Multi-Objective Particle Swarm Based Optimization of an Air Jet Impingement System

Abstract

1. Introduction

1.1. Electronics Thermal Management

1.2. Air Jet Impingement Cooling Enhancement

1.3. Particle Swarm Optimization

2. Methods

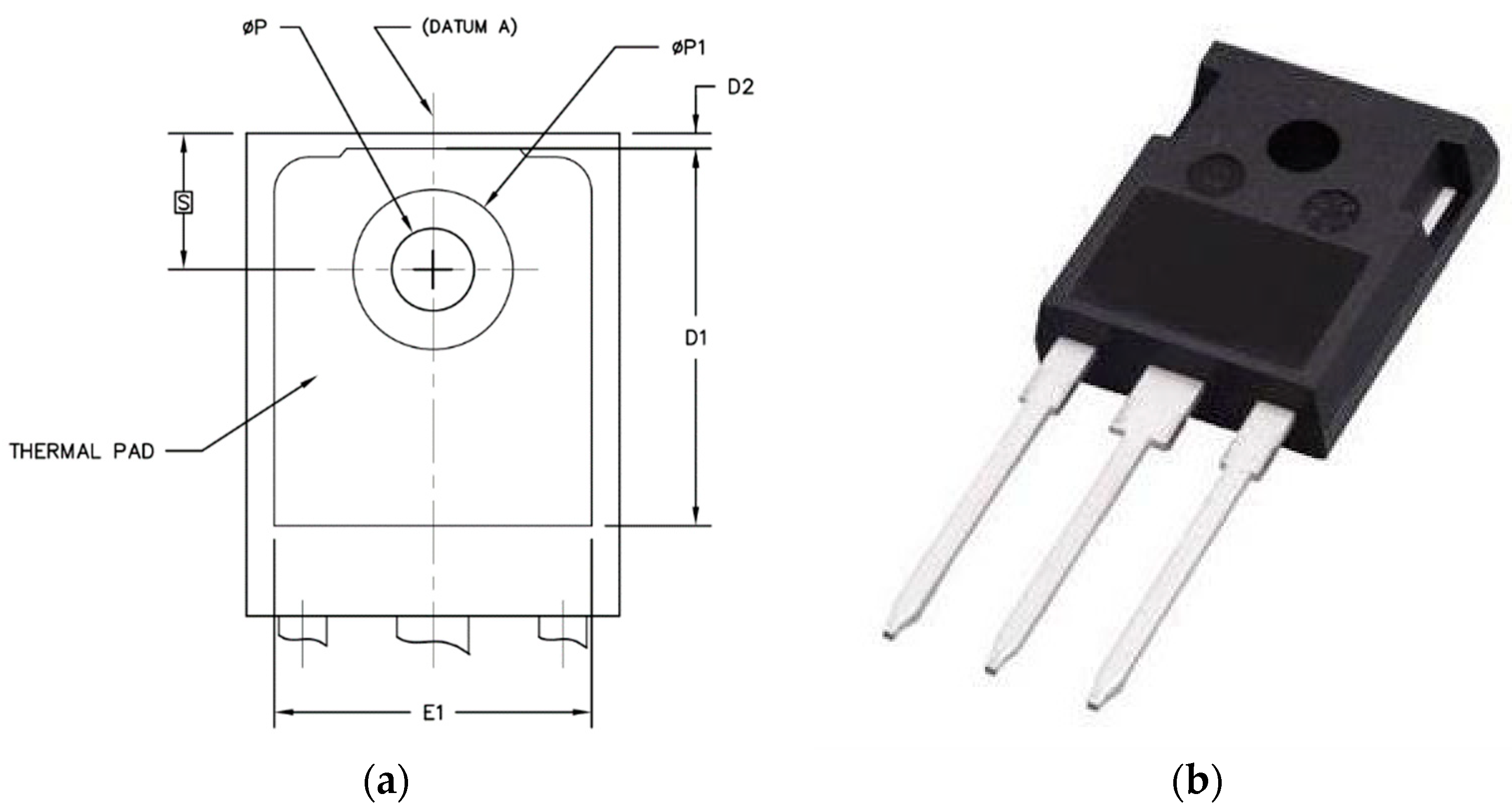

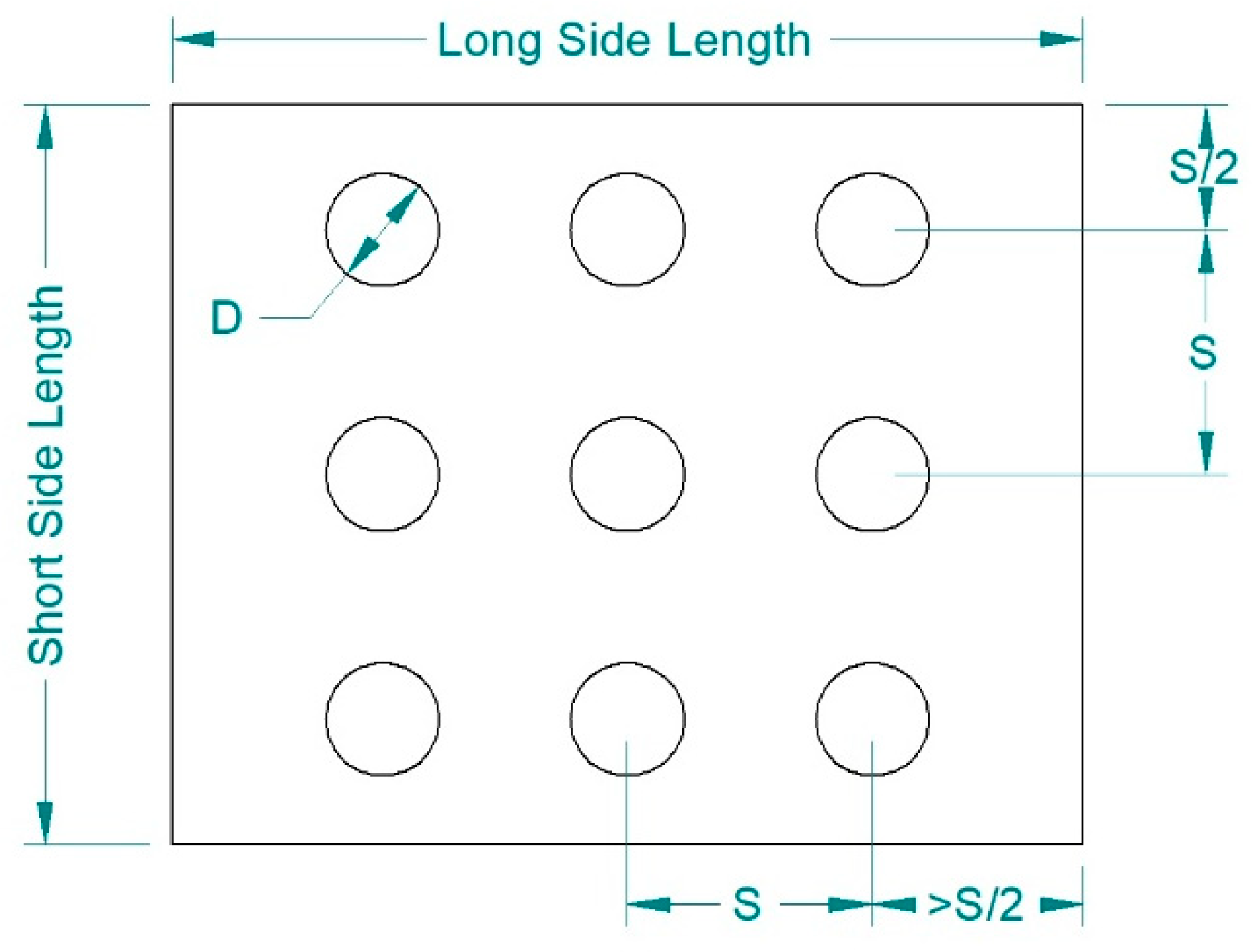

2.1. Air Jet Impingement Plate Design Procedure

2.2. Thermo-Hydraulic Performance Calculation

