Technology Development of Electric Vehicles: A Review

Abstract

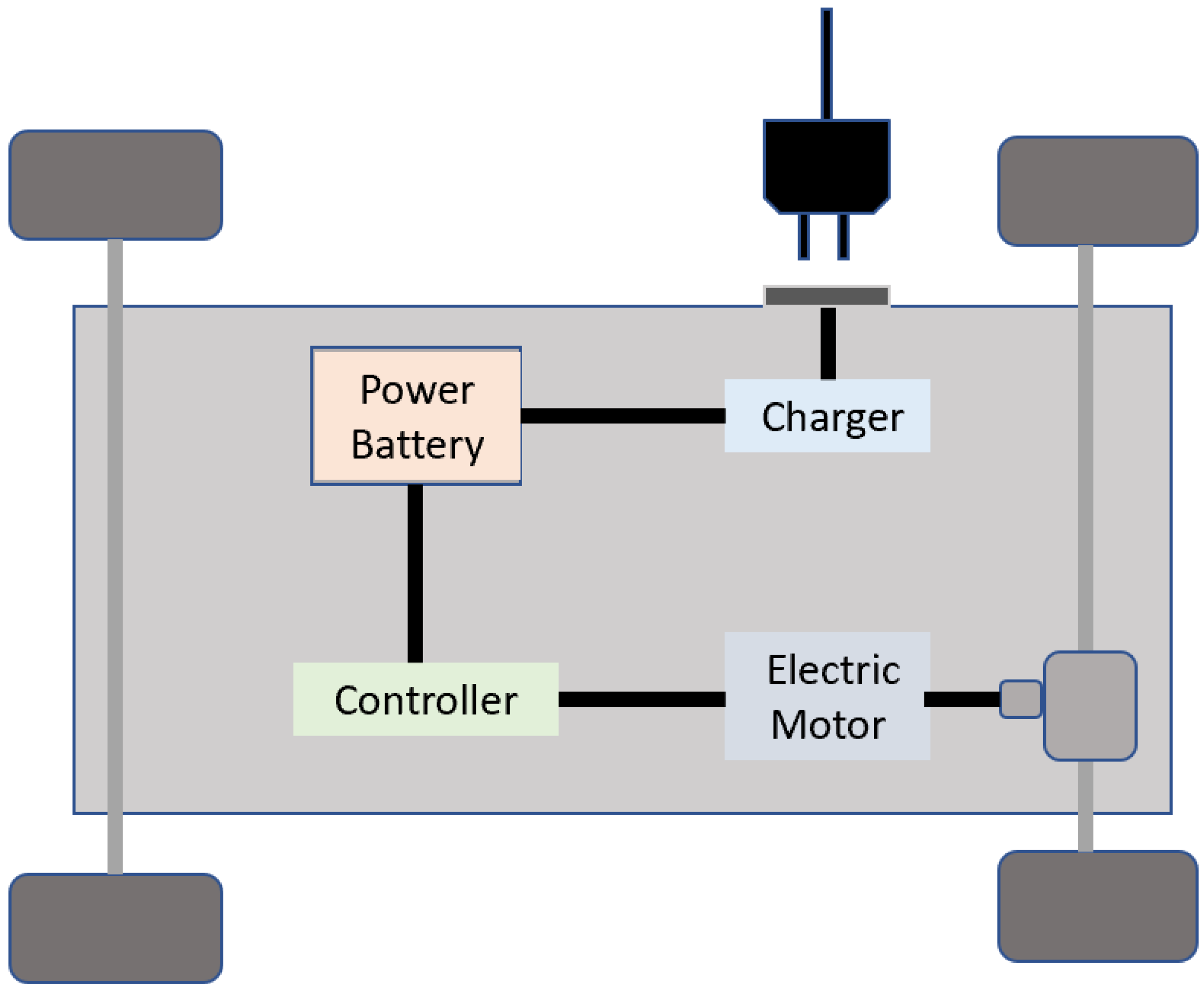

1. Introduction

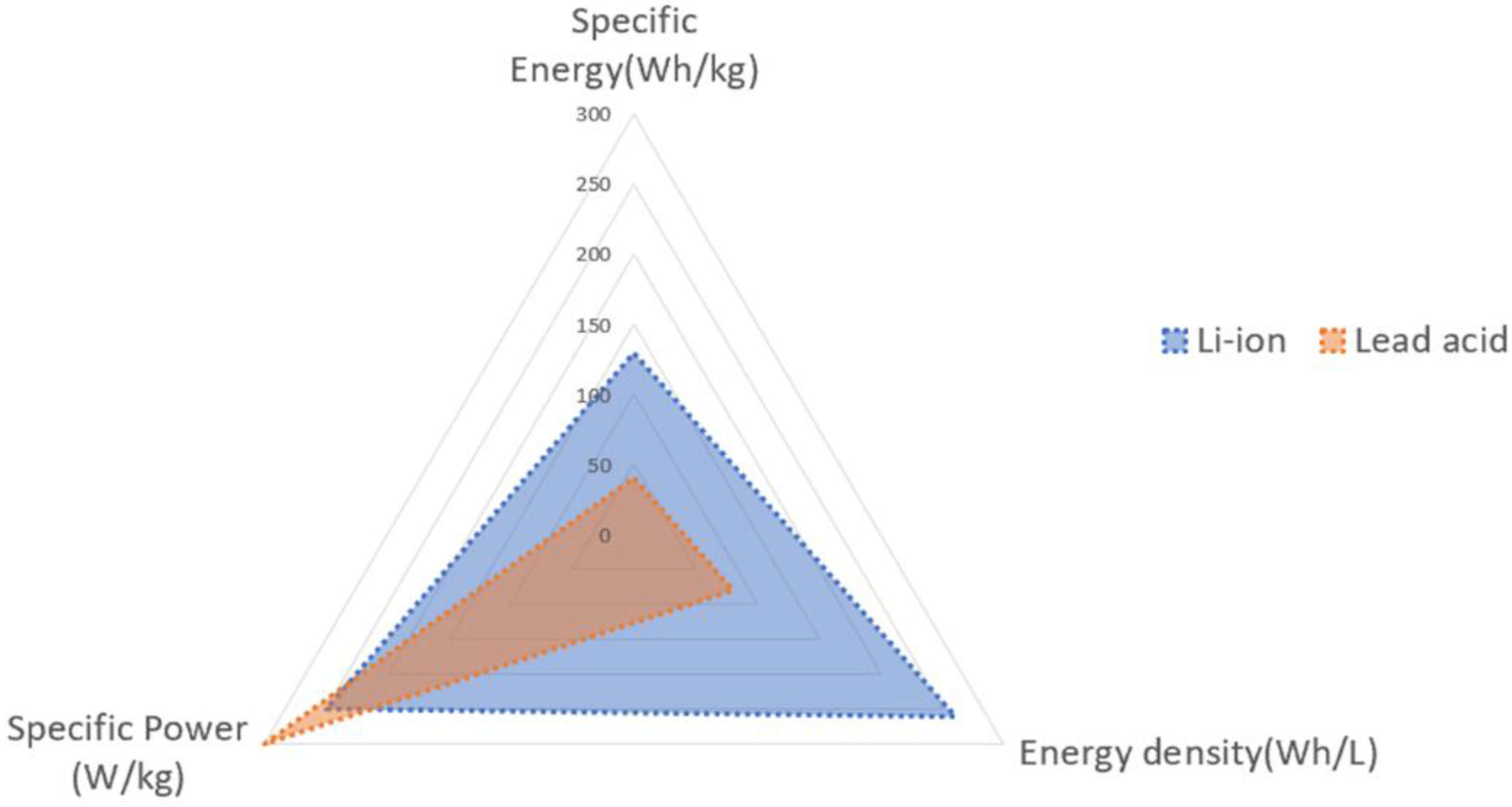

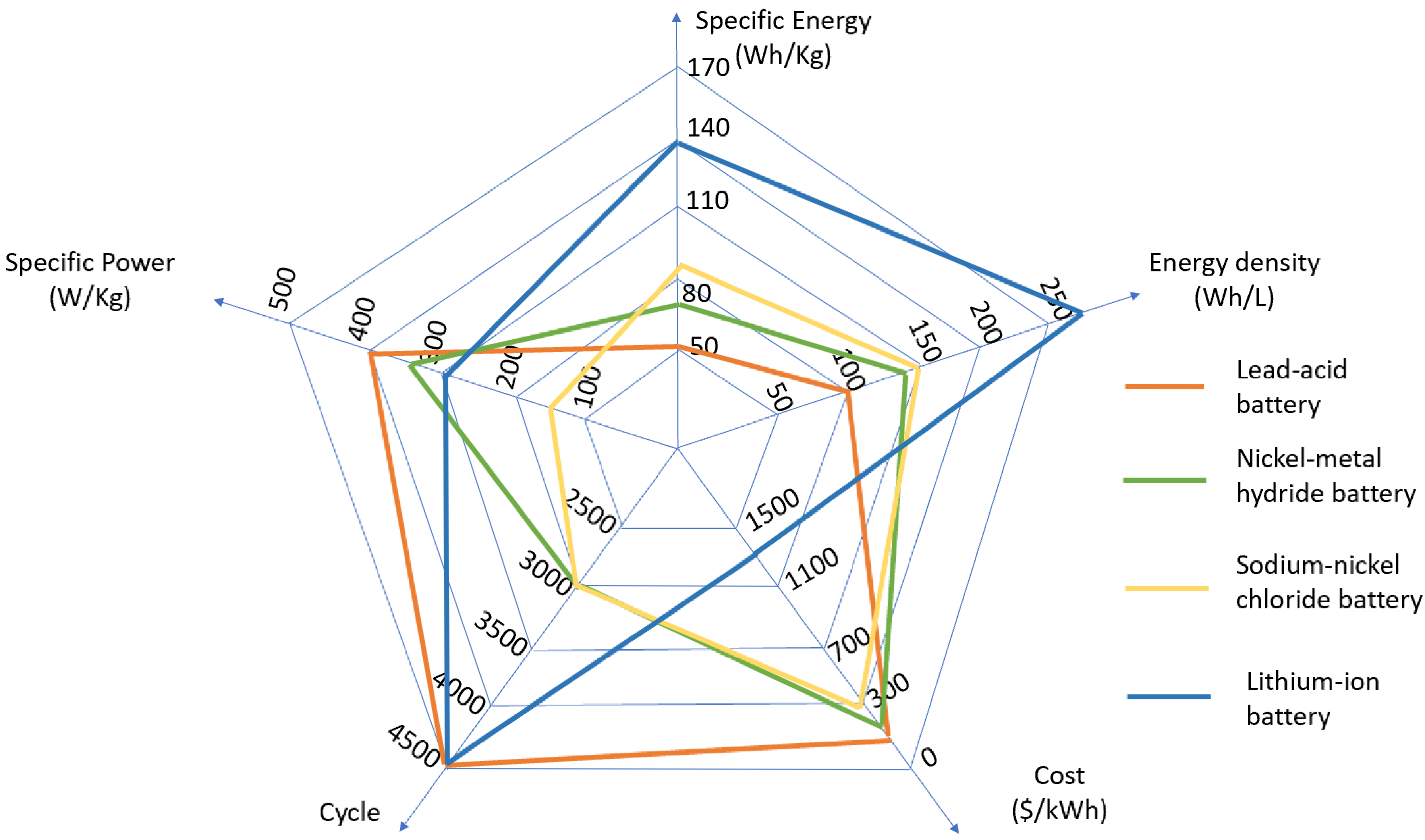

2. Battery Technology of EVs

2.1. Lead-Acid Batteries

2.2. Nickel-Metal Hydride Batteries

M(H) + 2NiO(OH)↔M + Ni(OH)2

H2 + NiO(OH)↔Ni(OH)2

2.3. Lithium-ion Batteries

2.4. Other Batteries

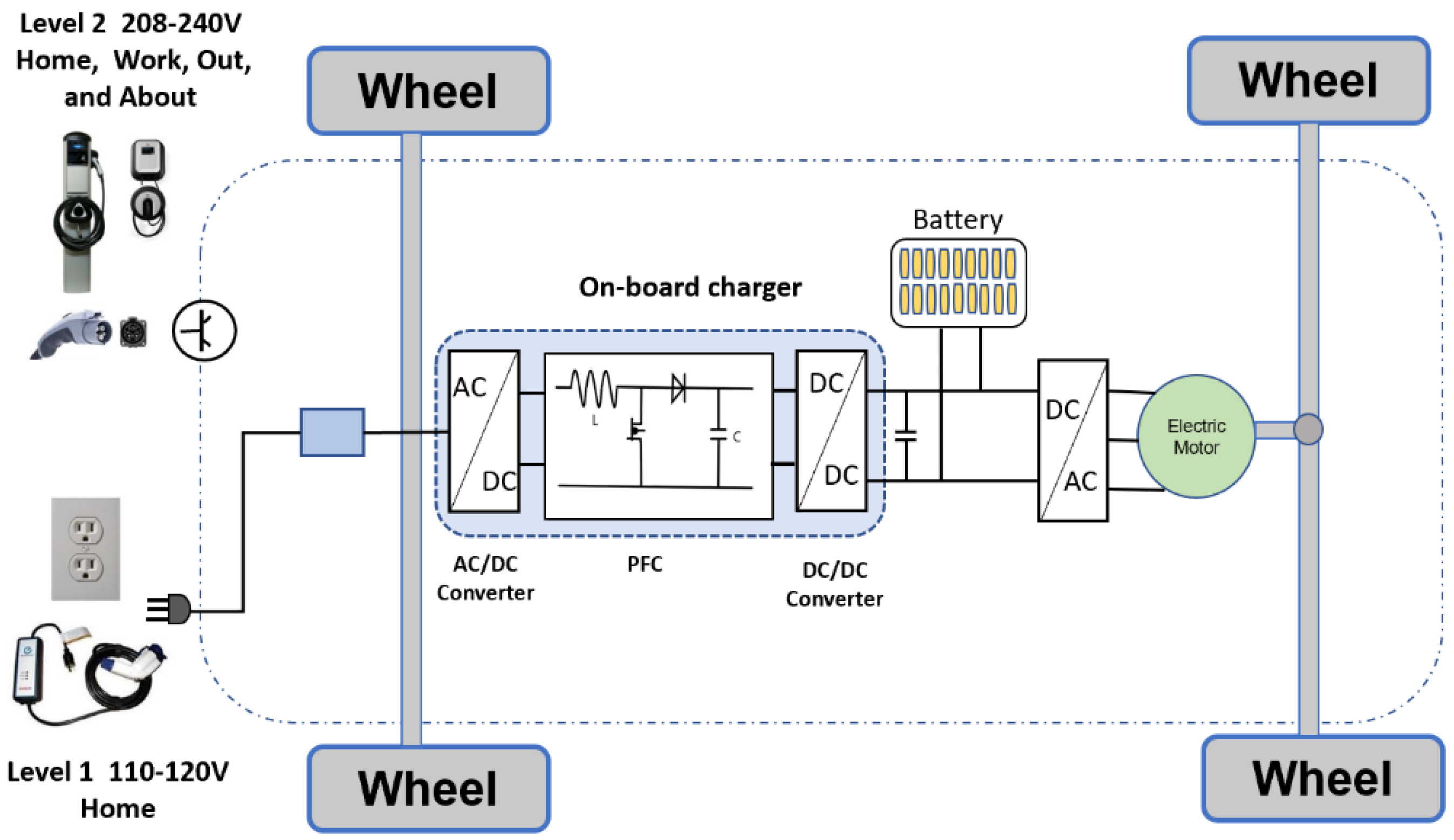

3. Charging Technology

3.1. Conductive Charging

3.1.1. Battery Charger

3.1.2. Charging Techniques of Conductive Charging

3.2. Inductive Charging

3.3. Battery Swapping

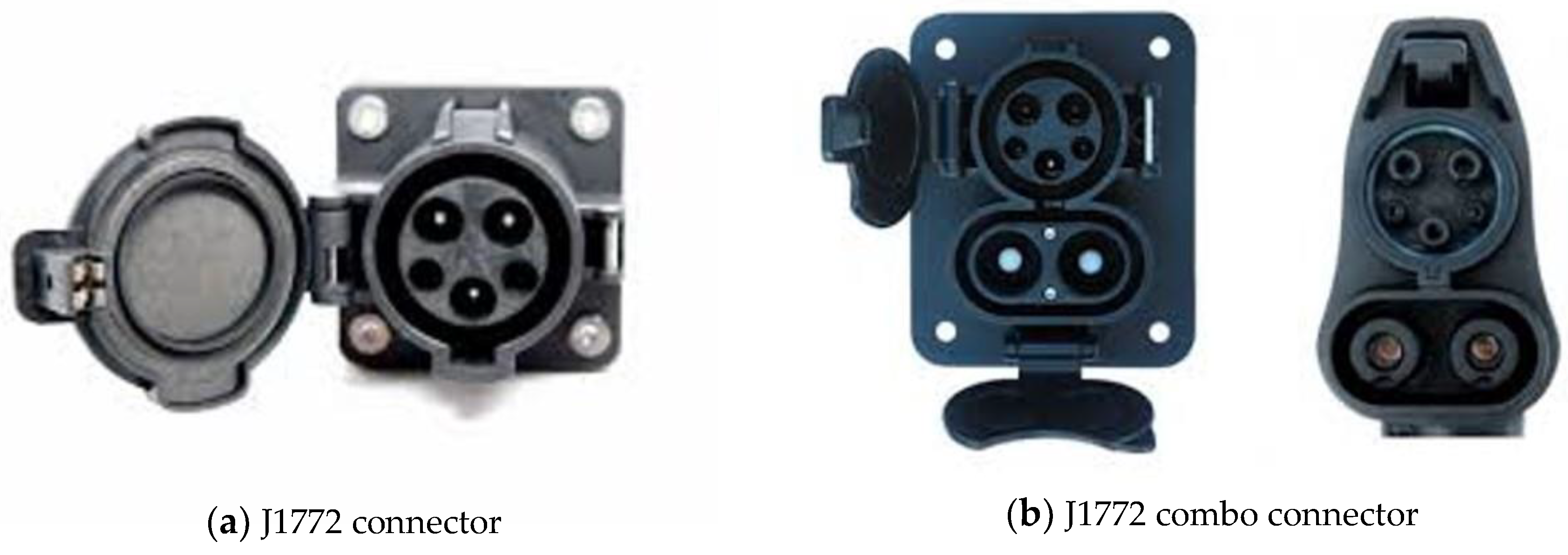

3.4. EV Charging Standards

3.5. Comparison of Charging Technology

4. Electric Motors

4.1. Induction Motor

4.2. Permanent Magnet Brushless DC Motor (PMBLDC)

4.3. Permanent Magnet Synchronous Motor (PMSM)

4.4. Switched Reluctance Motor

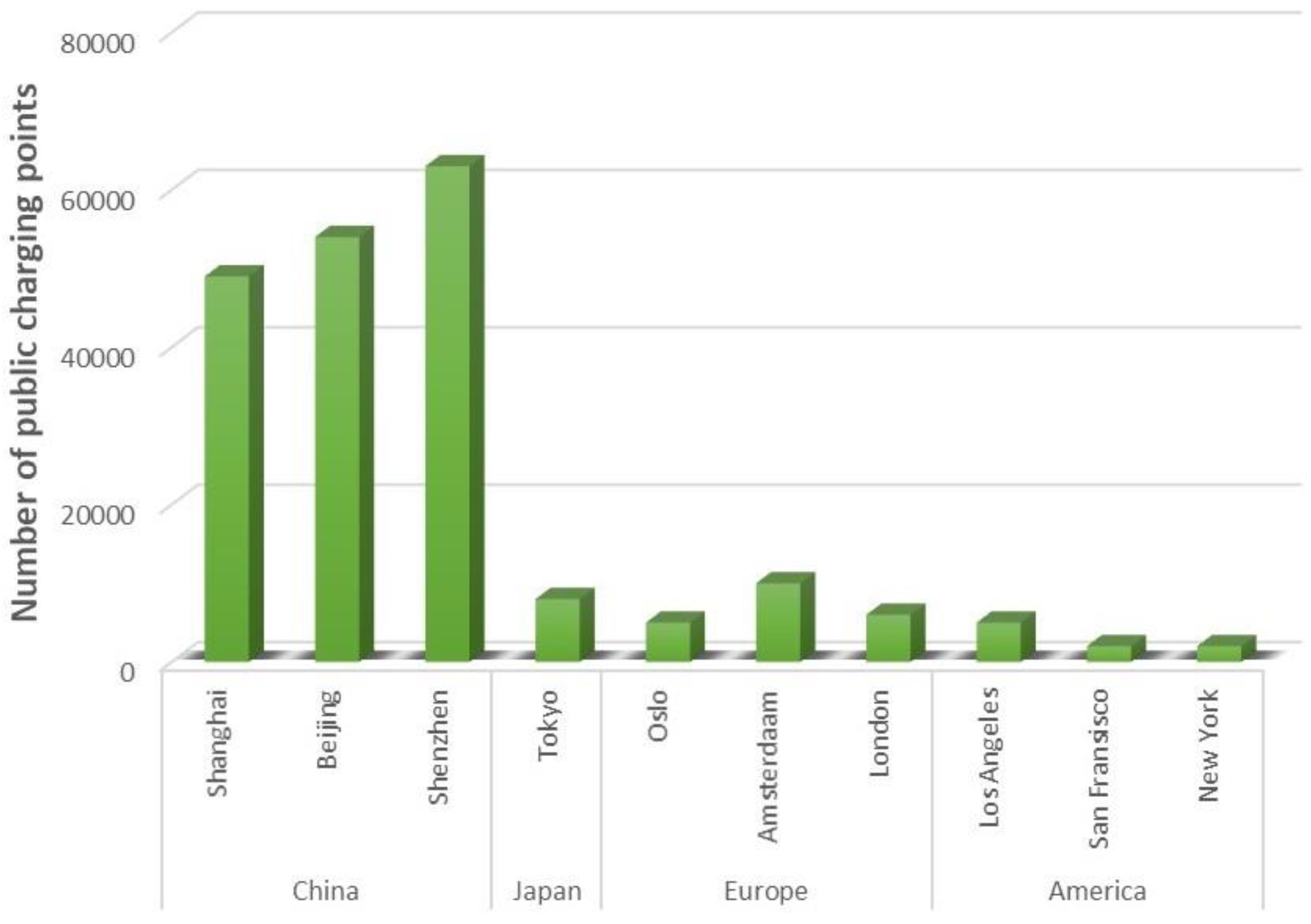

5. Charging Infrastructure

5.1. Organization of Charging Infrastructure

5.2. The Challenges of Charging Networks

5.3. Possibility of Fair Payment for EV Charging

6. Emerging Technologies for the Future Development of EVs

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qinyu, Q.; Fuquan, Z.; Zongwei, L.; Xin, H.; Han, H. Life cycle greenhouse gas emissions of Electric vehicles in China: Combining the vehicle cycle and fuel cycle. Energy 2019, 177, 222–233. [Google Scholar] [CrossRef]

- Li, C.; Negnevitsky, M.; Wang, X.; Yue, W.L.; Zou, X. Multi-criteria analysis of policies for implementing clean energy vehicles in China. Energy Policy 2019, 129, 826–840. [Google Scholar] [CrossRef]

- Wenbo, L.; Ruyin, L.; Hong, C. Consumers’ evaluation of national new energy vehicle policy in China: An analysis based on a four paradigm model. Energy Policy 2016, 99, 33–41. [Google Scholar] [CrossRef]

