Realization Energy Optimization of Complete Path Planning in Differential Drive Based Self-Reconfigurable Floor Cleaning Robot

Abstract

1. Introduction

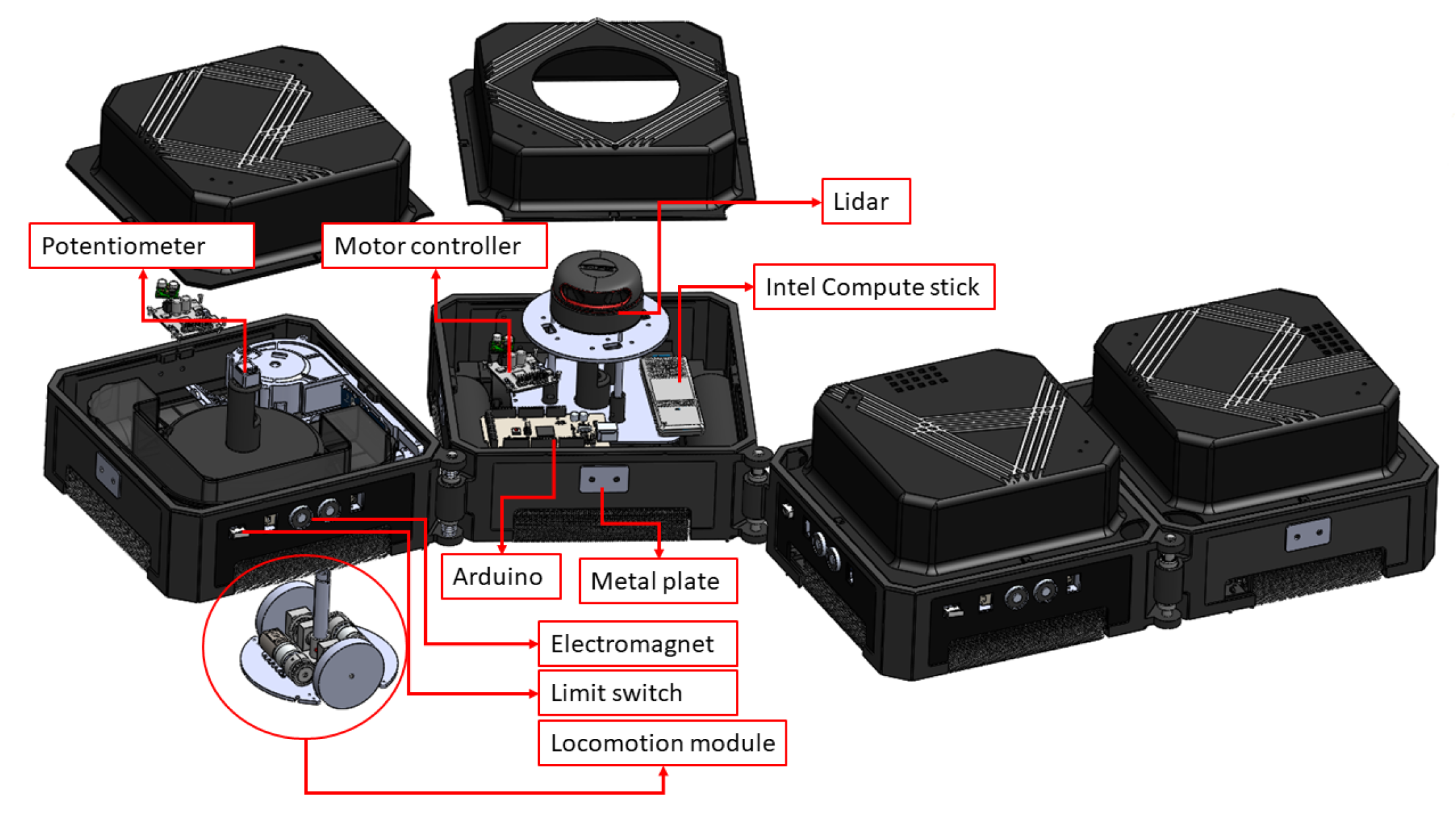

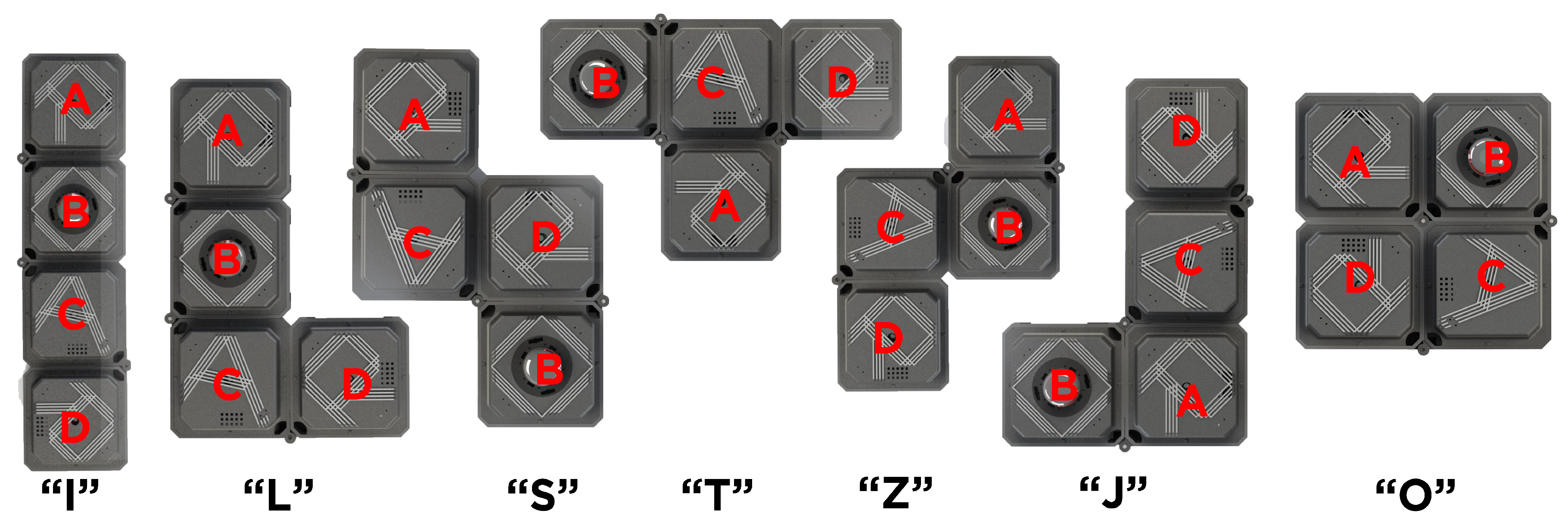

2. hTetro-Reconfigurable Floor Cleaning Robot

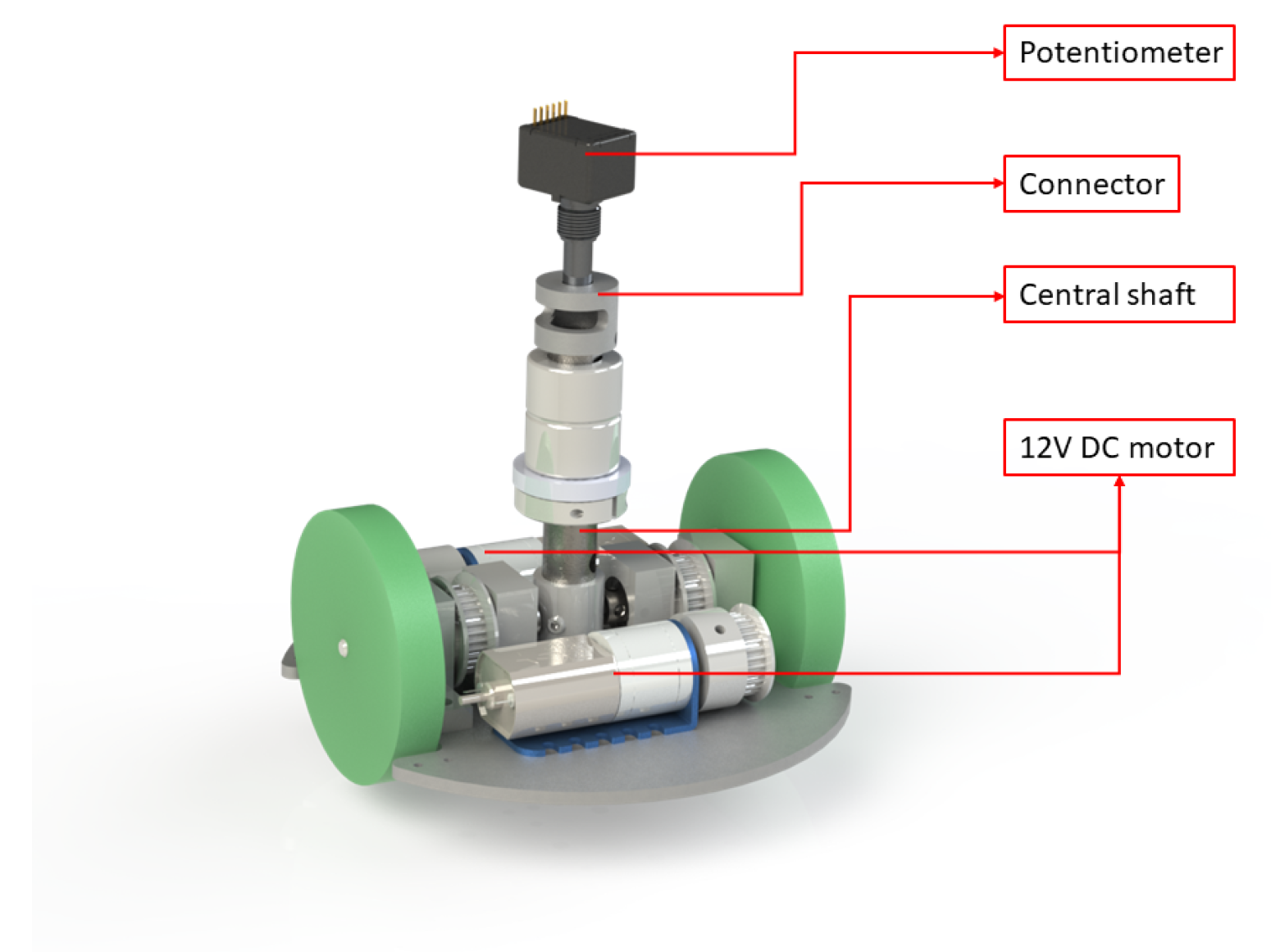

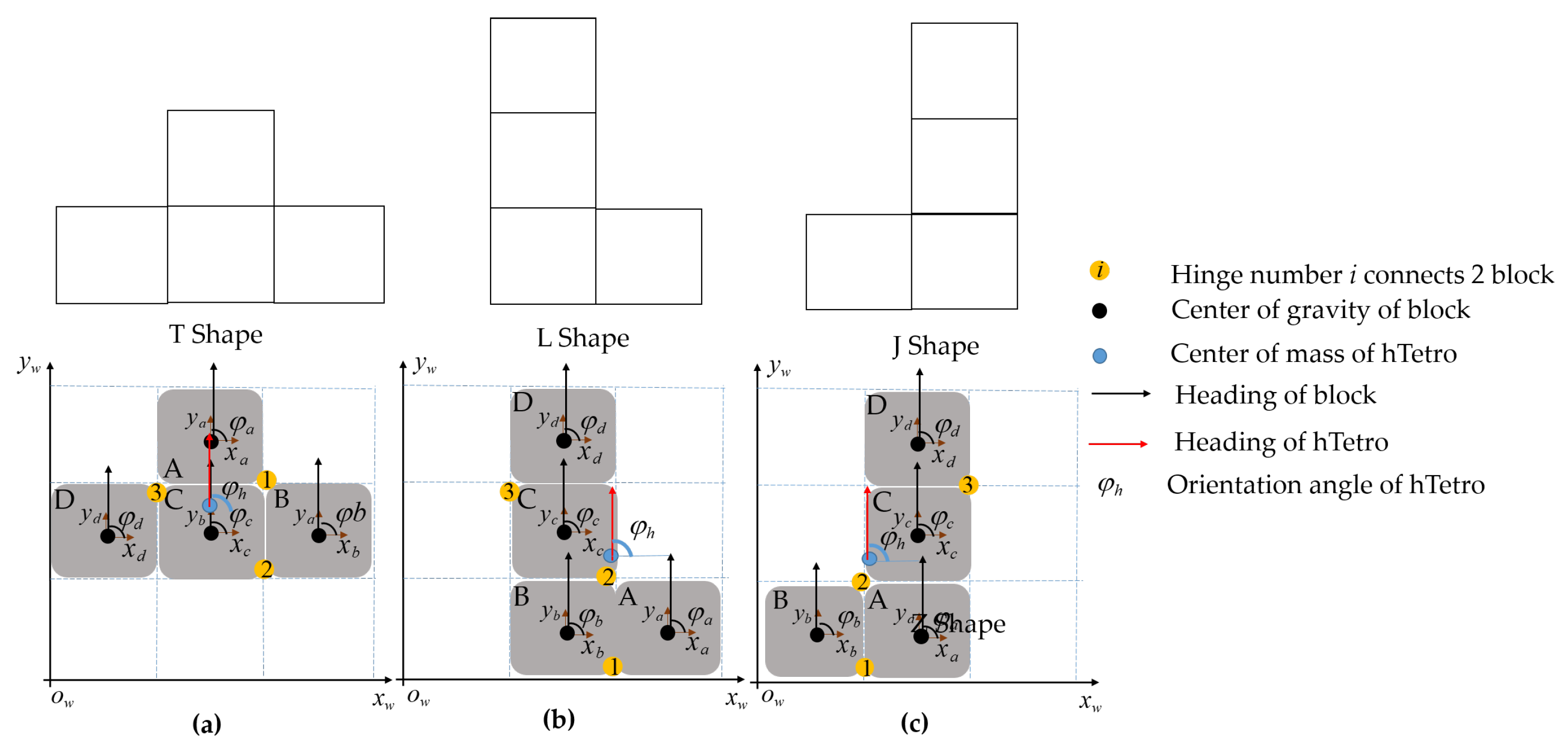

