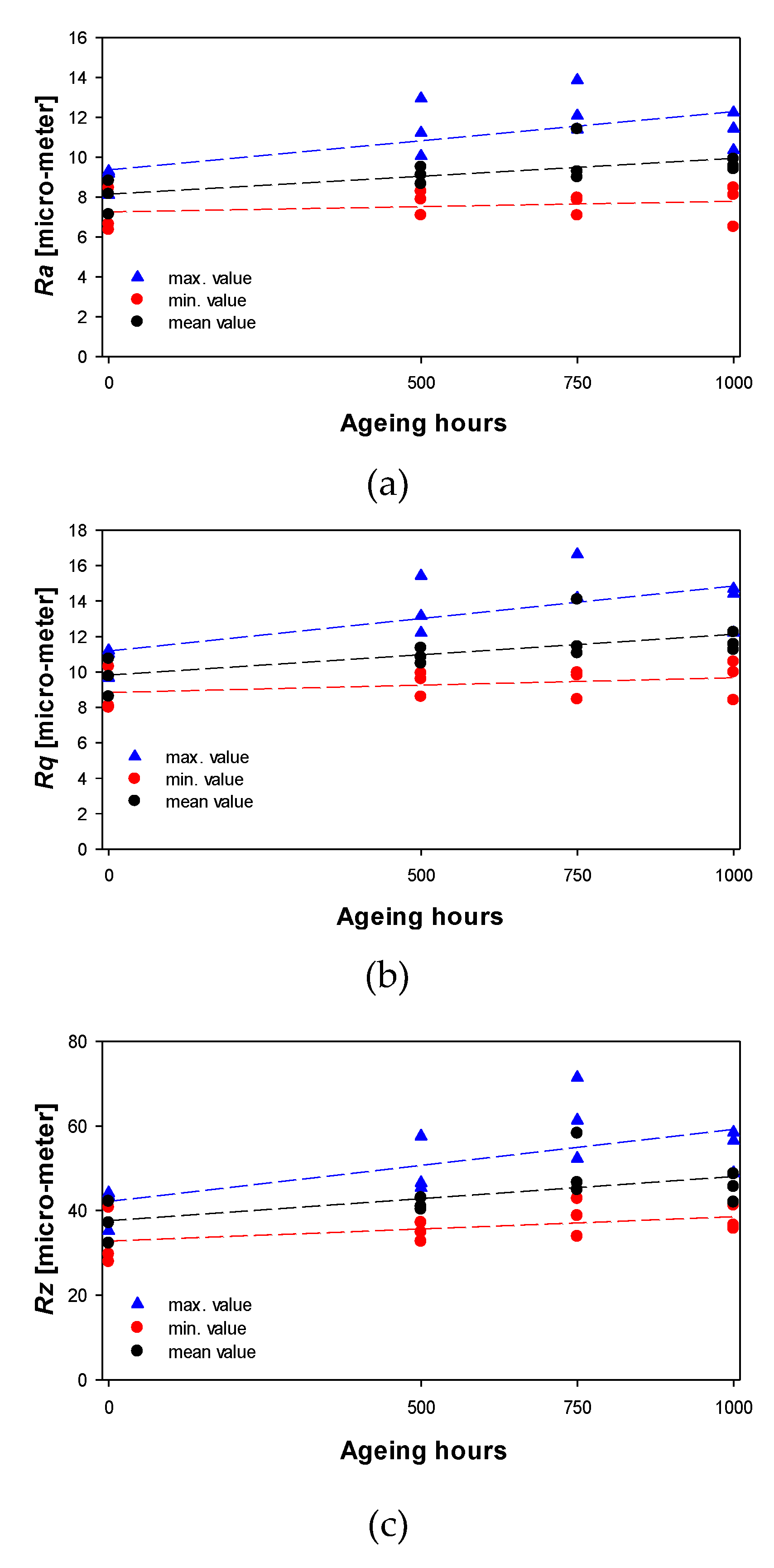

5.1. Surface Roughness Results

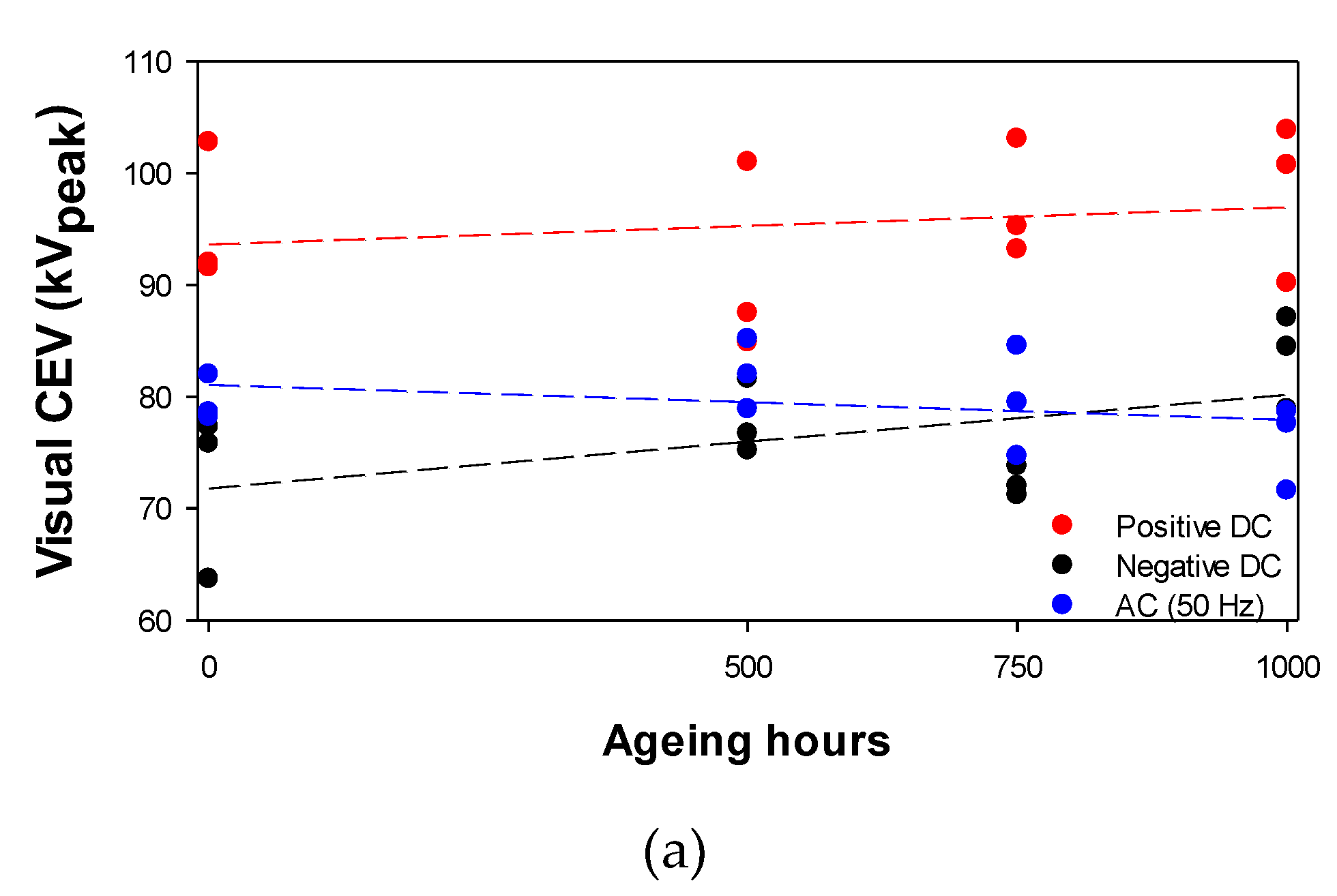

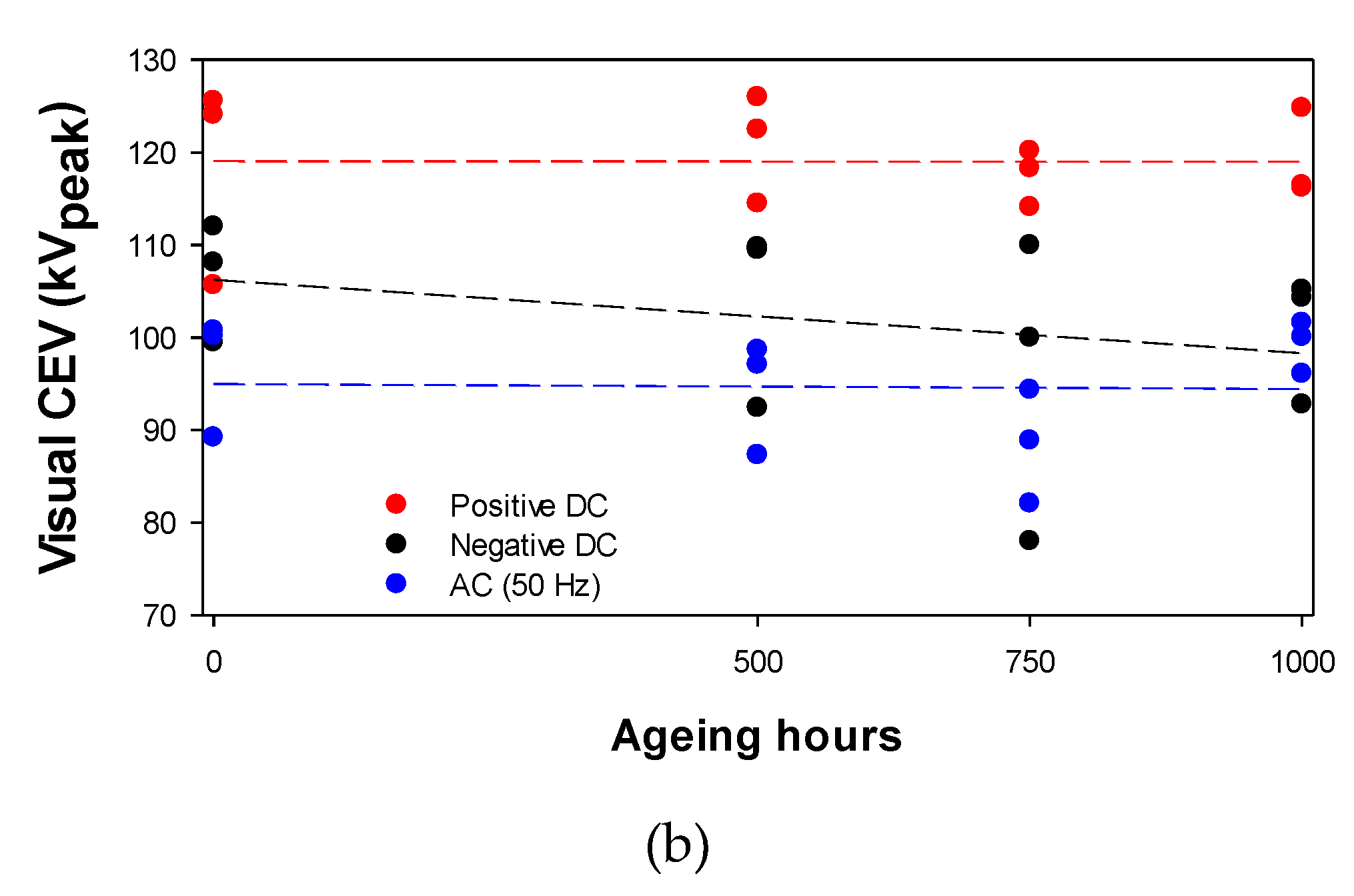

5.2. Visual CEV Tests

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, D.; Du, L.; Yao, C. Statistical Study on Space Charge effects and Stage Characteristics of Needle-Plate Corona Discharge under DC Voltage. Energies 2019, 12, 2732. [Google Scholar] [CrossRef]

- Bian, X.; Yu, D.; Chen, L.; MacAlpine, J.M.K.; Wang, L.; Guan, Z.; Chen, F. Influence of aged conductor surface conditions on AC corona discharge with a corona cage. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 809–818. [Google Scholar] [CrossRef]

