Visual Experimental Study on Gradation Optimization of Two-Stage Gravel Packing Operation in Unconventional Reservoirs

Abstract

1. Introduction

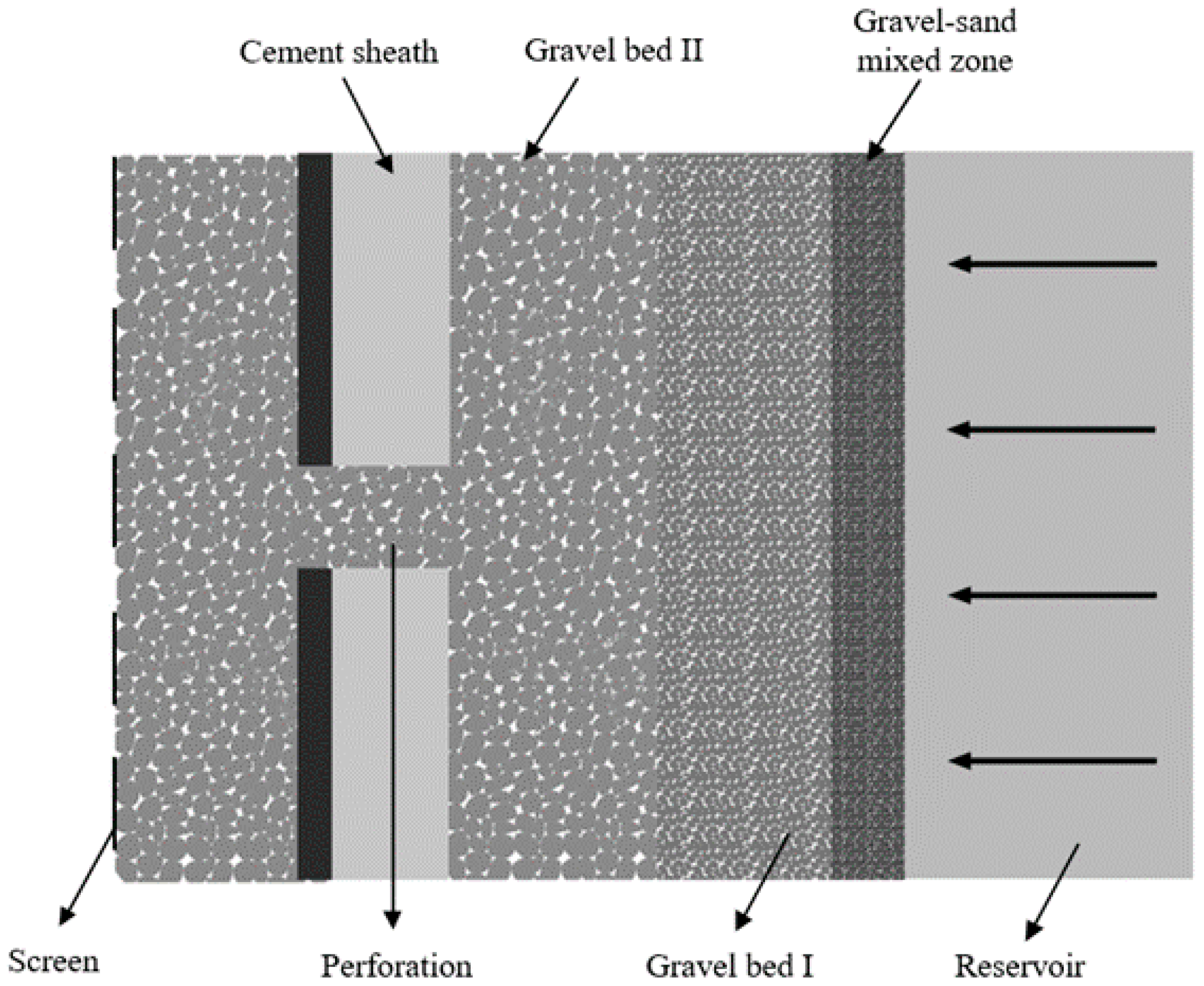

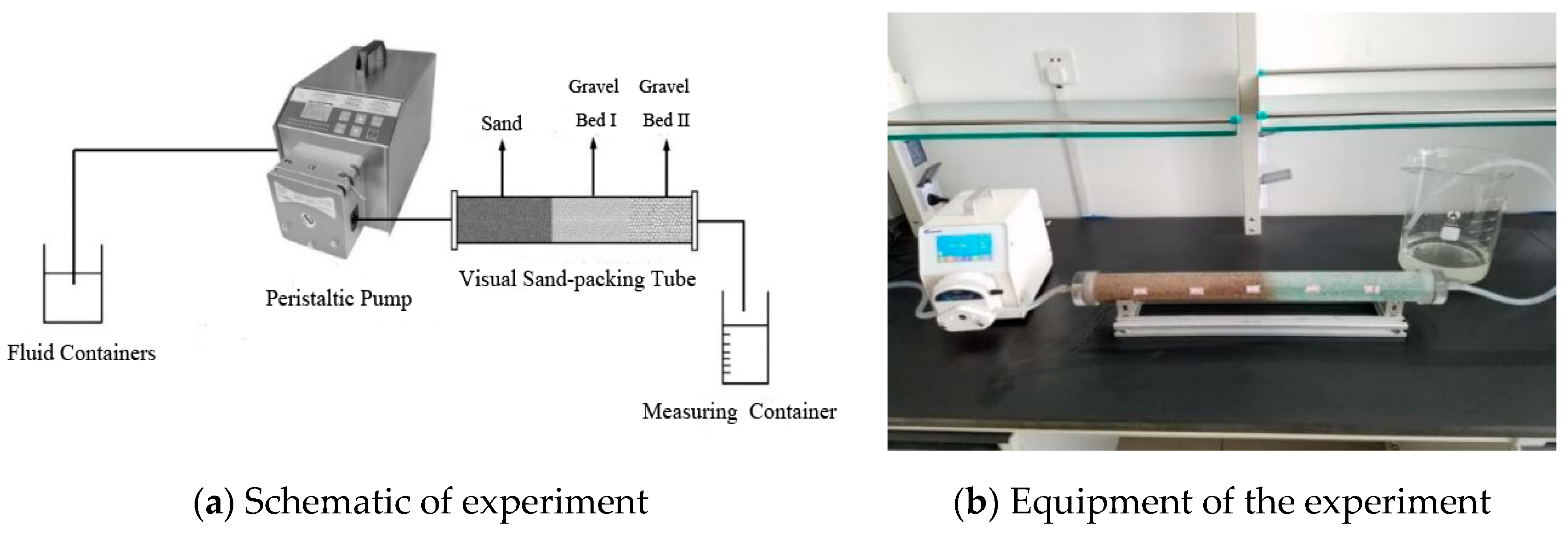

2. Experimental Design

2.1. Methodology

2.2. Experiment Materials

2.3. Experiment Procedure

- (1)

- Clean up the tube and place the metal gauze at the outlet joint to prevent the glass beads from discharging at the outlet. This can help to ensure the flow stability during the experiment.

