1. Introduction

The concept of microgrids (MGs) and corresponding applications have drawn considerable attention from researchers over the last decades, given that it is now possible to reliably and efficiently integrate distributed energy resources (DERs) into today’s power systems [

1,

2]. They can integrate distributed renewable energy generation and storage capacity to meet the electrical needs of customers. They greatly enhance local power supply reliability [

3]. However, many challenging issues are associated with MGs operation, the most common of which is the reliable integration of renewable energy sources (RESs), such as photovoltaic (PV) and wind turbine (WT), given their inherent variability and uncertainty in terms of power generation [

4,

5,

6,

7]. Sharp fluctuations in load demands on a MG constitute additional unpredictable variables [

8,

9]. However, the impact of these uncertainties can be compensated with the aid of the energy storage system (ESS) [

10,

11]. Optimal energy scheduling using an ESS is crucial to cope with the uncertainties of RESs and loads, and to ensure the reliable and economical operation of the MG. The MG can operate in the grid-connected and islanded modes [

12,

13]. MG energy management system (MEMS) successfully provides the reference signals in real time and scheduling time horizons, so that the MG operates in both modes reliably.

Single-stage approaches have been popular because they are easy to implement [

14,

15,

16,

17,

18,

19,

20,

21]. In reference [

14], online optimal control strategies for ESSs was developed. The optimization problem was formulated as a robust mixed integer linear programming (MILP) problem to handle uncertainty in the forecast load demands and RESs power generation. In reference [

15], a two-layer optimal dispatch model with ESSs and supercapacitors was formulated. An upper layer minimized the total operational costs, and a lower layer then mitigated load fluctuations and RES forecast errors. It demonstrated that two types of energy storage could be utilized in a hierarchical dispatch model. An execution monitoring and replanning approach for optimal 24-h dispatch considering the uncertainties in weather conditions and load profiles were developed in [

16]. A multi-objective function was devised to minimize energy losses, fuel costs, and carbon dioxide emissions. However, the single-stage approaches in [

14,

15,

16] were modeled only using numerical software.

Some studies have focused on actual-to-laboratory-scale MGs [

17,

18,

19,

20,

21]. An energy management system (EMS) was proposed to minimize the overall operations costs in [

17]. It considered a complete non-linear optimal power flow problem, which determined the active and reactive power injections at all network buses. It compared the solution that derived using a linearized optimal power flow problem. Optimal operation of an isolated system using a virtual power producer was proposed to minimize the generation costs and optimize battery charging/discharging in [

18]. Reference [

19] proposed the use of offline scheduling to minimize operating costs by using day-ahead forecast data. It focused on modeling a MG and design of an EMS. An EMS maximizing total MG profit considering the total capacities of the RESs and storage systems in terms of future expansion was developed in [

20]. Reference [

21] proposed the use of an EMS based on unit commitment with a rolling horizon to reduce the uncertainties of forecasting. The goal of their proposed optimization was to minimize the operational costs of the MG.

However, the day-ahead single-stage approach is vulnerable to forecasting errors and unpredictable variations in renewable power generation and load demands. Thus, the optimal operating schedule obtained using a single-stage approach may not guarantee optimal operation of an actual MG. Such issues focus attention on two-stage scheduling approaches, which are robust under forecasting errors and unpredicted changes in operation conditions [

22]. Most literature on the two-stage scheduling approach has focused on simulation-level demonstrations [

23,

24,

25,

26,

27,

28,

29]. Reference [

23] addressed energy resources scheduling for the day-ahead and in real time to minimize the total operation cost of a grid-connected MG. It considered the case where all types of loads were imposed in a demand response program. In references [

24,

25], day-ahead scheduling determined the hourly generation schedules to minimize MG operation costs. Real-time scheduling at a time scale of 5 min allowed the MG to follow the day-ahead scheduled power exchange with the main grid. Two different time scales were applied; 1 h for cooling energy and 5 min for electrical energy. In reference [

26], each stage of the two-stage scheduling was two-level. The lower level of the day-ahead scheduling module was to maximize the expected profit, and the upper level was to minimize the total cost of MG operation during the day. The second stage featured hour-ahead scheduling at 15-min intervals. The aim of the lower level of the second stage was to maximize the use of RESs when following the day-ahead schedule. The upper level of the second stage was the same as the upper level of the first stage. A two-stage robust optimization method to plan ESS charging/discharging, and direct load control (DLC) was developed to maximize the total profit of the MG in [

