1. Introduction

Although there is no agreed definition of energy poverty, there is some consensus in identifying it as the situation suffered by “individuals or households that are unable to adequately heat, cool or provide other necessary energy services in their homes at an affordable cost” [

1]. Approximately 40 million people in the Union (8% of the total population) suffer from this situation, according to data from the latest European Living Conditions Survey [

2,

3]. In Spain, the incidence ranges from 7.2% to 16.9% of the population [

4], depending on the indicator used, according to the latest update of the National Strategy against Energy Poverty.

In this context, there is a wide consensus in recognising that energy poverty is a key social challenge that must be addressed by Member States through their public policies. The private sector can also contribute to tackle this issue, by means of social entrepreneurship and the involvement of large corporations through their Corporate Social Responsibility [

5].

Energy poverty, indeed a manifestation of general poverty, is directly linked to low income, and many low-income households are energy poor. Nevertheless, energy poverty does not fully overlap with income poverty. Two energy-related variables, namely housing energy efficiency and energy prices, are also key features characterising the problem [

6].

In terms of consequences, focusing only on health impacts, it is well documented that living in households with inadequate heating or cooling has detrimental consequences for respiratory, circulatory and cardiovascular systems, as well as for mental health and well-being [

7]. Additionally, energy poverty impacts on other aspects of people life, namely economic, social, and educational ones, among others [

8]. In the thick of energy needs that remain totally or partially unmet in vulnerable households, heating needs are particularly noteworthy. A potential improvement in this respect could be the installation of clean and efficient heating systems, such as the centralised heat pump analysed in this paper.

The air source heat pumps are a promising alternative to replace the old heating installations of block dwellings suffering energy poverty. These dwellings usually have oversized radiators, which enables them to be fed with low temperature water, then having a temperature range that is suitable for air source heat pumps water heaters (ASHPWH) [

9]. European Union considers that the energy taken from the air in the evaporator can be accounted as renewable energy if the heating seasonal performance factor exceeds certain values [

10]. Due to this fact, the replacement of centralised gas boilers by heat pumps makes it possible to introduce renewable energies in heating, so achieving an efficient heating system more de-carbonised than the former boiler. Such replacement should take the impact of the electricity taken from the grid in terms of CO

2 emissions, which depends on the electricity generation mix of the country, into account. Furthermore, heat pumps must face two specific environmental issues, namely, the ozone deployment potential (solved some time ago with the hydrofluorocarbons, HFC) and the global warming potential (GWP). In fact, the GWP of the HFCs used as refrigerants is usually too high. European Union has regulated the use of fluorinated greenhouse gases (F-gases) [

11], establishing an agenda to move from HFC to natural refrigerants (propane, butane, ammonia, CO

2, etc.), passing through hydrofluoroolefins (HFO) as intermediate fluids. Spanish regulation [

12] recently included heat pumps as a renewable option to supply thermal services to buildings, especially domestic hot water. Despite this, the use of heat pumps for heating purposes is far away from common practice in Spain. Conversely, space heating from heat pumps is usually a by-product of cooling services, using the so-called reversible heat pumps. This situation is even considered by the European Union [

10], which penalises reversible heat pumps when counting renewable energy due to the fact that they are usually designed to operate in cooling mode.

Curve fitting from actual machines is a common methodology for modeling the behaviour of heat pumps. Accordingly, Underwood et al. [

13] develop a model that is based on refrigerant-side variables, which makes it suitable for the analysis of the performance of heat pumps in service. So, this type of model is used when the focus is on the representation of the entire system building-heat pump. For instance, Lohani et al. [

14] integrate correlation curves of coefficient of performance (COP) for ground and air source heat pumps in a building modelling software that lacks heat pump models. In some cases [

15], the curve fitting is based on the theoretical behaviour of Carnot efficiency, as compared with actual performance. These models are used to identify key performance parameters in a site, as carried out by Vieira et al. [

16].

Physical models of heat pumps are based on energy and heat transfer equations of the different components. The key components are the heat exchangers, which are modelled using the effectiveness-number of transfer units method or the equivalent logarithmic mean temperature difference method [

17]. These types of methods usually consider the single phase and phase change zones. For example, Fardoun et al. [

18] propose a quasi-steady state model that is based on an iterative procedure for the heat exchangers. In this sense, Patnode [

19] develops a model of heat exchangers that is based on the Dittus–Boelter correlation, which can obtain the overall heat transfer coefficient as a function of the mass flow rate. This type of models is the base of rules and standards that determine the COP of ASHPWH as a function of water temperature and air dry and wet temperature [

20].

Other studies use dynamic models, which are usually based on commercial software as TRNSYS. This type of analyses might pursue the improvement of the control strategies in the operation of heat pumps [

21] or enhance the coupling with the thermal inertia of the building [

22]. In short, dynamic models are useful when the seasonal performance is sought [

23].

The thermal load, which is required as an input data to simulate the behavior of the heat pump, can be calculated using hourly average data or load predictions. Xu et al. [

24] carry out a case study while using data that were recorded along two years of operation of a data center, evaluating the performance of the combined cooling, heat, and power (CCHP) system, also performing transient modeling. Gadd et al. performed an analysis of the heat meter readings that were obtained on an hourly basis along one year [

25], aiming to provide heat load patterns, whereas Bacher et al. [

26] attempted to develop a method for predicting the space heating thermal load in a dwelling. The latter model is based on measured data from actual houses in combination with local climate measurements and weather forecasts. Noussan et al. [

27] propose a thermal demand model built up while using heat measurements taken every six minutes along several years of operation. Energy Plus software from the U.S. Department of Energy [

28] was used by many researchers to determine the thermal load. In this sense, Wood et al. [

29] and Michopoulos et al. [

30] employed this software to analyse the use of biomass in space heating. Other authors used regressive models to obtain thermal energy demand prediction methods [

31] or autoregression analysis with exogenous time and temperature indexes [

32]. In this sense, Powell et al. [

33] selected nonlinear autoregressive models with exogenous inputs as the best methodology based on artificial neural networks.

Several scholars used the degree-day method to obtain the hourly thermal energy demand profile. For example, Büyükalaca et al. [

34] estimate the energy needs in a building in Turkey by calculating the heating and cooling degree-days using variable-base temperatures. Furthermore, Martinaitis et al. [

35] perform an exergy analysis of buildings based on the degree-days method. Moreover, Layberry [

36] analysed the errors in the degree-day method that may affect the building energy demand analysis. Carlos et al. [

37] combined solar radiation data with the degree-day method and compared several different simplified methodologies for building energy performance assessment in winter. In Spain, the winter climatic severity index is defined from the winter degree-days and solar radiation measurements [

38]. This index is used to determine the thermal energy demand and it makes it possible to characterise the country’s climatic zones in order to assess the energy requirements, according to the building energy performance regulations [

39]. This thermal energy demand modelling is also suitable for assessing the performance of other thermal devices for the evaluated scenario.

This paper analyses the efficiency of an electrically driven a heat pump as a realistic alternative to achieve winter thermal comfort in vulnerable households’ dwellings. Thermally driven heat pumps (driven by absorption or internal combustion engines) also constitute a feasible option; nevertheless, this research is focused on electrically driven heat pumps, due to its higher commercial deployment in Spain. In order to do so, the baseline case is defined for a block of dwellings with a middle-level of energy efficiency and, additionally, retrofitting alternatives are considered for under average situations. The performance of the heat pump in terms of cost and CO2 emissions is compared with other alternatives (centralized and decentralized boilers). The cost breakdown of the heat pump is detailed, allowing for the evaluation of subsidy schemes in order to fund this kind of devices.

