The Flow Characteristics of Supercritical Carbon Dioxide (SC-CO2) Jet Fracturing in Limited Perforation Scenarios

Abstract

1. Introduction

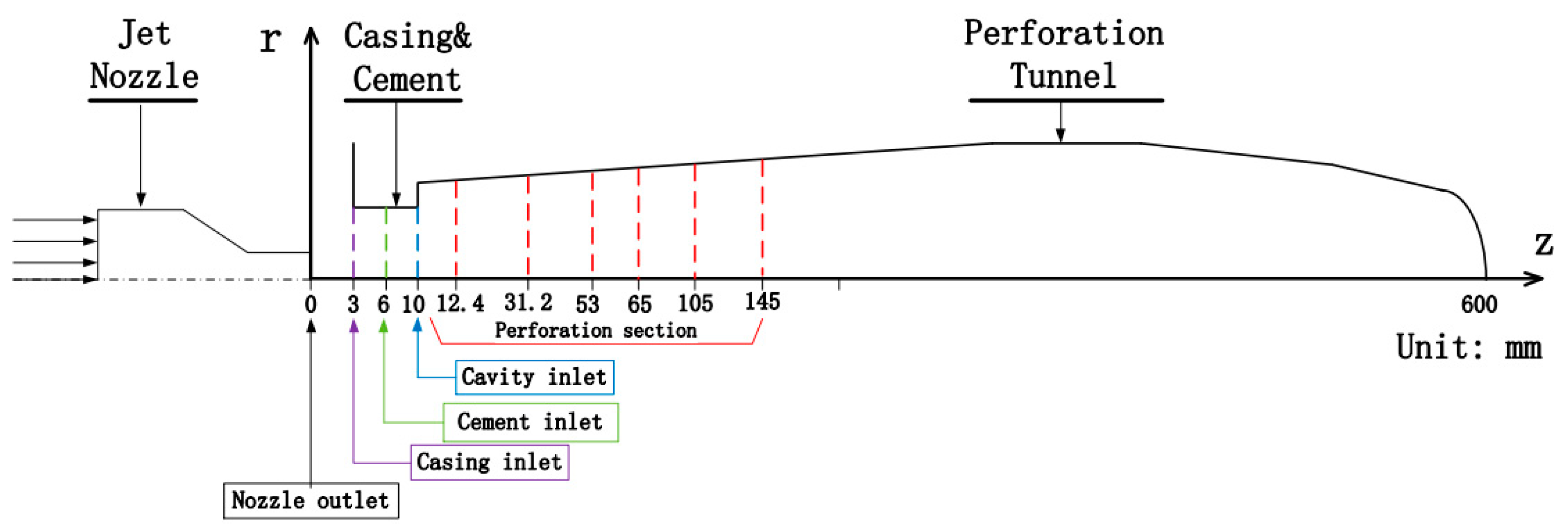

2. Models and Methods

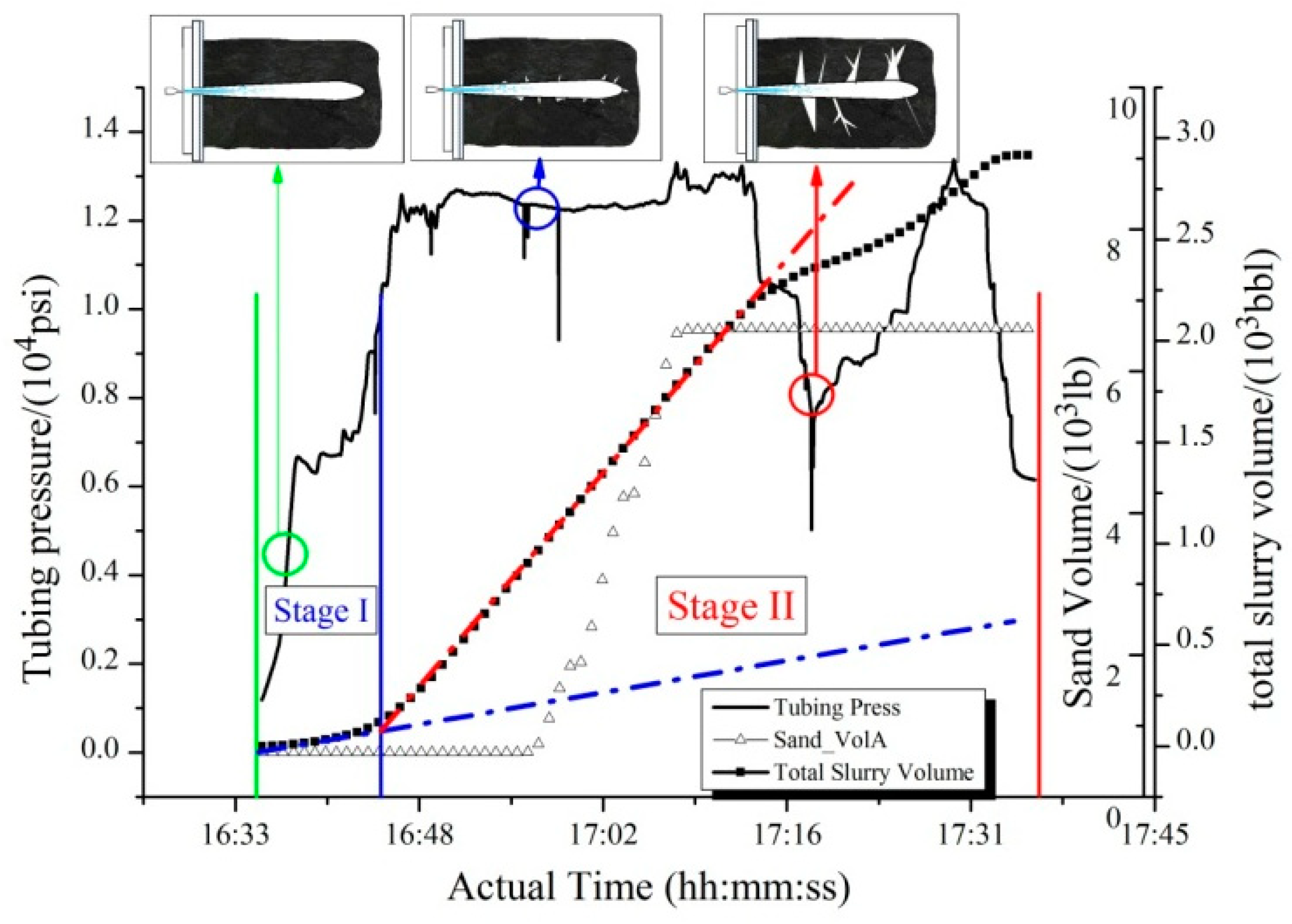

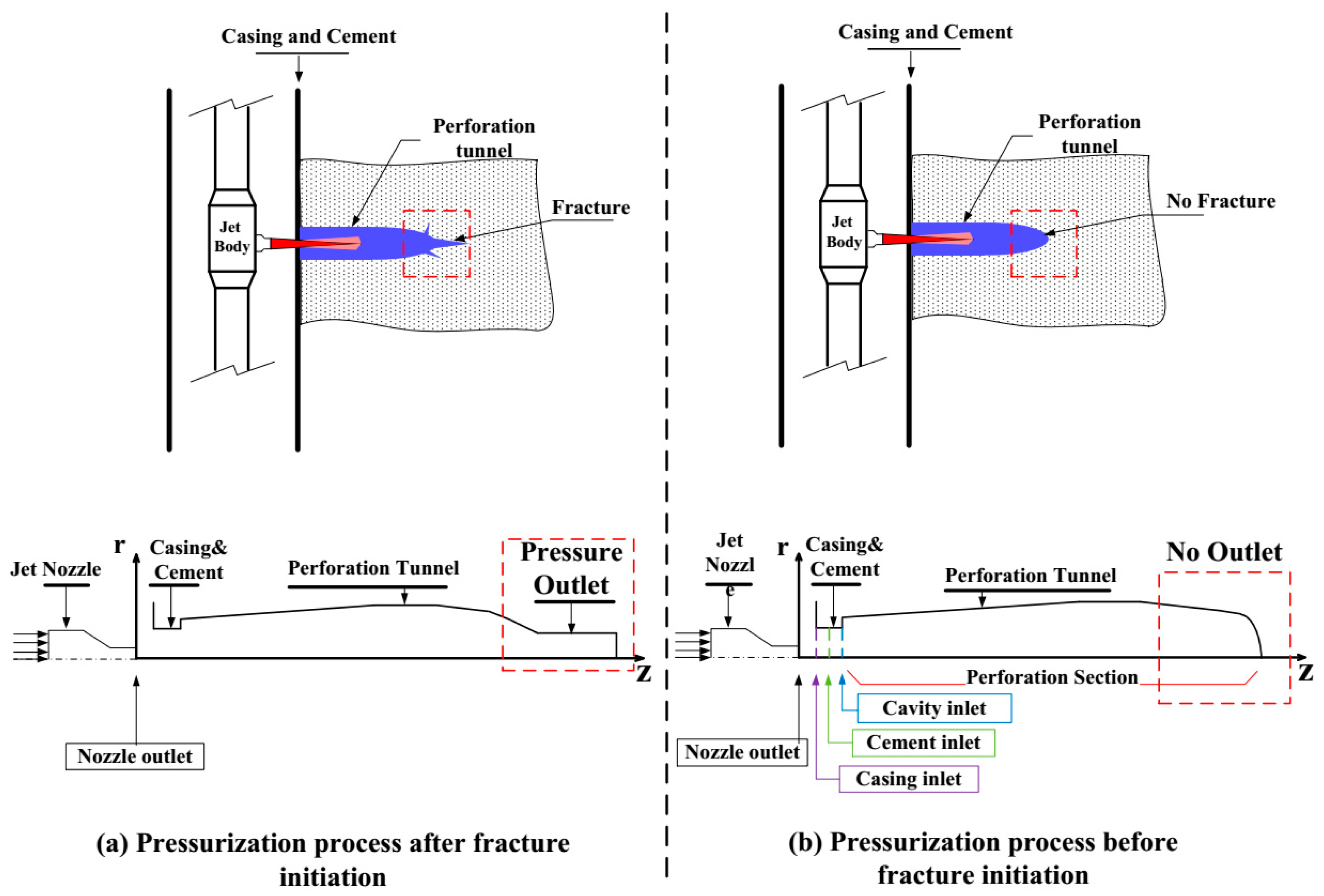

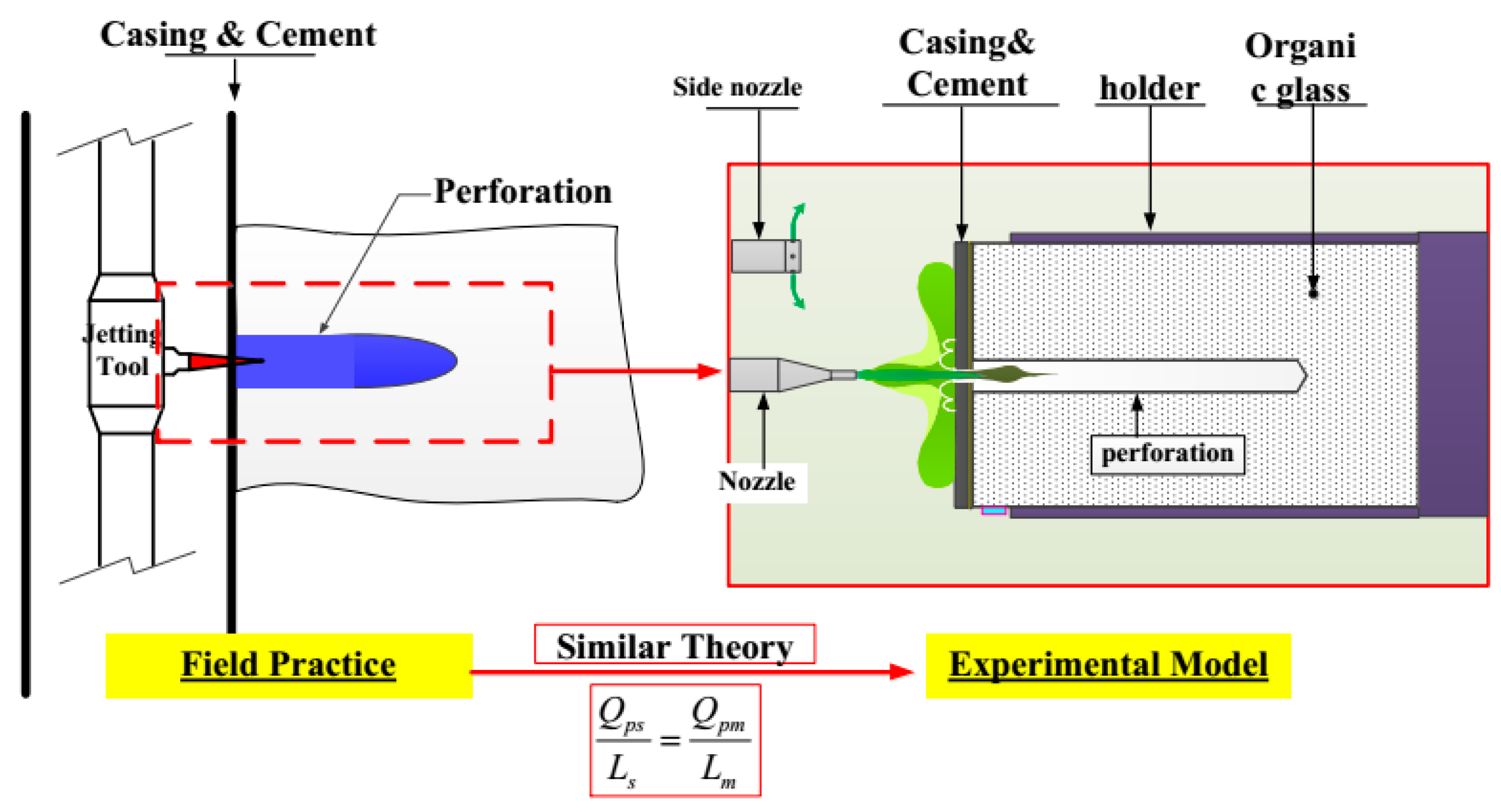

2.1. Engineering Background

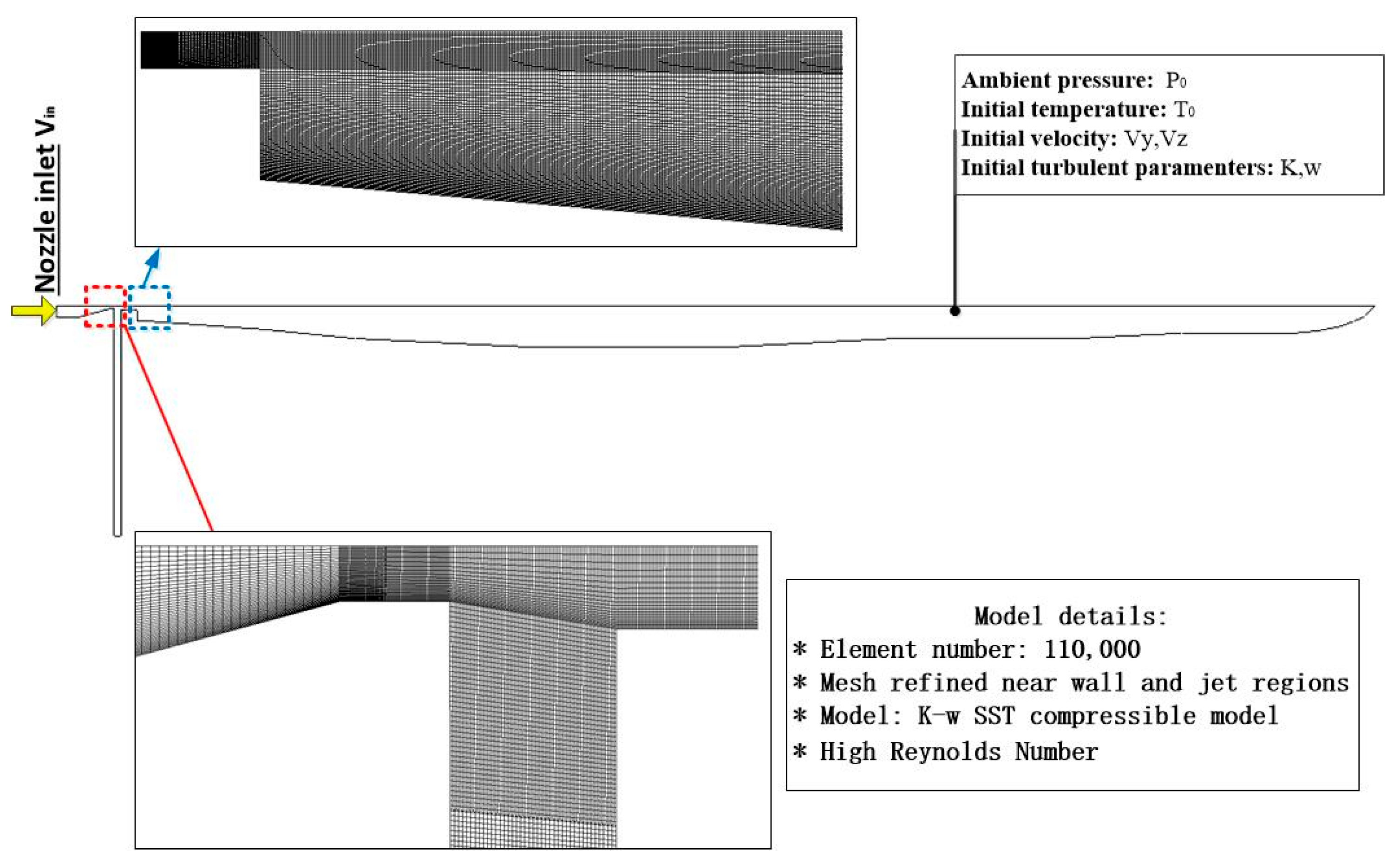

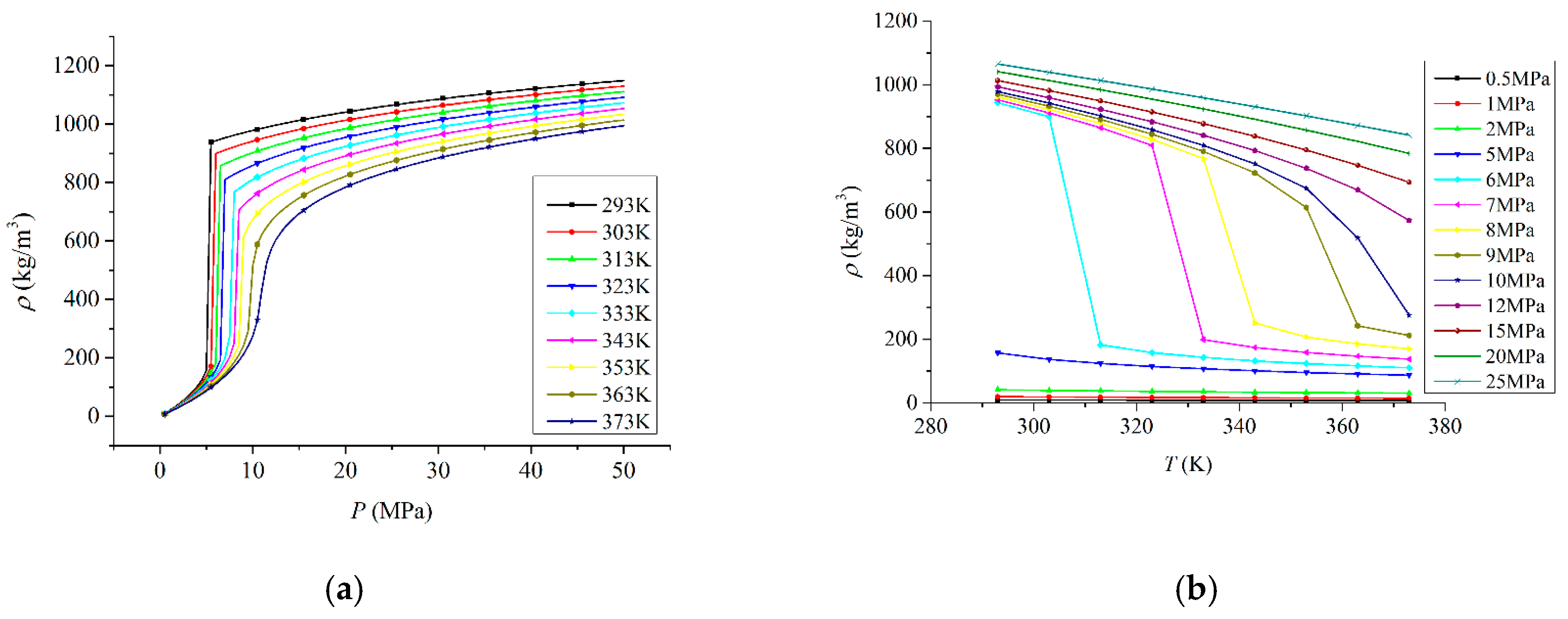

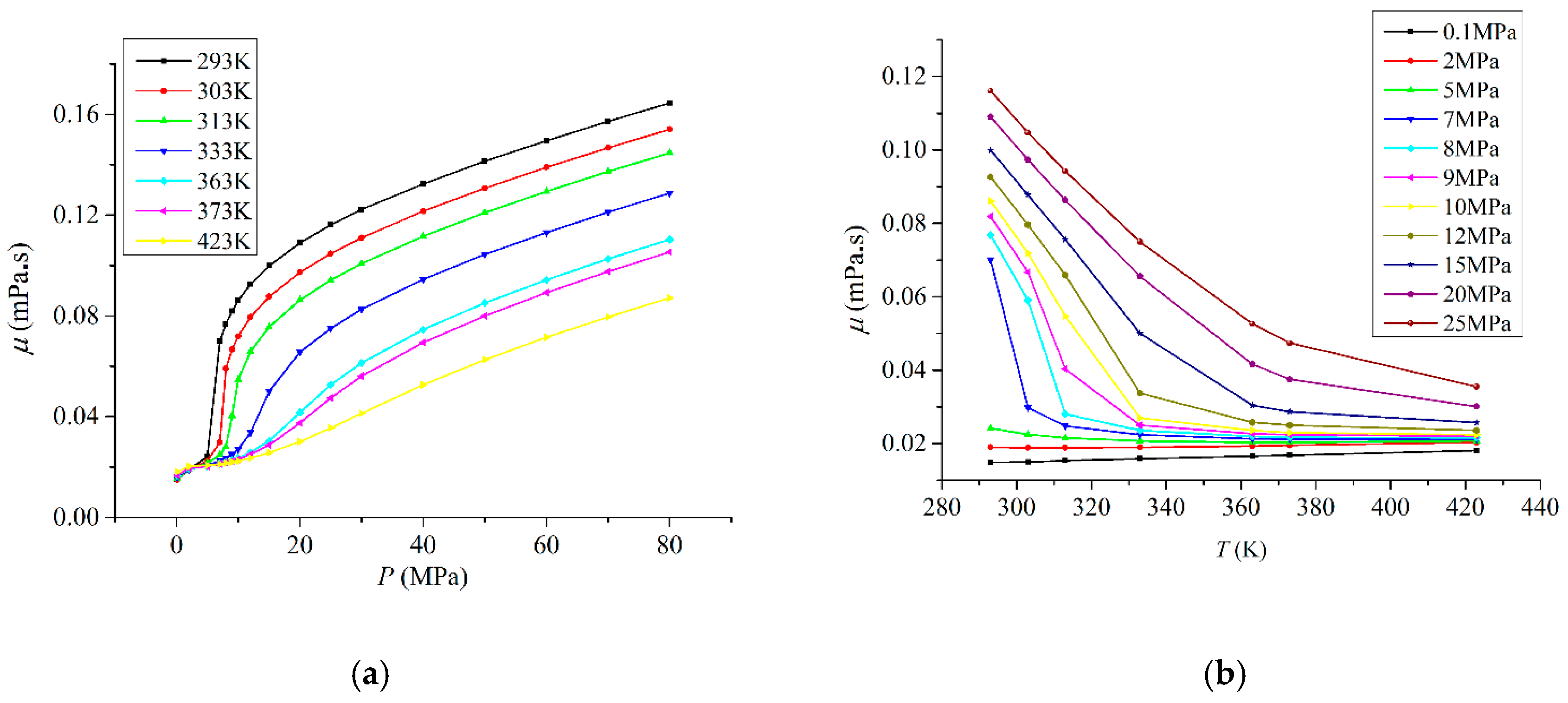

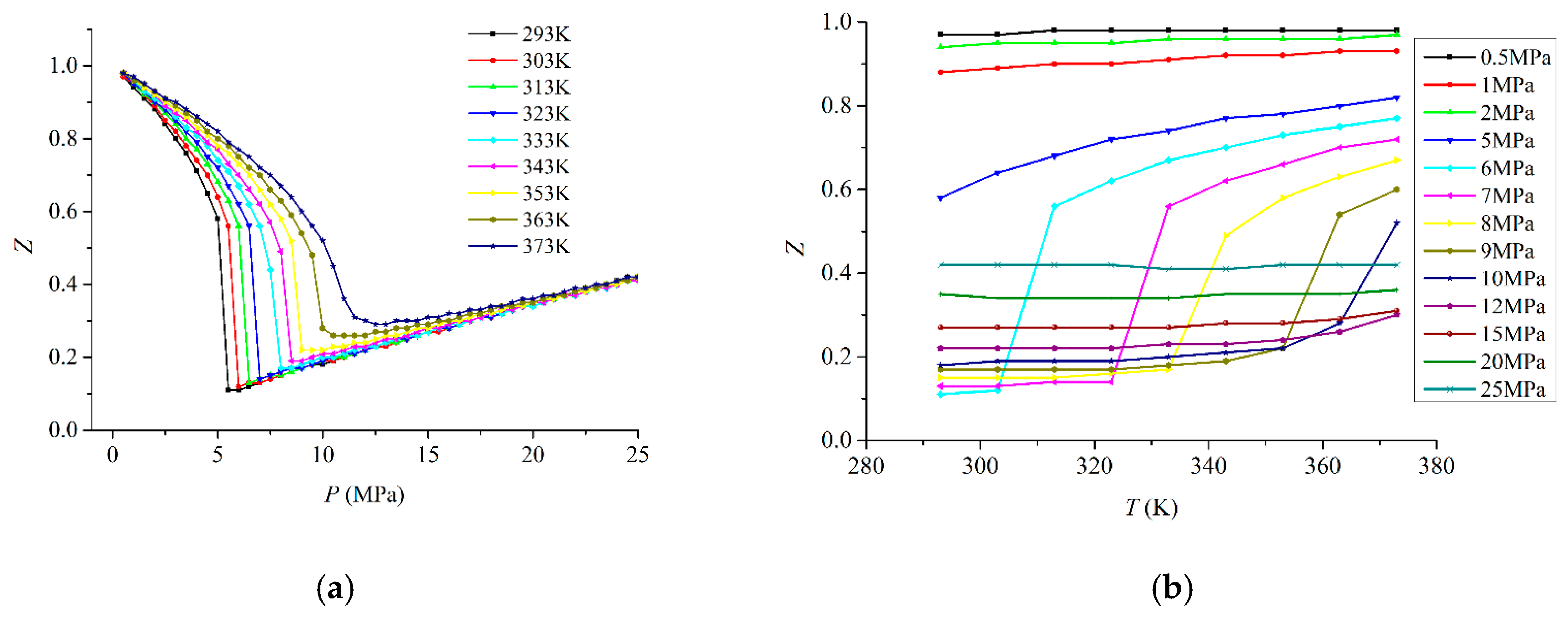

2.2. Numerical Model and CO2 Physical Characteristic

3. Results

3.1. Verification of Numerical Results

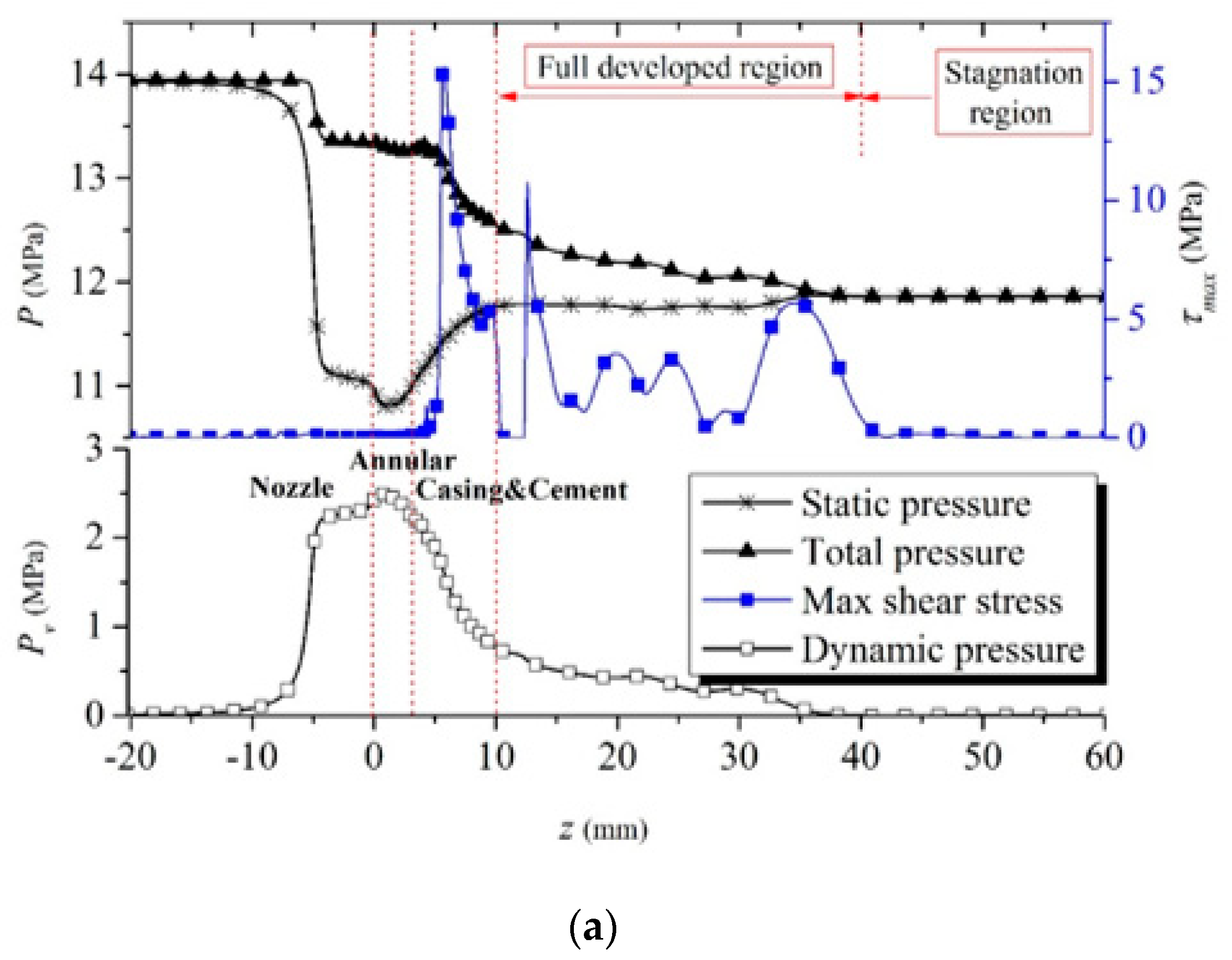

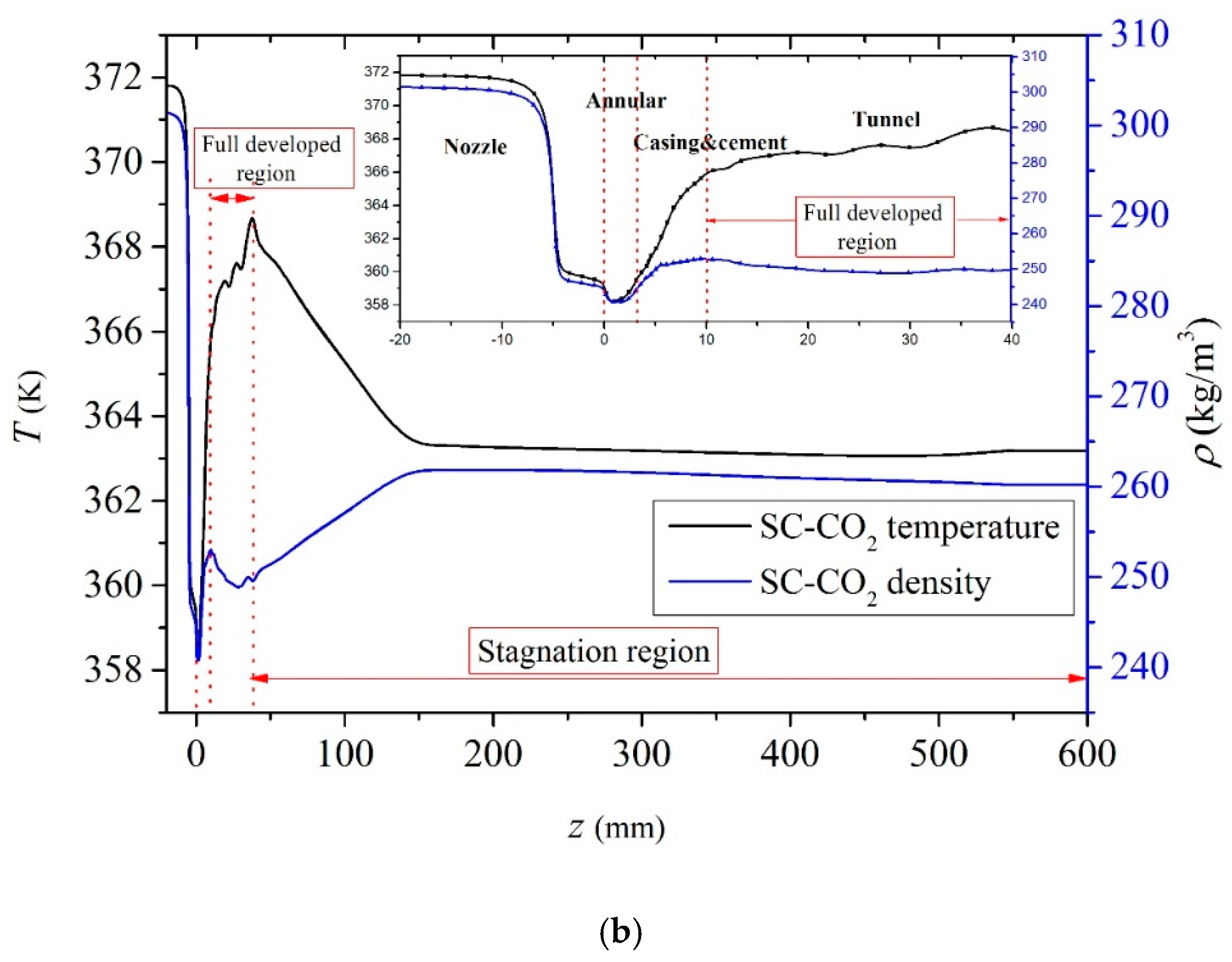

