Exergetic Life Cycle Assessment: A Review

Abstract

1. Introduction

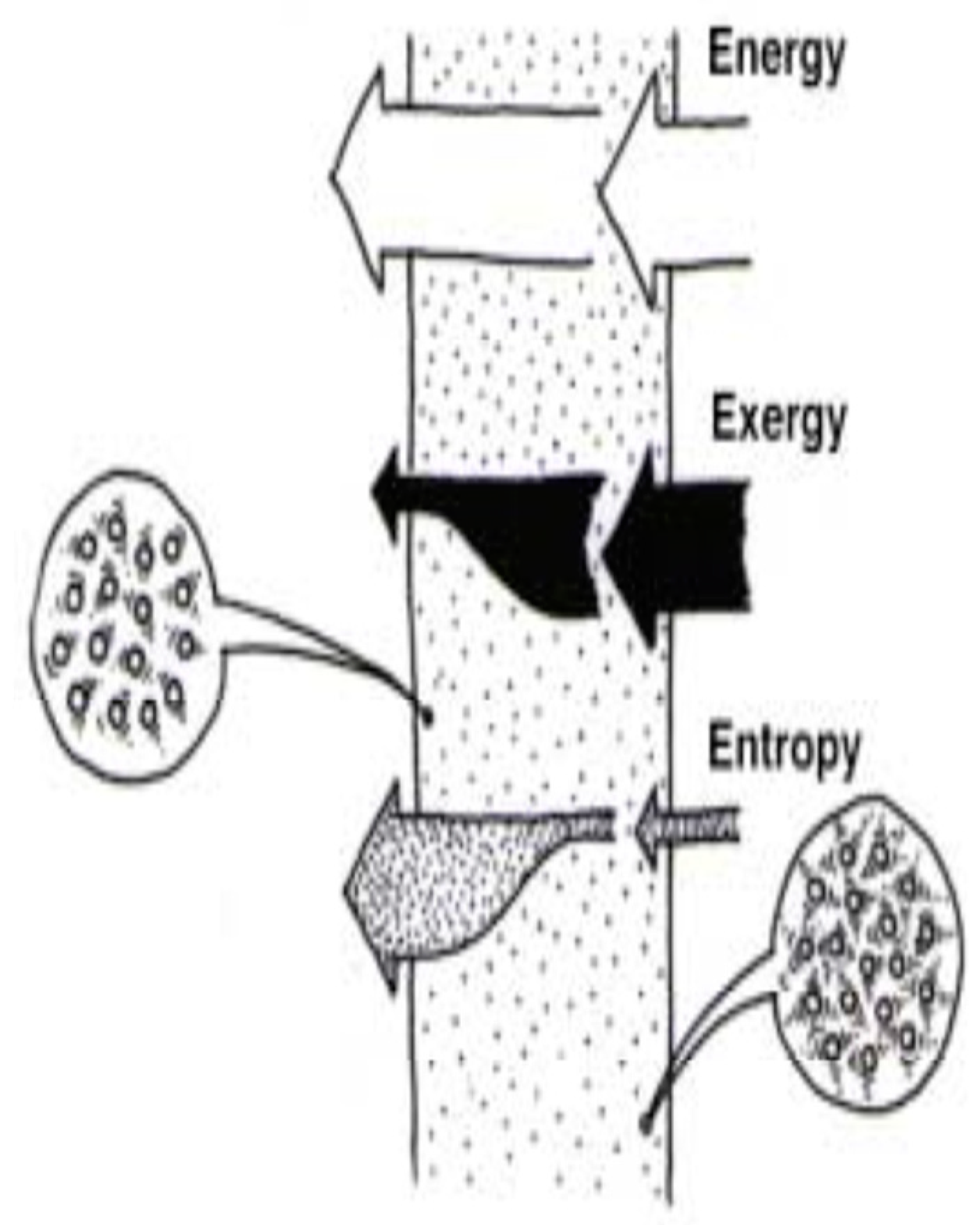

2. Description of Exergy

2.1. Definition of Exergy

- To calculate exergy, the idealized state is specified;

- Only common components such as atmosphere, hydrosphere, and lithosphere can be used as idealized systems because of thermodynamic disequilibrium in the surrounding nature;

- Being a measure of energy quality, exergy is used to investigate technological processes, in addition to analyze the processes of power plants and of other mechanical machines;

- Exergy losses occur from irreversible process, which either cause reduction of the useful results of the process or increase use of energy from whatever source of derivation.