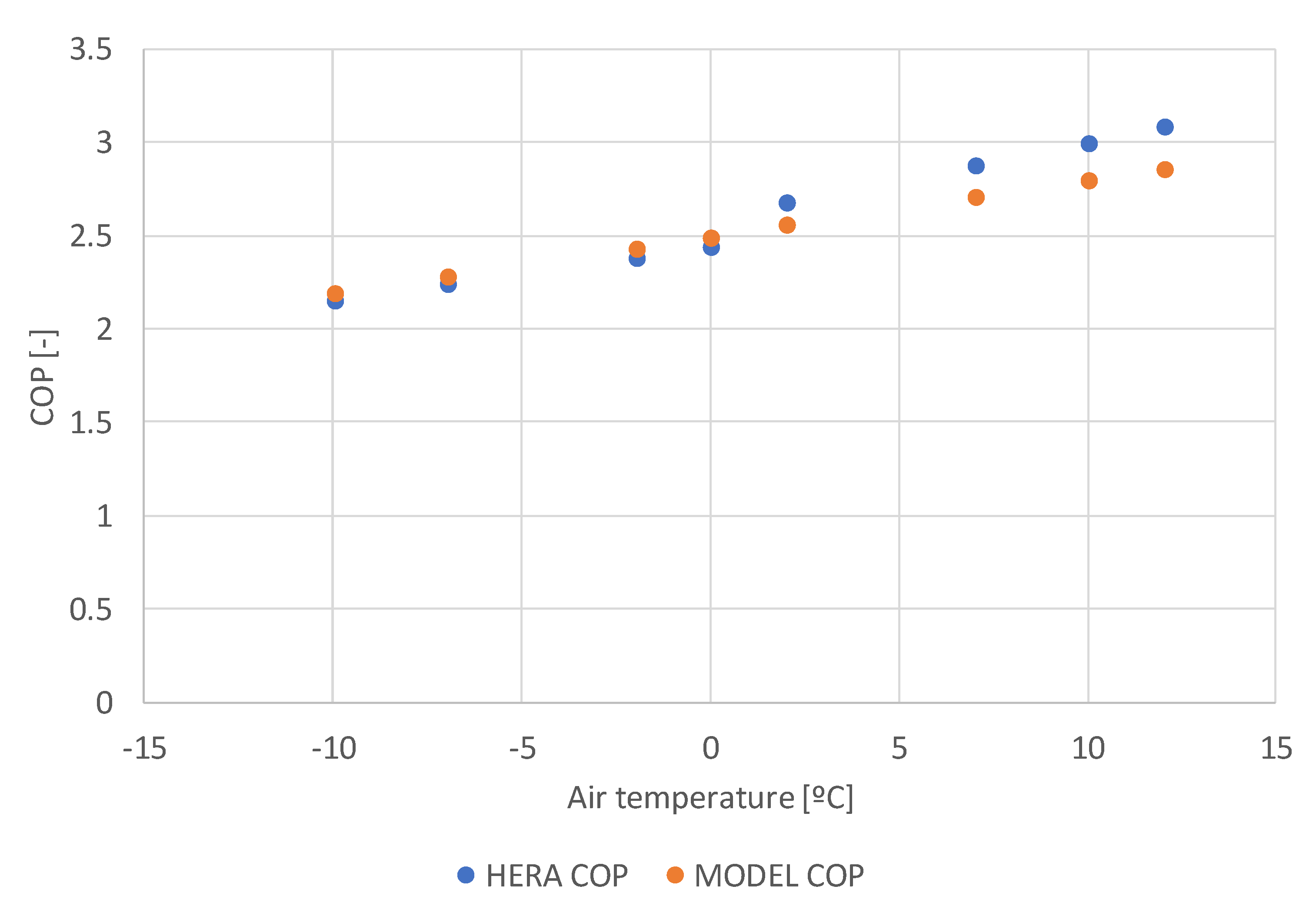

The novelty of this paper lies on the assessment of the use of centralised electrically driven heat pumps to meet the heating demand in Madrid. Such solutions are usually employed in northern Europe areas, especially with ground source heat pumps. However, the use of air source heat pumps is not common in Spain, as it can be followed from the support to these devices in the last release of the Spanish Technical Building Code [

12]. In this sense, the developed heat pump model is not sophisticated, although it is accurate enough, as can be derived from the comparison with a commercial machine. Regarding the heating demand forecasting model, a simpler version has been proposed by the authors [

40], but, as a novelty, the version that is used in this manuscript is able to retain information regarding thermal insulation of the building. This information made it possible to assess the effect of energy building retrofitting. Therefore, the aim of this paper is to analyse the feasibility of ASHPWH as active measure to fight energy poverty in dwelling blocks. The environmental and economic assessment performed in this paper can eventually provide insightful information to policy makers for implementing clean and efficient measures to tackle energy poverty.