3.2. The Pressurization in Limited Perforation

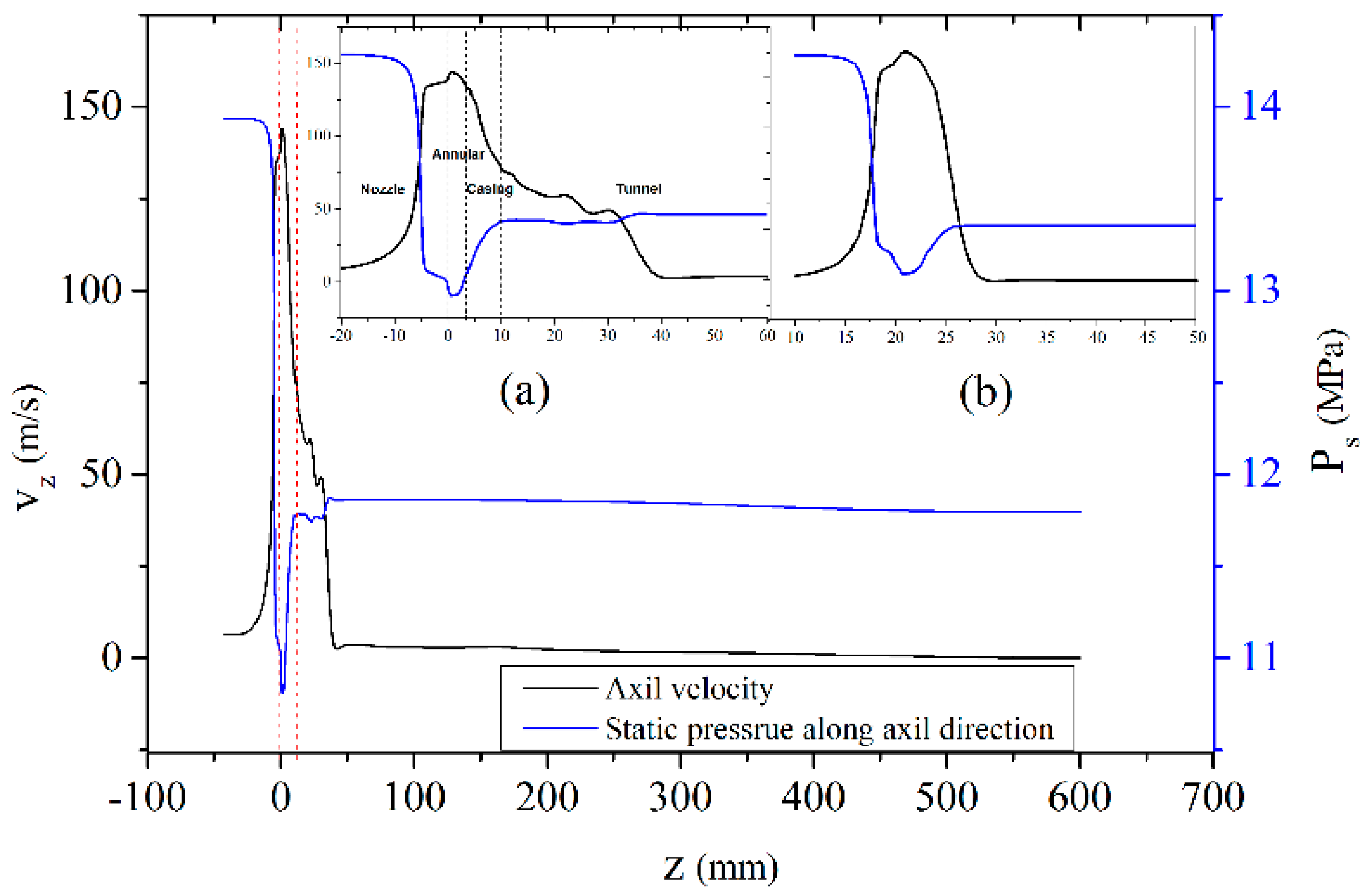

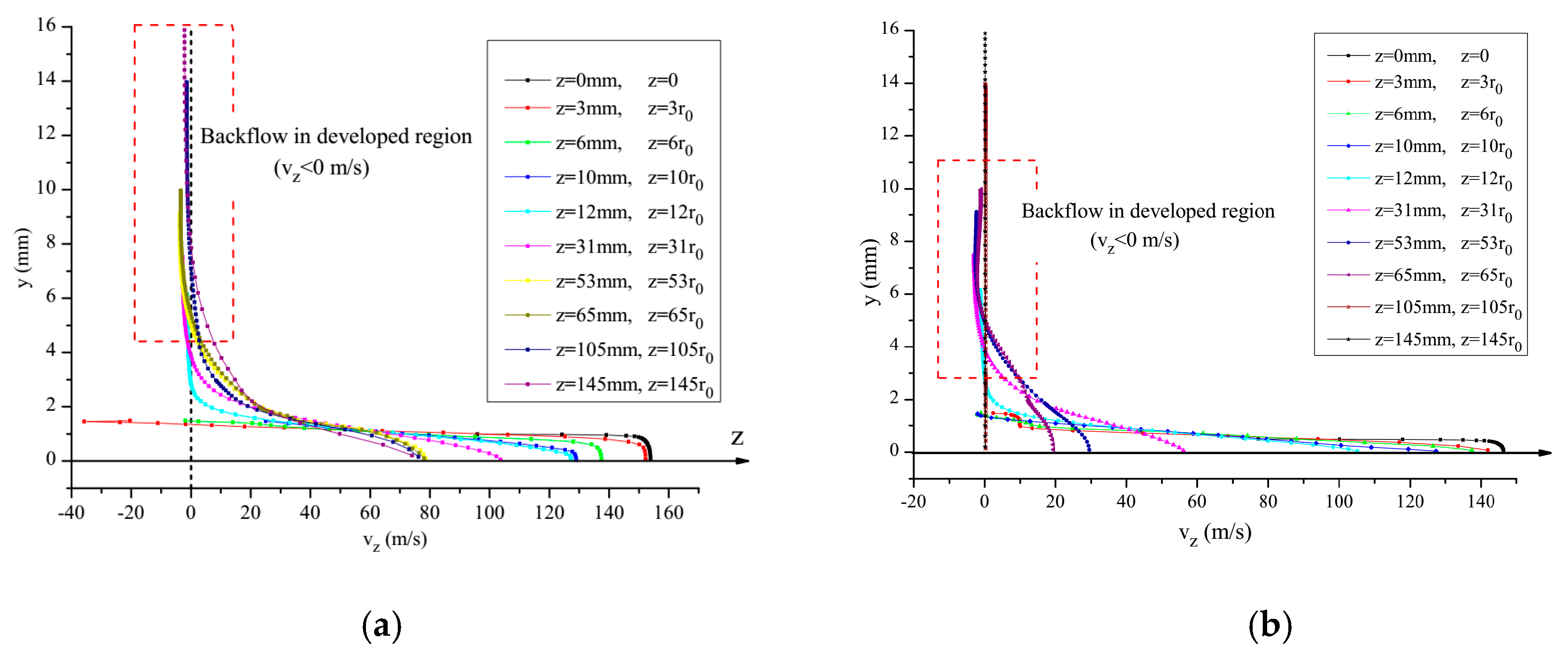

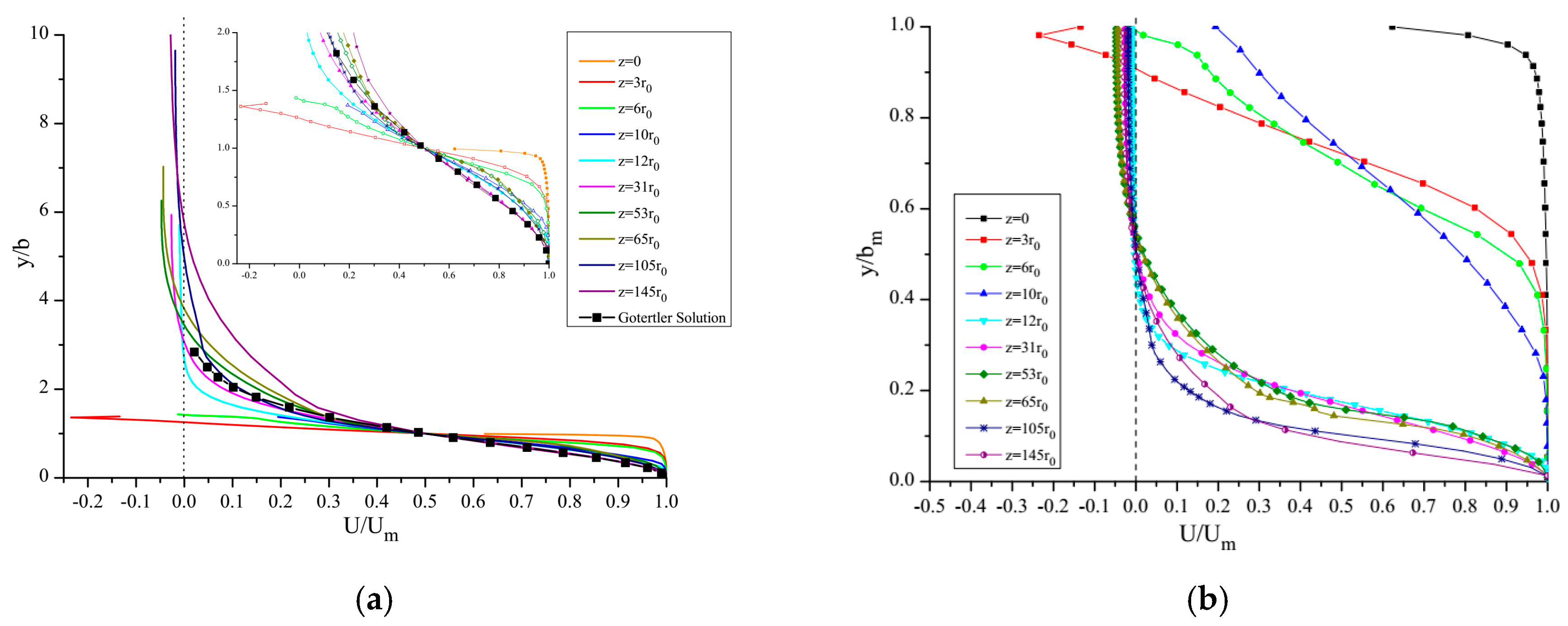

3.3. The Velocity Distribution in Limited Perforation

4. Discussion

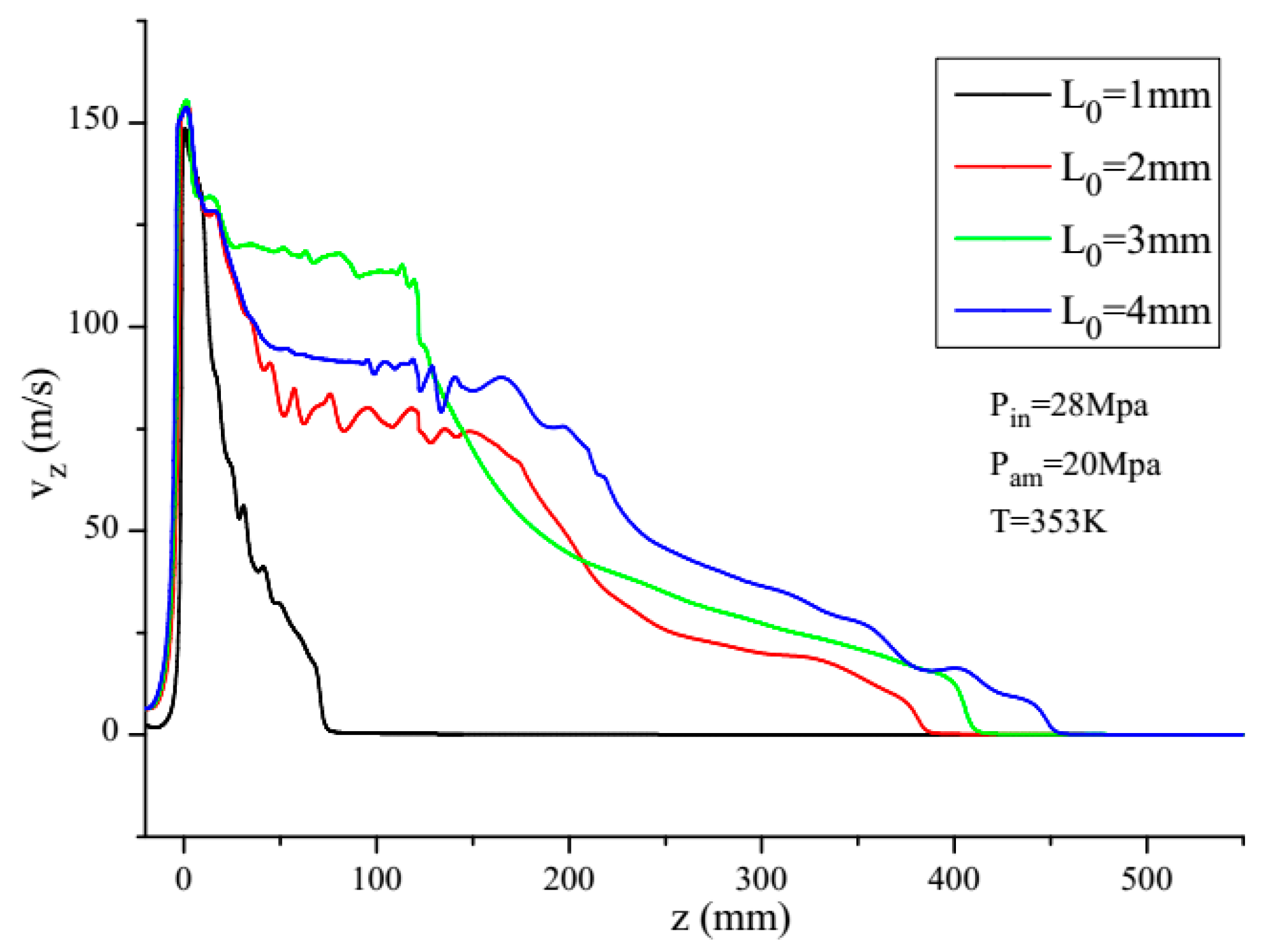

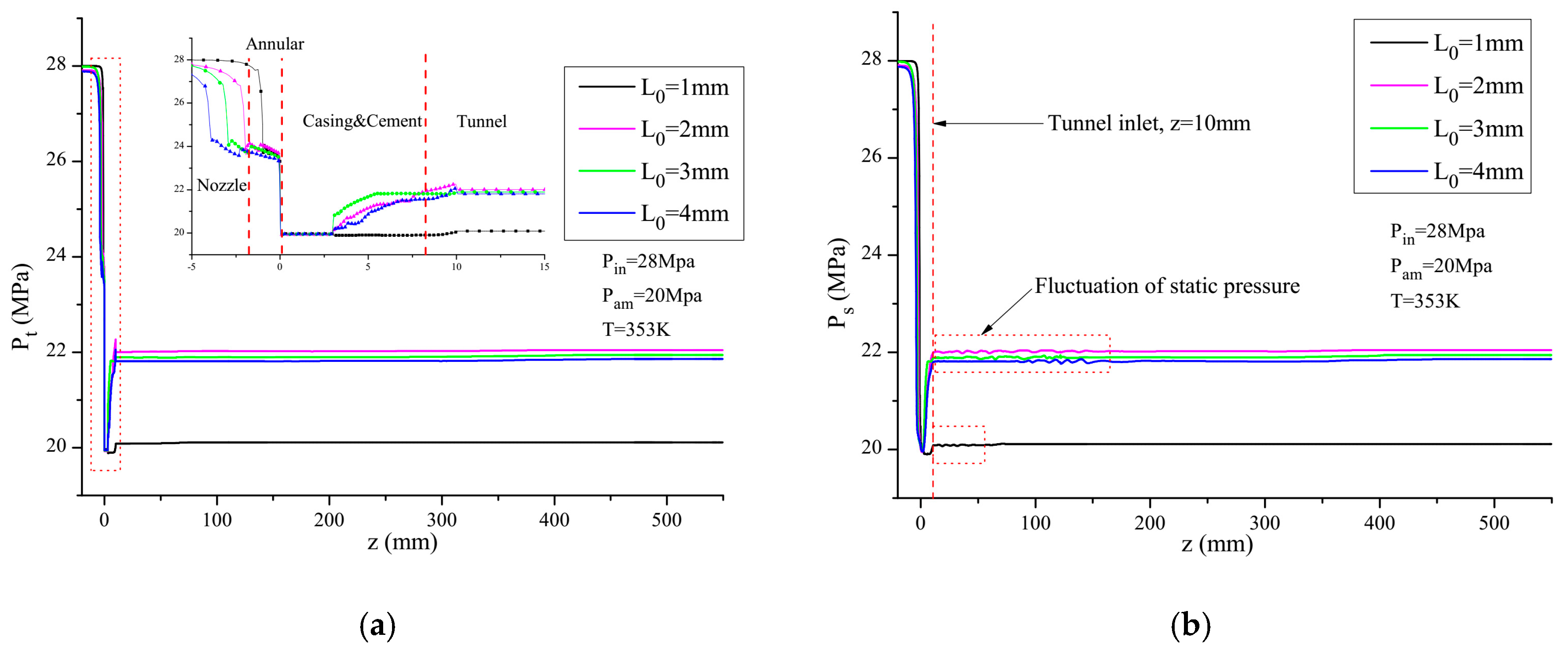

4.1. The Effect of Nozzle Outlet Length

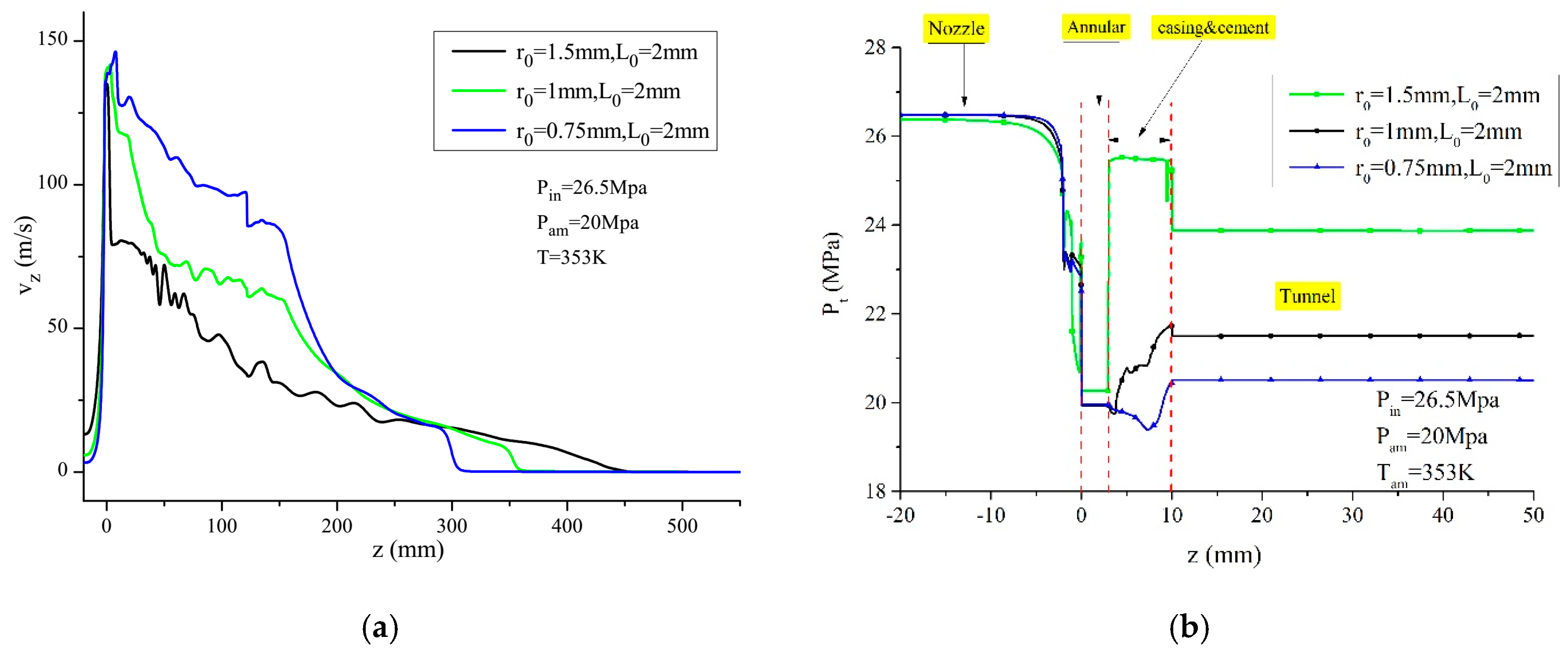

4.2. The Effect of Nozzle Outlet Radius

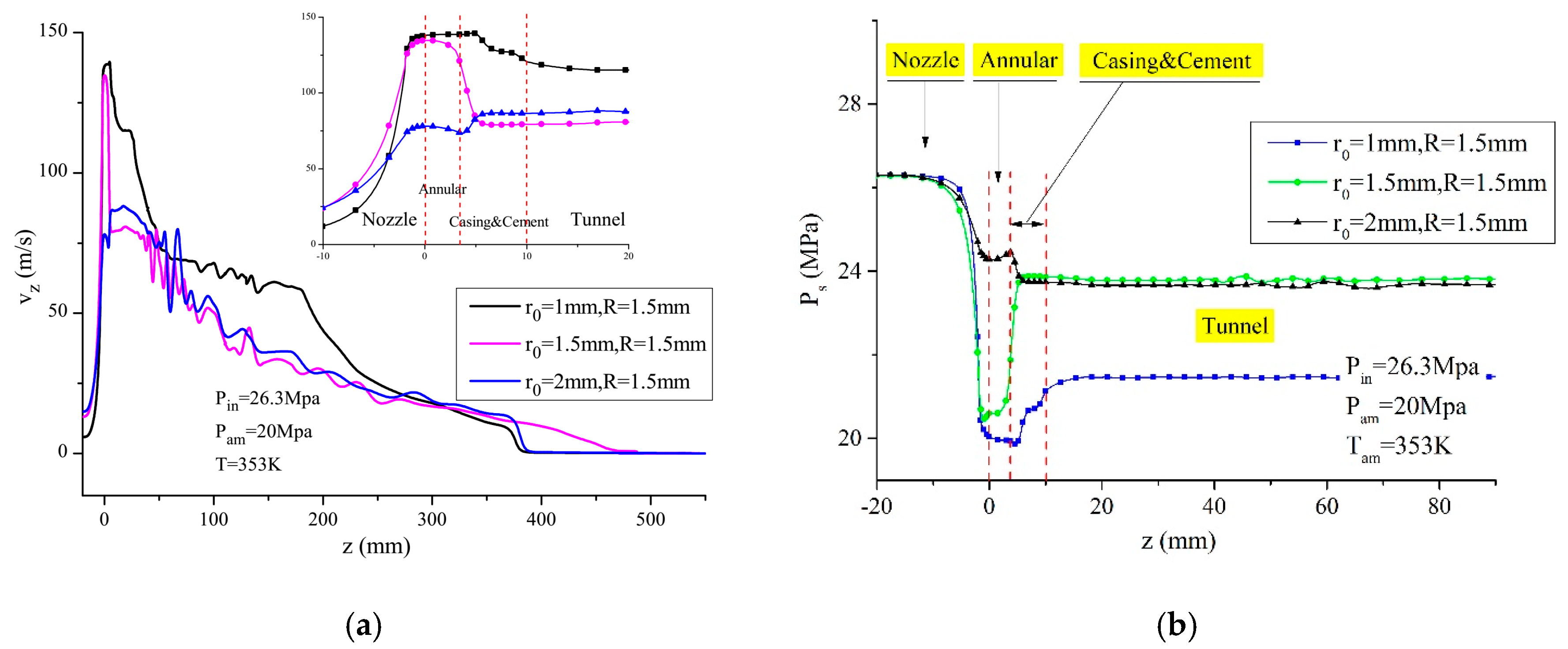

4.3. The Effect of Aperture Ratio

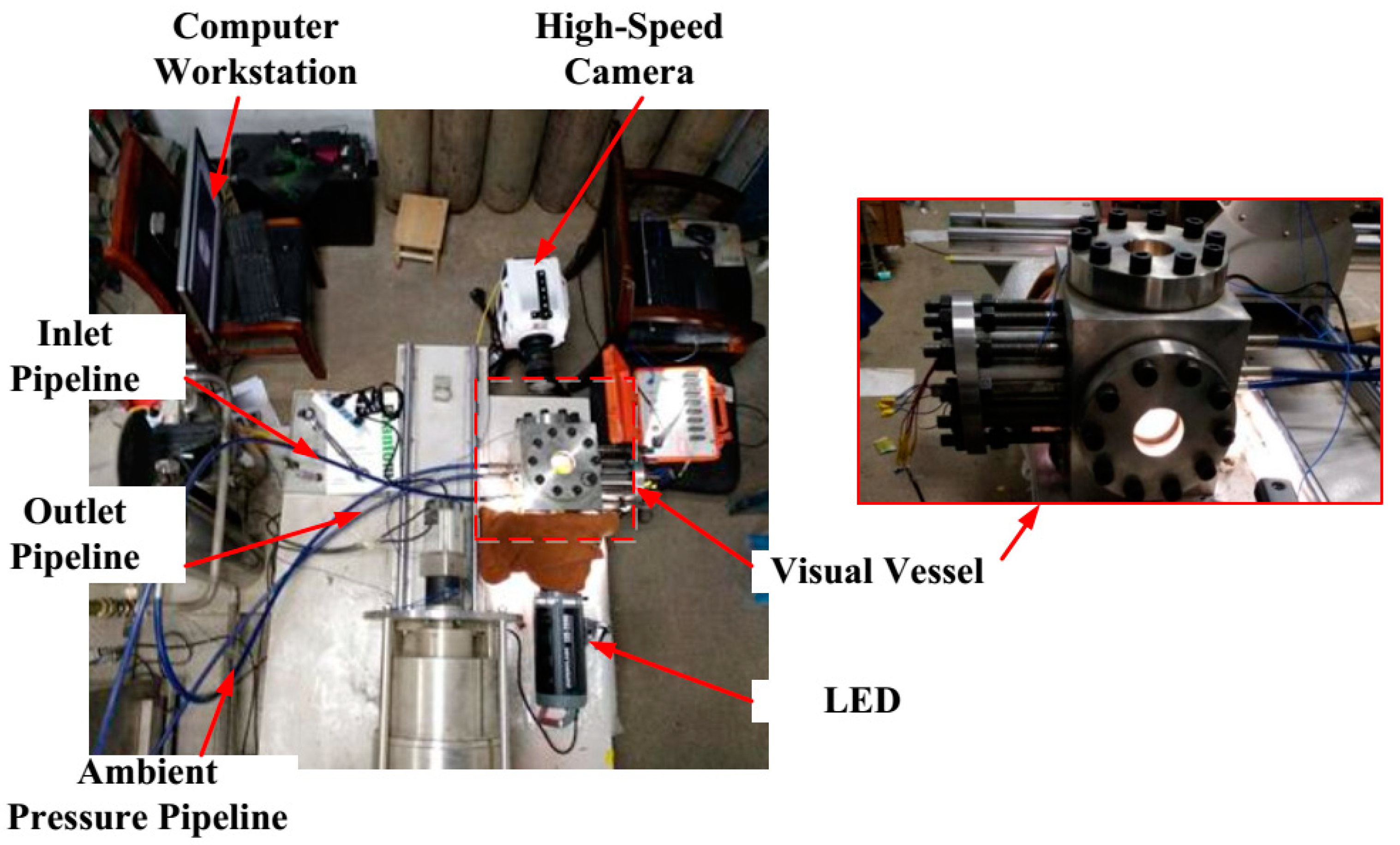

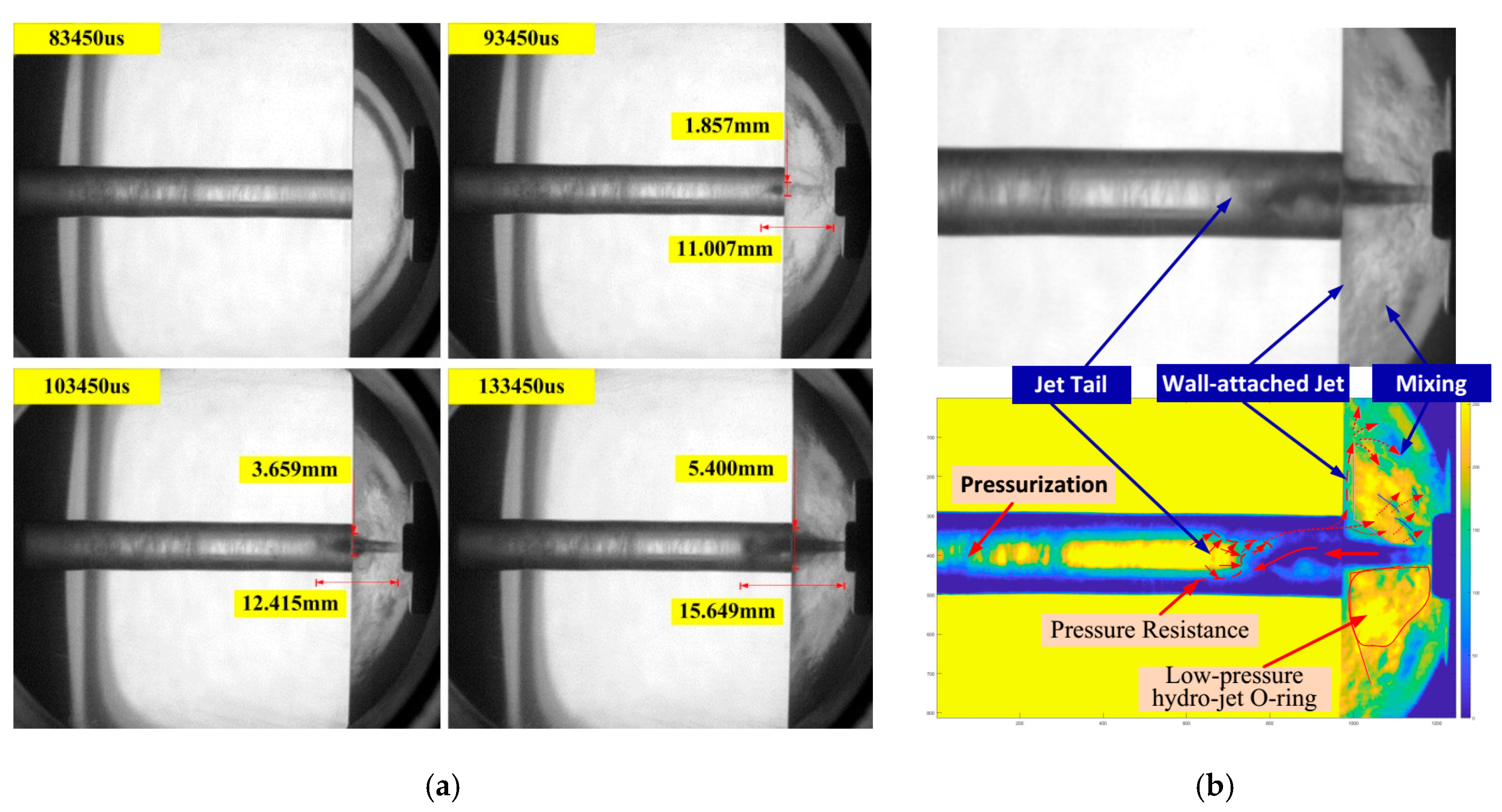

4.4. The Similar Experiments of SC-CO2 Jet Flowing

5. Conclusions

- (1)