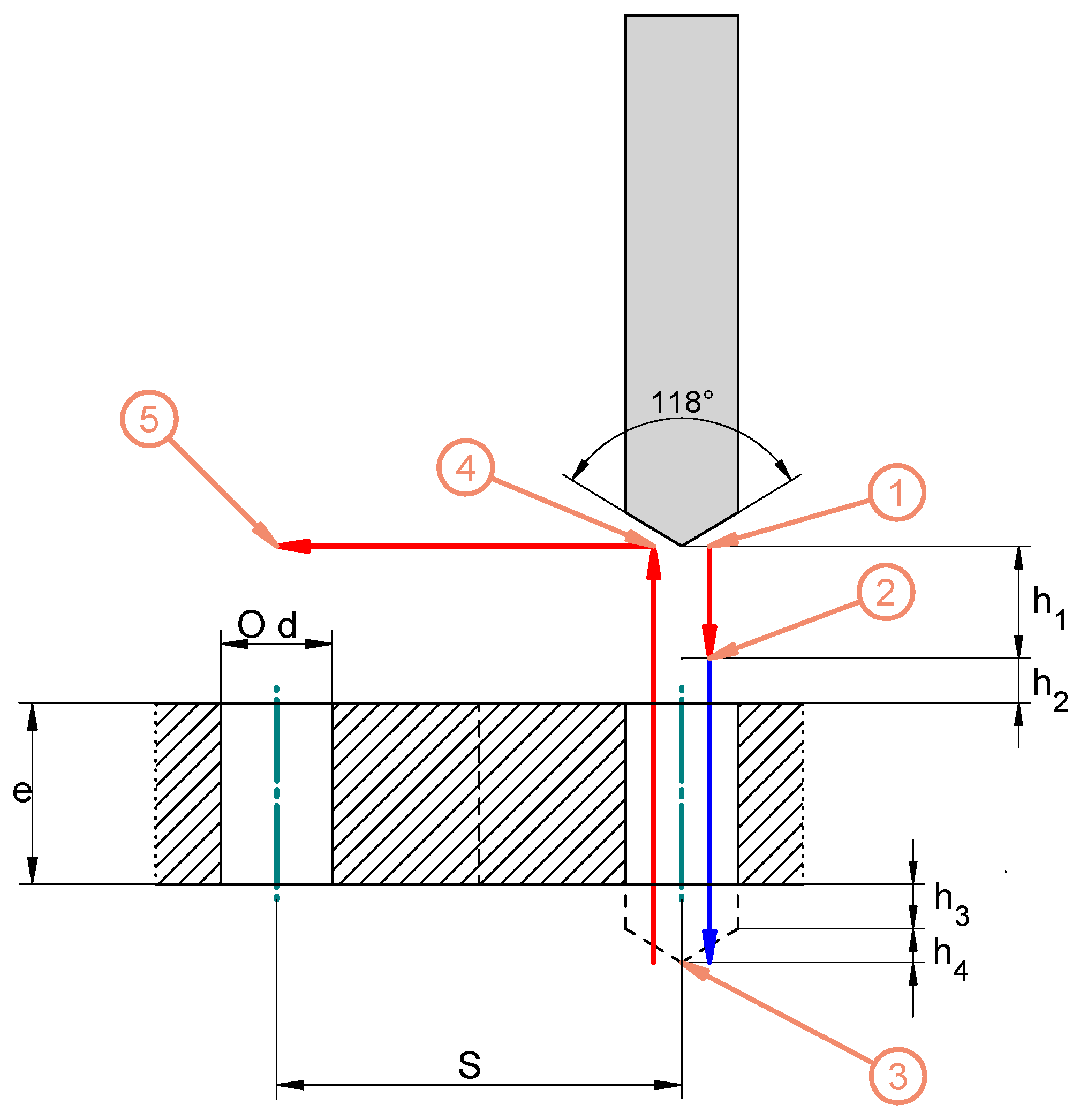

2.3. Machining Time

2.4. PSO Algorithm Structure

3. Proposed Solution

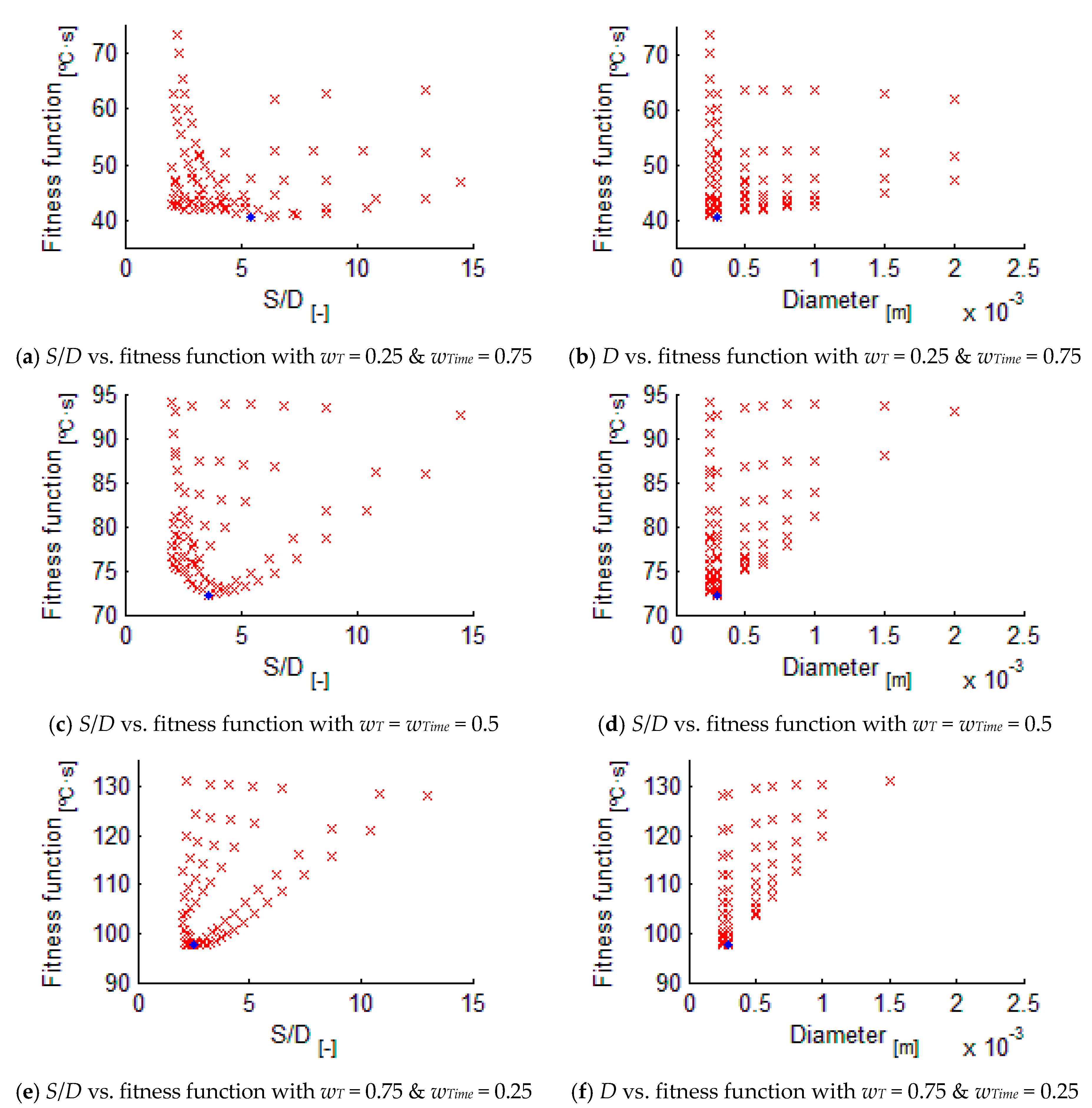

3.1. PSO Cost Function

3.2. PSO Parameters

4. Results and Discussion

4.1. Case Study Data

4.2. Computed Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lasance, C.J.M. The need for a change in thermal design philosophy. Electron. Cooling 1995, 1, 24–26. [Google Scholar]

- Page, R.W.; Hnatczuk, W.; Kozierowski, J. Thermal Management for the 21st Century—Improved Thermal Control and Fuel Economy in an Army Medium Tactical Vehicle; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Wang, Y.; Gao, Q.; Zhang, T.; Wang, G.; Jiang, Z.; Li, Y. Advances in Integrated Vehicle Thermal Management and Numerical Simulation. Energies 2017, 10, 1636. [Google Scholar] [CrossRef]

- Chen, K.; Li, Z.; Chen, Y.; Long, S.; Hou, J.; Song, M.; Wang, S. Design of Parallel Air-Cooled Battery Thermal Management System through Numerical Study. Energies 2017, 10, 1677. [Google Scholar] [CrossRef]

- The International Roadmap for Devices and Systems. 2017. Available online: https://irds.ieee.org/images/files/pdf/2017/2017IRDS_ES.pdf (accessed on 21 March 2019).

