Optimal Configuration with Capacity Analysis of a Hybrid Renewable Energy and Storage System for an Island Application

Abstract

1. Introduction

2. Materials and Methods

- Case 1: Stand-alone diesel system

- Case 2: PV-diesel HES

- Case 3: Wind-diesel HES

- Case 4: PV-wind-diesel HES

- Case 5: PV-diesel-storage HES

- Case 6: Wind-diesel-storage HES

- Case 7: PV-wind-diesel-storage HES

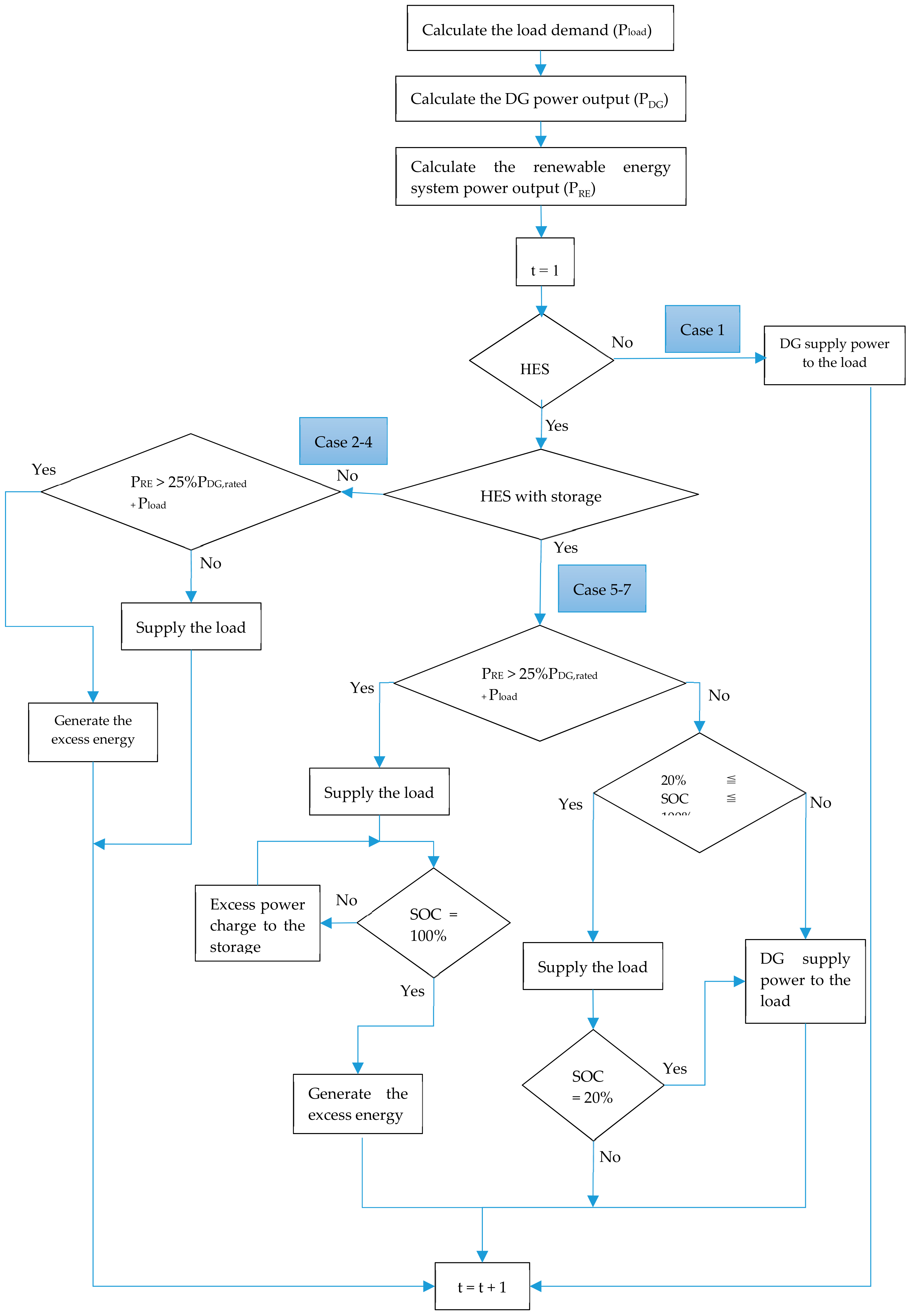

- Based on the load conditions and the specifications of existing diesel generator, the electrical and economic results of the stand-alone diesel system (Case 1) can be analyzed by HOMER (Pro.3.7.6.0, HOMER Energy, CO, USA)) and the result is considered as a reference for discussing different hybrid energy systems.

- According to the load conditions and climatic conditions, the electrical and the economic conditions in different capacity configuration are analyzed. The simulation of HES model without energy storage that is, PV-diesel HES (Case 2), wind-diesel HES (Case 3), PV-wind-diesel HES (Case 4) are analyzed. The optimal capacity configuration in the lowest COE for each case needs to be calculated.

- The HES with energy storage analyzed include PV-diesel-storage HES (Case 5), wind-diesel-storage HES (Case 6), PV-wind-diesel-storage HES (Case 7). The RF is in the range of 25–50% and each step is 5%. Finding a capacity configuration with an excess electricity fraction below 5% and a minimum COE for each case are the main points to be considered.

- From Cases 5–7, we select the one has a relatively low COE and use the entropy weight and TOPSIS method to analyze the optimal capacity configuration when the RF is in 25–50%, considering the capital cost, COE, fuel saving, and occupied area.

- The sensitivity analysis of parameters such as global horizontal irradiation data (GHI), wind speed, diesel fuel price, and load consumption. The parameters are used to discuss the economy and electricity of the system.