- (2)

- The end of the tube is sealed, and the composite simulated quartz sand sample is filled to one side. After packing to the design depth, the sand sample is compacted. Then, pack glass beads into the pipe from the other end and compact slightly. During packing, the quartz sand should be kept at the bottom to prevent a large amount of pre-intruding sand before the experiment.

- (3)

- After calibrating the flow rate of the peristaltic pump, the displacement container, the peristaltic pump, and the sand-packing tube are connected. The depth of sand invasion, the movement of the gravel-sand interface, and the sand distribution characteristics are recorded every 10 min during the experiment.

- (4)

- After displacement, unfold the sand-packing tube from the exit end. The glass beads and the retained sand are extracted from segments. The mixture is filtered, and the glass beads and the retained sand are recovered separately. The amount of retained sand of this packing section can be obtained by weighing the dried recycled sand.

2.4. Experiment Scheme

3. Results and Discussions

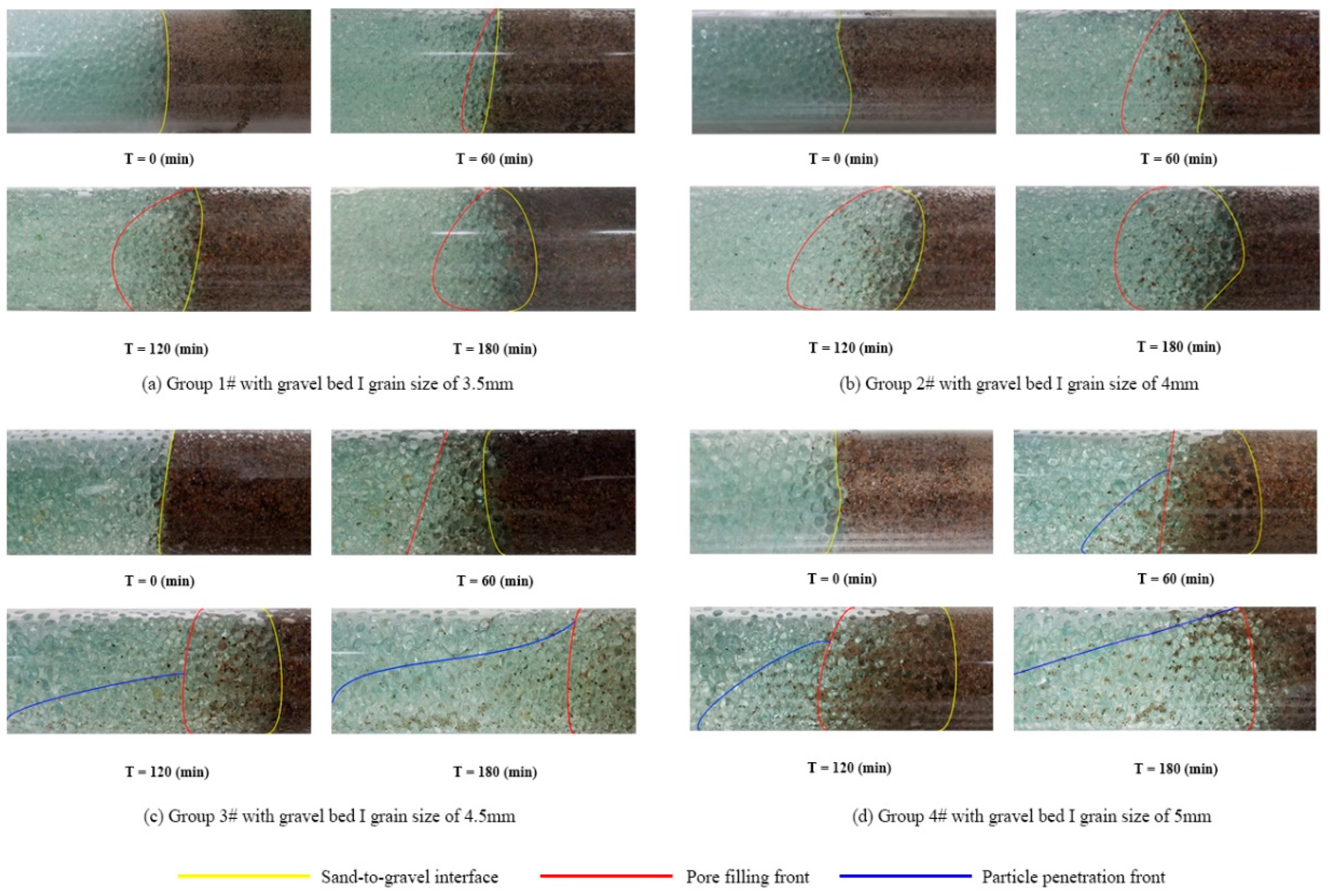

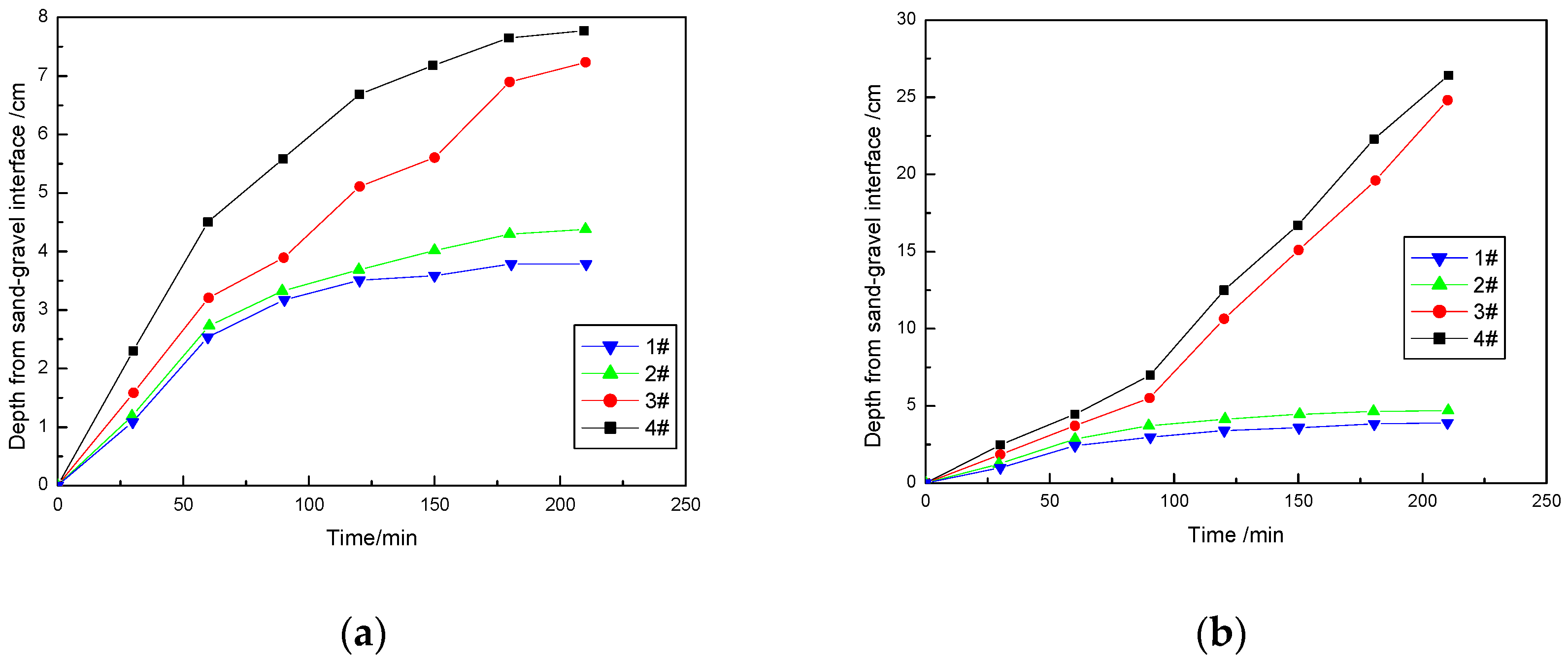

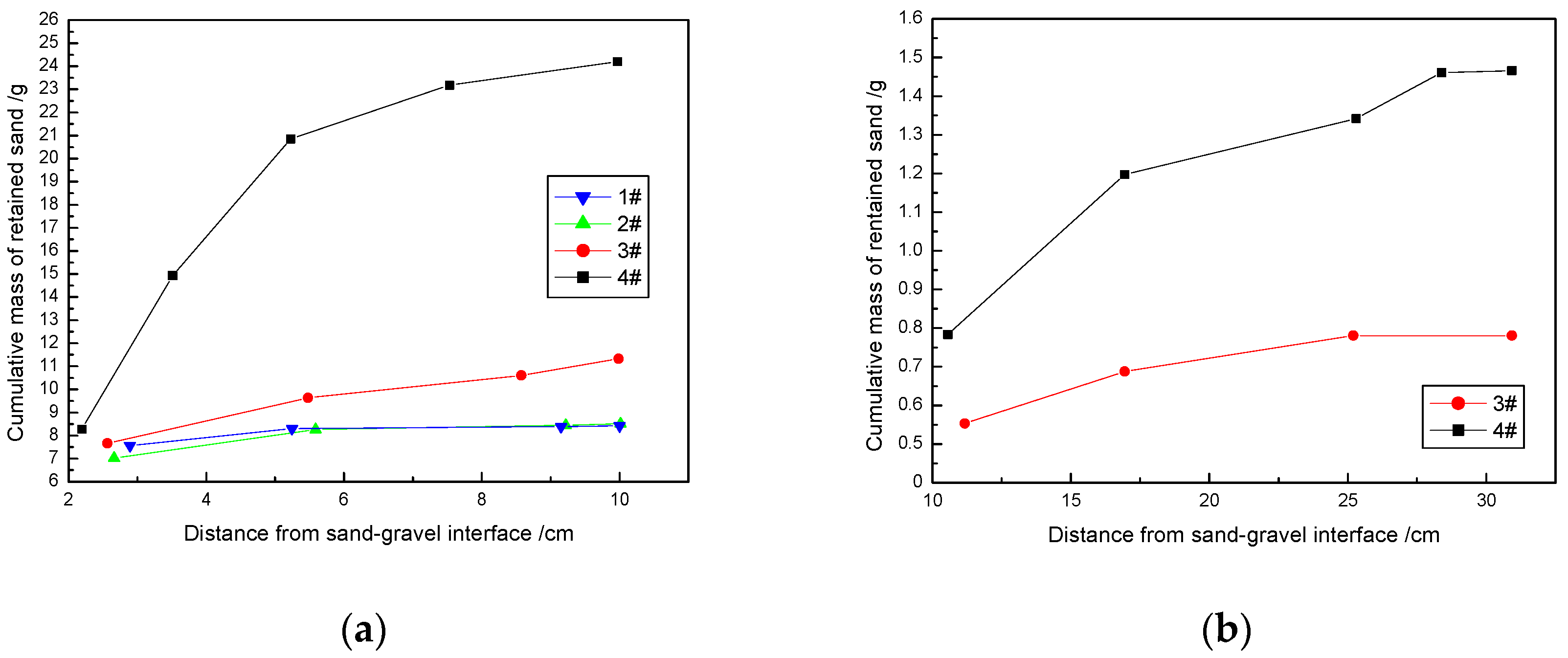

3.1. Particle Grain Size of Gravel Bed I

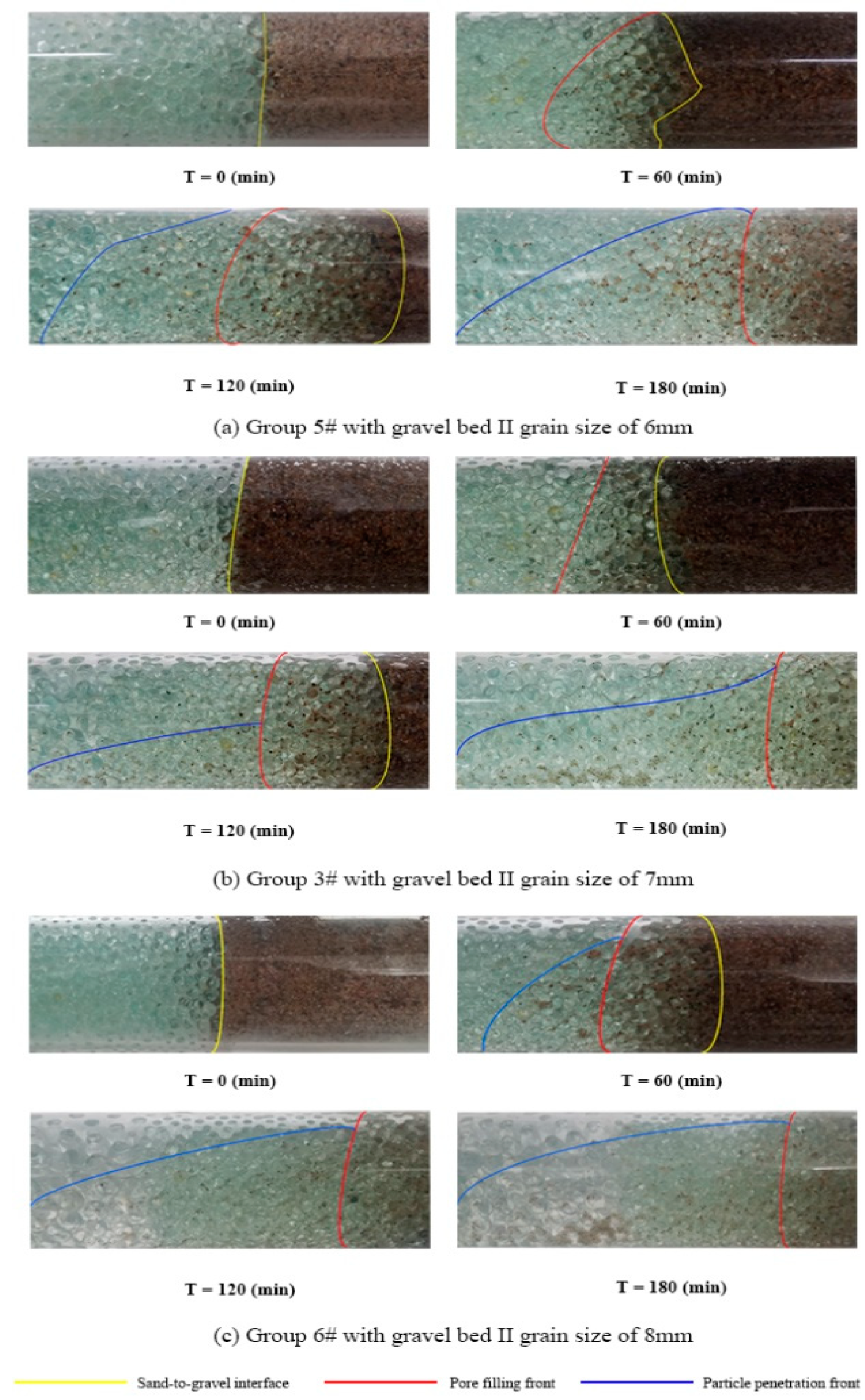

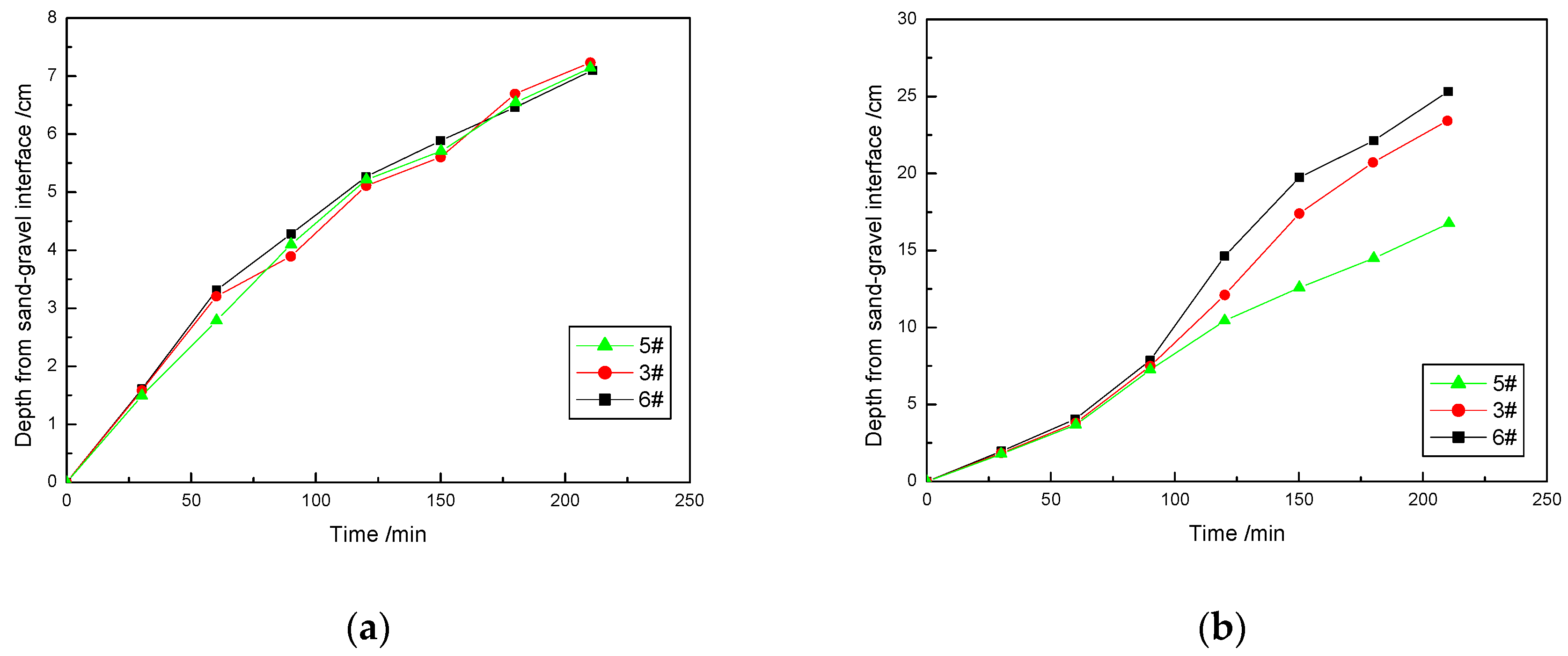

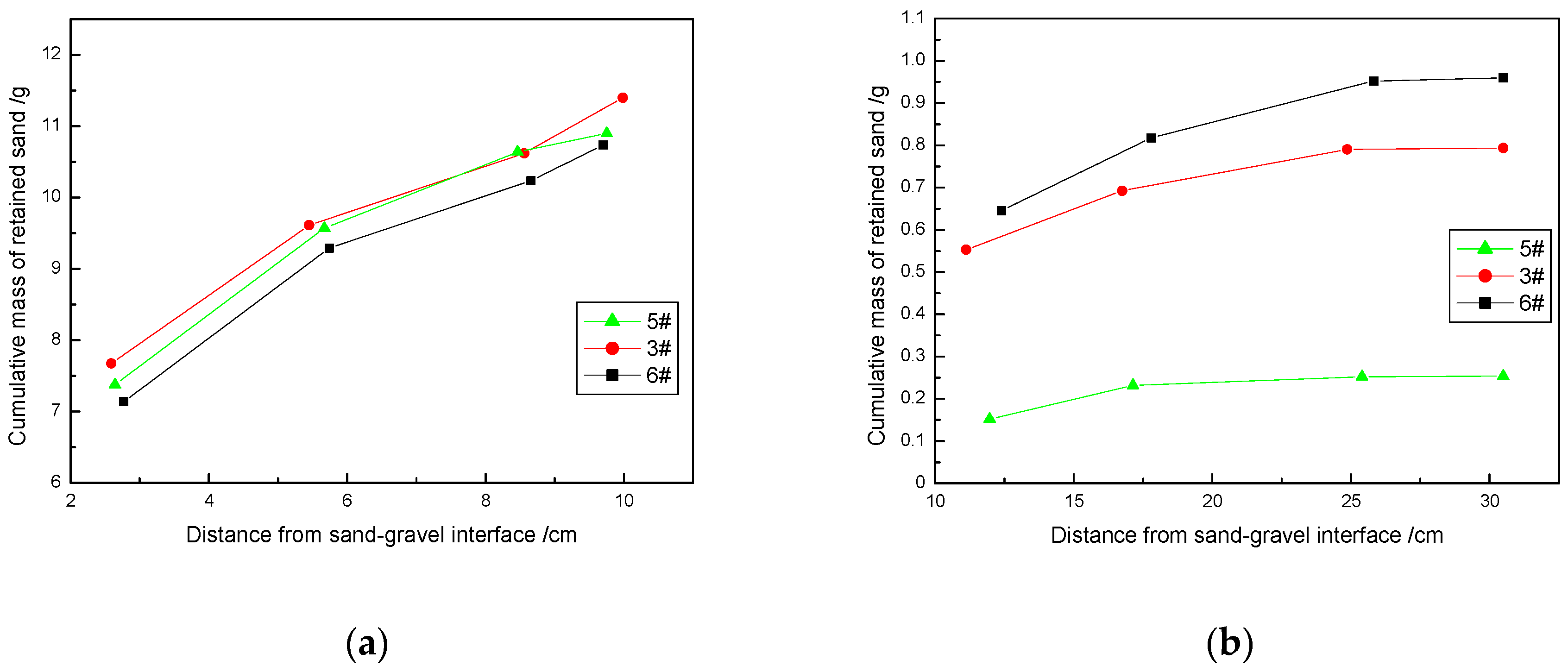

3.2. Particle Grain Size of Gravel Bed II

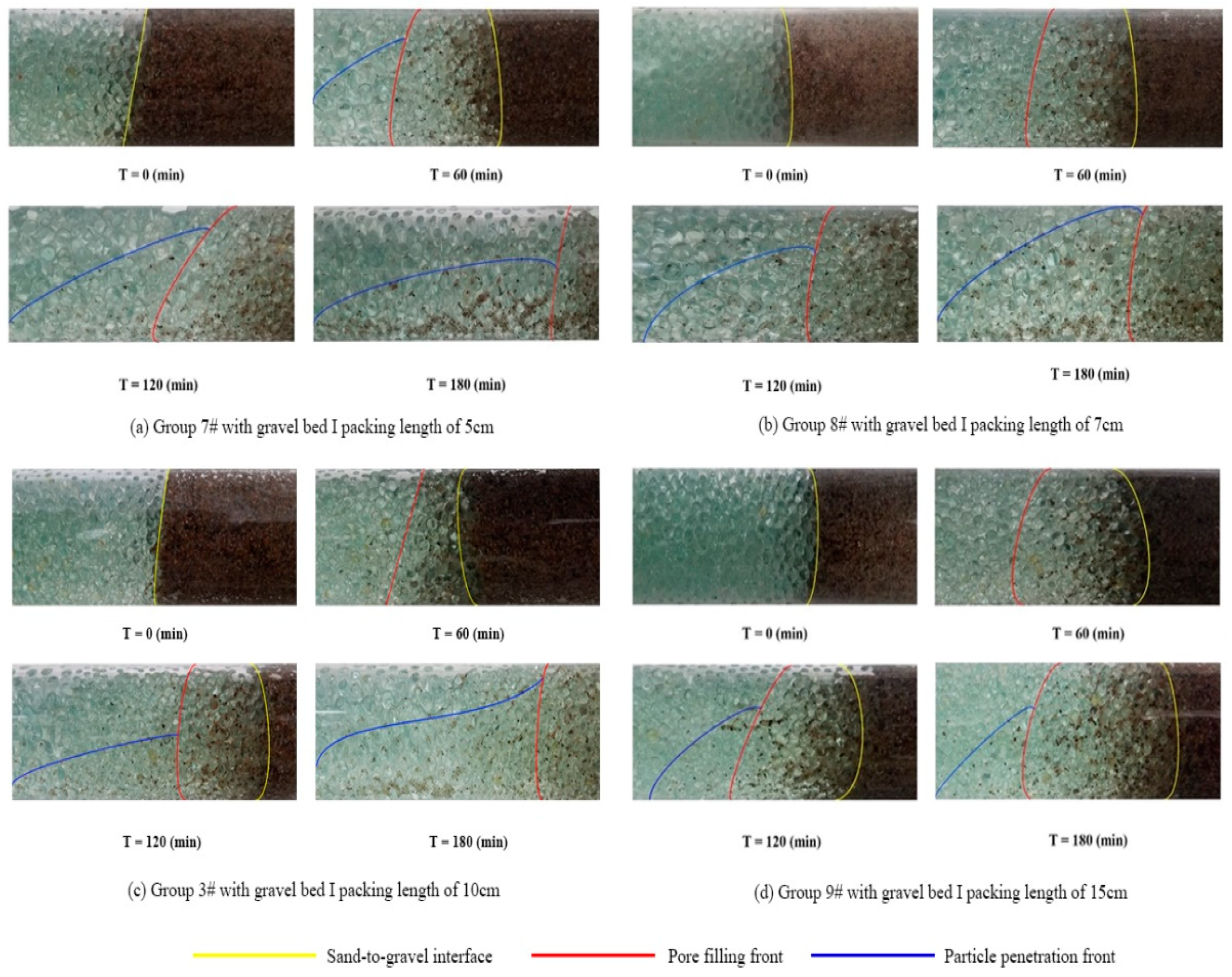

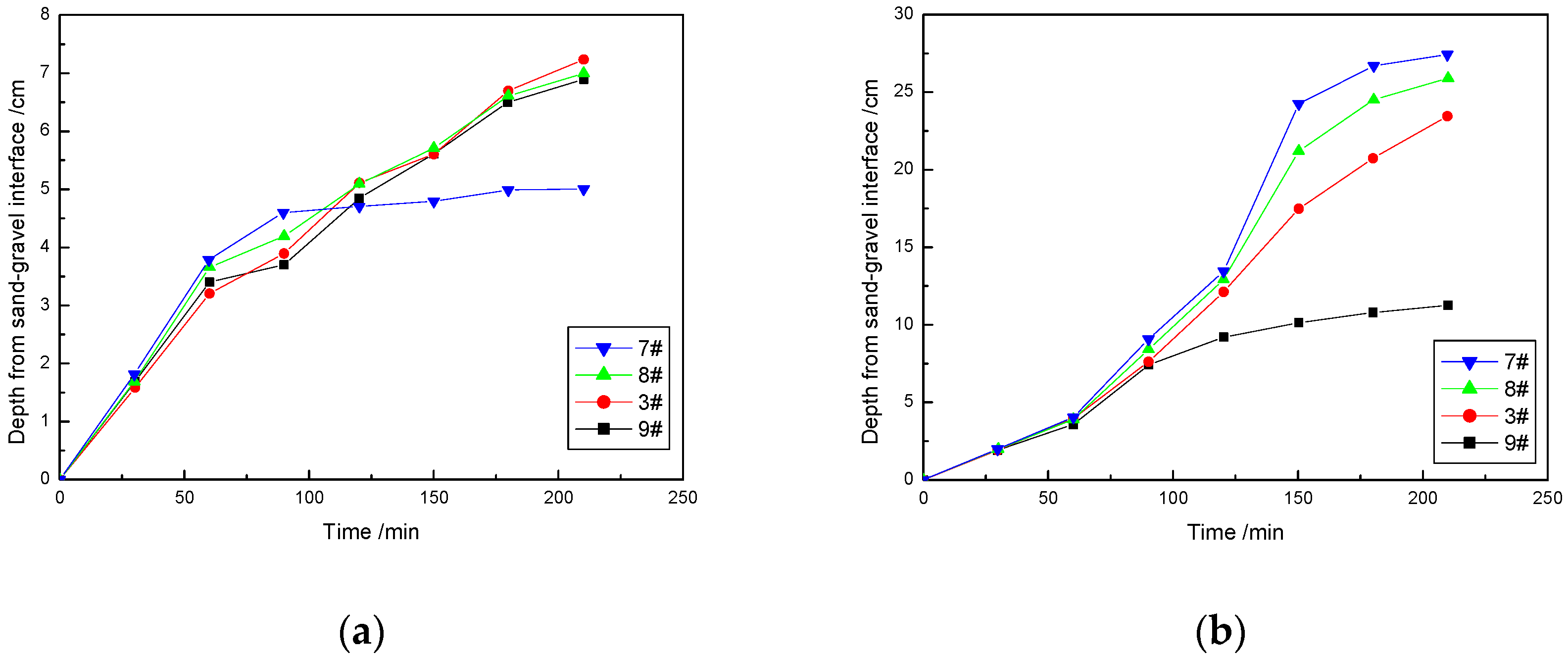

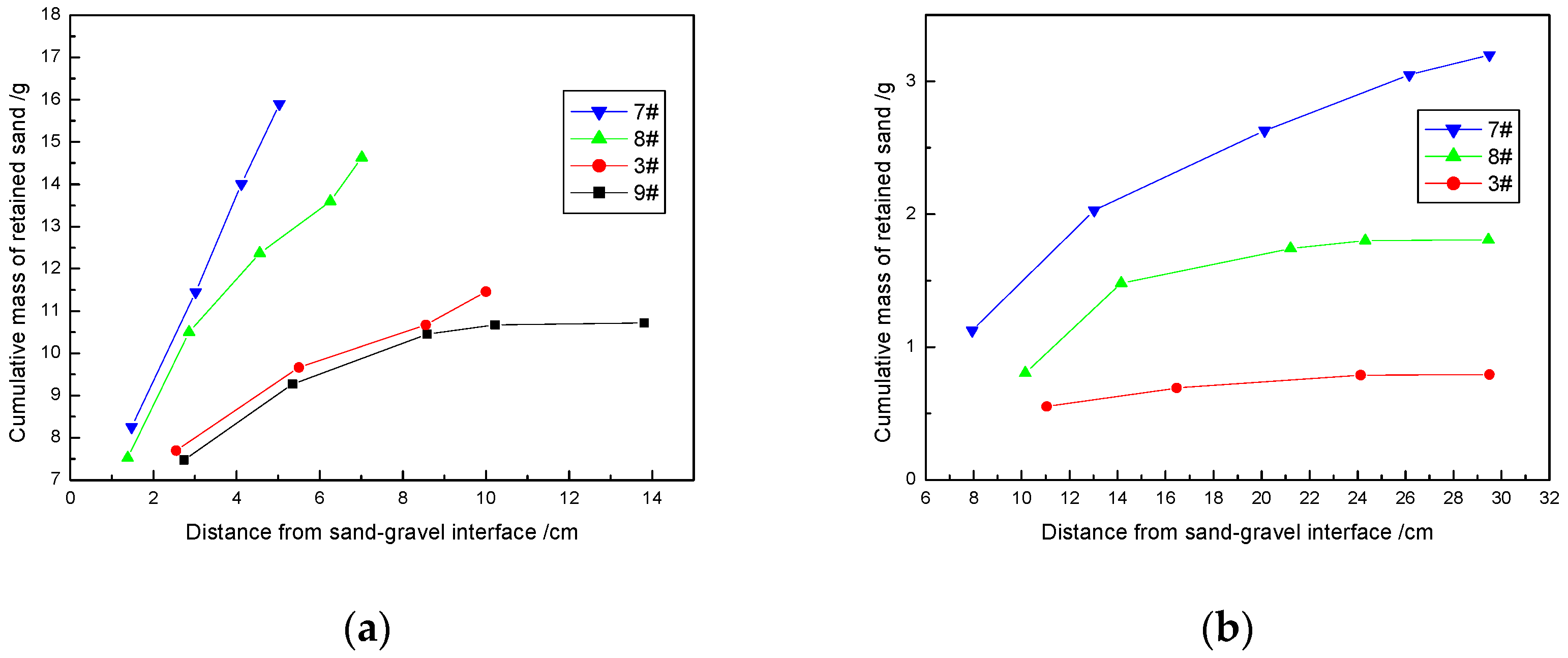

3.3. Two-Stage Gravel Packing Length

4. Conclusions

- (1)

- The pore filling depth could be shorter in the cases where grain ratio of gravel bed I to sand was less than five. The reason is that the sand bridge formed in the pore space of the gravel pack could restrain further particle penetration.

- (2)

- The grain size of gravel bed II had little influence on the length of the pore filling zone and the amount of retained particles in gravel beds I and II. It mainly affected the amount of retained sand at the two-stage interface and the particle penetration depth.

- (3)

