Automatic and Visual Processing Method of Non-Contact Monitoring for Circular Stormwater Sewage Tunnels Based on LiDAR Data

Abstract

1. Introduction

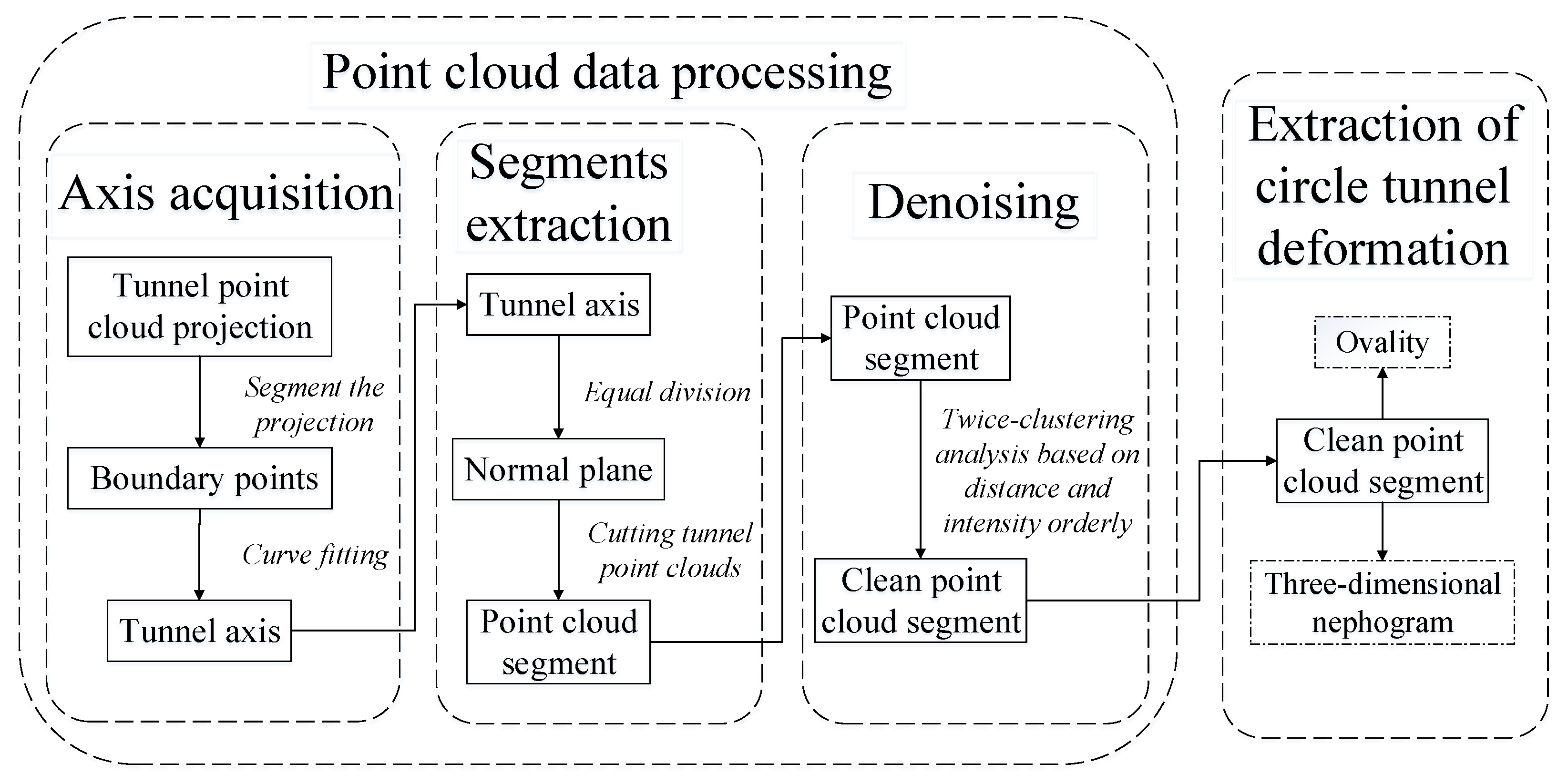

2. Automatic Data Processing

2.1. Registration of Point Clouds

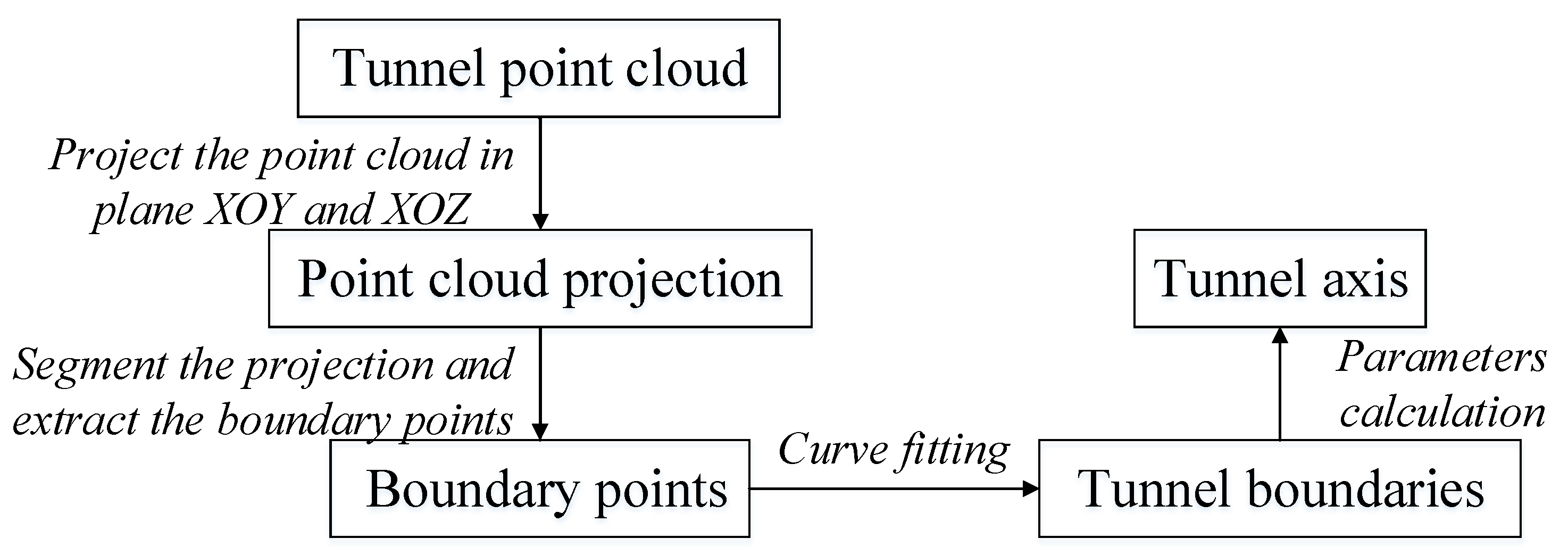

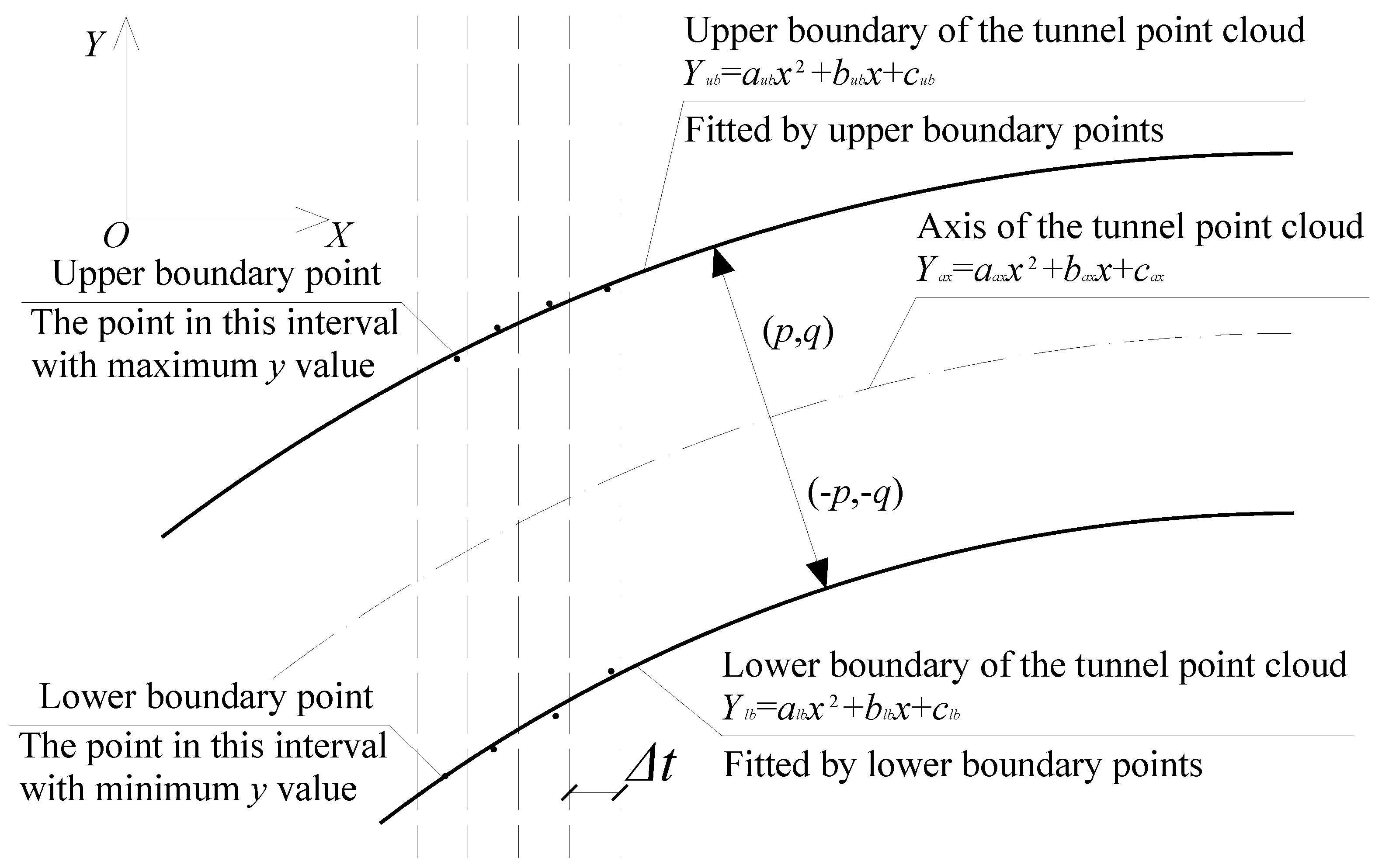

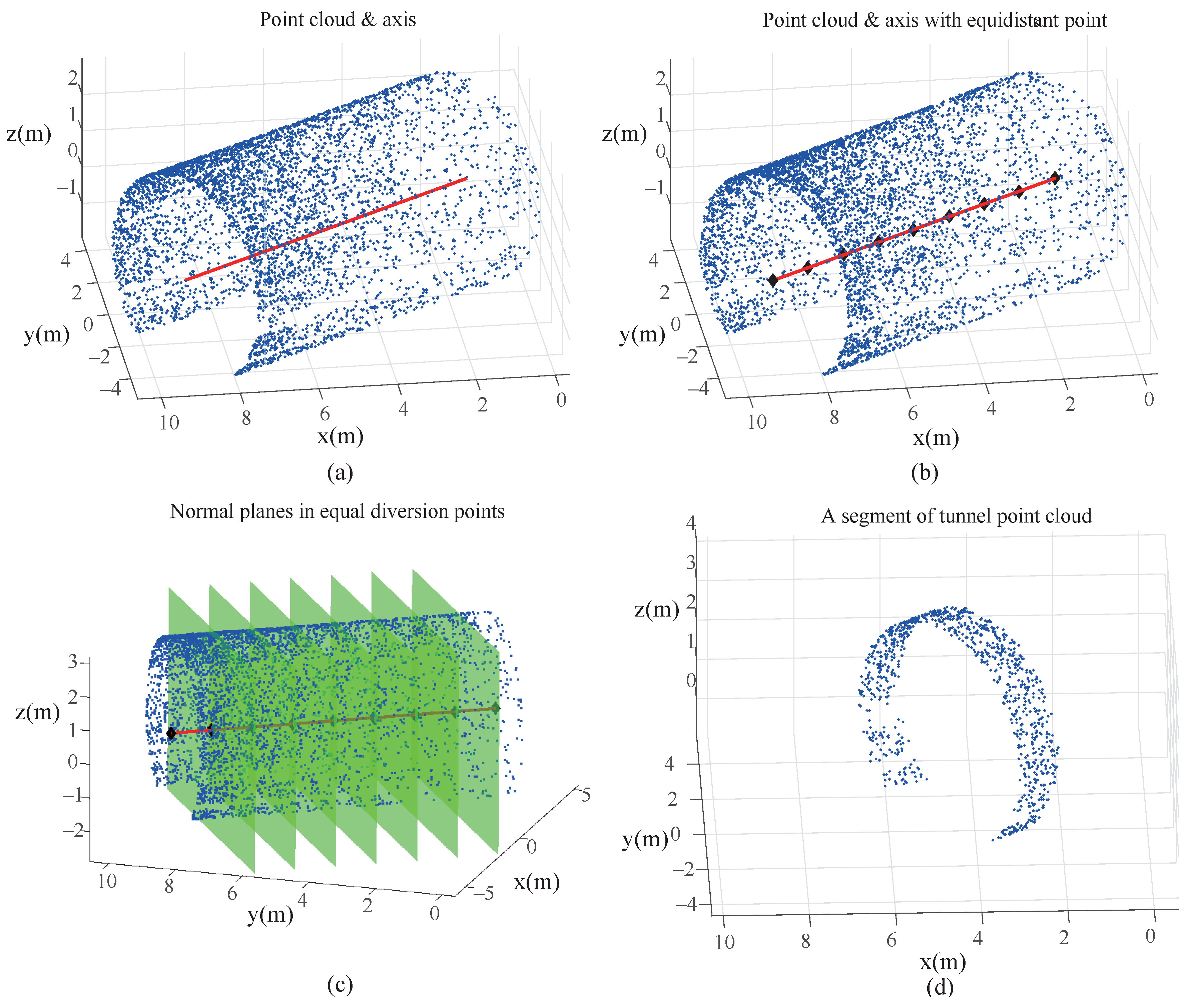

2.2. Acquisition of the Circular Tunnel Axis

- Compress point data automatically to reduce the amount of computation required. Take all of the z coordinates of the point clouds as zero to obtain the projection of the tunnel point clouds in the plane;

- Extract the maximum x coordinate value as and the minimum x coordinate value as among all the point coordinates;

- In order to acquire boundary points using computer programs, the projection of tunnel point cloud has to be divided into pieces due to the discreteness of the point clouds and the tunnel contour is fitted by these boundary points. The interval t is the width of one piece and determined by humans according to the accuracy of the contour line and the available time assigned to data post-processing. In the proposed algorithm, the value of t is 10 mm. In every interval from to , extract two points with the maximum and minimum y values as the upper and lower boundaries points, respectively;

- Considering that the length of city tunnel is usually shorter than 1000 m with little curvature, the proposed algorithm employs a quadratic curve to fit the upper and lower boundaries of the tunnel point clouds:where x and Y are the x and y coordinates of the boundary quadratic curves; a, b and c are the parameters of the quadratic polynomials. The corner marks “” and “” represent the upper and lower boundaries, respectively. The parameter estimation of the fitting function employs the widely used robust RANSAC algorithm.

- The upper and lower boundaries and the tunnel axis are supposed to be the same shape, and the function graphs of the upper and lower boundaries in the plane can be transformed by the tunnel axis graph along the two vectors which are of the same size but in opposite directions. Assume that the function of the axis in the plane iswhere x and are the x and y coordinates of the axis quadratic curve; , and are the parameters of the quadratic polynomial.Transform the axis to get upper and lower boundaries, and the translation vectors are and respectively:Simplify Formula (4) and contrast the coefficients:The parameters of the tunnel axis projection function in the plane can be calculated by Formula (4).

