Optimization of A Swirl with Impingement Compound Cooling Unit for A Gas Turbine Blade Leading Edge

Abstract

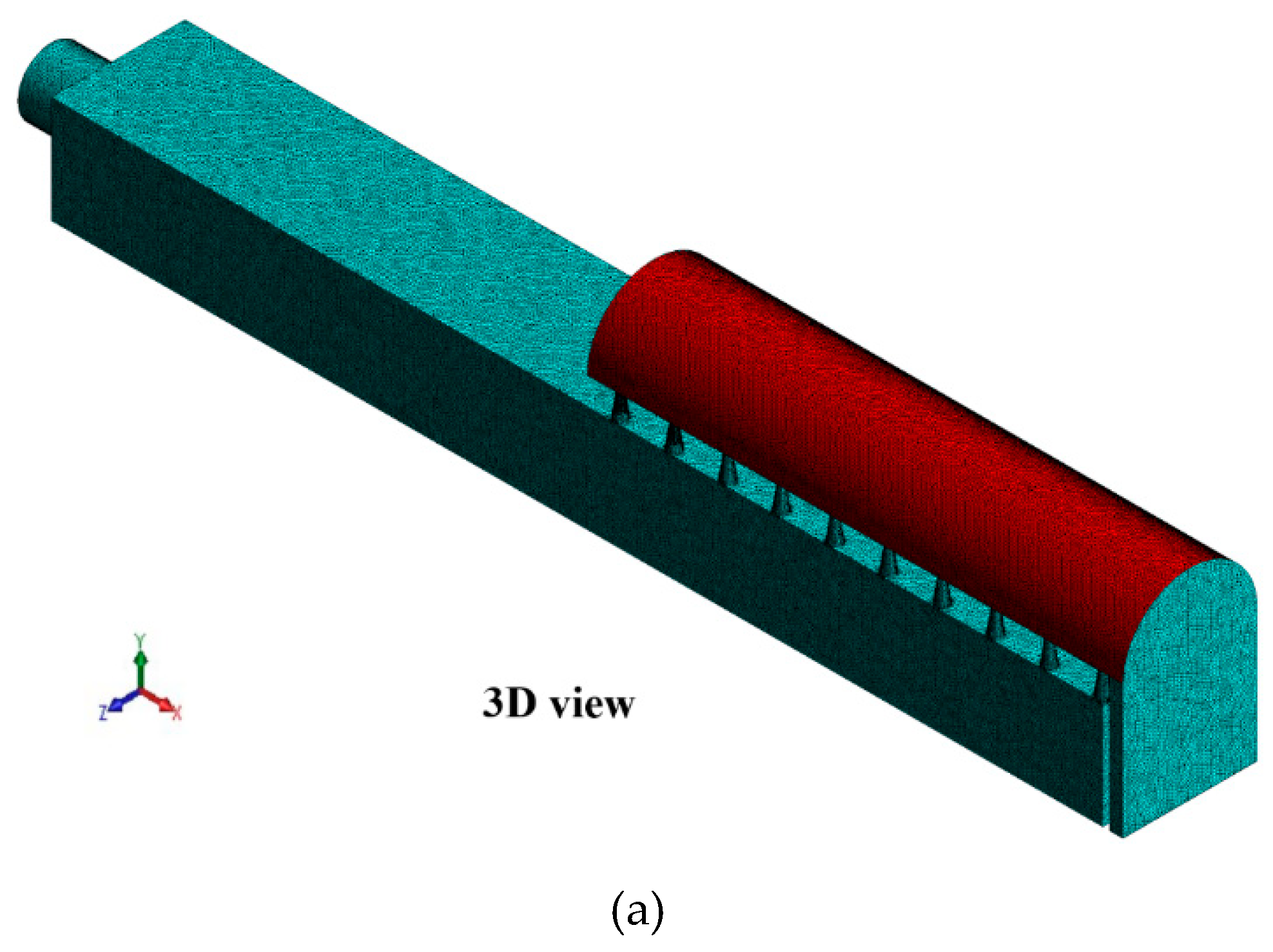

1. Introduction

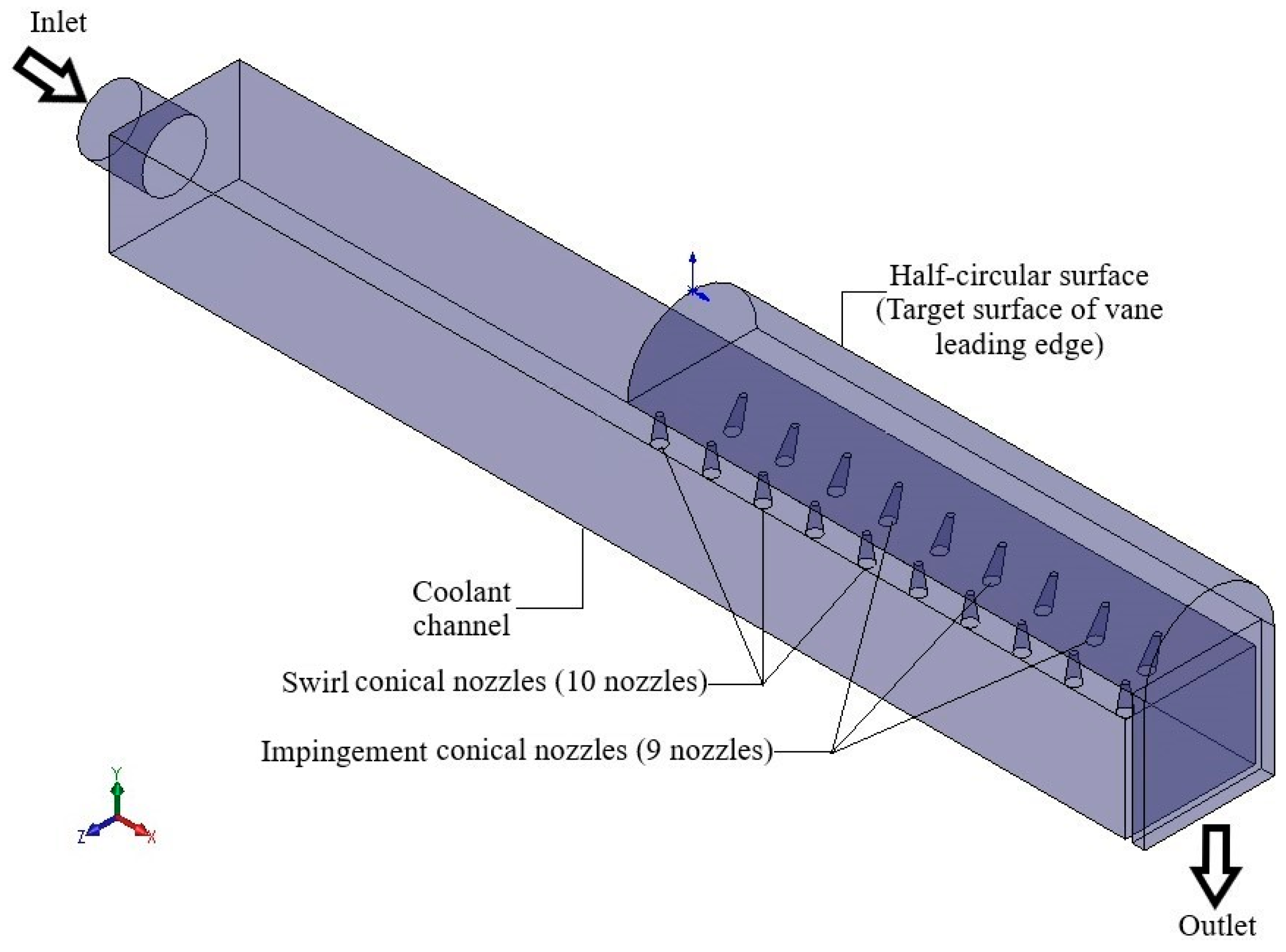

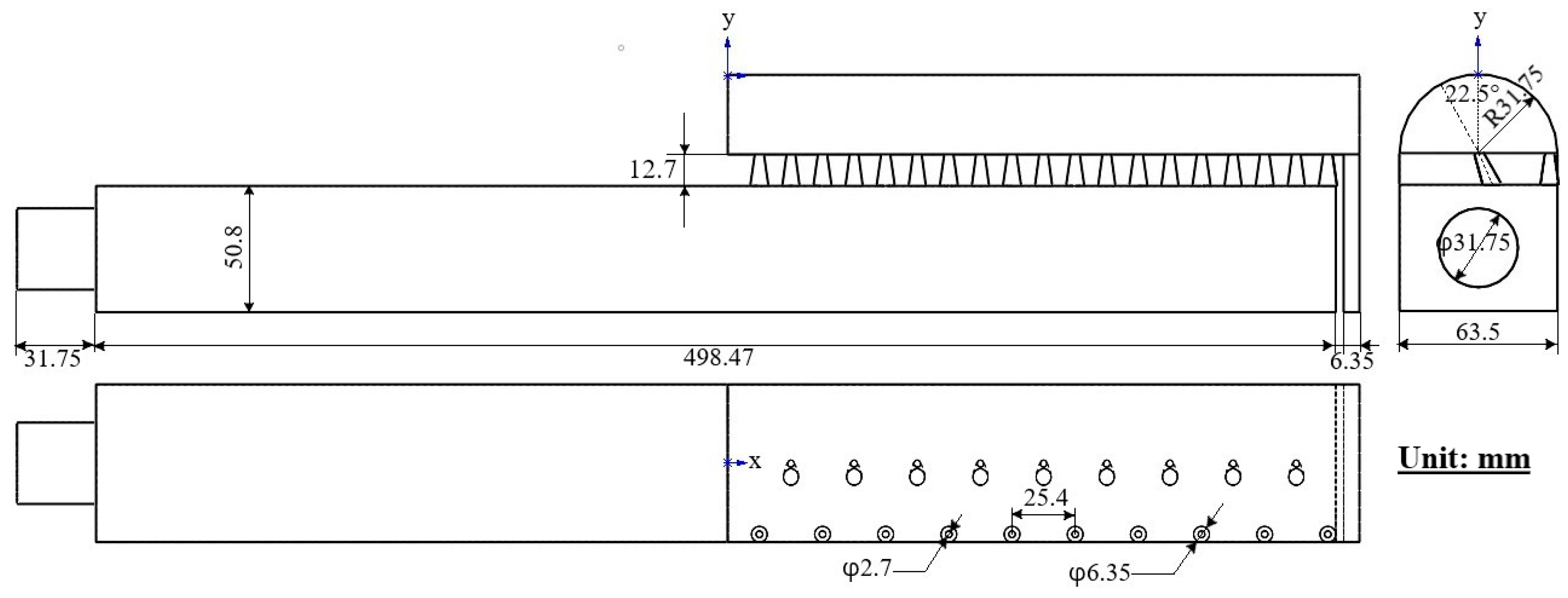

2. Description of the Physical Model and Solution Methods

2.1. Physical Geometry

2.2. Definition of Parameter

2.3. Computational Method

2.4. Boundary Conditions

