Abstract

Lithium-ion (Li-ion) batteries have been competitive in Electric Vehicles (EVs) due to their high energy density and long lifetime. However, there are still issues, which have to be solved, related to the fast-charging capability of EVs. The pulsed current charging technique is expected to improve the lifetime, charging speed, charging/discharging capacity, and the temperature rising of Li-ion batteries. However, the impact of the pulsed current parameters (i.e., frequency, duty cycle, and magnitude) on characteristics of Li-ion batteries has not been fully understood yet. This paper summarizes the existing pulsed current modes, which are positive Pulsed Current Mode (PPC) and its five extended modes, and Negative Pulsed Current (NPC) mode and its three extended modes. An overview of the impact of pulsed current techniques on the performance of Li-ion batteries is presented. Then the main impact factors of the PPC strategy and the NPC strategy are analyzed and discussed. The weight of these impact factors on lifetime, charging speed, charging/discharging capacity, and the temperature rising of batteries is presented, which provides guidance to design advanced charging/discharging strategies as well as to determine future research gaps.

1. Introduction

Electric Vehicles (EVs) have been an important part of the automotive industry due to their benefits in energy and environmental issues by decreasing the dependence on oil and reducing air pollution. Lithium-ion (Li-ion) batteries have become one of the most popular battery technologies with the development of EVs due to their higher energy density and longer lifetime compared to lead-acid batteries [1,2]. For consumers, the issues with EVs they are most concerned about are the total driving mileage, charging time, driving mileage after each charge, and the safety during battery charging/discharging processes, which are related to battery lifetime, charging speed, charging/discharging capacity, and the temperature rising, respectively [3]. To improve these characteristics of Li-ion batteries, the research on advanced charging strategies is a critical issue [4].