4. Discussion

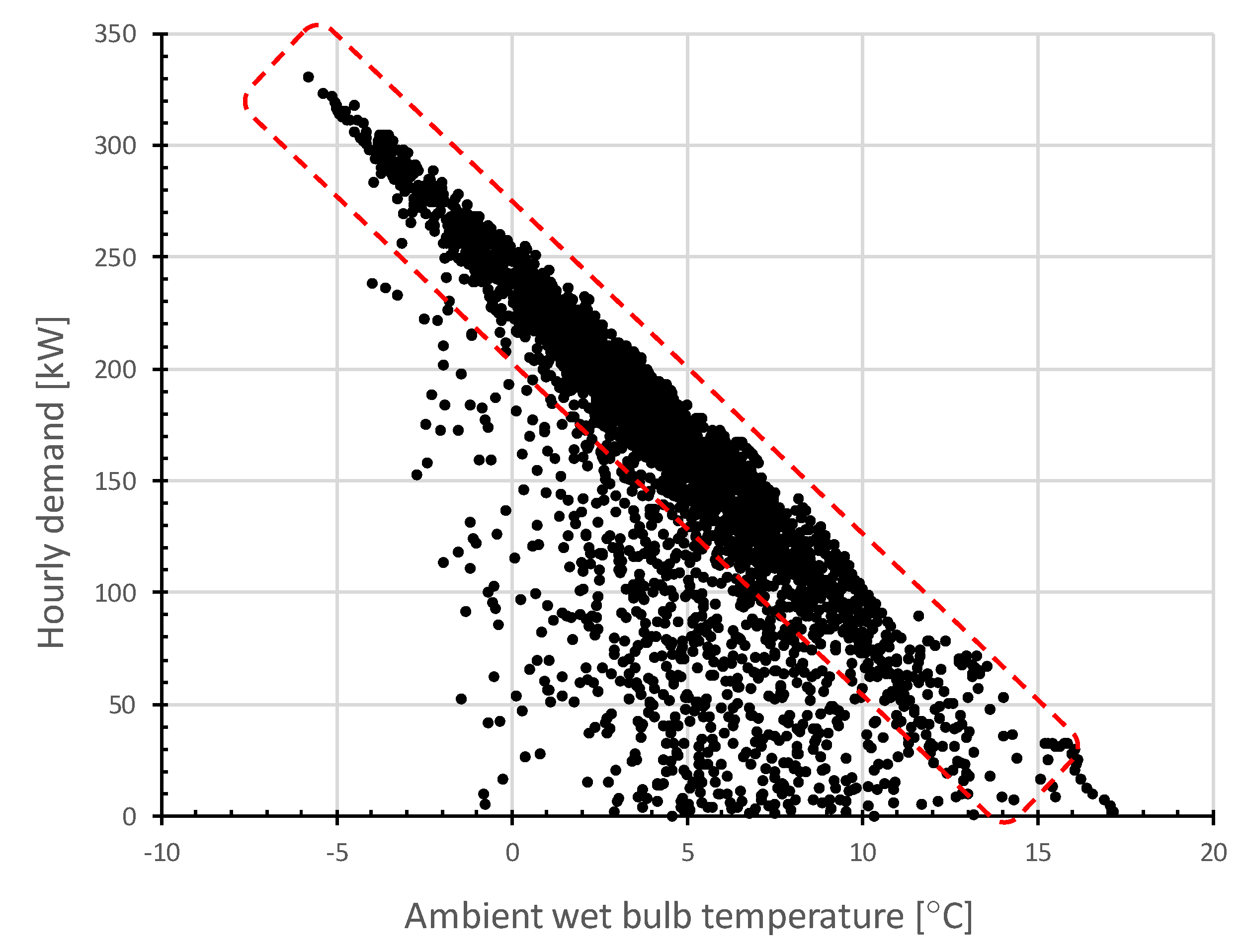

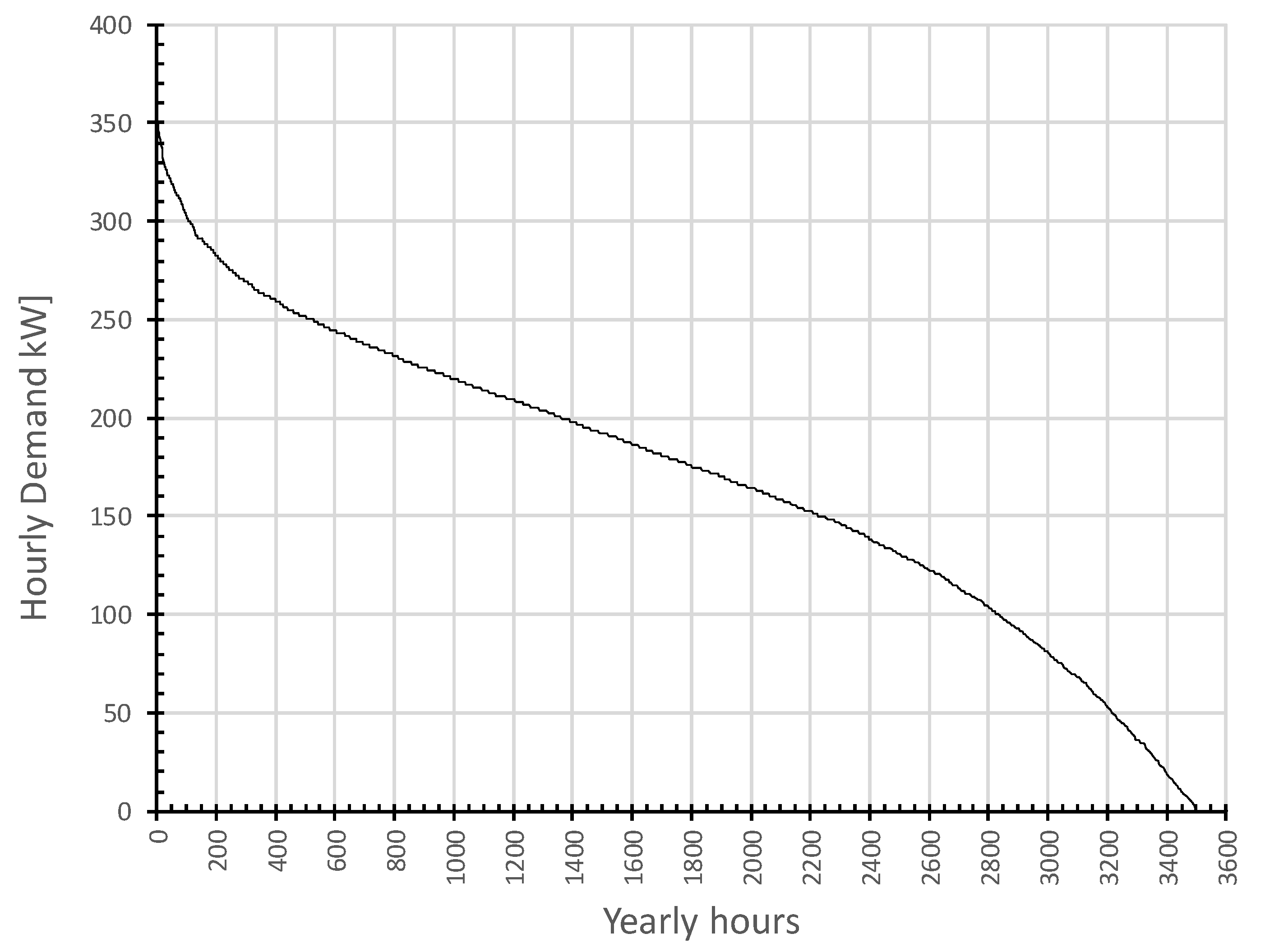

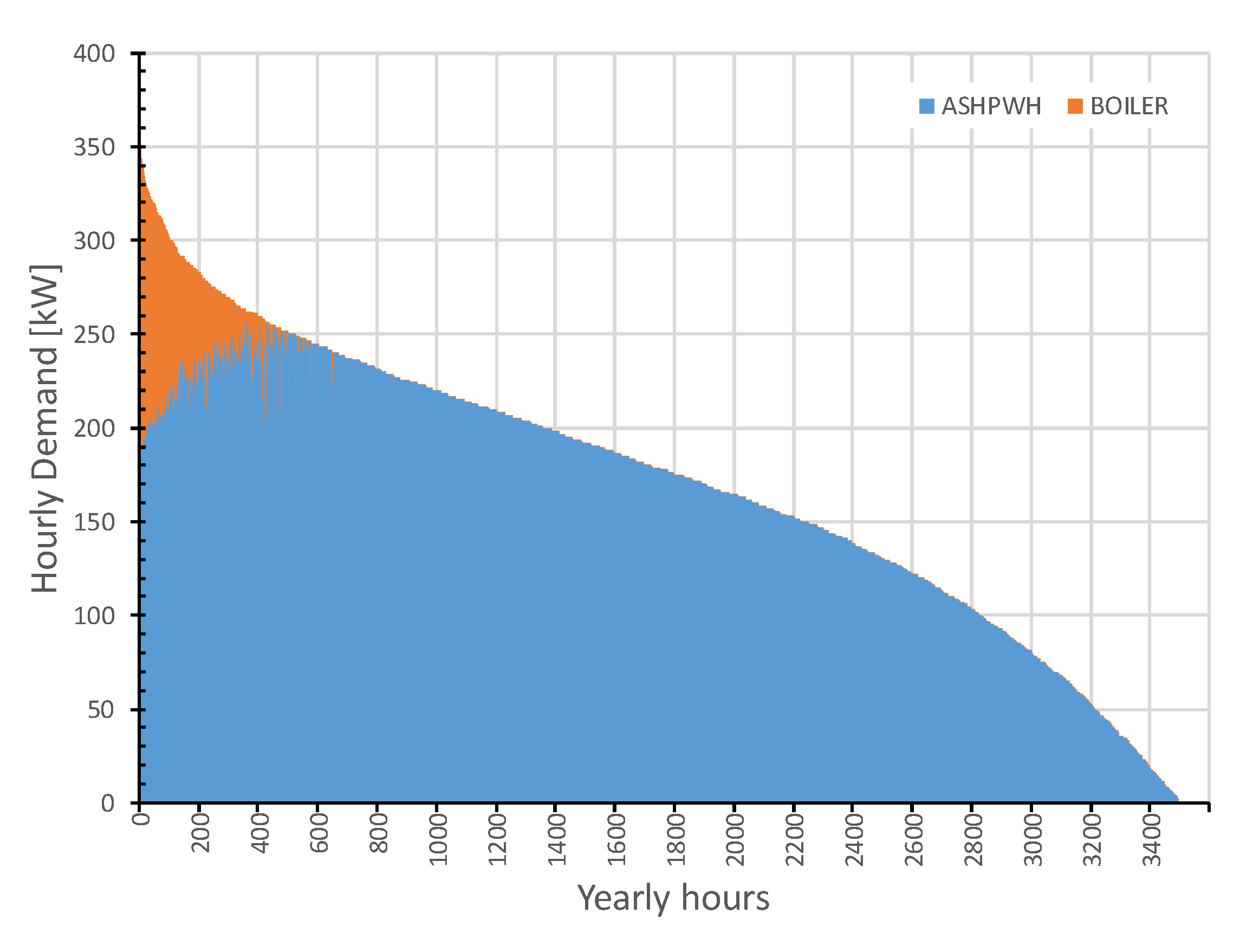

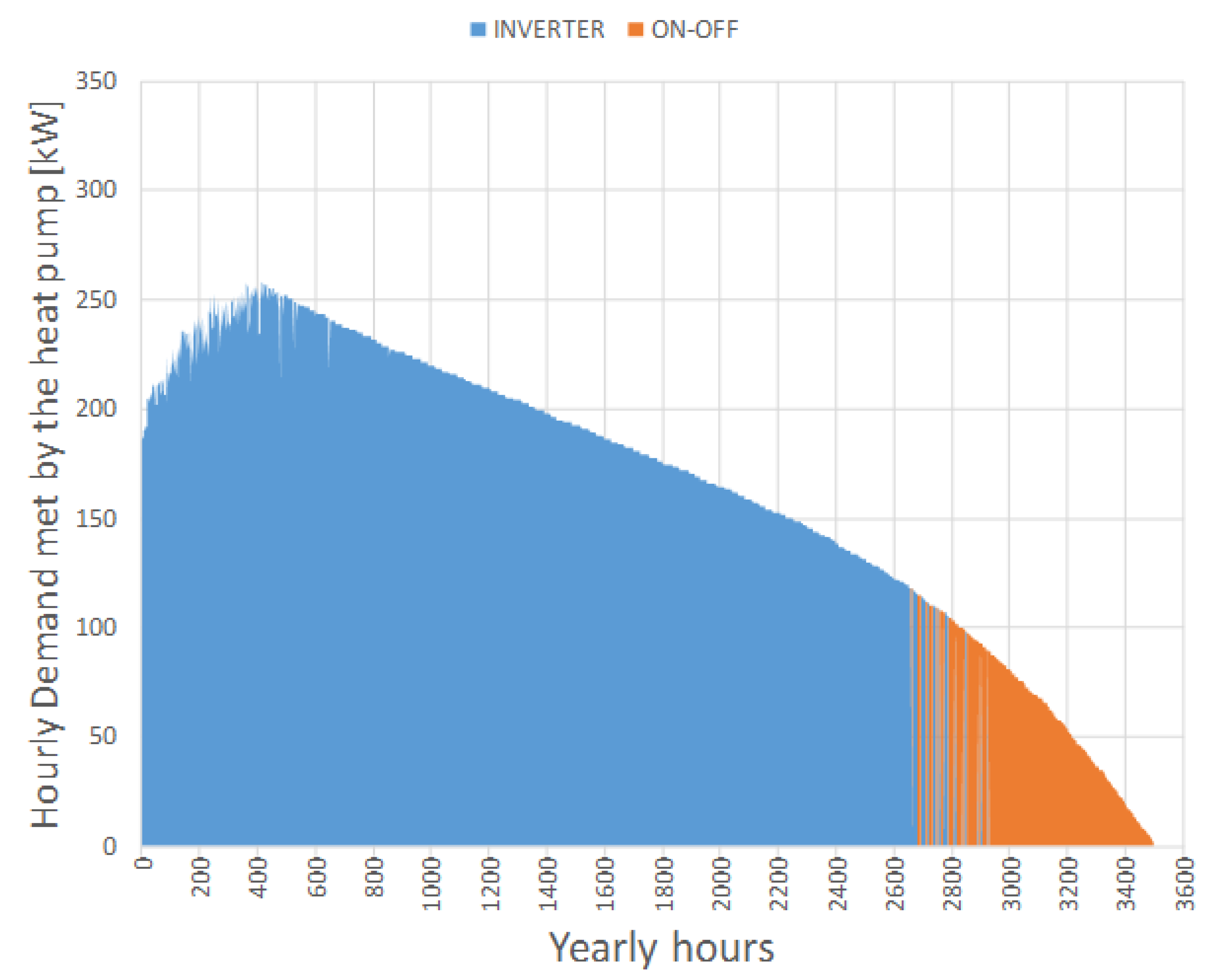

The proposed demand model makes it possible to obtain the hourly demand profile of a building, which is essential for working out the instantaneous consumptions of the heating system. The shape of the annual cumulative heating demand curve is consistent with the profiles that were obtained by other simulation tools [