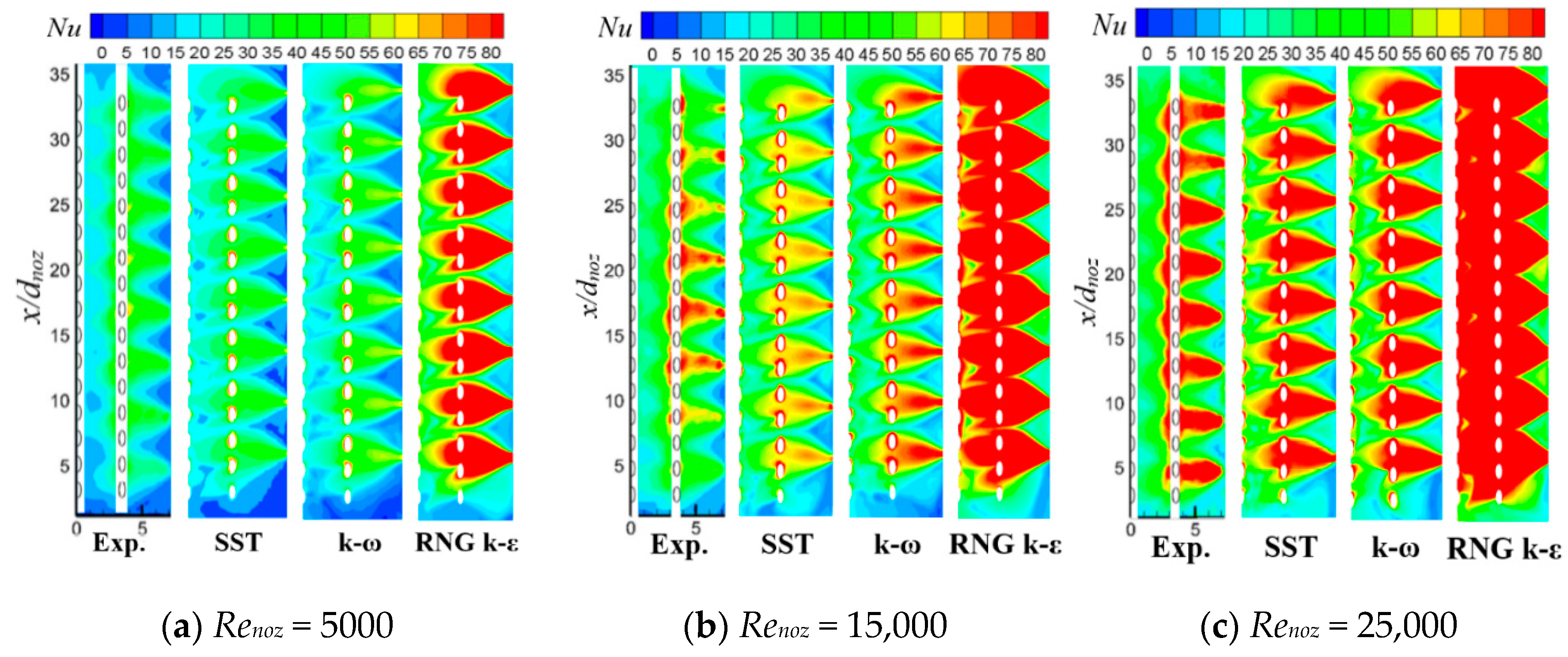

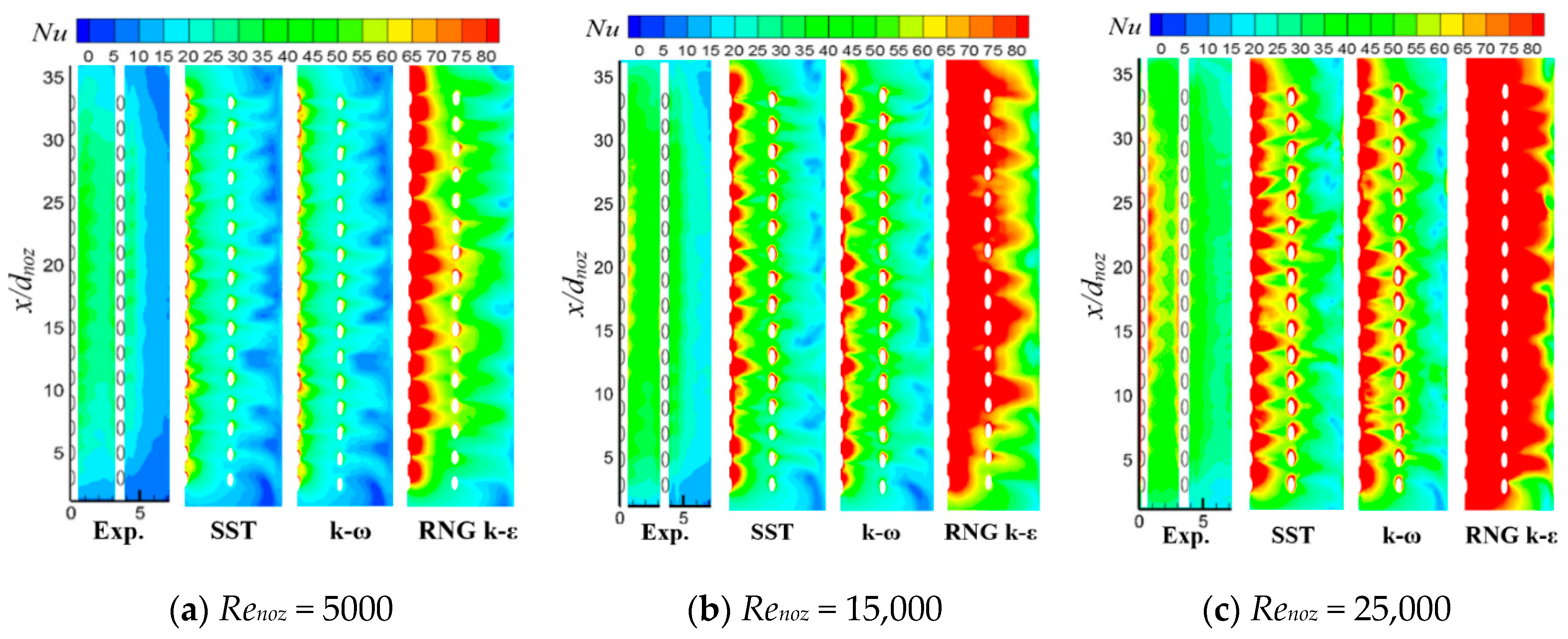

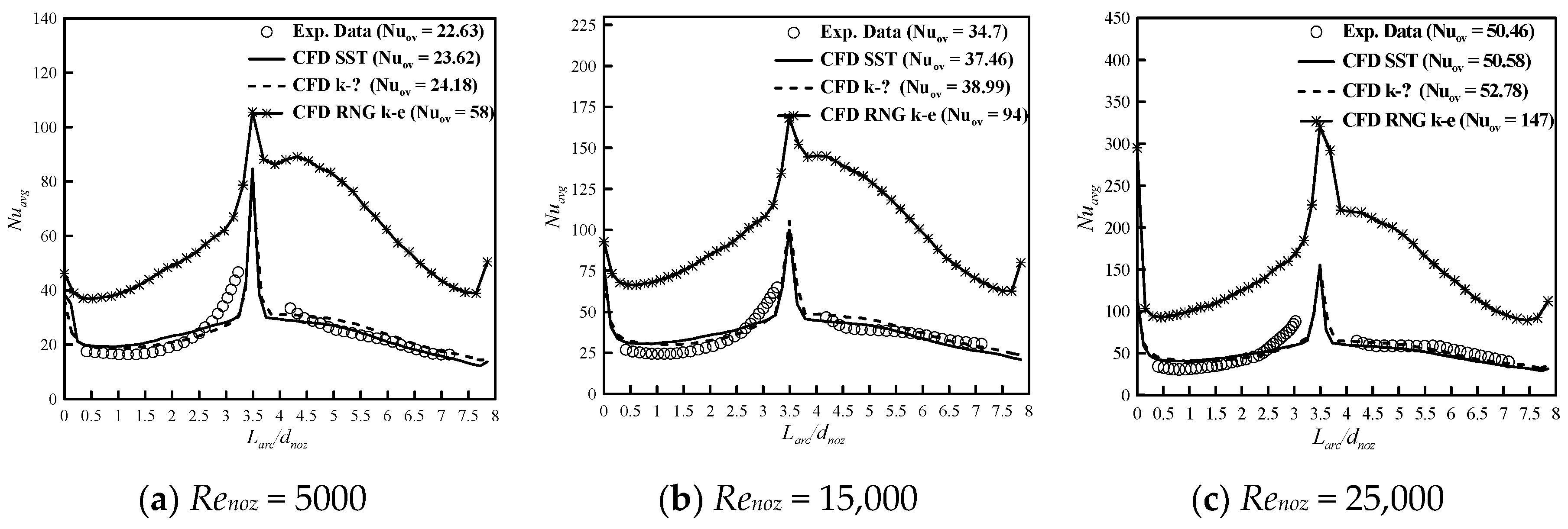

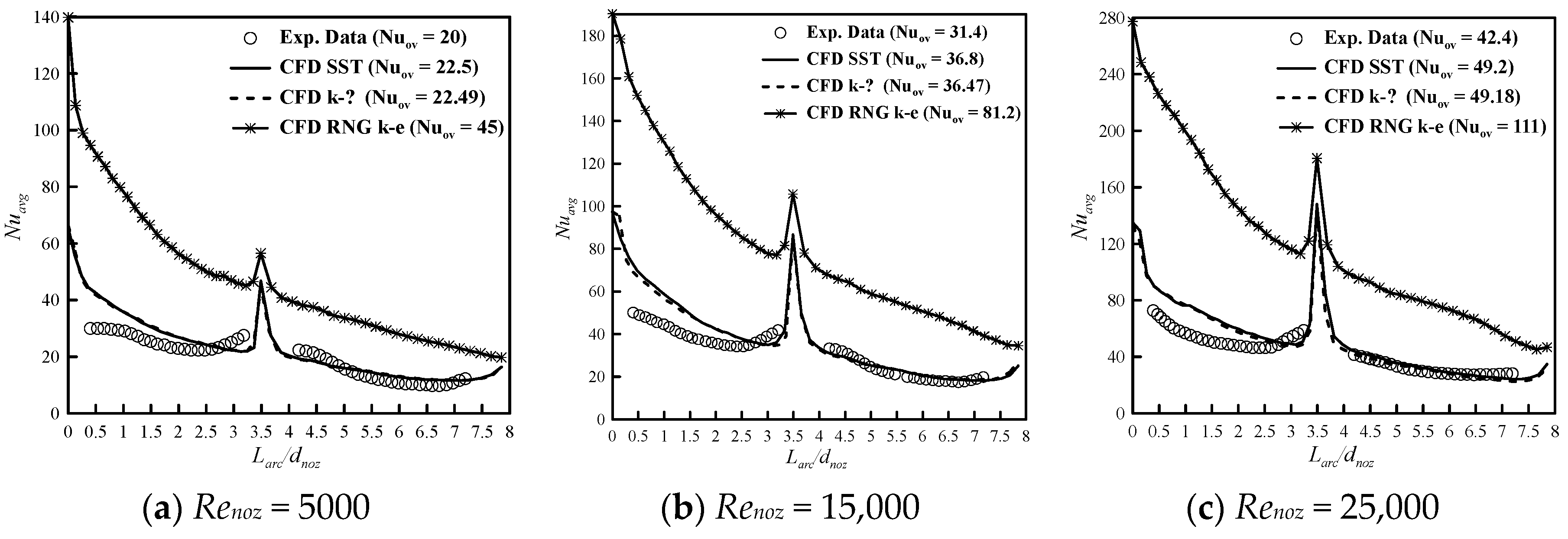

2.5. Turbulence Model Validation

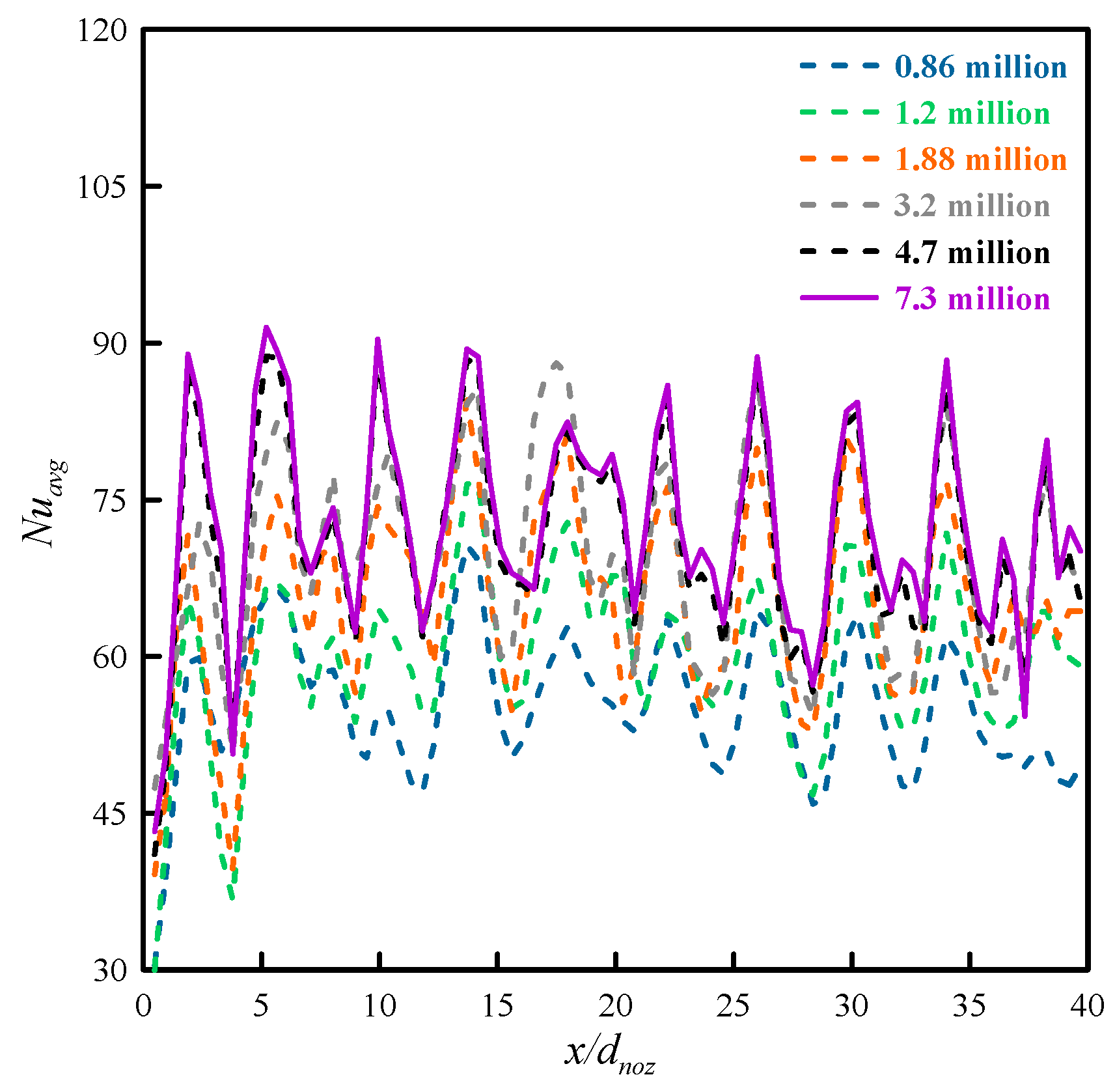

2.6. Mesh Generation and Grid Independence Test

3. Results

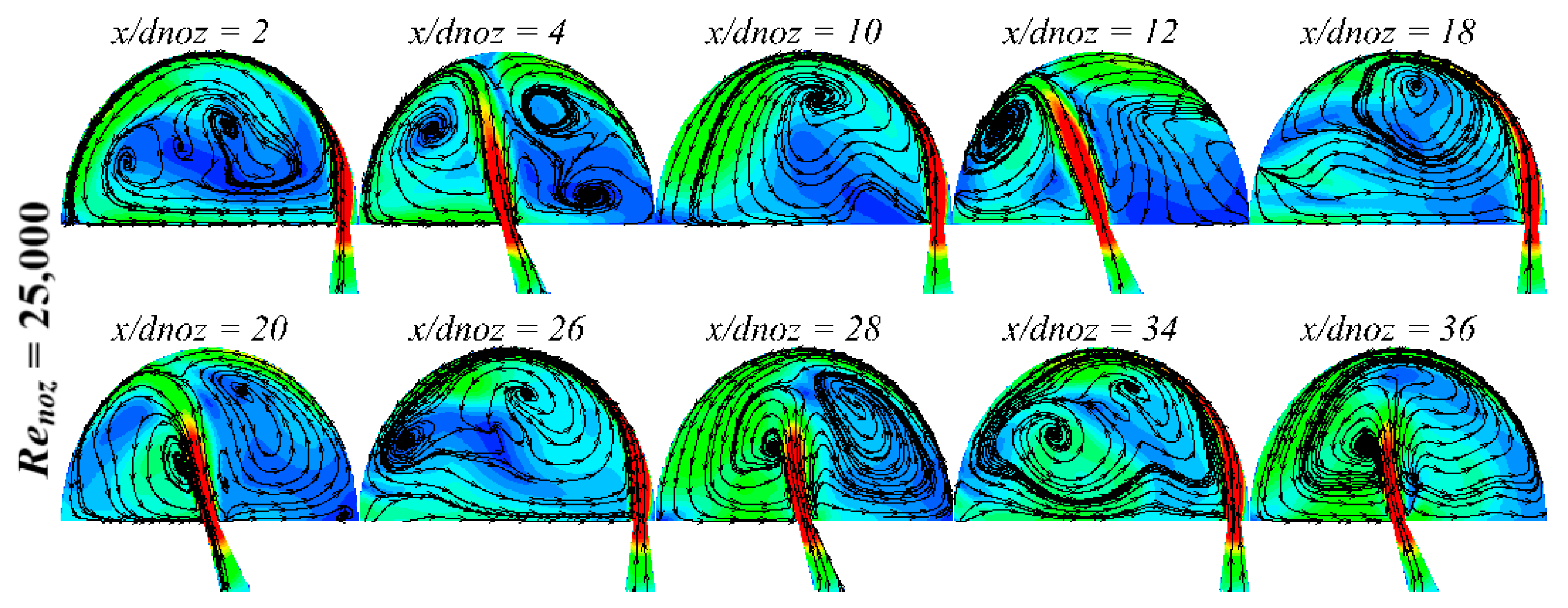

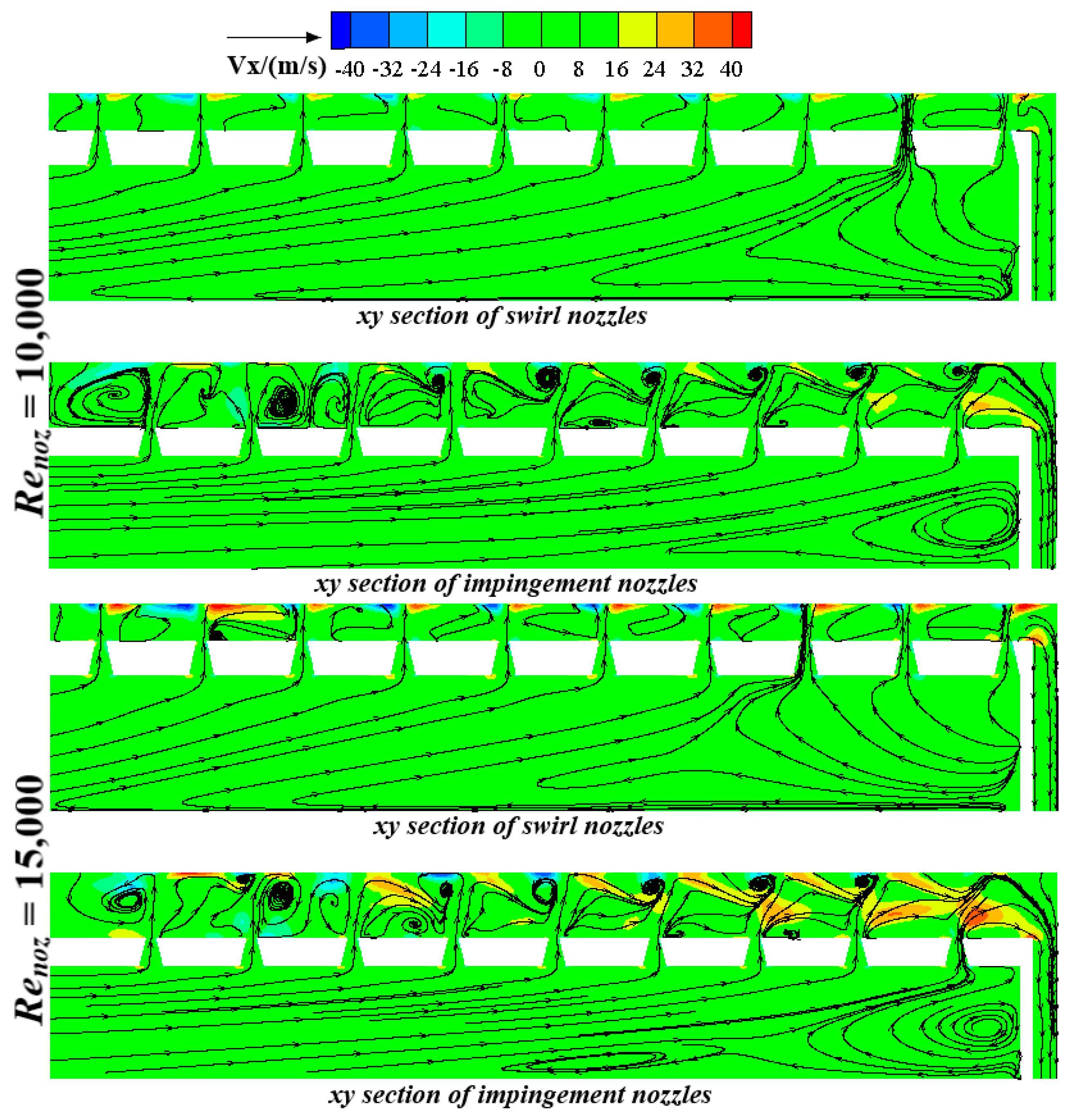

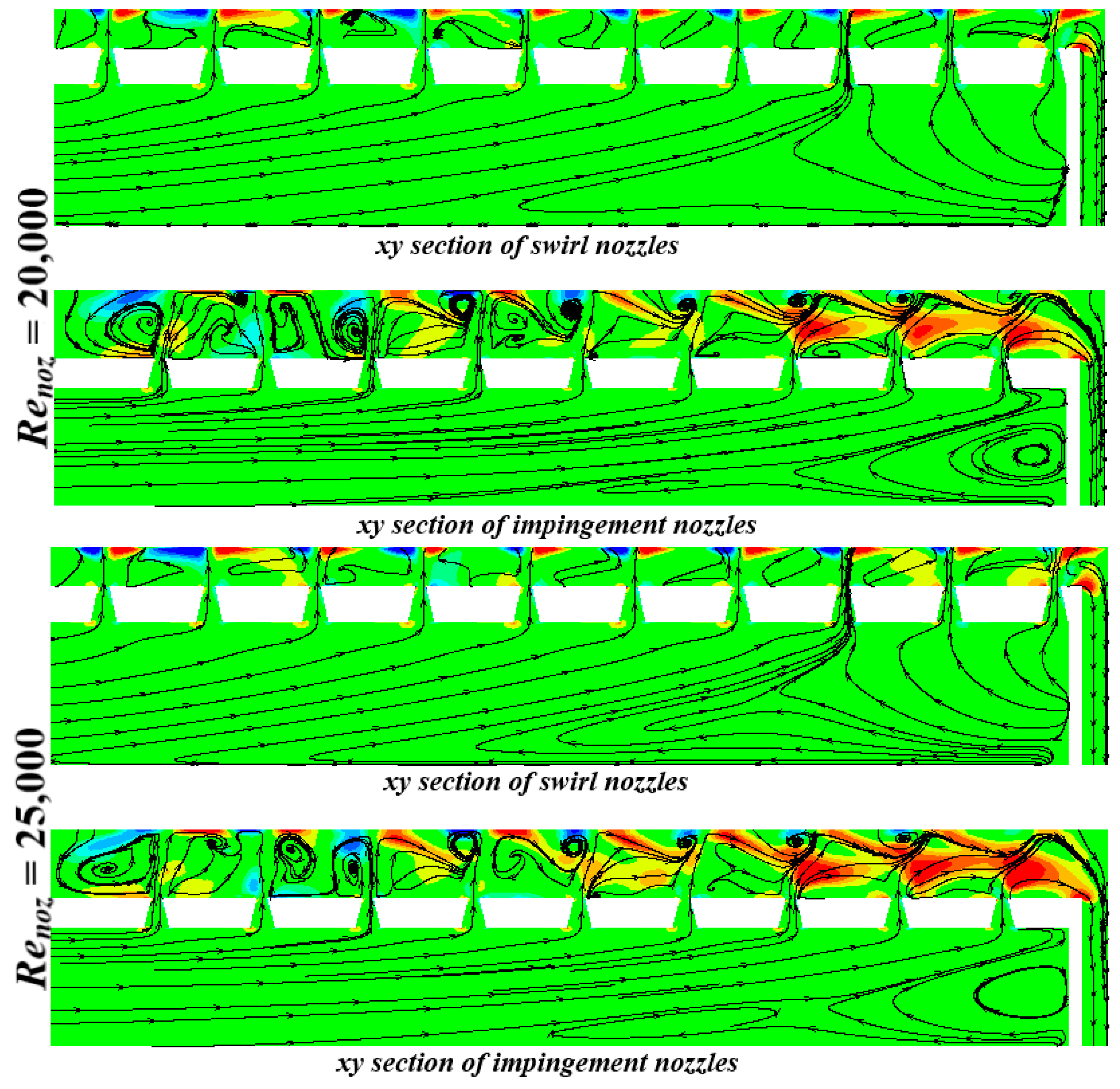