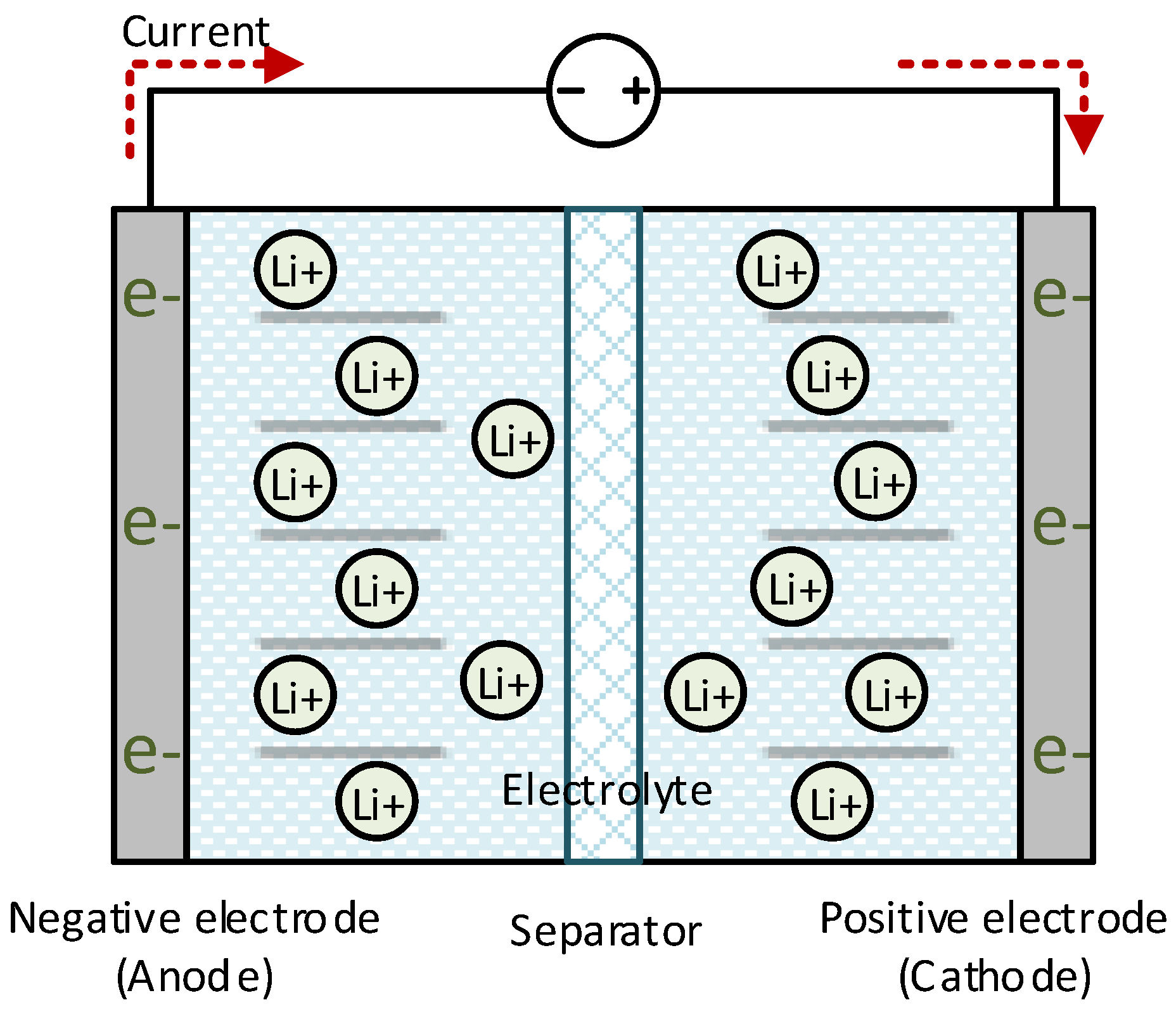

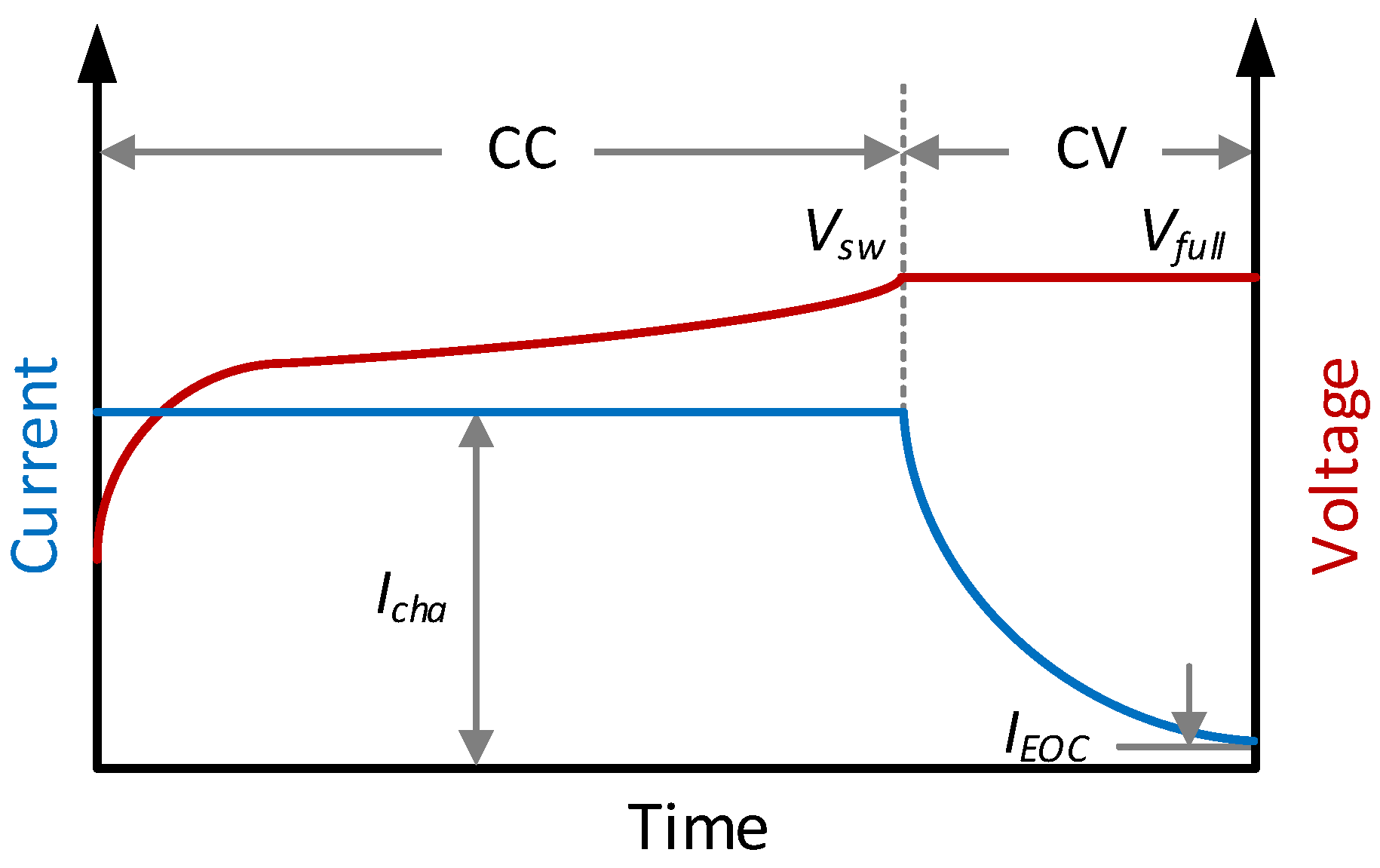

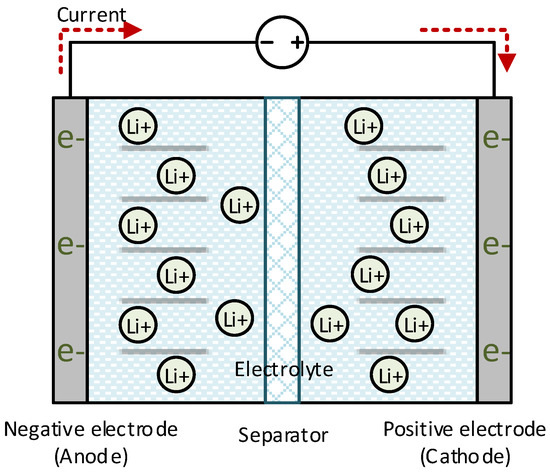

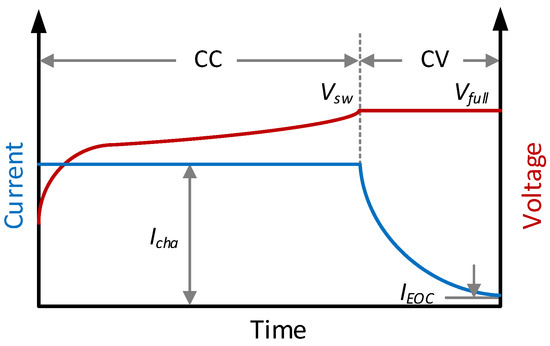

The schematic of a Li-ion battery cell during the charging process is presented in Figure 1 [5]. The ions are extracted from the positive electrode and intercalated to the negative electrode. The Constant Current (CC) charging strategy and Constant Voltage (CV) charging strategy are the two simple charging modes [6]. With the combination of the CC mode and CV mode, the Constant Current-Constant Voltage (CC-CV) charging strategy was proposed and regarded as a practical method to charge batteries due to the simple implementation [7]. There are two charging stages for the CC-CV charging strategy, as shown in Figure 2 [8]. At the first stage, the battery is charged using a constant current . When the voltage reaches the switch voltage , which is a predefined voltage that is very close to the full charge voltage , the CV stage starts. The current decreases until the end of charge current to prevent damage to the battery. The CC charging is more suitable for slow charging with a 0.5 C-rate (C) and a typical charging time of 2 h [9]. However, if the constant charging current is below 0.5 C, the charging time can be increased significantly [10]. In EVs, there are three charging levels [11,12]. Level 1 is the lowest power level where the charging time is normally above 10 h. Level 2 is applied with a higher input power and the corresponding charging time is 2–6 h. Level 3 is for fast charging where high currents, up to 10 C, are applied [13]. The charging time of Level 3 is only about 15–30 minutes, while the temperature rises higher than that of Level 1 and Level 2. Thus, the safety during the charging process needs to be carefully considered due to the potential for thermal runaway and explosion caused by high-temperature operation [14,15]. Moreover, the cycle life is affected negatively by the rising high temperature [10]. The CV mode that normally follows the CC mode can limit the overvoltage stress on the battery cells and can improve the charging capacity while resulting in a longer charging time [16]. Therefore, the balance between the charging speed and temperature rising still needs to be investigated and optimized. The cycle life and safety issues also need to be considered when the temperature rises to a higher level.

Figure 1.

Schematic illustration of the charging process in a Lithium-ion (Li-ion) battery cell [5].

Figure 2.

CC-CV (Constant Current-Constant Voltage) charging strategy.

The CC-CV strategy is usually a reference to evaluate the proposed novel charging strategy. A Multi-Stage Constant Current (MCC) charging strategy was designed to improve the charging speed and efficiency [17,18]. In [19], the author developed a Multi-Stage Constant Current-Constant Voltage (MCC-CV) charging mode to reduce the capacity fading. To improve the charging speed, a MCC-CV based on an Integer Linear Programming (ILP) algorithm charging strategy was proposed, which can seek for the optimal charging current profile for Li-ion batteries [20]. A Sinusoidal Ripple Current (SRC) charging strategy was proposed to improve the overall performances for Li-ion batteries [21,22]. Compared to the CC-CV strategy, the lifetime, charging speed, charging capacity were improved by 16.1%, 17%, and 1.3%, and the rising temperature also dropped by 2 C [21]. This method was further studied and proved to reduce the charging time, maximum temperature rising [23], and prolong the cycle life [24].

A pulsed current charging technique was previously proposed to improve the cycle life of lead-acid batteries [25,26,27,28]. Then, it was extended to the Li-ion battery technique [6,29,30]. The current pulse and voltage pulse are the two types of pulse modes. The difference between the two pulse modes is mainly reflected in different control methods during the charging process. Generally, the pulsed current is implemented by charging the battery cell using a charging protocol defined in advance, while the voltage pulse mode is implemented by controlling the duty cycle or frequency of the switching device to achieve the required average current. L. R. Chen proposed several voltage pulse charging strategies to reduce the charging time, including Variable-Frequency Pulse-Charge System (VFPCS) and Duty-Varied Voltage Pulse-Charge Strategy (DFVPCS) [31,32]. Based on L. R. Chen’s work, an Adaptive Pulse Charge System (APCS) was proposed to improve the charging performance by searching the optimal frequency and duty cycle of pulsed current. This method improved the charging speed by 13.7% [33,34].

For the pulsed current profile, Positive Pulsed Current (PPC) and Negative Pulse Current (NPC) are the two basic pulsed current modes. Based on these two modes, some extended pulsed current modes were studied. The variables of the PPC mode commonly include frequency, duty cycle, and magnitude. For the NPC mode, the number and amplitude of negative pulsed current, and the relaxation time are taken into account of the main impacts on the lifetime and charging performances of Li-ion batteries. However, there is no conclusions about the impact of pulsed current on batteries due to the different test objects, research goals, and test procedures in different studies [35,36]. Therefore, there is a need to review all works of literature and draw conclusions on the impact of pulsed current techniques on Li-ion batteries, which is important for guiding research on the optimal charging/discharging strategy.

This paper presents a comprehensive review of the pulsed current technique. Section 2 introduces the existing pulsed current modes. The impact of the pulsed current technique on the lifetime, charging speed, charging/discharging capacity, and the temperature rising of Li-ion batteries are presented in Section 3. Then, the main impact factors on these characteristics are analyzed and discussed in Section 4. Conclusions are given in Section 5.

2. Pulsed Current Mode

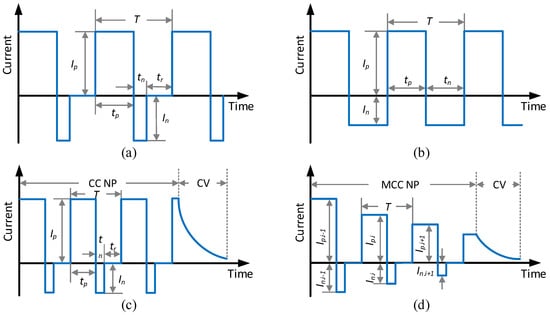

Standard PPC mode and standard NPC mode are the two basic pulsed current modes. The standard PPC mode is the constant current with periodic relaxation time. Based on this concept, some researchers proposed extended PPC modes, which are Pulsed Current with Constant Current (PCCC) mode, Pulse Modulation (PM) mode, Constant Current-Pulsed Current (CC-PC) mode, and Pulsed Current-Constant Voltage (PC-CV) mode, respectively. The first part of this section introduces the existing PPC modes. In the second part, the standard NPC mode and its extended modes are presented. The NPC mode commonly consists of periodic short discharging pulses and periodic short relaxation time. The extended NPC mode includes Alternating Current Pulse (ACP) mode, Constant Current-Constant Voltage with Negative Pulse (CC-CVNP) mode, Multi-Stage Constant Current-Constant Voltage with Negative Pulse (MCC-CVNP) mode. The main parameters of both PPC and NPC modes are provided.