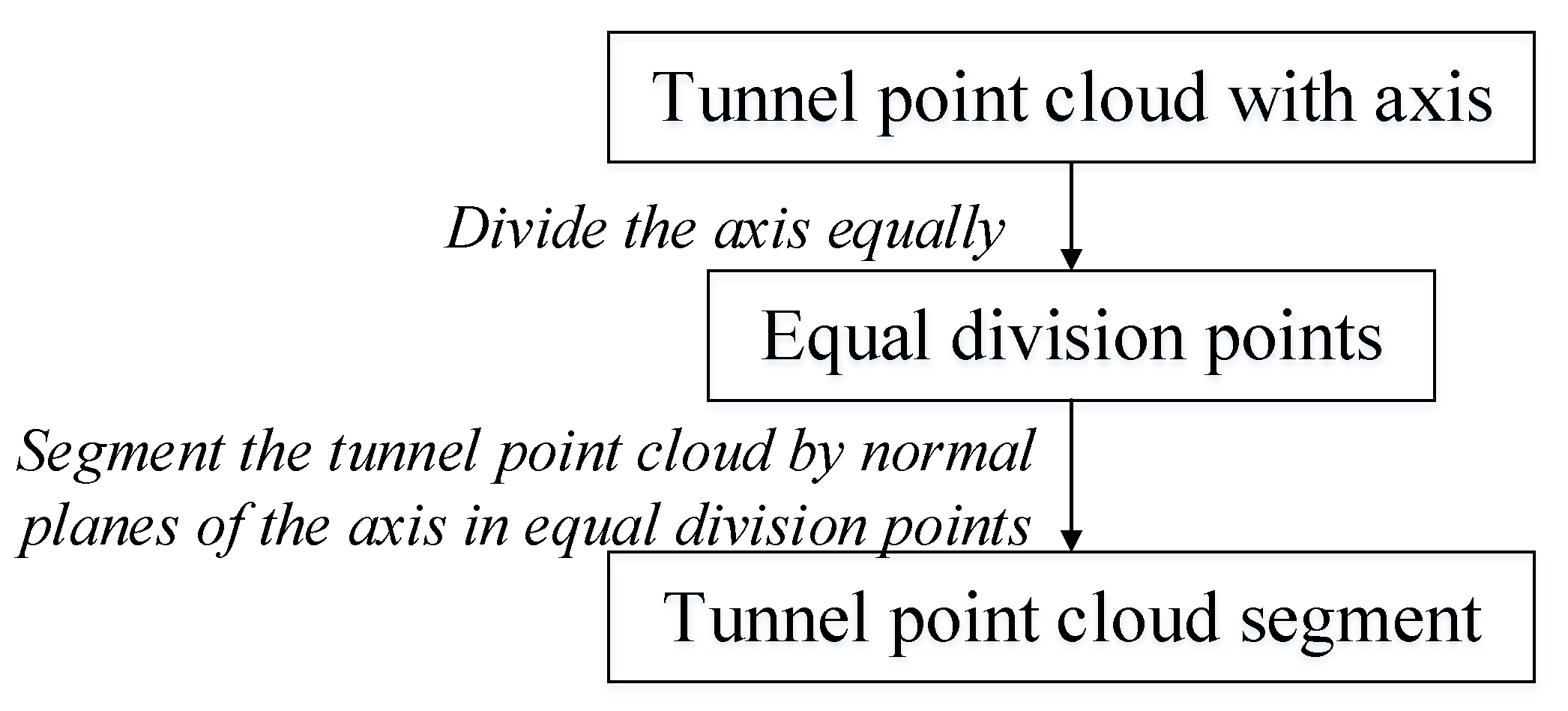

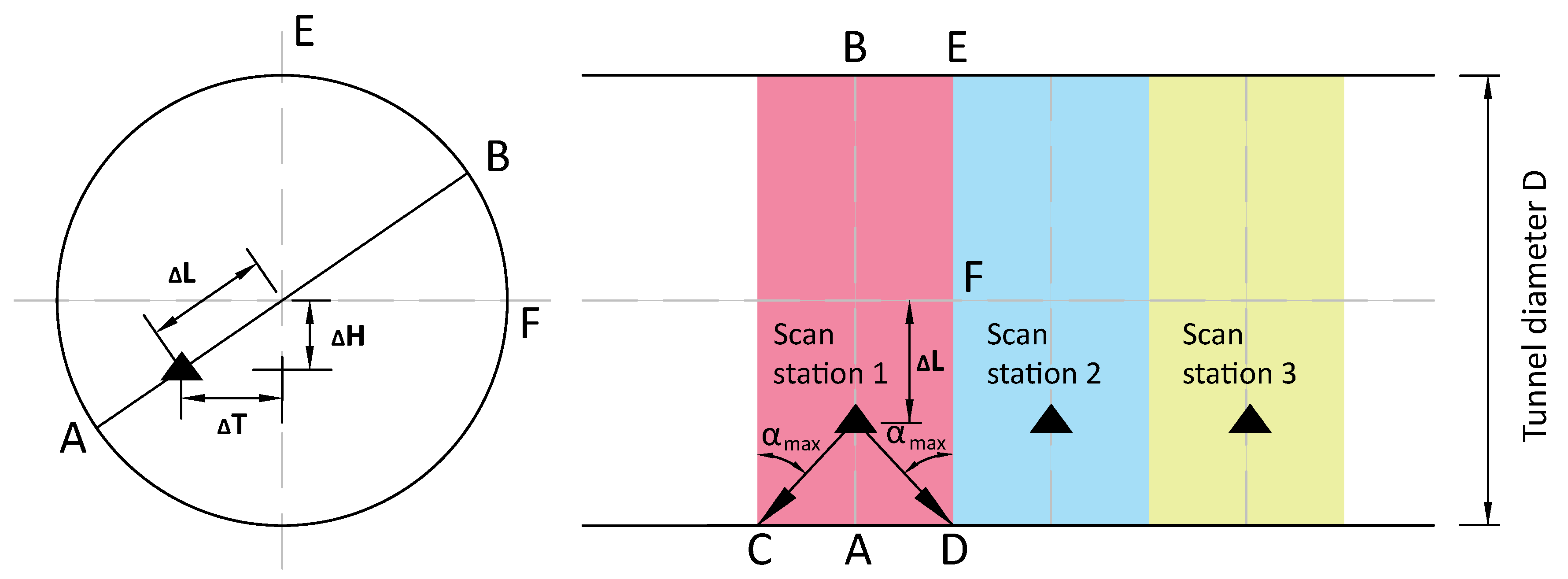

2.3. Tunnel Point Cloud Segment Extraction

- Cut out a section of the tunnel point clouds with n linings and the axis acquired in Section 2.2;

- Divide the axis into n segments equally and get equal division points in the axis;

- Divide the selected tunnel point clouds by the normal planes of the axis with equal division points into n segments;

- Extract the tunnel point cloud segments between the two adjacent normal planes.