2.2. Brief Historical Background on Exergy

2.3. Relationship between Exergy and Other Energy Qualities

3. Exergy-Based Methods and Life Cycle Assessment

3.1. Exergy-Based Methods

3.1.1. Cumulative Exergy Demand (CExD)

3.1.2. Thermo-Ecological Cost (TEC)

3.1.3. Cumulative Exergy Extraction from Natural Environment (CExENE)

3.1.4. Industrial/Ecological Cumulative Exergy Demand (ICExD/ECExD)

3.1.5. Extended Exergy Accounting (EExA)

3.1.6. Comparison of the Exergy-Based Methods

3.2. Life Cycle Assessment

3.2.1. Goal and Scope Definition

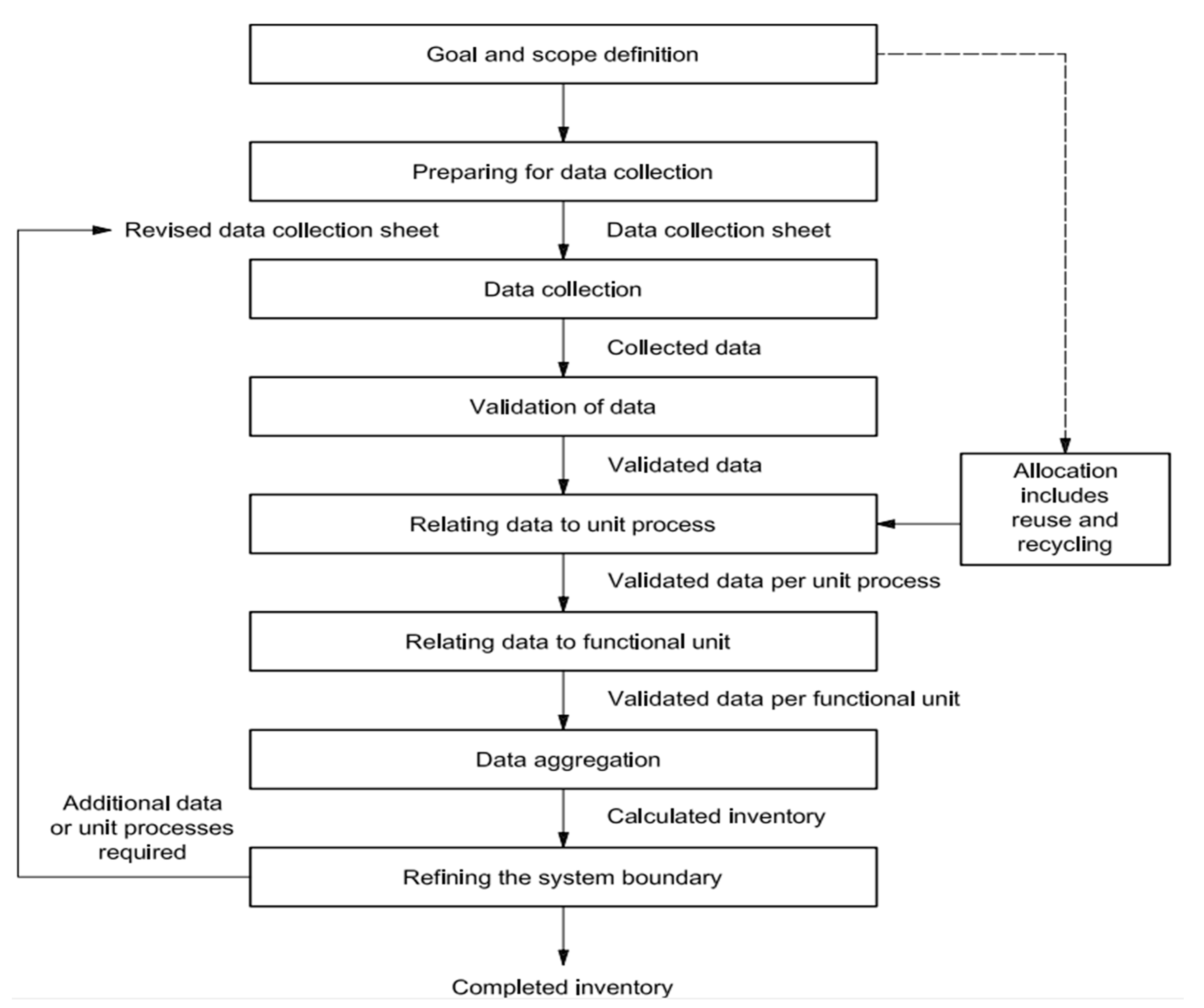

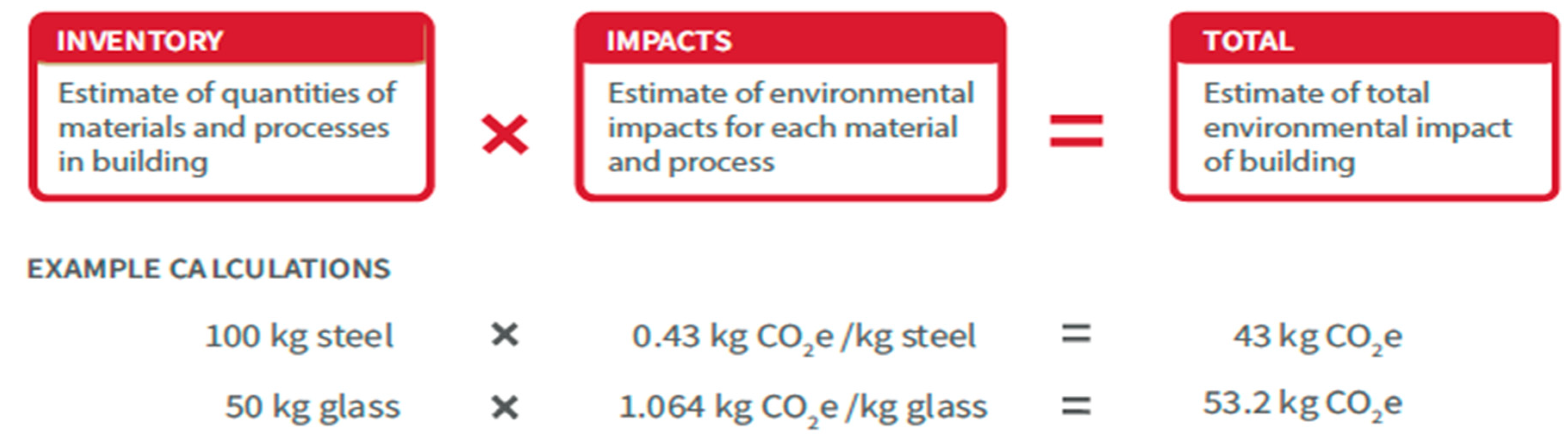

3.2.2. Life Cycle Inventory Analysis

3.2.3. Life Cycle Impact Assessment

3.2.4. Life Cycle Interpretation

3.3. Use of Exergy-Based Method in Life Cycle Assessment

- Process analysis which traces and evaluates exergy for the processes in the manufacturing of a product;

- Balance equations of cumulative exergy demand which utilizes a system of equations to express the CExD of products outcome as a summation of the cumulative exergy of the intermediate products and that of the natural resources extracted directly from the environment;

- Extension from cumulative energy consumption which calculates the CExD based on CED, which, in turn, can be obtained conveniently from commercial LCA tools.

4. A Review of Exergetic Life Cycle Assessment

4.1. Methodology for Articles Selection

- TI = "exergy life cycle assessment";

- TI = "exergetic life cycle assessment";

- TI = exerg* life cycle assessment;

- TS = "exerg* life cycle assessment".

4.2. Analysis of the Selected Articles

4.3. Findings from the Reviewed Studies

- The use of exergy method enables a sustainability assessment to be more objective and reasonable [63];

- The exergy indicator enables LCA to be expressed as a single objective function [24];

- The various exergy-based indicators have unique applications in various disciplines depending on the aim and objective of study [6];

- The CExD provides a more in-depth assessment than the conventionally used CEC [7];

- Use of exergy methods in LCA provides a more comprehensive measure of sustainability by accounting for non-energetic costs such as labor and capital [46];

- The use of the term “Exergetic LCA” was more popular than the use of the term “Exergy LCA” to describe the depletion of natural resources in terms of exergy loss over a life cycle;

- Exergetic LCA, as a field of study, is multi-disciplinary;

- The existing number of articles about exergetic life cycle assessment is few relative to the searched timeline, which implies that the subject is still emerging;

- Exergy analysis is most popular in disciplines such as environmental engineering, environmental sciences, energy fuels, thermodynamics, and mechanics;