- Ferranti, F.; Dhaene, T.; Russo, S.; Magnani, A.; de Magistris, M.; d’Alessandro, V.; Rinaldi, N. Parameterized thermal macromodeling for fast and effective design of electronic components and systems. In Proceedings of the 2014 IEEE 18th Workshop on Signal and Power Integrity (SPI), Ghent, Belgium, 11–14 May 2014; pp. 1–4. [Google Scholar]

- Arik, M.; Bar-Cohen, A. Immersion cooling of high heat flux microelectronics with dielectric liquids. In Proceedings of the 4th International Symposium on Advanced Packaging Materials Processes, Properties and Interfaces (Cat. No.98EX153), Braselton, GA, USA, 18 March 1998; pp. 229–247. [Google Scholar]

- Gould, K.; Cai, S.Q.; Neft, C.; Bhunia, A. Liquid Jet Impingement Cooling of a Silicon Carbide Power Conversion Module for Vehicle Applications. IEEE Trans. Power Electron. 2015, 30, 2975–2984. [Google Scholar] [CrossRef]

- Smakulski, P.; Pietrowicz, S. A review of the capabilities of high heat flux removal by porous materials, microchannels and spray cooling techniques. Appl. Therm. Eng. 2016, 104, 636–646. [Google Scholar] [CrossRef]

- Zebarjadi, M. Electronic cooling using thermoelectric devices. Appl. Phys. Lett. 2015, 106, 203506. [Google Scholar] [CrossRef]

- Chen, X.; Ye, H.; Fan, X.; Ren, T.; Zhang, G. A review of small heat pipes for electronics. Appl. Therm. Eng. 2016, 96, 1–17. [Google Scholar] [CrossRef]

- O’Donovan, T.S. Fluid Flow and Heat Transfer of an Impinging Air Jet. Ph.D. Thesis, University of Dublin, Dublin, Ireland, 2005. [Google Scholar]

- Ebadian, M.A.; Lin, C.X. A Review of High-Heat-Flux Heat Removal Technologies. J. Heat Transf. 2011, 133, 110801. [Google Scholar] [CrossRef]

- Gardon, R.; Cobonpue, J. Heat Transfer Between a Flat Plate and Jets of Air Impinging on It. In Proceedings of the International Developments in Heat Transfer, 1961–1962 Heat Transfer Conference, Boulder, CO, USA, 28 August–1 September 1961. [Google Scholar]

- Martin, H. Heat and Mass Transfer between Impinging Gas Jets and Solid Surfaces. In Advances in Heat Transfer; Hartnett, J.P., Irvine, T.F., Eds.; Elsevier: Amsterdam, The Netherlands, 1977; Volume 13, pp. 1–60. [Google Scholar]

- Obot, N.T.; Trabold, T.A. Impingement Heat Transfer Within Arrays of Circular Jets: Part 1—Effects of Minimum, Intermediate, and Complete Crossflow for Small and Large Spacings. J. Heat Transf. 1987, 109, 872–879. [Google Scholar] [CrossRef]

- Meola, C. A New Correlation of Nusselt Number for Impinging Jets. Heat Transf. Eng. 2009, 30, 221–228. [Google Scholar] [CrossRef]

- Rao, R.V.; Waghmare, G.G. Multi-objective design optimization of a plate-fin heat sink using a teaching-learning-based optimization algorithm. Appl. Therm. Eng. 2015, 76, 521–529. [Google Scholar] [CrossRef]

- Rahimi-Gorji, M.; Pourmehran, O.; Hatami, M.; Ganji, D.D. Statistical optimization of microchannel heat sink (MCHS) geometry cooled by different nanofluids using RSM analysis. Eur. Phys. J. Plus 2015, 130. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, S.; Gong, L.; Huang, Z. Numerical study and optimizing on micro square pin-fin heat sink for electronic cooling. Appl. Therm. Eng. 2016, 93, 1347–1359. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the IEEE International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995; Volume 1–6, pp. 1942–1948. [Google Scholar]

- Heppner, F.; Grenander, U. A Stochastic Nonlinear Model for Coordinate Bird Flocks. Available online: https://www.researchgate.net/publication/216300775_A_Stochastic_Nonlinear_Model_for_Coordinate_Bird_Flocks (accessed on 21 March 2019).