- In the fully developed region of the SC-CO2 jet, the max shear stress dramatically fluctuates between 1 MPa and 11 MPa during SC-CO2 jet boosting, which means strongly turbulent mixing occurs in the fully developed region. On the perforation wall surface, the axial velocity reduces to even less than 0 m/s, resulting in a backflow in the perforation tunnel.

- (2)

- The structure of the nozzle outlet distinctly affects the pressurization of the SC-CO2 jet. With the decreasing length of the nozzle outlet, the axial velocity drops more sharply in the annular and casing and cement sections. Moreover, when the diameter of the nozzle outlet increases, the axial velocity drops faster in the annular section and the boosting pressure becomes higher.

- (3)

- The aperture ratio between the nozzle outlet and casing perforation inlet significantly affects the jet flow field in SC-CO2 jet fracturing, resulting in the disappearance of the “hydraulic isolation ring” and a decrease of the boosting pressure.

- (4)

- Based on the similarity theory, High-Speed Photography results clearly show that the SC-CO2 develops into full jetting in only 0.07 s and there exists a strong mixing in the annular region between the jet core and the environment according to the numerical simulation.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| x, y, z | Third local coordinate, mm |

| r | Radial direction coordinate, mm |

| Specific heat at constant pressure, kJ/kg⋅K | |

| Specific heat at constant volume, kJ/kg⋅K | |

| T | Temperature, K |

| Critical temperature, K | |

| t | Time, s |

| μ | Fluid viscosity, pa sa⋅s |

| Z | Compressibility coefficient, - |

| ρ, | Density and critical density, kg/ |

| , | Pressure, critical pressure, MPa |

| , | Static and dynamic pressure, MPa |

| Total pressure, MPa | |

| Nozzle inlet pressure, MPa | |

| Ambient pressure, MPa | |

| Ambient temperature, K | |

| Critical specific volume, | |

| Specific gas constant, - | |

| k | Kinetic energy of turbulence, - |

| ω | Specific dissipation rate of turbulence, - |

| Axial velocity, m/s | |

| vmax | Max axial velocity, m/s |