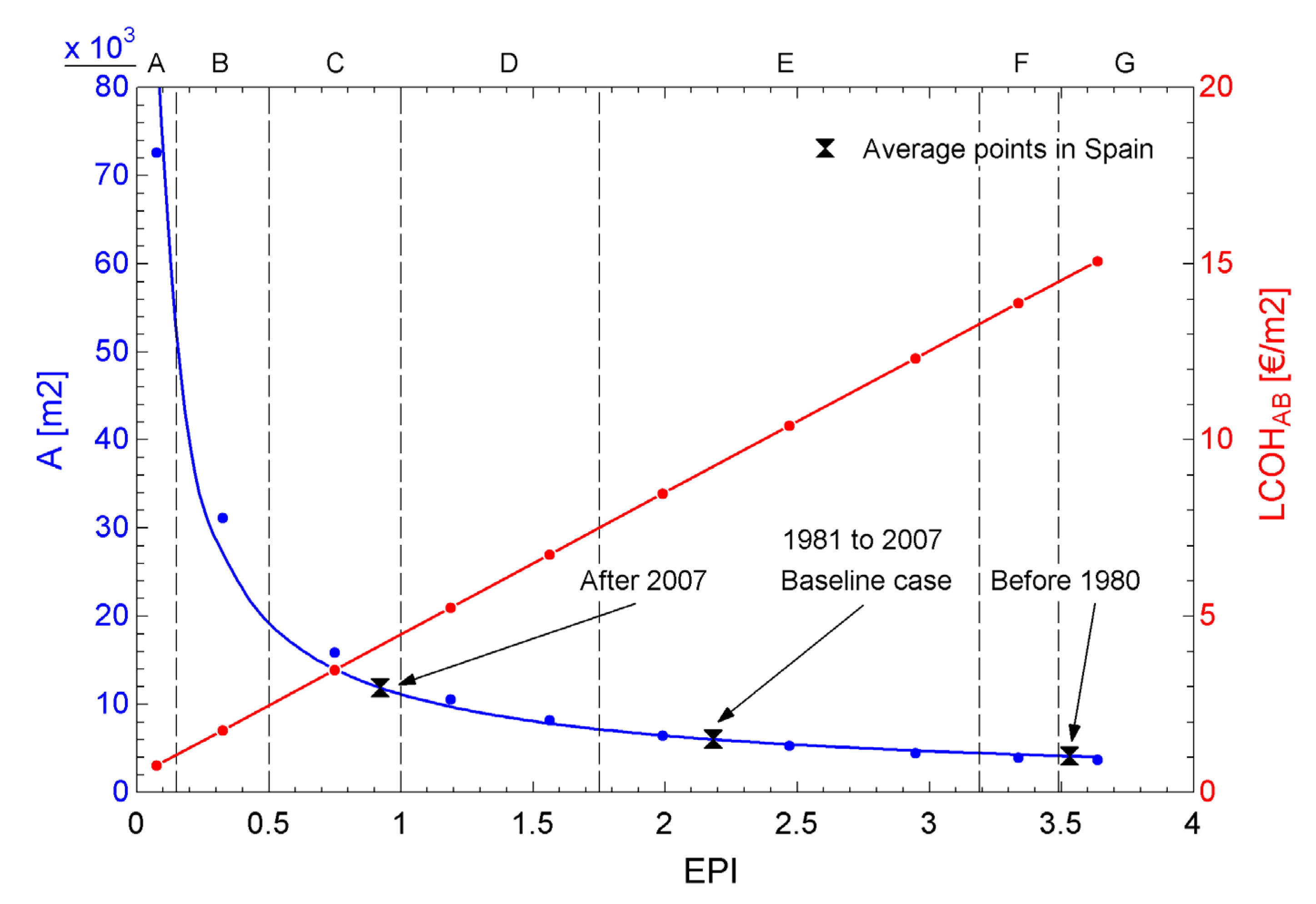

40]. This model only requires the location of the building, its useful area and the energy performance certification (EPC). A detailed simulation of the building thermal behaviour is necessary to assess the EPC, which leads to the EPI that is integrated in the proposed model. The fact that no specific additional information about the building is required by the model makes it very easy-to-use and helpful for planning purposes. The flexibility of the model has been used in order to solve a case study representative of vulnerable dwellings.