- Hu, Z.; Yuan, J. China’s NEV market development and its capability of enabling premium NEV: Referencing from the NEV market performance of BMW and Mercedes in China. Transp. Res. Part A Policy Pract. 2018, 118, 545–555. [Google Scholar] [CrossRef]

- Du, J.; Ouyang, D. Progress of Chinese electric vehicles industrialization in 2015: A review. Appl. Energy 2017, 188, 529–546. [Google Scholar] [CrossRef]

- Siqin, X.; Junping, J.; Xiaoming, M. Comparative Life Cycle Energy and GHG Emission Analysis for BEVs and phEVs: A Case Study in China. Energies 2019, 12, 834. [Google Scholar] [CrossRef]

- Gong, H.; Wang, M.Q.; Wang, H. New energy vehicles in China: Policies, demonstration, and progress. Mitig. Adapt. Strateg. Glob. Chang. 2013, 18, 207–228. [Google Scholar] [CrossRef]

- Steffen, B.; Jan, T.; Ulrich, F. Perspectives of electrical mobility: Total cost of ownership pf electric vehicles in Germany. Transp. Policy 2016, 50, 63–77. [Google Scholar] [CrossRef]

- Massiani, J. Cost-benefit analysis of policies for the development of electric vehicles in Germany: Methods and results. Transp. Policy 2015, 38, 19–26. [Google Scholar] [CrossRef]

- Palmer, K.; Tate, J.E.; Wadud, Z.; Nellthorp, J. Total cost of ownership and market share for hybrid and electric vehicles in the UK, US and Japan. Appl. Energy 2018, 209, 108–119. [Google Scholar] [CrossRef]

- She, Z.Y.; Sun, Q.; Ma, J.J.; Xie, B.C. What are the barriers to widespread adoption of Battery electric vehicles? A survey of public perception in Tianjin, China. Transp. Policy 2017, 56, 29–40. [Google Scholar] [CrossRef]

- Guarnieri, M. Looking back to electric cars. In Proceedings of the 2012 Third IEEE History of Electro-Technology Conference (HISTELCON), Pavia, Italy, 5–7 September 2012; pp. 1–6. [Google Scholar]