2.1. Simulation Software Description

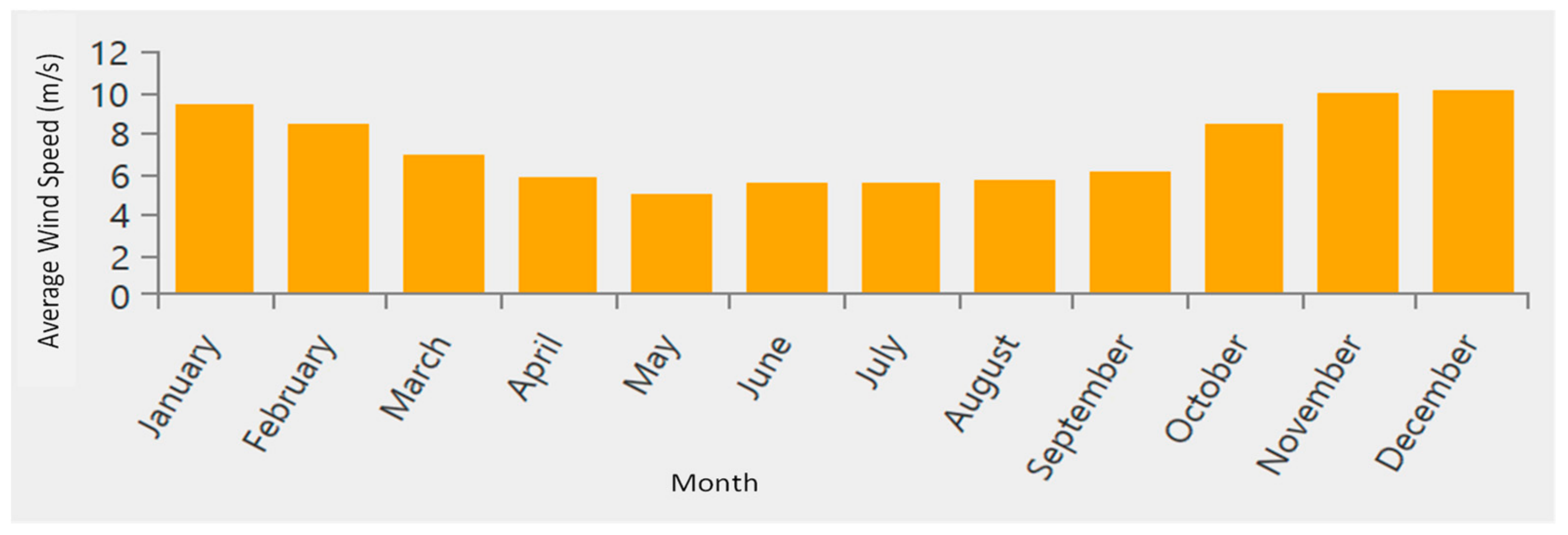

2.2. Global Horizontal Irradiation and Wind Speed

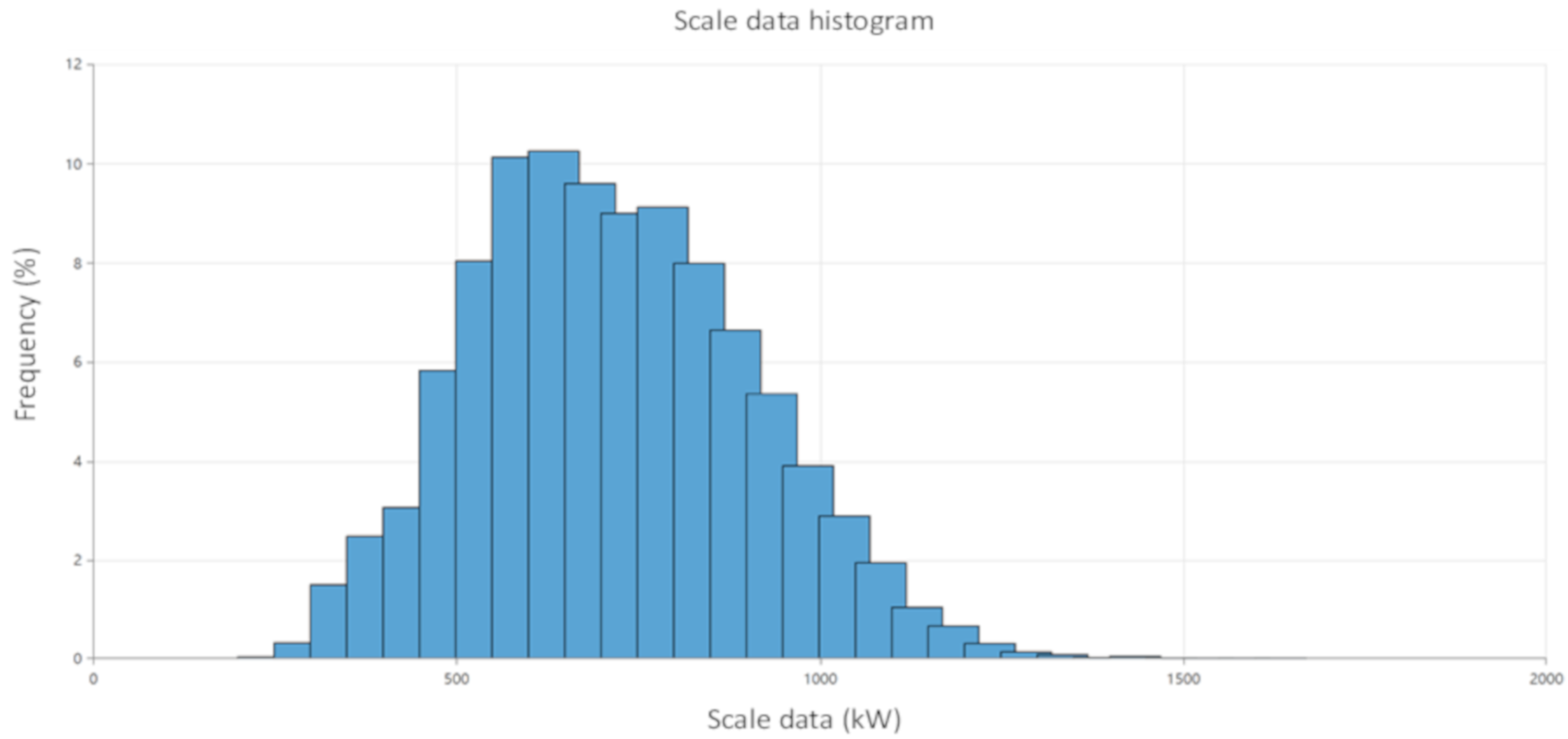

2.3. Load Profile

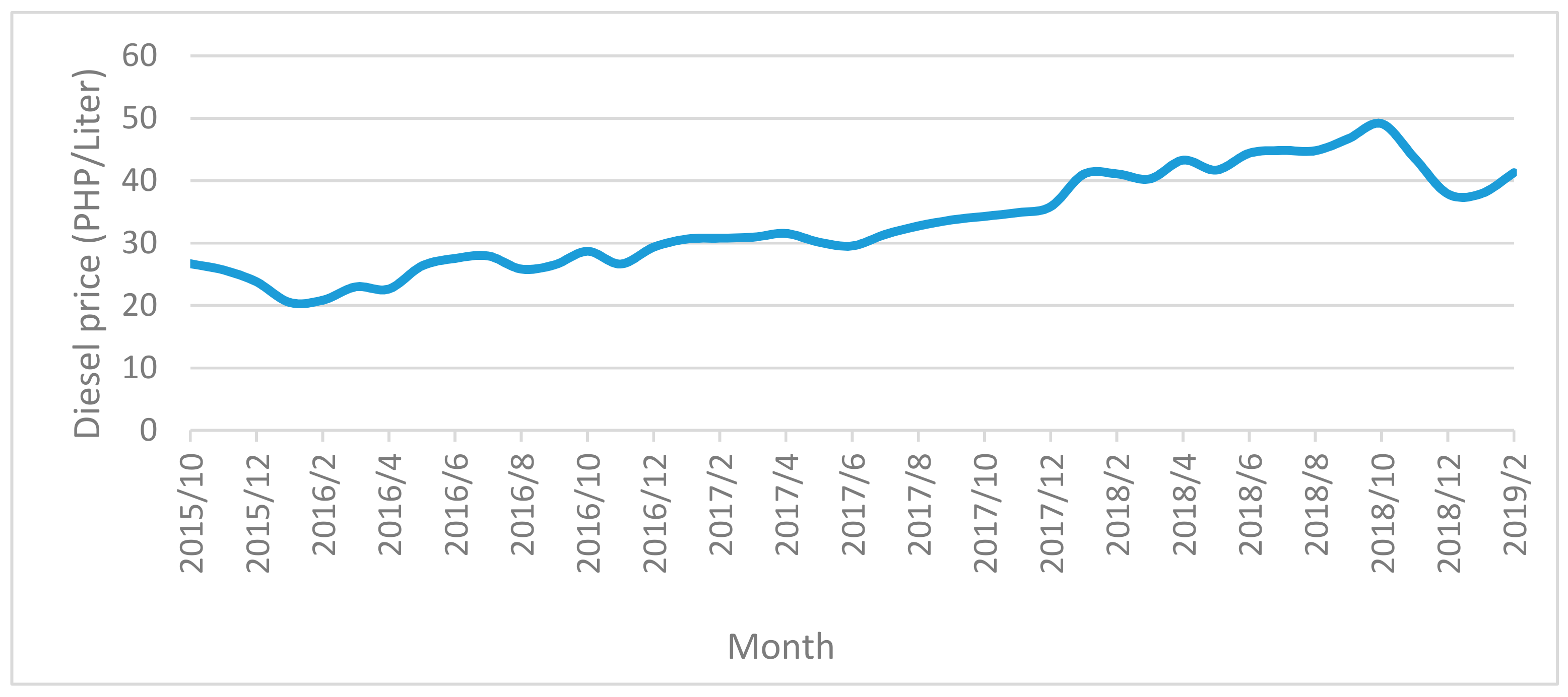

2.4. Diesel Price Data

2.5. Assignment Indexes

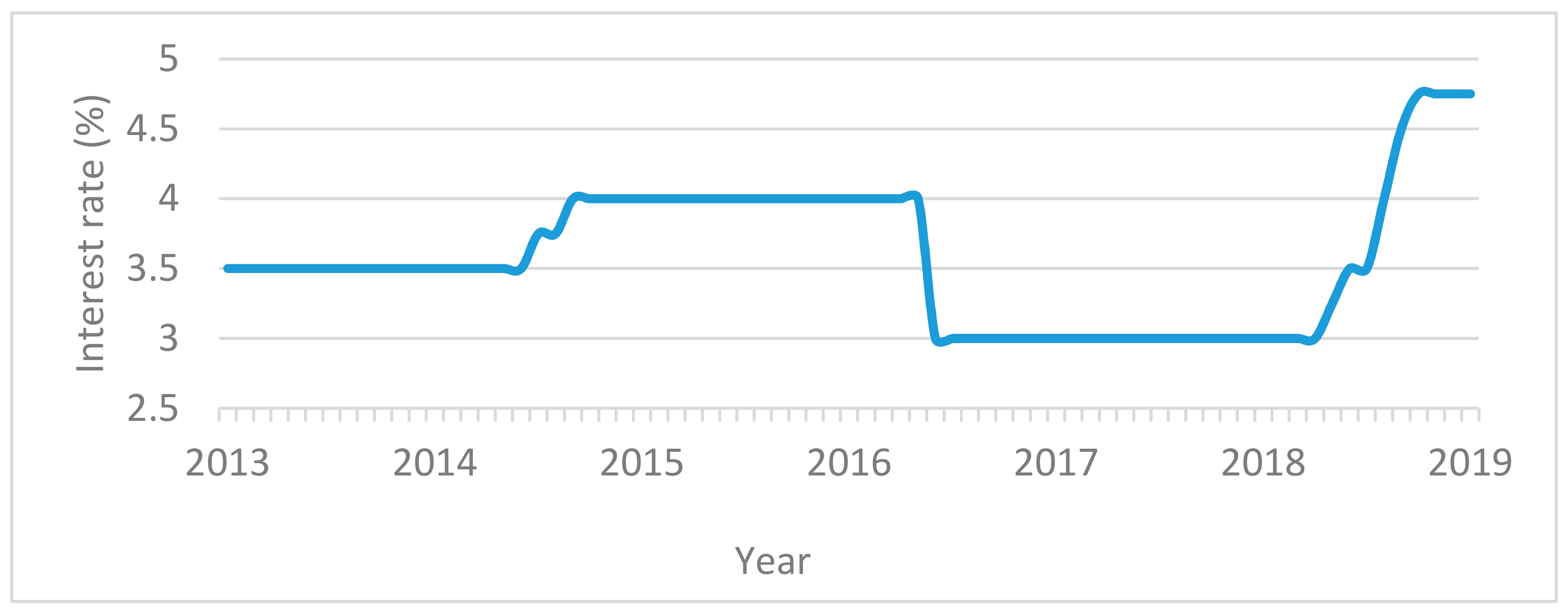

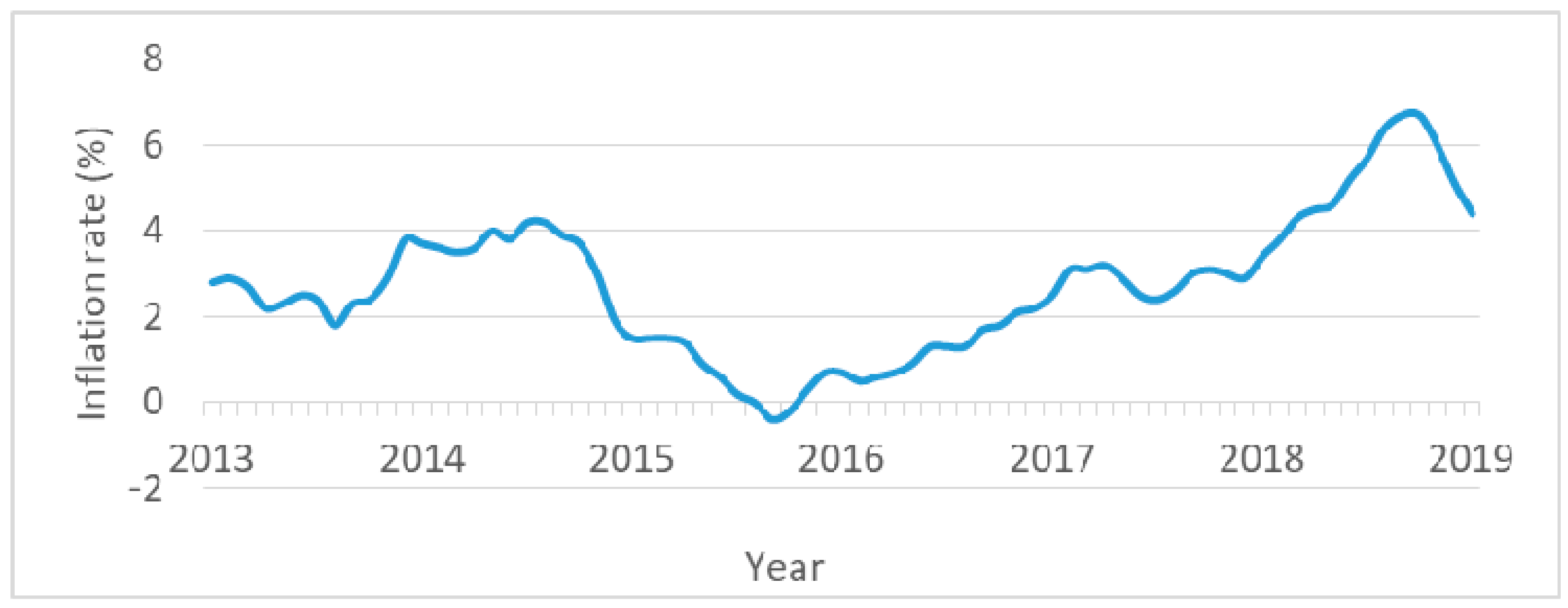

2.5.1. Annual Real Interest Rate

2.5.2. Net Present Cost

2.5.3. Capital Recovery Factor (CRF)

2.5.4. Cost of Energy

2.5.5. Renewable Fraction (RF)

2.5.6. Excess Electricity Fraction

2.5.7. Occupied Area

2.6. Entropy Weight and TOPSIS Method

3. Hybrid Energy System Description

3.1. Hybrid Energy System Schematic Diagram

3.2. PV System

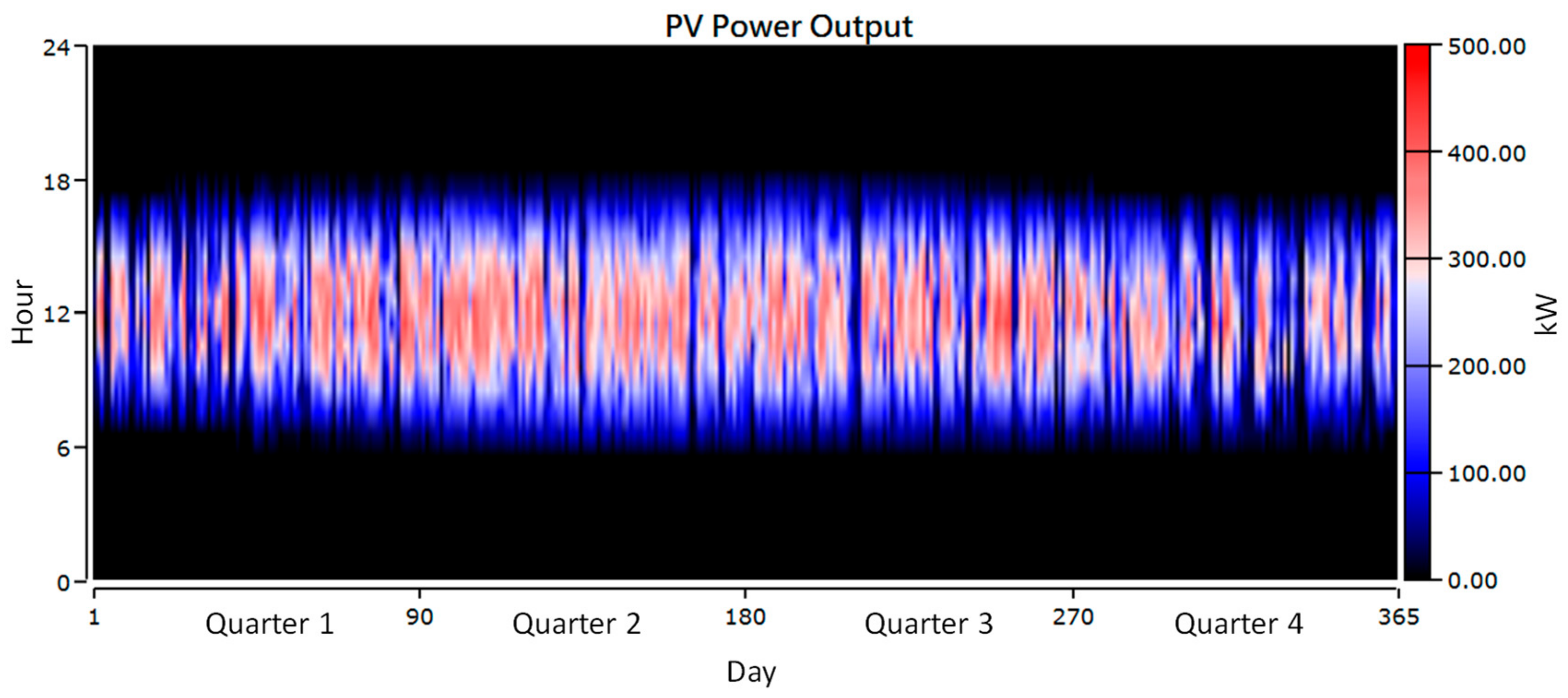

3.3. WG System

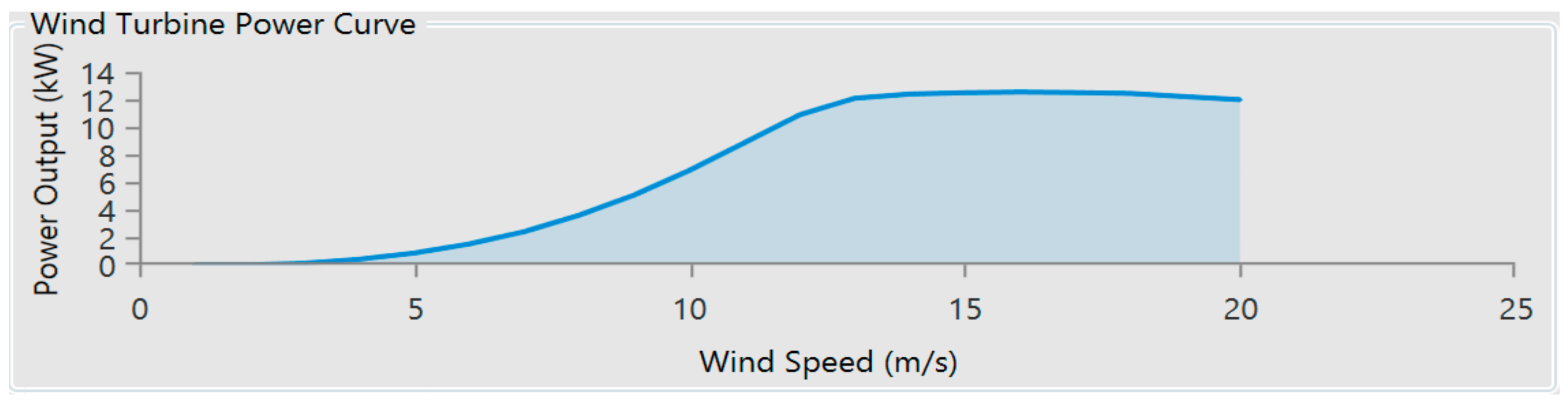

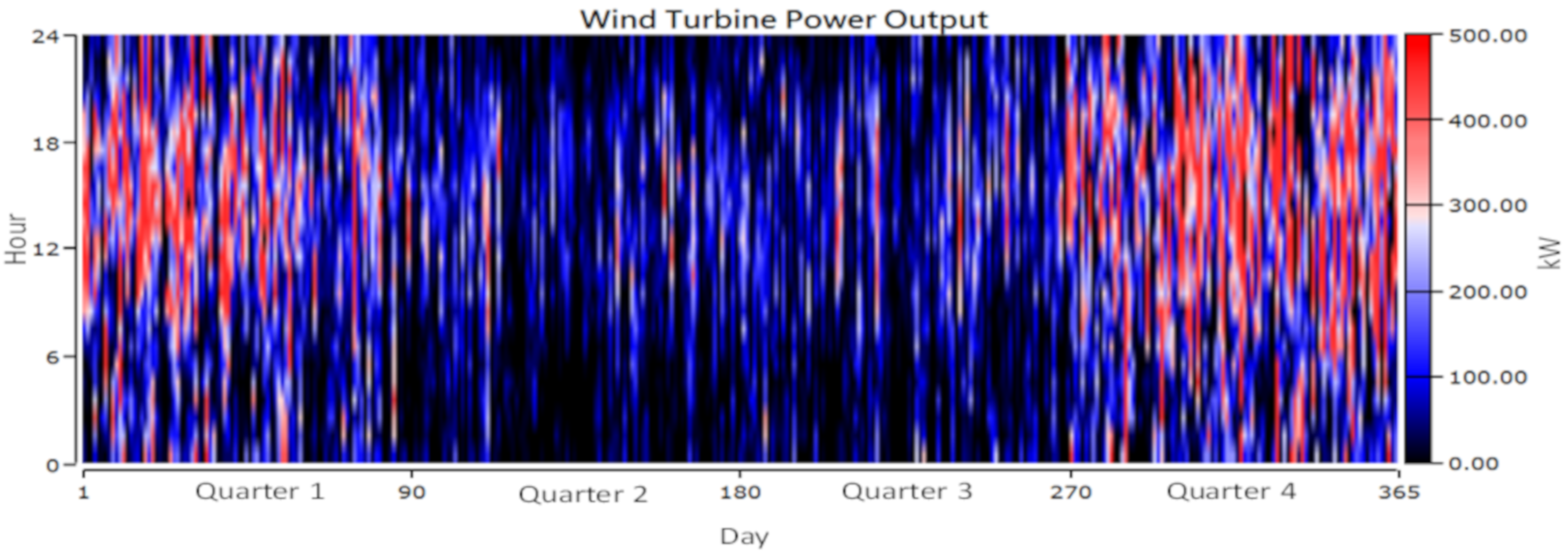

3.4. Storage System

3.5. Power Conversion System

3.6. Diesel Generators

3.7. System Dispatch Strategy

4. Component Cost and Financial Assumption

4.1. System Component Cost

4.2. Interest Rate and Inflation Rate

5. Simulation Results and Discussion

5.1. Case 1: Stand-Alone Diesel System

5.2. Hybrid Energy System without Storage

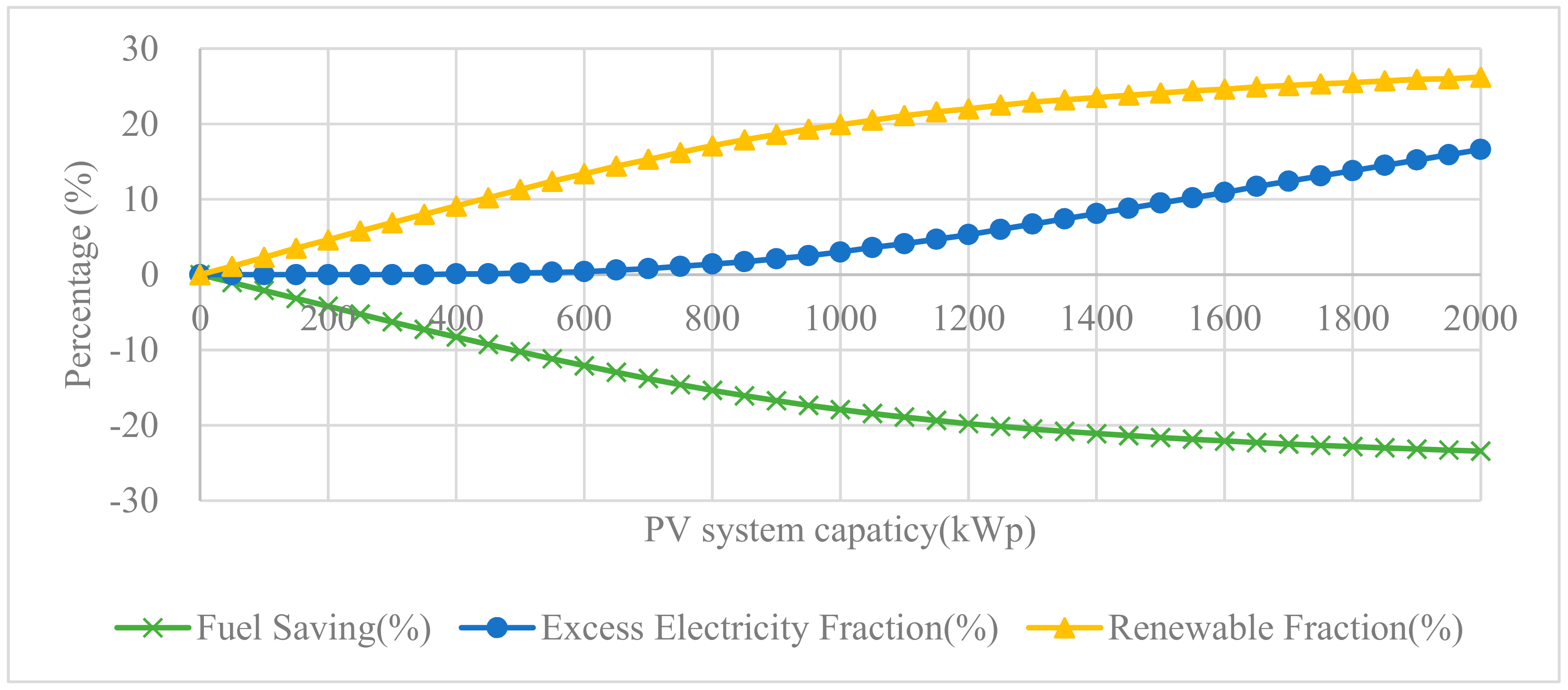

5.2.1. Case 2: PV-Diesel HES

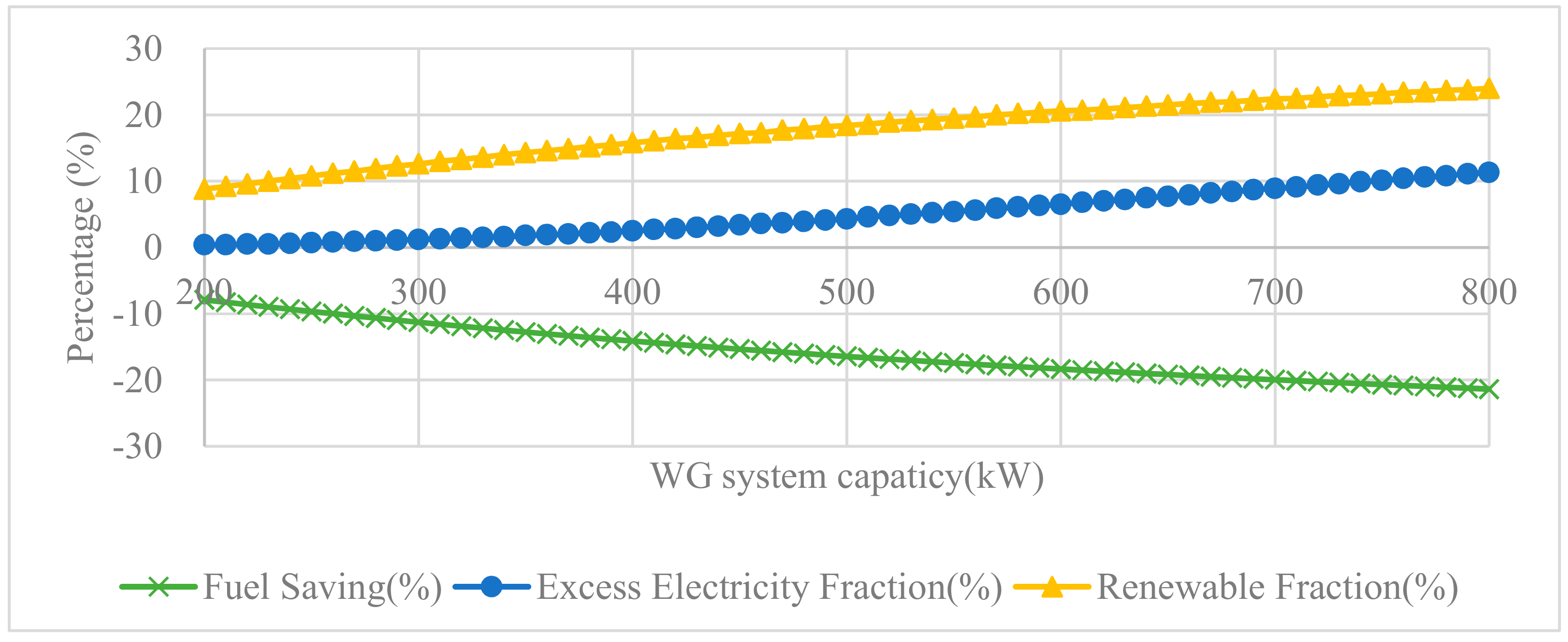

5.2.2. Case 3: Wind-Diesel HES

5.2.3. Case 4: PV-Wind-Diesel HES

5.3. Hybrid Energy System with Storage

5.3.1. Case 5: PV/Diesel/Storage HES

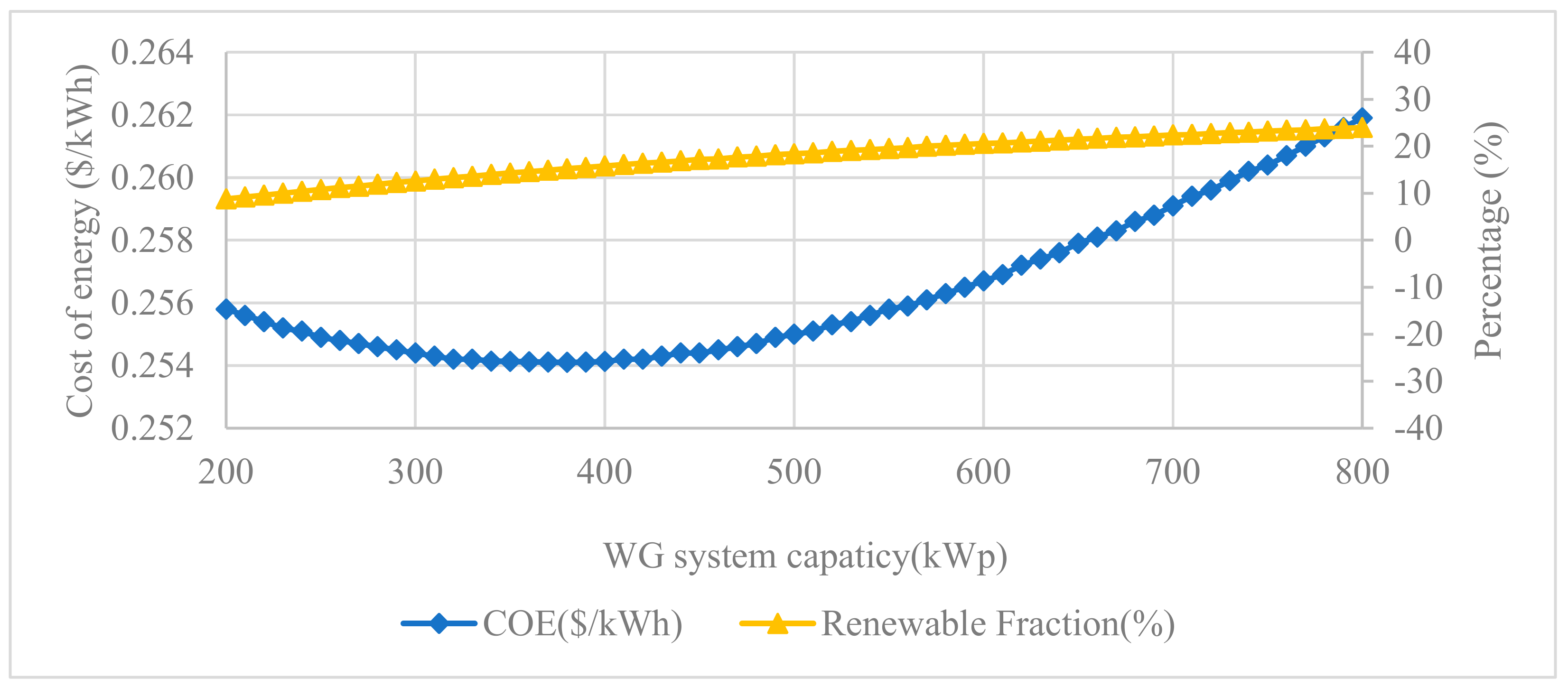

5.3.2. Case 6: Wind-Diesel-Storage HES

5.3.3. Case 7: PV-Wind-Diesel-Storage HES

5.3.4. Optimal Capacity Configuration Analysis of the PV-Wind-Diesel-Storage HES

5.4. Sensitivity Analysis

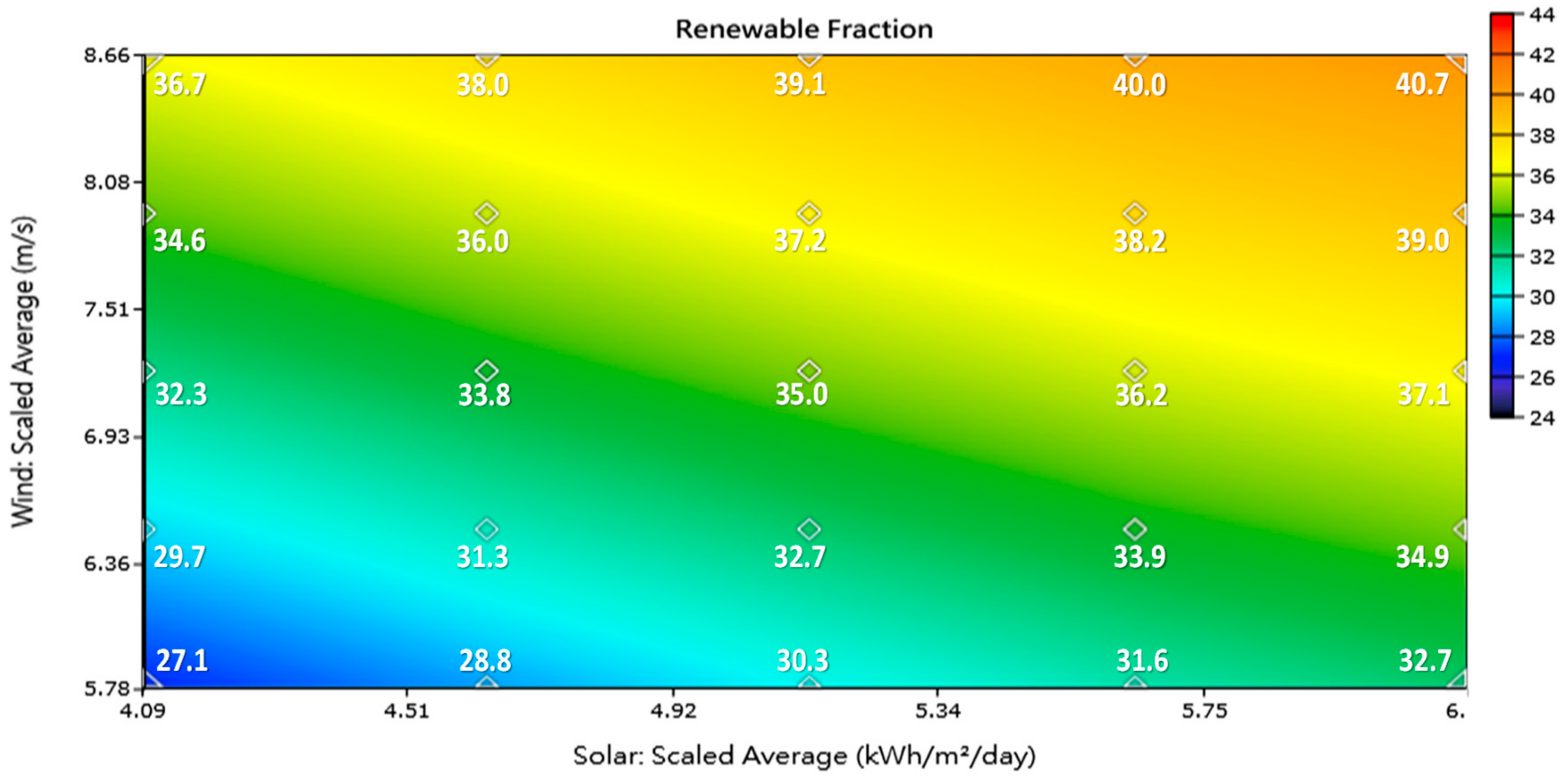

5.4.1. Global Horizontal Irradiation and Wind Speed

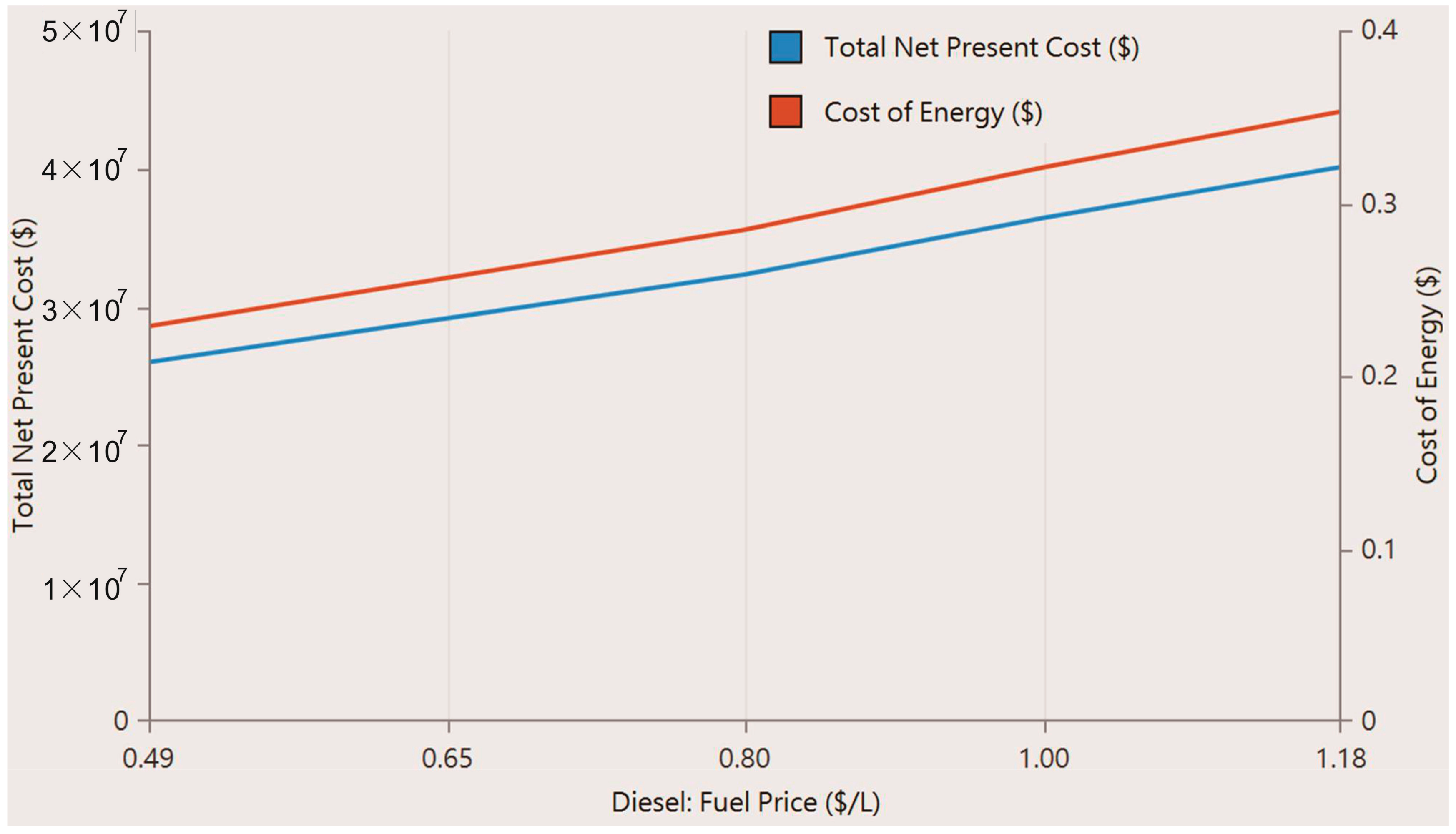

5.4.2. Diesel Fuel Price

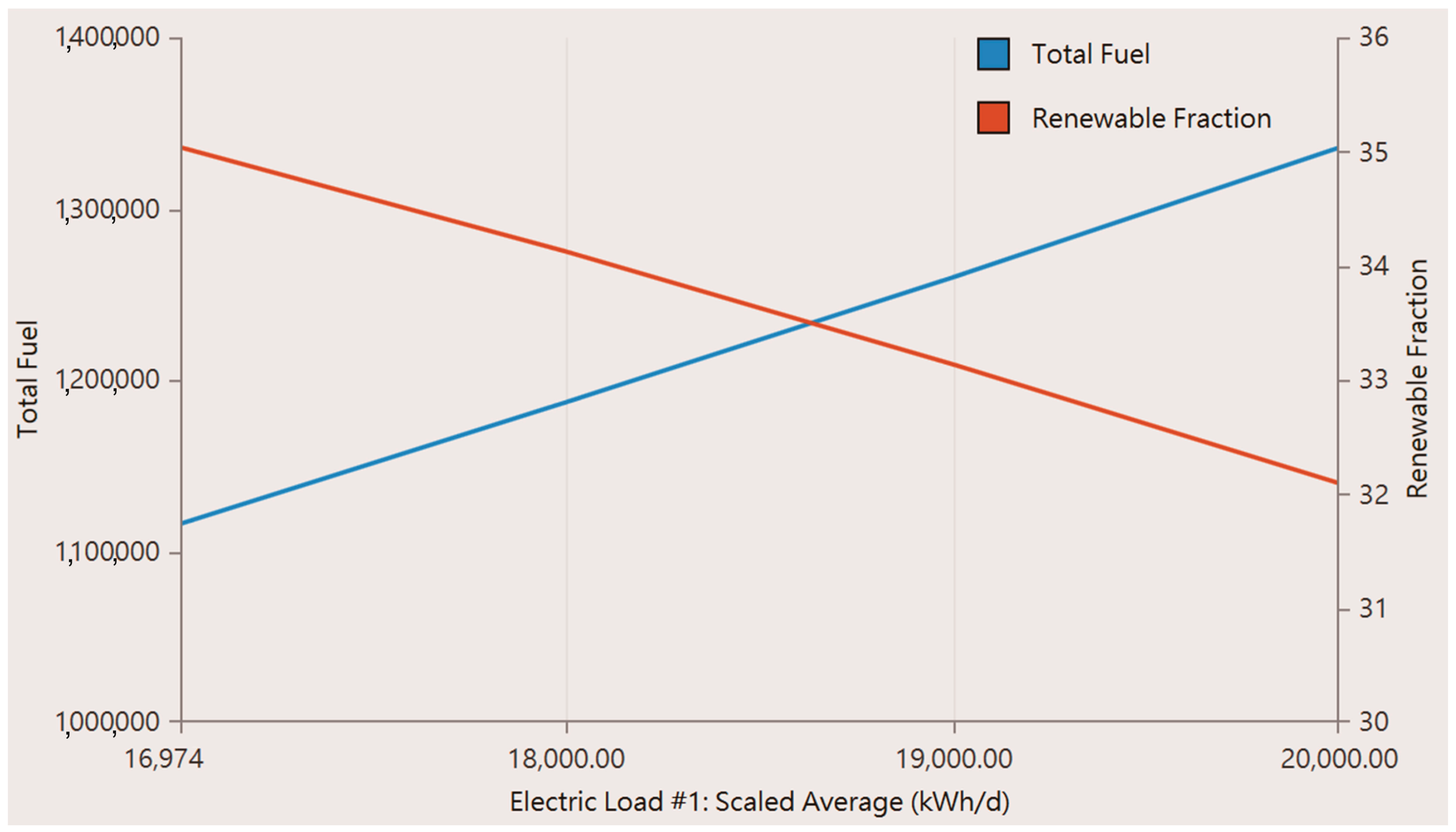

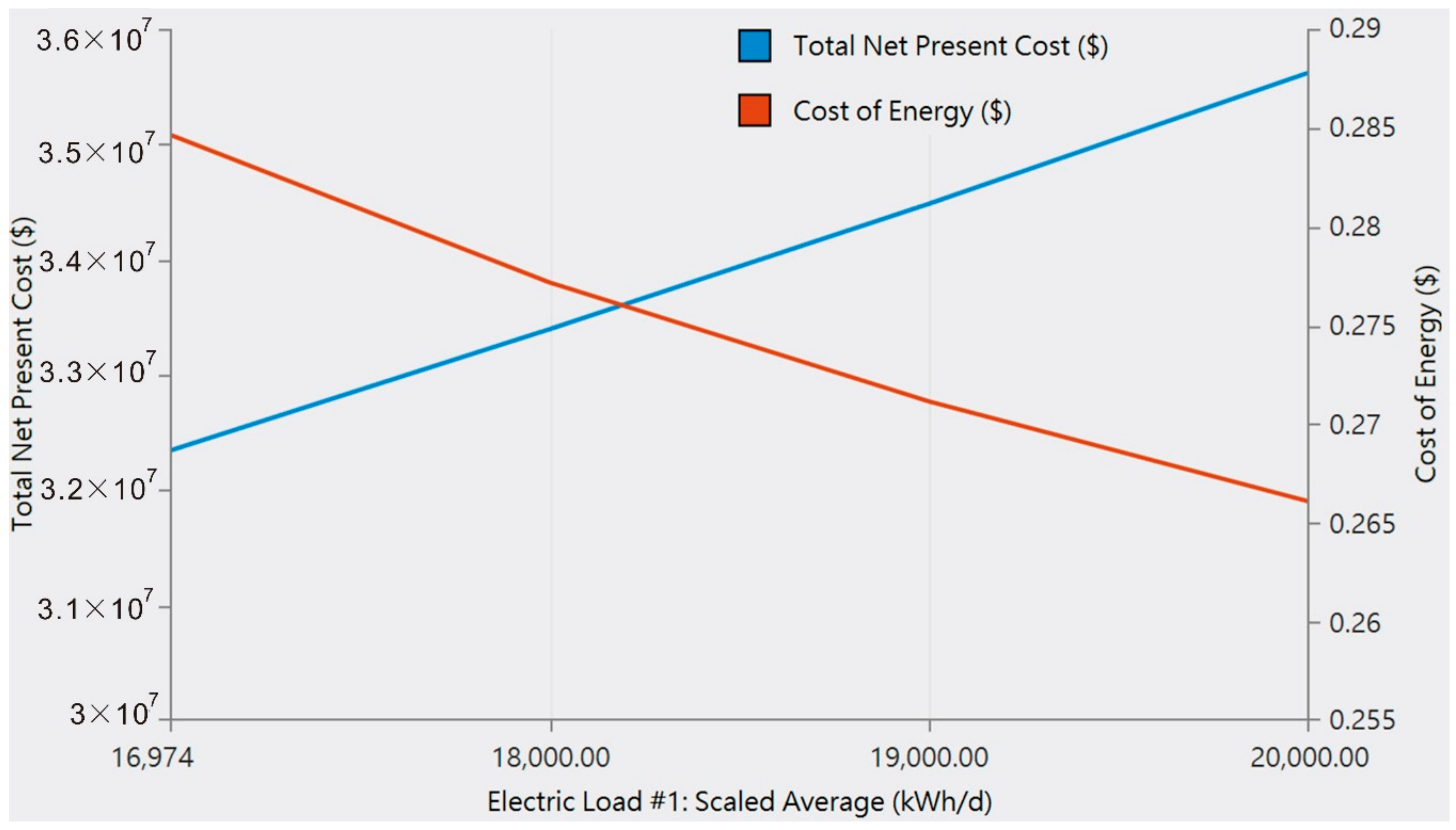

5.4.3. Load Consumption

6. Conclusions

- Based on the climate and load demand on the island, we simulate HES without an installing energy storage system such as PV-diesel HES, wind-diesel HES and PV-wind-diesel HES. Because solar energy and wind energy have characteristics of complementary seasonal power, the lowest COE obtained is 0.2539 $/kWh in PV-wind-diesel HES. The result is lower than the COE in the DG-only case. The capacity of PVs and WGs are 200 kWp and 340 kW, respectively. In addition, RF is 18.1% and fuel saving is −16.18%.