- Hernández-Guiteras, J.; Riba, J.-R.; Romeral, L. Redesign process of a 765 kVRMS AC substation connector by means of 3D-FEM simulations. Simul. Model. Pract. Theory 2014, 42, 1–11. [Google Scholar] [CrossRef]

- Hernández-Guiteras, J.; Riba, J.-R.; Casals-Torrens, P. Determination of the corona inception voltage in an extra high voltage substation connector. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 82–88. [Google Scholar] [CrossRef]

- Suda, T.; Hirayama, Y.; Sunaga, Y. Aging effects of conductor surface conditions on dc corona characteristics. IEEE Trans. Power Deliv. 1988, 3, 1903–1912. [Google Scholar] [CrossRef]

- Chudnovsky, B. Electrical Power Transmission and Distribution; CRC Press: London, UK, 2012. [Google Scholar]

- Rodrigo-Mor, A.; Muñoz, F.; Castro-Heredia, L. A Novel Antenna for Partial Discharge Measurements in GIS Based on Magnetic Field Detection. Sensors 2019, 19, 858. [Google Scholar] [CrossRef]

- Riba, J.-R.; Gómez-Pau, Á.; Moreno-Eguilaz, M. Experimental Study of Visual Corona under Aeronautic Pressure Conditions Using Low-Cost Imaging Sensors. Sensors 2020, 20, 411. [Google Scholar] [CrossRef]

- Electric Power Research Institute Transmission Line Reference Book 345 kV and Above, 2014 ed.; Electric Power Research Institute (EPRI): Palo Alto, CA, USA, 2014.

- Riba, J.-R.; Larzelere, W.; Rickmann, J.; Riba, J.-R.; Larzelere, W.; Rickmann, J. Voltage Correction Factors for Air-Insulated Transmission Lines Operating in High-Altitude Regions to Limit Corona Activity: A Review. Energies 2018, 11, 1908. [Google Scholar] [CrossRef]

- Carsimamovic, A.; Mujezinovic, A.; Carsimamovic, S.; Bajramovic, Z.; Kosarac, M. Electric Field Calculation on Surface of High-Voltage Transmission Line Conductors. In Lecture Notes in Networks and Systems; Springer: Berlin, Germany, 2018; Volume 28, pp. 941–951. [Google Scholar]

- Qin, H.; Lichun, S.; Xingliang, J.; Rong, X.; Qianfei, Y.; Shikun, Z. Calculation of conductors’ surface electric field of ±800kV UHVDC transmission lines with optimized charge simulation method. In Proceedings of the 2008 International Conference on High Voltage Engineering and Application, ICHVE 2008, Chongqing, China, 9–12 November 2008; pp. 362–365. [Google Scholar]

- Liu, Y.-P.; Zhu, L.; Lu, F.; Huang, Z. Corona Onset Characteristics of the 750-kV Bundle Conductor in Sand and Dust Weather in High-Altitude Area. IEEE Trans. Power Deliv. 2014, 29, 615–623. [Google Scholar] [CrossRef]

- Bian, X.; Chen, L.; Yu, D.; Wang, L.; Guan, Z. Impact of surface roughness on corona discharge for 30-year operating conductors in 500-kV ac power transmission line. IEEE Trans. Power Deliv. 2012, 27, 1693–1695. [Google Scholar] [CrossRef]

- Laforest, J.J.; Whepley, E.A. Radio Noise Aging Characteristics of Small Aluminum Conductors. Trans. Am. Inst. Electr. Eng. Part III Power Appar. Syst. 1962, 81, 424–427. [Google Scholar] [CrossRef]

- Booker, J.R. Natural aging of non-energized aluminum conductors. IEEE Trans. Power Deliv. 1986, 1, 269–274. [Google Scholar] [CrossRef]

- Ma, M.; Zhao, Y.; Guan, Z.; Wang, L. The influence of contaminations on HVDC conductor corona characteristics. In Proceedings of the Annual Report—Conference on Electrical Insulation and Dielectric Phenomena, CEIDP, Vancouver, BC, Canada, 14–17 October 2007; pp. 537–541. [Google Scholar]