- After completion of pore filling in gravel bed I in cases with packing lengths of 5 cm and 7 cm, no pore filling phenomenon occurred in gravel bed II. However, a large amount of sand settlement formed at the two-stage interface.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, Y.; Deng, J.; Zhao, W. Research on solutions of the influences of high pressure repeating packing sand control on productivity. Pet. Sci. Technol. 2013, 31, 88–93. [Google Scholar] [CrossRef]

- Deng, F.; Feng, Y.; Yan, C.; Lin, H.; Gong, N.; Wang, J. Experimental investigation of factors affecting gravel pack efficiency for thermal recovery wells in Bohai Bay, China. J. Pet. Sci. Eng. 2017, 156, 835–844. [Google Scholar] [CrossRef]

- Mirshekari, B.; Dadvar, M.; Modares, H.; Dabir, B. Modelling and simulation of gravel-pack damage due to particle transport by single phase flow in cased hole completion. Int. J. Oil Gas Coal Technol. 2014, 7, 152–168. [Google Scholar] [CrossRef]

- Sparlin, D.D. Sand and Gravel—A Study of Their Permeabilities. In Proceedings of the SPE Symposium on Formation Damage Control, New Orleans, LA, USA, 30 January–2 February 1974. [Google Scholar] [CrossRef]

- Li, Y.; Liu, L.; Sun, J.; Ye, Y.; Chen, Q. Sanding prediction and sand-control technology in hydrate exploitation: A review and discussion. Mar. Geol. Front. 2016, 32, 36–43. [Google Scholar]

- Deng, J.; Tan, Q.; Sun, Y.; Chen, Y.; Duan, Z.; Wei, L.; Wang, E. Influence of high pressure pack repeat sand control on productivity and solution. Fault Block Oil Gas Field 2010, 17, 494–496. [Google Scholar]

- Chen, Y.; Deng, J.; Zhao, W. Research of gravel size optimization in sand control with variable particle diameter packing. J. Oil Gas Technol. 2010, 6, 319–321. [Google Scholar]

- Bouhroum, A.; Civan, F. A Study of particulates migration in gravel pack. In Proceedings of the SPE Formation Damage Control Symposium, Lafayette, LA, USA, 7–10 February 1994. [Google Scholar]

- Bigno, Y.; Oyeneyin, M.B.; Peden, J.M. Investigation of pore-blocking mechanism in gravel packs in the management and control of fines migration. In Proceedings of the SPE Formation Damage Control Symposium, Lafayette, LA, USA, 7–10 February 1994. [Google Scholar]