- As the capacity of PVs or WGs increases, the RF will increase, but the excess electricity fraction will also increase. Although this will waste energy, the problem is mitigated by installing an energy storage system. In the three kinds of HES with the energy storage, discussing the capacity configuration of the lowest COE in each RF stage for PV-diesel-storage HES and the constraints are as follows: RF is 25%–50%, the interval is 5% and the excess electricity fraction must be less than 5% considering the utilization rate of the energy. In RF 25% hybrid system configuration: the minimum COE obtained is 0.2737 $/kWh. Required capacity of PVs, WGs and storage are 400 kWp, 440 kW and 168 kWh, respectively. The fuel savings is −22.38%.

- For the system with energy storage, the result of RF 35% is the best capacity configuration in this research: PVs capacity is 950 kWp, WGs capacity is 410 kW, and energy storage capacity is 1680 kWh.

- RF 35% PV-wind-diesel-storage HES is used to analyze the sensitivity. When GHI and wind speed increase, RF will continuously increase, so the fuel consumption of the DGs will also decrease. Since the cost of fuel intake is the maximum percentage of all costs, oil price increase has a significant influence on COE. As electricity demand rises, DG will increase the power generation to fulfill the demand. This causes the RF to decline, the fuel consumption and NPC the rise, and COE conversely.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Electrical Parameters | |

|---|---|

| Rated power @ standard test conditions | 300 Wp |

| Open circuit voltage, Voc | 39.24 V |

| Maximum power point voltage, Vmp | 31.51 V |

| Short circuit current, Isc | 9.93 A |

| Maximum power point current, Imp | 9.52 A |

| Temperature coefficient of maximum power | −0.4003%/°C |

| Temperature coefficient of open circuit voltage | −0.2906%/°C |

| Temperature coefficient of short circuit current | 0.0530%/°C |

| Module efficiency | 18.44% |

References

- Ma, T.; Javed, M.S. Integrated sizing of hybrid PV-wind-battery system for remote island considering the saturation of each renewable energy resource. Energy Convers. Manag. 2019, 182, 178–190. [Google Scholar] [CrossRef]