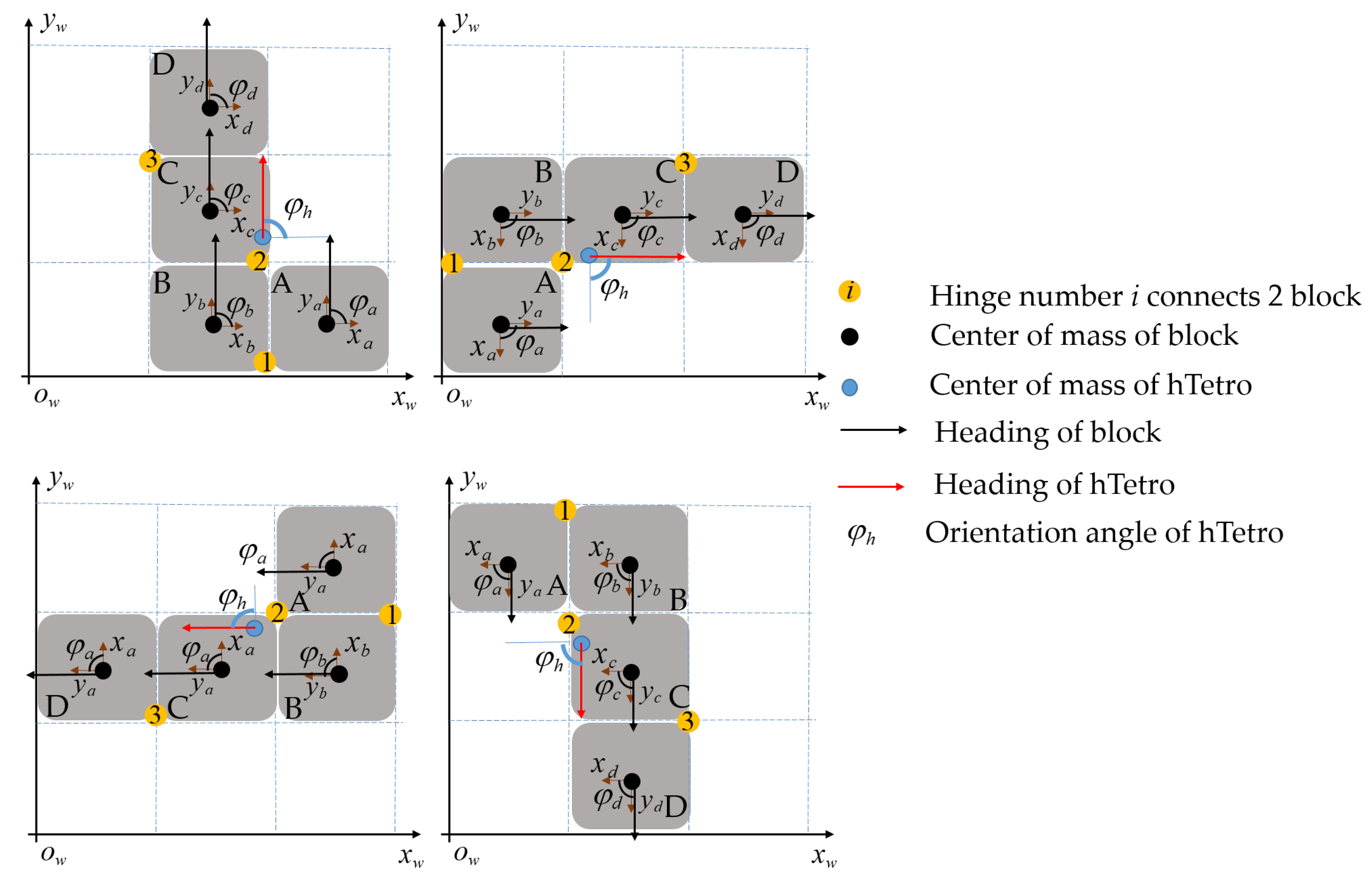

2.1. hTetro Kinematic Design with Differential Drive Mechanism

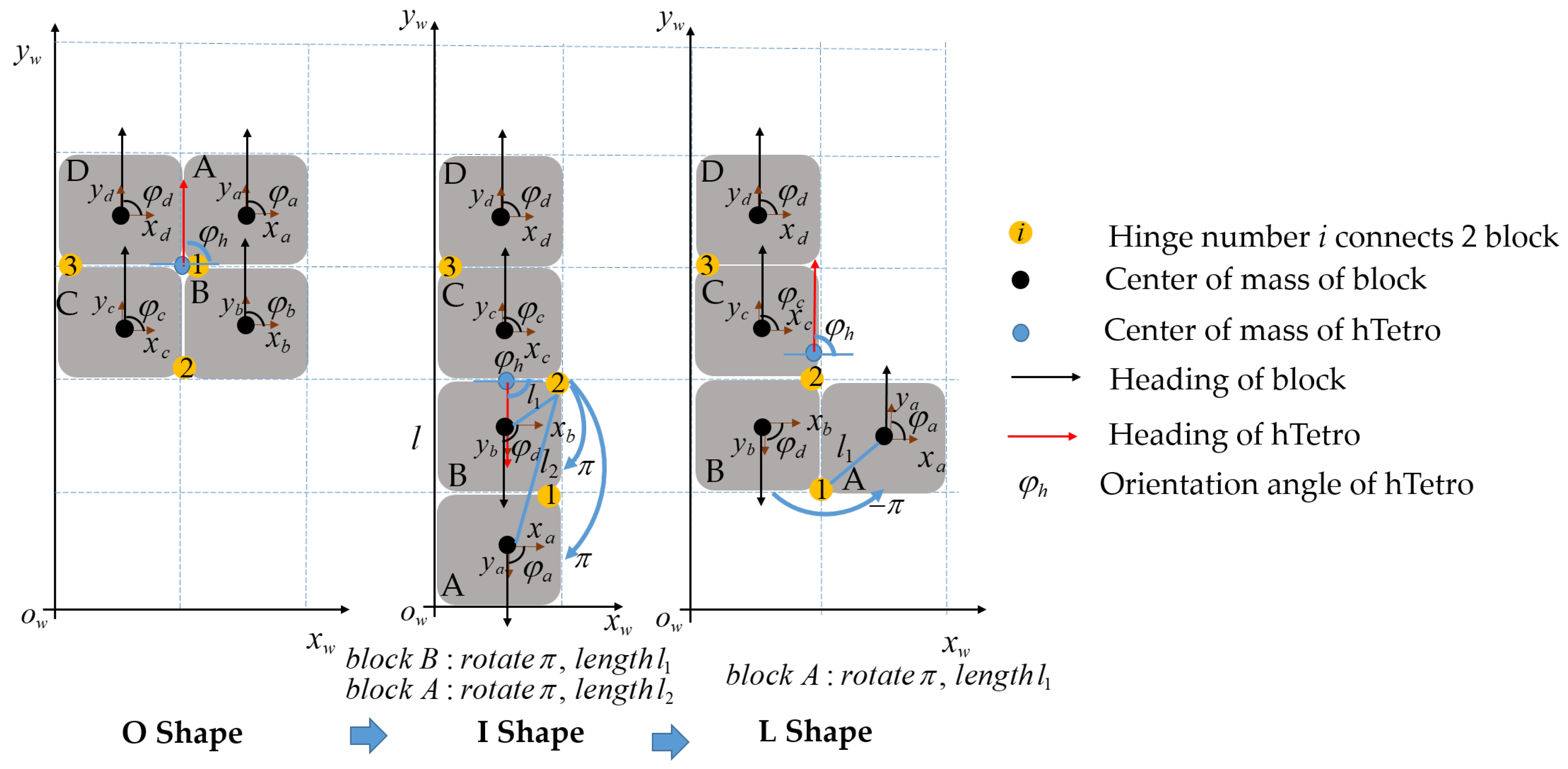

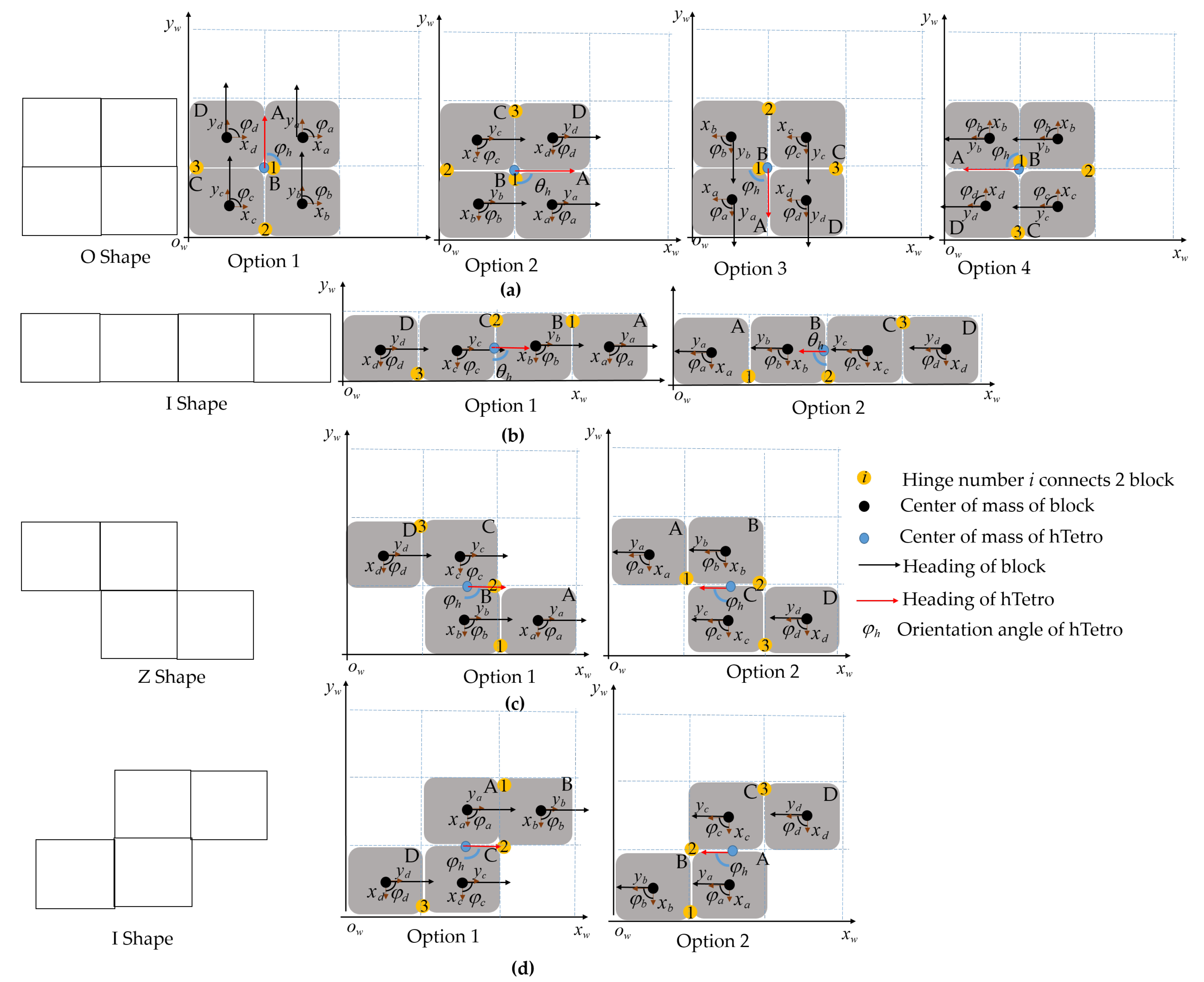

2.2. Representation of hTetro in a Workspace

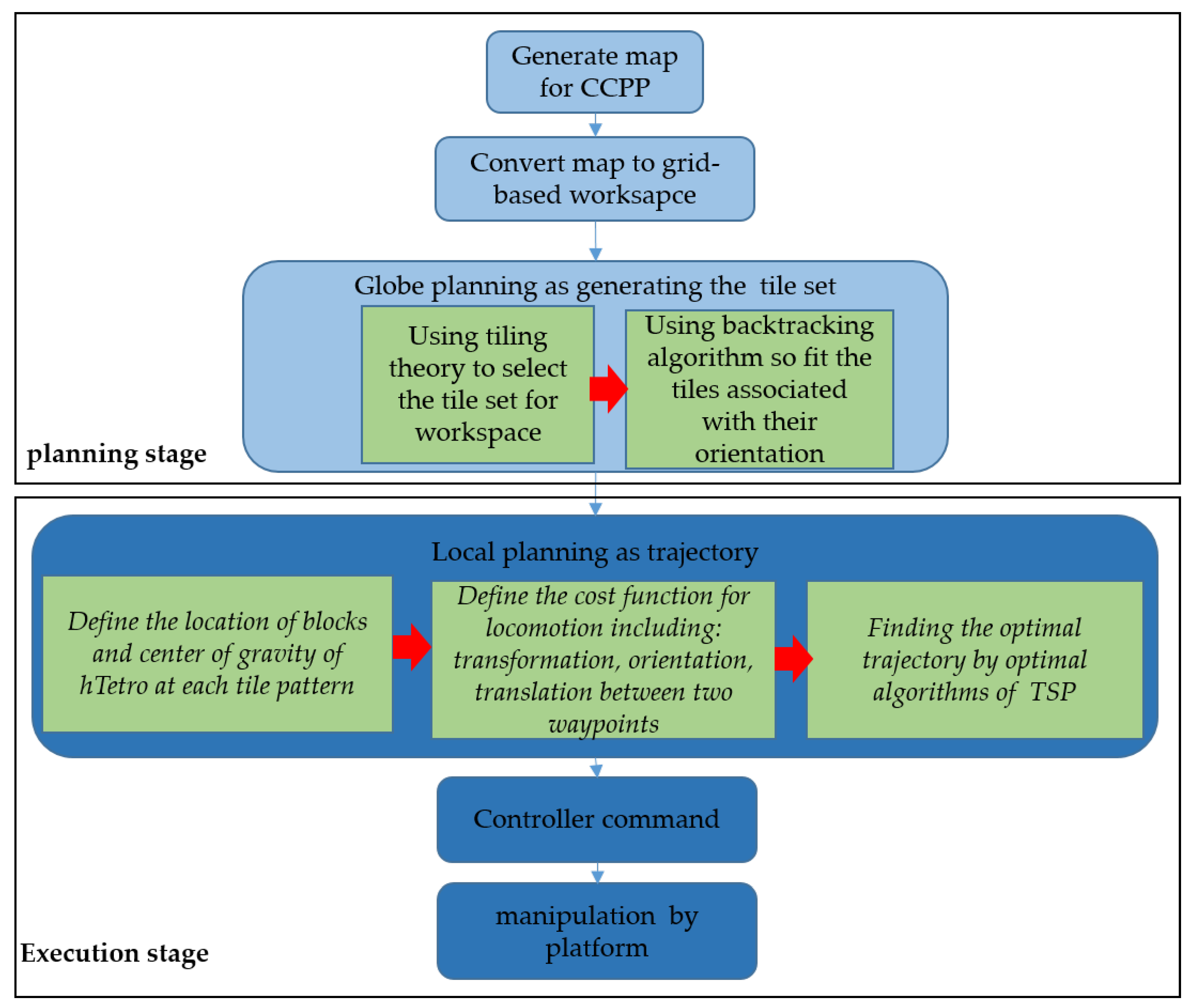

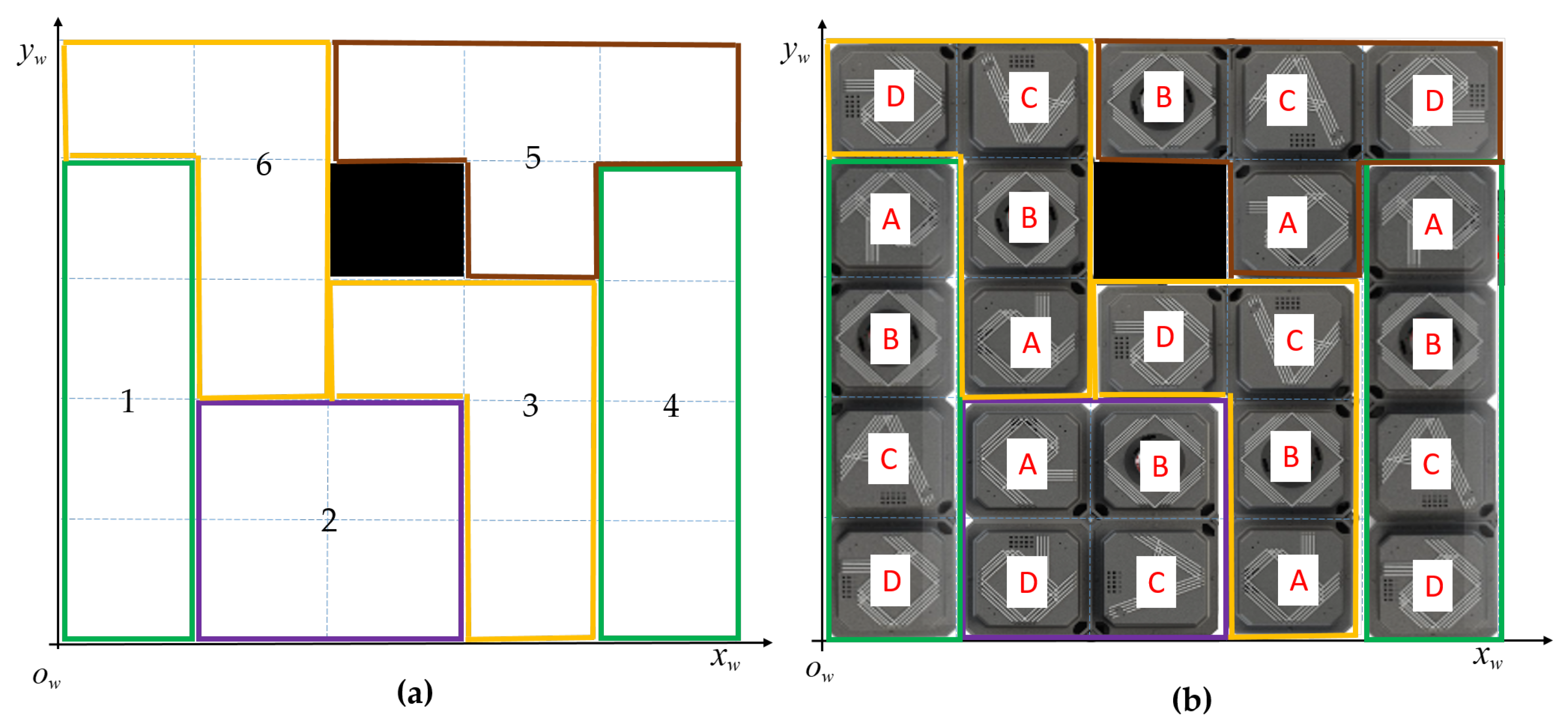

3. CCPP Framework for hTetro by Tilling Theory

3.1. Localization of hTetro Blocks for Tileset of Workspace

| Algorithm 1: Finding optimal blocks location for tileset. |

| 1 Function LOCATIONS OF BLOCKS ASSIGNMENT{workspace, tiling set}: 2 workspace{} 3 i ←1, j ←1, t ←1 4 for all i, i ←1, do 5 for all j, j ←1, do 6 if is COM of tiling pattern t then 7 if tiling pattern t is asymmetrical shape then 8 Assign: blocks locations of t according Figure 8 9 else if t is symmetrical shape then 10 Do: transformation from tile to tile t (note that orientation of hTetro is defined by Figure 4) 11 Find: tiling pattern blocks as in Figure 10 which yields the similar location in orientation with the orientation after transformation (note that orientation of hTetro is defined by Table 4) 12 Assign: blocks locations of t according Figure 9 13 end 14 end 15 end End Function |