27]. In the first stage, ESS charging/discharging power was scheduled to decrease energy purchases from the main grid, and DLC scheduling was then set 15 min earlier to complement ESS operation. In reference [

28], hourly scheduling of the day-ahead optimal economic dispatch was performed to minimize the daily MG operational costs, followed by intra-hour adjustment using two layers to smooth fluctuations and follow day-ahead scheduling. In the second stage, two different dispatch time intervals were set, one for virtual energy storage system and the other for the vehicle-to-building system. In reference [

29], a two-stage scheduling framework optimization problem was formulated to optimize the real-time operation of a battery and an ultracapacitor. Hour-ahead scheduling was first performed to minimize the operation cost of the MG, followed by real-time scheduling to eliminate power imbalances caused by the uncertainties in the RESs and loads.

Only a few studies have validated the two-stage optimization problem using real MGs [

30,

31]. A heuristic optimal operation was proposed to minimize the MG operating cost in [

30]. The proposed strategy featured both day-ahead and real time scheduling and performance of three different heuristic algorithms was compared. Reference [

31] assessed peak load shifting, onsite PV performance and grid support by formulating an MILP optimal dispatch problem, featuring both month-ahead and day-ahead scheduling. The first stage determines DERs scheduling to minimize total operating costs (on a monthly basis), and the second stage then considers the same optimization problem but over a day-long time horizon.

Table 1 presents a summary of previous studies on the optimal scheduling optimization problem types, and the validation methods used.