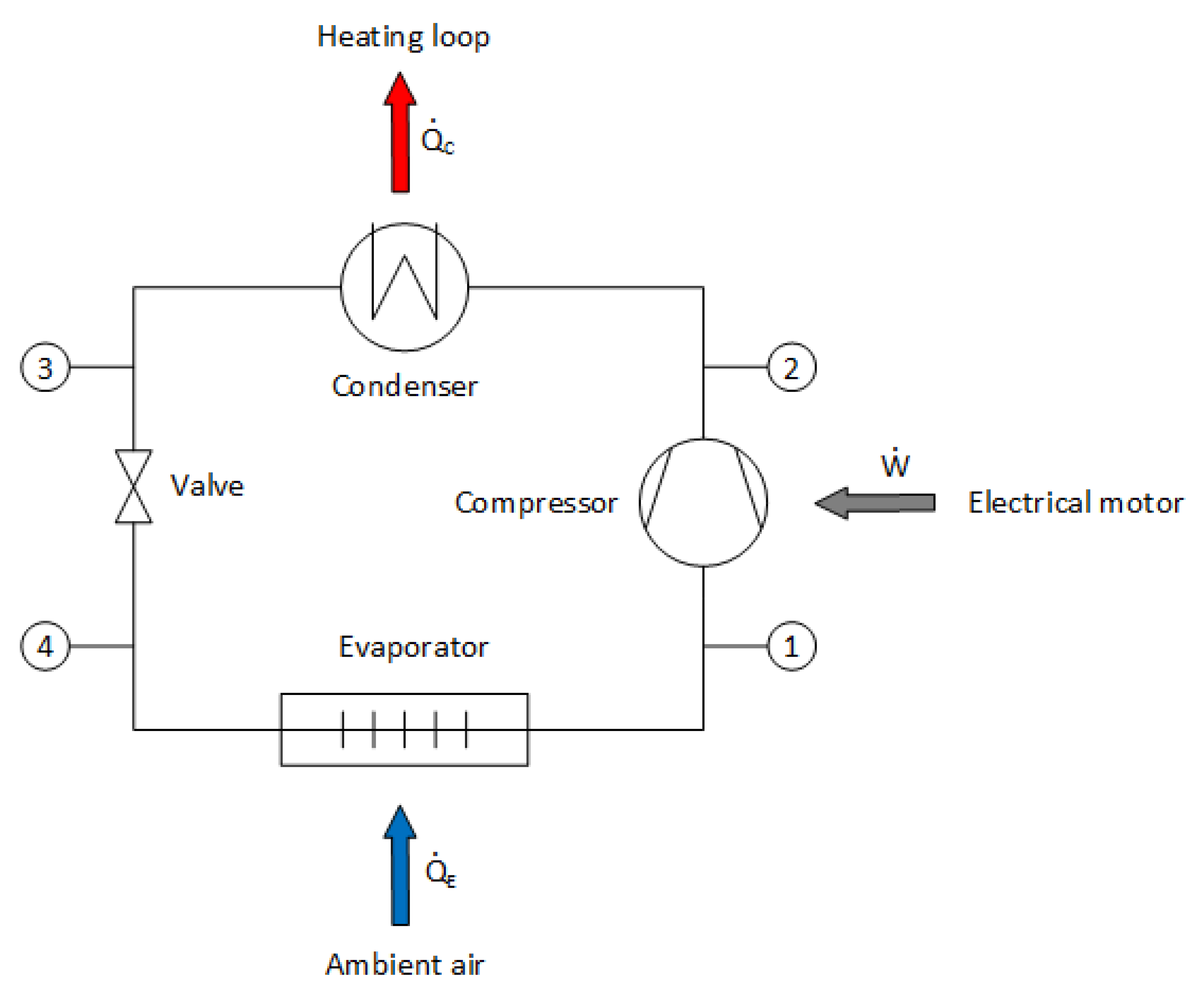

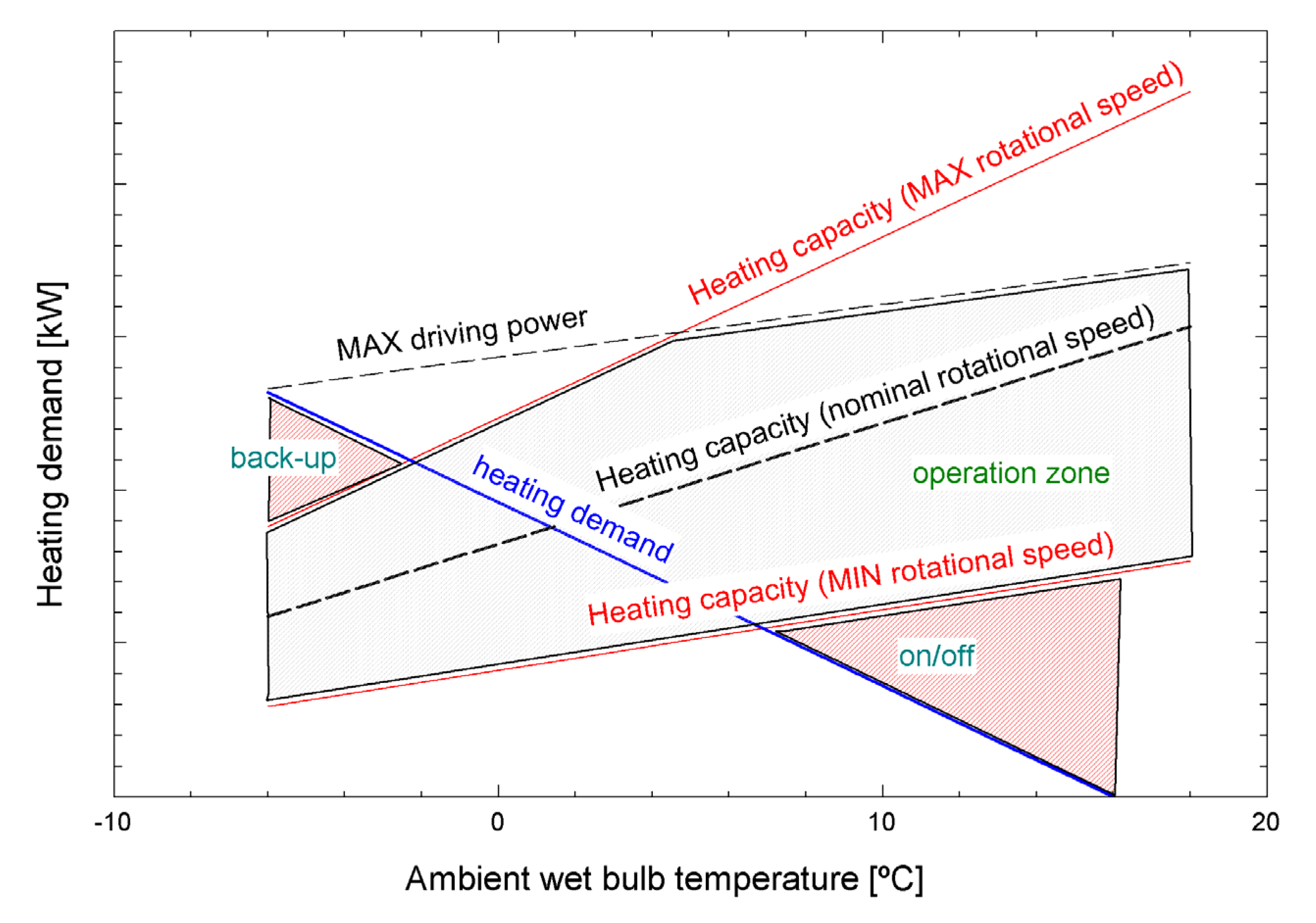

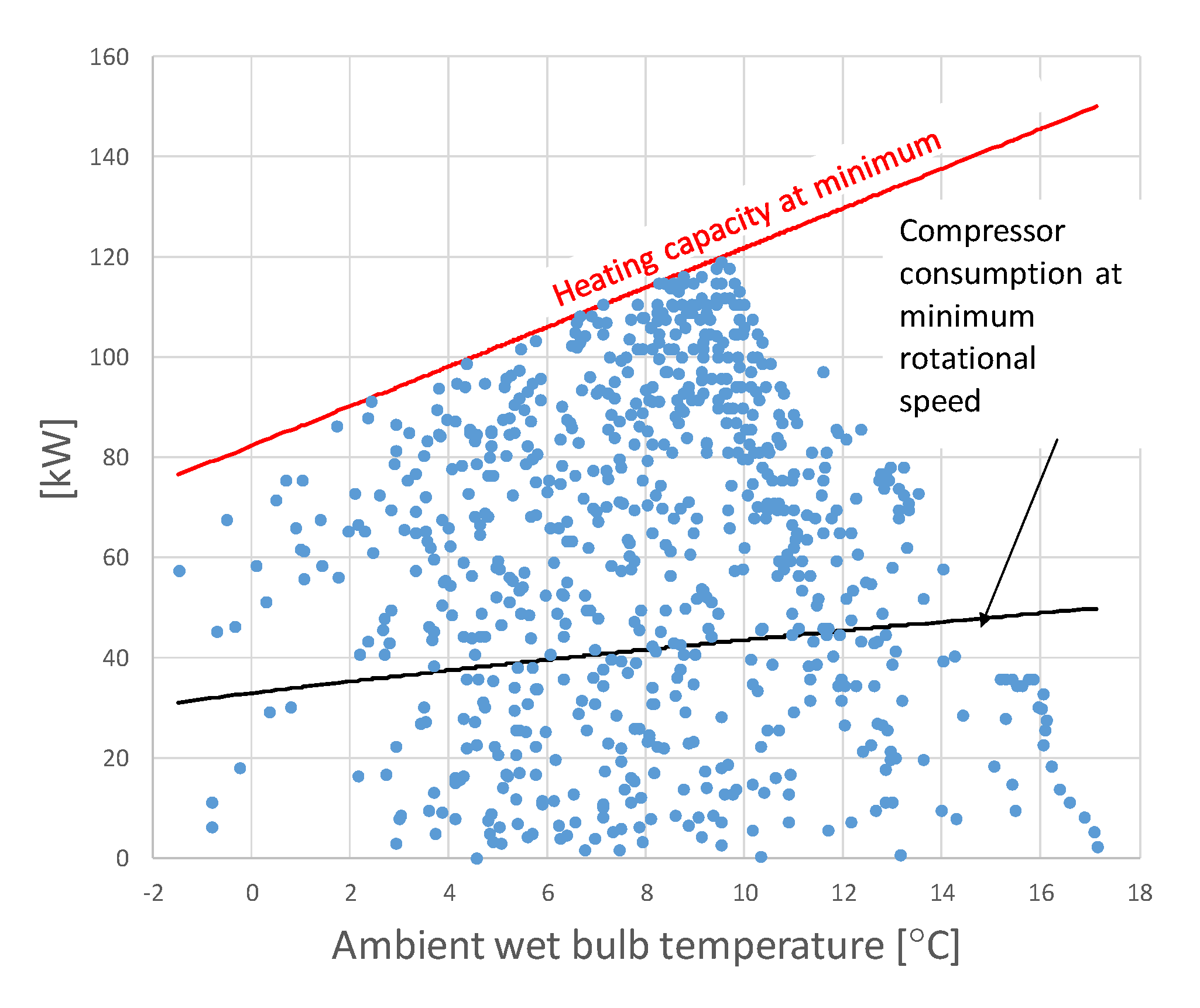

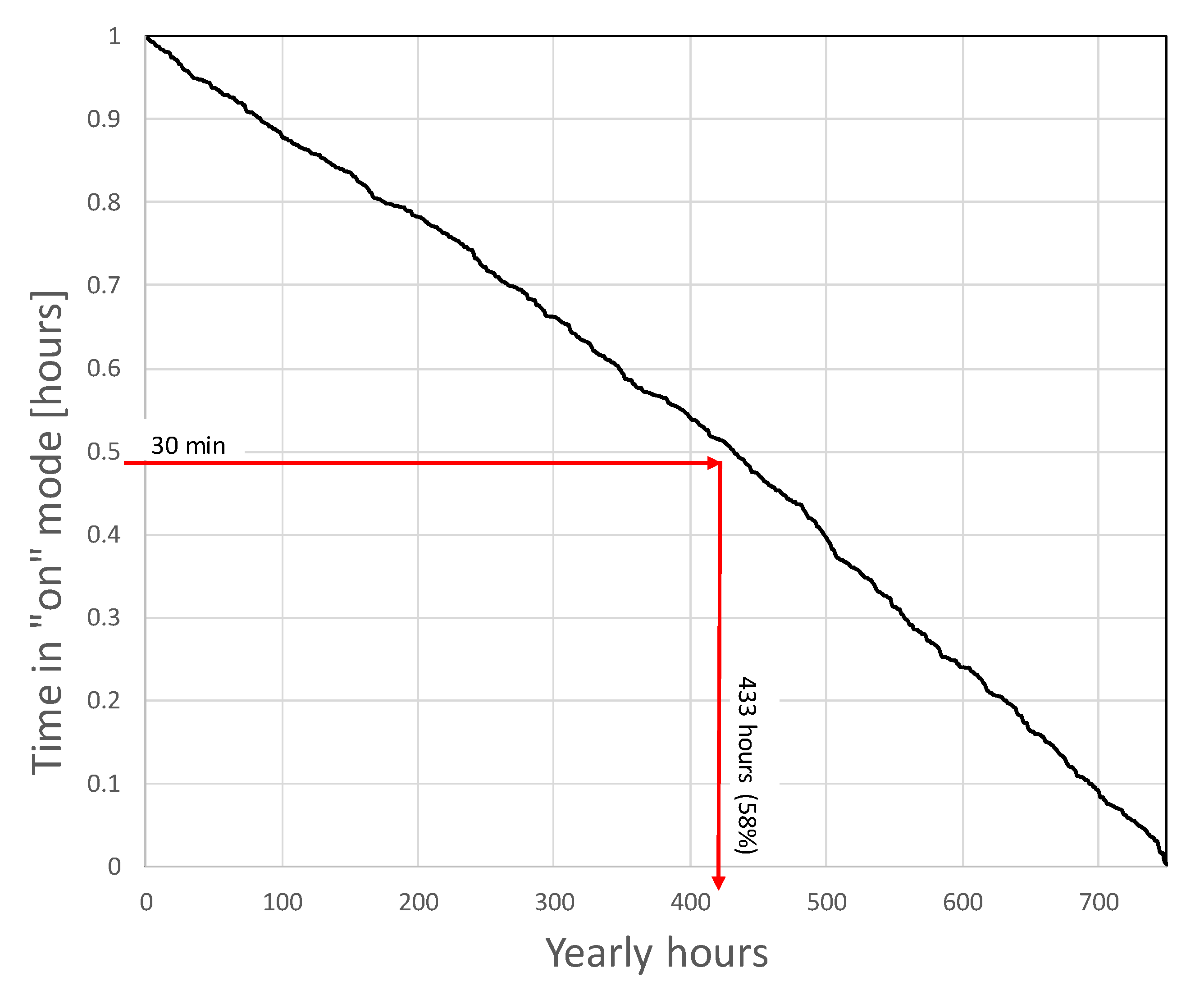

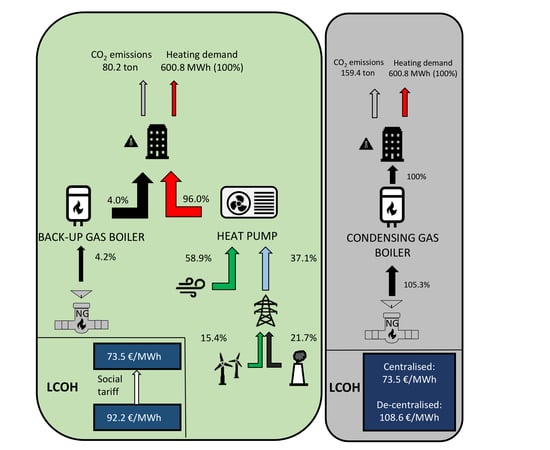

Regarding the heat pump, R290 (propane) has revealed as a suitable refrigerant for this application, and it is also supported by many manufacturers. It is a natural fluid, with zero ODP and very low GWP. The low compressor discharge temperature and the low de-superheating zone in the condenser advise taking this fluid into consideration for the future. Its high flammability is not relevant in the current case, since it is a centralised unit, with roof-top allocation and maintenance performed by professional workers. The speed control in the compressor gives to the heat pump the capability to meet nearly all of the heating demand (96% in the baseline case) with good efficiency. In the baseline case, the heating seasonal performance factor achieved is 2.585, exceeding the minimum that is required to consider the thermal energy taken from the air as renewable energy. Furthermore, the overall renewable energy to meet the heating demand is obtained, taking both the energy supplied by the air and the renewable share in the electricity mix into account (applied to the electricity consumption of the heat pump). Therefore, each kWh-th met with the proposed system avoids the emission of 131.7 g CO2, whereas 265.3 g CO2 are emitted if a boiler is used.

