Can Multiple Uses of Biomass Limit the Feedstock Availability for Future Biogas Production? An Overview of Biogas Feedstocks and Their Alternative Uses

Abstract

1. Introduction

2. Materials and Methods

2.1. Machine Learning Approach: The Co-Occurrence Analysis of Terms

- i.

- A co-occurrence matrix: We use one large grid matrix to demonstrate which biogas feedstock is mentioned along with certain applications. Here we define a co-occurrence as one pair of a specific feedstock and application which are co-mentioned at least once in the literature (e.g., maize stover and bioethanol, pig manure and compost). If there is at least one co-occurrence in the included literature, the connection between the biomass and the application is shown in the matrix. The order of the rows and columns (feedstocks and applications) in the matrix is based on the similarity of the terms in the literature collection. It presents similar types of feedstocks suitable for an application near each other and similar types of applications requiring a feedstock are also near each other. This ordering is done in two steps: first there is an automated ordering based on hierarchical clustering of the row and column values in the original matrix output by the algorithm [22]; second, we manually check and adjust the ordering.

- ii.

- A list of literature: This indicates the exact literature where each co-occurrence happened.

2.2. Collecting Literature on Biomass Applications

- Search query: queryString = “title-abs-key (technology OR process OR conversion OR treatment OR use OR production OR application) AND title-abs-key (product OR waste OR by-product OR byproduct OR feedstock OR additive OR catalyst) AND title-abs-key (organic OR bio OR biomass)”.

2.3. Identifying Biogas Feedstock and Biomass Application Terms

2.3.1. Identifying Biogas Feedstocks

- A generic stream and a specific stream: There are some streams which are general but seem to overlap with other streams such as dairy industry waste which may conceptually include cheese waste. However, in the context of their applications they are different streams. So, if the two main lists mentioned both, we will keep both the generic and the specific terms.

- Streams with names which may be interchangeable in literature but have very different physical properties according to the two main lists, such as beer barm and brewer’s grains. We decided to keep them as two separate terms in our list.

- Streams with names which may interchangeable in literature and have similar physical properties according to the two main lists (e.g: maize straw and maize stover) or just different in the water content (e.g., cattle slurry and cattle manure). We decided to combine them into one term.

- Streams which are rarely found in the scientific literature on biomass applications such as “barley feeding meal”. We excluded these from our lists.