- In terms of location, most of the publications are based in European countries.

5. Discussion

5.1. Exergetic Life Cycle Assessment and Benefit

- Fate—the amount of emissions released and the duration of the emitted substances in the environment;

- Exposure—determination of the species in the ecosystem exposed to the emissions;

- Effect—the resulting impact on the species in the ecosystem.

5.2. Opportunity for a More Comprehensive Exergetic Life Cycle Assessment

6. Summary and Conclusions

- Among others, exergy has importance and relevance in life cycle analysis, sustainability, energy systems, and built environment;

- Exergetic life cycle assessment is used for resource accounting in life cycle assessment;

- Exergy-based methods provide a more comprehensive measure of sustainability by accounting for both energetic and non-energetic resources such as labor, and capital;

- The existing studies use exergetic life cycle assessment as a supplement to conventional LCA in resource accounting;

- There is an opportunity for a more comprehensive exergetic life cycle assessment that includes exergy of life cycle emissions;

- A new terminology is required to describe a combination of exergy of life cycle resource use and exergy of life cycle emissions; “Exergy-based Life Cycle Assessment (Exe-LCA)” is proffered;

- Improved exergetic life cycle assessment has the potential to solve characterization and valuation problems in LCA methodology;

- The unification capacity of exergy-based method is a promising technique to achieving life cycle sustainability assessment.

Author Contributions

Funding

Conflicts of Interest

References

- Dincer, I.; Ratlamwala, T.A.H. Importance of exergy for analysis, improvement, design, and assessment. Energy Environ. 2013, 2, 335–349. [Google Scholar] [CrossRef]

- Favrat, D.; Maréchal, F.; Epelly, O. The challenge of introducing an exergy indicator in a local law on energy. Energy 2008, 33, 130–136. [Google Scholar] [CrossRef]

- Som, S.K.; Datta, A. Thermodynamic irreversibilities and exergy balance in combustion processes. Prog. Energy Combust. Sci. 2008, 34, 351–376. [Google Scholar] [CrossRef]

- Cornelissen, R.L.; Hirs, G.G. The value of the exergetic life cycle assessment besides the LCA. Energy Convers. Manag. 2002, 43, 1417–1424. [Google Scholar] [CrossRef]

- De Meester, B.; Dewulf, J.; Verbeke, S.; Janssens, A.; Van Langenhove, H. Exergetic life-cycle assessment (ELCA) for resource consumption evaluation in the built environment. Build. Environ. 2009, 44, 11–17. [Google Scholar] [CrossRef]

- Finnveden, G.; Arushanyan, Y.; Brandão, M. Exergy as a measure of resource use in life cycle assessment and other sustainability assessment tools. Resources 2016, 5, 23. [Google Scholar] [CrossRef]