2.1. PPC Mode

2.1.1. Standard PPC Mode

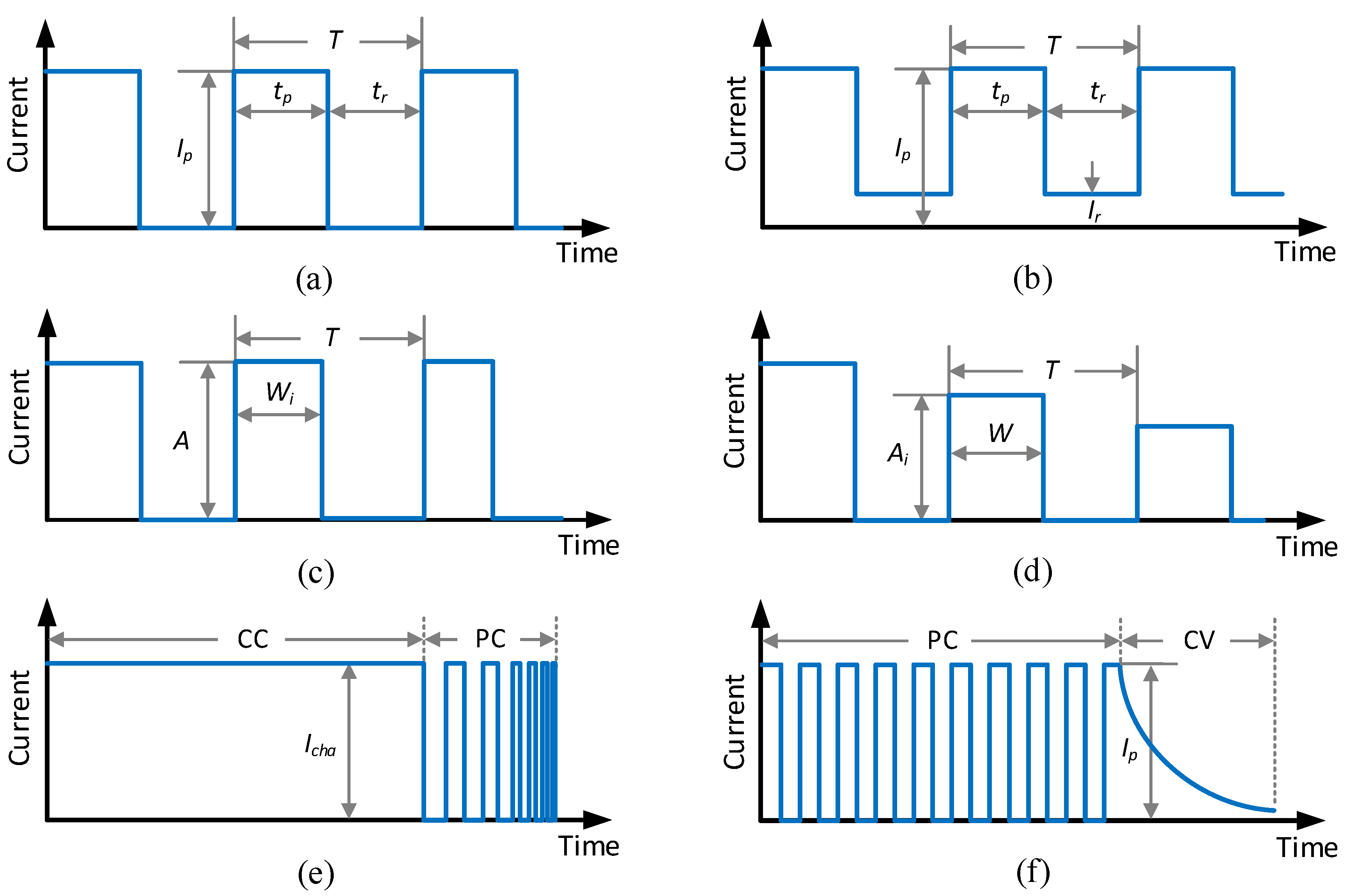

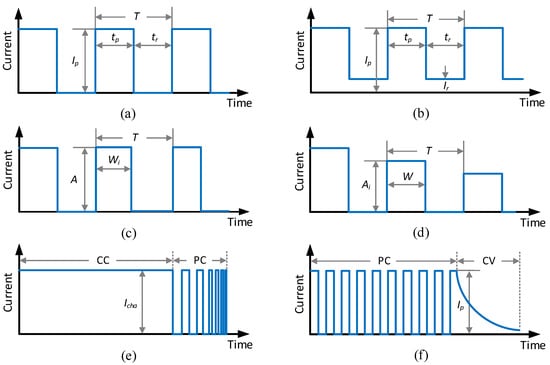

The standard PPC mode is the constant current with periodical rest time, as shown in Figure 3a [16,37]. The current of the positive pulse is a constant value , while the current is 0 at the relaxation time. The positive pulse period is T, and the frequency f is equal to . In a period, the width of the pulse current is , and the rest time is . The duty cycle of the positive pulsed current can be calculated by Equations (1) and (2) [16]:

Figure 3.

Six Pulsed Current Mode (PPC) modes for Li-ion batteries: (a) Standard PPC mode, (b) Pulsed Current with Constant Current (PCCC) mode, (c) Pulse Width Modulation (PWM) mode, (d) Pulse Amplitude Modulation (PAM) mode, (e) Constant Current-Pulsed Current (CC-PC) mode, and (f) Pulsed Current-Constant Voltage (PC-CV) mode.

The main parameters of the standard PPC mode are the period T, duty cycle , and the magnitude of the pulse current , the changes in which can have a different impact on the lifetime, charging/discharging capacity, and charging speed for Li-ion batteries.

2.1.2. PCCC Mode

The PCCC mode is the standard PCP mode followed by the CC mode, as shown in Figure 3b [38,39]. In one period, the PCCC mode starts with a high positive pulsed current, and then a low constant current followed. The only difference with the standard PPC mode is that the current is not zero during the rest period. Thus, except for the three parameters mentioned in the standard PPC mode, the current magnitude during the rest time needs to be considered. In [40], the author proposed that the PCCC mode can be divided into two phases and implemented by two current sources. The phase one is the high positive pulse, and the phase two can be varied to reach the final battery voltage. The PCCC mode can accelerate the charging process and also reduce the stress raising and capacity fade occurring in the standard PPC mode [38]. The mean current of the PCCC mode can be obtained by Equation (3) [38]:

2.1.3. PM Mode

The current PM mode was proposed to optimize the pulse charging strategy [41,42]. There are two operation modes: Pulse Width Modulation (PWM) mode and Pulse Amplitude Modulation (PAM) mode, respectively [43]. Under the operation of PWM mode, the current amplitude A of pulses is constant, while the pulse width is variable, as shown in Figure 3c. In contrast, during the PAM mode, the current width W of pulses is constant, while the pulse width is variable, as shown in Figure 3d. The period of the pulsed current T for both PM modes is constant and W should be less than T. The width and amplitude of the pulsed current are equivalent to and of the standard PPC mode, but they are varied instead of constant values. The PM mode is an effective way to reduce the impact on the battery capacity fade and shorten the charging time by controlling the charging/discharging current profile according to the different states of the battery cells.

2.1.4. CC-PC Mode

Similar to the CC-CV mode, the CC-PC mode starts with the constant current and followed by the pulsed current, which replaces the CV stage of the CC-CV mode, as shown in Figure 3e. The battery cell is charged by the CC mode until the voltage of the battery cell reaches , then the charging process switches to the PC mode. The magnitude of the pulsed current is equal to and the mean current follows the CV profile. The CC-CV mode was proposed used in lead-acid batteries by L. R. Chen [44], and then it was studied for the Li-ion battery technique [37].

2.1.5. PC-CV Mode

The first stage of the PC-CV mode is a standard PPC mode. The period, duty cycle, and magnitude of the current pulse in the PC stage are constant. When the battery voltage reaches , the battery is operated in the CV mode. The current profile of PC-CV mode is presented in Figure 3f. This method can be used in both charging and discharging processes to alleviate the capacity fade [45].

2.1.6. Other Modes

Except for the modes mentioned above, there are some novel modes based on the PPC mode. A Constant Current-Adaptive Pulsed Current mode (CC-APC) was proposed in [46]. The duty cycle of the PC stage is dynamic enough to implement fast charging for Li-ion batteries. In [47], a Constant Current-Pulsed Current-Constant Voltage (CC-PC-CV) charging strategy based on the different initial state-of-charge (SOC)range was proposed. In the range of 0%–20% initial SOC, CC mode is performed and between the range of 20%–80% initial SOC, positive pulse with a high current level is applied for reducing the charging time. To prevent the battery from overvoltage, the CV mode is used to charge the battery cell at the last range of the initial SOC. The three-stage charging strategy was expected to be a trade-off between the charging time and the capacity fade.