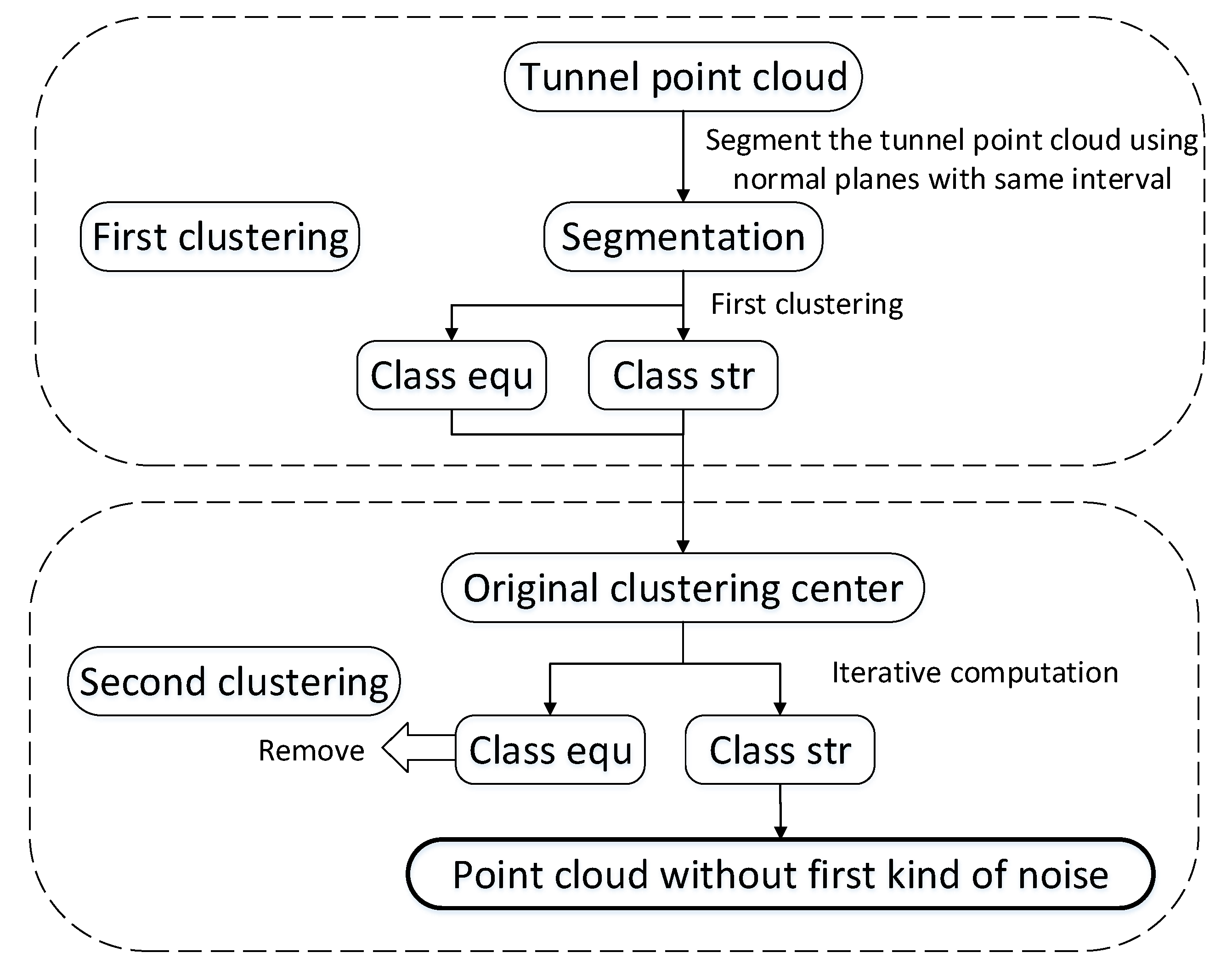

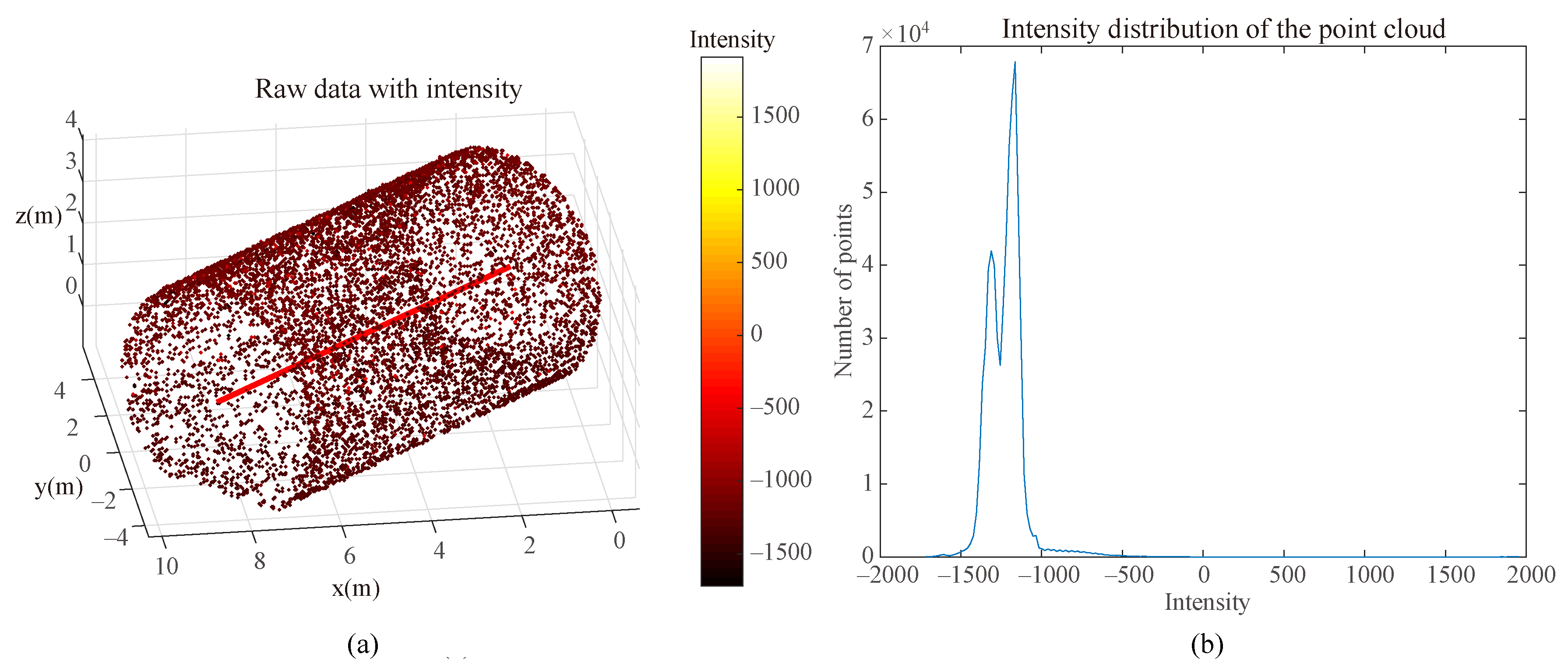

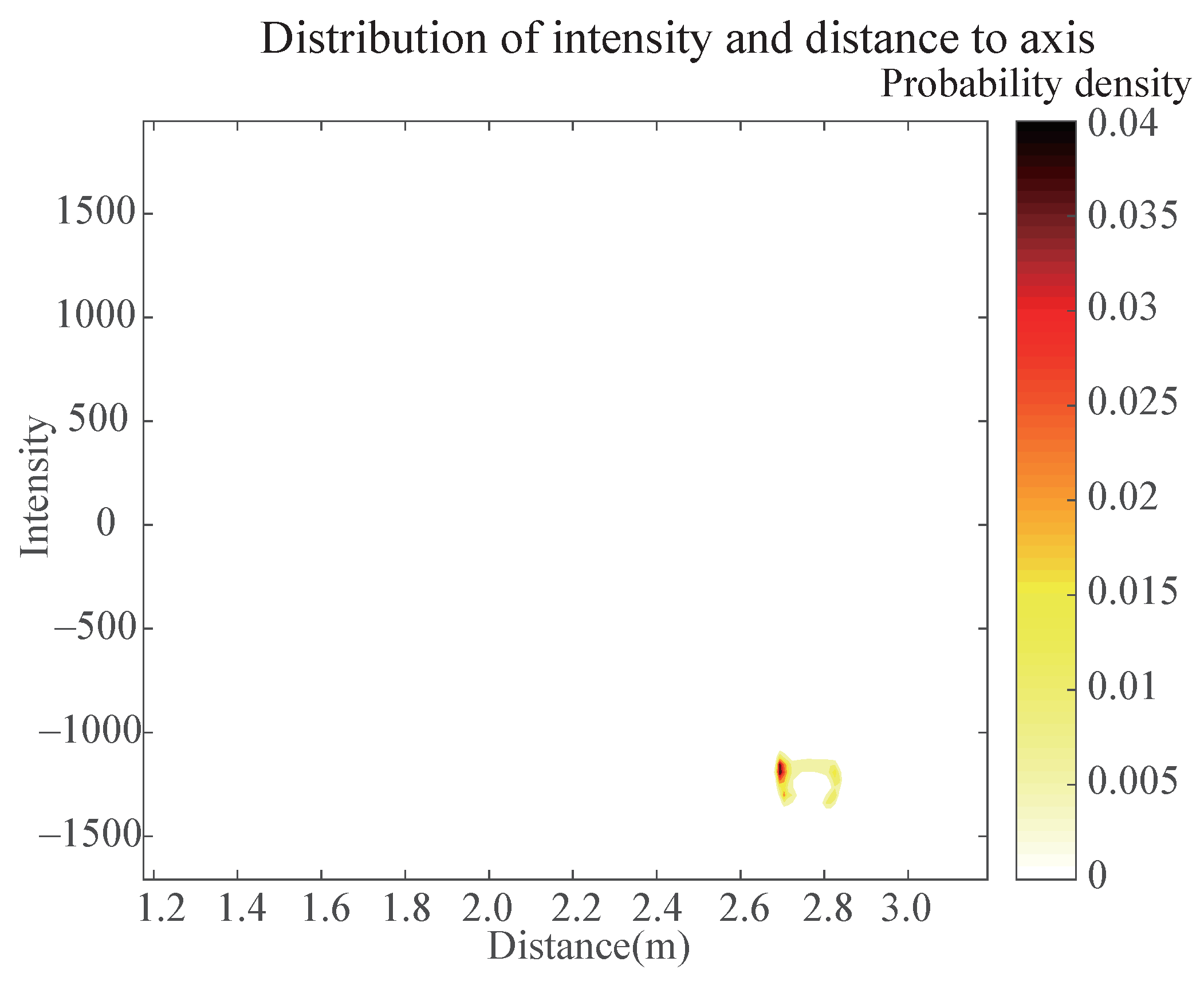

2.4. Point Cloud Data Denoising

- Implement the clustering analysis in every segment extracted, as described in Section 2.3, to reduce the complexity of the algorithm and improve the stability while assuring accuracy;

- Normalize the coordinates of the axis and tunnel point cloud segment. Transfer the tunnel point cloud segment using the coordinate transformation matrix to the point where the tunnel axis is coincident with the designed coordinate axis;

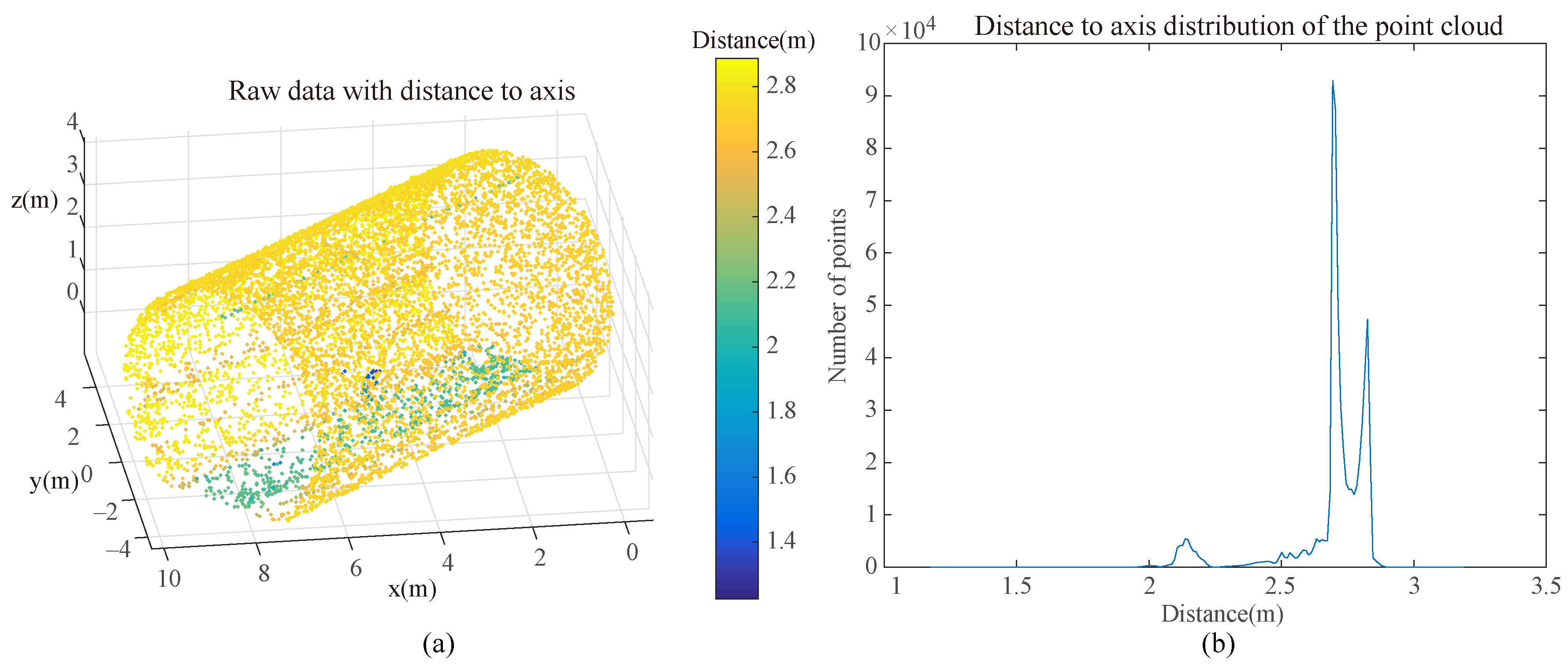

- Cluster the tunnel point clouds based on distance. Label points of classes as follows: stands for point clouds rejected by the structure and represents point clouds from facilities and equipment once point clouds have been clustered. Calculate the distances between every single point in the point clouds and the tunnel axis and then set threshold values (r and r) corresponding to the and classes, respectively, where R is the radius of the tunnel, and r is the distance threshold.

- Obtain the original clustering center of the two classes and from the result of the first clustering analysis:where is the initial clustering center, is the intensity value, C represents class or class , and is the total number of class or points;

- Calculate the distance between every residual point and the two initial clustering centers and cluster the points to the nearest class. Then, recalculate the clustering centers of the two classes:where k is the number of iterations.

- The iterative calculation ends when the difference between a new clustering center and last clustering center is equal to or less than the threshold.