- Ali, M.A.J.; Currie, P.K.; Salman, M.J. Measurement of the particle deposition profile in deep-bed filtration during produced water re-injection. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Kingdom of Bahrain, 12–15 March 2015. [Google Scholar]

- Shirinabadi, R.; Moarefvaand, P.; Goshtasbi, K.; Ahangari, K. The physical and numerical modeling of sand production and gravel pack in oil wells by designing and manufacturing the machine and presenting a relation estimating sand production rate. J. Min. Sci. 2016, 52, 300–312. [Google Scholar] [CrossRef]

- Villarroel, F.M.G.; Vargas, E.A.J.; Bloch, M. Experimental analysis of gravel pack mesh size effect on the screen deformation under high in situ stress contrast. J. Am. Chem. Soc. 2010, 95, 4634–4639. [Google Scholar]

- Lawal, K.A.; Vesovic, V.; Boek, E.S. Modeling permeability impairment in porous media due to asphaltene deposition under dynamic conditions. Energy Fuels 2011, 25, 5647–5659. [Google Scholar] [CrossRef]

- Gravelle, A.; Peysson, Y.; Tabary, R.; Egermann, P. Controlled release of colloidal particles and remediation: Experimental investigation and modelling. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 11–13 April 2011. [Google Scholar]

- Li, Y.; Li, M.; Wang, L.; Meng, W. A Productivity Prediction Model for the Gravel-packed Horizontal Well. Liq. Fuels Technol. 2013, 31, 633–642. [Google Scholar] [CrossRef]

- Li, Y.; Qin, G.; Li, M.; Wang, W. Numerical simulation study on gravel-packing layer damage by integration of innovative experimental observations. In Proceedings of the SPE Heavy Oil Conference Canada, Calgary, AB, Canada, 12–14 June 2012. [Google Scholar]

- Civan, F. Reservoir formation damage: Fundamentals, modeling, assessment, and mitigation. Herd Health Environ. Res. Des. J. 2000, 7, 60–77. [Google Scholar]

- Keller, A.A.; Auset, M. A review of visualization techniques of biocolloid transport processes at the pore scale under saturated and unsaturated conditions. Adv. Water Resour. 2007, 30, 1392–1407. [Google Scholar] [CrossRef]