2.2. NPC Mode

2.2.1. Standard NPC Mode

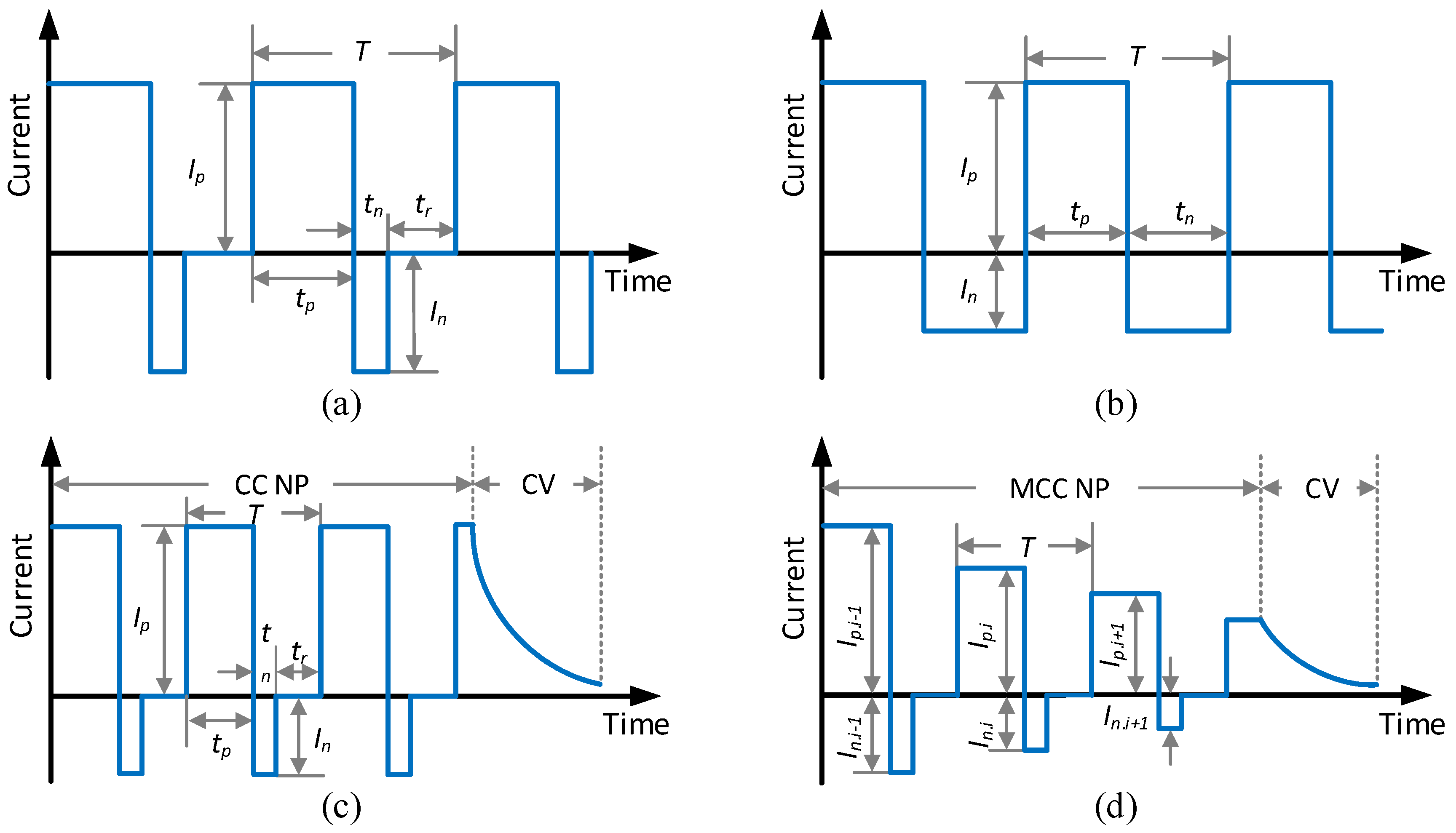

The standard NPC mode is the constant current with a short discharging pulse and a relaxation time periodically, as shown in Figure 4a [48]. Compared with the standard PPC mode, the NPC mode has periodic negative pulses to discharge the cell during the charging process. The period of NPC mode is T. The duration of the charging time, discharging time, and relaxation time are , , and , respectively. The magnitude of the positive current and the negative pulsed current are constant values. The standard NPC mode was firstly applied in lead-acid batteries [49], now it is developed for Li-ion batteries. The short discharging time and relaxation time can increase the utilization of the active materials to reach a higher charging/discharging capacity and a longer cycle life.

Figure 4.

Four Negative Pulsed Current (NPC) modes for Li-ion batteries: (a) Standard NPC mode, (b) Alternating Current Pulse (ACP) mode, (c) Constant Current-Constant Voltage with Negative Pulse (CC-CVNP) mode, and (d) Multi-Stage Constant Current-Constant Voltage with Negative Pulse (MCC-CVNP) mode.

2.2.2. ACP Mode

The ACP mode is operated in a periodic switch between the positive pulse and the negative pulse, as shown in Figure 4b [41,50]. Due to no relaxation time during the operating process, the ACP mode can be seen as a special case of the standard NPC mode. In Figure 4b, and are the corresponding charging and discharging pulsed current and all of them are constant. This strategy is also used as a heating method for the Li-ion batteries worked at a low-temperature environment without harm on battery health [51].

2.2.3. CC-CVNP Mode

The CC-CVNP mode is the conventional CC-CV mode with discharging pulses periodically at the CC stage, as shown in Figure 4c [52]. The profile of the current mode in the first stage is the same as the standard NPC mode. When the cell voltage reaches , the cell operates in CV mode. To investigate the effect of CC-CVNP mode on the batteries’ lifetime and performances, several parameters are considered as the impact factors, including the number of negative pulses , the time of the negative pulses and relaxation period , as well as the magnitude of both the positive current and negative current . After the determination of these parameters, the period T and the time of the positive pulse can be calculated by Equations (4) and (5) [52]:

where is the charging capacity of the battery.

2.2.4. MCC-CVNP Mode

The MCC-CVNP mode is a combination of the MCC-CV mode and the CC-CVNP mode, as shown in Figure 4d [53]. The same numbers of positive constant pulsed current and negative pulsed current are applied to charge batteries until the cell voltage reaches . Then the CC mode is performed. The charging current and the discharging current of the CC stage is gradually decreased, thus it is called the multi-stage CC-CVNP mode. A suitable profile of the MCC-CVNP mode can reduce the capacity loss for Li-ion batteries.

3. Impact of Pulsed Current Techniques on Li-ion Batteries

The benefits of the pulsed current technique used to charge/discharge Li-ion batteries have been demonstrated by some researchers. However, the pulsed current charging/discharging strategy does not always have positive impacts on the lifetime and other performances of batteries [54]. Thus, the pulsed current charging/discharging strategies need to be investigated with different pulsed current mode [55]. There are four aspects to evaluate the influence of pulsed current on the lifetime of battery cells: (1) Cycle life, (2) capacity loss, (3) impedance of the cell, and (4) maximum rising temperature. For the first point, a reference of the battery capacity is predefined. Then, battery cells are charged/discharged by a certain pulsed current profile until the capacity reaches . Finally, the number obtained for life cycles at is recorded and commonly compared to the number of the cycle life of the conventional CC-CV mode. For the second method, the cycle life test is also performed. The difference for the first method is that the cells are charged/discharged with the same number of cycles under different current modes, then the capacity of the cells is measured and compared. The impedance measurement is also a popular method to evaluate the health and predict the cycle life for battery cells. The impedance of the battery cell is measured by Electrochemical Impedance Spectroscopy (EIS). This method is usually combined with a cycle-life test and is performed after certain cycles, which can represent the resistance evolution over time. The impedance of the battery will increase, while the battery capacity fades. The cycle life of Li-ion batteries depends on the electrode materials and the interfaces among the anode, cathode, and electrolyte. However, the impedance obtained by EIS is mainly related to the surface film and interfacial charge-transfer resistance. Therefore, the impedance of the cell cannot directly reflect the capacity fade. The maximum temperature rising or the peak temperature is regarded as an auxiliary evaluation criterion as a higher temperature rising can result in a negative effect on the battery health during both charging and discharging processes. Thus, the cycle life and the capacity fade are the intuitive ways to evaluate the impact of different pulsed current modes on the battery lifetime. Furthermore, the charging/discharging capacity and the charging speed are also objectives to be investigated. The reason why these two battery performances are analyzed is that the impact of some pulsed current parameters on them is opposite. For example, a higher magnitude of the PPC mode can greatly improve the charging speed, while the charging capacity decreases.

The state of the art of the impact of pulsed current techniques on battery cells is introduced in this section. The first part and the second part are the corresponding impacts of different PPC strategies and different NPC strategies on the lifetime, charging/discharging capacity, and charging speed of Li-ion batteries. The temperature was also investigated in some research. The relevant references are listed in Tables to summarize all research results for readers to review.

3.1. Impact of PPC Strategies

To investigate the impact of pulsed current parameters on the cycle life of Li-ion batteries, JM Amanor-Boadu used Taguchi orthogonal to evaluate several possible impact factors [16]. The impact factors chosen were frequency (0.1 kHz, 1 kHz, 6 kHz, 12 kHz (), 50 kHz, and 100 kHz), duty cycle (20%, 50%, and 80%), and ambient temperature (0 C, 23 C, and 45 C), where is the frequency at the minimum impedance point of the battery cell. It was observed that the cycle life at higher frequencies (, 50 kHz, and 100 kHz) was higher than the cycle life obtained at lower frequencies (0.1 kHz, 1 kHz, and 6 kHz), and the best result was obtained at . The impedance parameters were obtained by EIS. As the number of cycles increased, the impedance increased linearly. At a low ambient temperature, a smaller duty cycle led to a smaller cell impedance. Conversely, at a high ambient temperature, a larger duty cycle could obtain a smaller cell impedance. However, in general, the impedance value of the battery operated in the PPC strategy was slightly higher than the impedance value obtained by the traditional CC-CV strategy. The optimal set of parameters for the PPC strategy was the pulsed current with frequency (12 kHz) and 50% duty cycle at 23 C, which could improve the cycle life by 100 cycles compared to the CC-CV strategy. In another publication by JM Amanor-Boadu [56], the frequency and duty cycle were the two factors with the largest impact on the performance of the battery. The charging speed at frequency and 50% duty cycle could be improved by 48% compared to the CC-CV charging strategy. The battery energy efficiency and battery charge efficiency were improved by 12% and 2%, respectively.

The impact of the high frequency on the capacity fade of Li-ion batteries was studied in [57]. The frequencies chosen were 1 Hz, 10 Hz, 0.1 kHz, 1 kHz, 10 kHz, and 100 kHz. To obtain calendar degradation, float-charging tests were performed and the results were regarded as a reference point to compare with the capacity fade by the pulsed current. After a 147-day cycle life test, the capacity fade ratios at 1 Hz and 10 Hz were about 13% and 15%, respectively, while the capacity fade ratios at high frequency were much lower. The capacity fade ratio at 0.1 kHz, 1 kHz, and 100 kHz was approximately 8%, and at 10 kHz was only 6%, which can be considered as calendar degradation. The temperature rising was measured for different frequencies at a certain voltage level. It was observed that the maximum temperature rise was around 1 C. With the frequency increased, the rising of the battery temperature had a decreasing trend. Therefore, high-frequency pulses did not cause a significant increase in battery temperature.

The frequency and the duty cycle were the two variables used to investigate the impact of the pulsed current strategy on the cycle life for lithium-metal batteries in [58]. The frequencies selected were 0.17 Hz, 0.03 Hz, and 0.017 Hz. The duty cycles chosen were 66.7%, 50%, 33.3%, 25%, 16.6%, and 9.1%. As the duty cycle decreased, the cycle life was prolonged and reached the maximum cycle number at a 16.6% duty cycle. At a duty cycle of 9.1%, the cycle life had a decrease. Higher frequencies have a more positive effect on battery life. When the duty cycle was 16.6%, the cycle life was improved by about 55%, 70%, and 130% at the corresponding frequency of 0.017 Hz, 0.03 Hz, and 0.17 Hz compared to the cycle life obtained by CC-CV strategy.