- Bösch, M.E.; Hellweg, S.; Huijbregts, M.A.; Frischknecht, R. Applying cumulative exergy demand (CExD) indicators to the ecoinvent database. Int. J. Life Cycle Assess. 2007, 12, 181. [Google Scholar] [CrossRef]

- Morosuk, T.; Tsatsaronis, G.; Koroneos, C. Environmental impact reduction using exergy-based methods. J. Clean. Prod. 2016, 118, 118–123. [Google Scholar] [CrossRef]

- Wang, Q.; Ma, Y.; Li, S.; Hou, J.; Shi, J. Exergetic life cycle assessment of Fushun-type shale oil production process. Energy Convers. Manag. 2018, 164, 508–517. [Google Scholar] [CrossRef]

- Costa, M.M.; Schaeffer, R.; Worrell, E. Exergy accounting of energy and materials flows in steel production systems. Energy 2001, 26, 363–384. [Google Scholar] [CrossRef]

- Dewulf, J.; Van Langenhove, H. Assessment of the sustainability of technology by means of a thermodynamically based life cycle analysis. Environ. Sci. Pollut. Res. 2002, 9, 267–273. [Google Scholar] [CrossRef] [PubMed]

- Aleksic, S.; Mujan, V. Exergy-based life cycle assessment of smart meters. ELEKTRO 2016, 2016, 248–253. [Google Scholar]

- Dewulf, J.; Van Langenhove, H.; Mulder, J.; Van den Berg, M.M.D.; Van der Kooi, H.J.; De Swaan Arons, J. Illustrations towards quantifying the sustainability of technology. Green Chem. 2000, 2, 108–114. [Google Scholar] [CrossRef]

- Shukuya, M. Exergy concept and its application to the built environment. Build. Environ. 2009, 44, 1545–1550. [Google Scholar] [CrossRef]

- Sakulpipatsin, P.; Itard, L.C.M.; Van der Kooi, H.J.; Boelman, E.C.; Luscuere, P.G. An exergy application for analysis of buildings and HVAC systems. Energy Build. 2010, 42, 90–99. [Google Scholar] [CrossRef]

- Zmeureanu, R. Exergy-based index for assessing the building sustainability. Build. Environ. 2013, 60, 202–210. [Google Scholar]

- Romero, J.C.; Linares, P. Exergy as a global energy sustainability indicator. A review of the state of the art. Renew. Sustain. Energy Rev. 2014, 33, 427–442. [Google Scholar] [CrossRef]

- Sangi, R.; Müller, D. Exergy-based approaches for performance evaluation of building energy systems. Sustain. Cities Soc. 2016, 25, 25–32. [Google Scholar] [CrossRef]

- Meggers, F.; Ritter, V.; Goffin, P.; Baetschmann, M.; Leibundgut, H. Low exergy building systems implementation. Energy 2012, 41, 48–55. [Google Scholar] [CrossRef]

- Torio, H.; Angelotti, A.; Schmidt, D. Exergy analysis of renewable energy-based climatisation systems for buildings: A critical view. Energy Build. 2009, 41, 248–271. [Google Scholar] [CrossRef]

- Schlueter, A.; Thesseling, F. Building information model-based energy/exergy performance assessment in early design stages. Autom. Constr. 2009, 18, 153–163. [Google Scholar] [CrossRef]

- Cassetti, G.; Colombo, E. Minimization of local impact of energy systems through exergy analysis. Energy Convers. Manag. 2013, 76, 874–882. [Google Scholar] [CrossRef]

- Koroneos, C.; Tsarouhis, M. Exergy analysis and life cycle assessment of solar heating and cooling systems in the building environment. J. Clean. Prod. 2012, 32, 52–60. [Google Scholar] [CrossRef]

- Wang, W.; Zmeureanu, R.; Rivard, H. Applying multi-objective genetic algorithms in green building design optimization. Build. Environ. 2005, 40, 1512–1525. [Google Scholar] [CrossRef]

- Szargut, J.; Morris, D.R.; Steward, F.R. Exergy Analysis of Thermal, Chemical, and Metallurgical Processes, 1st ed.; Hemisphere Publishing Corporation: New York, NY, USA, 1988. [Google Scholar]

- Lombardi, L. Life cycle assessment (LCA) and exergetic life cycle assessment (ELCA) of a semi-closed gas turbine cycle with CO2 chemical absorption. Energy Convers. Manag. 2001, 42, 101–114. [Google Scholar] [CrossRef]

- Peiró, L.T.; Lombardi, L.; Méndez, G.V.; i Durany, X.G. Life cycle assessment (LCA) and exergetic life cycle assessment (ELCA) of the production of biodiesel from used cooking oil (UCO). Energy 2010, 35, 889–893. [Google Scholar] [CrossRef]

- Sui, X.; Zhang, Y.; Shao, S.; Zhang, S. Exergetic life cycle assessment of cement production process with waste heat power generation. Energy Convers. Manag. 2014, 88, 684–692. [Google Scholar] [CrossRef]

- Guven, S. Calculation of optimum insulation thickness of external walls in residential buildings by using exergetic life cycle cost assessment method: Case study for Turkey. Environ. Prog. Sustain. Energy 2019, 38, e13232. [Google Scholar] [CrossRef]