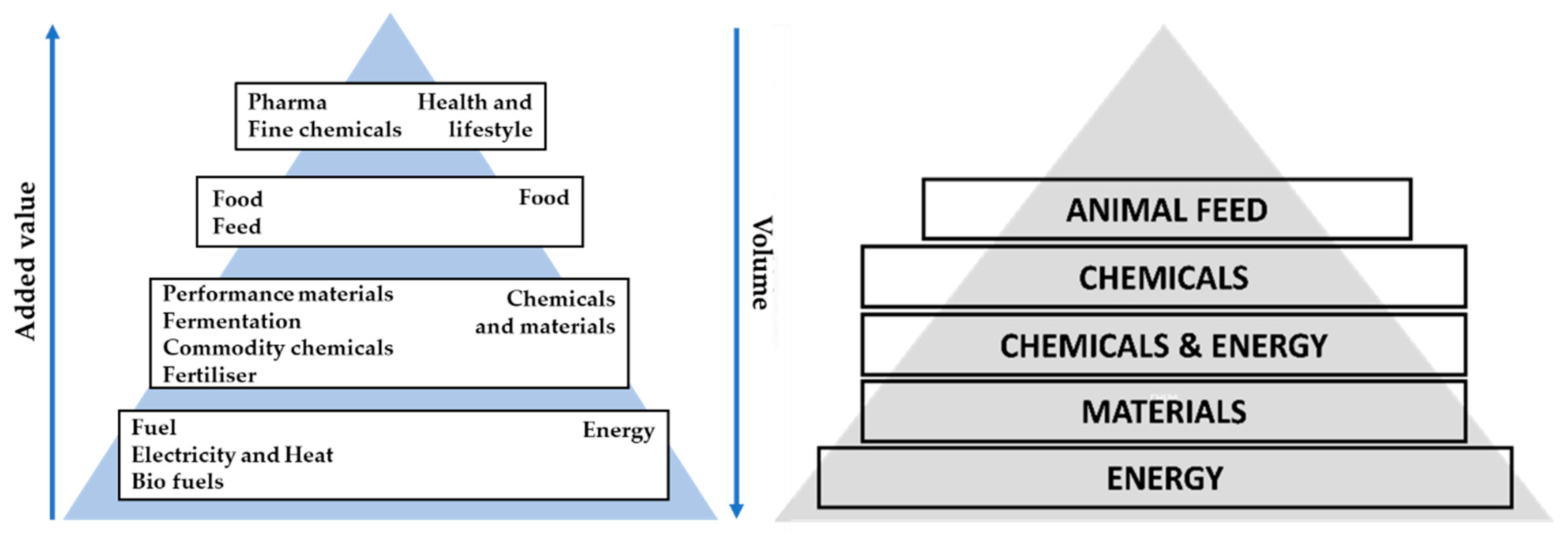

2.3.2. Identifying Biomass Applications

- Animal feed: The feedstocks that can be fed to animals raw or after processing. Although the processing consists of multiple steps with intermediate components, we only cared whether those components led to animal feed or not. As a result, we grouped terms found in literature such as forage, fodder, and animal feed supplements into a single term: animal feed.

- Chemicals: We used the original terms used in the approach from Davis et al. [22] supplemented by terms from other literature.

- Materials: We used the existing material terms mentioned by Davis et al. and added biobased materials mentioned in other bioeconomy literatures such as different types of bioplastics.

- Energy: Unlike chemical and materials which have multiple conversion processes, bioenergy has quite few and straightforward conversion processes. In literature, energy applications can be described by either end use products or the conversion processes, for example, torrefied biomass and torrefaction. We did an inventory of different bioenergy processes to make sure that we did not miss any bioenergy applications. Then the terms for energy applications were defined by their end products.

- Chemicals and Energy: Like energy, the terms included in this group have few conversion processes and can be described by either end use products or conversion processes. We defined the terms for chemical and energy applications using the end products.

2.3.3. Variants of the Terms

2.4. Co-Occurrence Validation

- i.

- The most frequent 20 co-occurrences which happened in the literature collection;

- ii.

- Random 20 co-occurrences which happened once in the literature collection: from the list of co-occurrences that happened once which was ordered alphabetically based on the feedstock terms, we first randomly chose the first co-occurrence to check. Then we checked the co-occurrence 20 below the previous one. This procedure was followed to collect 20 co-occurrences. However, if one of the collected co-occurrences was too similar to an earlier collected co-occurrence, we replaced it with the co-occurrence below it from the list;

- iii.

- Random 20 co-occurrences which are unexpected to the knowledge of the authors. For example, we checked co-occurrences where feedstocks are considered as waste and the applications belong to higher level of the BVP. The list of co-occurrences was ordered alphabetically based on the feedstock terms;

- iv.

- All co-occurrences of the feedstocks which have the lowest number of co-occurring applications.

3. Results

3.1. Results of Literature Collection and Identifying Biogas Feedstocks and Biomass Applications

3.2. Appeared Terms in the Co-Occurrences, Co-Occurrence Validation and Unexpected Connections

3.3. Co-Occurrence Matrix

3.4. Top Biogas Feedstocks Having Highest and Lowest Number of Co-Occurring Applications

4. Discussion

4.1. Limitations and Recommendations

4.2. Robustness of the Research

4.3. Implications for the Expectation of Future Biogas Production in Europe

4.4. Potential Use of the Overview in Research on Biogas Feedstock Competition in a Biobased Economy

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Deublein, D.; Seteinhauser, A. Biogas from Waste and Renewable Resources; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2008; ISBN 9783527318414. [Google Scholar]