The PC-CV strategy with 0.02 Hz frequency and 50% duty cycle were compared with the CC-CV strategy at different current levels (1 C, 2 C, and 3 C). After 100 cycles, the cells tested with the lower current rate had a higher capacity retention rate for both the pulsed current mode and continuous current mode. When the pulsed current mode and continuous current mode were compared at the same current level, the capacity retention rates of the pulsed current mode were improved slightly (0.26%) compared to the continuous current mode [45].

The CC-CV charging strategy was compared to three pulse charging strategies, which are CC-PC charging strategy, PCCC with 1 Hz frequency charging strategy, and PCCC with a 25 Hz frequency charging strategy [37]. The mean current of the charging strategies was the same for both continuous current mode and pulsed current mode. The cycle life of CC-PC and PCCC with 25 Hz frequency was similar to the one obtained for the CC-CV method, while 1-Hz PCCC had a faster capacity fade than the CC-CV method. The capacity utilization and charging speed were also investigated in this study. The capacity utilization of the three pulse strategies was lower than that of the conventional one. This results obtained were because the maximum charging voltage was set lower than that of CC-CV in case of the high overvoltage during the charging process, especially with the high current pulses. This means that the process of pulse charging ended at a lower SOC that led to a low charging capacity. For the charging speed, the CC-PC strategy had a longer charging time because there was relaxation time after the CC stage, while there was no relaxation time for CC-CV strategy. The charging speed of PCCC strategies was not impacted because the same mean charging current was used for the CC-CV charging mode.

The PPC charging mode with four different frequencies (1 Hz, 100 Hz, , and 10 kHz) at 50% duty cycle was investigated and compared with the CC-CV charging mode, where was 998 Hz, 996 Hz, and 1238 Hz for three different batteries obtained by EIS [21]. The pulsed current at presented the best performance for all batteries. The charging speed, discharging capacity, and efficiency at were average improved by 16.2%, 2.1%, and 1.6%, respectively. Moreover, the average rising temperature of the three batteries, which were tested using pulsed current was 2.8 C, which is lower than the average temperature rising (4.4 C) obtained by testing the battery using continuous current. Thus, the high frequency did not lead to a high temperature rising and had a positive trend compared to the traditional charging strategy.

The current amplitude (0.5 C, 1 C, and 2 C), pulse time (1.2 s, 1.5 s, and 2 s), and relaxation time (0.3 s, 0.5 s, 0.7 s, and 1 s) were selected as variables to investigated the impact of the PPC strategy on the performance of batteries [59,60]. With the increase of the pulse amplitude from 0.5 C to 1 C, the charging time decreased by 82.8%, while the charging capacity decreased significantly (32.9%), and the maximum temperature increased by 15.3 C. The increase in the pulse time from 1.2 s to 2 s could also decrease the charging time by 14.1%. The changes in relaxation time had no significant impact on the charging capacity and temperature rising. However, the increase in the relaxation time resulted in a longer charging time. The effect of relaxation time on the recovery capacity for pouch Lithium-sulfur battery cells was studied in [61]. During the discharging process, a longer rest time led to a higher discharging capacity. The effect of the capacity recovery rate was more significant with a higher discharge current and lower ambient temperature. The relaxation period could recover the battery capacity up to 20%.

The impact of PPC strategies on the lifetime for Li-ion batteries is summarized in Table 1. Reference [58] is not presented in Table 1 because in that work, lithium-mental batteries were used. The impact of PPC strategy on the charging speed and charging/discharging capacity for Li-ion batteries are listed in Table 2. Table 3 is the impact of various frequencies on temperature. Further analysis and discussion are conducted in Section 4.

Table 1.

The impact of PPC strategies on the lifetime of Li-ion batteries.

Table 2.

The impact of PPC strategies on the charging speed and charging/discharging capacity of Li-ion batteries.

Table 3.

The impact of PPC strategies on the temperature rising of Li-ion batteries.

3.2. Impact of NPC Strategies

The effect of the NPC strategy on the life performance of Li-ion batteries was studied and compared with continuous current charging in [48]. The author claimed that the negative pulse and the rest time could improve the active material utilization, which would result in a higher discharging capacity and longer lifetime. was defined to be used to compare the cycle life of the cells operated in the NPC strategy and continuous current strategy. The cell charged with the NPC profile experienced 1600 cycles before the capacity decreased to , while the cell charged with continuous current experienced only 700 cycles before the same capacity was reached.

In [52], CC-CVNP protocols with different amplitudes and a different number of negative pulses were built to investigate their impacts on the lifetime. The results showed that CC-CVNP with lower amplitude and fewer number of the negative pulse could reduce the capacity loss. The internal temperature of the cells was stable, and the surface temperature was not affected significantly since the temperature rising was around 1 C. Impedance measurements were performed and the obtained results demonstrated that the CC-CVNP with the lowest amplitude and the fewest numbers of negative pulses could reduce the impedance of the battery cell. Compared with other charging algorithms provided in this study, the CC-CVNP with the lowest amplitude and the fewest numbers of negative pulses could effectively slow down the aging process.

The lifetime of the MCC-CVNP strategy and of the CC-CVNP with different numbers of negative pulses strategies were evaluated using a certain procedure in [53]. Compared to the CC-CV strategy, the capacity retention improvement of the MCC-CVNP was 8%, but it was lower than that of the MCC-CV strategy and the CC-CVNP strategy, which could improve the capacity retention by 13% and 11%, respectively.

The negative pulse magnitude (0.5 C, 1 C, and 2 C) and negative pulse time (0.2 s, 0.3 s, and 0.5 s) were considered as the impact factor to evaluate the effect of the NPC strategy on the performances of Li-ion batteries in [59]. With the increase of the negative pulse time, the charging capacity increased by about 3.3%, while the battery charging time increased by 36.9%. The rising temperature was hardly affected. Similarly, the increase of the negative pulse amplitude did not have a significant positive effect on the charging capacity, but the charging time and battery temperature increased by 16.4% and 14.2%, respectively. Thus, the increase in the level of amplitude and time for negative pulse had a negative impact on the performances of batteries.

To investigate the effect of ACP charging strategy on performances of Li-ion batteries, the mean current (5 C and 20 C), the temperature (–10 C and 25 C), the frequency (200 mHz–100 Hz), and duty cycle of the negative pulse (1%–10%) were considered as factors in [50]. It was observed that the pulse discharging had no positive impact on battery performance. Moreover, compared to the CC-CV method when discharging the battery cells using a certain mean current, the pulse strategy had a negative effect on the battery’s performance.

In [62], the charging time at a different SOC range was investigated considering the NPC strategy. For the SOC range 0%–40%, the charging time was shortened by 50% compared to the continuous current charging, while for the SOC range 0%–60%, the charging time was reduced by 43% compared to the continuous current charging. After 60 cycles, the capacity fade reduced by 23% compared to the CC-CV strategy. Although the charging time of the NPC at full SOC range was slightly longer than the CC-CV strategy, the charging time of the NPC was less than the CC-CV after 40 cycles. Moreover, the capacity fade could be decreased by 23% compared to the CC-CV method after 60 cycles.

The impact of NPC strategy on the lifetime of Li-ion batteries is summarized in Table 4. Table 5 presents the impact of NPC strategy on temperature behavior. Further analysis and discussion are conducted in Section 4.

Table 4.

The impact of NPC strategies on the lifetime of Li-ion batteries.

Table 5.

The impact of NPC strategies on the temperature rising of Li-ion batteries.

4. Analysis and Discussion

This section analyzes the effects of the main parameters of different pulse current strategies on battery lifetime, charging speed, charge/discharge capacity, and the temperature. For the PPC strategy, the main parameters include pulse frequency f, duty cycle , relaxation time , and the magnitude of the positive pulse . For the NPC strategy, the main influence parameters are the negative pulse time , relaxation time , the magnitude of the negative pulse , and the number of the negative pulse . This section is divided into three parts. The first part and the second part analyze the impact factors for PPC strategy and NPC strategy, respectively. The last part evaluates the impact of these factors on the characteristics of Li-ion batteries.

4.1. Impact Factor for PPC Strategies

The PPC mode can be divided into single-stage charging mode and double-stage charging mode, as shown in Figure 3. The single-stage charging includes standard PPC mode, PPPC mode, PWM mode, and PAM mode, which only have pulsed current charging stage, as shown in Figure 3a–d. The two-stage charging includes CC-PC mode and PC-CV mode, which are a continuous constant current or a pulsed constant current followed by a CV charging stage, as shown in Figure 3e,f. When the average current is the same at the first charging stage, the two-stage charging mode spends more charging time due to the CV stage, while the charging capacity is being increased [16]. To increase the charging speed, the high charging current is applied, which might have a negative impact on the lifetime of batteries. The PWM mode and PAM mode provide an effective way to avoid the battery suffering from charging-induced harm to the lifetime without much slow down to the charging speed. The implementation of PM charging is more complex than that of other PCC modes because the PWM mode and PAM mode need to regulate the magnitude and width of the pulsed current, respectively. However, the computational cost of the PM mode is not high and can be implemented in embedded Battery Management Systems (BMSs) [43]. In the following part, the main impact factors of the PPC mode on Li-ion batteries’ lifetime and performances are discussed.