- Chan, C.C. The rise & fall of electric vehicles in 1828–1930: Lessons learned [scanning our past]. Proc. IEEE 2012, 101, 206–212. [Google Scholar] [CrossRef]

- Rajashekara, K. History of electric vehicles in General Motors. IEEE Trans. Ind. Appl. 1994, 30, 897–904. [Google Scholar] [CrossRef]

- History of the Electric Vehicle. Available online: https://en.wikipedia.org/wiki/History_of_the_electric_vehicle (accessed on 12 August 2019).

- 1 Million Pure EVs Worldwide: EV Revolution Begins! Available online: https://cleantechnica.com/2016/11/22/1-million-ev-revolution-begins/ (accessed on 22 November 2016).

- Electric and Plug-In Hybrid Cars Whiz Past 3m Mark Worldwide. Available online: https://www.theguardian.com/environment/2017/dec/25/electric-and-plug-in-hybrid-cars-3m-worldwide (accessed on 25 December 2017).

- Global Top. Available online: http://ev-sales.blogspot.com/2019/01/global-top-20-december-2018.html (accessed on 20 December 2018).

- Mersky, A.C.; Sprei, F.; Samaras, C.; Qian, Z.S. Effectiveness of incentives on electric vehicle adoption in Norway. Transp. Res. Part D 2016, 46, 56–68. [Google Scholar] [CrossRef]

- Matthews, L.; Lynes, J.; Riemer, M.; Del Matto, T.; Cloet, N. Do we have a car for you? Encouraging the uptake of electric vehicles at point of sale. Energy Policy 2017, 100, 79–88. [Google Scholar] [CrossRef]

- Das, H.S.; Tan, C.W.; Yatim, A.H. Fuel cell hybrid electric vehicles: A review on power conditioning units and topologies. Renew. Sustain. Energy Rev. 2017, 76, 268–291. [Google Scholar] [CrossRef]

- Hydrogen. Available online: https://www.iea.org/tcep/energyintegration/hydrogen/ (accessed on 15 May 2019).