- Li, Q.; Song, G.; Xiao, J.; Hao, J.; Li, H.; Yuan, Y. Exergetic life cycle assessment of hydrogen production from biomass staged-gasification. Energy 2020, 190, 116416. [Google Scholar] [CrossRef]

- Szargut, J. International progress in second law analysis. Energy 1980, 5, 709–718. [Google Scholar] [CrossRef]

- Srinivasan, R.; Moe, K. The Hierarchy of Energy in Architecture: Emergy Analysis, 1st ed.; Routledge: New York, NY, USA, 2015. [Google Scholar]

- Bejan, A.; Tsatsaronis, G.; Moran, M.J. Thermal Design and Optimization, 1st ed.; John Wiley & Sons: New York, NY, USA, 1995. [Google Scholar]

- Shukuya, M.; Hammache, A. Introduction to the Concept of Exergy for a Better Understanding of Low-Temperature Heating and High-Temperature Cooling Systems; VTT Technical Research Centre of Finland: Espoo, Finland, 2002. [Google Scholar]

- Bejan, A. Entropy Generation Minimization: The Method of Thermodynamic Optimization of Finite-Size Systems and Finite-Time Processes, 1st ed.; CRC Press: New York, NY, USA, 2013. [Google Scholar]

- Odum, H.T. Environmental Accounting: Emergy and Environmental Decision Making; John Wiley & Sons: New York, NY, USA, 1996. [Google Scholar]

- Bastianoni, S.; Facchini, A.; Susani, L.; Tiezzi, E. Emergy as a function of exergy. Energy 2007, 32, 1158–1162. [Google Scholar] [CrossRef]

- Rosen, M.A.; Dincer, I. Exergoeconomic analysis of power plants operating on various fuels. Appl. Therm. Eng. 2003, 23, 643–658. [Google Scholar] [CrossRef]

- Meyer, L.; Tsatsaronis, G.; Buchgeister, J.; Schebek, L. Exergoenvironmental analysis for evaluation of the environmental impact of energy conversion systems. Energy 2009, 34, 75–89. [Google Scholar] [CrossRef]

- Morosuk, T. Exergoenvironmental analysis is a new tool for evaluation of an energy conversion system. Енергетика та автоматика 2013, 4, 3–14. [Google Scholar]

- Tsatsaronis, G.; Morosuk, T. Understanding and improving energy conversion systems with the aid of exergy–based methods. Int. J. Exergy 2012, 11, 518–542. [Google Scholar] [CrossRef]

- Szargut, J.; Stanek, W. Thermo-ecological optimization of a solar collector. Energy 2007, 32, 584–590. [Google Scholar] [CrossRef]

- Dewulf, J.; Bösch, M.E.; Meester, B.D.; Vorst, G.V.D.; Langenhove, H.V.; Hellweg, S.; Huijbregts, M.A. Cumulative exergy extraction from the natural environment (CEENE): A comprehensive life cycle impact assessment method for resource accounting. Environ. Sci. Technol. 2007, 41, 8477–8483. [Google Scholar] [CrossRef]

- Hau, J.L.; Bakshi, B.R. Expanding exergy analysis to account for ecosystem products and services. Environ. Sci. Technol. 2004, 38, 3768–3777. [Google Scholar] [CrossRef]

- Yang, S.; Yang, S.; Qian, Y. The inclusion of economic and environmental factors in the ecological cumulative exergy consumption analysis of industrial processes. J. Clean. Prod. 2015, 108, 1019–1027. [Google Scholar] [CrossRef]

- Ukidwe, N.U.; Bakshi, B.R. Industrial and ecological cumulative exergy consumption of the United States via the 1997 input–output benchmark model. Energy 2007, 32, 1560–1592. [Google Scholar] [CrossRef]

- Sciubba, E. From engineering economics to extended exergy accounting: A possible path from monetary to resource-based costing. J. Ind. Ecol. 2004, 8, 19–40. [Google Scholar] [CrossRef]

- Dai, J.; Chen, B.; Sciubba, E. Ecological accounting based on extended exergy: A sustainability perspective. Environ. Sci. Technol. 2014, 48, 9826–9833. [Google Scholar] [CrossRef] [PubMed]

- Dewulf, J.; Van Langenhove, H.; Muys, B.; Bruers, S.; Bakshi, B.R.; Grubb, G.F.; Paulus, D.M.; Sciubba, E. Exergy: Its potential and limitations in environmental science and technology. Environ. Sci. Technol. 2008, 42, 2221–2232. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040. Environmental Management–Life Cycle Assessment–Principles and Framework; British Standards Institution: London, UK, 2006. [Google Scholar]

- Grant, A.; Ries, R.; Kibert, C. Life cycle assessment and service life prediction. J. Ind. Ecol. 2014, 18, 187–200. [Google Scholar] [CrossRef]

- Nwodo, M.N.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 106290. [Google Scholar] [CrossRef]

- Bovea, M.D.; Powell, J.C. Developments in life cycle assessment applied to evaluate the environmental performance of construction and demolition wastes. Waste Manag. 2016, 50, 151–172. [Google Scholar] [CrossRef]

- Rashid, A.F.A.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Bayer, C.; Gamble, M.; Gentry, R.; Joshi, S. AIA Guide to Building Life Cycle Assessment in Practice; The American Institute of Architects: Washington, DC, USA, 2010. [Google Scholar]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Seo, S.; Tucker, S.; Newton, P. Automated material selection and environmental assessment in the context of 3D building modelling. J. Green Build. 2007, 2, 51–61. [Google Scholar] [CrossRef]