- Krishan, O.; Suhag, S. Techno-economic analysis of a hybrid renewable energy system for an energy poor rural community. J. Energy Storage 2019, 23, 305–319. [Google Scholar] [CrossRef]

- Lu, J.; Wang, W.; Zhang, Y.; Cheng, S. Multi-Objective Optimal Design of Stand-Alone Hybrid Energy System Using Entropy Weight Method Based on HOMER. Energies 2017, 10, 1664. [Google Scholar] [CrossRef]

- Kartite, J.; Cherkaoui, M. Study of the different structures of hybrid systems in renewable energies: Cooling different structures of on hybrid systems renewable energies: A review Cherkaoui Assessing the Jihane feasibility using the heat demand-outdoor Cherkaoui temperature function for a long-term district heat demand forecast. Energy Procedia 2019, 157, 323–330. [Google Scholar]

- Padrón, I.; Avila, D.; Marichal, G.N.; Rodríguez, J.A. Assessment of Hybrid Renewable Energy Systems to supplied energy to Autonomous Desalination Systems in two islands of the Canary Archipelago. Renew. Sustain. Energy Rev. 2019, 101, 221–230. [Google Scholar] [CrossRef]

- Solar Vision 2025; Canadian Solar Industries Association: Ottawa, ON, Canada, 2010; Available online: http://www.pvinnovation.ca/files/CANSIA_Solar_Vision_2025_FINAL[1].pdf (accessed on 25 February 2019).

- Brenna, M.; Longo, M.; Yaici, W.; Abegaz, T.D. Simulation and Optimization of Integration of Hybrid Renewable Energy Sources and Storages for Remote Communities Electrification. In Proceedings of the 2017 IEEE PES Innovative Smart Grid Technologies Conference Europe (ISGT-Europe), Torino, Italy, 26–29 September 2017; pp. 1–6. [Google Scholar]

- Delucchi, M.A.; Jacobson, M.Z. Providing all global energy with wind, water, and solar power, Part II: Reliability, system and transmission costs, and policies. Energy Policy 2011, 39, 1170–1190. [Google Scholar] [CrossRef]

- Valenciaga, F.; Puleston, P.F. Supervisor Control for a Stand-Alone Hybrid Generation System Using Wind and Photovoltaic Energy. IEEE Trans. Energy Convers. 2005, 20, 398–405. [Google Scholar] [CrossRef]

- Wang, L.; Singh, C. Compromise between Cost and Reliability In Optimum Design of An Autonomous Hybrid Power System Using Mixed-Integer PSO Algorithm. In Proceedings of the IEEE 2007 International Conference on Clean Electrical Power, Capri, Italy, 21–23 May 2007. [Google Scholar]