- Yi, Y.; Wang, Y.; Wang, L. Conductor Surface Conditions Effects on Audible Noise Spectrum Characteristics of Positive Corona Discharge. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1872–1878. [Google Scholar] [CrossRef]

- McAllister, I.W. On the Concept of Electrode Surface Roughness with Reference to Discharge Phenomena in Strongly Electronegative Gases. IEEE Trans. Electr. Insul. 1986, EI-21, 659–662. [Google Scholar] [CrossRef][Green Version]

- Abomailek, C.; Riba, J.-R.; Casals-Torrens, P. Feasibility Analysis of Reduced-Scale Visual Corona Tests in High Voltage Laboratories. IET Gener. Transm. Distrib. 2018, 13, 2543–2549. [Google Scholar] [CrossRef]

- Capelli, F.; Riba, J.-R.; Pérez, J. Three-Dimensional Finite-Element Analysis of the Short-Time and Peak Withstand Current Tests in Substation Connectors. Energies 2016, 9, 418. [Google Scholar] [CrossRef]

- Abomailek, C.; Capelli, F.; Riba, J.-R.; Casals-Torrens, P. Transient thermal modelling of substation connectors by means of dimensionality reduction. Appl. Therm. Eng. 2017, 111, 562–572. [Google Scholar] [CrossRef]

- Ishfaq, K.; Ali, M.A.; Ahmad, N.; Zahoor, S.; Al-Ahmari, A.M.; Hafeez, F. Modelling the Mechanical Attributes (Roughness, Strength, and Hardness) of Al-alloy A356 during Sand Casting. Materials 2020, 13, 598. [Google Scholar] [CrossRef]

- Ran, G.; Zhou, J.E.; Wang, Q.G. Precipitates and tensile fracture mechanism in a sand cast A356 aluminum alloy. J. Mater. Process. Technol. 2008, 207, 46–52. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO—ISO 9227:2017—Corrosion tests in artificial atmospheres—Salt Spray Tests; International Organization for Standardization: Geneva, Switzerland, 2017; pp. 1–18. [Google Scholar]

- ASTM. B117—19 Standard Practice for Operating Salt Spray (Fog) Apparatus; ASTM: West Conshohocken, PA, USA, 2019; pp. 1–11. [Google Scholar]

- Capelli, F.; Riba, J.; Ruperez, E.; Sanllehi, J. A Genetic-Algorithm-Optimized Fractal Model to Predict the Constriction Resistance From Surface Roughness Measurements. IEEE Trans. Instrum. Meas. 2017, 66, 2437–2447. [Google Scholar] [CrossRef]

- ISO 4287:1997. Geometrical Product Specifications (GPS)—Surface texture: Profile method—Terms, Definitions and Surface Texture Parameters; ISO: Geneva, Switzerland, 1997; Volume 25. [Google Scholar]

- Riba, J.-R.; Abomailek, C.; Casals-Torrens, P.; Capelli, F. Simplification and cost reduction of visual corona tests. IET Gener. Transm. Distrib. 2018, 12, 834–841. [Google Scholar] [CrossRef]

- IEEE Std 1829-2017—IEEE Guide for Conducting Corona Tests on Hardware for Overhead Transmission Lines and Substations; IEEE: Piscataway, NJ, USA, 2017.

- IEEE Standard for High-Voltage Testing Techniques; IEEE Std 4-2013 (Revision IEEE Std 4-1995); IEEE: Piscataway, NJ, USA, 10 May 2013; pp. 1–213.