4.1.1. Frequency

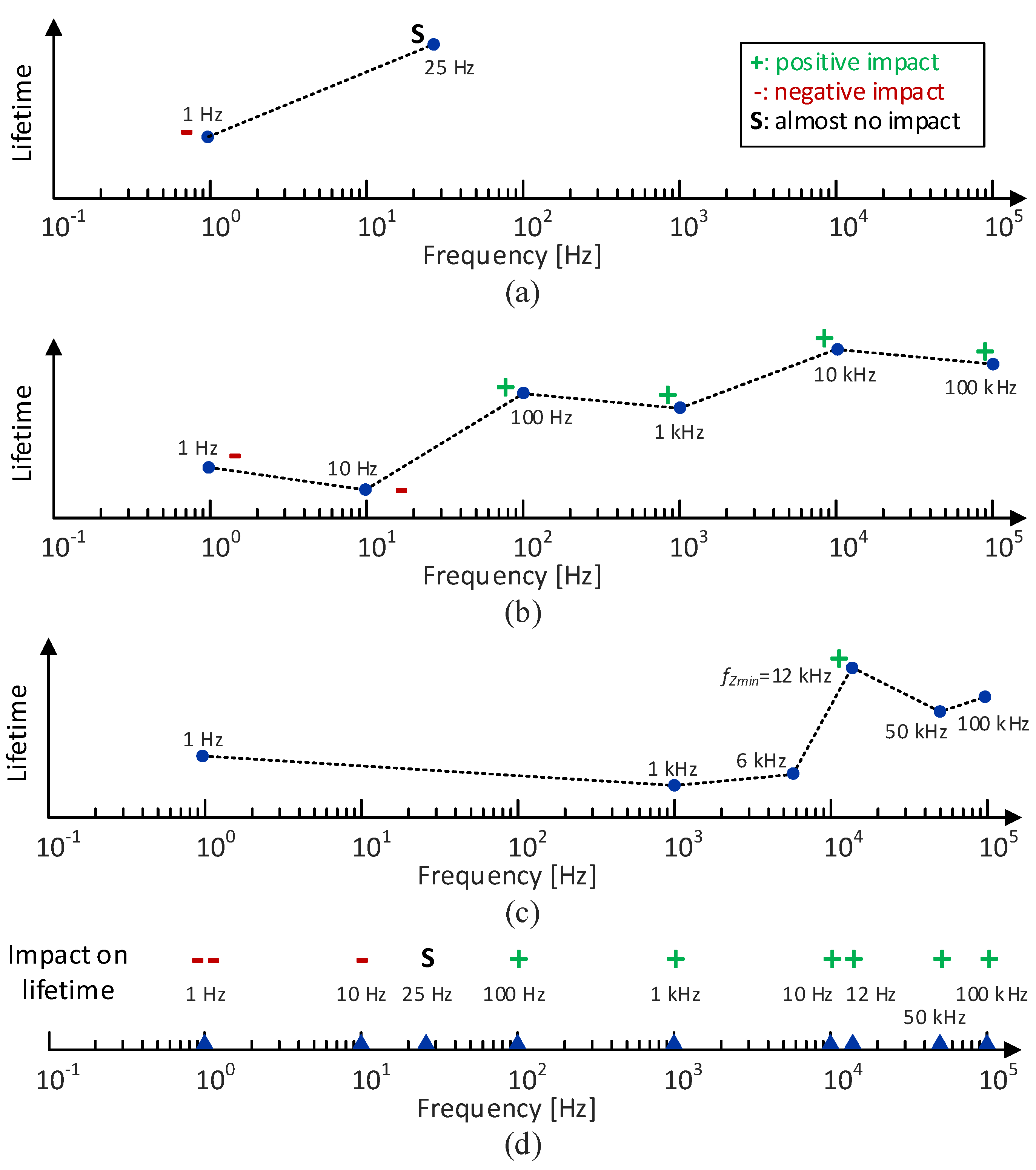

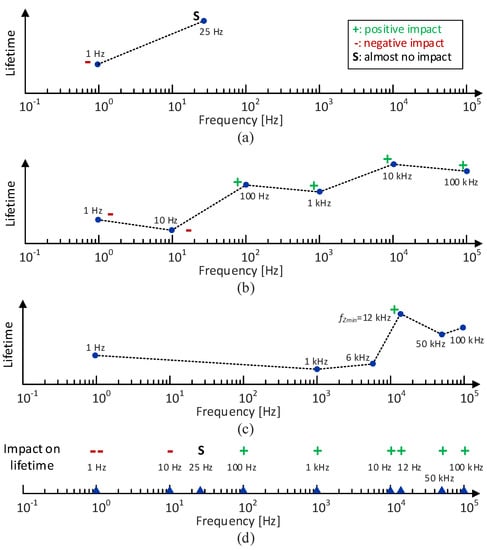

To investigate the impact of pulse frequency on the lifetime, the results available in the literature are placed into the same frequency coordinates for comparison, as shown in Figure 5. Although different studies used different parameters and Li-ion battery chemistries and even had special research and test procedures, some trends in the impact of frequency on battery lifetime can be observed in Figure 5. The abscissa is the exponential axis of frequency, and the ordinate is the lifetime. The lifetime axis does not represent any specific value, only the trend. In the same reference, the higher the point marked by the ordinate, the more positive impact on the lifetime. Figure 5a–c correspond to the reference [16,37,57], respectively. The reason for choosing these papers is because all of their battery tests were performed with different frequencies, which could allow them to be compared. The impact of different frequencies on the lifetime is marked according to the data or conclusions provided in the references. In Figure 5, the green plus ’+’ means that the lifetime at the corresponding frequency point was improved; the red minus ’−’ means the lifetime at the corresponding frequency point was affected negatively (i.e., the lifetime was not improved); and the point marked ’S’ indicates the lifetime was not impacted at the frequency point. For pulse frequencies between 1 Hz and 25 Hz, the pulsed current had a negative impact on battery health. When the pulse frequency was between 6 kHz and 100 kHz, the pulsed current could increase the battery lifetime. Due to the lack of data support, the impact of pulsed currents at frequencies between 25 Hz and 6 kHz on the battery cannot be fully determined. The impact of frequency on the battery lifetime is summarized in Figure 5d. Therefore, compared with the low-frequency pulsed current, pulsed current at the high frequency is more beneficial to the lifetime of batteries. The optimal charging frequency is first proposed in the SRC charging strategy [21]. The ac-impedance analysis was used to seek optimal charging performance. It was observed that the SRC with the frequency at the minimum impedance point could improve the lifetime by 17% compared with the CC-CV charging strategy. Then, the effect on the battery lifetime of the pulsed current at different frequencies was investigated in [16]. The pulsed current with frequency could improve the battery lifetime by 100 extra life cycles compared with the CC-CV charging method [16]. The frequency was 1 kHz and 12 kHz in [16,21], respectively. Thus, the high-frequency pulsed current showed a positive impact than low-frequency pulsed current on the lifetime of Li-ion batteries. The existing studies indicate that whether the pulsed current could impact the battery lifetime positively is related to the impedance of the battery cell at the operating frequency point.

Figure 5.

The impact of frequency on the lifetime with 50% duty cycle: (a) [37], (b) [57], (c) [16], and (d) a summary of the three studies.

The frequency at the minimum impedance could improve the charging speed greatly for the PPC strategy [56], but it has not been found that pulses with different frequencies have a significant impact on the charging speed or on the charging capacity [21]. Table 3 presents the rising of temperatures at various frequencies. When other impact factors, such as and are the same, the changes in a large range of frequency had no significant effect on the temperature of batteries.

4.1.2. Duty Cycle and Relaxation Time

When the period of the pulsed current is constant, and can be calculated from each other by Equations (1) and (2). There is no evidence that demonstrates that the changes in the duty cycle had a significant impact on the lifetime and temperature of batteries. Increasing the relaxation time at a limited frequency level could slightly increase the charging/discharging capacity, while the charging time increased greatly [60].

4.1.3. Magnitude of Positive Pulse Current

The lifetime is not affected when the mean current is the same as for the constant current mode of the CC-CV charging strategy [45]. The increase in the magnitude of the pulsed current could improve the charging speed, while the charging capacity decreased. In addition, a higher pulsed current could result in high temperature rising. In Table 3, high temperature rises only occurred when increased. This will bring safety issues as well as reduce the battery life [60].

4.2. Impact Factor for NPC Strategies

The increase of the negative pulse time leads to a very long charging time because the battery not only stops charging but it is also discharged by the negative pulsed current. In Table 5, the temperature is not impacted by the changes in negative pulse time. When the magnitude of the negative current pulse increased, the charging time increased, and the temperature also rose significantly [60]. The charging/discharging capacity was not impacted greatly by the changes of negative pulse time and magnitude. The lifetime could be improved by the NPC profile with a lesser number and lowest magnitude of the negative pulse [52].

4.3. Evaluation of Impact Factors

For PPC strategies, the main impact factors on the characteristic of batteries are the frequency, duty cycle, relaxation time, and magnitude of the pulsed current. For NPC strategies, negative pulse time, magnitude, and the number of the negative pulses are the three primary impact factors. Table 6 lists the weight of impact factors on the four characteristics of Li-ion batteries. The higher score represents the greater influence of the factors on the corresponding characteristics, and ’0’ means no impact or very low impact. Although many studies have begun to focus on pulsed current technologies, their research objects, test procedures, and analysis methods are not the same and do not completely cover all aspects. Therefore, the evaluation results in Table 6 are based on the current research level, where ’−’ presents that the impact results of the corresponding factor is uncertain or have not been studied.

Table 6.

The weight of impact factors on the lifetime, charging speed, charging/discharging capacity, and temperature rising of Li-ion batteries. (2: Great impact; 1: Less impact; 0: Almost no impact; -: Uncertain.)