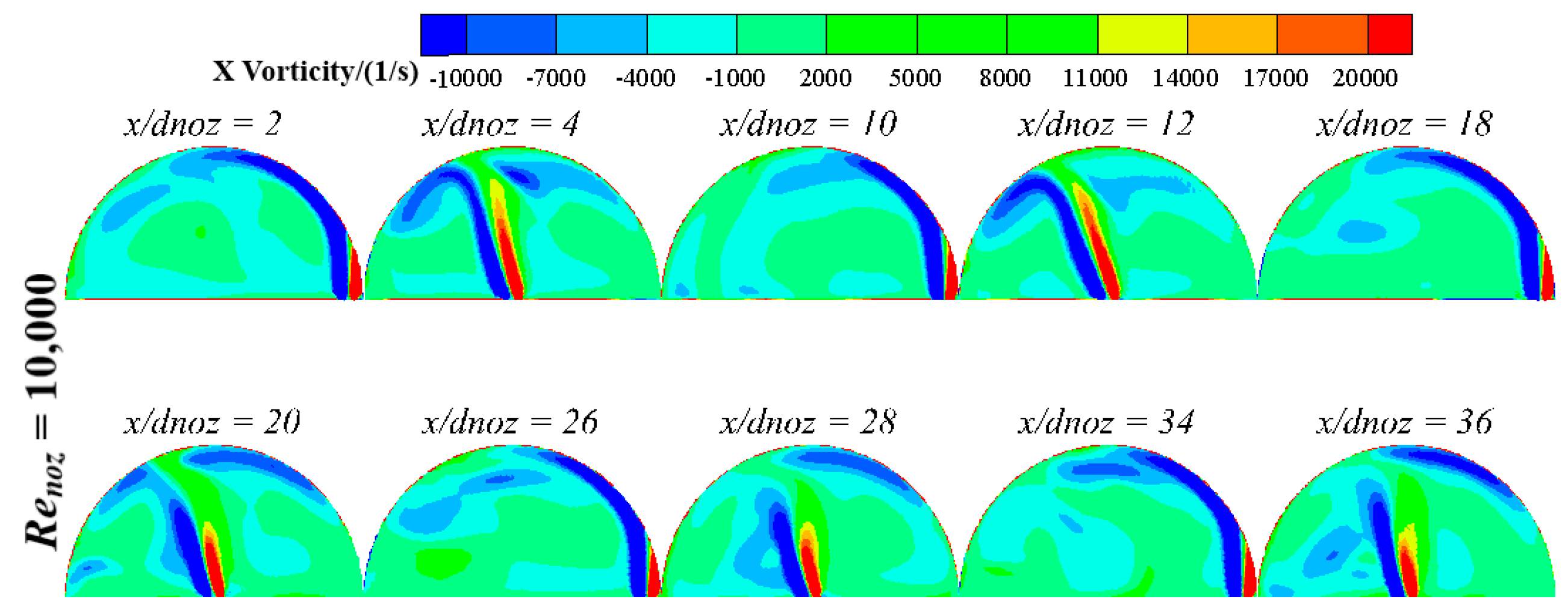

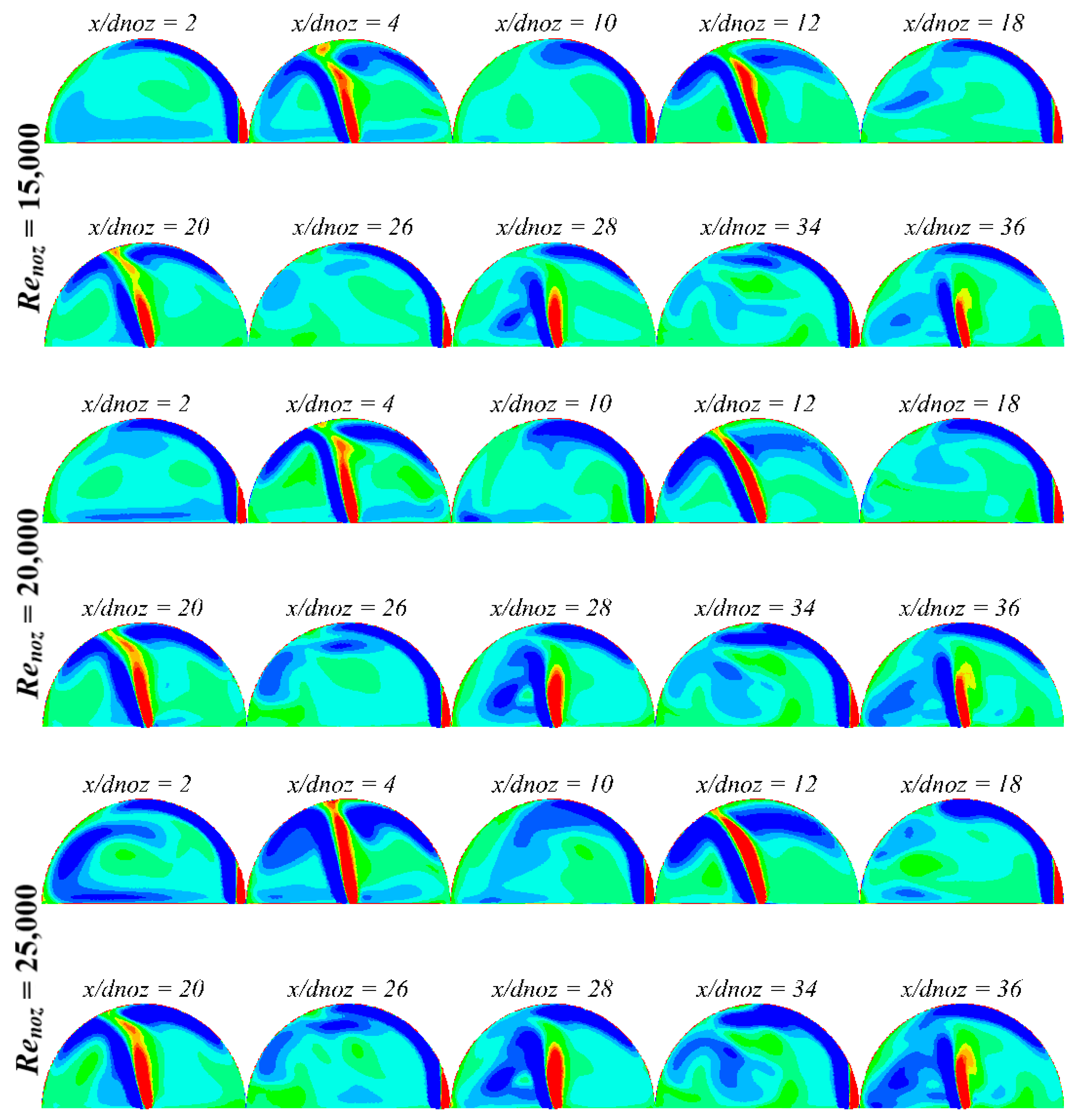

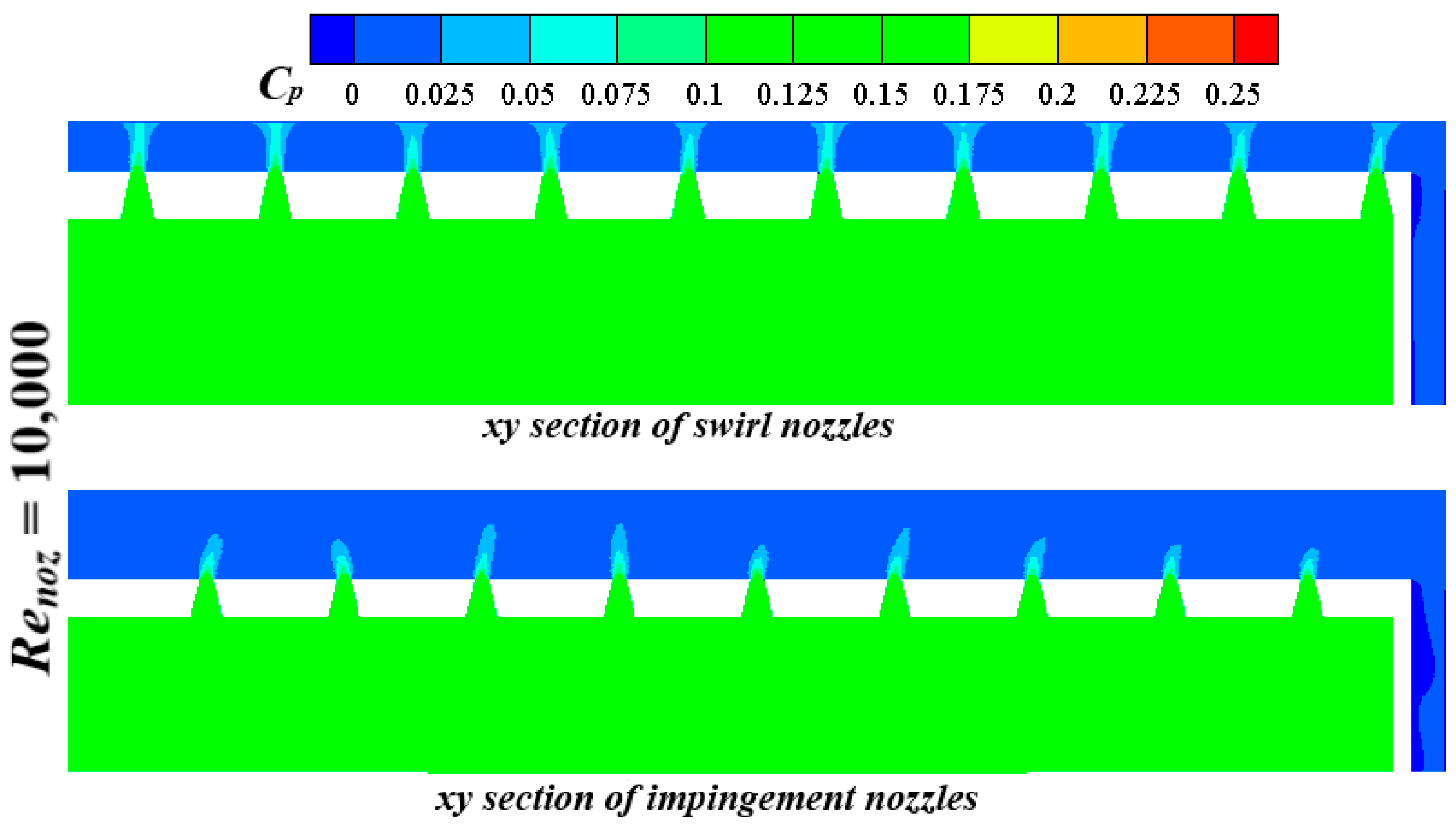

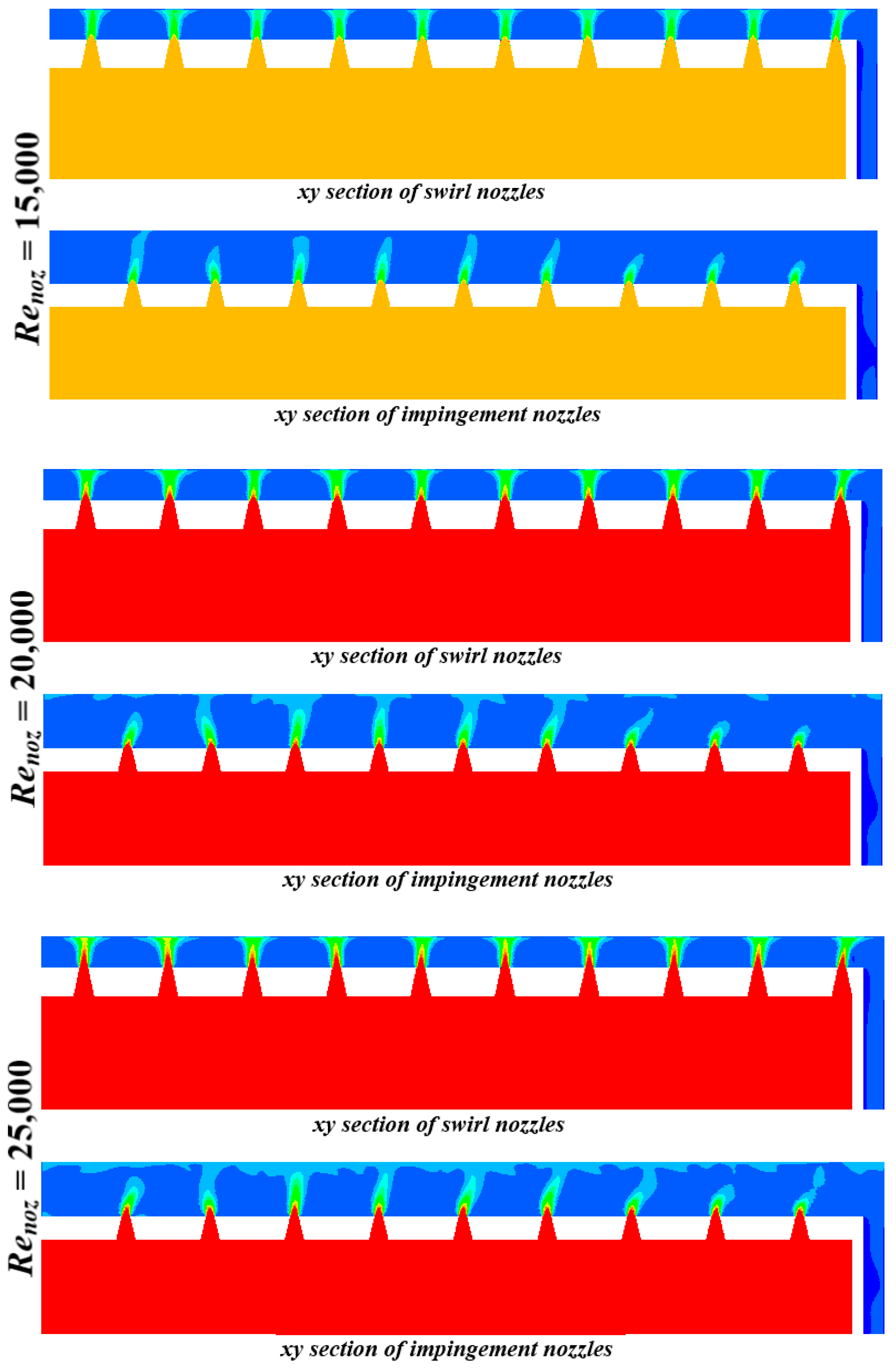

3.1. Coolant Flow Analyses

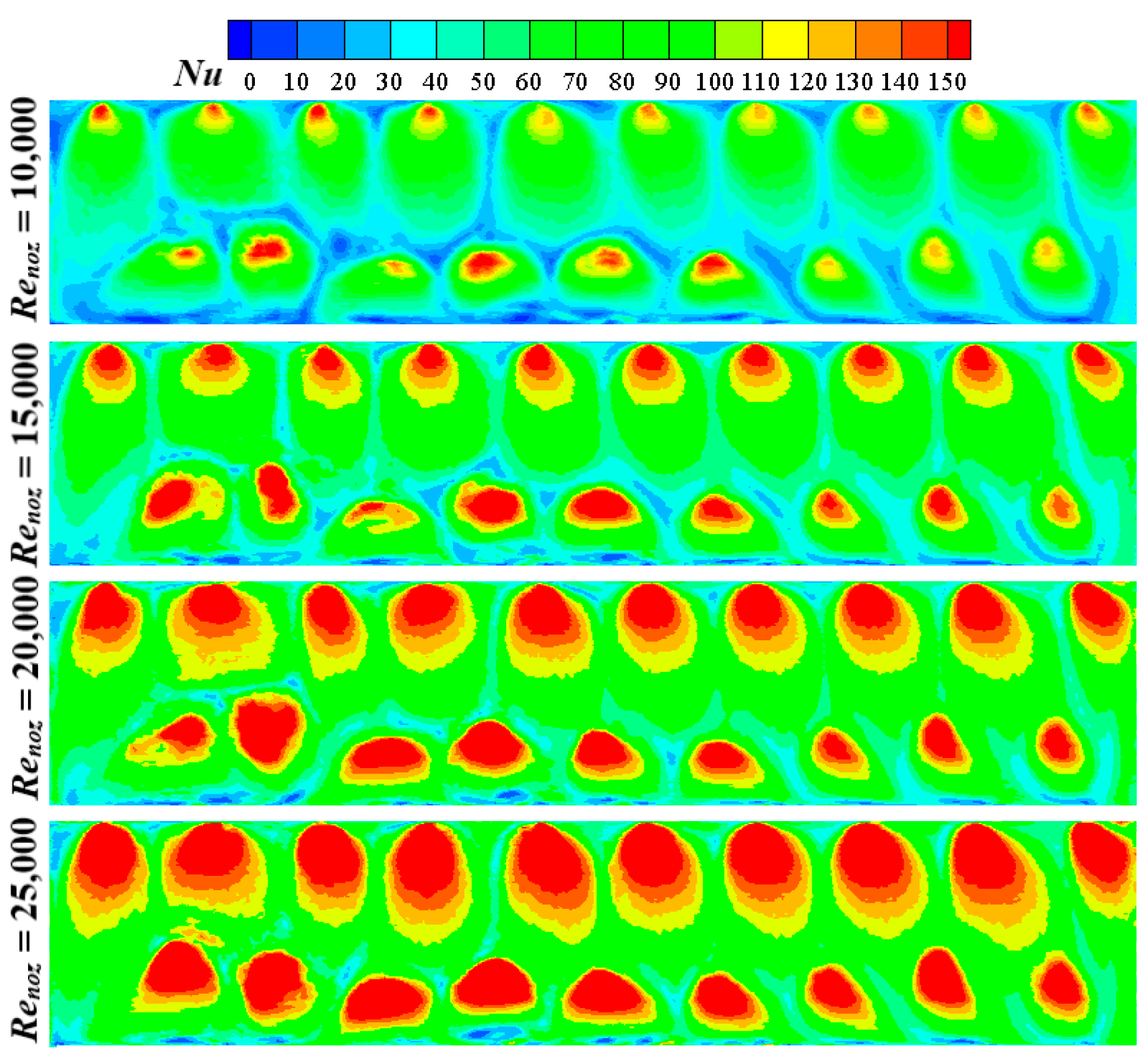

3.2. Thermal Analyses

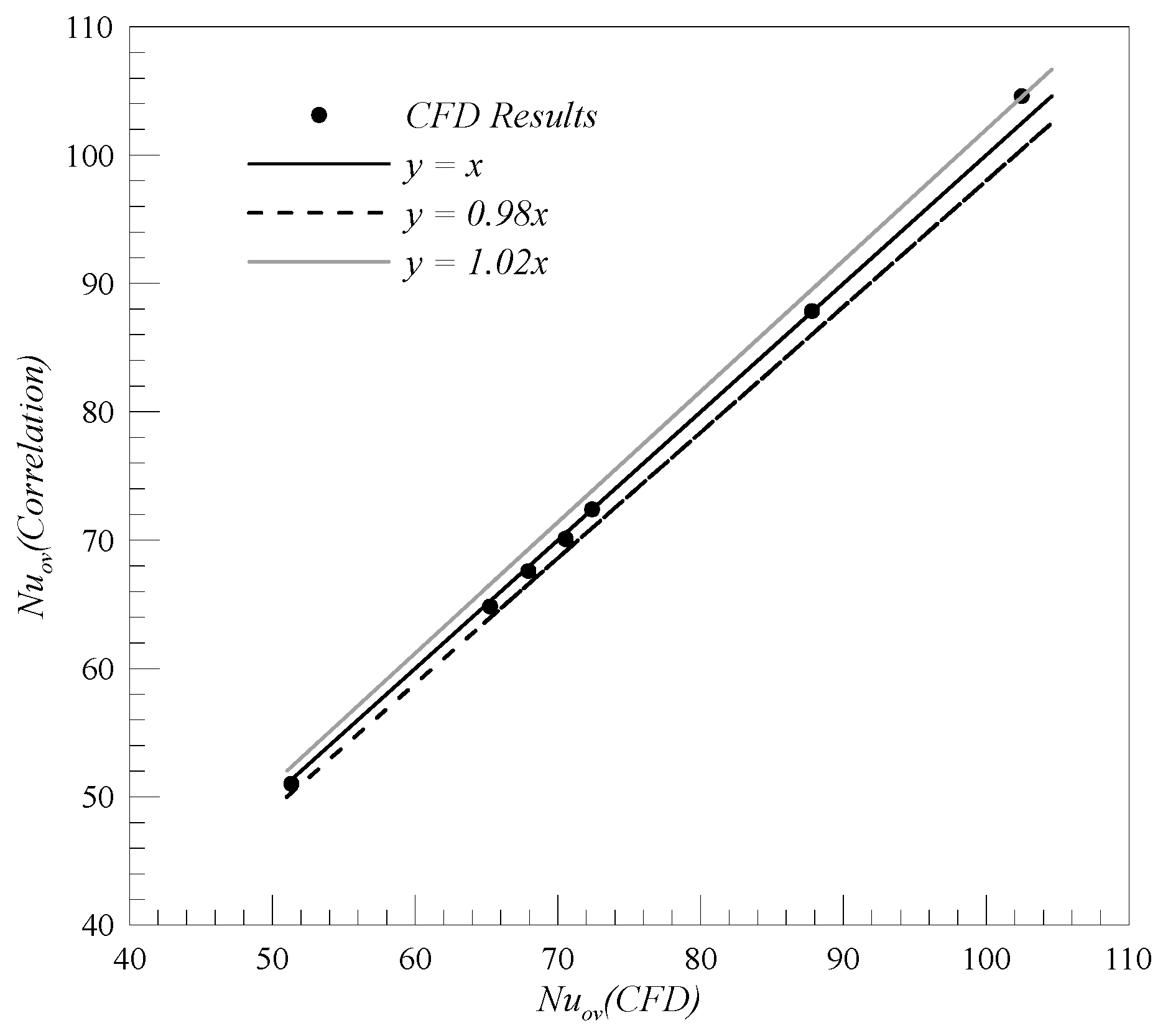

3.3. Correlations

4. Conclusions

- At identical nozzle Reynolds number, the area-average velocity of coolant increases dramatically by five and a half times through each conical nozzle. Also, the coolant area-average velocity increases near the leading-edge wall downstream of each nozzle and decreases further along the circumferential direction. The impingement nozzles generate heterogeneous vortices around the jet, where the impinging intensity increases with the increase of the nozzle Reynolds number.

- The staggered arrangement of both swirl and impingement nozzles obtain coolant contact and uniform on the target surface well, with low momentum losses. The axial velocity increases along the axial direction further downstream near the core-flow. There are complex vorticity distributions which hinder the continuous swirling intensity in the compound cooling unit. The pressure penalty is higher when the nozzle Reynolds number is greater due to the higher coolant velocity.