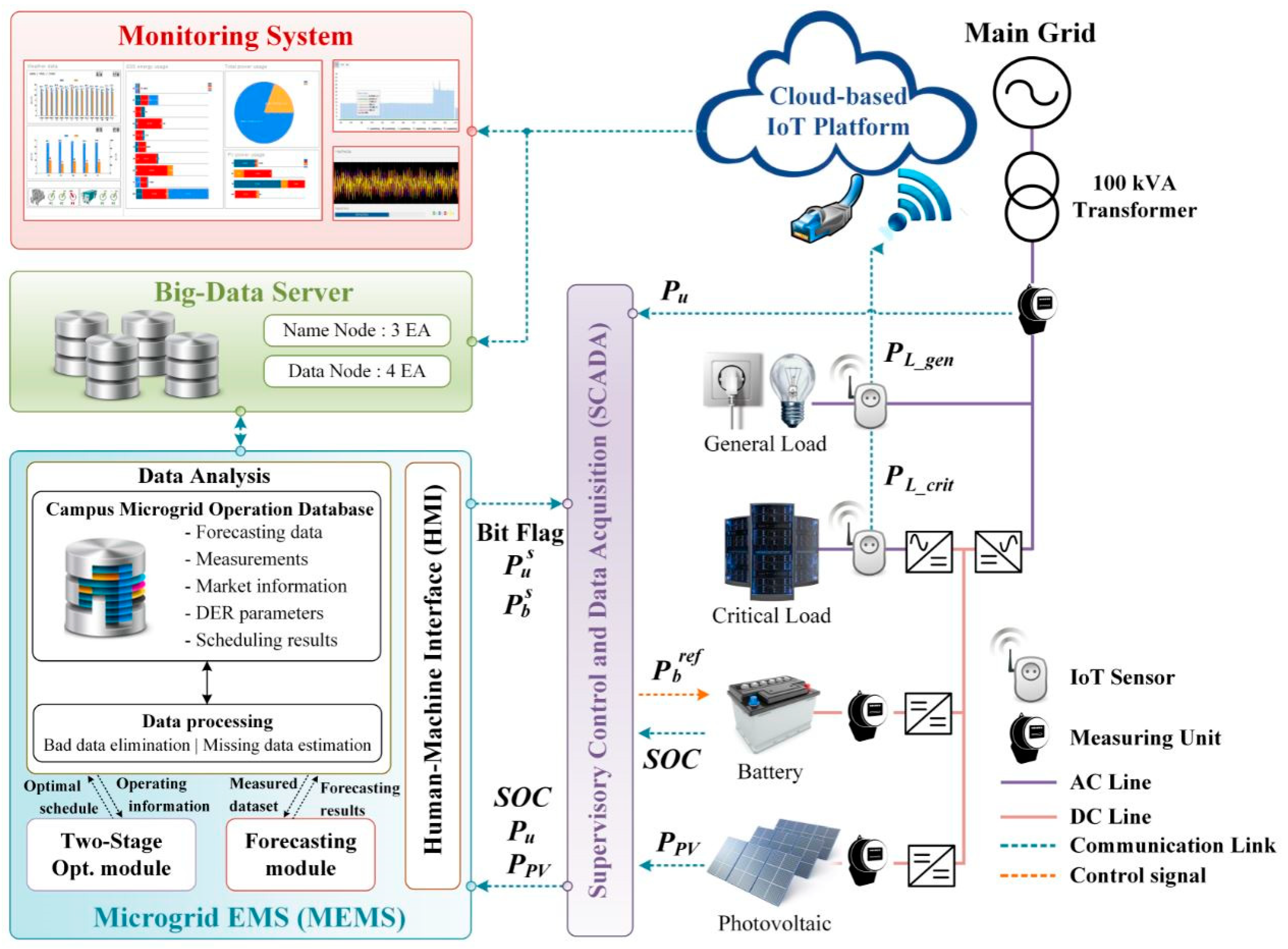

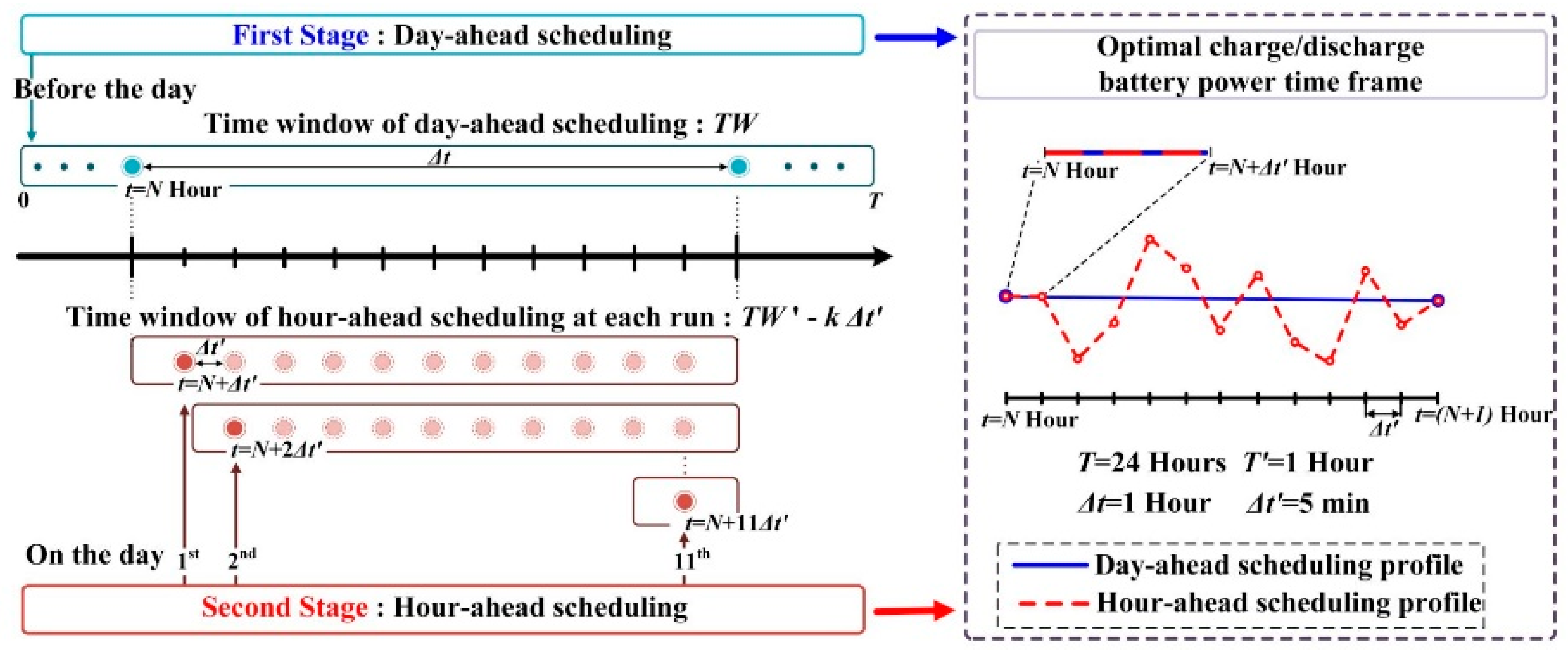

This paper proposes a two-stage scheduling, which consists of the day-ahead scheduling and the hour-ahead scheduling with consideration of the ESS. It is implanted in a MEMS in a campus MG and then validated both in actual case and in simulation to show the effectiveness of the proposed method. The main contributions of this paper are as follows:

