Torque Optimal Allocation Strategy of All-Wheel Drive Electric Vehicle Based on Difference of Efficiency Characteristics between Axis Motors

Abstract

:1. Introduction

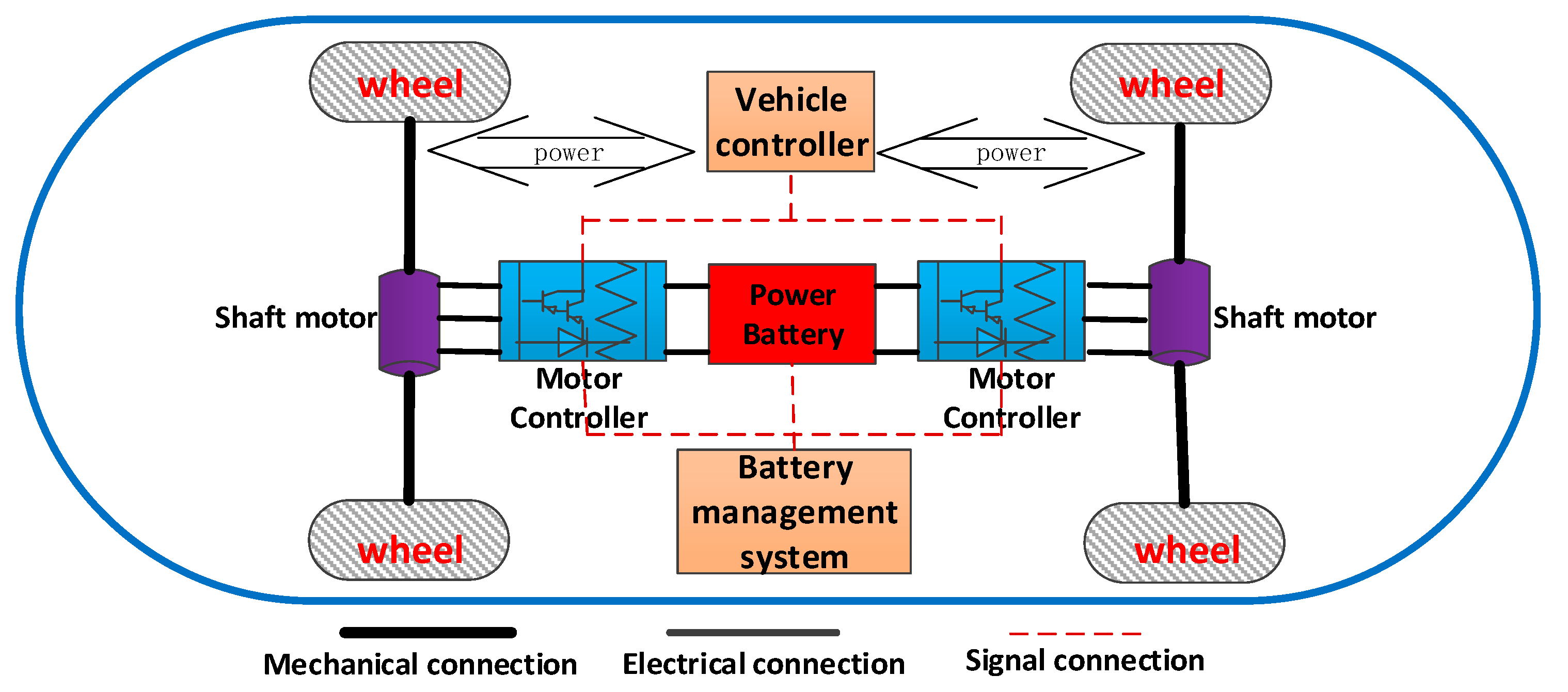

2. All-Wheel Drive Power System Structure and Working Mode

2.1. Vehicle Dynamic Model

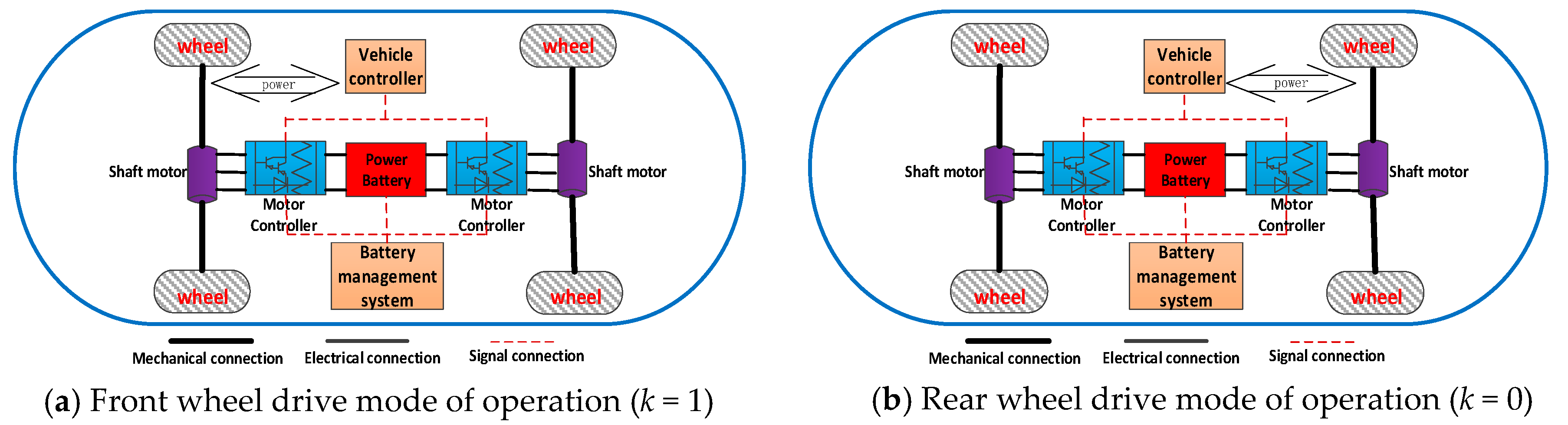

2.2. Working Mode

3. Power System Modeling

3.1. Vehicle Dynamic Model

3.2. Motor Model

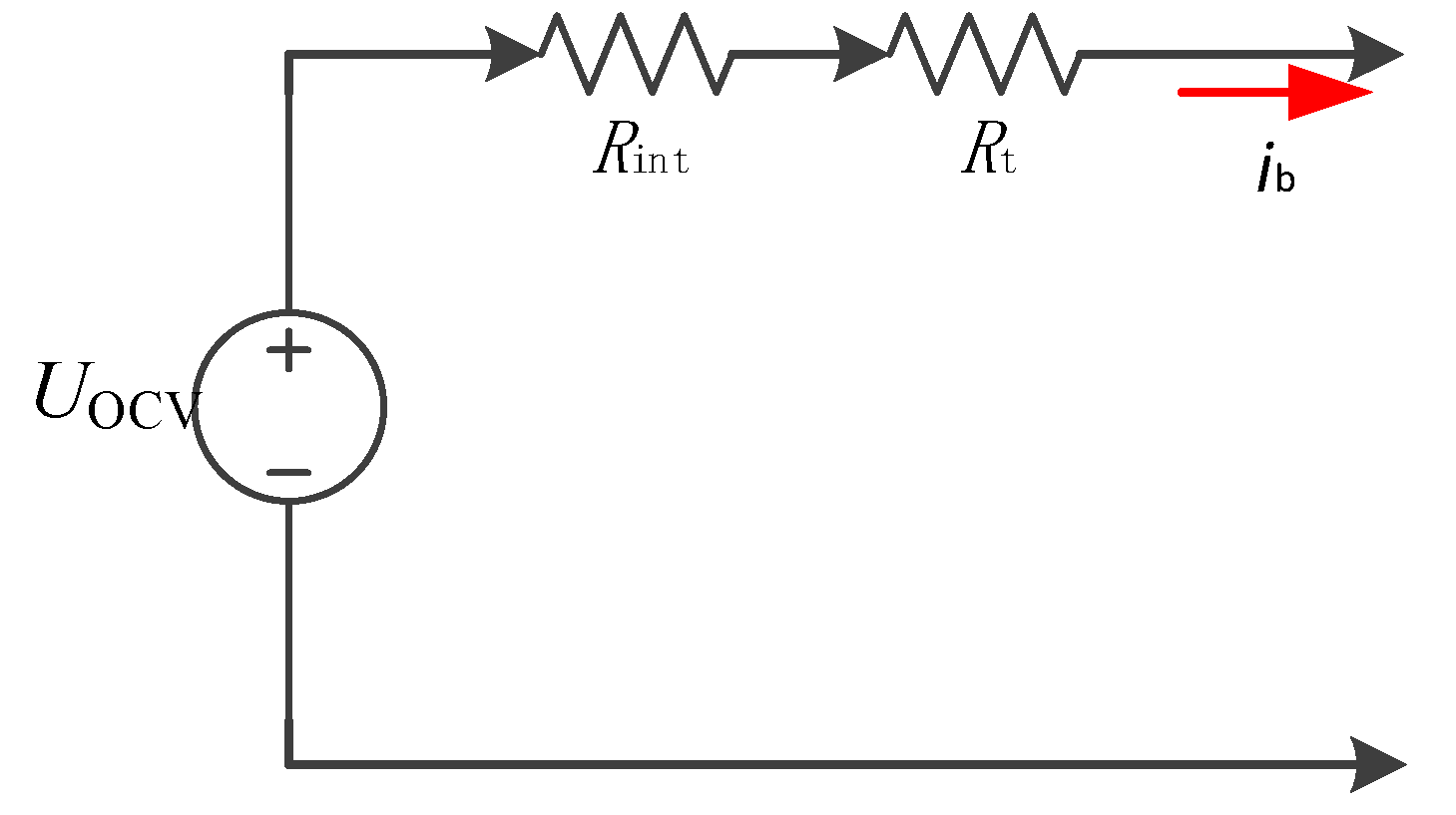

3.3. Power Battery Model

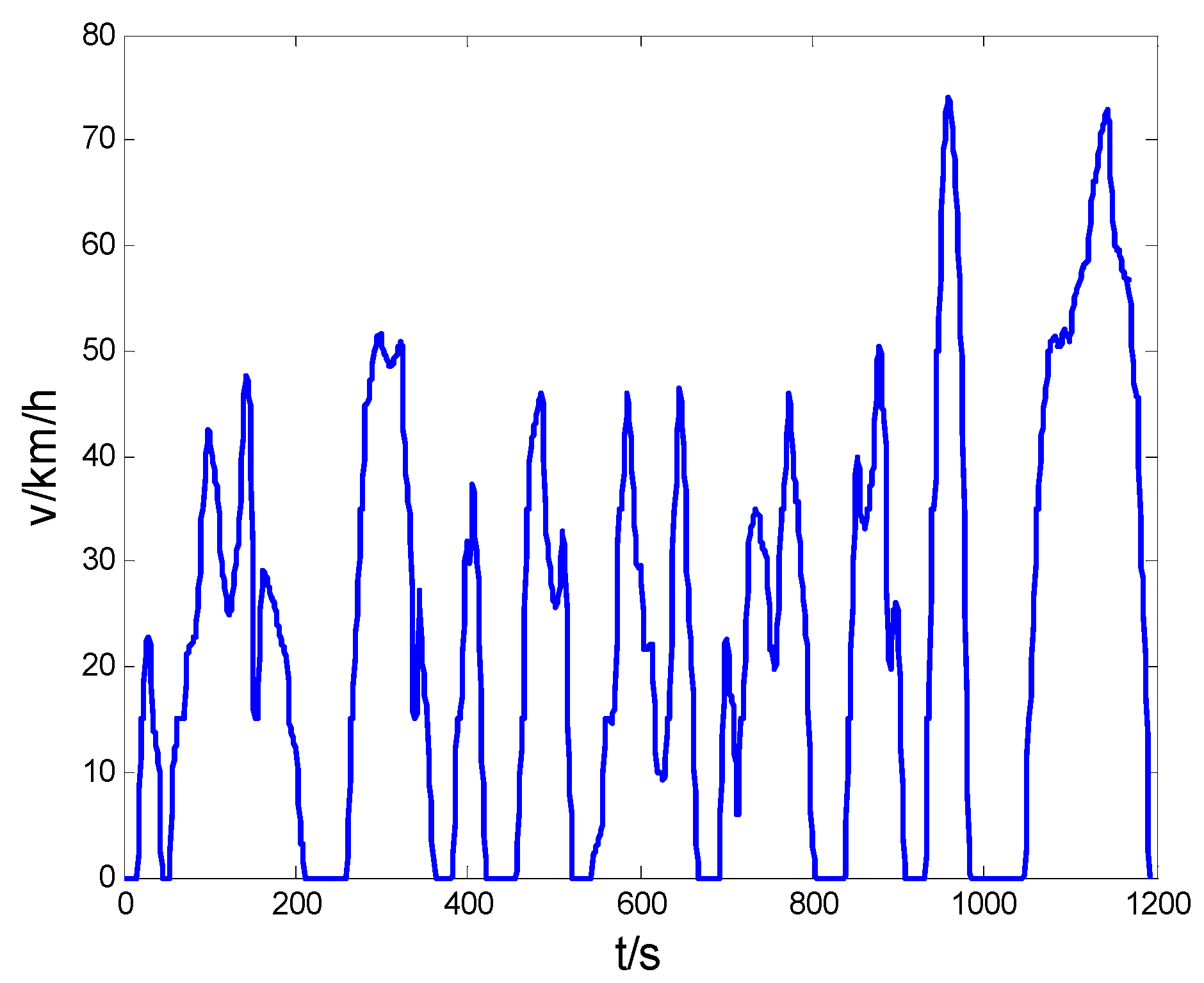

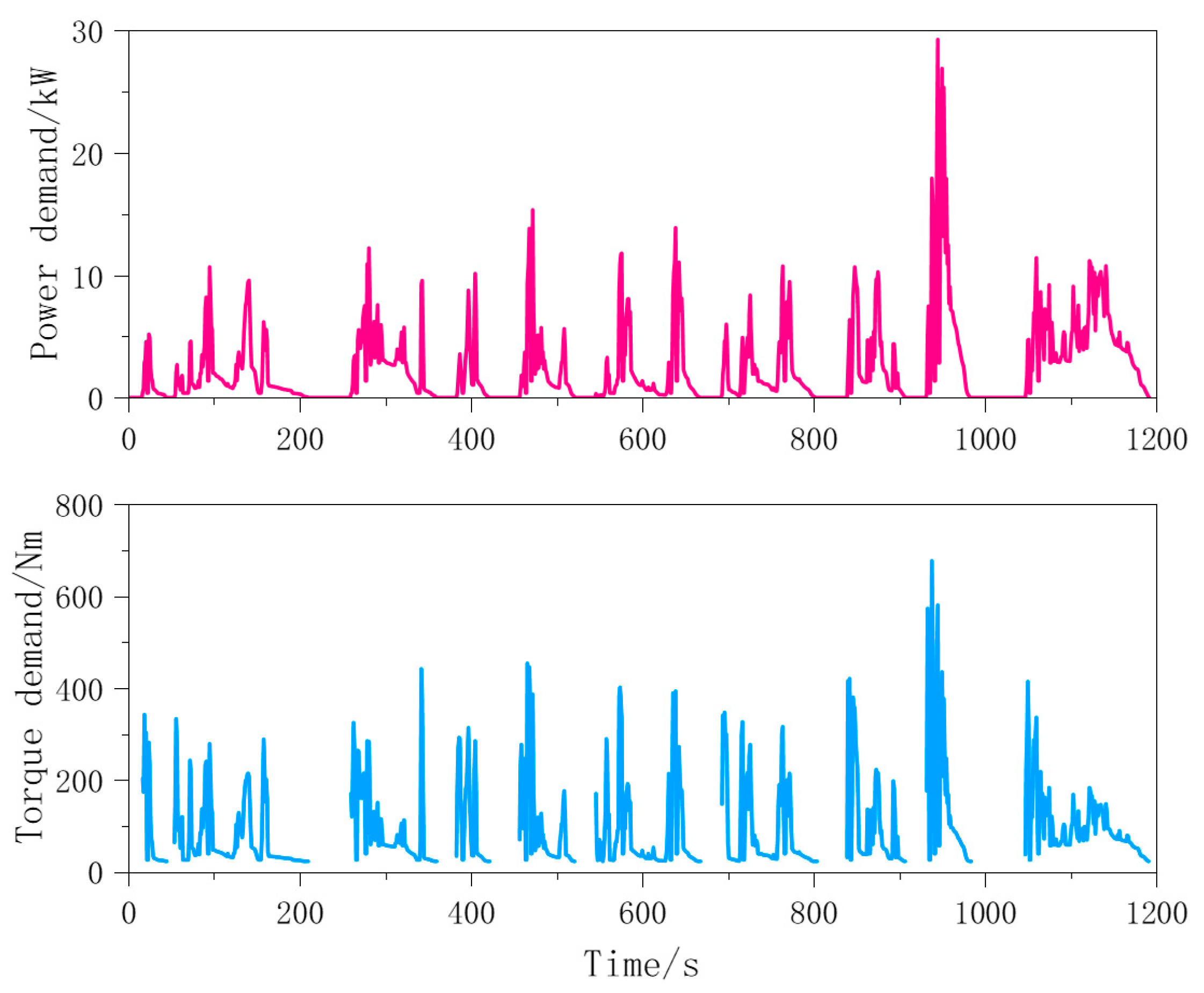

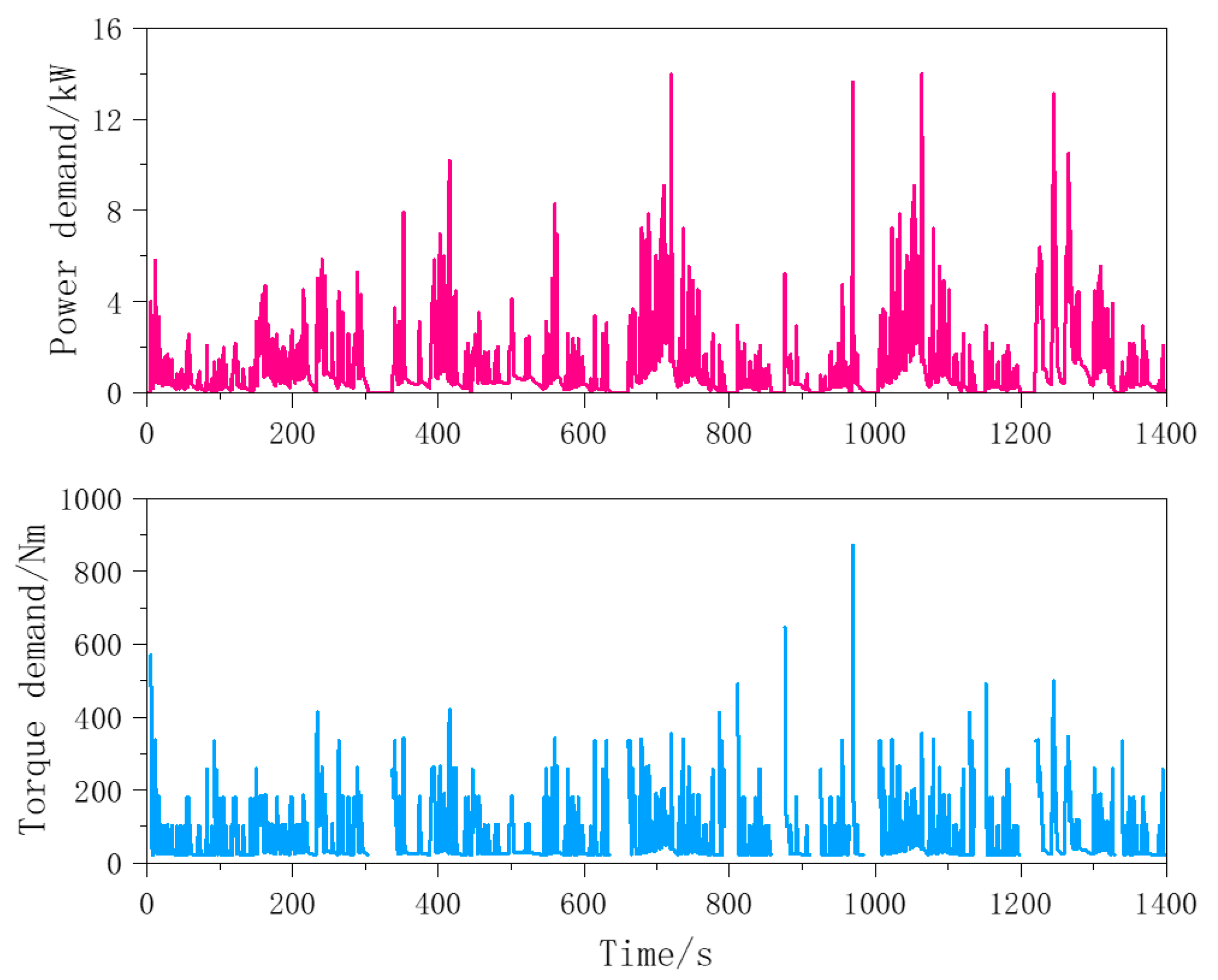

3.4. Operating Conditions

4. Torque Optimization Allocation Method Based on Difference in Efficiency Characteristics between Shafts