- European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council on the Promotion of the Use of Energy from Renewable Sources; European Parliament: Brussels, Belgium, 2018; Volume 2018. [Google Scholar]

- Kampman, B.; Leguijt, C.; Scholten, T.; Tallat-Kelpsaite, J.; Brückman, R.; Maroulis, G.; Lesschen, J.P.; Meesters, K.; Sikirica, N.; Elbersen, B. Optimal use of Biogas from Waste Streams An. Assessment of the Potential of Biogas from Digestion in the EU Beyond 2020 Digestion in the EU Beyond 2020 Optimal use of Biogas from Waste Streams; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- EU. Com in-depth analysis in support of the commission communication com (2018). In 773 A Clean Planet for all A European Long-Term Strategic Vision for A Prosperous, Modern, Competitive and Table of Contents; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Meyer, A.K.P.; Ehimen, E.A.; Holm-Nielsen, J.B. Future European biogas: Animal manure, straw and grass potentials for a sustainable European biogas production. Biomass Bioenergy 2018, 111, 154–164. [Google Scholar] [CrossRef]

- Pazera, A.; Slezak, R.; Krzystek, L.; Ledakowicz, S.; Bochmann, G.; Gabauer, W.; Helm, S.; Reitmeier, S.; Marley, L.; Gorga, F.; et al. Biogas in Europe: Food and Beverage (FAB) Waste Potential for Biogas Production. Energy Fuels 2015, 29, 4011–4021. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Muscat, A.; de Olde, E.M.; de Boer, I.J.M.; Ripoll-Bosch, R. The battle for biomass: A systematic review of food-feed-fuel competition. Glob. Food Sec. 2019, 100330. [Google Scholar] [CrossRef]

- Ben Fradj, N.; Jayet, P.A.; Aghajanzadeh-Darzi, P. Competition between food, feed, and (bio)fuel: A supply-side model based assessment at the European scale. Land Use Policy 2016, 52, 195–205. [Google Scholar] [CrossRef]

- Erisman, J.W.; van Grinsven, H.; Leip, A.; Mosier, A.; Bleeker, A. Nitrogen and biofuels; an overview of the current state of knowledge. Nutr. Cycl. Agroecosystems 2010, 86, 211–223. [Google Scholar] [CrossRef]

- Popp, J.; Lakner, Z.; Harangi-Rákos, M.; Fári, M. The effect of bioenergy expansion: Food, energy, and environment. Renew. Sustain. Energy Rev. 2014, 32, 559–578. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, F.; Liu, S.; Wang, L.; Qiu, L.; Alexandrov, G.; Jothiprakash, V. Bioenergy production and environmental impacts. Geosci. Lett. 2018, 5. [Google Scholar] [CrossRef]

- Paolini, V.; Petracchini, F.; Segreto, M.; Tomassetti, L.; Naja, N.; Cecinato, A. Environmental impact of biogas: A short review of current knowledge. J. Environ. Sci. Heal. Part. A Toxic Hazard. Subst. Environ. Eng. 2018, 53, 899–906. [Google Scholar] [CrossRef]

- Pierie, F.; van Someren, C.E.J.; Benders, R.M.J.; Bekkering, J.; van Gemert, W.J.T.; Moll, H.C. Environmental and energy system analysis of bio-methane production pathways: A comparison between feedstocks and process optimizations. Appl. Energy 2015, 160, 456–466. [Google Scholar] [CrossRef]

- Mohajer, A.; Tremier, A.; Barrington, S.; Teglia, C. Compost mixture influence of interactive physical parameters on microbial kinetics and substrate fractionation. Waste Manag. 2010, 30, 1464–1471. [Google Scholar] [CrossRef] [PubMed]

- Sietske Boschma, D.; Kees, I.; Kwant, W. Rice Straw Wheat Straw Potential Feedstocks for the Biobased Economy; NL Agency of Energy and Climate Change: Utrecht, The Netherlands, 2013. [Google Scholar]