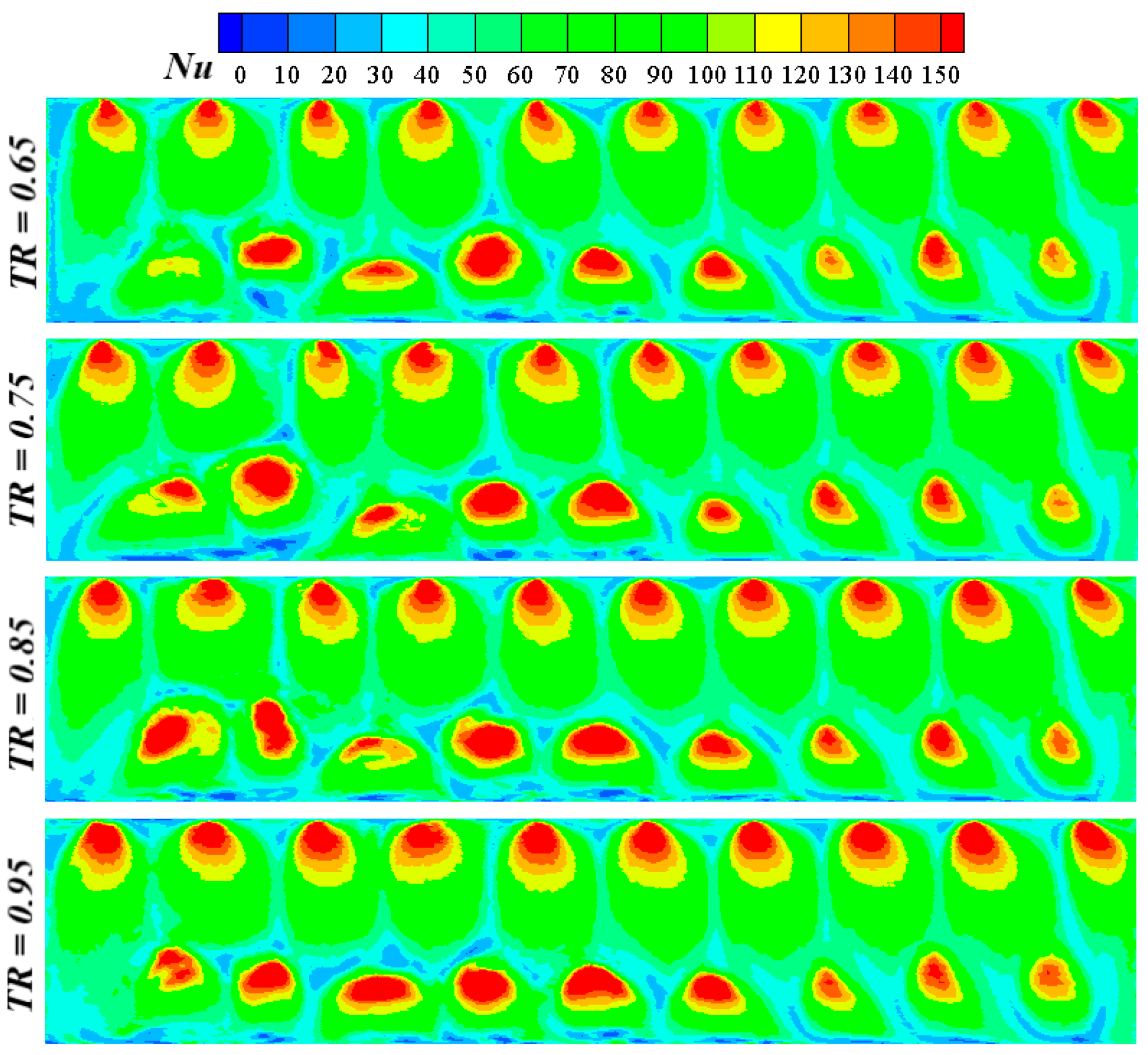

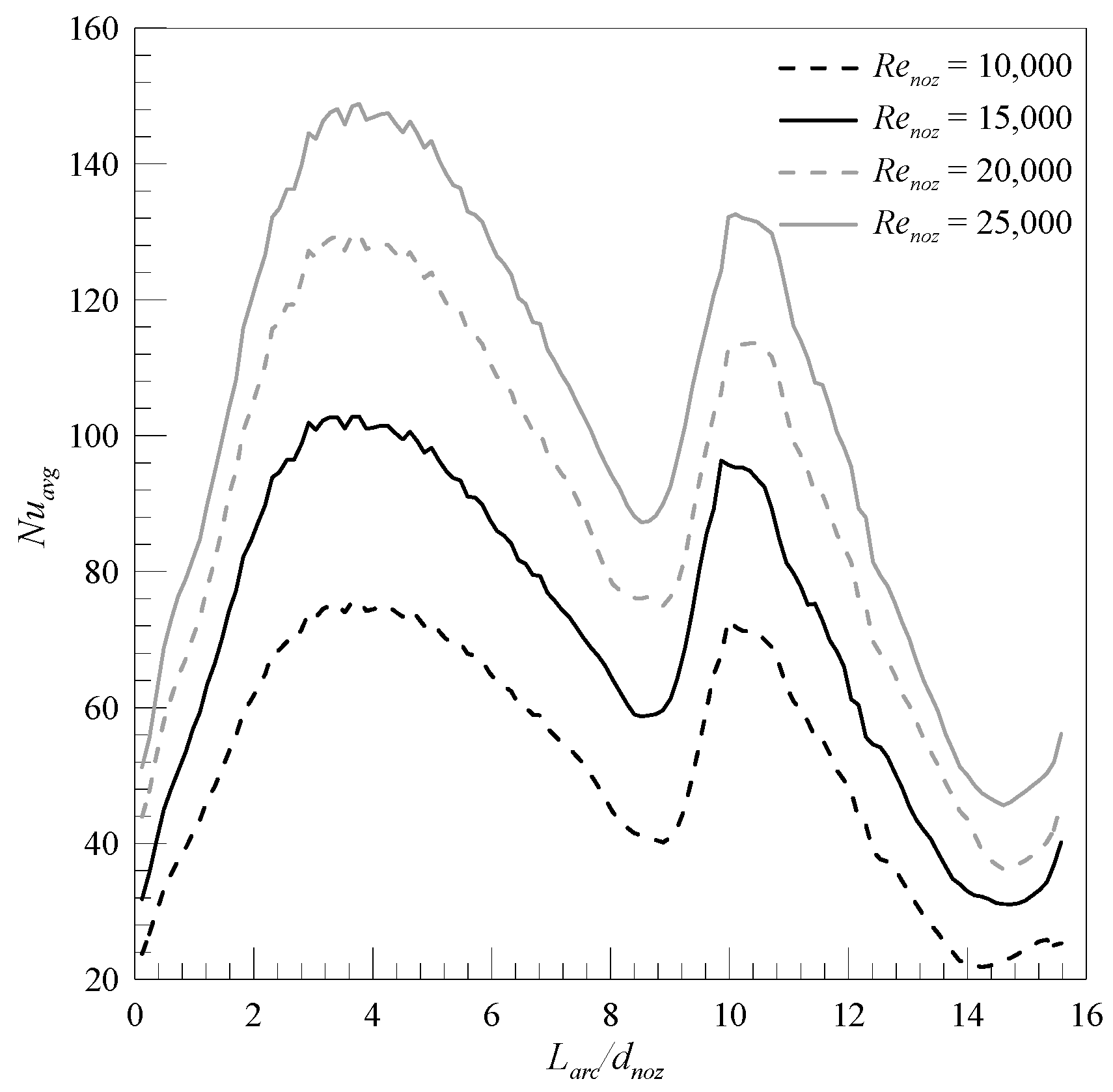

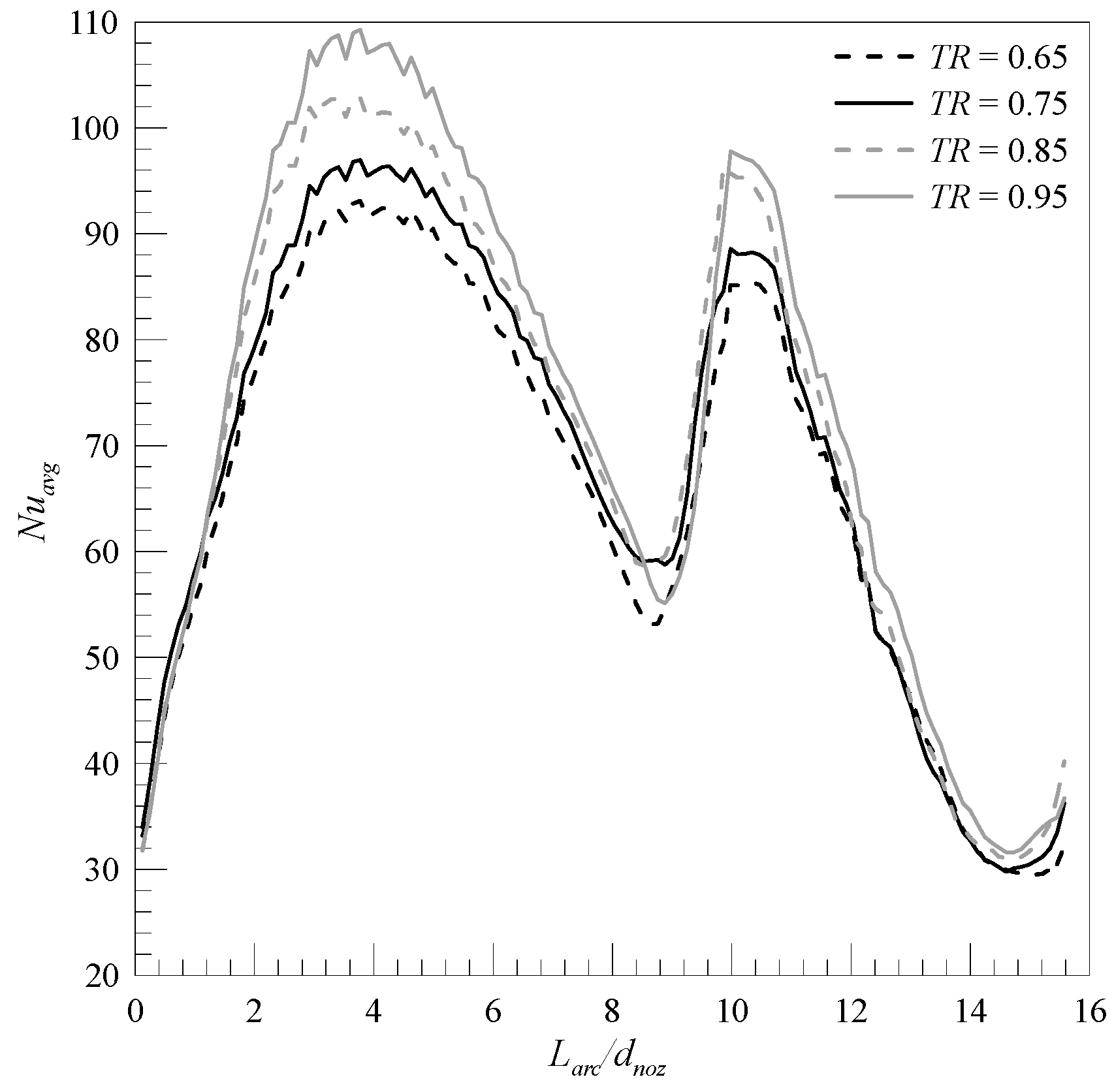

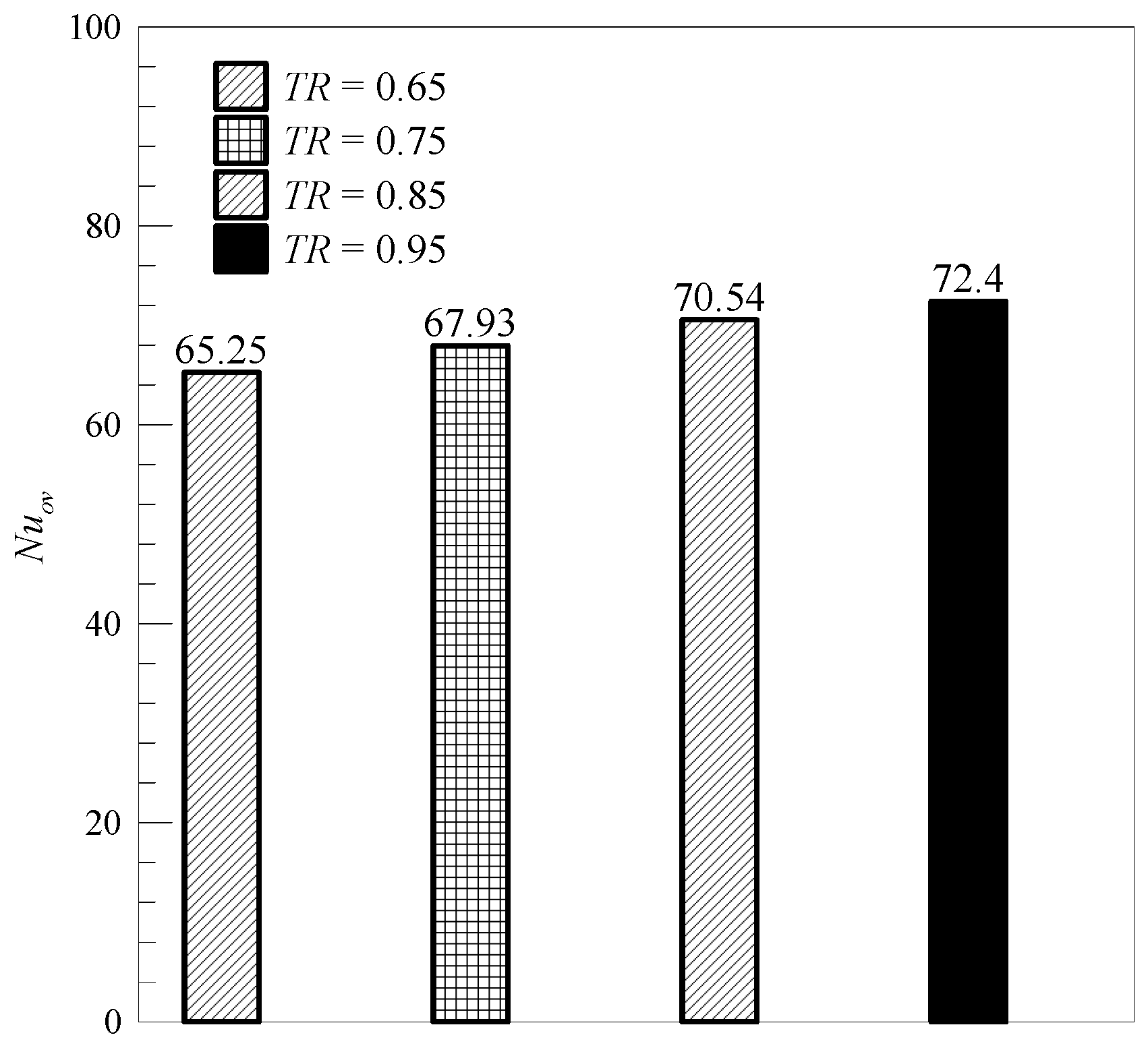

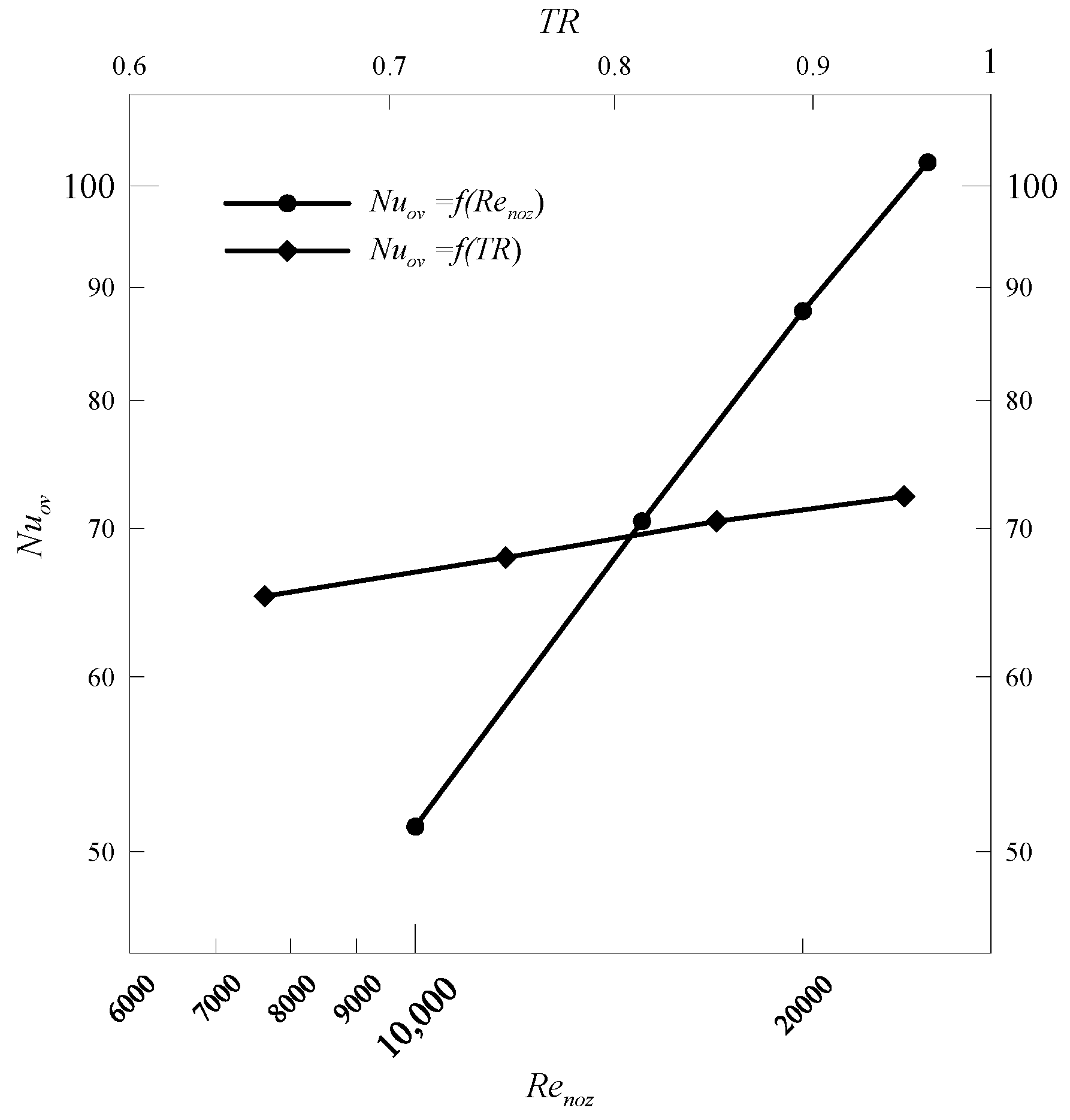

- In the compound cooling unit, the local heat transfer is enhanced with the increase in the nozzle Reynolds number. Also, the staggered distribution of the impingement nozzles with respect to the swirl nozzles, have a major role in decreasing the cross-flow effect. In addition, it contributes to a decrease in the area of the low Nusselt number zone which in turn enhances the cooling performance. There is a little effect of the temperature ratio on the Nusslet number under a constant nozzle Reynolds number.