According to the discussion and evaluation results above, some conclusions can be obtained:

- PPC Mode

- –

- Among all the impact factors, the frequency of positive pulsed current had the highest impact on the lifetime of Li-ion batteries. In the 1 Hz–100 kHz frequency range, a higher frequency commonly presented a higher positive impact on the lifetime, and the frequency at the minimum impedance point could be considered as a priority;

- –

- The charging speed was influenced by several factors, including the duty cycle, relaxation time, and the magnitude of the current pulse. For the standard PPC mode, the duty cycle and relaxation time were interrelated. Increasing the duty cycle was equivalent to having a longer charging time and a shorter rest time in one period, thus the charging speed increased;

- –

- The magnitude of the pulsed current had the highest impact on the characteristics of the battery. The increase of the magnitude could greatly shorten the charging time, while the capacity utilization decreased significantly and the battery temperature also rose rapidly;

- –

- Frequency of the current pulse had no significant impact on temperature rising. The temperature rise was mainly caused by the increase of pulsed current magnitude. A higher temperature rising had a negative impact on the safety and lifetime of the battery system.

- NPC Mode

- –

- More time and a higher magnitude of negative pulse resulted in a slow charging speed because the battery discharged during the negative pulse period;

- –

- A higher current rate of the negative pulse could lead to a temperature rising and subsequently to a reduction of the battery life. Moreover, the charging capacity would be affected significantly;

- –

- NPC charging profile with a lesser number of negative pulses and low negative pulsed current could increase the charging capacity and reduce the capacity fade;

- –

- The impact of related parameters on Li-ion batteries needs to be further studied because some impact factors listed in Table 6 on the battery characteristics have not been researched. The main impact factor for the battery lifetime needs to be investigated.

5. Conclusions

This paper summarizes the existing pulsed current modes, including six PPC modes (standard PPC mode, PCCC mode, PWM mode, PAM mode, CC-PC mode, and PC-CV mode) and four NPC modes (standard NPC mode, ACP mode, CC-CVNP mode, and MCC-CVNP mode). Based on these pulsed current modes, different charging/discharging strategies were proposed and studied by researches. An overview of pulsed current technique and their impact on Li-ion batteries are presented. Then the main impact factors are determined, which are analyzed and discussed. The frequency of PPC strategy had the largest impact on the battery lifetime. Moreover, the higher frequency that at the range of 6 kHz–100 kHz presented a positive impact compared to the low frequency at 1 Hz–25 Hz. Duty cycle and relaxation time had a great impact on charging speed. However, the improvement of charging speed could result in a low charging/discharging capacity, which means a low available capacity for batteries. Therefore, these two parameters need to be carefully designed to achieve a balance between the charging speed and available capacity. The magnitude of pulsed current had the largest impact on the overall characteristics of batteries. A high magnitude current could shorten the charging time, while the charging capacity had a decrease and the battery temperature rose quickly. For the NPC strategy, the negative pulse time mainly impacted the charging speed. Short negative pulse time and low magnitude negative current could implement the fast charging speed, increase the charging/discharging capacity, and decrease the temperature rising. The NPC with less number and low magnitude had a positive impact on the lifetime and charging/discharging capacity. However, there still had some impact on the corresponding characteristic that were uncertain and have not been researched that could be seen in Table 6. To develop an advanced charging/discharging algorithm, the impact of different pulsed current modes need to be further studied. In addition, the impact factors for both PPC strategies and NPC strategies on lifetime, charging speed, charging/discharging capacity, and temperature of Li-ion batteries also need to be investigated in future work.

Author Contributions

X.H. wrote the paper, X.H., D.-I.S., and R.T. designed the structures of the paper; Y.L., A.B.A., J.M., and X.S. reviewed the paper; H.X. and D.-I.S. edited the paper. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

The authors would like to thank the China Scholarship Council (CSC) for supporting the study in the Department of Energy Technology, Aalborg University.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gao, Y.; Zhang, X.; Cheng, Q.; Guo, B.; Yang, J. Classification and review of the charging strategies for commercial lithium-ion batteries. IEEE Access 2019, 7, 43511–43524. [Google Scholar] [CrossRef]

- Xiong, R.; Li, L.; Tian, J. Towards a smarter battery management system: A critical review on battery state of health monitoring methods. J. Power Sources 2018, 405, 18–29. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Xiong, R. Battery Management Algorithm for Electric Vehicles; Springer: Singapore, 2020. [Google Scholar]

- Thackeray, M.M.; Wolverton, C.; Isaacs, E.D. Electrical energy storage for transportation—approaching the limits of, and going beyond, lithium-ion batteries. Energy Environ. Sci. 2012, 5, 7854–7863. [Google Scholar] [CrossRef]

- Collin, R.; Miao, Y.; Yokochi, A.; Enjeti, P.; von Jouanne, A. Advanced electric vehicle fast-charging technologies. Energies 2019, 12, 1839. [Google Scholar] [CrossRef]

- Hussein, A.A.H.; Batarseh, I. A review of charging algorithms for nickel and lithium battery chargers. IEEE Trans. Veh. Technol. 2011, 60, 830–838. [Google Scholar] [CrossRef]

- Yoshida, T. Constant Current and Constant Voltage Battery Charger. U.S. Patent No. 6,087,810, 11 July 2000. [Google Scholar]

- Zhang, S.S. The effect of the charging protocol on the cycle life of a Li-ion battery. J. Power Sources 2006, 161, 1385–1391. [Google Scholar] [CrossRef]

- Patnaik, L.; Praneeth, A.; Williamson, S.S. A closed-loop constant-temperature constant-voltage charging technique to reduce charge time of lithium-ion batteries. IEEE Trans. Ind. Electron. 2018, 66, 1059–1067. [Google Scholar] [CrossRef]

- Yilmaz, M.; Krein, P.T. Review of battery charger topologies, charging power levels, and infrastructure for plug-in electric and hybrid vehicles. IEEE Trans. Power Electron. 2012, 28, 2151–2169. [Google Scholar] [CrossRef]

- Williamson, S.S.; Rathore, A.K.; Musavi, F. Industrial electronics for electric transportation: Current state-of-the-art and future challenges. IEEE Trans. Ind. Electron. 2015, 62, 3021–3032. [Google Scholar] [CrossRef]

- Zaghib, K.; Dontigny, M.; Guerfi, A.; Charest, P.; Rodrigues, I.; Mauger, A.; Julien, C.M. Safe and fast-charging Li-ion battery with long shelf life for power applications. J. Power Sources 2011, 196, 3949–3954. [Google Scholar] [CrossRef]

- Smith, K.; Wang, C.Y. Power and thermal characterization of a lithium-ion battery pack for hybrid-electric vehicles. J. Power Sources 2006, 160, 662–673. [Google Scholar] [CrossRef]

- Shin, K.G.; Kim, E. Real-Time Battery Thermal Management for Electric Vehicles. U.S. Patent No. 9,893,394, 13 February 2018. [Google Scholar]

- Amanor-Boadu, J.; Guiseppi-Elie, A.; Sánchez-Sinencio, E. The impact of pulse charging parameters on the life cycle of lithium-ion polymer batteries. Energies 2018, 11, 2162. [Google Scholar] [CrossRef]

- Di Yin, M.; Youn, J.; Park, D.; Cho, J. Dynamic frequency and duty cycle control method for fast pulse-charging of lithium battery based on polarization curve. In Proceedings of the 2015 Ninth International Conference on Frontier of Computer Science and Technology, Dalian, China, 26–28 August 2015; pp. 40–45. [Google Scholar]

- Yin, M.D.; Cho, J.; Park, D. Pulse-based fast battery IoT charger using dynamic frequency and duty control techniques based on multi-sensing of polarization curve. Energies 2016, 9, 209. [Google Scholar] [CrossRef]

- Anseán, D.; González, M.; Viera, J.; García, V.; Blanco, C.; Valledor, M. Fast charging technique for high power lithium iron phosphate batteries: A cycle life analysis. J. Power Sources 2013, 239, 9–15. [Google Scholar] [CrossRef]

- Dung, L.R.; Yen, J.H. ILP-based algorithm for Lithium-ion battery charging profile. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010; pp. 2286–2291. [Google Scholar]

- Chen, L.R.; Wu, S.L.; Shieh, D.T.; Chen, T.R. Sinusoidal-ripple-current charging strategy and optimal charging frequency study for Li-ion batteries. IEEE Trans. Ind. Electron. 2012, 60, 88–97. [Google Scholar] [CrossRef]

- Nguyen, C.L.; Primiani, P.; Viglione, L.; Woodward, L. A low-cost battery charger usable with sinusoidal ripple-current and pulse charging algorithms for e-bike applications. In Proceedings of the 2019 IEEE 28th International Symposium on Industrial Electronics (ISIE), Vancouver, BC, Canada, 12–14 June 2019; pp. 2085–2090. [Google Scholar]

- Chen, P.T.; Yang, F.H.; Cao, Z.T.; Jhang, J.M.; Gao, H.M.; Yang, M.H.; Huang, K.D. Reviving Aged Lithium-Ion Batteries and Prolonging their Cycle Life by Sinusoidal Waveform Charging Strategy. Batter. Supercaps 2019, 2, 673–677. [Google Scholar] [CrossRef]

- Chen, P.T.; Yang, F.H.; Sangeetha, T.; Gao, H.M.; Huang, K.D. Moderate Energy for Charging Li-Ion Batteries Determined by First-Principles Calculations. Batter. Supercaps 2018, 1, 209–214. [Google Scholar] [CrossRef]

- Serhan, H.A.; Ahmed, E.M. Effect of the different charging techniques on battery life-time. In Proceedings of the 2018 International Conference on Innovative Trends in Computer Engineering (ITCE), Aswan, Egypt, 19–21 February 2018; pp. 421–426. [Google Scholar]