- Bilo, F.; Pandini, S.; Sartore, L.; Depero, L.E.; Gargiulo, G.; Bonassi, A.; Federici, S.; Bontempi, E. A sustainable bioplastic obtained from rice straw. J. Clean. Prod. 2018, 200, 357–368. [Google Scholar] [CrossRef]

- Maina, S.; Kachrimanidou, V.; Koutinas, A. A roadmap towards a circular and sustainable bioeconomy through waste valorization. Curr. Opin. Green Sustain. Chem. 2017, 8, 18–23. [Google Scholar] [CrossRef]

- Zhang, W.; Qiu, L.; Gong, A.; Cao, Y.; Wang, B. Solid-state Fermentation of Kitchen Waste for Production of Bacillus thuringiensis-based Bio-pesticide. BioResources 2013, 8, 1124–1135. [Google Scholar] [CrossRef]

- Stegmann, P.; Londo, M.; Junginger, M. The circular bioeconomy: Its elements and role in European bioeconomy clusters. Resour. Conserv. Recycl. X 2020, 6, 100029. [Google Scholar] [CrossRef]

- Bosman, R.; Rotmans, J. Transition governance towards a bioeconomy: A comparison of Finland and The Netherlands. Sustainability 2016, 8, 1017. [Google Scholar] [CrossRef]

- Davis, C.B.; Aid, G.; Zhu, B. Secondary Resources in the Bio-Based Economy: A Computer Assisted Survey of Value Pathways in Academic Literature. Waste Biomass Valorization 2017, 8, 2229–2246. [Google Scholar] [CrossRef]

- Shai, S.-S.; Shai, B.-D. Understanding Machine Learning: From Theory to Algorithms; Cambridge University Press: New York, NY, USA, 2014; ISBN 978-1-107-05713-5. [Google Scholar]

- RStudio | Open Source & Professional Software for data Science Teams-RStudio. Available online: https://rstudio.com/ (accessed on 5 April 2020).

- ScienceDirect ScienceDirect.com | Science, Health and Medical Journals, Full Text Articles and Books. Available online: https://www.sciencedirect.com/ (accessed on 6 November 2019).

- ScienceDirect APIs-ScienceDirect | Learn & Support | Elsevier. Available online: https://www.elsevier.com/solutions/sciencedirect/support/api (accessed on 6 November 2019).

- FAO. BIOGAS INDUSTRIAL User Manual Bioenergy and Food Security Rapid Appraisal (BEFS RA); Food and Agriculture Organization of the United Nations: Rome, Italy, 2017. [Google Scholar]

- FAO. Energy end-use options | Energy | Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org/energy/bioenergy/befs/assessment/befs-ra/energy-end-use/en/ (accessed on 18 April 2020).

- KTBL. European Feedstock Atlas-Feedstock List; KTBL: Darmstadt, Germany, 2010. [Google Scholar]

- KTBL. Feedstock Atlas. Available online: https://daten.ktbl.de/euagrobiogasbasis/startSeite.do;jsessionid=0B98622076229B9E15308366CEE1623B (accessed on 18 April 2020).

- Feedipedia Feedipedia: An on-line encyclopedia of animal feeds | Feedipedia. Available online: https://www.feedipedia.org/ (accessed on 18 April 2020).

- Feedbase. FeedBase.com-Economic and technical feed information. Available online: http://www.feedbase.com/index.php?Lang=E (accessed on 18 April 2020).

- Luske, B.; Blonk, H. Milieueffecten van Dierlijke Bijproducten Blonk Milieuadvies Werken aan Duurzaamheid; Blonk Milieu Advies: Gouda, The Netherlands, 2009. [Google Scholar]

- Quik, J.T.K.; Mesman, M.; van der Grinten, E. Assessing Sustainability of Residual Biomass Applications Finding the Optimal Solution for A Circular Economy; Rijksinstituut voor Volksgezondheid en Milieu RIVM: Bildhofen, The Netherlands, 2016. [Google Scholar]