- Bare, J. TRACI 2.0: The tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean Technol. Environ. Policy 2011, 13, 687–696. [Google Scholar] [CrossRef]

- Margni, M.; Curran, M.A. Life cycle impact assessment. In Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products; Curran, M.A., Ed.; John Wiley & Sons: New York, NY, USA, 2012. [Google Scholar]

- Hollberg, A.; Ruth, J. LCA in architectural design—A parametric approach. Int. J. Life Cycle Assess. 2016, 21, 943–960. [Google Scholar] [CrossRef]

- Huang, M. Life Cycle Assessment of Buildings: A Practice Guide, 1st ed.; The Carbon Leadership Forum, Department of Architecture, University of Washington: Seattle, WA, USA, 2018. [Google Scholar]

- Zeng, R.; Chini, A. A review of research on embodied energy of buildings using bibliometric analysis. Energy Build. 2017, 155, 172–184. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Zhao, Y.; Li, Z.; Zheng, C. Exergy life cycle assessment model of “CO2 zero-emission” energy system and application. Sci. China Technol. Sci. 2011, 54, 3296–3303. [Google Scholar] [CrossRef]

- Alvarenga, R.A.; Dewulf, J.; Van Langenhove, H.; Huijbregts, M.A. Exergy-based accounting for land as a natural resource in life cycle assessment. Int. J. Life Cycle Assess. 2013, 18, 939–947. [Google Scholar] [CrossRef]

- Acıkkalp, E.; Hepbasli, A.; Yucer, C.T.; Karakoc, T.H. Advanced exergoenvironmental assessment of a building from the primary energy transformation to the environment. Energy Build. 2015, 89, 1–8. [Google Scholar] [CrossRef]

- Laner, D.; Rechberger, H.; De Soete, W.; De Meester, S.; Astrup, T.F. Resource recovery from residual household waste: An application of exergy flow analysis and exergetic life cycle assessment. Waste Manag. 2015, 46, 653–667. [Google Scholar] [CrossRef]

- Ashouri, M.; Astaraei, F.R.; Ghasempour, R.; Ahmadi, M.H.; Feidt, M. Optimum insulation thickness determination of a building wall using exergetic life cycle assessment. Appl. Therm. Eng. 2016, 106, 307–315. [Google Scholar] [CrossRef]

- Rocco, M.V.; Di Lucchio, A.; Colombo, E. Exergy life cycle assessment of electricity production from waste-to-energy technology: A hybrid input-output approach. Appl. Energy 2017, 194, 832–844. [Google Scholar] [CrossRef]

- Milanovic, B.; Agarski, B.; Vukelic, D.; Budak, I.; Kiss, F. Comparative exergy-based life cycle assessment of conventional and hybrid base transmitter stations. J. Clean. Prod. 2017, 167, 610–618. [Google Scholar] [CrossRef]

- Xie, H.; Gong, G.; Fu, M.; Wang, P.; Li, L. A thermodynamic method to calculate energy & exergy consumption and CO2 emission of building materials based on economic indicator. Build. Simul. 2018, 11, 235–244. [Google Scholar]

- Ghannadzadeh, A.; Meymivand, A. Environmental sustainability assessment of an ethylene oxide production process through Cumulative Exergy Demand and ReCiPe. Clean Technol. Environ. Policy 2019, 21, 1765–1777. [Google Scholar] [CrossRef]

- Zhang, Q.; Gao, J.; Wang, Y.; Wang, L.; Yu, Z.; Song, D. Exergy-based analysis combined with LCA for waste heat recovery in coal-fired CHP plants. Energy 2019, 169, 247–262. [Google Scholar] [CrossRef]

- Sun, B.; Liu, Y.; Nie, Z.; Gao, F.; Wang, Z.; Cui, S. Exergy-based resource consumption analysis of cement clinker production using natural mineral and using calcium carbide sludge (CCS) as raw material in China. Int. J. Life Cycle Assess. 2020, 25, 667–677. [Google Scholar] [CrossRef]

- Açıkkalp, E.; Kandemir, S.Y.; Altuntaş, Ö.; Karakoç, T.H. Exergetic approach to determine optimum insulation thickness for cooling applications with life cycle integrated economic analysis. Int. J. Exergy 2020, 30, 307–321. [Google Scholar] [CrossRef]

- Farajzadeh, R.; Zaal, C.; van Den Hoek, P.; Bruining, J. Life-cycle assessment of water injection into hydrocarbon reservoirs using exergy concept. J. Clean. Prod. 2019, 235, 812–821. [Google Scholar] [CrossRef]

- Antonio, V.C.; Alicia, V.C. Thanatia: Thermodynamics of mineral resources. In The Destiny of the Earth’s Mineral Resources: A Thermodynamic Cradle-to-Cradle Assessment, 1st ed.; Yun, A., Ed.; World Scientific Publishing: Hackensack, NJ, USA, 2014; pp. 253–290. [Google Scholar] [CrossRef]

- Dassisti, M.; Semeraro, C.; Chimenti, M. Hybrid Exergetic Analysis-LCA approach and the Industry 4.0 paradigm: Assessing Manufacturing Sustainability in an Italian SME. Procedia Manuf. 2019, 33, 655–662. [Google Scholar] [CrossRef]