| Max shear stress. MPa | |

| , | Constants of PR equation, - |

| Acentric factor, - | |

| V | specific Volume, |

| n | Constants of PR equation, - |

| d | Nozzle outlet diameter, mm |

| l | Nozzle outlet length, mm |

| r0 | Nozzle outlet radius, mm |

| rmax | Max radius of the perforation tunnel, mm |

| Inlet diameter of casing, mm | |

| R | Radius of casing tunnel cross-section, mm |

| Reynolds number, dimensionless | |

| ϕ | Dimensionless axial velocity, - |

| η | Dimensionless radius, - |

| γ | Dimensionless radius, - |

| Tf | Internal friction, N |

| μ | Viscosity, Pa.s |

| A | area, m2 |

| F | Inertia force, N |

| Res | Reynolds number in experimental model, - |

| μs | Viscosity in experimental model, Pa.s |

| Ls | Length in experimental model, m |

| vs | Velocity in experimental model, m/s |

| ρs | Density in experimental model, kg/m3 |

| Qps | Flow rate in experimental model, m3/s |

| Rem | Reynolds number in field practice, - |

| μm | Viscosity in field practice, Pa.s |

| Lm | Length in field practice, m |

| vm | Velocity in field practice, m/s |

| ρm | Density in field practice, kg/m3 |

| Qpm | Flow rate field practice, m3/s |

References

- Middleton, R.; Viswanathan, H.; Currier, R.; Gupta, R. CO2 as a fracturing fluid: Potential for commercial-scale shale gas production and CO2 sequestration. Energy Procedia 2014, 63, 7780–7784. [Google Scholar] [CrossRef]