- Jacobsen, O.H.; Moldrup, P.; Larsen, C.; Petersen, L.W. Particle transport in macropores of undisturbed soil columns. J. Hydrol. 1997, 196, 185–203. [Google Scholar] [CrossRef]

- Benamar, A.; Ahfir, N.D.; Wang, H.Q.; Alem, A. Particle transport in a saturated porous medium: Pore structure effects. Comptes Rendus Géosci. 2007, 339, 674–681. [Google Scholar] [CrossRef]

- Moghadasi, J.; Müller-Steinhagen, H.; Jamialahmadi, M.; Sharif, A. Theoretical and experimental study of particle movement and deposition in porous media during water injection. J. Pet. Sci. Eng. 2004, 43, 163–181. [Google Scholar] [CrossRef]

- Rolle, M.; Hochstetler, D.; Chiogna, G.; Kitanidis, P.K.; Grathwohl, P. Experimental Investigation and Pore-Scale Modeling Interpretation of Compound-Specific Transverse Dispersion in Porous Media. Transp. Porous Media 2012, 93, 347–362. [Google Scholar] [CrossRef]

- Parker, S.E.; Lee, W.W. A fully nonlinear characteristic method for gyrokinetic simulation. Phys. Fluids B Plasma Phys. 1993, 5, 77–86. [Google Scholar] [CrossRef]

- Shin, C. Numerical simulation for particle penetration depth distribution in deep bed filtration. Chem. Eng. Technol. 2006, 29, 905–909. [Google Scholar] [CrossRef]

- Ma, S.; Dong, M.; Li, Z.; Shirif, E. Evaluation of the effectiveness of chemical flooding using heterogeneous sandpack flood test. J. Pet. Sci. Eng. 2007, 55, 294–300. [Google Scholar] [CrossRef]

- Liu, Q.; Cui, X.; Zhang, C.; Huang, S. Experimental investigation of suspended particles transport through porous media: Particle and grain size effect. Environ. Technol. Lett. 2016, 37, 11. [Google Scholar] [CrossRef]

- Bedrikovetsky, P.; Marchesin, D.; Shecaira, F.; Souza, A.L.; Milanez, P.V.; Rezende, E. Characterisation of deep bed filtration system from laboratory pressure drop measurements. J. Pet. Sci. Eng. 2001, 32, 167–177. [Google Scholar] [CrossRef]

- Bedrikovetsky, P. Upscaling of stochastic micro model for suspension transport in porous media. Transp. Porous Media 2008, 75, 335–369. [Google Scholar] [CrossRef]

- Kim, Y.S.; Whittle, A.J. Filtration in a porous granular medium: 1. simulation of pore-scale particle deposition and clogging. Transp. Porous Media 2006, 65, 53–87. [Google Scholar] [CrossRef]

- Guedes, R.G.; Al-Abduwani, F.A.H.; Bedrikovetsky, P.; Currie, P.K. Deep-bed filtration under multiple particle-capture mechanisms. SPE J. 2009, 14, 477–487. [Google Scholar] [CrossRef]

- Araújo, J.A.; Santos, A. Analytic model for DBF under multiple particle retention mechanisms. Transp. Porous Media 2013, 97, 135–145. [Google Scholar] [CrossRef]

- Kuhnen, F.; Barmettler, K.; Bhattacharjee, S.; Elimelech, M.; Kretzschmar, R. Transport of iron oxide colloids in packed quartz sand media: Monolayer and multilayer deposition. J. Colloid Interface Sci. 2000, 231, 32–41. [Google Scholar] [CrossRef]

- Carlson, D.R.; Widnall, S.E.; Peeters, M.F. A flow-visualization study of transition in plane Poiseuille flow. J. Fluid Mech. 1982, 121, 487–505. [Google Scholar] [CrossRef]

- Zamani, A.; Maini, B. Flow of dispersed particles through porous media—Deep bed filtration. J. Pet. Sci. Eng. 2009, 69, 71–88. [Google Scholar] [CrossRef]

- Saucier, R.J. Considerations in gravel pack design. J. Pet. Technol. 1974, 26, 205–212. [Google Scholar] [CrossRef]

| Group Number | Sand Median Grain size (mm) | Gravel Bed I Grain Size (mm) | Gravel Bed II Grain Size (mm) | Displacement Rate (mL/min) | Packing Length (I)/cm | Packing Length (II)/cm |

|---|---|---|---|---|---|---|

| 1# | 0.85 | 3.5 | 7 | 200 | 10 | 20 |

| 2# | 0.85 | 4 | 7 | 200 | 10 | 20 |

| 3# | 0.85 | 4.5 | 7 | 200 | 10 | 20 |

| 4# | 0.85 | 5 | 7 | 200 | 10 | 20 |

| 5# | 0.85 | 4.5 | 6 | 200 | 10 | 20 |

| 6# | 0.85 | 4.5 | 8 | 200 | 10 | 20 |

| 7# | 0.85 | 4.5 | 7 | 200 | 5 | 25 |

| 8# | 0.85 | 4.5 | 7 | 200 | 7 | 23 |

| 9# | 0.85 | 4.5 | 7 | 200 | 15 | 15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, X.; Qi, M.; Meng, Z.; Li, T.; Niu, Z. Visual Experimental Study on Gradation Optimization of Two-Stage Gravel Packing Operation in Unconventional Reservoirs. Energies 2019, 12, 1519. https://doi.org/10.3390/en12081519

Meng X, Qi M, Meng Z, Li T, Niu Z. Visual Experimental Study on Gradation Optimization of Two-Stage Gravel Packing Operation in Unconventional Reservoirs. Energies. 2019; 12(8):1519. https://doi.org/10.3390/en12081519

Chicago/Turabian StyleMeng, Xingbang, Minhui Qi, Zhan Meng, Tong Li, and Zhongxiao Niu. 2019. "Visual Experimental Study on Gradation Optimization of Two-Stage Gravel Packing Operation in Unconventional Reservoirs" Energies 12, no. 8: 1519. https://doi.org/10.3390/en12081519

APA StyleMeng, X., Qi, M., Meng, Z., Li, T., & Niu, Z. (2019). Visual Experimental Study on Gradation Optimization of Two-Stage Gravel Packing Operation in Unconventional Reservoirs. Energies, 12(8), 1519. https://doi.org/10.3390/en12081519