- Kadda, F.Z.; Zouggar, S.; el Hafyani, M.; Rabhi, A. Contribution to the Optimization of the Electrical Energy Production from a Hybrid Renewable Energy System. In Proceedings of the IEEE 2014 5th International Renewable Energy Congress (IREC), Hammamet, Tunisia, 25–27 March 2014; pp. 1–6. [Google Scholar]

- Das, B.K.; Zaman, F. Performance analysis of a PV/Diesel hybrid system for a remote area in Bangladesh: Effects of dispatch strategies, batteries, and generator selection. Energy 2019, 169, 263–276. [Google Scholar] [CrossRef]

- Halabi, L.M.; Mekhilef, S. Flexible hybrid renewable energy system design for a typical remote village located in Tropical climate. J. Clean. Prod. 2018, 177, 908–924. [Google Scholar] [CrossRef]

- Yazici, M.S.; Yavasoglu, H.A.; Eroglu, M. A mobile off-grid platform powered with photovoltaic / wind / battery / fuel cell hybrid power systems. Int. J. Hydrogen Energy 2013, 38, 11639–11645. [Google Scholar] [CrossRef]

- Zhou, X.; Feng, C. The impact of environmental regulation on fossil energy consumption in China: Direct and indirect effects. J. Clean. Prod. 2017, 142, 3174–3183. [Google Scholar] [CrossRef]

- Ma, W.; Xue, X.; Liu, G. Techno-economic evaluation for hybrid renewable energy system: Application and merits. Energy 2018, 159, 385–409. [Google Scholar] [CrossRef]

- Rehman, S.; Al-Hadhrami, L.M. Study of a solar PV-diesel-battery hybrid power system for a remotely located population near Rafha, Saudi Arabia. Energy 2010, 35, 4986–4995. [Google Scholar] [CrossRef]

- Nayak, A.; Kasturi, K.; Nayak, M.R. Cycle-charging dispatch strategy based performance analysis for standalone PV system with DG & BESS. In Proceedings of the IEEE 2018 Technologies for Smart-City Energy Security and Power (ICSESP), Bhubaneswar, India, 28–30 March 2018; pp. 1–5. [Google Scholar]

- Das, B.K.; Hoque, N.; Mandal, S.; Pal, T.K.; Raihan, M.A. A techno-economic feasibility of a stand-alone hybrid power generation for remote area application in Bangladesh. Energy 2017, 134, 775–788. [Google Scholar] [CrossRef]

- Ghasemi, A.; Enayatzare, M. Optimal energy management of a renewable-based isolated microgrid with pumped-storage unit and demand response. Renew. Energy 2018, 123, 460–474. [Google Scholar] [CrossRef]