4.1. Torque Optimization Problem

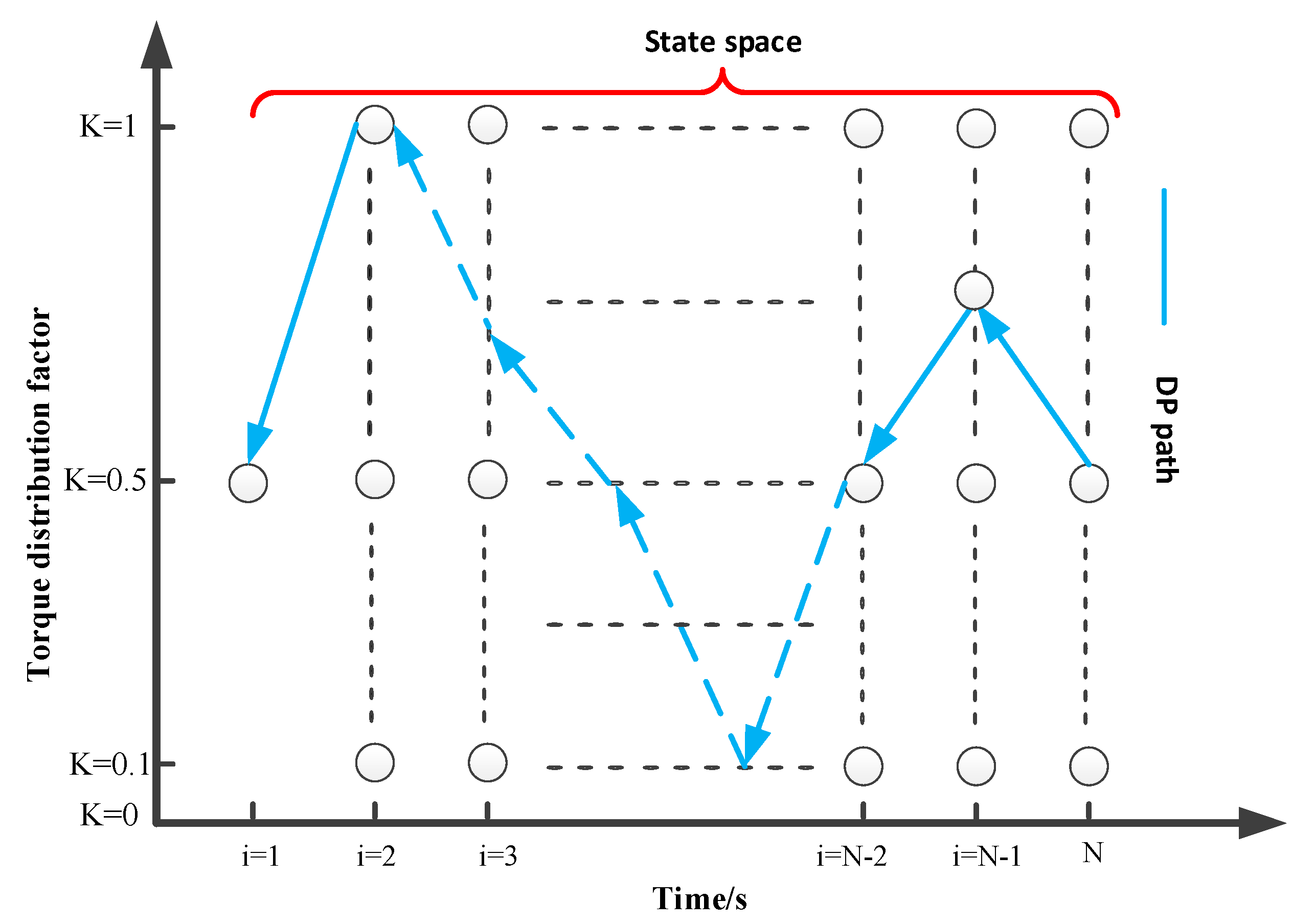

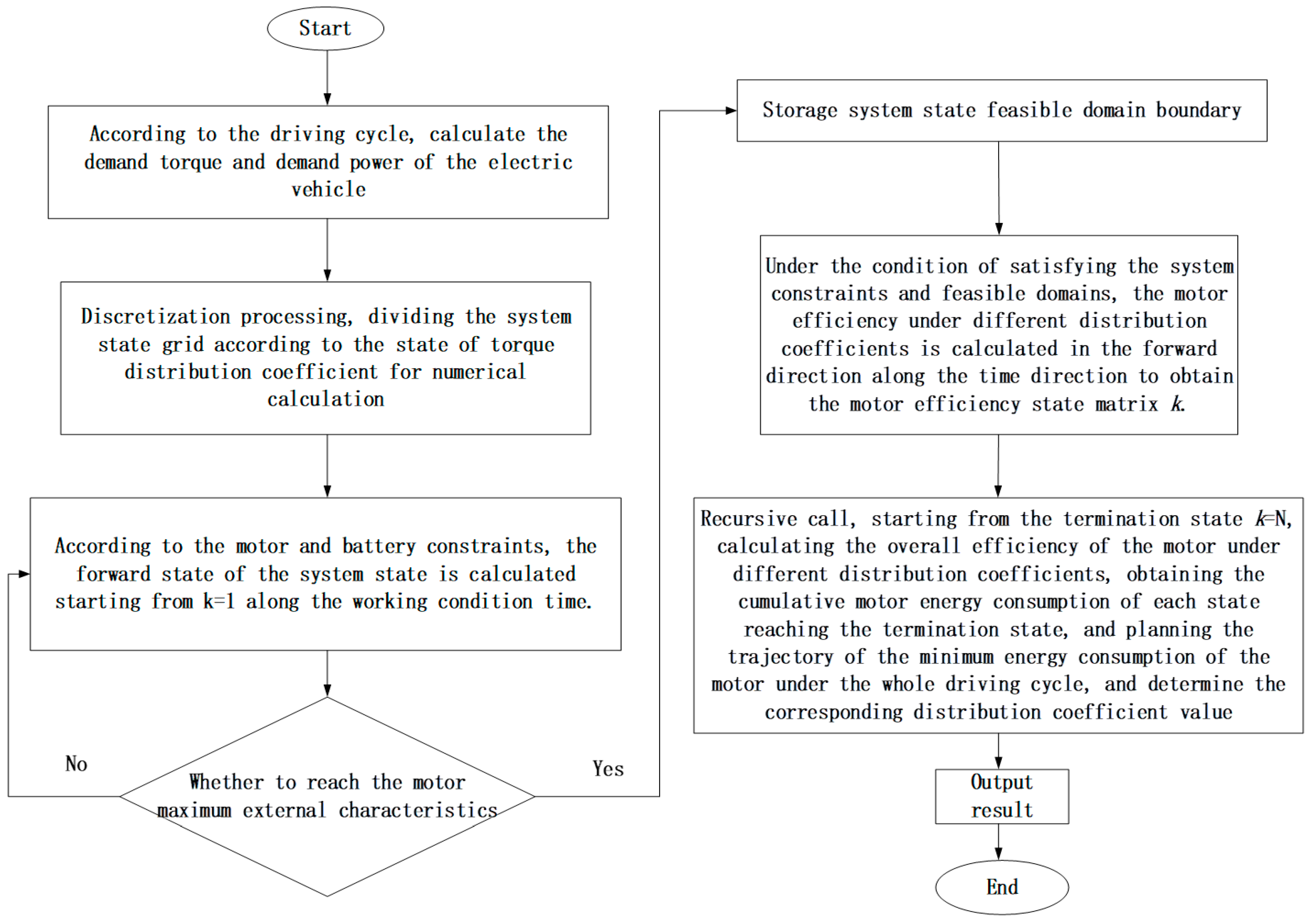

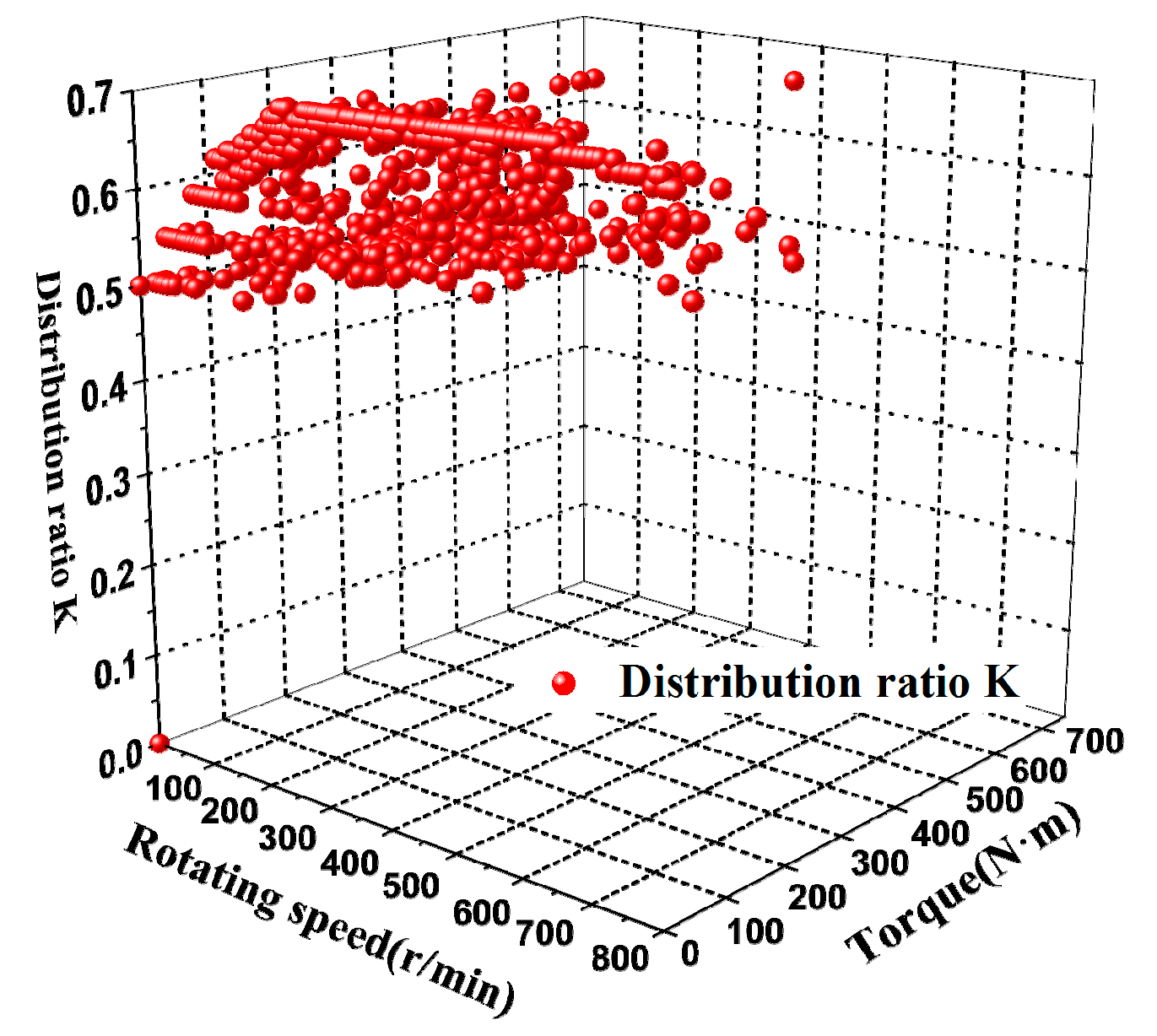

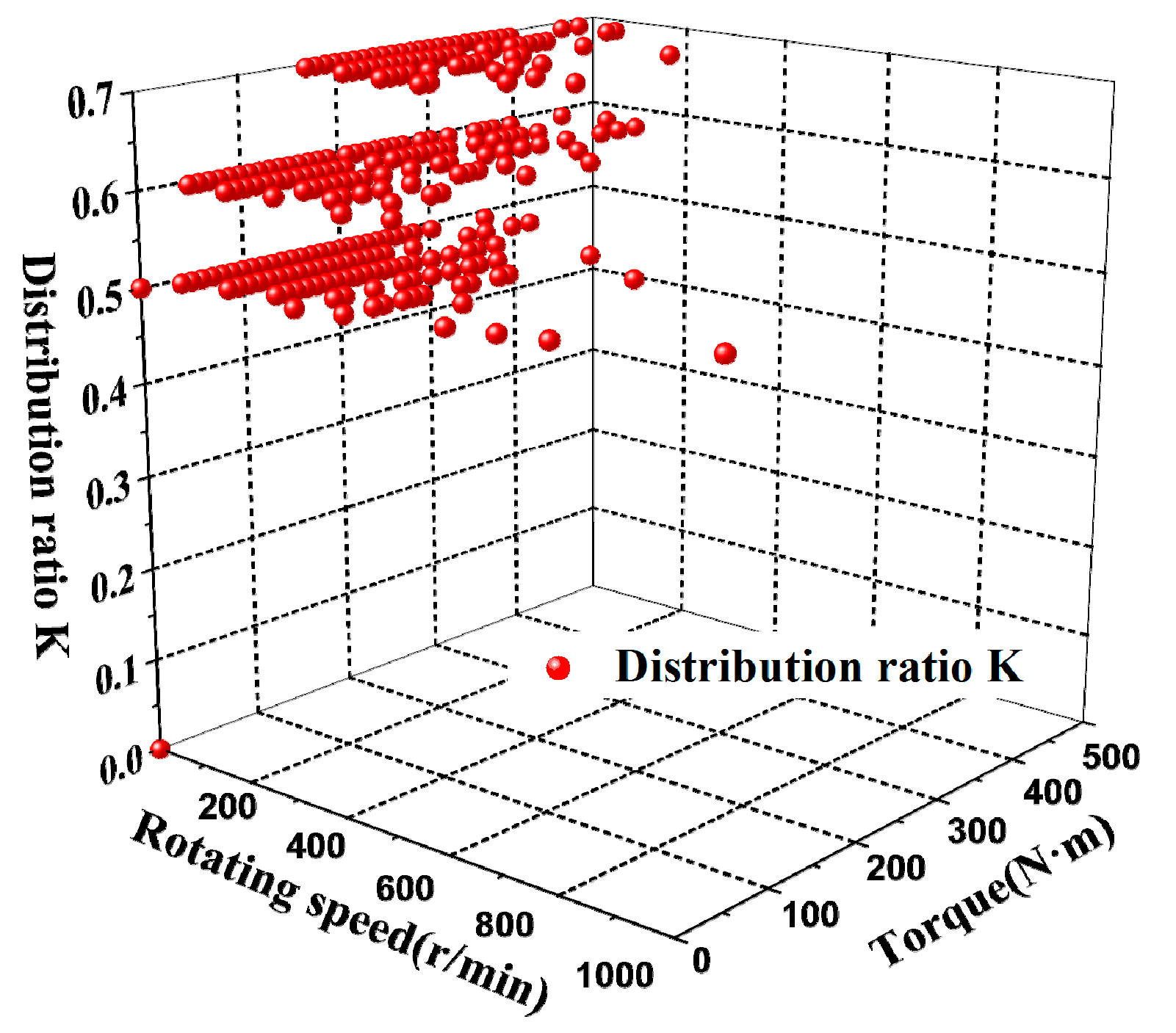

4.2. Application of DP Algorithm

5. Simulation and Result Analysis

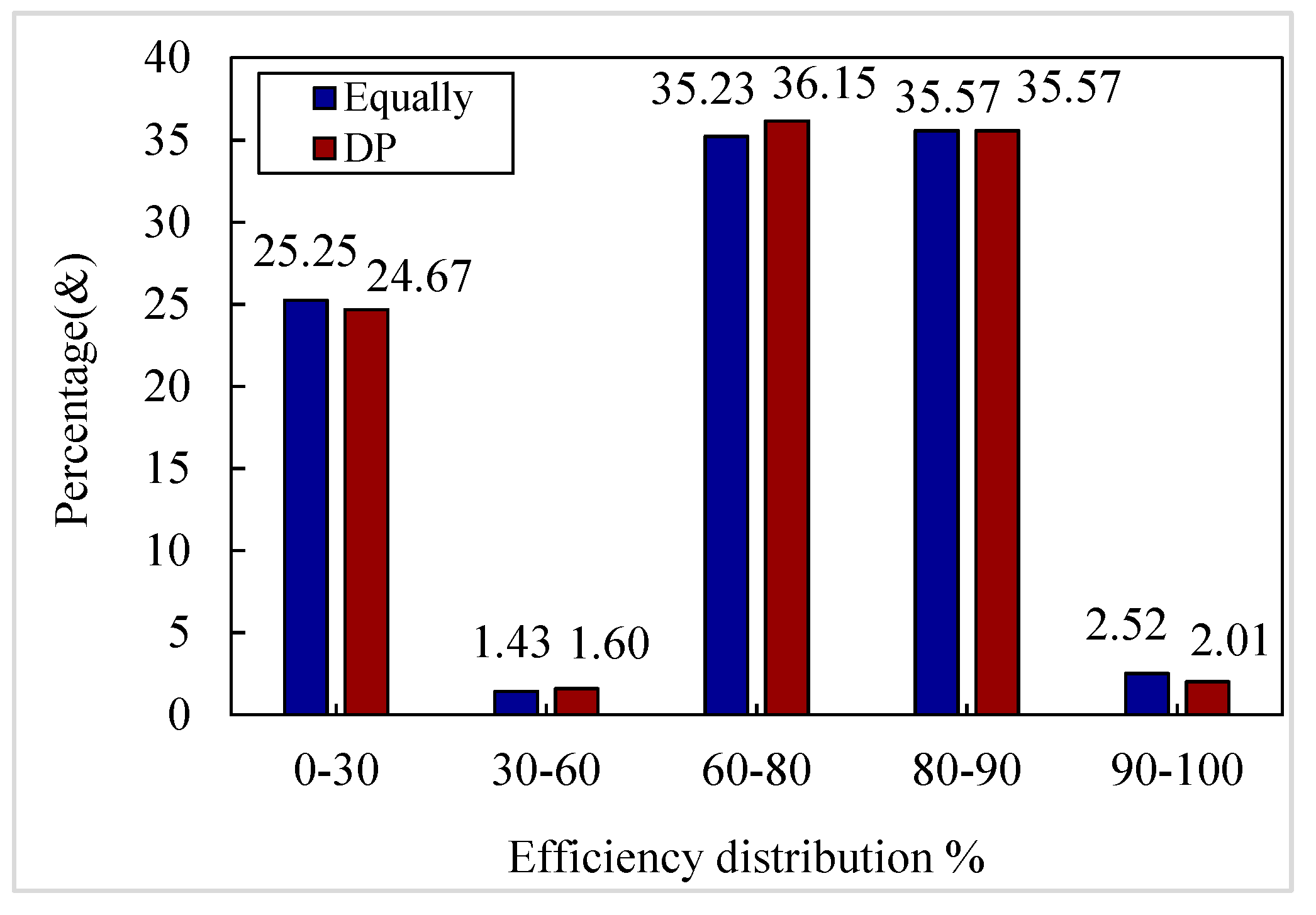

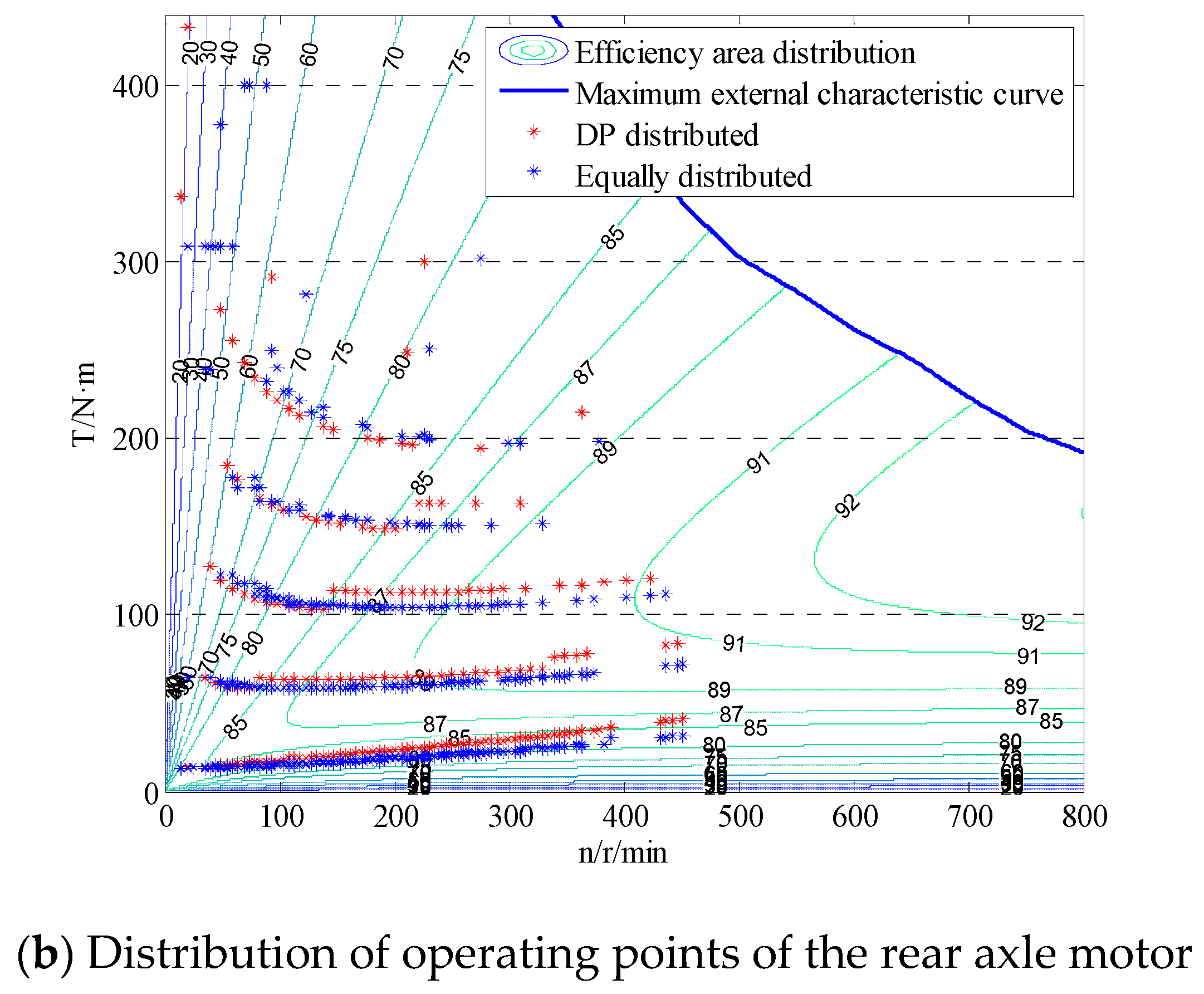

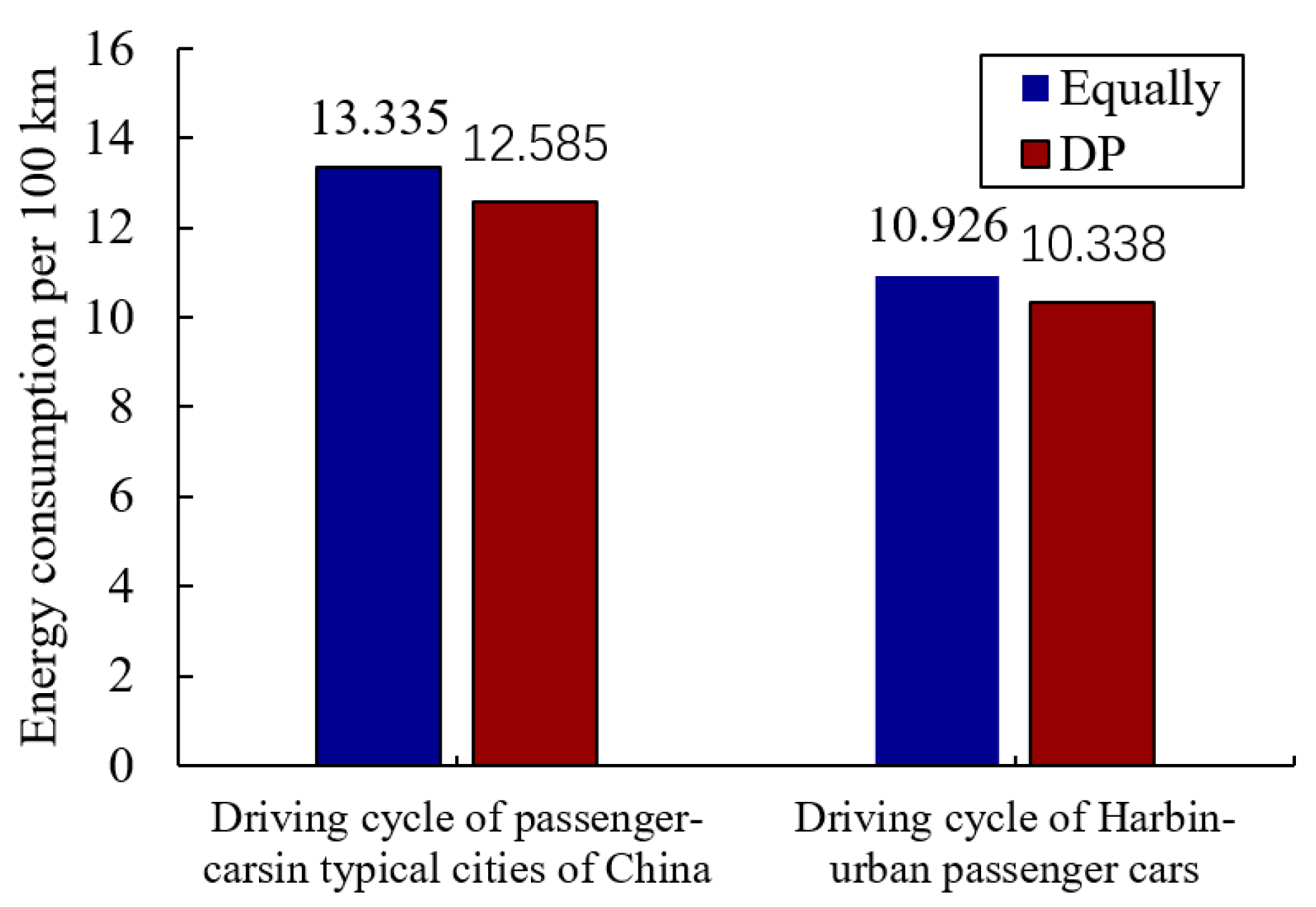

5.1. Comparative Analysis of Torque Distribution Strategies for Chinese Passenger Car under Different Cycles

5.2. Comparative Analysis of Torque Distribution Strategies for HUPDC

5.3. Energy Consumption Analysis of Electric Drive System