- Boqiang, L.; Wei, W. Why people want to buy electric vehicle: An empirical study in first-tier cities of China. Energy Policy 2018, 112, 233–241. [Google Scholar] [CrossRef]

- Andwari, A.M.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of Battery Electric Vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Un-Noor, F.; Padmanaban, S.; Mihet-Popa, L.; Mollah, M.N.; Hossain, E. A Comprehensive Study of Key Electric Vehicle Components, Technologies, Challenges, Impacts, and Future Direction of Development. Energies 2017, 10, 1217. [Google Scholar] [CrossRef]

- Coffman, M.; Bernstein, P.; Wee, S. Electric vehicles revisited: A review of factors that affect adoption. Transp. Rev. 2017, 37, 79–93. [Google Scholar] [CrossRef]

- Liao, F.; Molin, E.; van Wee, B. Consumer preferences for electric vehicles: A literature review. Transp. Rev. 2017, 37, 252–275. [Google Scholar] [CrossRef]

- Yong, J.Y.; Vigna, K.R.; Tan, K.M.; Mithulananthan, N. A review on the state-of-the-art technologies of electric vehicle, its impacts and prospects. Renew. Sustain. Energy Rev. 2015, 49, 365–385. [Google Scholar] [CrossRef]

- Cuma, M.U.; Koroglu, T. A comprehensive review on estimation strategies used in hybrid and battery electric vehicles. Renew. Sustain. Energy Rev. 2015, 42, 517–531. [Google Scholar] [CrossRef]

- Groger, O.; Gasteiger, H.A.; Suchsland, J.P. Review-Electromobility: Batteries or Fuel Cells? J. Electrochem. Soc. 2015, 162, A2605–A2622. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Pelegov, D.; Pontes, J. Main Drivers of Battery Industry Changes: Electric Vehicles—A Market Overview. Batteries 2018, 4, 65. [Google Scholar] [CrossRef]

- Saxena, S.; Le Floch, C.; MacDonald, J.; Moura, S. Quantifying EV battery end-of-life through analysis of travel needs with vehicle powertrain models. J. Power Sources 2015, 282, 265–276. [Google Scholar] [CrossRef]

- Alshahrani, S.; Khalid, M.; Almuhaini, M. Electric Vehicles Beyond Energy Storage and Modern Power Network: Challenges and Applications. IEEE Access 2019, 7, 99031–99064. [Google Scholar] [CrossRef]

- Nykvist, B.; Nilsson, M. Rapidly falling costs of battery packs for electric vehicles. Nat. Clim. Chang. 2015, 5, 329–332. [Google Scholar] [CrossRef]

- Reddy, T.B. Linden’s Handbook of Batteries; McGraw-Hill: New York, NY, USA, 2011; pp. 167–201. [Google Scholar]

- Toyota to Make Over 10 Battery EV Models in Early 2020s. Available online: https://www.cnbc.com/2017/12/18/toyota-to-make-over-10-battery-ev-models-in-early-2020s.html (accessed on 18 December 2017).

- Horkos, P.G.; Yammine, E.; Karami, N. Review on different charging techniques of lead-acid batteries. In Proceedings of the 2015 Third International Conference on Technological Advances in Electrical, Electronics and Computer Engineering (TAEECE), Beirut, Lebanon, 29 April–1 May 2015; pp. 27–32. [Google Scholar] [CrossRef]

- May, G.J.; Davidson, A.; Monahov, B. Lead batteries for utility energy storage: A review. J. Energy Storage 2018, 15, 145–157. [Google Scholar] [CrossRef]

- Tie, S.F.; Tan, C.W. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

- Chau, K.T.; Wong, Y.S.; Chan, C.C. An overview of energy sources for electric vehicles. Energy Convers. Manag. 1999, 40, 1021–1039. [Google Scholar] [CrossRef]

- Electrical Energy Storage. White paper. In Proceedings of the International Electrotechnical Commission (IEC), Geneva, Switzerland, 14 November 2011; Available online: https://www.iec.ch/whitepaper/energystorage/ (accessed on 11 November 2019).

- Li, G.S.; Lu, X.C.; Kim, J.Y.; Meinhardt, K.D.; Chang, H.J.; Canfield, N.L.; Sprenkel, V.I. Advanced intermediate temperature sodium-nickel chloride batteries with ultra-high energy density. Nat. Commun. 2016, 7, 10683. [Google Scholar] [CrossRef] [PubMed]

- Hannan, M.A.; Hoque, M.M.; Mohamed, A.; Ayob, A. Review of energy storage systems for electric vehicle applications: Issues and challenges. Renew. Sustain. Energy Rev. 2017, 69, 771–789. [Google Scholar] [CrossRef]

- Khalgh, A.; Li, Z.H. Battery, Ultracapacitor, Fuel Cell, and Hybrid Energy Storage System for Electric, Hybrid Electric, Fuel Cell, and Plug-in Hybrid Electric Vehicles: State of the Art. IEEE Trans. Veh. Technol. 2010, 59, 2806–2824. [Google Scholar] [CrossRef]

- Chen, A.X.; Sen, P.K. Advancement in battery technology: A state-of-the-art review. In Proceedings of the Industry Applications Society Annual Meeting (IAS), Portland, OR, USA, 2–6 October 2016. Accession Number: 16447436. [Google Scholar] [CrossRef]

- Shen, Y.; Noréus, D.; Starborg, S. Increasing NiMH battery cycle life with oxygen. Int. J. Hydrog. Energy 2018, 43, 18626–18631. [Google Scholar] [CrossRef]

- Manzetti, S.; Mariasiu, F. Electric vehicle battery technologies: From present state to future systems. Renew. Sustain. Energy Rev. 2015, 51, 1004–1012. [Google Scholar] [CrossRef]

- Ding, Y.; Cano, Z.P.; Yu, A.; Lu, J.; Chen, Z. Automotive Li-Ion Batteries: Current Status and Future Perspectives. Electrochem. Energy Rev. 2019, 2, 1–28. [Google Scholar] [CrossRef]

- Bresser, D.; Hosoi, K.; Howell, D.; Li, H.; Zeisel, H.; Amine, K.; Passerini, S. Perspectives of automotive battery R&D in China, Germany, Japan, and the USA. J. Power Sources 2018, 382, 176–178. [Google Scholar] [CrossRef]

- Lee, J.H.; Yoon, C.S.; Hwang, J.Y.; Kim, S.J.; Maglia, F.; Lamp, P.; Myung, S.T.; Sun, Y.K. High-energy-density lithium-ion battery using a carbon-nanotube-Si composite anode and a compositionally graded Li[Ni0.85Co0.05Mn0.10]O-2 cathode. Energy Environ. Sci. 2016, 9, 2152–2158. [Google Scholar] [CrossRef]

- Akhil, A.A.; Huff, G.; Currier, A.B.; Kaun, B.C.; Rastler, D.M.; Chen, S.B.; Cotter, A.L.; Bradshaw, D.T.; Gauntlett, W.D. DOE/EPRI 2013 Electricity Storage Handbook in Collaboration with NRECA. In Sandia Report, Sand; Sandia National Laboratories: Albuquerque, NM, USA, 2013; pp. 201–213. [Google Scholar]

- Nazri, G.A.; Pistoia, G. Lithium Batteries: Science and Technology (Paperback); Springer: Berlin, Germany, 2009; pp. 455–478. [Google Scholar]

- Kucinskis, G.; Bajars, G.; Kleperis, J. Graphene in lithium ion battery cathode materials: A review. J. Power Sources 2013, 240, 66–79. [Google Scholar] [CrossRef]

- Son, I.H.; Park, J.H.; Park, S.; Park, K.; Han, S.; Shin, J.; Doo, S.G.; Hwang, H.; Choi, J.W. Graphene balls for lithium rechargeable batteries with fast charging and high volumetric energy densities. Nat. Commun. 2017, 8, 1561. [Google Scholar] [CrossRef] [PubMed]

- Suberu, M.Y.; Mustafa, M.W.; Bashir, N. Energy storage systems for renewable energy power sector integration and mitigation of intermittency. Renew. Sustain. Energy Rev. 2014, 35, 499–514. [Google Scholar] [CrossRef]

- Veneri, O.; Capasso, C.; Patalano, S. Experimental study on the performance of a Zebra battery based propulsion system for urban commercial vehicles. Appl. Energy 2017, 185 Pt 2, 2005–2018. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Kouchachvili, L.; Yaïci, W.; Entchev, E. Hybrid battery/supercapacitor energy storage system for the electric vehicles. J. Power Sources 2018, 374, 237–248. [Google Scholar] [CrossRef]

- Stokes, L.C.; Breetz, H.L. Politics in the U.S. energy transition: Case studies of solar, wind, biofuels and electric vehicles policy. Energy Policy 2018, 113, 76–86. [Google Scholar] [CrossRef]

- Dominkovića, D.F.; Bačekovićb, I.B.; Pedersena, A.S.; Krajačićc, G. The future of transportation in sustainable energy systems: Opportunities and barriers in a clean energy transition. Renew. Sustain. Energy Rev. 2018, 82, 1823–1838. [Google Scholar] [CrossRef]

- Rahman, I.; Vasant, P.M.; Singh, B.S.M.; Abdullah-Al-Wadud, M.; Adnan, N. Review of recent trends in optimization techniques for plug-in hybrid, and electric vehicle charging infrastructures. Renew. Sustain. Energy Rev. 2016, 58, 1039–1047. [Google Scholar] [CrossRef]

- Electric Light & Power [Internet]. IEC Publishes Tow International EV Standards. Available online: http://www.elp.com/articles/2011/10/iec-publishes-two-international-ev-standards.html (accessed on 19 October 2011).