- Eberhart, R.; Kennedy, J. A new optimizer using particle swarm theory. In Proceedings of the MHS’95 Sixth International Symposium on Micro Machine and Human Science (Cat. No.95TH8079), Nagoya, Japan, 4–6 October 1995; pp. 39–43. [Google Scholar]

- Kennedy, J.; Eberhart, R.C. A discrete binary version of the particle swarm algorithm. In Proceedings of the 1997 IEEE International Conference on Systems, Man, and Cybernetics. Computational Cybernetics and Simulation, Orlando, FL, USA, 12–15 October 1997; pp. 4104–4108. [Google Scholar]

- Kennedy, J.; Spears, W.M. Matching algorithms to problems: An experimental test of the particle swarm and some genetic algorithms on the multimodal problem generator. In Proceedings of the 1998 IEEE International Conference on Evolutionary Computation Proceedings. IEEE World Congress on Computational Intelligence (Cat. No.98TH8360), Anchorage, AK, USA, 4–9 May 1998. [Google Scholar]

- Kennedy, J. Probability and dynamics in the particle swarm. In Proceedings of the 2004 Congress on Evolutionary Computation (IEEE Cat. No.04TH8753), Portland, OR, USA, 19–23 June 2004. [Google Scholar]

- Kennedy, J. Small worlds and mega-minds: Effects of neighborhood topology on particle swarm performance. In Proceedings of the Small Worlds and Mega-Minds: Effects of Neighborhood Topology on Particle Swarm Performance, Washington, DC, USA, 6–9 July 1999. [Google Scholar]

- Fang, H.; Chen, L.; Shen, Z. Application of an improved PSO algorithm to optimal tuning of PID gains for water turbine governor. Energy Convers. Manag. 2011, 52, 1763–1770. [Google Scholar] [CrossRef]

- Zulueta, E.; Kurt, E.; Uzun, Y.; Lopez-Guede, J.M. Power control optimization of a new contactless piezoelectric harvester. Int. J. Hydrogen Energy 2017, 42, 18134–18144. [Google Scholar] [CrossRef]

- Hong, W.-C. Chaotic particle swarm optimization algorithm in a support vector regression electric load forecasting model. Energy Convers. Manag. 2009, 50, 105–117. [Google Scholar] [CrossRef]

- Javaid, N.; Ullah, I.; Akbar, M.; Iqbal, Z.; Khan, F.A.; Alrajeh, N.; Alabed, M.S. An Intelligent Load Management System with Renewable Energy Integration for Smart Homes. IEEE Access 2017, 5, 13587–13600. [Google Scholar] [CrossRef]

- Eberhart, R.C.; Shi, Y.H. Particle swarm optimization: Developments, applications and resources. In Proceedings of the 2001 Congress on Evolutionary Computation (IEEE Cat. No.01TH8546), Seoul, Korea, 27–30 May 2001. [Google Scholar]

- Epitropakis, M.G.; Plagianakos, V.P.; Vrahatis, M.N. Evolving cognitive and social experience in Particle Swarm Optimization through Differential Evolution: A hybrid approach. Inf. Sci. 2012, 216, 50–92. [Google Scholar] [CrossRef]

- Suresh, K.; Ghosh, S.; Kundu, D.; Sen, A.; Das, S.; Abraham, A. Inertia-Adaptive Particle Swarm Optimizer for Improved Global Search. In Proceedings of the 2008 Eighth International Conference on Intelligent Systems Design and Applications, Kaohsiung, Taiwan, 26–28 November 2008. [Google Scholar]

- International Rectifier TO-247AC Package Outline Drawing. Available online: http://www.irf.com/package/outline/po_to247ac.pdf (accessed on 28 January 2019).

- Guhring Guhroguía Brocas. Available online: https://www.guhring.es/Archivos/guias/84.pdf (accessed on 7 February 2019).

- Xing, Y.; Spring, S.; Weigand, B. Experimental and Numerical Investigation of Heat Transfer Characteristics of Inline and Staggered Arrays of Impinging Jets. J. Heat Transf. 2010, 132, 092201. [Google Scholar] [CrossRef]

- Atalla, M.A.M. Experimental Investigation of Heat Transfer Characteristics from Arrays of Free Impinging Circular Jets and Hole Channels. Ph.D. Thesis, Otto-von-Guericke-Universität, Magdeburg, Germany, 2005. [Google Scholar]

- Royne, A.; Dey, C.J. Effect of nozzle geometry on pressure drop and heat transfer in submerged jet arrays. Int. J. Heat Mass Transf. 2006, 49, 800–804. [Google Scholar] [CrossRef]

- Idelchik, I.E. Handbook of Hydraulic Resistance; Hemisphere Publishing Corp.: Washington, DC, USA, 1986; p. 662. [Google Scholar]

- Marler, R.T.; Arora, J.S. Survey of multi-objective optimization methods for engineering. Struct. Multidisc. Optim. 2004, 26, 369–395. [Google Scholar] [CrossRef]

- Coello, C.A.C.; Pulido, G.T.; Lechuga, M.S. Handling multiple objectives with particle swarm optimization. IEEE Trans. Evol. Comput. 2004, 8, 256–279. [Google Scholar] [CrossRef]

- Multiobjective Optimization Using Dynamic Neighborhood Particle Swarm Optimization–IEEE Conference Publication. Available online: https://ieeexplore.ieee.org/abstract/document/1004494 (accessed on 1 March 2019).