- Praisuwanna, C.; Khomfoi, S. A pulse frequency technique for a quick charger. In Proceedings of the 2013 10th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology, Krabi, Thailand, 15–17 May 2013; pp. 1–6. [Google Scholar]

- Gumera, X.D.G.; Caberos, A.B.; Huang, S.C.; Liou, W.R.; Lin, J.C. A Variable Duty Cycle Pulse Train Charger for Improving Lead-Acid Battery Performance. In Proceedings of the 2017 Asian Conference on Energy, Power and Transportation Electrification (ACEPT), Singapore, 24–26 October 2017; pp. 1–4. [Google Scholar]

- Chu, Y.; Chen, R.; Liang, T.; Changchien, S.; Chen, J. Positive/negative pulse battery charger with energy feedback and power factor correction. In Proceedings of the Twentieth Annual IEEE Applied Power Electronics Conference and Exposition, Austin, TX, USA, 6–10 March 2005; Volume 2, pp. 986–990. [Google Scholar]

- Shen, W.; Vo, T.T.; Kapoor, A. Charging algorithms of lithium-ion batteries: An overview. In Proceedings of the 2012 7th IEEE Conference on Industrial Electronics and Applications (ICIEA), Singapore, 18–20 July 2012; pp. 1567–1572. [Google Scholar]

- Wagner, O.C. Method of Increasing the Useful Life of Rechargeable Lithium Batteries. U.S. Patent No. 4,736,150, 5 April 1988. [Google Scholar]

- Chen, L.R. A design of an optimal battery pulse charge system by frequency-varied technique. IEEE Trans. Ind. Electron. 2007, 54, 398–405. [Google Scholar] [CrossRef]

- Chen, L.R. Design of duty-varied voltage pulse charger for improving Li-ion battery-charging response. IEEE Trans. Ind. Electron. 2008, 56, 480–487. [Google Scholar] [CrossRef]

- Niroshana, S.I.; Sirisukprasert, S. An adaptive pulse charging algorithm for lithium batteries. In Proceedings of the 2017 14th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Phuket, Thailand, 27–30 June 2017; pp. 218–221. [Google Scholar]

- Niroshana, S.I.; Sirisukprasert, S. Adaptive pulse charger for Li-ion batteries. In Proceedings of the 2017 8th International Conference of Information and Communication Technology for Embedded Systems (IC-ICTES), Chonburi, Thailand, 7–9 May 2017; pp. 1–6. [Google Scholar]

- Majid, N.; Hafiz, S.; Arianto, S.; Yuono, R.; Astuti, E.; Prihandoko, B. Analysis of effective pulse current charging method for lithium ion battery. J. Physics Conf. Ser. 2017, 817, 012008. [Google Scholar] [CrossRef]

- Saito, Y. Thermal behaviors of lithium-ion batteries during high-rate pulse cycling. J. Power Sources 2005, 146, 770–774. [Google Scholar] [CrossRef]

- Keil, P.; Jossen, A. Charging protocols for lithium-ion batteries and their impact on cycle life—An experimental study with different 18650 high-power cells. J. Energy Storage 2016, 6, 125–141. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, B.; Song, Y.; Zhang, J. A modified pulse charging method for lithium-ion batteries by considering stress evolution, charging time and capacity utilization. Front. Struct. Civ. Eng. 2019, 13, 294–302. [Google Scholar] [CrossRef]

- Jiang, Z.; Dougal, R.A. Synergetic control of power converters for pulse current charging of advanced batteries from a fuel cell power source. IEEE Trans. Power Electron. 2004, 19, 1140–1150. [Google Scholar] [CrossRef]

- Keskin, N.; Liu, H. Fast charging method for wireless and mobile devices using double-pulse charge technique. In Proceedings of the 2014 IEEE Wireless Power Transfer Conference, Jeju, Korea, 8–9 May 2014; pp. 44–47. [Google Scholar]

- Purushothaman, B.; Morrison, P.; Landau, U. Reducing mass-transport limitations by application of special pulsed current modes. J. Electrochem. Soc. 2005, 152, J33–J39. [Google Scholar] [CrossRef]

- Purushothaman, B.; Landau, U. Rapid charging of lithium-ion batteries using pulsed currents a theoretical analysis. J. Electrochem. Soc. 2006, 153, A533–A542. [Google Scholar] [CrossRef]

- Fang, H.; Depcik, C.; Lvovich, V. Optimal pulse-modulated Lithium-ion battery charging: Algorithms and simulation. J. Energy Storage 2018, 15, 359–367. [Google Scholar] [CrossRef]

- Chen, L.R.; Young, C.M.; Chu, N.Y.; Liu, C.S. Phase-locked bidirectional converter with pulse charge function for 42-V/14-V dual-voltage PowerNet. IEEE Trans. Ind. Electron. 2010, 58, 2045–2048. [Google Scholar] [CrossRef]

- Lv, H.; Huang, X.; Liu, Y. Analysis on pulse charging–discharging strategies for improving capacity retention rates of lithium-ion batteries. Ionics 2020, 26, 1749–1770. [Google Scholar] [CrossRef]

- Hua, C.C.; Lin, Z.X. Two-stage fast charging method using dual-switch flyback converter. Energy Procedia 2019, 156, 366–370. [Google Scholar] [CrossRef]

- Arabsalmanabadi, B.; Tashakor, N.; Javadi, A.; Al-Haddad, K. Charging techniques in lithium-ion battery charger: Review and new solution. In Proceedings of the IECON 2018-44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 5731–5738. [Google Scholar]

- Li, J.; Murphy, E.; Winnick, J.; Kohl, P.A. The effects of pulse charging on cycling characteristics of commercial lithium-ion batteries. J. Power Sources 2001, 102, 302–309. [Google Scholar] [CrossRef]

- Liang, T.J.; Wen, T.; Tseng, K.; Chen, J.F. Implementation of a regenerative pulse charger using hybrid buck-boost converter. In Proceedings of the 4th IEEE International Conference on Power Electronics and Drive Systems, Denpasar, Indonesia, 25–25 October 2001; Volume 2, pp. 437–442. [Google Scholar]

- Savoye, F.; Venet, P.; Millet, M.; Groot, J. Impact of periodic current pulses on Li-ion battery performance. IEEE Trans. Ind. Electron. 2011, 59, 3481–3488. [Google Scholar] [CrossRef]

- Zhu, J.; Sun, Z.; Wei, X.; Dai, H.; Gu, W. Experimental investigations of an AC pulse heating method for vehicular high power lithium-ion batteries at subzero temperatures. J. Power Sources 2017, 367, 145–157. [Google Scholar] [CrossRef]

- Monem, M.A.; Trad, K.; Omar, N.; Hegazy, O.; Mantels, B.; Mulder, G.; Van den Bossche, P.; Van Mierlo, J. Lithium-ion batteries: Evaluation study of different charging methodologies based on aging process. Appl. Energy 2015, 152, 143–155. [Google Scholar] [CrossRef]

- Abdel-Monem, M.; Trad, K.; Omar, N.; Hegazy, O.; Van den Bossche, P.; Van Mierlo, J. Influence analysis of static and dynamic fast-charging current profiles on ageing performance of commercial lithium-ion batteries. Energy 2017, 120, 179–191. [Google Scholar] [CrossRef]

- Zhu, S.; Hu, C.; Xu, Y.; Jin, Y.; Shui, J. Performance improvement of lithium-ion battery by pulse current. J. Energy Chem. 2019. [Google Scholar] [CrossRef]

- Hafiz, S.; Arianto, S.; Yunaningsih, R.Y.; Majid, N.; Prihandoko, B. Analysis of capacity fading effect on Lithium Cobalt cells caused by pulse current technique in fast charging methods. J. Physics: Conf. Ser. 2017, 817, 012026. [Google Scholar] [CrossRef]

- Amanor-Boadu, J.M.; Guiseppi-Elie, A. Improved Performance of Li-ion Polymer Batteries Through Improved Pulse Charging Algorithm. Appl. Sci. 2020, 10, 895. [Google Scholar] [CrossRef]

- Uno, M.; Tanaka, K. Influence of high-frequency charge–discharge cycling induced by cell voltage equalizers on the life performance of lithium-ion cells. IEEE Trans. Veh. Technol. 2011, 60, 1505–1515. [Google Scholar] [CrossRef]

- Li, Q.; Tan, S.; Li, L.; Lu, Y.; He, Y. Understanding the molecular mechanism of pulse current charging for stable lithium-metal batteries. Sci. Adv. 2017, 3, e1701246. [Google Scholar] [CrossRef] [PubMed]

- Ji, D.; Chen, L.; Ma, T.; Wang, J.; Liu, S.; Ma, X.; Wang, F. Research on adaptability of charging strategy for electric vehicle power battery. J. Power Sources 2019, 437, 226911. [Google Scholar] [CrossRef]

- Liduo, C.; Dengyue, J.; Yue, X.; Jinjie, Z.; Tianyi, M.; Mohan, W. Research and characterization of pulse charging strategy for lithium-ion traction battery. Energy Storage Sci. Technol. 2019, 8, 1182. [Google Scholar]

- Knap, V.; Zhang, T.; Stroe, D.I.; Schaltz, E.; Teodorescu, R.; Propp, K. Significance of the Capacity Recovery Effect in Pouch Lithium-Sulfur Battery Cells. ECS Trans. 2016, 74, 95–100. [Google Scholar] [CrossRef]

- Song, M.; Choe, S.Y. Fast and safe charging method suppressing side reaction and lithium deposition reaction in lithium ion battery. J. Power Sources 2019, 436, 226835. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).