- Riba, J.-R.; Gómez-Pau, Á.; Moreno-Eguilaz, M.; Bogarra, S. Arc Tracking Control in Insulation Systems for Aeronautic Applications: Challenges, Opportunities, and Research Needs. Sensors 2020, 20, 1654. [Google Scholar] [CrossRef] [PubMed]

- ANSI/NEMA CC1. In Proceedings of the Electric Power Connection for Substation, Wuhan, China, 26–29 May 2009.

| Ageing Level | Number of Specimens | Ageing Time | Sample Number |

|---|---|---|---|

| A0 (new) | 3 | 0 hours | 1, 2, 3 |

| A500 | 3 | 500 hours | 4, 5, 6 |

| A750 | 3 | 750 hours | 7, 8, 9 |

| A1000 | 3 | 1000 hours | 10, 11, 12 |

| Ra [μm] | Rq [μm] | Rz [μm] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ageing Level | Sample Number | Max. Value | Min. Value | Mean Value | Max. Value | Min. Value | Mean Value | Max. Value | Min. Value | Mean Value |

| A0 (new) | 1 | 8.868 | 6.880 | 7.926 | 10.495 | 8.152 | 9.468 | 38.557 | 30.761 | 35.284 |

| 2 | 8.498 | 7.168 | 7.965 | 10.264 | 8.380 | 9.481 | 40.517 | 31.354 | 35.939 | |

| 3 | 8.487 | 6.697 | 8.008 | 10.468 | 7.877 | 9.653 | 54.661 | 29.449 | 40.900 | |

| A500 | 4 | 8.302 | 5.812 | 7.091 | 10.247 | 7.693 | 8.894 | 44.538 | 31.664 | 38.078 |

| 5 | 11.595 | 8.401 | 9.763 | 13.734 | 9.858 | 11.445 | 49.805 | 36.400 | 41.441 | |

| 6 | 10.430 | 6.829 | 8.337 | 12.800 | 8.220 | 10.125 | 48.658 | 34.314 | 40.643 | |

| A750 | 7 | 10.019 | 5.579 | 7.077 | 11.859 | 7.089 | 8.764 | 44.918 | 28.706 | 36.332 |

| 8 | 7.626 | 6.791 | 7.365 | 9.971 | 8.542 | 9.278 | 44.868 | 35.578 | 39.926 | |

| 9 | 10.075 | 7.100 | 8.516 | 12.256 | 8.834 | 10.424 | 51.651 | 38.713 | 43.217 | |

| 10 | 8.522 | 5.505 | 7.277 | 10.398 | 6.955 | 8.755 | 42.073 | 26.788 | 33.930 | |

| A1000 | 11 | 12.387 | 7.926 | 9.781 | 14.636 | 9.700 | 11.884 | 55.567 | 38.279 | 47.490 |

| 12 | 9.700 | 7.630 | 8.721 | 11.799 | 9.232 | 10.588 | 45.845 | 38.673 | 42.308 | |

| Ra [μm] | Rq [μm] | Rz [μm] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ageing Level | Sample Number | Max. Value | Min. Value | Mean Value | Max. Value | Min. Value | Mean Value | Max. Value | Min. Value | Mean Value |

| A0 (new) | 1 | 9.187 | 6.651 | 8.163 | 11.033 | 7.989 | 9.765 | 43.456 | 29.694 | 37.150 |

| 2 | 8.118 | 6.356 | 7.141 | 9.670 | 8.099 | 8.617 | 35.274 | 27.928 | 32.303 | |

| 3 | 9.302 | 8.471 | 8.824 | 11.220 | 10.307 | 10.750 | 44.177 | 40.779 | 42.207 | |

| A500 | 4 | 10.065 | 7.096 | 8.668 | 12.210 | 8.608 | 10.483 | 45.418 | 32.706 | 40.318 |

| 5 | 12.952 | 7.896 | 9.522 | 15.423 | 9.599 | 11.363 | 57.593 | 34.919 | 43.052 | |

| 6 | 11.230 | 8.297 | 9.114 | 13.165 | 9.939 | 10.838 | 46.574 | 37.213 | 40.961 | |

| A750 | 7 | 11.405 | 7.089 | 9.011 | 14.172 | 8.460 | 11.062 | 61.343 | 33.879 | 44.940 |

| 8 | 12.089 | 7.980 | 9.297 | 14.182 | 9.815 | 11.443 | 52.305 | 38.799 | 46.622 | |

| 9 | 13.869 | 7.879 | 11.423 | 16.637 | 9.975 | 14.094 | 71.402 | 42.879 | 58.276 | |

| 10 | 12.253 | 6.510 | 9.557 | 14.701 | 8.415 | 11.572 | 56.542 | 36.574 | 45.675 | |