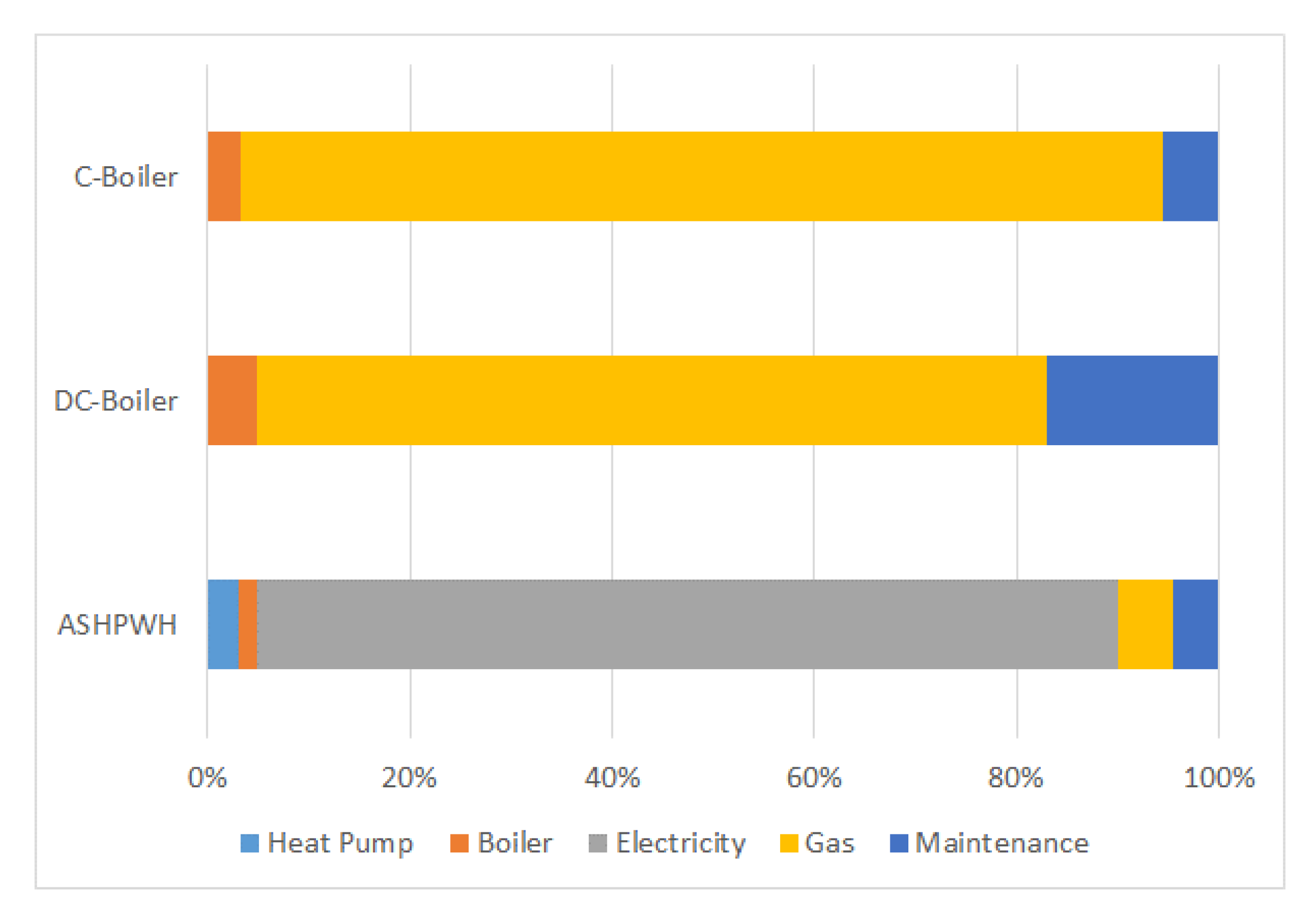

Regarding the cost for the baseline case, the proposed technology (heat pump plus boiler back-up) reduces the levelised cost of heating by 15% with respect to the de-centralised boiler. However, the proposed system increases the cost by 25% with respect to the centralised boiler. On the other hand, with centralised gas neither renewables sources are employed nor carbon dioxide emissions are avoided. The cost breakdown reveals that the energy cost, which facilitates the integration of subsidy policies to the operation, is the most important contribution to the overall cost. Therefore, a discount of 23.75% in electricity bill (comparable with the current social-tariff average-discount) would be enough to equalise the levelised cost of heating of the proposed system with the centralised boiler (the most economical scenario). Furthermore, the innovative and social aspect of this system makes it possible to integrate funding by non-profit organisations, energy companies, Public Administration, or even the actual consumers (depending on their vulnerability level). These subsidies to the proposed system would be endorsed due to its excellent environmental performance, balancing this way de-carbonisation with energy affordability.

Finally, the effect of energy retrofitting has been investigated. The results show that, if the energy performance assessment is improved from E to C due to a retrofit, the same heat pump would be able to meet the demand of 160 dwellings of 100 m2 instead of 60 of the baseline case. Regarding the heating cost per square meter, the cost drops 4 €/m2 for every EPI unit reduction. Accordingly, in the same example, the levelised cost of heating decreases 500 € for a dwelling of 100 m2 (with a baseline cost of 848 €).

5. Conclusions

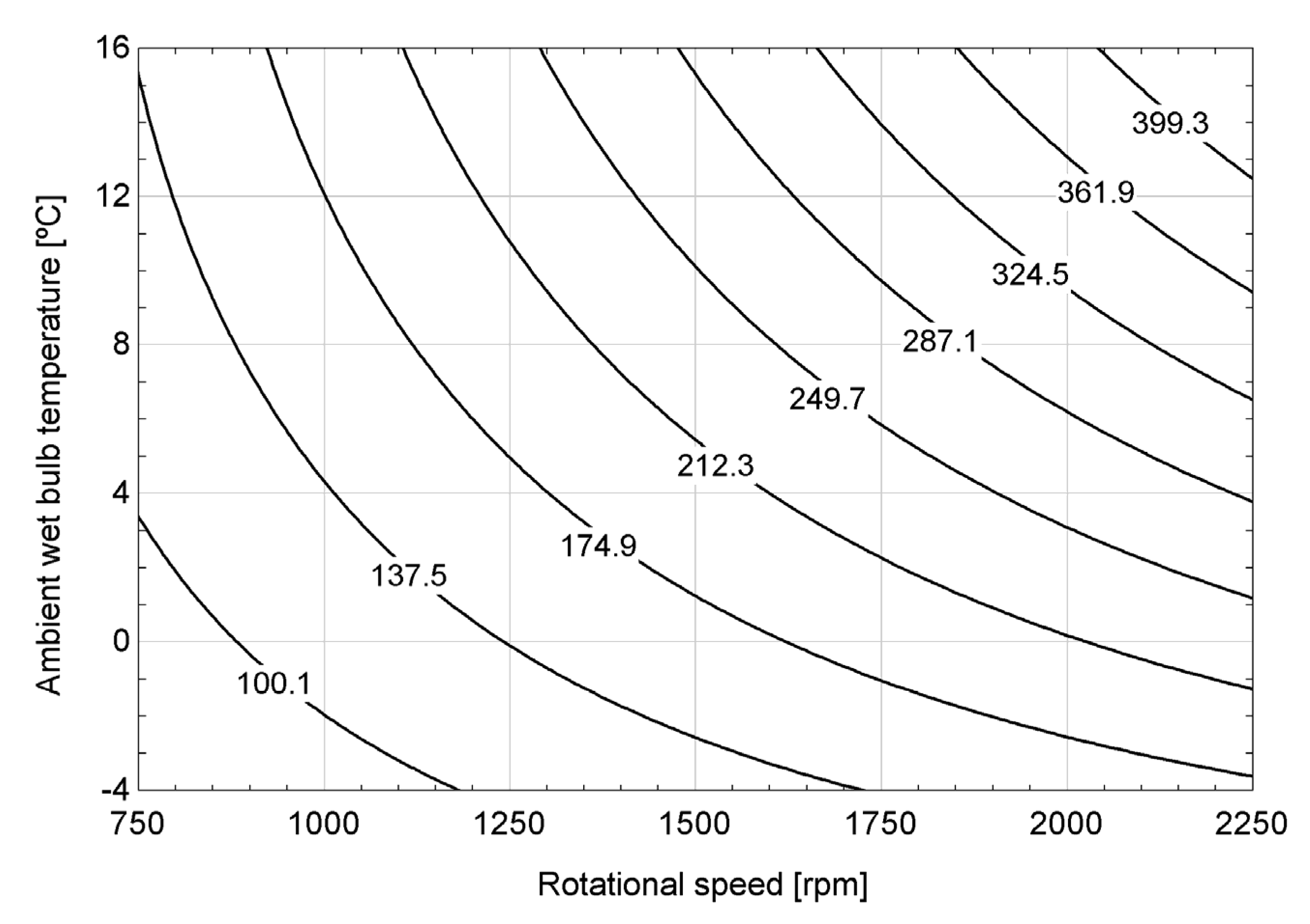

The feasibility of heating a block dwelling in Madrid by an air-source heat-pump water heater has been investigated in the framework of energy poverty research. The implementation of the heat pump is planned as a retrofit of the heating system. Therefore, an existing system that is based on radiators is assumed, and the operation temperatures of the heat pump are adapted to this configuration. A global methodology has been used to forecast the hourly heating demand while using an expansion method that is based on the Spanish regulation. The performance map has been obtained after selecting an eco-friendly refrigerant (R290), and considering a speed variation control over the compressor. This control makes it possible to meet nearly the whole demand with a high efficiency. Finally, the demand has been coupled to the performance of the heat pump.

When considering environmental and efficiency indicators, the obtained results show an excellent behaviour of the heat-pump as compared with the classical solution of the natural gas centralised boiler system. However, the levelised cost of heating is 25% higher than the centralised boiler, due to the low prices of gas for high consumption volumes. In this sense, a discount in electricity bill for vulnerable households might be taken into account, considering both social and environmental benefits, to equalise the energy costs of this technology with the one of a centralised gas boiler. The situation is reversed in the case of comparing the heat pump with the de-centralised boiler solution, with the heating cost of the heat pump being 15% lower than the boiler one. In all the scenarios, the main contribution to the overall cost is the operation, especially the energy cost.

Therefore, the heat pump has revealed as an efficient and sustainable system to tackle energy poverty in a typical case of vulnerable households, such as the building blocks analysed, especially when compared with a de-centralised boiler heating system. In any case, a new electricity tariff frame that reduces the operation costs of heat pumps with respect to the centralised boiler solution would be highly recommended.

In future works, the model will be expanded to summer season (cooling demand), taking advantage of the reversible ability of heat pumps. In the context of energy poverty, this is a new trend, especially in countries in Southern Europe. Other technologies, such as thermally driven heat pumps (both absorption and internal combustion engine), might be also considered to be alternatives. Moreover, the application to the different climatic zones of Spain will be carried out and policy implications will be pointed out.