- China and Japan Plan to Develop a Unified Standard for Electric Vehicle Charging. Available online: http://www.mofcom.gov.cn/article/i/jyjl/m/201808/20180802778707.shtml (accessed on 23 August 2018).

- Li, B.; Lee, F.C.; Li, Q.; Liu, Z. Bi-directional on-board charger architecture and control for achieving ultra-high efficiency with wide battery voltage range. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 2470–6647. [Google Scholar] [CrossRef]

- Whitaker, B.; Barkley, A.; Cole, Z.; Passmore, B.; Martin, D.; McNutt, T.R.; Lostetter, A.B.; Lee, J.S.; Shiozaki, K. A High-Density, High-Efficiency, Isolated On-Board Vehicle Battery Charger Utilizing Silicon Carbide Power Device. IEEE Trans. Power Electron. 2014, 29, 2606–2617. [Google Scholar] [CrossRef]

- Shin, C.J.; Lee, J.Y. An Electrolytic Capacitor-less Bi-Directional EV On-Board Charger Using Harmonic Modulation Technique. IEEE Trans. Power Electron. 2014, 29, 5195–5203. [Google Scholar] [CrossRef]

- Tera, T.; Taki, H.; Shimizu, T. Loss Reduction of Laminated Core Inductor used in On-board Charger for EVs. J. Ind. Appl. 2015, 4, 626–633. [Google Scholar] [CrossRef]

- Kisacikoglu, M.C.; Kesler, M.; Tolbert, L.M. Single-Phase On-Board Bidirectional PEV Charger for V2G Reactive Power Operation. IEEE Trans. Smart Grid 2015, 6, 767–775. [Google Scholar] [CrossRef]

- Bojrup, M.; Karlsson, P.; Alakula, M.; Simonsson, B. A dual purpose battery charger for electric vehicle. In Proceedings of the PESC 98 Record. 29th Annual IEEE Power Electronics Specialists Conference, Fukuoka, Japan, 22–22 May 1998. (Cat. No.98CH36196). [Google Scholar] [CrossRef]

- Ota, Y.; Taniguchi, H.; Suzuki, H.; Nakajima, T.; Baba, J.; Yokoyama, A. Implementation of grid-friendly charging scheme to electric vehicle off-board charger for V2G. In Proceedings of the 3rd IEEE PES Innovative Smart Grid Technologies Europe (ISGT Europe), Berlin, Germany, 14–17 October 2012. [Google Scholar] [CrossRef]

- Seung-Ki, S.; Sang-Joon, L. An integral battery charger for four-wheel drive electric vehicle. IEEE Trans. Ind. Appl. 1995, 31, 1096–1099. [Google Scholar] [CrossRef]

- Muneret, X.; Coux, M.; Lenain, P. Analysis of the partial charge reactions within a standby VRLA battery leading to an understanding of intermittent charging techniques. In Proceedings of the INTELEC, Twenty-Second International Telecommunications Energy Conference, Phoenix, AZ, USA, 10–14 September 2000. (Cat. No.00CH37131). [Google Scholar] [CrossRef]

- Chopra, S.; Bauer, P. Driving Range Extension of EV With On-Road Contactless Power Transfer-A Case Study. IEEE Trans. Ind. Electron. 2013, 60, 329–338. [Google Scholar] [CrossRef]

- Li, S.; Mi, C.C. Wireless power taransfer for electric vehicle applications. J. Emerg. Sel. Top. Power Electron. 2015, 3, 4–17. [Google Scholar] [CrossRef]

- Choi, S.Y.; Gu, B.W.; Jeong, S.Y.; Rim, C.T. Advances in Wireless Power Transfer Systems for Roadway-Powered Electric Vehicles. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 18–36. [Google Scholar] [CrossRef]

- Thai, V.X.; Choi, S.Y.; Choi, B.H.; Kim, J.H.; Rim, C.T. Coreless Power Supply Rails Compatible with Both Stationary and Dynamic Charging of Electric Vehicles. In Proceedings of the IEEE 2nd International Future Energy Electronics Conference (IFEEC), Taipei, Taiwan, 1–4 November 2015. [Google Scholar] [CrossRef]

- Onar, O.C.; Miller, J.M.; Campbell, S.L.; Coomer, C.; White, C.P.; Seiber, L.E. A Novel Wireless Power Transfer for In-Motion EV/PHEV Charging. In Proceedings of the Twenty-Eighth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013. [Google Scholar] [CrossRef]

- Miller, J.M.; Onar, O.C.; Chinthavali, M. Primary-Side Power Flow Control of Wireless Power Transfer for Electric Vehicle Charging. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 147–162. [Google Scholar] [CrossRef]

- Miller, J.M.; Onar, O.C.; White, C.; Campbell, S.; Coomer, C.; Seiber, L.; Sepe, R.J.; Steyerl, A. Demonstrating Dynamic Wireless Charging of an Electric Vehicle—The benefit of electrochemical capacitor smoothing. IEEE Power Electron. Mag. 2014, 12–24. [Google Scholar] [CrossRef]

- Miller, J.M.; Jones, P.; Li, J.-M.; Onar, O.C. ORNL Experience and challenges Facing Dynamic Wireless Power Charging of EV’s. IEEE Circuits Syst. Mag. 2015, 15, 40–53. [Google Scholar] [CrossRef]

- Miller, J.M.; White, C.P.; Onar, O.C.; Ryan, P.M. Grid Side Regulation of Wireless Power Charging of Plug-In Electric Vehicles. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012. [Google Scholar] [CrossRef]

- Jones, P.; Onar, O. Impact of Wireless Power Transfer in transportation: Future transportation enablerm or near term distraction. In Proceedings of the IEEE International Electric Vehicle Conference (IEVC), Florence, Italy, 17–19 December 2014. [Google Scholar] [CrossRef]

- Onar, O.C.; Miller, J.M.; Campbell, S.L.; Coomer, C.; White, C.P.; Seiber, L.E. Oak Ridge National Laboratory Wireless Power Transfer Development for Sustainable Campus Initiative. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 16–19 June 2013. [Google Scholar] [CrossRef]

- Budhia, M.; Covic, G.; Boys, J. A New IPT Magnetic Coupler for Electric Vehicle Charging Systems. In Proceedings of the 36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010. [Google Scholar] [CrossRef]

- Machura, P.; Li, Q. A critical review on wireless charging for electric vehicles. Renew. Sustain. Energy Rev. 2019, 104, 209–234. [Google Scholar] [CrossRef]

- Sarker, M.R.; Pandzic, H.; Ortega-Vazquez, M.A. Electric vehicle battery swapping station: Business case and optimization model. In Proceedings of the 2013 International Conference on Connected Vehicles and Expo (ICCVE), Las Vegas, NV, USA, 2–6 December 2013; pp. 289–294. [Google Scholar] [CrossRef]

- Avci, B.; Girotra, K.; Netessine, S. Electric vehicles with a battery switching station: Adoption and environmental impact. Manag. Sci. 2015, 61, 772–794. [Google Scholar] [CrossRef]

- Ban, M.; Yu, J.; Li, Z.; Guo, D.; Ge, J. Battery Swapping: An aggressive approach to transportation electrification. IEEE Electrif. Mag. 2019, 7, 44–54. [Google Scholar] [CrossRef]

- Sarker, M.R.; Pandzic, H.; Ortega-Vazquez, M.A. Optimal Operation and Services Scheduling for an Electric Vehicle Battery Swapping Station. IEEE Trans. Power Syst. 2015, 30, 901–910. [Google Scholar] [CrossRef]

- Yan, J.; Menghwar, M.; Asghar, E.; Panjwani, M.K.; Liu, Y.Q. Real-time energy management for a smart community microgrid with battery swapping and renewables. Appl. Energy 2019, 238, 180–194. [Google Scholar] [CrossRef]

- Mahoor, M.; Hosseini, Z.S.; Khodaei, A. Least-cost operation of a battery swapping station with random customer requests. Energy 2019, 172, 913–921. [Google Scholar] [CrossRef]

- Sultana, U.; Khairuddin, A.B.; Sultana, B.; Rasheed, N.; Qazi, S.H.; Malik, N.R. Placement and sizing of multiple distributed generation and battery swapping stations using grasshopper optimizer algorithm. Energy 2018, 165, 408–421. [Google Scholar] [CrossRef]

- Zheng, J.; Mehndiratta, S.; Guo, J.Y.; Liu, Z. Strategic policies and demonstration program of electric vehicle in China. Transp. Policy 2012, 19, 17–25. [Google Scholar] [CrossRef]

- Scott, H. Understanding the impact of reoccurring and non-financial incentives on plug-in electric vehicle adoption—A review. Transp. Res. Part A Policy Pract. 2019, 119, 1–14. [Google Scholar] [CrossRef]

- Hao, H.; Ou, X.; Du, J.; Wang, H.; Ouyang, M. China’s electric vehicle subsidy scheme: Rationale and impacts. Energy Policy 2014, 73, 722–732. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, Y.; Yu, E.; Rao, R.; Xie, J. Review of electric vehicle policies in China: Content summary and effect analysis. Renew. Sustain. Eng. Rev. 2017, 70, 698–714. [Google Scholar] [CrossRef]

- Lee, H.K.; Nam, K.H. An Overview: Current Control Technique for Propulsion Motor for EV. Trans. Korean Inst. Power Electron. 2016, 21, 388–395. [Google Scholar] [CrossRef][Green Version]

- Rajashekara, K. Present status and future trends in electric vehicle propulsion technologies. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 3–10. [Google Scholar] [CrossRef]