- Bos-Brouwers, H.; Langelaan, B.; Sanders, J. Chances for Biomass; Wageningen University & Research: Wageningen, The Netherlands, 2012. [Google Scholar]

- Wang, S.J.; Huang, S.H.; Wong, D.S.H.; Jang, S.S. Novel plant-wide process design of dichlorohydrin production by glycerol hydrochlorination. J. Taiwan Inst. Chem. Eng. 2017, 73, 50–61. [Google Scholar] [CrossRef]

- Okoye, P.U.; Abdullah, A.Z.; Hameed, B.H. Synthesis of oxygenated fuel additives via glycerol esterification with acetic acid over bio-derived carbon catalyst. Fuel 2017, 209, 538–544. [Google Scholar] [CrossRef]

- Zhou, H.; Long, Y.Q.; Meng, A.H.; Li, Q.H.; Zhang, Y.G. Interactions of three municipal solid waste components during co-pyrolysis. J. Anal. Appl. Pyrolysis 2015, 111, 265–271. [Google Scholar] [CrossRef]

- Rafiee, A.; Gordi, E.; Lu, W.; Miyata, Y.; Shabani, H.; Mortezazadeh, S.; Hoseini, M. The impact of various festivals and events on recycling potential of municipal solid waste in Tehran, Iran. J. Clean. Prod. 2018, 183, 77–86. [Google Scholar] [CrossRef]

- Markidis, I.; Komilis, D.; Tsagas, F.; Petalas, A. A fractional factorial field experiment to study the decomposition of municipal solid wastes stored in wrapped bales. J. Environ. Manage. 2013, 115, 32–41. [Google Scholar] [CrossRef] [PubMed]

- Yao, R.S.; Zhang, P.; Wang, H.; Deng, S.S.; Zhu, H.X. One-step fermentation of pretreated rice straw producing microbial oil by a novel strain of Mortierella elongata PFY. Bioresour. Technol. 2012, 124, 512–515. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Li, Q.; Gao, Y.; Zheng, L.; Liu, Z. Biodiesel production from swine manure via housefly larvae (Musca domestica L.). Renew. Energy 2014, 66, 222–227. [Google Scholar] [CrossRef]

- Lu, J.; Watson, J.; Zeng, J.; Li, H.; Zhu, Z.; Wang, M.; Zhang, Y.; Liu, Z. Biocrude production and heavy metal migration during hydrothermal liquefaction of swine manure. Process. Saf. Environ. Prot. 2018, 115, 108–115. [Google Scholar] [CrossRef]

- Theegala, C.S.; Midgett, J.S. Hydrothermal liquefaction of separated dairy manure for production of bio-oils with simultaneous waste treatment. Bioresour. Technol. 2012, 107, 456–463. [Google Scholar] [CrossRef]

- Li, Q.; Zheng, L.; Cai, H.; Garza, E.; Yu, Z.; Zhou, S. From organic waste to biodiesel: Black soldier fly, Hermetia illucens, makes it feasible. Fuel 2011, 90, 1545–1548. [Google Scholar] [CrossRef]

- Contreras-Ramos, S.M.; Escamilla-Silva, E.M.; Dendooven, L. Vermicomposting of biosolids with cow manure and oat straw. Biol. Fertil. Soils 2005, 41, 190–198. [Google Scholar] [CrossRef]

- Mandl, M.G. Status of green biorefining in Europe. Biofuels Bioprod. Biorefining 2010, 6, 268–274. [Google Scholar] [CrossRef]

- Xiu, S.; Shahbazi, A. Development of Green Biorefinery for Biomass Utilization: A Review. Trends Renew. Energy 2015, 1, 4–15. [Google Scholar] [CrossRef]

- Gerssen-Gondelach, S.J.; Saygin, D.; Wicke, B.; Patel, M.K.; Faaij, A.P.C. Competing uses of biomass: Assessment and comparison of the performance of bio-based heat, power, fuels and materials. Renew. Sustain. Energy Rev. 2014, 40, 964–998. [Google Scholar] [CrossRef]