3.2. Local Navigation Weight Function

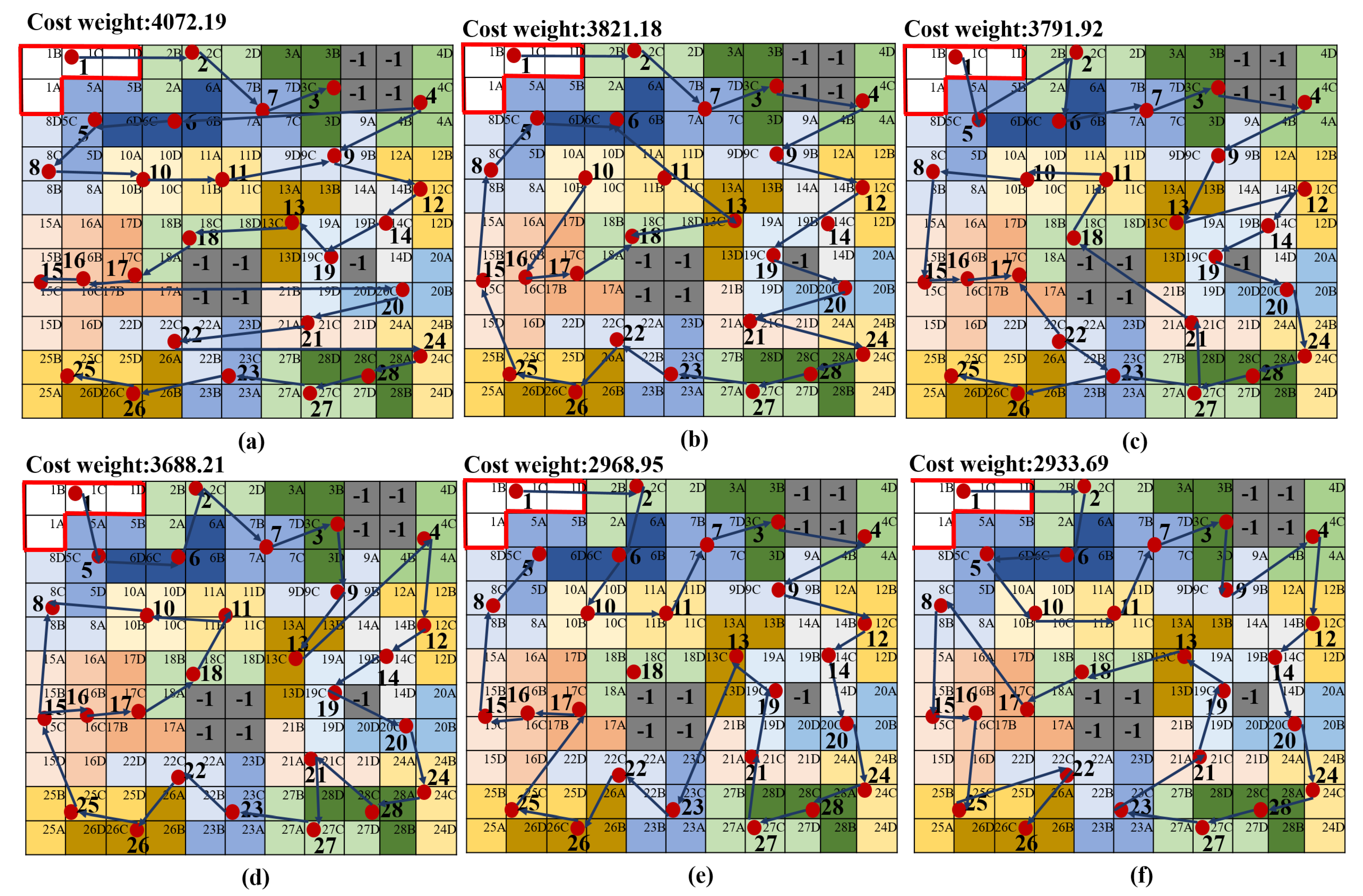

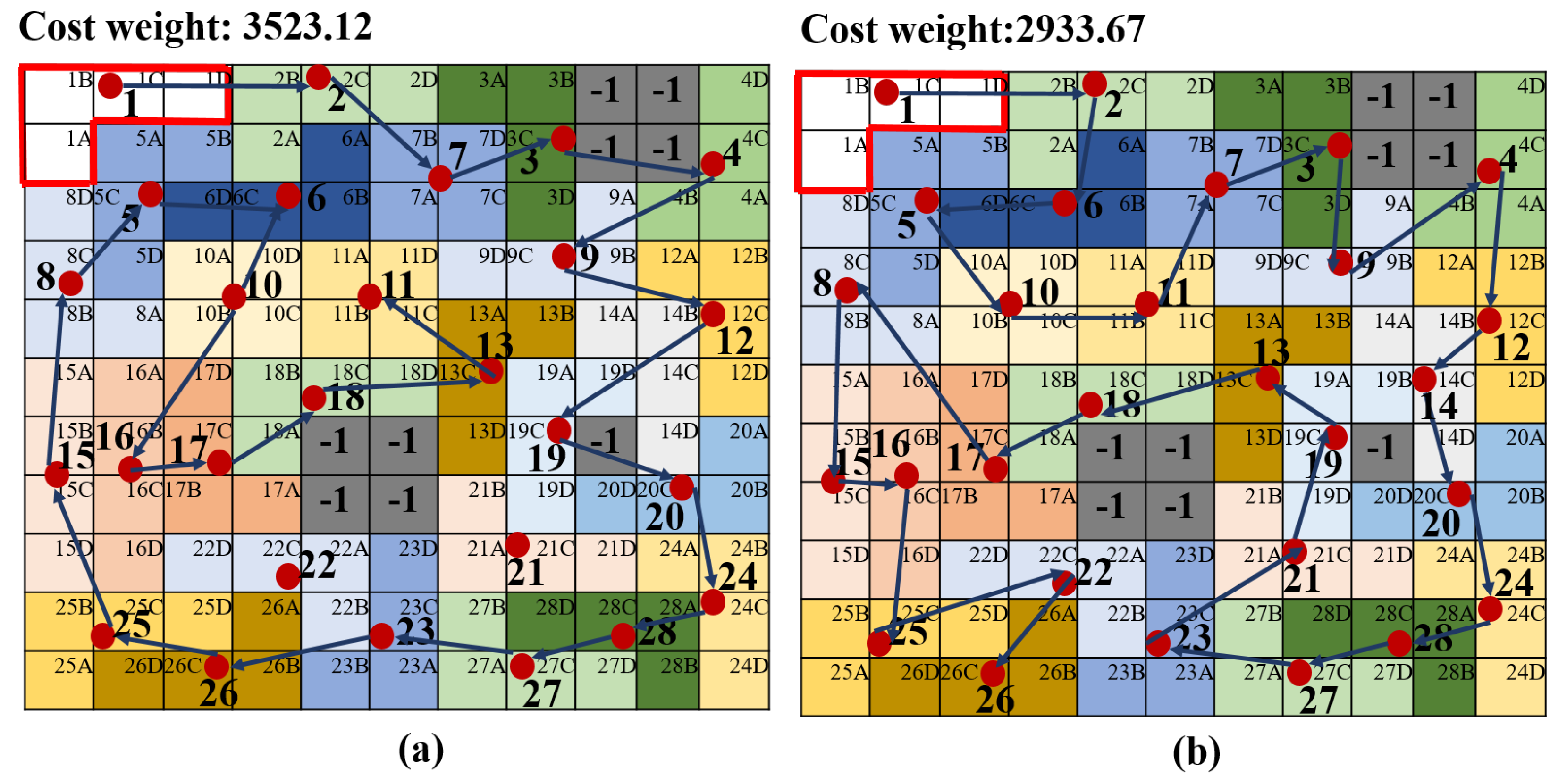

3.3. Optimization of Trajectory

4. Experimental Results

4.1. Simulation Environment

4.2. Real Environment Testbed

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Richter, F. Infographic: Let the Robot Do the Cleaning; Statista: Hamburg, Germany, 2017. [Google Scholar]

- Cleaning Robot Market by Type, Product (Floor-Cleaning Robot, Lawn-Cleaning Robot, Pool-Cleaning Robot, Window-Cleaning Robot), Application (Residential, Commercial, Industrial, Healthcare), and Geography—Global Forecast to 2023. 2018. Available online: https://www.marketsandmarkets.com/Market-Reports/cleaning-robot-market-22726569.html (accessed on 3 March 2019).

- Joseph, L.J.; Newton, E.M.; David, M.N.; Paul, E.S. Autonomous Floor Cleaning Robot. U.S. Patent 7,448,113, 11 November 2008. [Google Scholar]

- Yuan, X.; Zhao, C.X.; Tang, Z.M. Lidar scan-matching for mobile robot localization. Inf. Technol. J. 2010, 9, 27–33. [Google Scholar] [CrossRef]

- Hasan, K.M.; Reza, K.J. Path planning algorithm development for autonomous vacuum cleaner robots. In Proceedings of the IEEE 2014 International Conference on Informatics, Electronics & Vision (ICIEV), Dhaka, Bangladesh, 23–24 May 2014; pp. 1–6. [Google Scholar]

- Gao, X.; Li, K.; Wang, Y.; Men, G.; Zhou, D.; Kikuchi, K. A floor cleaning robot using Swedish wheels. In Proceedings of the IEEE International Conference on Robotics and Biomimetics, ROBIO 2007, Sanya, China, 15–18 December 2007; pp. 2069–2073. [Google Scholar]

- Fink, J.; Bauwens, V.; Kaplan, F.; Dillenbourg, P. Living with a vacuum cleaning robot. Int. J. Soc. Robot. 2013, 5, 389–408. [Google Scholar] [CrossRef]

- Galceran, E.; Carreras, M. A survey on coverage path planning for robotics. Robo. Auton. Syst. 2013, 61, 1258–1276. [Google Scholar] [CrossRef]