- Marler, R.T.; Arora, J.S. The weighted sum method for multi-objective optimization: New insights. Struct. Multidisc. Optim. 2010, 41, 853–862. [Google Scholar] [CrossRef]

- Nickabadi, A.; Ebadzadeh, M.M.; Safabakhsh, R. A novel particle swarm optimization algorithm with adaptive inertia weight. Appl. Soft. Comput. 2011, 11, 3658–3670. [Google Scholar] [CrossRef]

- Arumugam, M.S.; Chandramohan, A.; Rao, M.V.C. Competitive approaches to PSO algorithms via new acceleration co-efficient variant with mutation operators. In Proceedings of the Sixth International Conference on Computational Intelligence and Multimedia Applications (ICCIMA’05), Las Vegas, NV, USA, 16–18 August 2005. [Google Scholar]

- Ratnaweera, A.; Halgamuge, S.K.; Watson, H.C. Self-organizing hierarchical particle swarm optimizer with time-varying acceleration coefficients. IEEE Trans. Evol. Comput. 2004, 8, 240–255. [Google Scholar] [CrossRef]

- Ghasemi, M.; Aghaei, J.; Hadipour, M. New self-organising hierarchical PSO with jumping time-varying acceleration coefficients. Electron. Lett. 2017, 53, 1360–1361. [Google Scholar] [CrossRef]

- Suganthan, P.N. Particle swarm optimiser with neighbourhood operator. In Proceedings of the 1999 Congress on Evolutionary Computation-CEC99 (Cat. No. 99TH8406), Washington, DC, USA, 6–9 July 1999. [Google Scholar]

- Yamaguchi, T.; Yasuda, K. Adaptive particle swarm optimization—Self-coordinating mechanism with updating information. In Proceedings of the 2006 IEEE International Conference on Systems, Man and Cybernetics, Taipei, Taiwan, 8–11 October 2006. [Google Scholar]

- Chou, W. Choose Your IGBTs Correctly for Solar Inverter Applications. Available online: https://www.infineon.com/dgdl/524pet0808.pdf?fileId=5546d462533600a4015356926b322b5f (accessed on 21 March 2019).