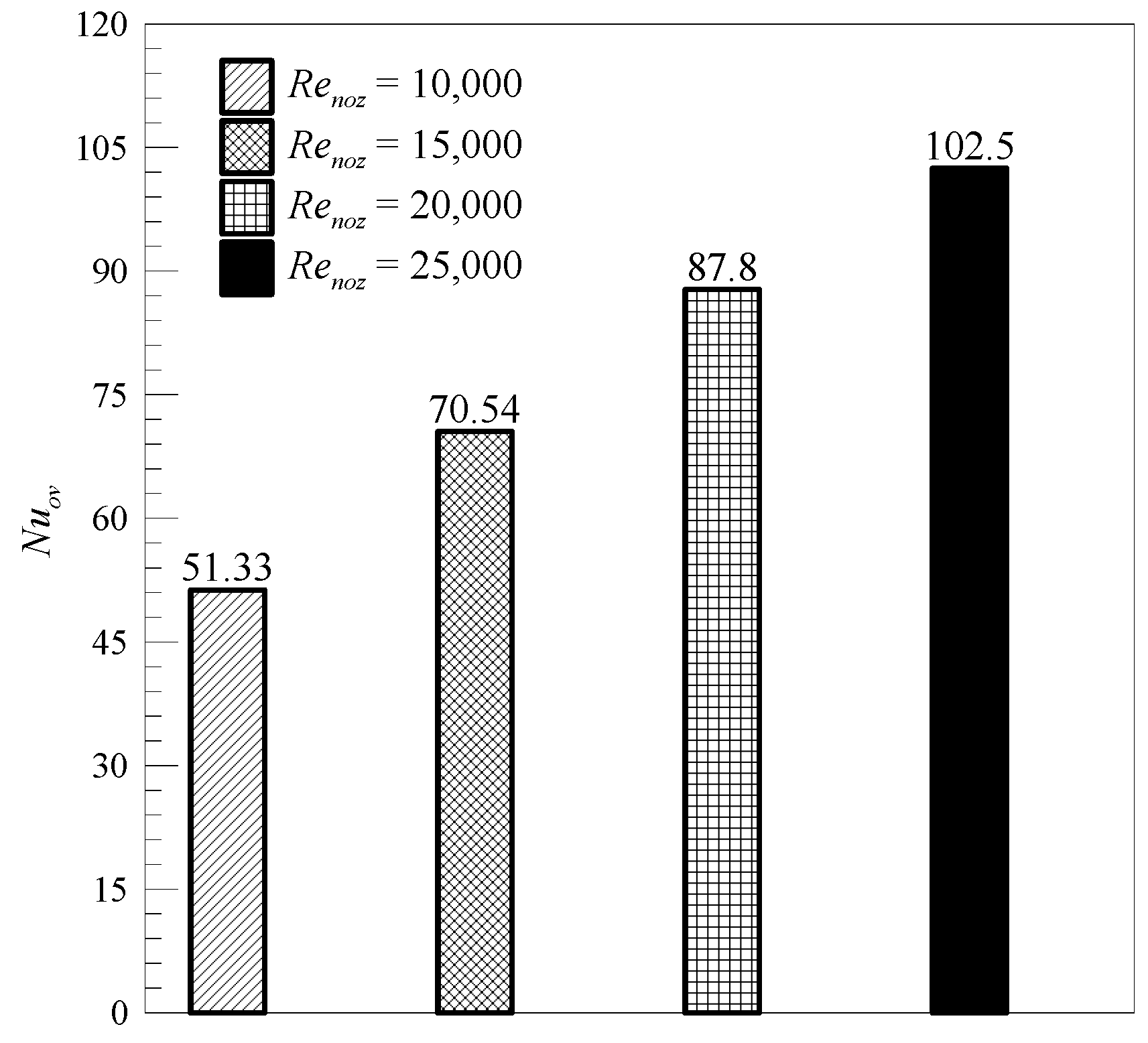

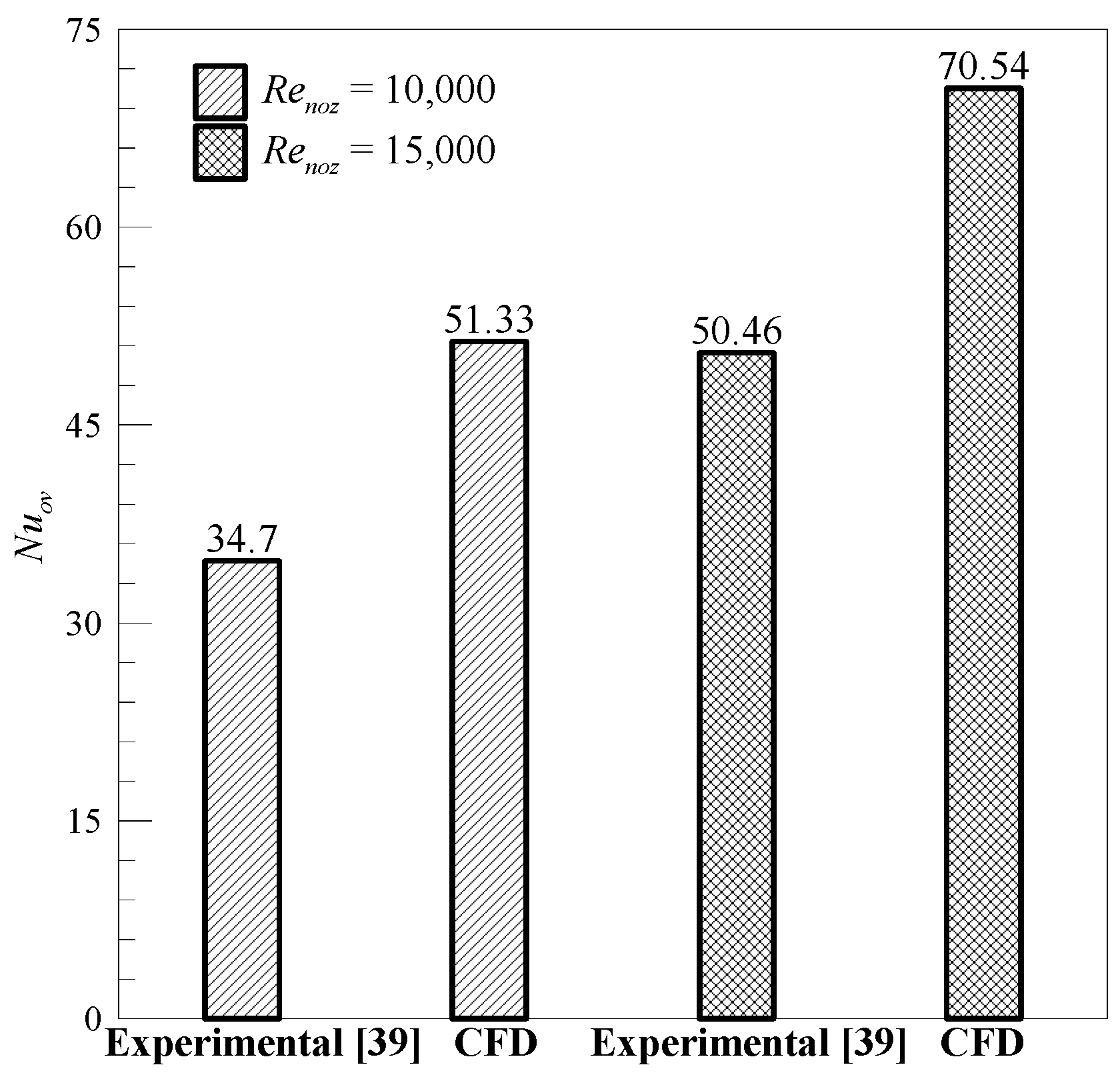

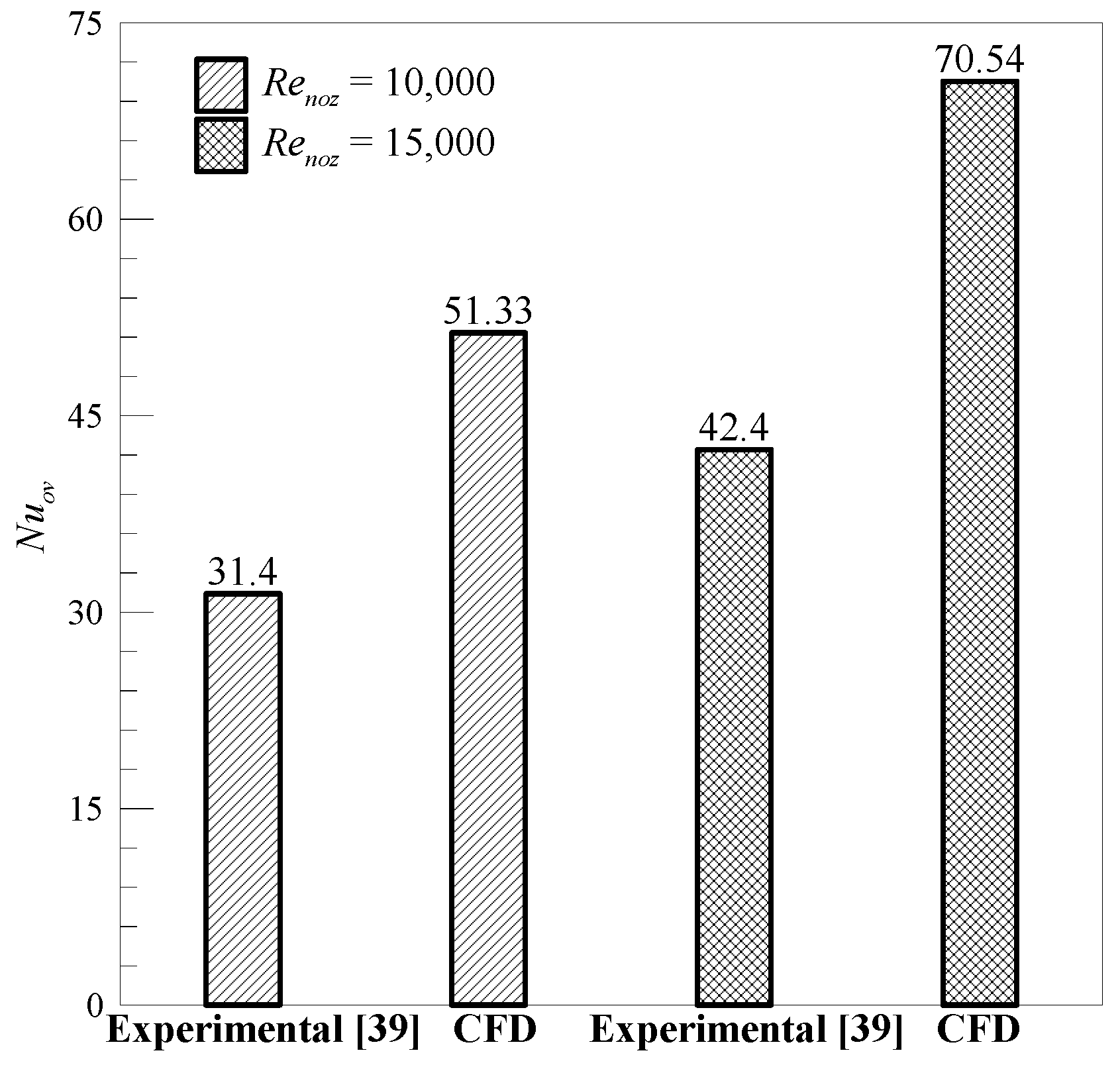

- The overall Nusselt number increases by 99.7% when the nozzle Reynolds number increases from 10,000 to 25,000 at a fixed temperature ratio. Also, at constant nozzle Reynolds number, the compound cooling unit achieves an 11% increase in the overall Nusselt number when the temperature ratio increases from 0.65 to 0.95. Moreover, the compound cooling unit could achieve a 47.9% increase and a 39.8% increase in the overall Nusselt number comparing with the swirl experimental model at nozzle Reynolds numbers of 10,000 and 15,000, respectively. Furthermore, there are increases in the overall Nusselt number of 63.5% and 66.3% at nozzle Reynolds numbers of 10,000 and 15,000, respectively compared to the impingement experimental model. A correlation for the overall Nusselt number is derived as a function of nozzle Reynolds number and coolant to mainstream temperature ratio at a specified range of these parameters.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Latin Characters | ||

| dnoz,in | Inlet diameter of the conical nozzle | m |

| r | Radius of curvature of the target surface | m |

| Re | Reynolds number | |

| Renoz | Reynolds number based on conical nozzle inlet diameter | |

| qw | Target wall heat flux | W/m2 |

| Nu | Nusselt number | |

| Nuov | Overall Nusselt number | |

| Nuavg | Area average Nusselt number | |

| Ptot | Total pressure | Pa |

| ΔPt | Percentage of total pressure drop | Pa |

| Cp | Local pressure coefficient | |

| TR | Temperature ratio | |

| Tc | Coolant temperature | K |

| Tw | Target wall temperature | K |

| V, U | Magnitude of velocity | m/s |

| y+ | Non-dimensional wall distance | |

| X, Y, Z | Cartesian coordinates | |

| Greek Letters | ||

| ρ | Fluid density | kg/m3 |

| λ | Thermal conductivity | W/m. K |

| μ | Dynamic viscosity | N.s/m2 |

| τ | Viscous shear stress | Pa |

| θ | Angle of curvature of the target surface | |

References

- Rosini, A.; Palmieri, A.; Lanzarotto, D.; Procopio, R.; Bonfiglio, A. A Model Predictive Control Design for Power Generation Heavy-Duty Gas Turbines. Energies 2019, 12, 2182. [Google Scholar] [CrossRef]