| A1000 | 11 | 10.355 | 8.116 | 9.417 | 12.222 | 9.983 | 11.251 | 48.909 | 35.821 | 42.006 |

| 12 | 11.447 | 8.484 | 9.923 | 14.417 | 10.586 | 12.250 | 58.475 | 41.324 | 48.694 | |

| Corrected CEV (kVpeak) | |||||||

|---|---|---|---|---|---|---|---|

| Ageing Level | Sample Number | Positive DC | Negative DC | AC (50 Hz) | |||

| A0 (new) | 1 | 102.8 | 63.7 | 78.2 | |||

| 2 | 91.6 | 7.7% | 75.8 | 11.9% | 82.0 | 3.0% | |

| 3 | 92.0 | 77.3 | 78.6 | ||||

| A500 | 4 | 87.5 | 76.7 | 82.0 | |||

| 5 | 84.9 | 10.8% | 75.2 | 4.8% | 78.9 | 3.9% | |

| 6 | 101.0 | 81.6 | 85.2 | ||||

| A750 | 7 | 95.3 | 73.8 | 84.6 | |||

| 8 | 93.2 | 6.1% | 72.0 | 2.0% | 74.7 | 6.3% | |

| 9 | 103.1 | 71.2 | 79.5 | ||||

| 10 | 103.87 | 84.5 | 78.7 | ||||

| A1000 | 11 | 100.76 | 8.2% | 87.1 | 5.5% | 77.6 | 5.7% |

| 12 | 90.2 | 78.9 | 71.6 | ||||

| Percentages: maximum CEV deviation among the 3 sample replicas with respect their average value | |||||||

| Corrected CEV (kVpeak) | |||||||

|---|---|---|---|---|---|---|---|

| Ageing Level | Sample Number | Positive DC | Negative DC | AC (50 Hz) | |||

| A0 (new) | 1 | 124.1 | 108.1 | 100.2 | |||

| 2 | 125.6 | 10.8% | 112.0 | 6.6% | 100.8 | 7.8% | |

| 3 | 105.7 | 99.5 | 89.2 | ||||

| A500 | 4 | 114.5 | 92.4 | 87.3 | |||

| 5 | 126.0 | 5.4% | 109.8 | 11.1% | 98.7 | 7.5% | |

| 6 | 122.5 | 109.5 | 97.1 | ||||

| A750 | 7 | 120.2 | 100.0 | 88.9 | |||

| 8 | 118.3 | 2.9% | 110.0 | 14.6% | 94.4 | 7.2% | |

| 9 | 114.1 | 78.0 | 82.1 | ||||

| 10 | 116.5 | 104.3 | 101.6 | ||||

| A1000 | 11 | 116.2 | 4.7% | 92.8 | 7.9% | 96.1 | 3.2% |

| 12 | 124.79 | 105.2 | 100.1 | ||||

| Percentages: maximum CEV deviation among the 3 sample replicas with respect their average value | |||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riba, J.-R.; Bogarra, S.; Gómez-Pau, Á.; Moreno-Eguilaz, M. Experimental Study of the Corona Performance of Aged Sand-Cast Substation Connectors. Energies 2020, 13, 2785. https://doi.org/10.3390/en13112785

Riba J-R, Bogarra S, Gómez-Pau Á, Moreno-Eguilaz M. Experimental Study of the Corona Performance of Aged Sand-Cast Substation Connectors. Energies. 2020; 13(11):2785. https://doi.org/10.3390/en13112785

Chicago/Turabian StyleRiba, Jordi-Roger, Santiago Bogarra, Álvaro Gómez-Pau, and Manuel Moreno-Eguilaz. 2020. "Experimental Study of the Corona Performance of Aged Sand-Cast Substation Connectors" Energies 13, no. 11: 2785. https://doi.org/10.3390/en13112785

APA StyleRiba, J.-R., Bogarra, S., Gómez-Pau, Á., & Moreno-Eguilaz, M. (2020). Experimental Study of the Corona Performance of Aged Sand-Cast Substation Connectors. Energies, 13(11), 2785. https://doi.org/10.3390/en13112785