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, H.; Huang, X.; Wang, J.; Karimi, H.R. Robust energy-to-peak sideslip angle estimation with applications to ground vehicles. Mechatronics 2015, 30, 338–347. [Google Scholar] [CrossRef]

- Shuai, Z.; Zhang, H.; Wang, J.; Li, J.; Ouyang, M. Lateral motion control for four-wheel-independent-drive electric vehicles using optimal torque allocation and dynamic message priority scheduling. Control Eng. Pract. 2014, 24, 55–66. [Google Scholar] [CrossRef]

- Zhao, Z.; Lei, D.; Chen, J.; Li, H. Optimal control of mode transition for four-wheel-drive hybrid electric vehicle with dry dual-clutch transmission. Mech. Syst. Signal Process. 2018, 105, 68–89. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, F.; Jing, H.; Liu, Z.; Güvenç, L. Coordinated longitudinal and lateral motion control for four wheel independent motor-drive electric vehicle. IEEE Trans. Veh. Technol. 2018, 67, 3782–3790. [Google Scholar] [CrossRef]

- Chen, T.; Chen, L.; Xu, X.; Cai, Y.; Jiang, H.; Sun, X. Estimation of longitudinal force and sideslip angle for intelligent four-wheel independent drive electric vehicles by observer iteration and information fusion. Sensors 2018, 18, 1268. [Google Scholar] [CrossRef]

- Chen, T.; Xu, X.; Chen, L.; Jiang, H.; Cai, Y.; Li, Y. Estimation of longitudinal force, lateral vehicle speed and yaw rate for four-wheel independent driven electric vehicles. Mech. Syst. Signal Process. 2018, 101, 377–388. [Google Scholar] [CrossRef]