- Sutikno, T.; Idris, N.R.N.; Jidin, A. A review of direct torque control of induction motors for sustainable reliability and energy efficient drives. Renew. Sustain. Energy Rev. 2014, 32, 548–558. [Google Scholar] [CrossRef]

- Kumar, M.S.; Revankar, S.T. Development scheme and key technology of an electric vehicle: An overview. Renew. Sustain. Energy Rev. 2017, 70, 1266–1285. [Google Scholar] [CrossRef]

- Ameid, T.; Menacer, A.; Talhaoui, H.; Azzoug, Y. Discrete wavelet transform and energy eigen value for rotor bars fault detection in variable speed field-oriented control of induction motor drive. ISA Trans. 2018, 79, 217–231. [Google Scholar] [CrossRef]

- Chan, C.C. The state of the art of electric and hybrid vehicles. Proc. IEEE 2002, 90, 247–275. [Google Scholar] [CrossRef]

- Hoand, L.H. Comparison of field-oriented control and direct torque control for induction motor drives. In Proceedings of the IEEE 34th IAS Annual Meeting Conference Record of the Industry Applications Conference, Phoenix, AZ, USA, 3–7 October 1999; pp. 1245–1252. [Google Scholar] [CrossRef]

- Casadei, D.; Profumo, F.; Serra, G.; Tani, A. FOC and DTC: Two viable schemes for induction motors torque control. IEEE Trans. Power Electron. 2002, 17, 779–787. [Google Scholar] [CrossRef]

- Singh, B.; Jain, P.; Mittal, A.P.; Gupta, J.R.P. Direct torque control: A practical approachto electric vehicle. IEEE Power India Conf. 2006, 4. [Google Scholar] [CrossRef]

- Farasat, M.; Karaman, E. Speed sensorless electric vehicle propulsion system using hybrid FOC-DTC induction motor drive. In Proceedings of the International Conference on Electrical Machines and Systems (ICEMS), Beijing, China, 20–23 August 2011; pp. 1–5. [Google Scholar] [CrossRef]

- Rehman, H.; Longya, X. Alternative energy vehicles drive system: Control. Flux and torque estimation and efficiency optimization. IEEE Trans. Veh. Technol. 2011, 60, 3625–3634. [Google Scholar] [CrossRef]

- Singh, B.; Singh, S. State of art on permanent magnet brushless DC motor drives. J. Power Electron. 2009, 9, 1–17. [Google Scholar]

- Chan, C.C. An overview of Electric Vehicle Technology. Proc. IEEE 1993, 81, 1202–1213. [Google Scholar] [CrossRef]

- Chan, C.C.; Chau, K.T. Modern Electric Vehicles Technology; Oxford University Press: Oxford, UK, 2001; pp. 167–180. [Google Scholar]

- Kim, T.; Lee, W.; Parsa, L.; Ehsani, M. Optimal power and torque control of a brushless DC (BLDC) motor/generator drive in electric and hybrid electric vehicles. In Proceedings of the IEEE Industry Applications Conference, Tampa, FL, USA, 8–12 October 2006; pp. 1276–1281. [Google Scholar] [CrossRef]

- Gamazo-Real, J.C.; Vazquez-Sanchez, E.; Gomez-Gil, J. Position and speed control of brushless DC motors using sensorless techniques and application trends. Sensors 2010, 10, 6901–6947. [Google Scholar] [CrossRef] [PubMed]

- Hubik, V.; Sveda, M.; Singule, V. On the Development of BLDC Motor Control Run-Up Algorithms for Aerospace Application. In Proceedings of the 13th Power Electronics and Motion Control Conference (EPE-PEMC2008), Poznan, Poland, 1–3 September 2008; pp. 1620–1624. [Google Scholar] [CrossRef]

- Sundeep, S.; Singh, B. Robust Position Sensorless Technique for a PMBLDC Motor. IEEE Trans. Power Electron. 2018, 33, 6936–6945. [Google Scholar] [CrossRef]

- Singh, S.; Singh, S. Position Sensorless Control for PMBLDC Motor Drive Using Digital Signal Processor. J. Circuits Syst. Comput. 2016, 25, 1650077. [Google Scholar] [CrossRef]

- Kumar, M.; Singh, B.; Singh, B.P. DSP based sensorless control of permanent magnet brushless DC motor. IETE J. Res. 2003, 49, 269–275. [Google Scholar] [CrossRef]

- Carpiuc, S.; Lazar, C. Modeling of synchronous electric machines for real-time simulation and automotive applications. J. Frankl. Inst. 2017, 354, 6258–6281. [Google Scholar] [CrossRef]

- Finken, T.; Hombitzer, M.; Hameyer, K. Study and comparison of several permanent-magnet excited rotor types regarding their applicability in electric vehicles. In Proceedings of the 2010 Emobility-Electrical Power Train conference, Leipzig, Germany, 8–9 November 2010. [Google Scholar] [CrossRef]

- Chaoui, H.; Khyamy, M.; Okoye, O. MTPA based operation point speed tracking for PMSM drives without explicit current regulation. Electr. Power Syst. Res. 2017, 151, 125–135. [Google Scholar] [CrossRef]

- Boubaker, N.; Matt, D.; Enrici, P.; Nierlich, F.; Durand, G.; Orlandini, F.; Longère, X.; Aïgba, J.S. Study of eddy-current loss in the sleeves and Sm-Co magnets of a high-performance SMPM synchronous machine (10 kRPM, 60 kW). Electr. Power Syst. Res. 2017, 142, 20–28. [Google Scholar] [CrossRef]

- Feng, G.; Lai, C.; Iyer, K.; Kar, N. Improved high-frequency voltage injection based permanent magnet temperature estimation for PMSM condition monitoring for EV applications. IEEE Trans. Veh. Technol. 2018, 67, 216–225. [Google Scholar] [CrossRef]

- Lara, J.; Xu, J.; Chandra, A. Effects of rotor position error in the performance of field-oriented-controlled PMSM drives for electric vehicle traction applications. IEEE Trans. Ind. Electron. 2016, 63, 4738–4751. [Google Scholar] [CrossRef]

- Fodorean, D.; Sarrazin, M.; Martis, C.; Anthonis, J.; van der Auweraer, H. Electromagnetic and structural analysis for a surface-mounted PMSM used for light-EV. IEEE Trans. Ind. Electron. 2016, 52, 2892–2899. [Google Scholar] [CrossRef]

- Niu, F.; Wang, B.; Babel, A.; Li, K. Comparative evaluation of direct torque control strategies for permanent magnet synchronous machines. IEEE Trans. Power Electron. 2015, 31, 1408–1424. [Google Scholar] [CrossRef]

- Hassan, A.; Shehata, E. High performance direct torque control schemes for an IPMSM drive. Electr. Power Syst. Res. 2012, 89, 171–182. [Google Scholar] [CrossRef]

- Rocha-Osorio, C.M.; Solís-Chaves, J.; Casella, R.; Capovilla, C.; Azcue-Puma, J.; Sguarezi-Filho, A. GPRS/EGPRS standards applied to DTC of a DFIG using fuzzy PI controllers. Int. J. Electr. Power Energy Syst. 2017, 93, 365–373. [Google Scholar] [CrossRef]

- Khooban, M.H.; Vafamand, N.; Niknam, T. T-S fuzzy model predictive speed control of electrical vehicles. ISA Trans. 2016, 64, 231–240. [Google Scholar] [CrossRef]

- Niu, H.; Yu, J.; Yu, H.; Lin, C.; Zhao, L. Adaptive fuzzy output feedback and command filtering error compensation control for permanent magnet synchronous motors in electric vehicle drive systems. J. Frankl. Inst. 2017, 354, 6610–6629. [Google Scholar] [CrossRef]

- Yu, J.; Shi, P.; Dong, W.; Lin, C. Reduced-order observer-based adaptive fuzzy tracking control for chaotic permanent magnet synchronous motors. Neurocomputing 2016, 214, 201–209. [Google Scholar] [CrossRef]

- Pellegrino, G.; Armando, E.; Guglielmi, P. Optimal exploitation of the constant power region of IPM drives based on field oriented control. In Proceedings of the IEEE Industry Applications Conference, New Orleans, LA, USA, 23–27 September 2007; pp. 1335–1340. [Google Scholar] [CrossRef]

- Chinchilla, M.; Arnaltes, S.; Burgos, J. Control of permanent-magnet generators applied to variable-speed wind energy system connected to the grid. IEEE Trans. Energy Convers. 2006, 87, 130–135. [Google Scholar] [CrossRef]

- Lara, A. Chandra. Performance investigation of two novel HSFSI demodulation algorithms for encoderless FOC of PMSMs intended for EV propulsion. IEEE Trans. Ind. Electron. 2018, 65, 1074–1083. [Google Scholar] [CrossRef]

- Tang, Z.; Akin, B. A new LMS algorithm based deadtime compensation method for PMSM FOC drives. IEEE Trans. Ind. Appl. 2018, 54, 6472–6484. [Google Scholar] [CrossRef]

- Jung, S.; Hong, J.K. Nam Current minimizing torque control of the IPMSM using Ferrari’s method. IEEE Trans. Power Electron. 2013, 28, 5603–5617. [Google Scholar] [CrossRef]

- Arias, A.; Ibarra, E.; Tarancho, E.; Grino, R.; Kortabarria, I.; Caum, J. Comprehensive high speed automotive SM-PMSM torque control stability analysis including novel control approach. Int. J. Electr. Power Energy Syst. 2019, 109, 423–433. [Google Scholar] [CrossRef]