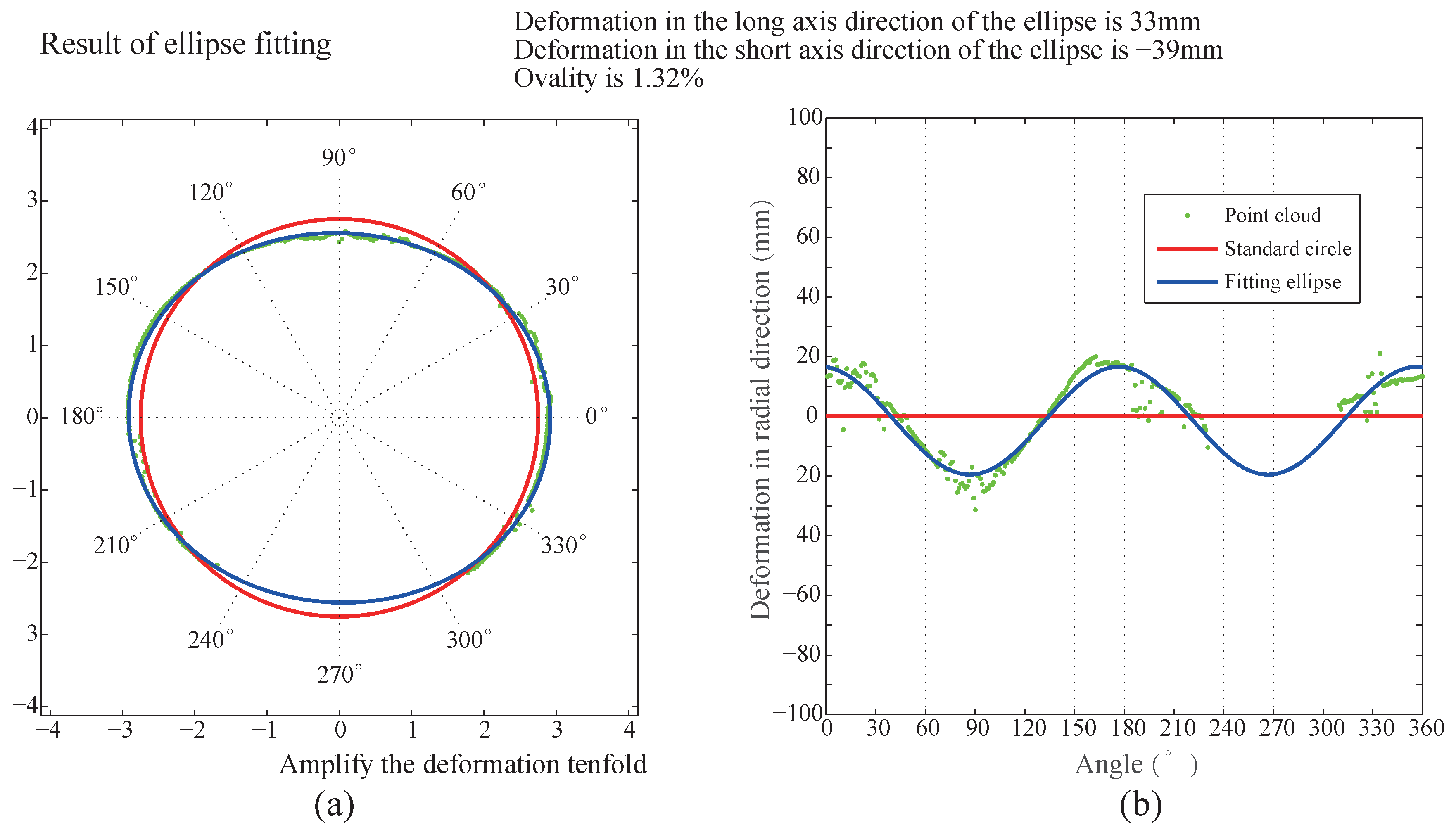

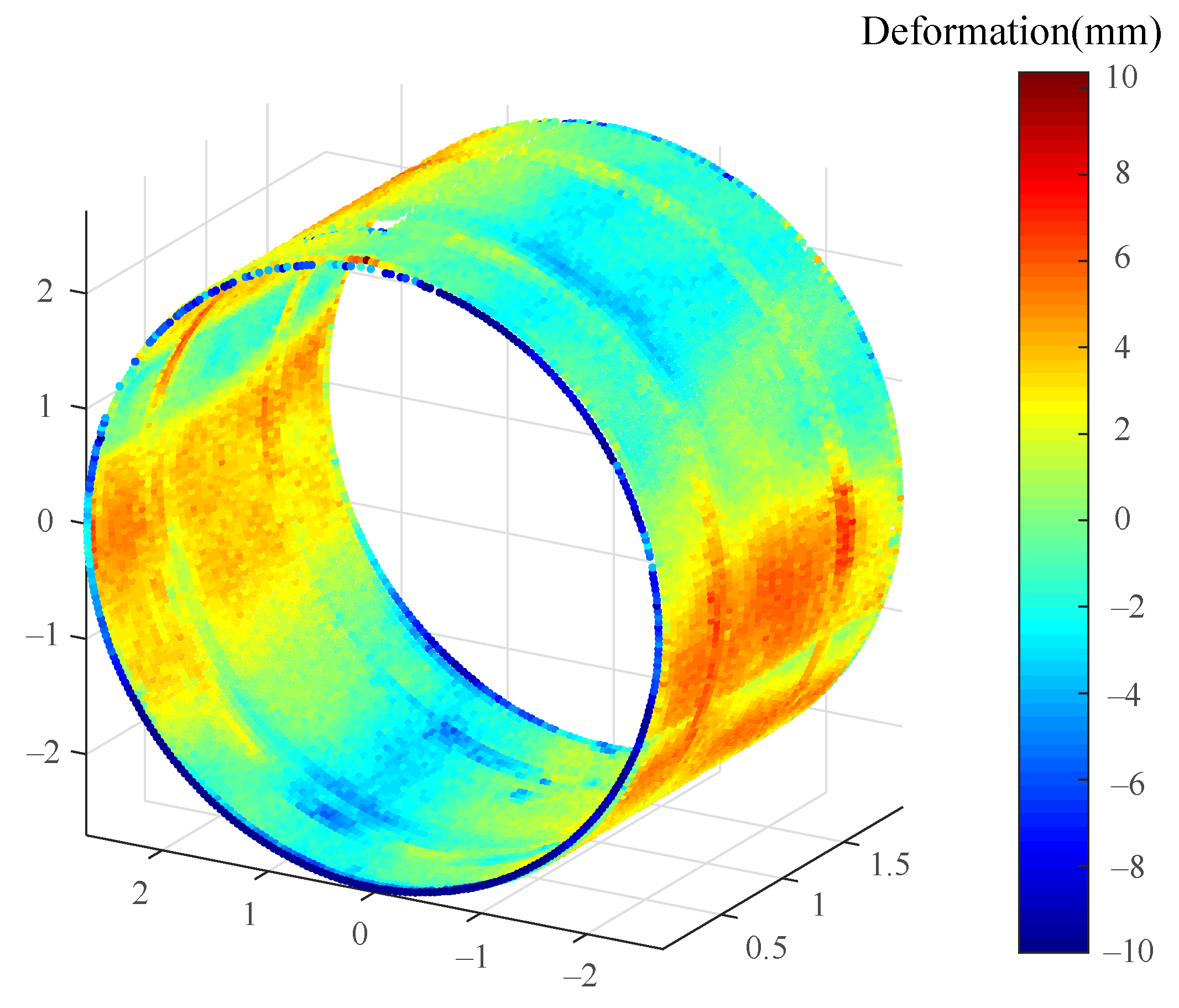

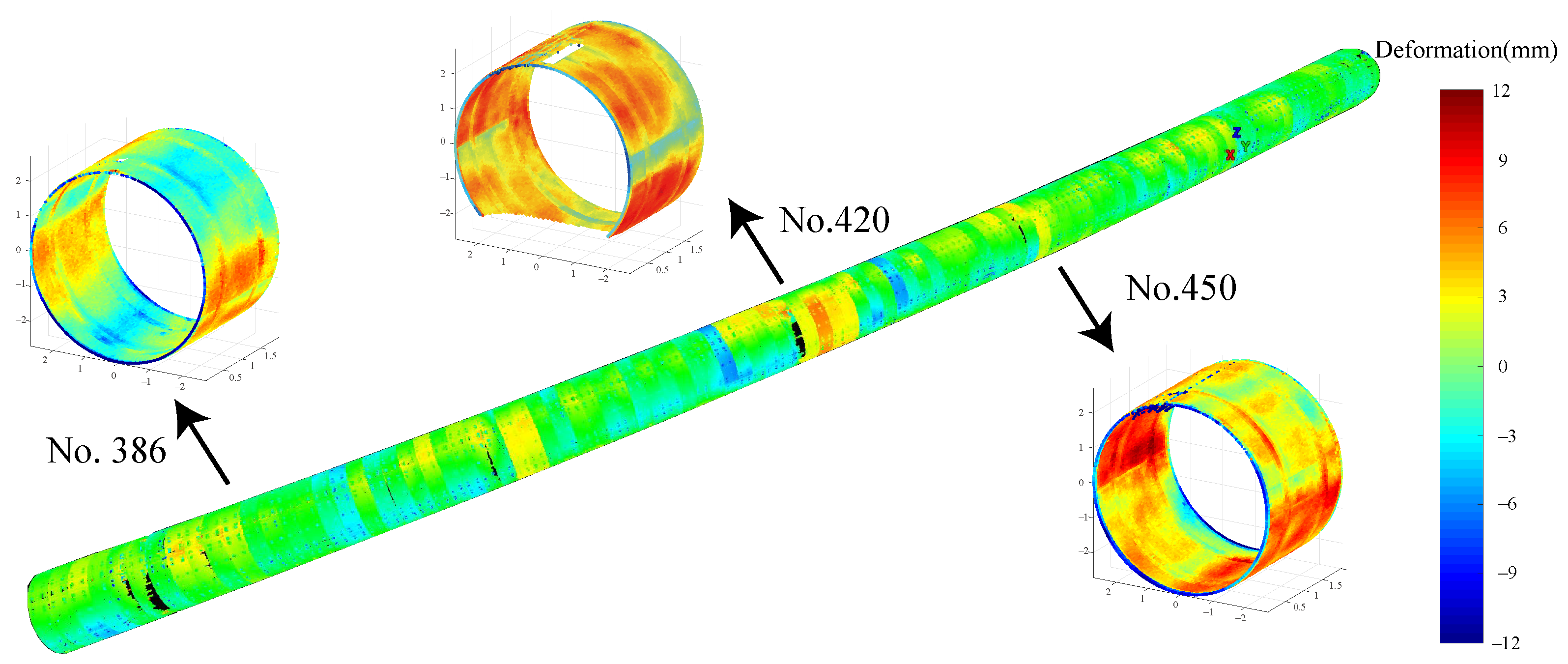

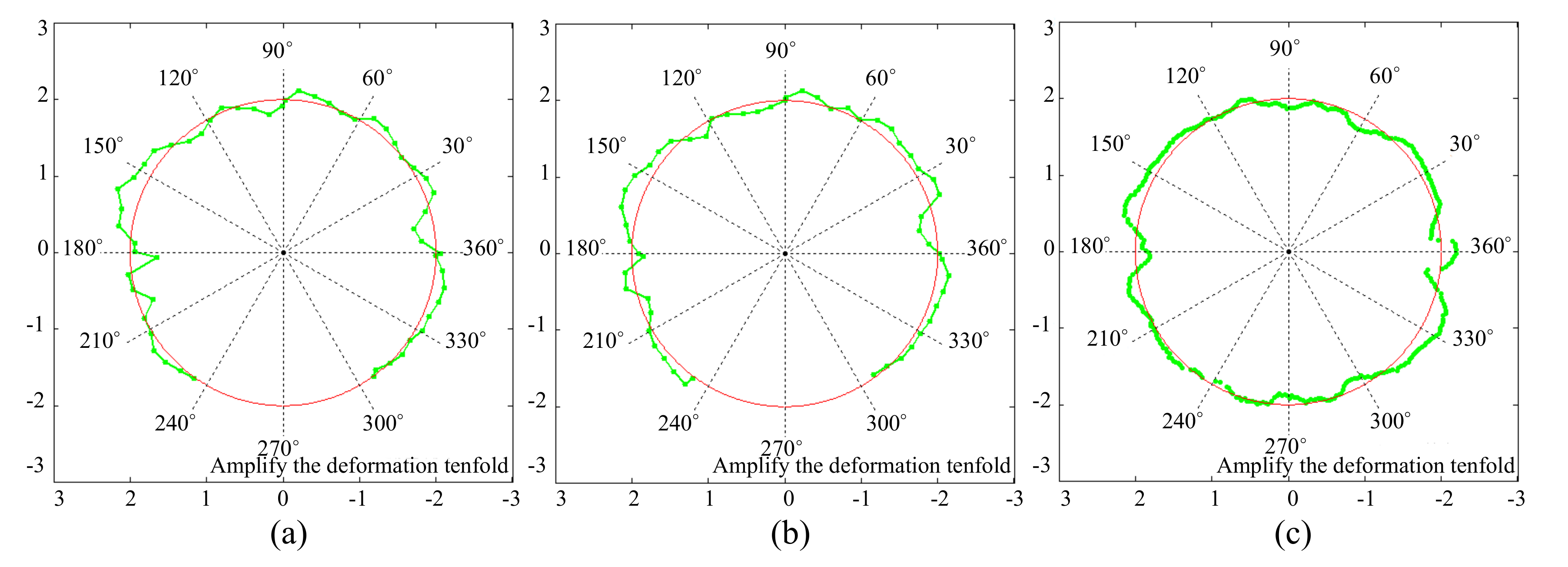

2.5. Extraction of Circular Tunnel Deformation

3. Application

3.1. Practical Monitoring Project

3.2. Analysis of the Project Efficiency

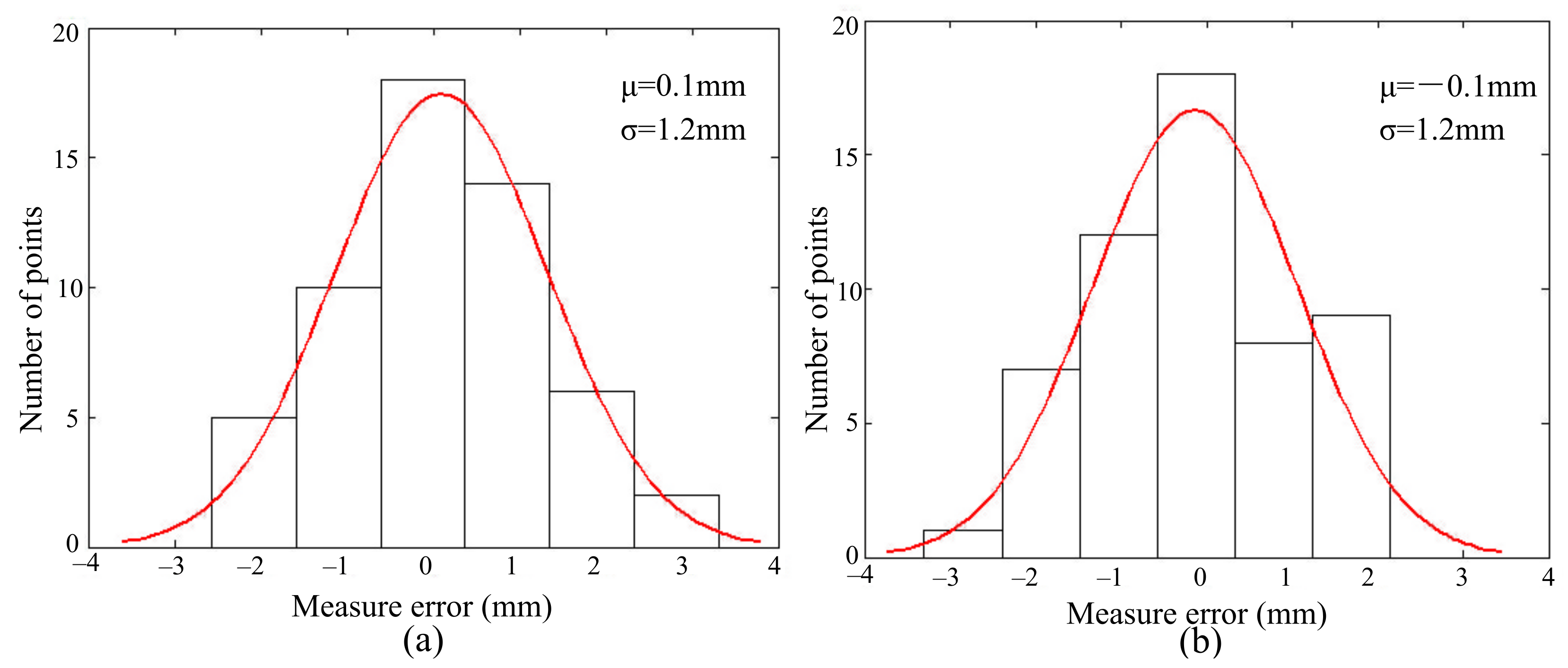

4. Error Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Riveiro, B.; DeJong, M.J.; Conde, B. Automated processing of large point clouds for structural health monitoring of masonry arch bridges. Autom. Constr. 2016, 72, 258–268. [Google Scholar] [CrossRef]

- Díaz-Vilariño, L.; González-Jorge, H.; Bueno, M. Automatic classification of urban pavements using mobile LiDAR data and roughness descriptors. Constr. Build. Mater. 2016, 102, 208–215. [Google Scholar] [CrossRef]

- Vazaios, I.; Vlachopoulos, N.; Diederichs, M.S. Integration of Lidar-based structural input and discrete fracture network generation for underground applications. Geotech. Geol. Eng. 2017, 35, 2227–2251. [Google Scholar] [CrossRef]

- Palmer, D.; Koumpli, E.; Cole, I. A GIS-Based Method for Identification of Wide Area Rooftop Suitability for Minimum Size PV Systems Using LiDAR Data and Photogrammetry. Energies 2018, 12, 3506. [Google Scholar] [CrossRef]

- Le Clainche, S.; Lorente, L.; Vega, J.; Vega Jose, M. Wind Predictions Upstream Wind Turbines from a LiDAR Database. Energies 2018, 3, 543. [Google Scholar] [CrossRef]

- Yan, Y.; Tan, Z.; Su, N. Building Extraction Based on an Optimized Stacked Sparse Autoencoder of Structure and Training Samples Using LIDAR DSM and Optical Images. Sensors 2017, 17, 1957. [Google Scholar] [CrossRef] [PubMed]