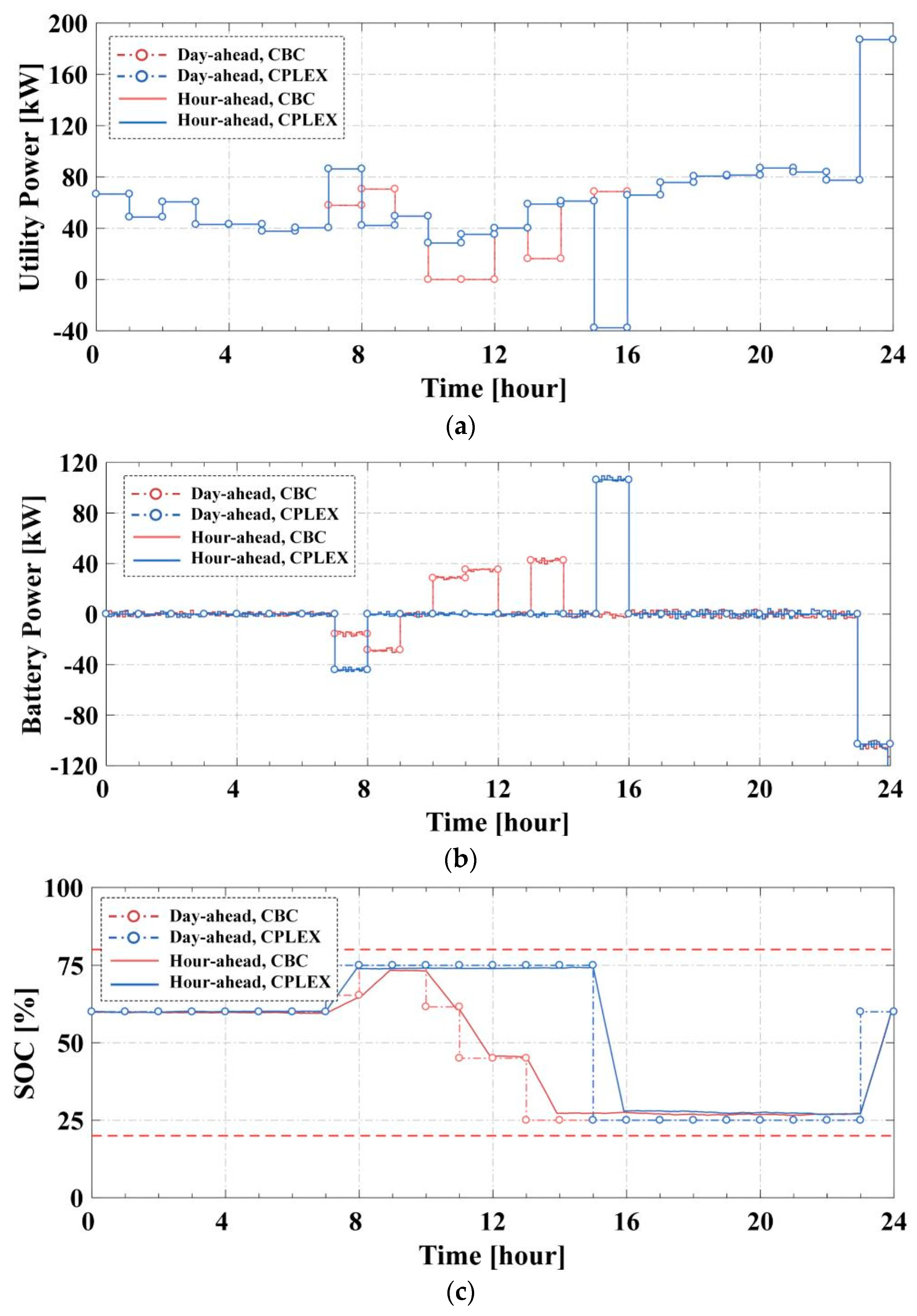

This paper proposes two-stage scheduling—day-ahead and hour-ahead scheduling—to mitigate uncertainty and forecasting errors. The first stage is performed one day in advance to minimize the operation cost, while the second stage is performed every 5 min to minimize the difference between the input power from the main grid before the day and that during the day.