- Choset, H.; Pignon, P. Coverage path planning: The boustrophedon cellular decomposition. In Proceedings of the International Conference on Field and Service Robotics, Leuven, Belgium, 16–20 May 1998; Springer: London, UK, 1998; pp. 203–209. [Google Scholar]

- Acar, E.U.; Choset, H.; Rizzi, A.A.; Atkar, P.N.; Hull, D. Morse decompositions for coverage tasks. Int. J. Robot. Res. 2002, 21, 331–344. [Google Scholar] [CrossRef]

- Wang, L.; Gao, H.; Cai, Z. Topological mapping and navigation for mobile robots with landmark evaluation. In Proceedings of the 2009 International Conference on Information Engineering and Computer Science, Wuhan, China, 19–20 December 2009; IEEE: Piscataway, NJ, USA, 2009. [Google Scholar] [CrossRef]

- Xu, L. Graph Planning for Environmental Coverage. Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, USA, 2011; p. 135. [Google Scholar]

- Jin, J.; Tang, L. Coverage path planning on three-dimensional terrain for arable farming. J. Field Robot. 2011, 28, 424–440. [Google Scholar] [CrossRef]

- Cheng, P.; Keller, J.; Kumar, V. Time-optimal UAV trajectory planning for 3D urban structure coverage. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems (IROS 2008), Nice, France, 22–26 September 2008; pp. 2750–2757. [Google Scholar]

- Choset, H. Coverage for robotics—A survey of recent results. Annals Math. Artif. Intell. 2001, 31, 113–126. [Google Scholar] [CrossRef]

- Lumelsky, V.J.; Mukhopadhyay, S.; Sun, K. Dynamic path planning in sensor-based terrain acquisition. IEEE Trans. Robot. Autom. 1990, 6, 462–472. [Google Scholar] [CrossRef]

- Zelinsky, A.; Jarvis, R.A.; Byrne, J.; Yuta, S. Planning paths of complete coverage of an unstructured environment by a mobile robot. Proceedings of International Conference on Advanced Robotics, Tokyo, Japan, 8–9 November 1993; Volume 13, pp. 533–538. [Google Scholar]