- Bosché, F.; Ahmed, M.; Turkan, Y. The value of integrating Scan-to-BIM and Scan-vs-BIM techniques for construction monitoring using laser scanning and BIM: The case of cylindrical MEP components. Autom. Constr. 2015, 49, 201–213. [Google Scholar] [CrossRef]

- Argüelles-Fraga, R.; Ordóñez, C.; García-Cortés, S. Measurement planning for circular cross-section tunnels using terrestrial laser scanning. Autom. Constr. 2013, 31, 1–9. [Google Scholar] [CrossRef]

- Roca-Pardiñas, J.; Argüelles-Fraga, R.; de Asís López, F. Analysis of the influence of range and angle of incidence of terrestrial laser scanning measurements on tunnel inspection. Tunn. Undergr. Space Technol. 2014, 43, 133–139. [Google Scholar] [CrossRef]

- Pejić, M. Design and optimisation of laser scanning for tunnels geometry inspection. Tunn. Undergr. Space Technol. 2013, 37, 199–206. [Google Scholar] [CrossRef]

- Guo, J.; Tsai, M.J.; Han, J.Y. Automatic reconstruction of road surface features by using terrestrial mobile lidar. Autom. Constr. 2015, 58, 165–175. [Google Scholar] [CrossRef]

- Cabo, C.; Cortés, S.G.; Ordoñez, C. Mobile Laser Scanner data for automatic surface detection based on line arrangement. Autom. Constr. 2015, 58, 28–37. [Google Scholar] [CrossRef]

- Kim, J.U.; Kang, H.B. A new 3D object pose detection method using LIDAR shape set. Sensors 2018, 18, 882. [Google Scholar] [CrossRef] [PubMed]

- Puente, I.; González-Jorge, H.; Martínez-Sánchez, J. Automatic detection of road tunnel luminaires using a mobile LiDAR system. Measurement 2014, 47, 569–575. [Google Scholar] [CrossRef]

- Kashani, A.G.; Graettinger, A.J. Cluster-Based Roof Covering Damage Detection in Ground-Based Lidar Data. Autom. Constr. 2015, 58, 19–27. [Google Scholar] [CrossRef]

- Kashani, A.G.; Olsen, M.J.; Graettinger, A.J. Laser Scanning Intensity Analysis for Automated Building Wind Damage Detection. Cong. Comput. Civ. Eng. Proc. 2015, 199–205. [Google Scholar] [CrossRef]

- Nuttens, T.; Stal, C.; De Backer, H. Methodology for the ovalization monitoring of newly built circular train tunnels based on laser scanning: Liefkenshoek Rail Link (Belgium). Autom. Constr. 2014, 43, 1–9. [Google Scholar] [CrossRef]

- Han, J.Y.; Guo, J.; Jiang, Y.S. Monitoring tunnel profile by means of multi-epoch dispersed 3-D LiDAR point clouds. Tunn. Undergr. Space Technol. 2013, 33, 186–192. [Google Scholar] [CrossRef]

- Han, J.Y.; Guo, J.; Jiang, Y.S. Monitoring tunnel deformations by means of multi-epoch dispersed 3D LiDAR point clouds: An improved approach. Tunn. Undergr. Space Technol. 2013, 38, 385–389. [Google Scholar] [CrossRef]

- Janowski, A. The circle object detection with the use of Msplit estimation. EDP Sci. 2018, 26, 00014. [Google Scholar] [CrossRef]

- Janowski, A.; Bobkowska, K.; Szulwic, J. 3D modelling of cylindrical-shaped objects from lidar data-an assessment based on theoretical modelling and experimental data. Metrol. Meas. Syst. 2018, 25, 47–56. [Google Scholar] [CrossRef]

- Arastounia, M. Automated as-built model generation of subway tunnels from mobile LiDAR data. Sensors 2016, 16, 1486. [Google Scholar] [CrossRef] [PubMed]

- Puente, I.; Akinci, B.; González-Jorge, H. A semi-automated method for extracting vertical clearance and cross sections in tunnels using mobile LiDAR data. Tunn. Undergr. Space Technol. 2016, 59, 48–54. [Google Scholar] [CrossRef]

- Ge, Y.; Tang, H.; Xia, D. Automated measurements of discontinuity geometric properties from a 3D-point cloud based on a modified region growing algorithm. Eng. Geol. 2018, 242, 44–54. [Google Scholar] [CrossRef]

- Chen, S.; Walske, M.L.; Davies, I.J. Rapid mapping and analysing rock mass discontinuities with 3D terrestrial laser scanning in the underground excavation. Int. J. Rock Mech. Min. Sci. 2018, 110, 28–35. [Google Scholar] [CrossRef]

- Sánchez-Rodríguez, A.; Riveiro, B.; Soilán, M. Automated detection and decomposition of railway tunnels from Mobile Laser Scanning Datasets. Autom. Constr. 2018, 96, 171–179. [Google Scholar] [CrossRef]

- Fumarola, M.; Poelman, R. Generating virtual environments of real world facilities: Discussing four different approaches. Autom. Constr. 2011, 20, 263–269. [Google Scholar] [CrossRef]

- Fischler, M.A.; Bolles, R.C. Random sample consensus: A paradigm for model fitting with applications to image analysis and automated cartography. Commun. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.; Ruwanpura, J. Robust Segmentation of Planar and Linear Features of Terrestrial Laser Scanner Point Clouds Acquired from Construction Sites. Sensors 2018, 18, 819. [Google Scholar] [CrossRef]

- Pfeifer, N.; Dorninger, P.; Haring, A. Investigating terrestrial laser scanning intensity data: Quality and functional relations. In Proceedings of the 8th Conference on Optical 3-D Measurement Techniques, Zurich, Switzerland, 9–12 July 2007; pp. 328–337. [Google Scholar]

- Akca, D. Matching of 3D surfaces and their intensities. ISPRS J. Photogramm. Remote Sens. 2007, 62, 112–121. [Google Scholar] [CrossRef]

- Qingwu, H.; Wanling, Y. Tempo-space Deformation Detection of Subway Tunnel based on Sequence Temporal 3D Point Cloud. Disaster Adv. 2012, 5, 1326–1330. [Google Scholar]

- Li, X.; Yang, B.; Xie, X. Influence of Waveform Characteristics on LiDAR Ranging Accuracy and Precision. Sensors 2018, 18, 1156. [Google Scholar] [CrossRef]

- Gao, Z.; Lao, M.; Sang, Y. Fast Sparse Coding for Range Data Denoising with Sparse Ridges Constraint. Sensors 2018, 18, 1449. [Google Scholar] [CrossRef] [PubMed]

| The Proposed Monitoring System | Conventional Manual Way | ||

|---|---|---|---|

| Steps | Times/s | Steps | Times/s |

| Axis acquisition | 30 | Label linings | 5000 |

| Segment extraction | 2.5 | Segment extraction | 6500 |

| Denoising | 17.5 | Denoising | 8000 |

| Axis extraction | 10,000 | ||

| Error correction | 5000 | ||

| Total Station | Laser Scanner | |

|---|---|---|

| Name | Leica TS30 | Leica C10 |

| Angle accuracy | 0.5 | 12 |

| Range accuracy | 2 mm + 2 ppm | 4 mm (50 m) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, X.; Zhao, M.; He, J.; Zhou, B. Automatic and Visual Processing Method of Non-Contact Monitoring for Circular Stormwater Sewage Tunnels Based on LiDAR Data. Energies 2019, 12, 1599. https://doi.org/10.3390/en12091599

Xie X, Zhao M, He J, Zhou B. Automatic and Visual Processing Method of Non-Contact Monitoring for Circular Stormwater Sewage Tunnels Based on LiDAR Data. Energies. 2019; 12(9):1599. https://doi.org/10.3390/en12091599

Chicago/Turabian StyleXie, Xiongyao, Mingrui Zhao, Jiamin He, and Biao Zhou. 2019. "Automatic and Visual Processing Method of Non-Contact Monitoring for Circular Stormwater Sewage Tunnels Based on LiDAR Data" Energies 12, no. 9: 1599. https://doi.org/10.3390/en12091599

APA StyleXie, X., Zhao, M., He, J., & Zhou, B. (2019). Automatic and Visual Processing Method of Non-Contact Monitoring for Circular Stormwater Sewage Tunnels Based on LiDAR Data. Energies, 12(9), 1599. https://doi.org/10.3390/en12091599