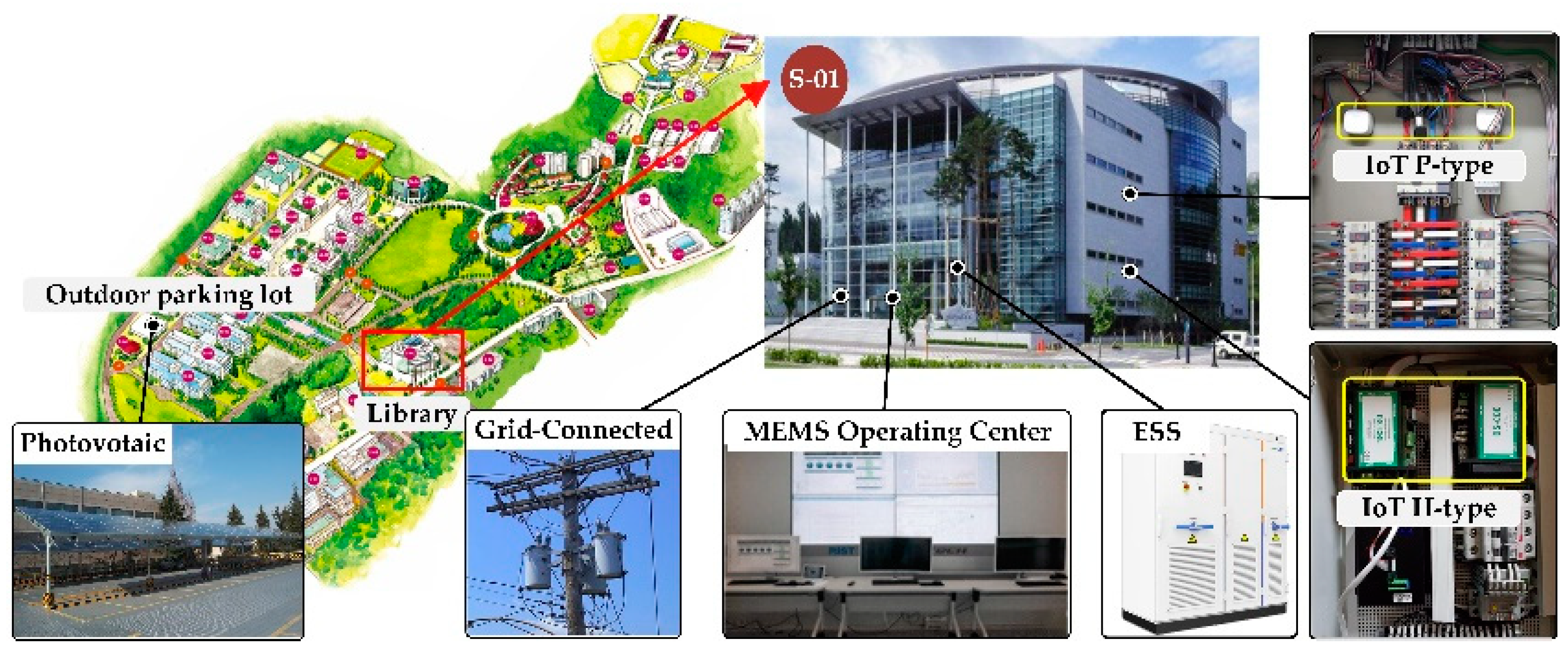

Unlike previous papers [

23,

24,

25,

26,

27,

28,

29], we engage in practical implementation of the proposed two-stage scheduling system. An Internet-of-Things (IoT)-based campus MG, composed of PV and ESS, is used as a case study to evaluate the proposed method. The method is developed using not only the forecast data on load demand and required PV generation but also actual data on electricity prices and device parameters.

The proposed scheduling optimization problem is modelled in PuLP (i.e., a modeling environment in Python) using an open-source solver coin-or branch and cut (CBC). The optimization module in the implemented MEMS is completely open-source based.

Additional case studies are performed to deal with limitations of the implementation in the campus MG. We verify that completely open-source software can be used to develop the small-scale MG and that the algorithm is applicable at various PV and battery capacities.

The remaining manuscript of this paper outlines as follows:

Section 2 describes an overview of the implemented campus MG;

Section 3 formulates our proposed two-stage scheduling;

Section 4 describes the results of not only implementation but also simulation case studies; and

Section 5 concludes the paper. Note that this paper focuses especially on optimization.