- Rosen, M.A.; Dincer, I. Exergy analysis of waste emissions. Int. J. Energy Res. 1999, 23, 1153–1163. [Google Scholar] [CrossRef]

- Nwodo, M.N. Investigation of Exergy-Based Life Cycle Assessment of Buildings. Ph.D. Thesis, University of Florida, Gainesville, FL, USA, 2020. [Google Scholar]

- Kloepffer, W. Life cycle sustainability assessment of products. Int. J. Life Cycle Assess. 2008, 13, 89–95. [Google Scholar] [CrossRef]

- Simpson, A.P.; Edwards, C.F. An exergy-based framework for evaluating environmental impact. Energy 2011, 36, 1442–1459. [Google Scholar] [CrossRef]

| Topic | Importance | References |

|---|---|---|

| Life cycle analysis | Exergy enables the analysis of cumulative consumption of resources | [5,6] |

| Exergetic LCA is a more appropriate approach to quantify the environmental problem of the depletion of natural resources | [4,6] | |

| Exergy provides additional indicator for LCA, energy efficiency, and resource quality need | [7,8,9] | |

| Production processes | Exergy analysis accounts for exergy losses and efficiencies and thus provides a more accurate inventory | [10] |

| Exergy quantifies various results of manufacture, use and disposal of goods, and services on a single scale—exergy loss | [11,12] | |

| Technological sustainability | Exergy enables both qualitative and quantitative evaluations of resource consumptions | [5,13] |

| Built environment | Exergy concept deepens the understanding of space heating and cooling to develop low-exergy systems for future buildings | [14,15] |

| Sustainability index | Exergy-based index overcomes the limitations of the subjectively defined weights used in other sustainability assessment tools | [16,17] |

| Energy systems | Exergy analysis evaluates the performance of energy systems to optimize their efficiencies | [18,19,20,21] |

| Global impacts | By improving the efficiency of a process, exergy analysis reduces global impacts related to the process | [22,23] |

| Exergy-Based Method | Scope | Limitations |

|---|---|---|

| Cumulative exergy demand | Measures energy quality, exergy losses of materials, and emissions | Limited to exergy losses of natural resource; excludes that of the ecological system |

| Thermo-ecological cost | Focus on cumulative consumption of non-renewable primary exergy resources | It does not include renewable primary exergy resources |

| Cumulative exergy extraction from natural environment | Measures quality of energetic and non-energetic resources, and land occupation | It does not track exergy transferred into the technological system |

| Industrial/ecological cumulative exergy demand | Focus on exergy losses in the industrial and ecological stages of a production chain | It is limited to production processes |

| Extended exergy accounting | Resource equivalent value of a commodity including labor, capital, and environmental emissions | It is intrinsically limited to time and region |

| Parameter | Setting |

|---|---|

| Keywords | Exergy, exergetic, exergies, life cycle assessment |

| Type | Article or review |

| Time Span | 1990–2018 (December) |

| Citation Index | SCI-EXPANDED, SSCI, A&HCI, ESCI |

| Language | All languages |

| Article | Aim | Method | Result/Discussion | Conclusion |

|---|---|---|---|---|

| [24] | To develop a multi-objective optimization model for green building structure design | Case study; life cycle analysis methodology; expanded cumulative exergy consumption | The expanded cumulative exergy consumption method enabled LCA to be classified into one objective function | The multi-objective optimization model can be used to locate optimum or near optimum green building designs |

| [43] | To initiate an extensive resource-based life cycle impact assessment method based on exergy concept | Cumulative Exergy Extraction from the Natural Environment (CExENE) | Fossil resources and land use had high CExENE scores when applied to materials in ecoinvent database | Although they differ in concept, CExENE is like CExD but further includes land use |

| [7] | To apply CExD indicators to ecoinvent database | CExD; use of resources in the ecoinvent database | In comparison to CED, non-energy resources are likely weighted more strongly by the CExD method | CExD is a more in-depth indicator than CED |

| [42] | To optimize thermo-ecological cost of a solar collector | Thermo-ecological cost; case study | The depletion of non-renewable natural exergy resources is the objective function for thermo-ecological optimization | The formulated objective function could also be used in economic optimization by introducing purchase prices |

| [46] | To develop a thermodynamic input-output model of the 1997 U.S. economy | Thermodynamic Input-Output Analysis; Industrial (I)CExD; Ecological (E)CExD | ICExD/money and ECExD/money ratios are useful to perform thermodynamic LCA at economy and ecosystem scales | The model and data encourage the development of sustainable engineering |

| [5] | To quantify the embodied and operational energy and materials for a family dwelling in Belgium | Case study; CExD; use of resources in the ecoinvent database | Findings show that annual CExD is around 65 GJexergy/year, with a minimal reliance on the construction type | Reduction of heating requirements is necessary to make family dwellings less fossil resource dependent |

| [63] | Use of exergy LCA model to assess a 2 × 300 MW coal-fired power plant | Cumulative Exergy Demand (CExD) | Direct exergy (i.e., operational fuel consumption) input accounted for about 93% while indirect exergy input accounted for about 7% | Using exergy as the basic physical parameter made the assessment more objective and reasonable |