- Luo, C.; Yang, S.X. A real-time cooperative sweeping strategy for multiple cleaning robots. In Proceedings of the 2002 IEEE International Symposium on Intelligent Control, Vancouver, BC, Canada, 27–30 October 2002; pp. 660–665. [Google Scholar]

- Gabriely, Y.; Rimon, E. Spiral-stc: An on-line coverage algorithm of grid environments by a mobile robot. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA 2002), Washington, DC, USA, 11–15 May 2002; Volume 1, pp. 954–960. [Google Scholar]

- Yang, S.X.; Luo, C. A neural network approach to complete coverage path planning. IEEE Trans. Syst. Man Cybern. Part B 2004, 34, 718–724. [Google Scholar] [CrossRef]

- Veerajagadheswar, P.; Mohan, E.R.; Pathmakumar, T.; Ayyalusami, V. A tiling-theoretic approach to efficient area coverage in a tetris-inspired floor cleaning robot. IEEE Access 2018, 6, 35260–35271. [Google Scholar] [CrossRef]

- Le, A.; Arunmozhi, M.; Veerajagadheswar, P.; Ku, P.C.; Minh, T.H.; Sivanantham, V.; Mohan, R. Complete path planning for a tetris-inspired self-reconfigurable robot by the genetic algorithm of the traveling salesman problem. Electronics 2018, 7, 344. [Google Scholar] [CrossRef]

- Arkin, E.M.; Fekete, S.P.; Mitchell, J.S. Approximation algorithms for lawn mowing and milling. Comput. Geom. 2000, 17, 25–50. [Google Scholar] [CrossRef]

- Geng, X.; Chen, Z.; Yang, W.; Shi, D.; Zhao, K. Solving the traveling salesman problem based on an adaptive simulated annealing algorithm with greedy search. Appl. Soft Comput. 2011, 11, 3680–3689. [Google Scholar] [CrossRef]

- Larranaga, P.; Kuijpers, C.M.H.; Murga, R.H.; Inza, I.; Dizdarevic, S. Genetic algorithms for the travelling salesman problem: A review of representations and operators. Artif. Intell. Rev. 1999, 13, 129–170. [Google Scholar] [CrossRef]

- Dorigo, M.; Di Caro, G. Ant colony optimization: A new meta-heuristic. In Proceedings of the IEEE 1999 Congress on Evolutionary Computation, CEC 1999, Washington, DC, USA, 6–9 July 1999; Volume 2, pp. 1470–1477. [Google Scholar]

- Thomas, B. Evolutionary Algorithms in Theory and Practice: Evolution Strategies, Evolutionary Programming, Genetic Algorithms; Oxford University Press: Oxford, UK, 1996. [Google Scholar]

- Le, A.; Veerajagadheswar, P.; Sivanantham, V.; Mohan, R. Modified a-star algorithm for efficient coverage path planning in tetris inspired self-reconfigurable robot with integrated laser sensor. Sensors 2018, 18, 2585. [Google Scholar] [CrossRef] [PubMed]

- Conway, J.H.; Lagarias, J.C. Tiling with polyominoes and combinatorial group theory. J. Comb. Theory Ser. A 1990, 53, 183–208. [Google Scholar] [CrossRef]

- A Polyomino Tiling Algorithm. 2018. Available online: https://gfredericks.com/gfrlog/99 (accessed on 3 March 2019).

- Held, M.; Karp, R.M. A dynamic programming approach to sequencing problems. J. Soc. Ind. Appl. Math. 1962, 10, 196–210. [Google Scholar] [CrossRef]

| Terms | Meaning |

|---|---|

| Mass of the module i where | |

| Center of mass of module i where at waypoint s | |

| Center of the mass of the robot at waypoint s | |

| Center of the mass of the robot at waypoint s after transformation | |

| Center of the mass of the robot at next destination waypoint d | |

| Function to calculate the total distance translated by all modules towards the desired target location | |

| The required angle to perform the transformation by module i where | |

| Turning radius for the module in Single Module Locomotion (SML) | |

| Turning radius for the outermost module in Double Module Locomotion (DML) | |

| Function to calculate the total distance travelled by all module to perform transformation | |

| Magnitude of the distance between center of the mass of each module and that of the robot where at waypoint s | |

| Desired orientation of the robot at waypoint d with respect to the global frame | |

| Current orientation of the robot at waypoint s with respect to the global frame | |

| Orientation offset of the robot after tramsfomation from waypoint s to waypoint d as in Table 4 | |

| Function to calculate the total distance travelled by all modules towards the desired orientation | |

| Total travelled distance for a pair n by the robot from one source waypoint to next destination waypoint performing transformation, translation, orientation correction |

| O Shape A B C D | I Shape A B C D | L Shape A B C D | Z Shape A B C D | T Shape A B C D | J Shape A B C D | S Shape A B C D | ||

|---|---|---|---|---|---|---|---|---|

| O Shape | 0 0 0 0 | 0 0 | (,) 0 0 | 0 (,) | 0 0 | (,) 0 | (,) 0 0 | |

| I Shape | 0 0 | 0 0 0 0 | 0 0 0 | 0 0 | 0 (,) | (,) 0 | (,) 0 0 | |

| L Shape | (,) 0 0 | 0 0 0 | 0 0 0 0 | 0 0 0 | 0 ( ) | 0 0 0 | 0 0 | |

| Z Shape | 0 (,) | 0 0 | 0 0 0 | 0 0 0 0 | 0 | 0 0 | 0 | |

| T Shape | 0 0 | 0 ( ) | 0 | 0 | 0 0 0 0 | 0 | (, ) 0 | |

| J Shape | (,) 0 | (,) 0 | 0 0 0 | 0 0 | 0 | 0 0 0 0 | 0 0 0 | |

| S Shape | (,) 0 0 | (,) 0 0 | 0 0 | 0 | 0 (,) | 0 0 0 | 0 0 0 0 | |

| O Shape A B C D | I Shape A B C D | L Shape A B C D | Z Shape A B C D | T Shape A B C D | J Shape A B C D | S Shape A B C D | ||

|---|---|---|---|---|---|---|---|---|

| O Shape | 0 0 0 0 | 0 0 | (,) 0 0 | 0 (,) | 0 0 | (,) 0 | (,) 0 0 | |

| I Shape | 0 0 | 0 0 0 0 | 0 0 0 | 0 0 | 0 (,) | (,) 0 | (,) 0 0 | |

| L Shape | (,) 0 0 | 0 0 0 | 0 0 0 0 | 0 0 0 | 0 | 0 | 0 (,) | |

| Z shape | 0 (,) | 0 0 | 0 0 0 | 0 0 0 0 | 0 | 0 0 | 0 | |

| T Shape | 0 0 | 0 (,) | 0 | (,) 0 | 0 0 0 0 | 0 | 0 (,) | |

| J Shape | (,) 0 | (,) 0 | 0 | 0 0 | 0 | 0 0 0 0 | 0 0 0 | |

| S Shape | (,) 0 0 | (,) 0 0 | 0 (,) | 0 | 0 (,) | 0 0 0 | 0 0 0 0 | |

| O Shape | I Shape | L Shape | Z Shape | T Shape | J Shape | S Shape | ||

|---|---|---|---|---|---|---|---|---|

| O Shape | 0 | 0 | ||||||

| I Shape | 0 | |||||||

| L Shape | 0 | 0 | 0 | 0 | ||||

| Z shape | 0 | 0 | ||||||

| T Shape | 0 | 0 | ||||||

| J Shape | 0 | 0 | 0 | |||||

| S Shape | 0 | 0 | ||||||

| Method | Euclidean Distance | Proposed Cost Weight | Trajectory Generating Time |