| e/D | |||

|---|---|---|---|

| 2 | 1.4 | 1.43 | 0.613 |

| 1 | 1.4 | 0.71 | 0.582 |

| 0.021 | 1.4 | 0.015 | 0.57 |

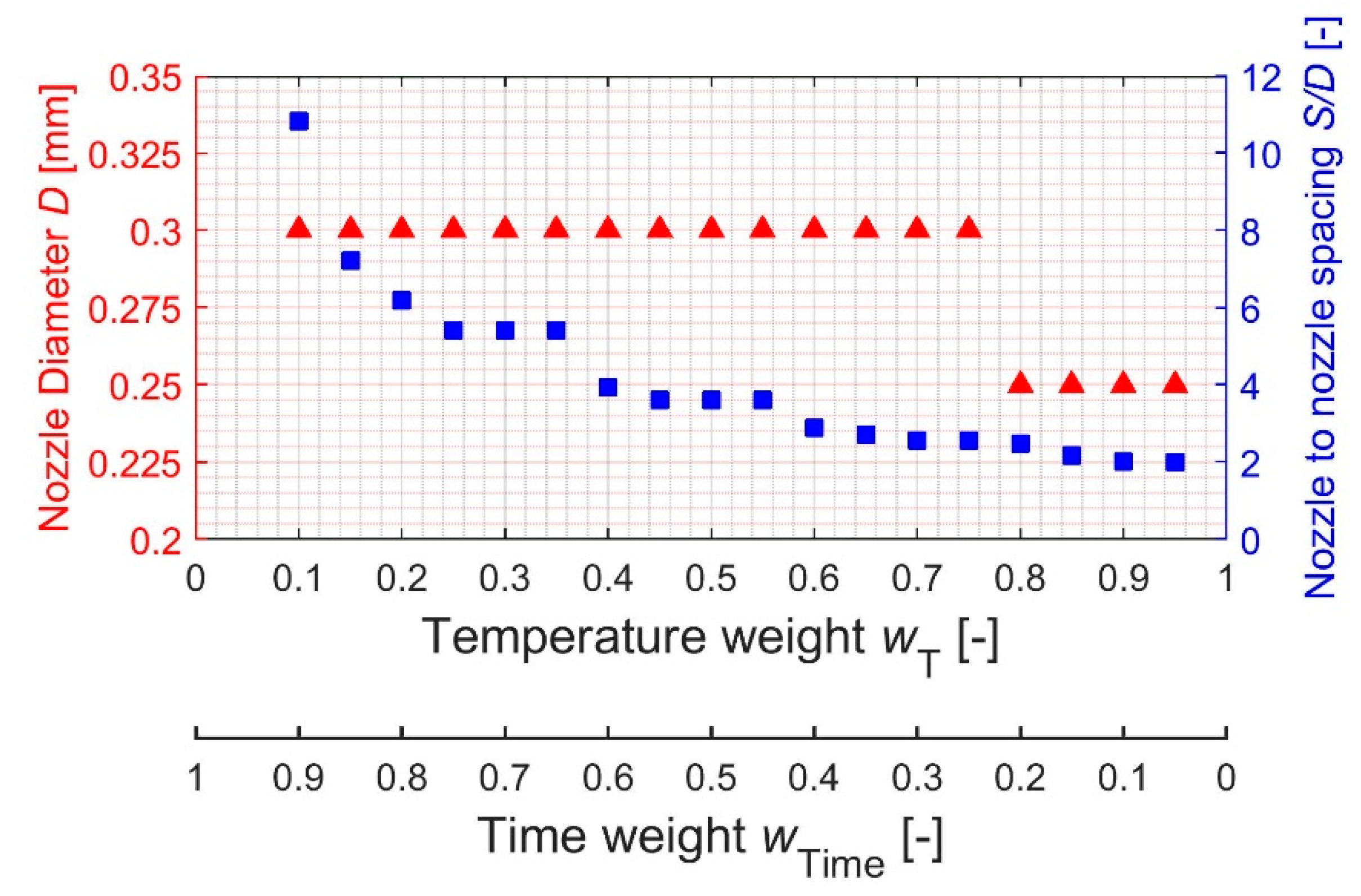

| Parameters | wT = 0.25 & wTime = 0.75 | wT = 0.5 & wTime = 0.5 | wT = 0.75 & wTime = 0.25 |

|---|---|---|---|

| Diameter | 0.3 mm | 0.3 mm | 0.3 mm |

| N° of Nozzles in short side | 8 | 12 | 17 |

| N° of Nozzles in long side | 9 | 14 | 20 |

| Total N° of Nozzles | 72 | 168 | 340 |

| Z | 0.9 mm | 0.9 mm | 0.9 mm |

| Surface T° | 137.52 °C | 124.40 °C | 114’95 °C |

| Junction T° | 142.91 °C | 129.79 °C | 120.34 °C |

| Build Time | 6.34 s | 14.61 s | 29.36 s |

| Nozzle center to nozzle center spacing | 1.625 mm | 1.083 mm | 0.765 mm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-Filgueira, P.; Zulueta, E.; Sánchez-Chica, A.; Fernández-Gámiz, U.; Soriano, J. Multi-Objective Particle Swarm Based Optimization of an Air Jet Impingement System. Energies 2019, 12, 1627. https://doi.org/10.3390/en12091627

Martínez-Filgueira P, Zulueta E, Sánchez-Chica A, Fernández-Gámiz U, Soriano J. Multi-Objective Particle Swarm Based Optimization of an Air Jet Impingement System. Energies. 2019; 12(9):1627. https://doi.org/10.3390/en12091627

Chicago/Turabian StyleMartínez-Filgueira, Pablo, Ekaitz Zulueta, Ander Sánchez-Chica, Unai Fernández-Gámiz, and Josu Soriano. 2019. "Multi-Objective Particle Swarm Based Optimization of an Air Jet Impingement System" Energies 12, no. 9: 1627. https://doi.org/10.3390/en12091627

APA StyleMartínez-Filgueira, P., Zulueta, E., Sánchez-Chica, A., Fernández-Gámiz, U., & Soriano, J. (2019). Multi-Objective Particle Swarm Based Optimization of an Air Jet Impingement System. Energies, 12(9), 1627. https://doi.org/10.3390/en12091627