- Ma, T.; Yang, H.; Lu, L. Electrical Power and Energy Systems Study on stand-alone power supply options for an isolated community. Int. J. Electr. Power Energy Syst. 2015, 65, 1–11. [Google Scholar] [CrossRef]

- Ismail, M.S.; Moghavvemi, M.; Mahlia, T.M.I. Techno-economic analysis of an optimized photovoltaic and diesel generator hybrid power system for remote houses in a tropical climate. Energy Convers. Manag. 2013, 69, 163–173. [Google Scholar] [CrossRef]

- Chauhan, A.; Saini, R.P. A review on Integrated Renewable Energy System based power generation for stand-alone applications: Con fi gurations, storage options, sizing methodologies and control. Renew. Sustain. Energy Rev. 2014, 38, 99–120. [Google Scholar] [CrossRef]

- Guangqian, D.; Bekhrad, K.; Azarikhah, P.; Maleki, A. A hybrid algorithm based optimization on modeling of grid independent biodiesel-based hybrid solar/wind systems. Renew. Energy 2018, 122, 551–560. [Google Scholar] [CrossRef]

- Akiki, H.; Eng, C.; Avenue, T. A decision support technique for the design of hybrid solar-wind power system. IEEE Trans. Energy Convers. 1998, 13, 76–83. [Google Scholar]

- Venkataramanan, G.; Marnay, C.; Siddiqui, A.S.; Stadler, M.; Chandran, B.; Firestone, R. Optimal Technology Selection and Operation of Commercial-Building Microgrids. IEEE Trans. Power Syst. 2008, 23, 975–982. [Google Scholar]

- Giraud, F.; Member, I.S.; Salameh, Z.M.; Member, S. Steady-State Performance of a Grid-Connected Rooftop Hybrid Power System with Battery Storage of Massachusetts, Lowell. IEEE Power Eng. Rev. 2001, 21, 54. [Google Scholar] [CrossRef]

- Baneshi, M.; Hadianfard, F. Techno-economic feasibility of hybrid diesel/PV/wind/battery electricity generation systems for non-residential large electricity consumers under southern Iran climate conditions. Energy Convers. Manag. 2016, 127, 233–244. [Google Scholar] [CrossRef]

- Murugaperumal, K.; Vimal, P.A.D. Feasibility design and techno-economic analysis of hybrid renewable energy system for rural electrification. Sol. Energy 2019, 188, 1068–1083. [Google Scholar] [CrossRef]

- Batanes—Wikipedia. Available online: https://en.wikipedia.org/wiki/Batanes (accessed on 16 February 2019).