- Wu, D.; Ding, H.; Du, C. Dynamics characteristics analysis and control of FWID EV. Int. J. Automot. Technol. 2018, 19, 135–146. [Google Scholar] [CrossRef]

- Joa, E.; Park, K.; Koh, Y.; Yi, K.; Kim, K. A tyre slip-based integrated chassis control of front/rear traction distribution and four-wheel independent brake from moderate driving to limit handling. Veh. Syst. Dyn. 2018, 56, 579–603. [Google Scholar] [CrossRef]

- Han, K.; Choi, M.; Lee, B.; Choi, S.B. Development of a traction control system using a special type of sliding mode controller for hybrid 4wd vehicles. IEEE Trans. Veh. Technol. 2018, 67, 264–274. [Google Scholar] [CrossRef]

- Koehler, S.; Viehl, A.; Bringmann, O.; Rosenstiel, W. Energy-efficiency optimization of torque vectoring control for battery electric vehicles. IEEE Intell. Transp. Syst. Mag. 2017, 9, 59–74. [Google Scholar] [CrossRef]

- Xin, X.; Zhang, W.; Shen, C.; Zheng, H. Control strategy of four-wheel independent drive electric vehicle based on vehicle velocity estimation and switchover. Trans. Inst. Meas. Control 2017, 37, 965–975. [Google Scholar] [CrossRef]

- Qiu, L.; Qian, L.; Zomorodi, H.; Pisu, P. Global optimal energy management control strategies for connected four-wheel-drive hybrid electric vehicles. IET Intell. Transp. Syst. 2017, 11, 264–272. [Google Scholar] [CrossRef]

- Zhang, X.; Wei, K.; Yuan, X.; Tang, Y. Optimal torque distribution for the stability improvement of a four-wheel distributed-driven electric vehicle using coordinated control. J. Comput. Nonlinear Dyn. 2016, 11, 051017. [Google Scholar] [CrossRef]