- He, L.; Feng, W.; Zhang, J.; Siwei, M.; Yongwei, D. Fracturing with carbon dioxide: Application status and development trend. Pet. Explor. Dev. 2014, 41, 513–519. [Google Scholar]

- Middleton, R.S.; Carey, J.W.; Currier, R.P.; Hyman, J.D.; Kang, Q.; Karra, S.; Jiménez-Martínez, J.; Porter, M.L.; Viswanathan, H.S. Shale gas and non-aqueous fracturing fluids: Opportunities and challenges for supercritical CO2. Appl. Energy 2015, 147, 500–509. [Google Scholar] [CrossRef]

- Kolle, J.J. Coiled-tubing Drilling with Supercritical Carbon Dioxide, SPE 65534; Society of Petroleum Engineers: Richardson, TX, USA, 2000. [Google Scholar]

- Du, Y.K.; Wang, R.H.; Ni, H.J.; Li, M.K.; Song, W.Q.; Song, H.F. Determination of rock-breaking performance of high-pressure supercritical carbon dioxide jet. J. Hydrodyn. Ser. B 2012, 24, 554–560. [Google Scholar] [CrossRef]

- Kolle, J.J.; Marvin, M.H. Jet Assisted Drilling with Supercritical Carbon Dioxide; Tempress Technologies Inc.: Renton, WA, USA, 2000. [Google Scholar]

- Du, Y.K.; Wang, R.H.; Ni, H.J.; Huang, Z.Y.; Li, M.K. Dynamical analysis of high-pressure supercritical carbon dioxide jet in well drilling. J. Hydrodyn. Ser. B 2013, 25, 528–534. [Google Scholar] [CrossRef]

- Wang, H.; Li, G.; Shen, Z.; Tian, S.; Sun, B.; He, Z.; Lu, P. Experiment on rock breaking with supercritical carbon dioxide jet. J. Pet. Sci. Eng. 2015, 127, 305–310. [Google Scholar] [CrossRef]

- Sheng, M.; Li, G.; Huang, Z.; Tian, S.; Qu, H. Experimental study on hydraulic isolation mechanism during hydra-jet fracturing. Exp. Ther. Fluid Sci. 2013, 44, 722–726. [Google Scholar] [CrossRef]

- Fang, C.; Chen, W.; Amro, M. Simulation Study of Hydraulic Fracturing Using Super Critical CO2 in Shale. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Society of Petroleum Engineers, Abu Dhabi, UAE, 10–13 November 2014. [Google Scholar]

- Kizaki, A.; Tanaka, H.; Ohashi, K.; Sakaguchi, K.; Matsuki, K. Hydraulic fracturing in Inada granite and Ogino tuff with super critical carbon dioxide. In Proceedings of the ISRM Regional Symposium-7th Asian Rock Mechanics Symposium, International Society for Rock Mechanics, Seoul, Korea, 15–19 October 2012. [Google Scholar]

- Khalil, I.; Miller, D.R. The structure of supercritical fluid free—jet expansions. AIChE J. 2004, 50, 2697–2704. [Google Scholar] [CrossRef]

- De Gregorio, F. Free compressible jet investigation. Exp. Fluids 2014, 55, 1693. [Google Scholar] [CrossRef]

- Liu, J.; Do-Quang, M.; Amberg, G. Numerical simulation of rapid expansion of supercritical carbon dioxide. AIChE J. 2015, 61, 317–332. [Google Scholar] [CrossRef]

- Wang, H.Z.; Li, G.S.; Tian, S.C.; Cheng, Y.X.; He, Z.G.; Yu, S.J. Flow field simulation of supercritical carbon dioxide jet: Comparison and sensitivity analysis. J. Hydrodyn. Ser. B 2015, 27, 210–215. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, Y.; Li, G.; Shen, Z.; Tian, S.; Fan, X. Pressure boosting effect in perforation cavity during supercritical carbon dioxide jet fracturing. At. Sprays 2013, 23, 463–474. [Google Scholar]

- He, Z.; Tian, S.; Li, G.; Wang, H.; Shen, Z.; Xu, Z. The pressurization effect of jet fracturing using supercritical carbon dioxide. J. Nat. Gas Sci. Eng. 2015, 27, 842–851. [Google Scholar] [CrossRef]

- Yamamoto, S.; Furusawa, T.; Matsuzawa, R. Numerical simulation of supercritical carbon dioxide flows across critical point. Int. J. Heat Mass Transf. 2011, 54, 774–782. [Google Scholar] [CrossRef]

- Christen, W.; Rademann, K. Probing free jet expansions of supercritical fluids. Phys. Scr. 2009, 80, 048127. [Google Scholar] [CrossRef]

- Seebald, P.J. Turbulence in Transcritical CO2 Jets. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, August 2014. [Google Scholar]

- Liu, T. Shear-coaxial Injection and Mixing of Cryogenic Fluids under Supercritical Conditions. Ph.D. Thesis, The Pennsylvania State University, Pennsylvania, PA, USA, December 2007. [Google Scholar]

- Menter, F.R. Two-Equation Eddy-Viscosity Turbulence Models for Engineering Applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Peng, D.; Robinson, D.B. A New Two-Constant Equation of State. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, Y.; Cai, C.; Kang, Y.; Wang, X.; Huang, M.; Chen, F. Fracture initiation of an inhomogeneous shale rock under a pressurized supercritical CO2 jet. Appl. Sci. 2017, 7, 1093. [Google Scholar] [CrossRef]

- Rajaratnam, N. Turbulent Jets; Elsevier: New York, NY, USA, 1976; pp. 1–49. [Google Scholar]

- Cai, C.; Wang, X.; Yuan, X.; Kang, Y.; Wang, Z.; Huang, M.; Chen, H. Experimental investigation on perforation of Chinese shale with ultra-high pressure abrasive water jet: Shape, mechanism and sensitivity. J. Nat. Gas Sci. Eng. 2019, 67, 196–213. [Google Scholar] [CrossRef]

- Goertler, H. Berechnung von aufgaben der freien turbulenz auf grund eines neuen naherungsansatzes. ZAMM-J. Appl. Math. Mech. 1942, 22, 244–254. [Google Scholar] [CrossRef]

- OSTA, A.R. Effect of Nozzle Length-to-diameter Ratio on Atomization of Turbulent Kiquid Jets. Ph.D. Thesis, The Oklahoma State University, Stillwater, OK, USA, 2010. [Google Scholar]

- Lee, J.; Lee, S.J. The effect of nozzle aspect ratio on stagnation region heat transfer characteristics of elliptic impinging jet. Int. J. Heat Mass Transf. 2000, 43, 555–575. [Google Scholar] [CrossRef]

- Ksibi, H.; Tenaud, C.; Subra, P.; Garrabos, Y. Numerical Simulation of the Rapid Expansion of Supercritical Fluid Flow. Eur. J. Mech. B/Fluids 1996, 15, 569–596. [Google Scholar]

- Cai, C.; Kang, Y.; Wang, X.; Hu, Y.; Huang, M.; Liu, Y.; Liu, J.; Chen, H.; Li, X. Experimental study on shale fracturing enhancement by using multi-times pulse supercritical carbon dioxide (SC-CO2) jet. J. Pet. Sci. Eng. 2019, 178, 948–963. [Google Scholar] [CrossRef]

- Huang, Z. High Pressure Water Jet Assisted Fracturing Mechanism and Experimental Study; China University of Petroleum: Beijing, China, 2007. [Google Scholar]

| Verified Group | 1 | 2 | 3 | |||

|---|---|---|---|---|---|---|

| Item | Exp. | Sim. | Exp. | Sim. | Exp. | Sim. |

| Pressure difference (MPa) | 3.98 | 3.939 | 9.11 | 8.99 | 14.15 | 13.95 |

| Jet inlet pressure (MPa) | 14.96 | 13.939 | 20.03 | 18.99 | 25.08 | 23.87 |

| Ambient pressure (MPa) | 10.98 | 10.00 | 10.92 | 10.00 | 10.93 | 10.00 |

| Measured tunnel pressure (MPa) | 12.13 | 11.8 | 13.17 | 12.27 | 14.22 | 13.64 |

| Pressure increment (MPa) | 1.15 | 1.80 | 2.25 | 2.27 | 3.29 | 3.64 |

| Item | Value |

|---|---|

| Nozzle outlet length (mm) | 1/2/3/4 |

| Nozzle outlet radius (mm) | 0.75/1/1.5 |

| Nozzle-to-casing inlet radius ratio | /1/ |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, C.; Xie, S.; Liu, Q.; Kang, Y.; Lian, D.; Li, B. The Flow Characteristics of Supercritical Carbon Dioxide (SC-CO2) Jet Fracturing in Limited Perforation Scenarios. Energies 2020, 13, 2627. https://doi.org/10.3390/en13102627

Cai C, Xie S, Liu Q, Kang Y, Lian D, Li B. The Flow Characteristics of Supercritical Carbon Dioxide (SC-CO2) Jet Fracturing in Limited Perforation Scenarios. Energies. 2020; 13(10):2627. https://doi.org/10.3390/en13102627

Chicago/Turabian StyleCai, Can, Song Xie, Qingren Liu, Yong Kang, Dong Lian, and Banrun Li. 2020. "The Flow Characteristics of Supercritical Carbon Dioxide (SC-CO2) Jet Fracturing in Limited Perforation Scenarios" Energies 13, no. 10: 2627. https://doi.org/10.3390/en13102627

APA StyleCai, C., Xie, S., Liu, Q., Kang, Y., Lian, D., & Li, B. (2020). The Flow Characteristics of Supercritical Carbon Dioxide (SC-CO2) Jet Fracturing in Limited Perforation Scenarios. Energies, 13(10), 2627. https://doi.org/10.3390/en13102627