- Welcome to HOMER. Available online: https://www.homerenergy.com/ (accessed on 25 February 2019).

- Oil Monitor as of 16 October 2018 DOE Department of Energy Portal. Available online: https://www.doe.gov.ph/oil-monitor-16-october-2018 (accessed on 19 March 2019).

- Halabi, L.M.; Mekhilef, S.; Olatomiwa, L.; Hazelton, J. Performance analysis of hybrid PV/diesel/battery system using HOMER: A case study Sabah, Malaysia. Energy Convers. Manag. 2017, 144, 322–339. [Google Scholar] [CrossRef]

- Homer Energy, Welcome to HOMER. 2017. Available online: https://www.homerenergy.com/products/pro/docs/3.11/index.html (accessed on 16 February 2019).

- Shannon, C.; Weaver, W. The Mathematical Theory of Communication; The University of Illinois Press: Champaign, IL, USA, 1964. [Google Scholar]

- Shi, G.; Buffen, A.M.; Ma, H.; Hu, Z.; Sun, B.; Li, C.; Li, Y. Science Direct Distinguishing summertime atmospheric production of nitrate across the East Antarctic Ice Sheet. Geochim. Cosmochim. Acta 2018, 231, 1–14. [Google Scholar] [CrossRef]

- Huang, J. Combining Entropy Weight and TOPSIS Method for Information System Selection. In Proceedings of the 2008 IEEE Conference on Cybernetics and Intelligent Systems, Chengdu, China, 21–24 September 2008; pp. 1281–1284. [Google Scholar]

- Abusara, M.; Mallick, T.; al Badwawi, R.; Abusara, M.; Mallick, T. A Review of Hybrid Solar PV and Wind Energy System. Smart Sci. 2016, 3, 127–138. [Google Scholar]

- Kolhe, M.L.; Ranaweera, K.M.I.U.; Gunawardana, A.G.B.S. Techno-economic sizing of off-grid hybrid renewable energy system for rural electrification in Sri Lanka. Sustain. Energy Technol. Assess. 2020, 11, 53–64. [Google Scholar] [CrossRef]

- Li, C.; Ge, X.; Zheng, Y.; Xu, C.; Ren, Y.; Song, C. Techno-economic feasibility study of autonomous hybrid wind/PV/battery power system for a household in Urumqi, China. Energy 2013, 55, 263–272. [Google Scholar] [CrossRef]

- Rohani, G.; Nour, M. Techno-economical analysis of stand-alone hybrid renewable power system for Ras Musherib in United Arab Emirates. Energy 2014, 64, 828–841. [Google Scholar] [CrossRef]

- Sansone, G.; Hills, O.; Bohl, R. Power Your Dream with the Wind. 2001. Available online: www.bergey.com (accessed on 19 March 2019).

- Nasser, Y.; Oumarou, H.; Lucien, M.; Benoit, N.; Jean, N. Analyzing of a Photovoltaic/Wind/Biogas/Pumped- Hydro Off-Grid Hybrid System for Rural Electrification in Sub-Saharan Africa—Case Study of Djoundé in Northern Cameroon. Energies 2018, 11, 2644. [Google Scholar]

- Adaramola, M.S.; Agelin-chaab, M.; Paul, S.S. Analysis of hybrid energy systems for application in southern Ghana. Energy Convers. Manag. 2015, 88, 284–295. [Google Scholar] [CrossRef]

- Adaramola, M.S.; Agelin-chaab, M.; Paul, S.S. Assessment of wind power generation along the coast of Ghana. Energy Convers. Manag. 2015, 77, 61–69. [Google Scholar] [CrossRef]

- ESS Batteries by Samsung SDI Top Safety & Reliability Solutions. Available online: http://www.samsungsdi.com/upload/ess_brochure/201803_SamsungSDI%20ESS_EN.pdf (accessed on 16 February 2019).

- Bangko Sentral ng Pilipinas—Publications & Research. Available online: http://www.bsp.gov.ph/publications/media.asp?id=4935 (accessed on 25 February 2019).

- Philippines inflation Rates. Available online: http://www.bsp.gov.ph/statistics/spei_new/tab34_inf.htm (accessed on 25 February 2019).

- Philippines Interest Rate 2019 Data Chart Calendar Forecast News. Available online: https://tradingeconomics.com/philippines/interest-rate (accessed on 25 February 2019).

| Hybrid Energy Systems | Storage | Operating Strategy | Grid Connection | Methodology | Performance Measures |

|---|---|---|---|---|---|

| PV/Diesel/Batt [12] | LA, Li-ion | LF, CC, CD | Off-grid | HOMER | NPC, COE, EE, RF, DF, CO2 emissions |

| PV/Diesel/Batt [13] | LA | LF | Off-grid/grid connected | HOMER | NPC, COE, RF, CO2 emissions |

| PV/Diesel/Batt [17] | LA | LF | Off-grid | HOMER | NPC, COE, EE, CO2 emissions |

| PV/Diesel/Batt [18] | Li-ion | CC | Off-grid | MATLAB | NPC |

| PV/Wind/Biogas/Diesel/Batt [19] | LA | - | Off-grid | HOMER | NPC, COE, RF, O&M cost |

| PV/Wind/Diesel/Batt [28] | CELLCUBE | LF | Off-grid/grid connected | HOMER | NPC, COE, RF, CO2 emissions |

| PV/Wind/Biogas/Batt [29] | LA | LF, CC | Off-grid | HOMER | NPC, COE, RF, CO2 emissions |

| Number | Prime Power | Type | Fuel Consumption Slope (Liter/kWh) | Operation Schedule |

|---|---|---|---|---|

| DG1 | 600 kW | Cummins QSK23-G3 | 0.2376 | AM 00–11 |

| DG2 | 600 kW | Cummins QSK23-G3 | 0.2376 | AM 00–11 |

| DG3 | 600 kW | Cummins KTA38-G1 | 0.2273 | PM 12–23 |

| DG4 | 600 kW | Denyo DCA series | 0.2351 | PM 12–23 |

| DG5 | 450 kW | MAN B & W-8L20/27 | 0.2440 | Backup |

| Description | Data Description |

|---|---|

| PV system | |

| Capital cost ($/kW) | 4000 |

| Replacement cost ($/kW) | 4000 |

| Operation and maintenance cost ($/kW/yr) | 20 |

| WG system | |

| Capital cost ($/kW) | 5800 |

| Replacement cost ($/kW) | 5800 |

| Operation and maintenance cost ($/kW/yr) | 40 |

| Storage system | |

| Capital cost ($/kWh) | 690 |

| Replacement cost ($/kWh) | 690 |

| Operation and maintenance cost ($/kWh/yr) | 5 |

| Power converter | |

| Capital cost ($/kW) | 700 |

| Replacement cost ($/kW) | 700 |

| Operation and maintenance cost ($/kW/yr) | 1 |

| Diesel generator | |

| Capital cost ($/kW) | 0 |

| Replacement cost ($/kW) | 400 |

| Operation and maintenance ($/h) | 0.03 |

| Component | Operation Schedule | Hours of Operation (H/yr) | Electrical Production (kWh/yr) | Fuel Consumption (L/yr) | Specific Fuel Consumption (L/kWh) |

|---|---|---|---|---|---|

| DG1 | AM 0–11 | 4380 | 2,002,495 | 511,230 | 0.26 |

| DG2 | AM 0–11 | 4380 | 783,942 | 221,714 | 0.28 |

| DG3 | PM 12–23 | 4380 | 2,373,373 | 606,795 | 0.26 |

| DG4 | PM 12–23 | 4380 | 1,010,918 | 275,641 | 0.27 |

| DG5 | Backup | 219 | 25,159 | 7720 | 0.31 |

| System | 6,195,887 | 1,623,100 | 0.26 | ||

| Component | Capital | Replacement | O&M | Fuel | Salvage | NPC | COE |

|---|---|---|---|---|---|---|---|

| ($) | ($) | ($) | ($) | ($) | ($) | ($/kWh) | |

| DG1 | 0 | 0 | 1,445,869 | 7,500,470 | 0 | 8,946,339 | 0.2436 |

| DG2 | 0 | 0 | 1,445,869 | 3,252,855 | 0 | 4,698,724 | 0.3268 |

| DG3 | 0 | 0 | 1,445,869 | 8,902,549 | 0 | 10,348,418 | 0.2377 |

| DG4 | 0 | 0 | 1,445,869 | 4,044,047 | 0 | 5,489,916 | 0.2961 |

| DG5 | 0 | 0 | 54,220 | 113,267 | 0 | 167,487 | 0.3630 |

| System | 0 | 0 | 5,837,696 | 23,813,188 | 0 | 29,650,884 | 0.2609 |

| Genset | PVS | Electrical Production | Excess Electricity | PVS Capacity Factor | Renewable Fraction | Fuel Consumption | Fuel Saving |

|---|---|---|---|---|---|---|---|

| (kW) | (kWp) | (kWh/yr) | (kWh/yr) | (%) | (%) | (liter/yr) | (%) |

| 2850 (5 sets) | 550 | 6,214,612 | 19,231.4 (0.3%) | 16.32 | 12.4 | 1,441,803 | −11.17 |

| Component | Capital | Replacement | O&M | Fuel | Salvage | NPC | COE |

|---|---|---|---|---|---|---|---|

| ($) | ($) | ($) | ($) | ($) | ($) | ($/kWh) | |

| DG1 | 0 | 0 | 1,445,869 | 6,504,553 | 0 | 7,950,422 | 0.2525 |

| DG2 | 0 | 0 | 1,445,869 | 2,892,353 | 0 | 4,338,222 | 0.3476 |

| DG3 | 0 | 0 | 1,445,869 | 8,170,166 | 0 | 9,616,035 | 0.2434 |

| DG4 | 0 | 0 | 1,445,869 | 3,552,188 | 0 | 4,998,057 | 0.3133 |

| DG5 | 0 | 0 | 16,093 | 34,043 | 0 | 50,135 | 0.3603 |

| PVS | 2,200,000 | 0 | 201,732 | 0 | 0 | 2,401,732 | 0.1666 |

| System | 2,200,000 | 0 | 6,001,301 | 21,153,303 | 0 | 29,354,604 | 0.2583 |

| Genset | WGS | Electrical Production | Excess Electricity | Capacity Factor | Renewable Fraction | Fuel Consumption | Fuel Saving |