| [23] | Exergy analysis and LCA of solar heating and cooling systems in the building environment in Greece | Exergy model; LCA framework; case study | Solar cooling system has high environmental impacts because of the fan coil units and the cooling tower | The environmental impacts of the systems are significant only at the production phase of their life cycle |

| [64] | Proposes and implements a framework for exergy-based accounting for land as a natural resource in LCA | Framework; case studies | Site-dependent characterization factors allow for spatial differentiation in exergetic LCA | Using exergy, the framework was able to account for more comprehensive land resources |

| [48] | To present the sustainability perspective of ecological accounting based on extended exergy | Extended Exergy Accounting (EExA); case study | An extended exergy-based sustainability index system was established to assess the performance of flows in the system | EExA can be used to rate the sustainability level of a place or process |

| [65] | To determine the environmental effects of a heating system at various stages in building using exergy and LCA | Advanced exergo- environmental analysis | Environmental effects of the exogenous and preventable exergy destruction rates are low | Advanced exergo- environmental analysis provides information not included in the conventional exergy analysis |

| [66] | To determine the efficiencies of recovering resources from household waste based on exergy analysis and Exergetic LCA | Exergy flow analysis; CExENE for Exergetic LCA | The exergy flow analysis showed scenario efficiencies of between 17% and 27% while Exergetic LCA had about 14% | Cumulative exergy consumption measures in waste LCA should be complimented by other impact categories |

| [67] | To conduct an optimization of thickness of insulation in a building wall based on Exergetic LCA | Case study | Sensitivity analysis shows that temperature affects total exergetic environmental impact | Walls with lower optimized insulation thickness show increased net savings and fewer payback periods |

| [6] | Use of case studies to illustrate and compare exergy-based thermodynamic approach with other approaches | Case studies | Different methods produced strikingly different results; this shows the need to be clear about the scope and limitations of the methods | There is a solid scientific base for thermodynamic approach based on exergy; results can be relevant for decision-making |

| [68] | Exergetic LCA of electricity production from waste-to-energy technology | Hybrid Input-Output method; case study | Primary non-renewable exergy embodied in electricity is non-negligible for both the construction and the operation phases | Joint application of exergy analysis and Exergetic LCA improved the overall thermodynamic performances of the system |

| [69] | Comparative exergy-based LCA of conventional and hybrid base transmitter stations | Cumulative Exergy Demand | The results elaborated the means of development and sources of environmental impacts during the systems’ life cycles | Such details provide the basis for the evolvement and production of sustainable products and processes |

| [70] | In production phase, to evaluate energy, exergy use, and CO2 emission of building materials | Thermodynamic method; case study | Although life cycle energy use and life cycle CO2 emissions are correlated, the latter was higher than the former in production phase | Thermodynamic method practically and significantly improves sustainable building evaluation tools and in making energy policies in building sector |

| [71] | Environmental sustainability evaluation of an ethylene oxide manufacturing process using CExD and ReCiPe | CExD and ReCiPe | Reduction in environmental impacts expressed in MJ (CExD) and dimensionless (ReCiPe) | CExD is useful in sustainability evaluation of process technology |

| [72] | Exergy-based study of coal-fired power generation | Case studies | Exergy-based method was successfully used to evaluate the thermal, economic, and environmental benefits | Exergy-based method can improve efficiency of systems |

| [73] | Exergy-based quantification of resource use during cement clinker production | CExD method | Chemical exergy provided an improved understanding of the resource use | Theoretical gap is needed to be filled in CExD characterization models |

| [74] | Environmental and economic optimization of insulation thickness | Exergy-based life cycle integrated economic analysis | The approach enabled comparative analysis between environment, economy, and both effects | Exergy-based method enables optimization of environmental and economic effects |

| [75] | Exergy-based LCA of water injection into hydrocarbon reservoirs | Exergy-based method | Exergy quantified efficiency and CO2 emission during the process | Exergy method is important even in water driven recovery of oil |

| [30] | Exergetic LCA of hydrogen production | CExD method | Exergy measures deviation levels of emissions from the reference environment | Exergetic life cycle environmental model is based on LCA and exergy theory |

| [76] | A thermodynamic assessment with a cradle-to-cradle view | Second law of thermodynamics (Exergy law) | Energy and materials dissipate and deteriorate, and quality is lost irreversibly | Exergy explains the need for global management of the earth’s resources |

| [77] | Assessment of manufacturing sustainability | Hybrid analysis (LCA and Exergy) | While LCA can estimate resource use, exergy includes quality of resource use | Exergy predicts ideal solution, which informs process improvement |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nwodo, M.N.; Anumba, C.J. Exergetic Life Cycle Assessment: A Review. Energies 2020, 13, 2684. https://doi.org/10.3390/en13112684

Nwodo MN, Anumba CJ. Exergetic Life Cycle Assessment: A Review. Energies. 2020; 13(11):2684. https://doi.org/10.3390/en13112684

Chicago/Turabian StyleNwodo, Martin N., and Chimay J. Anumba. 2020. "Exergetic Life Cycle Assessment: A Review" Energies 13, no. 11: 2684. https://doi.org/10.3390/en13112684

APA StyleNwodo, M. N., & Anumba, C. J. (2020). Exergetic Life Cycle Assessment: A Review. Energies, 13(11), 2684. https://doi.org/10.3390/en13112684