- Miranda, R.S.; Fernandes, E.M.; Jacobina, C.N.; Lima, A.M.N.; Oliveira, A.C.; Correa, M.B.R. Sensorless control of a PMSM synchronous motor at low speed. In Proceedings of the IECON 2006–32ND Annual Conference on IEEE Industrial Electronics, Paris, France, 6–10 November 2006. [Google Scholar] [CrossRef]

- Monteiro, J.R.; Oliveira, A.A.; Aguiar, M.L.; Sanagiotti, E.R. Electromagnetic torque ripple and copper losses reduction in permanent magnet synchronous machines. Eur. Trans. Electr. Power 2012, 22, 627–644. [Google Scholar] [CrossRef]

- Gan, C.; Wu, J.H.; Sun, Q.G.; Kong, W.B.; Li, H.Y.; HU, Y.H. A review on machine topologies and control techniques for low-noise switched reluctance motors in electric vehicle application. IEEE Access 2018, 6, 31430–31443. [Google Scholar] [CrossRef]

- Jing, L.B.; Cheng, J. Research on torque ripple optimization of switched reluctance motor based on finite element method. Prog. Electromagn. Res. 2018, 74, 115–123. [Google Scholar] [CrossRef]

- Millithaler, P.; Dupont, J.B.; Ouisse, M.; Sadoulet-Reboul, E.; Bouhaddi, N. Viscoelastic property tuning for reducing noise radiated by switched-reluctance machines. J. Sound Vib. 2017, 407, 191–208. [Google Scholar] [CrossRef]

- Klein-Hessling, A.; Hofmann, A.; de Doncher, R.M. Direct instantaneous torque and force control: A control approach for switched reluctance machines. IET Electr. Power Appl. 2013, 11, 935–943. [Google Scholar] [CrossRef]

- Shin, S.; Kawagoe, N.; Kosaka, T.; Matsui, N. Study on commutation control method for reducing noise and vibration in SRM. IEEE Trans. Ind. Appl. 2018, 54, 4415–4424. [Google Scholar] [CrossRef]

- Hall, D.; Lutsey, N. Emerging Best Practices for Electric Vehicle Charging Infrastructure; The International Council on Clean Transportation (ICCT): Washington, DC, USA, 2017. [Google Scholar]

- Dong, J.; Liu, C.; Lin, Z. Charging infrastructure planning for promoting battery electric vehicles: An activity-based approach using multiday travel data. Transp. Res. Part C Emerg. Technol. 2014, 38, 44–55. [Google Scholar] [CrossRef]

- Sweda, T.; Klabjan, D. An agent-based decision support system for electric vehicle charging infrastructure deployment. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011; pp. 1–5. [Google Scholar] [CrossRef]

- Ghamami, M.; Nie, Y.; Zockaie, A. Planning charging infrastructure for plug-in electric vehicles in city centers. Int. J. Sustain. Transp. 2016, 10, 343–353. [Google Scholar] [CrossRef]

- Liu, J. Electric vehicle charging infrastructure assignment and power grid impacts assessment in Beijing. Energy Policy 2012, 51, 544–557. [Google Scholar] [CrossRef]

- Schroeder, A.; Traber, T. The economics of fast charging infrastructure for electric vehicles. Energy Policy 2012, 43, 136–144. [Google Scholar] [CrossRef]

- Xi, X.; Sioshansi, R.; Marano, V. Simulation–optimization model for location of a public electric vehicle charging infrastructure. Transp. Res. Part D Transp. Environ. 2013, 22, 60–69. [Google Scholar] [CrossRef]

- San Román, T.G.; Momber, I.; Abbad, M.R.; Miralles, A.S. Regulatory framework and business models for charging plug-in electric vehicles: Infrastructure, agents, and commercial relationships. Energy Policy 2011, 39, 6360–6375. [Google Scholar] [CrossRef]

- Wang, B.; Hu, Y.; Zeng, F. A user cost and convenience oriented EV charging and discharging scheduling algorithm in V2G based microgrid. In Proceedings of the 2017 International Conference on Circuits, Devices and Systems (ICCDS), Chengdu, China, 5–8 September 2017; pp. 156–162. [Google Scholar] [CrossRef]

- Chung, H.M.; Alinia, B.; Crespi, N.; Wen, C.K. An EV Charging Scheduling Mechanism to Maximize User Convenience and Cost Efficiency. arXiv 2016, arXiv:1606.00998. [Google Scholar]

- Teng, J.H.; Liao, S.H.; Wen, C.K. Design of a fully decentralized controlled electric vehicle charger for mitigating charging impact on power grids. IEEE Trans. Ind. Appl. 2016, 53, 1497–1505. [Google Scholar] [CrossRef]

- Liao, S.H.; Teng, J.H.; Wen, C.K. Developing a smart charger for EVs’ charging impact mitigation. In Proceedings of the IEEE 2nd International Future Energy Electronics Conference (IFEEC), Taipei, Taiwan, 1–4 November 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Dubarry, M.; Devie, A.; McKenzie, K. Durability and reliability of electric vehicle batteries under electric utility grid operations: Bidirectional charging impact analysis. J. Power Sources 2017, 358, 39–49. [Google Scholar] [CrossRef]

- He, J.; Yang, H.; Tang, T.Q.; Huang, H.J. An optimal charging station location model with the consideration of electric vehicle’s driving range. Transp. Res. Part C Emerg. Technol. 2018, 86, 641–654. [Google Scholar] [CrossRef]

- Tang, M.; Gong, D.; Liu, S.; Lu, X. Finding key factors affecting the locations of EV charging Station: A simulation an anova approach. Int. J. Simul. Model. (IJSIMM) 2017, 16. [Google Scholar] [CrossRef]

- Zhou, Y. The Overview of the EV Charging Station Regulation. In Proceedings of the 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 8969–8974. [Google Scholar] [CrossRef]

- Guo, F.; Yang, J.; Lu, J. The battery charging station location problem: Impact of users’ range anxiety and distance convenience. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 1–18. [Google Scholar] [CrossRef]

- Thomas, C.S. US marginal electricity grid mixes and EV greenhouse gas emissions. Int. J. Hydrog. Energy 2012, 37, 19231–19240. [Google Scholar] [CrossRef]

- Traut, E.; Hendrickson, C.; Klampfl, E.; Liu, Y.; Michalek, J.J. Optimal design and allocation of electrified vehicles and dedicated charging infrastructure for minimum life cycle greenhouse gas emissions and cost. Energy Policy 2012, 51, 524–534. [Google Scholar] [CrossRef]

- Kim, J.D.; Rahimi, M. Future energy loads for a large-scale adoption of electric vehicles in the city of Los Angeles: Impacts on greenhouse gas (GHG) emissions. Energy Policy 2014, 73, 620–630. [Google Scholar] [CrossRef]

- Nienhueser, I.A.; Qiu, Y. Economic and environmental impacts of providing renewable energy for electric vehicle charging–A choice experiment study. Appl. Energy 2016, 180, 256–268. [Google Scholar] [CrossRef]

- Jin, C.; Sheng, X.; Ghosh, P. Optimized electric vehicle charging with intermittent renewable energy sources. IEEE J. Sel. Top. Signal Process. 2014, 8, 1063–1072. [Google Scholar] [CrossRef]

- Babic, J.; Carvalho, A.; Ketter, W.; Podobnik, V. Modelling electric vehicle owners’ willingness to pay for a charging service. In Proceedings of the Erasmus Energy Forum, Energy Informatics & Management, Rotterdam, The Netherlands, 18–19 May 2016; pp. 1–8. [Google Scholar]

- Liu, X.; Yang, Y.; He, Y.; Zhang, J.; Zheng, X.; Ma, M.; Zeng, G. A new dynamic SOH estimation of lead-acid battery for substation application. Int. J. Energy Res. 2017, 41, 579–592. [Google Scholar] [CrossRef]

- Cacciato, M.; Nobile, G.; Scarcella, G.; Scelba, G. Real-time model-based estimation of SOC and SOH for energy storage systems. IEEE Trans. Power Electron. 2016, 32, 794–803. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Z.; Zhang, C. On-line remaining energy prediction: A case study in embedded battery management system. Appl. Energy 2017, 194, 688–695. [Google Scholar] [CrossRef]

- Melo, D.F.R.; Trippe, A.; Gooi, H.B.; Massier, T. Robust electric vehicle aggregation for ancillary service provision considering battery aging. IEEE Trans. Smart Grid 2016, 9, 1728–1738. [Google Scholar] [CrossRef]

- Burnham, A.; Dufek, E.J.; Stephens, T.; Francfort, J.; Michelbacher, C.; Carlson, R.B.; Scoffield, D. Enabling fast charging–Infrastructure and economic considerations. J. Power Sources 2017, 367, 237–249. [Google Scholar] [CrossRef]

- Tian, Z.; Jung, T.; Wang, Y.; Zhang, F.; Tu, L.; Xu, C.; Li, X.Y. Real-time charging station recommendation system for electric-vehicle taxis. IEEE Trans. Intell. Transp. Syst. 2016, 17, 3098–3109. [Google Scholar] [CrossRef]

- Li, M.; Wu, X.K.; He, X.Z.; Yu, G.Z.; Wang, Y.P. An Eco-driving system for electric vehicles with signal control under V2X environment. Transp. Res. Part C Emerg. Technol. 2018, 93, 335–350. [Google Scholar] [CrossRef]