|---|---|---|---|---|---|---|---|

| (kW) | (kW) | (kWh/yr) | (kWh/yr) | (%) | (%) | (liter/yr) | (%) |

| 2850 (5 sets) | 380 | 6,333,993 | 138,612.4 (2.2%) | 32.48 | 15.2 | 1,402,500 | −13.59 |

| Component | Capital | Replacement | O&M | Fuel | Salvage | NPC | COE |

|---|---|---|---|---|---|---|---|

| ($) | ($) | ($) | ($) | ($) | ($) | ($/kWh) | |

| DG1 | 0 | 0 | 1,445,869 | 6,455,536 | 0 | 7,901,405 | 0.2530 |

| DG2 | 0 | 0 | 1,445,869 | 3,077,750 | 0 | 4,523,619 | 0.3362 |

| DG3 | 0 | 0 | 1,445,869 | 7,497,764 | 0 | 8,943,633 | 0.2498 |

| DG4 | 0 | 0 | 1,445,869 | 3,491,624 | 0 | 4,937,493 | 0.3158 |

| DG5 | 0 | 0 | 25,748 | 54,001 | 0 | 79,750 | 0.3621 |

| WGS | 2,204,000 | 0 | 278,757 | 0 | 0 | 2,482,757 | 0.1252 |

| System | 2,204,000 | 0 | 6,087,982 | 20,576,675 | 0 | 28,868,656 | 0.2541 |

| Genset | PVS | WGS | Electrical Production | Excess Electricity | Renewable Fraction | Fuel Consumption | Fuel Saving |

|---|---|---|---|---|---|---|---|

| (kW) | (kWp) | (kW) | (kWh/yr) | (kWh/yr) | (%) | (liter/yr) | (%) |

| 2850 (5 sets) | 200 | 340 | 6,330,194 | 134,813.6 (2.1%) | 18.1 | 1,360,550 | −16.18 |

| Component | Capital | Replacement | O&M | Fuel | Salvage | NPC | COE |

|---|---|---|---|---|---|---|---|

| ($) | ($) | ($) | ($) | ($) | ($) | ($/kWh) | |

| DG1 | 0 | 0 | 1,445,869 | 6,225,212 | 0 | 7,671,081 | 0.2556 |

| DG2 | 0 | 0 | 1,445,869 | 2,951,936 | 0 | 4,397,805 | 0.3437 |

| DG3 | 0 | 0 | 1,445,869 | 7,395,589 | 0 | 8,841,458 | 0.2509 |

| DG4 | 0 | 0 | 1,445,869 | 3,365,351 | 0 | 4,811,220 | 0.3214 |

| DG5 | 0 | 0 | 10,894 | 23,121 | 0 | 34,014 | 0.3597 |

| PVS | 800,000 | 0 | 73,357 | 0 | 0 | 873,357 | 0.1666 |

| WGS | 1,972,000 | 0 | 249,414 | 0 | 0 | 2,221,414 | 0.1252 |

| System | 2,772,000 | 0 | 6,117,141 | 19,961,209 | 0 | 28,850,350 | 0.2539 |

| Renewable Fraction | Genset | PVS | Storage | Electrical Production | Excess Electricity | Fuel Consumption | Fuel Saving |

|---|---|---|---|---|---|---|---|

| (%) | (kW) | (kWp) | (kWh) | (kWh) | (kWh/yr) | (kWh/yr) | (liter/yr) |

| 25 | 2850 (five sets) | 1200 | 1260 | 6,359,813 | 122,652.0 (1.9) | 1,259,864 | −22.38 |

| 30 | 1500 | 2100 | 6,478,906 | 200,845.9 (3.1) | 1,188,383 | −26.78 | |

| 35 | 1750 | 3444 | 6,528,063 | 196,732.8 (3.0) | 1,117,409 | −31.16 | |

| 40 | 2050 | 4872 | 6,630,449 | 239,512.0 (3.6) | 1,041,868 | −35.81 | |

| 45 | 2300 | 6804 | 6,691,938 | 243,681.9 (3.6) | 972,643 | −40.07 | |

| 50 | 2600 | 12,600 | 6,813,660 | 308,601.5 (4.5) | 900,837 | −44.50 |

| Renewable Fraction | Capital | Replacement | O&M | Fuel | Salvage | NPC | COE |

|---|---|---|---|---|---|---|---|

| (%) | ($) | ($) | ($) | ($) | ($) | ($) | ($/kWh) |

| 25 | 6,716,295 | 965,724 | 6,379,540 | 18,484,004 | 0 | 32,545,563 | 0.2864 |

| 30 | 8,493,825 | 965,724 | 6,562,887 | 17,435,266 | 0 | 33,457,702 | 0.2945 |

| 35 | 10,417,873 | 965,724 | 6,775,842 | 16,393,978 | 0 | 34,553,418 | 0.3041 |

| 40 | 12,599,674 | 965,724 | 7,013,354 | 15,285,686 | 0 | 35,864,438 | 0.3157 |

| 45 | 14,927,993 | 965,724 | 7,280,970 | 14,270,060 | 0 | 37,444,747 | 0.3296 |

| 50 | 20,112,950 | 965,724 | 7,921,983 | 13,216,565 | 0 | 42,217,222 | 0.3716 |

| Renewable Fraction | Genset | WGS | Storage | Electrical Production | Excess Electricity | Fuel Consumption | Fuel Saving |

|---|---|---|---|---|---|---|---|

| (%) | (kW) | (kW) | (kWh) | (kWh) | (kWh/yr) | (kWh/yr) | (liter/yr) |

| 25 | 2850 (five sets) | 670 | 2520 | 6,541,615 | 299,274.0 (4.6) | 1,258,831 | −22.44 |

| 30 | 800 | 20,244 | 6,609,215 | 326,952.9 (4.9) | 1,188,672 | −26.77 | |

| 35 | 1060 | 67,200 | 7,034,297 | 727,785.1 (10.3) | 1,115,342 | −31.28 |

| Renewable Fraction | Capital | Replacement | O&M | Fuel | Salvage | NPC | COE |

|---|---|---|---|---|---|---|---|

| (%) | ($) | ($) | ($) | ($) | ($) | ($) | ($/kWh) |

| 25 | 6,668,590 | 965,724 | 6,552,369 | 18,468,839 | 0 | 32,655,522 | 0.2874 |

| 30 | 19,608,473 | 965,724 | 8,271,475 | 17,439,515 | 0 | 46,285,187 | 0.4074 |

| 35 | 53,400,400 | 965,724 | 12,765,424 | 16,363,651 | 0 | 83,495,199 | 0.7349 |

| Renewable Fraction | Genset | PVS | WGS | Storage | Electrical Production | Excess Electricity | Fuel Consumption | Fuel Saving |

|---|---|---|---|---|---|---|---|---|

| (%) | (kW) | (kWp) | (kW) | (kWh) | (kWh/yr) | (kWh/yr) | (liter/yr) | (%) |

| 25 | 2850 (five sets) | 400 | 440 | 168 | 6,468,587 | 264,437.6 (4.1) | 1,259,850 | −22.38 |

| 30 | 700 | 420 | 504 | 6,528,221 | 311,155.0 (4.8) | 1,187,107 | −26.86 | |

| 35 | 950 | 410 | 1680 | 6,548,999 | 297,053.1 (4.5) | 1,115,897 | −31.25 | |

| 40 | 1300 | 370 | 3108 | 6,623,216 | 322,638.7 (4.9) | 1,043,925 | −35.68 | |

| 45 | 1750 | 280 | 5292 | 6,702,660 | 331,642.6 (4.9) | 972,740 | −40.07 | |

| 50 | 2400 | 100 | 11,508 | 6,810,636 | 336101.2 (4.9) | 900,511 | −44.52 |

| Renewable Fraction | Capital | Replacement | O&M | Fuel | Salvage | NPC | COE |

|---|---|---|---|---|---|---|---|

| (%) | ($) | ($) | ($) | ($) | ($) | ($) | ($/kWh) |

| 25 | 5,317,506 | 1,066,934 | 6,303,798 | 18,483,799 | −71,670 | 31,100,367 | 0.2737 |

| 30 | 6,632,518 | 1,261,386 | 6,429,230 | 17,416,549 | −277,216 | 31,462,467 | 0.2769 |

| 35 | 8,383,060 | 965,724 | 6,620,930 | 16,371,799 | 0 | 32,341,513 | 0.2846 |

| 40 | 10,532,861 | 965,724 | 6,849,419 | 15,315,875 | 0 | 33,663,880 | 0.2963 |

| 45 | 13,312,439 | 965,724 | 7,147,231 | 14,271,476 | 0 | 35,696,871 | 0.3142 |

| 50 | 19,142,161 | 965,724 | 7,821,603 | 13,211,782 | 0 | 41,141,271 | 0.3621 |

| Indices | Capital | COE | Fuel Saving | Occupied Area |

|---|---|---|---|---|

| Information entropy | 0.87577 | 0.88614 | 0.83210 | 0.85829 |

| Weighting factors (%) | 22.68% | 20.79% | 30.66% | 25.87% |

| RF-25% | RF-30% | RF-35% | RF-40% | RF-45% | RF-50% | |

|---|---|---|---|---|---|---|

| D+ | 0.30656 | 0.24911 | 0.20730 | 0.20175 | 0.25112 | 0.40201 |

| D− | 0.40201 | 0.36488 | 0.33507 | 0.30944 | 0.29627 | 0.30656 |

| C | 0.56736 | 0.59428 | 0.61779 | 0.60533 | 0.54124 | 0.43264 |

| Ranking | 4 | 3 | 1 | 2 | 5 | 6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, C.-T.; Beza, T.M.; Wu, W.-B.; Kuo, C.-C. Optimal Configuration with Capacity Analysis of a Hybrid Renewable Energy and Storage System for an Island Application. Energies 2020, 13, 8. https://doi.org/10.3390/en13010008

Tsai C-T, Beza TM, Wu W-B, Kuo C-C. Optimal Configuration with Capacity Analysis of a Hybrid Renewable Energy and Storage System for an Island Application. Energies. 2020; 13(1):8. https://doi.org/10.3390/en13010008

Chicago/Turabian StyleTsai, Chih-Ta, Teketay Mulu Beza, Wei-Bin Wu, and Cheng-Chien Kuo. 2020. "Optimal Configuration with Capacity Analysis of a Hybrid Renewable Energy and Storage System for an Island Application" Energies 13, no. 1: 8. https://doi.org/10.3390/en13010008

APA StyleTsai, C.-T., Beza, T. M., Wu, W.-B., & Kuo, C.-C. (2020). Optimal Configuration with Capacity Analysis of a Hybrid Renewable Energy and Storage System for an Island Application. Energies, 13(1), 8. https://doi.org/10.3390/en13010008