- Liu, Z.; Ren, X.; Yan, Z.; Zhu, H.; Zhang, T.; Zhu, W.; Li, X. Effect of Inlet Air Heating on Gas Turbine Efficiency under Partial Load. Energies 2019, 12, 3327. [Google Scholar] [CrossRef]

- Chupp, R.E.; Helms, H.E.; McFadden, P.W. Evaluation of internal heat-transfer coefficients for impingement-cooled turbine airfoils. J. Aircr. 1969, 6, 203–208. [Google Scholar] [CrossRef]

- Tabakoff, W.; Clevenger, W. Gas Turbine Blade Heat Transfer Augmentation by Impingement of Air Jets Having Various Configurations. J. Eng. Gas Turbines Power 1972, 94, 51–58. [Google Scholar] [CrossRef]

- Yang, G.; Choi, M.; Lee, J.S. An experimental study of slot jet impingement cooling on concave surface: Effects of nozzle configuration and curvature. Int. J. Heat Mass Transf. 1999, 42, 2199–2209. [Google Scholar] [CrossRef]

- Choi, M.; Yoo, H.S.; Yang, G.; Lee, J.S.; Sohn, D.K. Measurements of impinging jet flow and heat transfer on a semi-circular concave surface. Int. J. Heat Mass Transf. 2000, 43, 1811–1822. [Google Scholar] [CrossRef]

- Kayansayan, N.; Küçüka, S. Impingement cooling of a semi-cylindrical concave channel by confined slot-air-jet. Exp. Therm. Fluid Sci. 2001, 25, 383–396. [Google Scholar] [CrossRef]

- Florschuetz, L.W.; Berry, R.A.; Metzger, D.E. Periodic Streamwise Variations of Heat Transfer Coefficients for Inline and Staggered Arrays of Circular Jets with Crossflow of Spent Air. J. Heat Transf. 1980, 102, 132–137. [Google Scholar] [CrossRef]

- Florschuetz, L.W.; Truman, C.R.; Metzger, D.E. Streamwise Flow and Heat Transfer Distributions for Jet Array Impingement with Crossflow. J. Heat Transf. 1981, 103, 337–342. [Google Scholar] [CrossRef]

- Florschuetz, L.W.; Isoda, Y. Flow Distributions and Discharge Coefficient Effects for Jet Array Impingement with Initial Crossflow. In Proceedings of the 27th International Gas Turbine Conference and Exhibit, London, UK, 18–22 April 1982. [Google Scholar]

- Taslim, M.E.; Setayeshgar, L.; Spring, S.D. An Experimental Evaluation of Advanced Leading Edge Impingement Cooling Concepts. J. Turbomach. 2001, 123, 147–153. [Google Scholar] [CrossRef]

- Taslim, M.E.; Bakhtari, K.; Liu, H. Experimental and Numerical Investigation of Impingement on a Rib-Roughened Leading-Edge Wall. J. Turbomach. 2003, 125, 682–691. [Google Scholar] [CrossRef]

- Taslim, M.E.; Khanicheh, A. Experimental and Numerical Study of Impingement on an Airfoil Leading Edge with and Without Showerhead and Gill Film Holes. J. Turbomach. 2005, 128, 310–320. [Google Scholar] [CrossRef]

- Taslim, M.E.; Bethka, D. Experimental and Numerical Impingement Heat Transfer in an Airfoil Leading-Edge Cooling Channel with Cross-Flow. J. Turbomach. 2008, 131, 011021. [Google Scholar] [CrossRef]

- Rajamani, K.; Ganesh, M.; Paramanandam, K.; Jayamurugan, C.; Narayanan, S.R.; Srinivasan, B.; Chandra, A. Cooling Efficiency Enhancement Using Impingement Cooling Technique for Turbine Blades. In Proceedings of the ASME 2013 Gas Turbine India Conference, Bangalore, India, 5–6 December 2013. [Google Scholar]

- Liu, Z.; Feng, Z.; Song, L. Numerical Study of Flow and Heat Transfer of Impingement Cooling on Model of Turbine Blade Leading Edge. In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010; pp. 657–674. [Google Scholar]

- Liu, Z.; Feng, Z. Numerical simulation on the effect of jet nozzle position on impingement cooling of gas turbine blade leading edge. Int. J. Heat Mass Transf. 2011, 54, 4949–4959. [Google Scholar] [CrossRef]

- Liu, H.-Y.; Liu, S.-L.; Qiang, H.-F.; Liu, C.-L. Aerodynamic investigation of impingement cooling in a confined channel with staggered jet array arrangement. Exp. Therm. Fluid Sci. 2013, 48, 184–197. [Google Scholar] [CrossRef]

- Yang, L.; Kan, R.; Ren, J.; Jiang, H. Effect of Film Cooling Arrangement on Impingement Heat Transfer on Turbine Blade Leading Edge. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Kreith, F.; Margolis, D. Heat transfer and friction in turbulent vortex flow. Appl. Sci. Res. Sect. A 1959, 8, 457–473. [Google Scholar] [CrossRef]

- Hay, N.; West, P.D. Heat Transfer in Free Swirling Flow in a Pipe. J. Heat Transf. 1975, 97, 411–416. [Google Scholar] [CrossRef]

- Fan, X.; Li, L.; Zou, J.; Wang, J.; Wu, F. Local heat transfer of vortex cooling with multiple tangential nozzles in a gas turbine blade leading edge cooling passage. Int. J. Heat Mass Transf. 2018, 126, 377–389. [Google Scholar] [CrossRef]

- Kusterer, K.; Lin, G.; Bohn, D.; Sugimoto, T.; Tanaka, R.; Kazari, M. Heat Transfer Enhancement for Gas Turbine Internal Cooling by Application of Double Swirl Cooling Chambers. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Kusterer, K.; Lin, G.; Bohn, D.; Sugimoto, T.; Tanaka, R.; Kazari, M. Leading Edge Cooling of a Gas Turbine Blade with Double Swirl Chambers. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Kusterer, K.; Lin, G.; Sugimoto, T.; Bohn, D.; Tanaka, R.; Kazari, M. Novel Gas Turbine Blade Leading Edge Cooling Configuration Using Advanced Double Swirl Chambers. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015. [Google Scholar]

- Luan, Y.; Du, C.; Fan, X.; Wang, J.; Li, L. Investigations of flow structures and heat transfer in a swirl chamber with different inlet chambers and various aerodynamic parameters. Int. J. Heat Mass Transf. 2018, 118, 551–561. [Google Scholar] [CrossRef]

- Rao, Y.; Biegger, C.; Weigand, B. Heat transfer and pressure loss in swirl tubes with one and multiple tangential jets pertinent to gas turbine internal cooling. Int. J. Heat Mass Transf. 2017, 106, 1356–1367. [Google Scholar] [CrossRef]

- Fan, X.; Du, C.; Li, L.; Li, S. Numerical simulation on effects of film hole geometry and mass flow on vortex cooling behavior for gas turbine blade leading edge. Appl. Therm. Eng. 2017, 112, 472–483. [Google Scholar] [CrossRef]

- Biegger, C.; Rao, Y.; Weigand, B. Flow and heat transfer measurements in swirl tubes with one and multiple tangential inlet jets for internal gas turbine blade cooling. Int. J. Heat Fluid Flow 2018, 73, 174–187. [Google Scholar] [CrossRef]

- Liu, Y.; Rao, Y.; Weigand, B. Heat transfer and pressure loss characteristics in a swirl cooling tube with dimples on the tube inner surface. Int. J. Heat Mass Transf. 2019, 128, 54–65. [Google Scholar] [CrossRef]

- Ling, J.P.C.W.; Ireland, P.T.; Harvey, N.W. Measurement of Heat Transfer Coefficient Distributions and Flow Field in a Model of a Turbine Blade Cooling Passage with Tangential Injection. In Proceedings of the ASME Turbo Expo 2006: Power for Land, Sea, and Air, Barcelona, Spain, 8–11 May 2006; pp. 325–340. [Google Scholar]

- Du, C.; Li, L.; Wu, X.; Feng, Z. Effect of jet nozzle geometry on flow and heat transfer performance of vortex cooling for gas turbine blade leading edge. Appl. Therm. Eng. 2016, 93, 1020–1032. [Google Scholar] [CrossRef]

- Du, C.; Li, L.; Chen, X.; Fan, X.; Feng, Z. Numerical Study on Effects of Jet Nozzle Angle and Number on Vortex Cooling Behavior for Gas Turbine Blade Leading Edge. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Korea, 13–17 June 2016. [Google Scholar]

- Du, C.; Li, L.; Li, S.; Feng, Z. Effects of aerodynamic parameters on steam vortex cooling behavior for gas turbine blade leading edge. Proc. Inst. Mech. Eng. Part A J. Power Energy 2016, 230, 354–365. [Google Scholar] [CrossRef]

- Du, H.; Mei, Z.; Zou, J.; Jiang, W.; Xie, D. Conjugate Heat Transfer Investigation on Swirl-Film Cooling at the Leading Edge of a Gas Turbine Vane. Entropy 2019, 21, 1007. [Google Scholar] [CrossRef]

- Wang, N.; Chen, A.F.; Zhang, M.; Han, J.-C. Turbine Blade Leading Edge Cooling with One Row of Normal or Tangential Impinging Jets. J. Heat Transf. 2018, 140, 062201. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; Li, J.; Hou, W. Comparison between impingement/effusion and double swirl/effusion cooling performance under different effusion hole diameters. Int. J. Heat Mass Transf. 2019, 141, 1097–1113. [Google Scholar] [CrossRef]

- Wu, F.; Li, L.; Du, C.; Wang, J.; Fan, X. Effects of circumferential nozzle number and temperature ratio on swirl cooling characteristics. Appl. Therm. Eng. 2019, 154, 332–342. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, N.; Han, J.-C. Internal heat transfer of film-cooled leading edge model with normal and tangential impinging jets. Int. J. Heat Mass Transf. 2019, 139, 193–204. [Google Scholar] [CrossRef]

- Seifi, A.R.; Akbari, O.A.; Alrashed, A.A.A.A.; Afshary, F.; Shabani, G.A.S.; Seifi, R.; Goodarzi, M.; Pourfattah, F. Effects of external wind breakers of Heller dry cooling system in power plants. Appl. Therm. Eng. 2018, 129, 1124–1134. [Google Scholar] [CrossRef]

- Jiang, Y.; Zheng, Q.; Dong, P.; Yue, G.; Gao, J. Numerical Simulation on Turbine Blade Leading-Edge High-Efficiency Film Cooling by the Application of Water Mist. Numer. Heat Transf. Part A Appl. 2014, 66, 1341–1364. [Google Scholar] [CrossRef]

- Rehman, A.; Liu, B.; Asghar, M.A. Secondary Flow and Endwall Optimization of a Transonic Turbine. Energies 2019, 12, 4103. [Google Scholar] [CrossRef]

- Gong, J.; Gao, T.; Zeng, J.; Hou, J.; Li, Z. Effect of Actual Gas Turbine Operating Conditions on Mist/Steam Cooling Performance in a Ribbed Passage. Energies 2019, 12, 2015. [Google Scholar] [CrossRef]

- Dzido, A.; Krawczyk, P.; Kurkus-Gruszecka, M. Numerical Analysis of Dry Ice Blasting Convergent-Divergent Supersonic Nozzle. Energies 2019, 12, 4787. [Google Scholar] [CrossRef]

- Safaei, M.R.; Togun, H.; Vafai, K.; Kazi, S.N.; Badarudin, A. Investigation of Heat Transfer Enhancement in a Forward-Facing Contracting Channel Using FMWCNT Nanofluids. Numer. Heat Transf. Part A Appl. 2014, 66, 1321–1340. [Google Scholar] [CrossRef]

| Mesh (million) | Overall Nu |

|---|---|

| 0.86 | 55 |

| 1.2 | 59.46 |

| 1.88 | 65 |

| 3.2 | 69.3 |

| 4.7 | 71.3 |

| 7.3 | 71.49 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fawzy, H.; Zheng, Q.; Ahmad, N.; Jiang, Y. Optimization of A Swirl with Impingement Compound Cooling Unit for A Gas Turbine Blade Leading Edge. Energies 2020, 13, 210. https://doi.org/10.3390/en13010210

Fawzy H, Zheng Q, Ahmad N, Jiang Y. Optimization of A Swirl with Impingement Compound Cooling Unit for A Gas Turbine Blade Leading Edge. Energies. 2020; 13(1):210. https://doi.org/10.3390/en13010210

Chicago/Turabian StyleFawzy, Hamza, Qun Zheng, Naseem Ahmad, and Yuting Jiang. 2020. "Optimization of A Swirl with Impingement Compound Cooling Unit for A Gas Turbine Blade Leading Edge" Energies 13, no. 1: 210. https://doi.org/10.3390/en13010210

APA StyleFawzy, H., Zheng, Q., Ahmad, N., & Jiang, Y. (2020). Optimization of A Swirl with Impingement Compound Cooling Unit for A Gas Turbine Blade Leading Edge. Energies, 13(1), 210. https://doi.org/10.3390/en13010210