- Zhu, B.; Wu, D.; Zheng, M.Y. Electric vehicle energy predictive optimal control by V2I communication. Adv. Mech. Eng. 2019, 11, 1687814018821523. [Google Scholar] [CrossRef]

- Yilmaz, M.; Krein, P.T. Review of the impact of vehicle-to-grid technologies on distribution systems and utility interfaces. IEEE Trans. Power Electron. 2013, 28, 5673–5689. [Google Scholar] [CrossRef]

- Habib, S.; Kamran, M.; Rashid, U. Impact analysis of vehicle-to-grid technology and charging strategies of electric vehicles on distribution networks—A review. J. Power Sources 2015, 277, 205–214. [Google Scholar] [CrossRef]

- Sewalkar, P.; Seitz, J. Vehicle-to-pedestrian communication for vulnerable road users: Survey, design considerations, and challenges. Sensors 2019, 19, 358. [Google Scholar] [CrossRef]

- Alnasser, A.; Sun, H.J.; Jian, J. Cyber security challenges and solutions for V2X communications: A survey. Comput. Netw. 2019, 151, 52–67. [Google Scholar] [CrossRef]

- Wang, J.; Shao, Y.M.; Ge, Y.M. A Survey of Vehicle to Everything (V2X) Testing. Sensors 2019, 19, 334. [Google Scholar] [CrossRef]

- Tong, W.; Hussain, A.; Bo, W.X. Artificial Intelligence for Vehicle-to-Everything: A Survey. IEEE Access 2019, 7, 10823–10843. [Google Scholar] [CrossRef]

- Helmer, E.; Marx, P. Electric cars: Technical Characteristics and Environmental Impacts. Environ. Sci. Eur. 2012. Available online: http://www.enveurope.com/content/24/1/14 (accessed on 26 April 2012). [CrossRef]

- Guo, C.L.; Chan, C.C. Whole-system thinking, development control, key barriers and promotion mechanism for EV development. J. Mod. Power Syst. Clean Energy 2015, 3, 160–169. [Google Scholar] [CrossRef]

- Deng, D. Li-ion batteries: Basic, progress, and challenges. Energy Sci. Eng. 2015, 3, 385–418. [Google Scholar] [CrossRef]

| Cathode Material | Specific Energy (Wh/kg) | Cycle | Optimal Working Temp (°C) | Efficiency (%) | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| Lead acid | 30–50 | 2000–4500 | −20–60 | 70–90 | Low cost, mature technology, high specific power | Low specific energy, short service life, high maintenance requirements |

| Ni-Fe | 30–55 | 1200–4000 | −10–45 | 75 | Good scope for traction applications | Low specific energy, power and energy density; high self-discharge, hydrogen evolution, high purchase and maintenance cost |

| Ni-Zn | 60–65 | 100–300 | −10–50 | 76 | High specific energy | High cost, short service life |

| Ni-Cd | 40–50 | 2000–3000 | −40–60 | 60–90 | High specific energy | High cost cadmium toxicity, recycling issues |

| Ni-MH | 50–70 | 500–3000 | −40–50 | 50–80 | High specific energy, safety, long service life | High cost, high self-discharge, memory effect |

| Ni-H2 | 60–70 | 6000–40000 | −20–60 | 80–90 | Extreme long-life cycle and tolerance to overcharge or over-discharge without damage | Expensive, low volumetric energy density, self-discharge proportional to H2 pressure |

| LiCoO2 | 150–190 | 500–1000 | 150 | 80–90 | In common use, high power density, high energy density | Low self-discharge, low safety, high cost |

| LiMn2O4 | 100–135 | 500–1000 | 250 | 85 | High power density, very good thermal stability | Moderate cycle life, lower energy |

| LiFePO4 | 90–120 | 1000–2000 | 270 | 90 | Very good thermal stability and cycle life, good power capability no memory effect, lighter and smaller | Low energy density |

| LiNiMnCoO2 | 140–180 | 1000–2000 | 210 | 90–95 | High power density, high energy density, high energy efficiency, good cycle life | Structural/chemical instabilities during repeated cycling |

| Code | Refer to |

|---|---|

| SAE | |

| SAE Electric Vehicle Conductive charge coupler | |

| J-1773 | SAE Electric Vehicle Inductively-coupler charging |

| J-2954 | Wireless power transfer for light-duty plug-in Electric vehicles and alignment methodology |

| ICE | |

| 62196-X | Plug, Socket-Outlets, Vehicle Couplers and Vehicle inlets–Conductive charging of electric vehicles |

| 61851-X | Electric vehicles conductive charging system |

| 62840-X | Electric vehicle battery swap system |

| 62983 | Electric charge station |

| 61980-1:2015 | Electric vehicle wireless power transfer systems |

| GB | |

| GB/T 18487.X-2015 | Electri J-1772c vehicles conductive charging system |

| GB/T 20234.X-2015 | Electric vehicles conduction charging connecting device |

| GB/T 27930-2015 | Communication protocol between the off-board charger and battery management system |

| QC/T 895-2011 | Electric vehicles onboard charger |

| QC/T 841-2010 | Electric vehicles conductive charging interface |

| JEVS | |

| C601: 2000 | Plugs and receptacles for EV charging |

| G105: 1993 | Connectors applicable to quick charging system at Eco-Station for EVs |

| G106: 2000 | EV Inductive charging system: General requirements |

| G107: 2000 | Inductive charging system: Manual connection |

| G108: 2001 | EV Inductive charging system: Software interface |

| G109: 2001 | EV Inductive charging system: General requirements |

| Type | Charging Method | Electrical | Time | Cost ($) | Advantages & Disadvantages |

|---|---|---|---|---|---|

| Opportunity (Level 1) | Conductive | 120 V, 15 A | >10 h | 500–880 | Cheap, simple installation and usage, time consuming |

| Primary (Level 2) | Conductive | 208–240 V, up to 80 A | 2–12 h | 150–3000 | Required a dedicated equipment and a connection installation for household or communal, faster charging time |

| Fast charging (Level 3) | Conductive | 400 V, 32 A | 15–20 min | 30,000–160,000 | Required an off-board charger, influence of power grid, expensive |

| Stationary charging systems | Inductive | 2–15 kW 1, 20 k–1 MHz 2, 100–500 mm 3 | 3–3.5 h | 1500–3000 | Required a power receiver attached to the car, a larger size of charger, misalignment tolerance |

| Dynamic charging systems | Inductive | 0.3–25 kW 1, 20–100 kHz 2, 10–200 mm 3 | depending on the length of charging track | 1 million/km | Low efficiency, a limited amount of transferred energy |

| Battery swap station | Battery swapping | 400 V 4, 70–250 set 5 | 5 min | 5–10 million | Fast, centralized charging of batteries, lack of standardization for power batteries, required special tools for battery swapping |

| Country | Program | Budget and Form of Support |

|---|---|---|

| China | Expansion of infrastructure in pilot cities Fast charging plaza and corridors by State Grid Investment by auto manufactures | Utility program in national level Collaboration of government and private partner Financial subsidies to local government |

| Japan | Next Generation Vehicle Charging Infrastructure Development Promotion Project Nippo Charge service | 1 billion US dollars budget Collaboration of government and private partner |

| Germany | Nationwide promotion program for EV | 300 million Euros budget Subsidies to cover 60% cost of authorized business |

| Netherlands | Electric Mobility Gets Up to Speed Green Deal | 33 million Euros budget Incentives from local government |

| United Kingdom | Plugged-In Places Go Ultra Low | 32 million dollars budget Incentives to cover 75% cost of charging station buildout Legislative measures |

| United States | Funding through American Recovery and Reinvestment Act Transportation Investment Generating Economic Recovery program | 15 million dollars budget Federal funding for local government |

| Challenge | System | Future Development |

|---|---|---|

| Improve the battery characteristics | Battery | Higher capacity, higher energy density, safety, more efficient battery management, new battery such as graphene battery |

| High cost, toxic material in the battery | Battery | Long-life-cycle, battery recycling |

| Elimination of range anxiety | Charging | Fast charging, charging standard |

| DWPT | Charging | Higher efficiency, power converter, compensation topology, emerging coil material, foreign object detection and communication, the health and safety concerns of the WPT system |

| Adoption of battery swapping | Charging infrastructure | Optimal distribution of BSS, energy and ancillary service to the distribution grid |

| Enhance the characteristics of PMSM | Electric motor | Reduce the impact of demagnetization of permanent material, more reliable |

| Lower efficiency and lower power density of induction motor | Electric motor | DTC, copper rotor induction motor |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Li, Z.; Wang, X.; Li, C. Technology Development of Electric Vehicles: A Review. Energies 2020, 13, 90. https://doi.org/10.3390/en13010090

Sun X, Li Z, Wang X, Li C. Technology Development of Electric Vehicles: A Review. Energies. 2020; 13(1):90. https://doi.org/10.3390/en13010090

Chicago/Turabian StyleSun, Xiaoli, Zhengguo Li, Xiaolin Wang, and Chengjiang Li. 2020. "Technology Development of Electric Vehicles: A Review" Energies 13, no. 1: 90. https://doi.org/10.3390/en13010090

APA StyleSun, X., Li, Z., Wang, X., & Li, C. (2020). Technology Development of Electric Vehicles: A Review. Energies, 13(1), 90. https://doi.org/10.3390/en13010090