|---|---|---|---|

| Zigag | 3814.12 | 4072.19 | 0.012 |

| Sprial | 3612.21 | 3821.18 | 0.155 |

| Greedy search | 2994.52 | 3791.92 | 30.24 |

| Method [22] | 2943.32 | 3688.21 | 1.150 |

| Propsed method GA | 3122.56 | 2968.95 | 1.158 |

| Propsed method ACO | 3125.52 | 2933.19 | 1.166 |

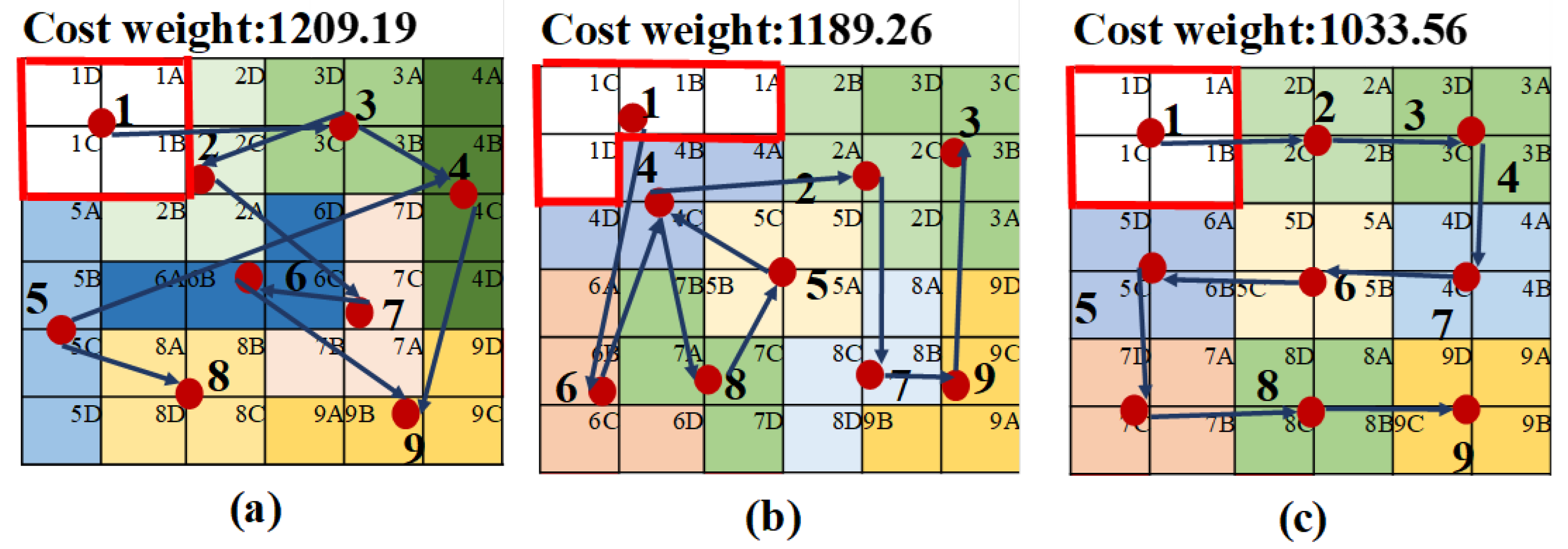

| Coefficient Values | Meaning | Cost Weight Action | Cost Weight All Actions | Energy (Ws) on Real Workspace |

|---|---|---|---|---|

| Only transformation | 1192.35 | 1239.29 | 24.32 | |

| Only translation | 1198.165 | 1259.35 | 25.34 | |

| Only orientation | 1201.32 | 1279.91 | 28.32 | |

| transformation and translation | 1182.251 | 1256.80 | 25.61 | |

| Only translation and orientation | 1198.31 | 1218.83 | 24.25 | |

| All three actions | 1209.19 | 1209.19 | 22.03 |

| Workspace | Tiling Set | Cost Weight |

|---|---|---|

| 6 × 6 | Tileset 1: O, I, J, L | 1209.19 |

| Tileset 2: J, O, L, S, N | 1189.26 | |

| 8 × 7 | Tiling set 1: I, L, J | 1502.16 |

| Tileset 2: I, O, L, T | 1558.44 | |

| 11 × 11 | Tileset 1: J, T, S, L | 2933.69 |

| Tileset 2: O, I, L, J | 2892.68 |

| Cost Weight | Trajectory Generating Time | |

|---|---|---|

| chromosome = 30, mutation probability = 0.01 | 3176.59 | 1.22 |

| chromosome = 30, mutation probability = 0.05 | 3371.18 | 1.31 |

| chromosome = 30, mutation probability = 0.1 | 3381.32 | 1.340 |

| chromosome = 100, mutation probability = 0.01 | 2988.21 | 1.150 |

| chromosome = 100, mutation probability = 0.05 | 2998.95 | 1.662 |

| chromosome = 100, mutation probability = 0.1 | 2968.95 | 1.580 |

| Cost Weight | Trajectory Generating Time | |

|---|---|---|

| number of ants = 50, evaporation probability = 0.1 | 3372.29 | 1.412 |

| number of ants = 50, evaporation probability = 0.5 | 3321.68 | 1.555 |

| number of ants = 50, evaporation probability = 0.9 | 3211.97 | 1.740 |

| number of ants = 100, evaporation probability = 0.1 | 3688.21 | 1.850 |

| number of ants = 100, evaporation probability = 0.5 | 2958.95 | 1.762 |

| number of ants = 100, evaporation probability = 0.9 | 2933.19 | 1.660 |

| Method | Cost Weight | Running Time (s) | Power (W) | Energy (Ws) |

|---|---|---|---|---|

| Zigzag | 1412.35 | 147.09 | 0.285 | 41.92 |

| Spiral | 1391.19 | 146.42 | 0.257 | 40.27 |

| Greedy search | 1352.19 | 136.92 | 0.238 | 32.59 |

| Method [22] | 1301.25 | 129.87 | 0.198 | 25.71 |

| Proposed method GA | 1216.59 | 122.92 | 0.185 | 22.74 |

| Proposed method ACO | 1209.19 | 121.04 | 0.182 | 22.03 |

| Transform | O to O | O to J | J to J | J to L | L to L | L to I | I to I | I to O |

|---|---|---|---|---|---|---|---|---|

| Navigation sequence | 1 to 3 | 3 to 2 | 2 to 7 | 7 to 6 | 6 to 9 | 9 to 4 | 4 to 5 | 5 to 8 |

| Consumed energy (Ws) | 1.82 | 3.51 | 2.11 | 3.16 | 2.25 | 3.32 | 2.31 | 3.55 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le, A.V.; Ku, P.-C.; Than Tun, T.; Huu Khanh Nhan, N.; Shi, Y.; Mohan, R.E. Realization Energy Optimization of Complete Path Planning in Differential Drive Based Self-Reconfigurable Floor Cleaning Robot. Energies 2019, 12, 1136. https://doi.org/10.3390/en12061136

Le AV, Ku P-C, Than Tun T, Huu Khanh Nhan N, Shi Y, Mohan RE. Realization Energy Optimization of Complete Path Planning in Differential Drive Based Self-Reconfigurable Floor Cleaning Robot. Energies. 2019; 12(6):1136. https://doi.org/10.3390/en12061136

Chicago/Turabian StyleLe, Anh Vu, Ping-Cheng Ku, Thein Than Tun, Nguyen Huu Khanh Nhan, Yuyao Shi, and Rajesh Elara Mohan. 2019. "Realization Energy Optimization of Complete Path Planning in Differential Drive Based Self-Reconfigurable Floor Cleaning Robot" Energies 12, no. 6: 1136. https://doi.org/10.3390/en12061136

APA StyleLe, A. V., Ku, P.-C., Than Tun, T., Huu Khanh Nhan, N., Shi, Y., & Mohan, R. E. (2019). Realization Energy Optimization of Complete Path Planning in Differential Drive Based Self-Reconfigurable Floor Cleaning Robot. Energies, 12(6), 1136. https://doi.org/10.3390/en12061136