- Pavlenko, N.; El Takriti, S.; Malins, C.; Searle, S. Beyond the Biofrontier: Balancing Competing Uses for the Biomass Resource; International Council on Clean Transportation: Washington, USA, 2016. [Google Scholar]

- Philippidis, G.; Bartelings, H.; Helming, J.; M’barek, R.; Smeets, E.; van Meijl, H. Levelling the playing field for EU biomass usage. Econ. Syst. Res. 2019, 31, 158–177. [Google Scholar] [CrossRef]

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

| Type of Bioenergy | Conversion Processes | Common Feedstocks | ||

|---|---|---|---|---|

| Common Name 1 | Other Names | |||

| Liquid fuels | Biodiesel | Biodiesel | transesterification | oil crops feedstocks, animal fats |

| Syndiesel | gasification + Fischer Tropsch | cellulose feedstocks | ||

| Renewable diesel | hydrogenation | oil crops feedstocks, animal fats | ||

| HTU diesel | hydro thermal upgrading (HTU) | wet feedstocks (e.g., beet pulp) | ||

| Bio gasoline | gasification + Fischer Tropsch | wood waste, algae | ||

| Bio jet fuel | Bio jet fuel | alcohol-to-jet | various feedstocks | |

| oil-to-jet | various feedstocks | |||

| sugar-to-jet | various feedstocks | |||

| Synthetic jet fuel | gas-to-jet | cellulose feedstocks | ||

| Bioethanol 2 | sugar fermentation | sugar and starch feedstocks | ||

| hydrolysis + fermentation | cellulose feedstocks, algae | |||

| gasification + fermentation | various feedstocks, waste | |||

| Pyrolysis oil 2 | pyrolysis | wood, algae | ||

| hydrothermal Liquefaction | algae | |||

| Direct vegetable oil 2 | New oil3 | oil pressing/oil extraction | oil crops feedstocks | |

| Recycled oil | - | waste vegetable oil | ||

| Dimethyl ether 2 | gasification + dehydration (of methanol) | black liquor, cellulose feedstocks | ||

| gasification + synthesis (with CH4 from anaerobic digestion) | various feedstocks, waste | |||

| Methanol 2 | gasification + synthesis (from CO, CO2, H2) | various feedstocks | ||

| biosynthesis (from CH4) | ||||

| Butanol 2 | ABE fermentation | cellulose feedstocks, sugar and starch feedstocks, algae | ||

| Others 2 | ||||

| Bio-ethers 2 | chemical synthesis | - | ||

| Dimethylfuran 2 | chemical synthesis | - | ||

| Gaseous fuels | Biomethane 4 | biogas | anaerobic digestion | various feedstocks |

| biomethane | gasification + synthesis | cellulose feedstocks | ||

| Biohydrogen 2 | dark fermentation | carbohydrates | ||

| photobiological hydrogen production | algae, waste water | |||

| Syngas 2 | gasification | cellulose feedstocks | ||

| Solid fuels | Use biomass as it is | combustion, firing | cellulose feedstocks, manure | |

| incineration | various feedstocks | |||

| Briquette | desification, pelletization, briquetting | cellulose feedstocks, manure | ||

| Torrefied biomass | torrefaction | cellulose feedstocks | ||

| Feedstocks | Number of Applications on Category of | Total | ||||

|---|---|---|---|---|---|---|

| Animal Feed | Chemicals | Chemicals and Energy | Energy | Materials | ||

| Glycerol | 1 | 77 | 5 | 6 | 21 | 110 |

| organic housewaste | 1 | 35 | 5 | 7 | 18 | 66 |

| wheat straw | 1 | 33 | 4 | 7 | 15 | 60 |

| sugar beet melasse | 1 | 31 | 3 | 5 | 10 | 50 |

| maize stover | 1 | 27 | 4 | 8 | 9 | 49 |

| food leftovers | 1 | 22 | 5 | 8 | 9 | 45 |

| rice straw | 1 | 22 | 5 | 7 | 9 | 44 |

| distiller’s grains | 1 | 25 | 3 | 5 | 3 | 37 |

| cattle manure | 0 | 13 | 4 | 4 | 8 | 29 |

| wheat bran | 1 | 25 | 2 | 0 | 1 | 29 |

| malt coffee marc | 1 | 8 | 4 | 4 | 10 | 27 |

| pig manure | 1 | 11 | 3 | 5 | 6 | 26 |

| used paper | 0 | 10 | 2 | 3 | 9 | 24 |

| citrus bagasse | 1 | 10 | 1 | 3 | 6 | 21 |

| grape marc | 1 | 8 | 2 | 3 | 6 | 20 |

| poultry manure | 1 | 7 | 2 | 5 | 5 | 20 |

| animal fats | 0 | 11 | 2 | 4 | 3 | 20 |

| Feedstocks Co-Occurred with 1–3 Applications | Feedstocks with no Application Co-Occurrences | ||

|---|---|---|---|

| natural grass | roadside grass | rabbit manure | apricot fiber |

| brewer’s grains | distiller’s residues | beer barm | succory waste |

| brewer’s yeast | flax extraction meal | hemp press cake | asparagus waste |

| coconut extraction meal | maize germ extraction meal | safflower extraction meal | cauliflower residues |

| sunflower extraction meal | palm-kernel extraction meal | sesame extraction meal | eggplant residues |

| cotton seed extraction meal | peanut extraction meal | barley bran | turnip residues |

| sunflower peelings | oat straw | oat bran | spinach waste |

| rye straw | pea straw | rye bran | fruit industry wastewater |

| ryegrass straw | meadow hay | coffee industry wastewater | potatoes wastewater |

| cut flower wastes | slaughterhouse wastewater | dairy industry wastewaters | pulp and paper industry wastewater |

| brewery industry wastewaters | oilseed processing wastewater | slaughterhouse flotate fat | bakery residues |

| meat waste | rumen content | animal offals | old bread |

| animal bloodmeal | fish liver meal | animal hairmeal | |

| dairy industry wastes (general) | milk whey | cheese waste | |

| feeding beet leaves | sugar beet scraps | ||

| olive pulp | |||

| Main Feedstocks for Future European Biogas Expected by Current Literatures | Likely Number of Alternative Uses |

|---|---|

| Manure [2,3,5,7] | High |

| Straws [2,3,5,7] | |

| Organic housewaste [2,3,7] | |

| Varied industrial by-products [2,6,7] | |

| Varied industrial by-products [2,6,7] | Medium |

| Sewage sludge [2,3,7] | |

| Natural grass [5,7] | Low |

| Roadside grass [3,7] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoang, D.L.; Davis, C.; Moll, H.C.; Nonhebel, S. Can Multiple Uses of Biomass Limit the Feedstock Availability for Future Biogas Production? An Overview of Biogas Feedstocks and Their Alternative Uses. Energies 2020, 13, 2747. https://doi.org/10.3390/en13112747

Hoang DL, Davis C, Moll HC, Nonhebel S. Can Multiple Uses of Biomass Limit the Feedstock Availability for Future Biogas Production? An Overview of Biogas Feedstocks and Their Alternative Uses. Energies. 2020; 13(11):2747. https://doi.org/10.3390/en13112747

Chicago/Turabian StyleHoang, Dieu Linh, Chris Davis, Henri C. Moll, and Sanderine Nonhebel. 2020. "Can Multiple Uses of Biomass Limit the Feedstock Availability for Future Biogas Production? An Overview of Biogas Feedstocks and Their Alternative Uses" Energies 13, no. 11: 2747. https://doi.org/10.3390/en13112747

APA StyleHoang, D. L., Davis, C., Moll, H. C., & Nonhebel, S. (2020). Can Multiple Uses of Biomass Limit the Feedstock Availability for Future Biogas Production? An Overview of Biogas Feedstocks and Their Alternative Uses. Energies, 13(11), 2747. https://doi.org/10.3390/en13112747