- Zhai, L.; Sun, T.; Wang, J. Electronic stability control based on motor driving and braking torque distribution for a four in-wheel motor drive electric vehicle. IEEE Trans. Veh. Technol. 2016, 65, 4725–4739. [Google Scholar] [CrossRef]

- Shuai, Z.; Zhang, H.; Wang, J.; Li, J.; Ouyang, M. Combined AFS and DYC control of four-wheel-independent-drive electric over CAN network with time-varying delays. IEEE Trans. Veh. Technol. 2014, 63, 591–602. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, H.; Wang, J. Linear parameter-varying controller design for four-wheel independently actuated electric ground vehicles with active steering systems. IEEE Trans. Control Syst. Technol. 2014, 22, 1281–1296. [Google Scholar]

- Du, J.; Chen, J.; Song, Z.; Gao, M.; Ouyang, M. Design method of a power management strategy for variable battery capacities range-extended electric vehicles to improve energy efficiency and cost-effectiveness. Energy 2017, 121, 32–42. [Google Scholar] [CrossRef]

- Xiong, R.; Zhang, Y.; He, H.; Zhou, X.; Pecht, M.G. A double-scale, particle-filtering, energy state prediction algorithm for lithium-ion batteries. IEEE Trans. Ind. Electron. 2018, 65, 1526–1538. [Google Scholar] [CrossRef]

- Xiong, R.; He, H.; Sun, F.; Liu, X.; Liu, Z. Model-based state of charge and peak power capability joint estimation of lithium-ion battery in plug-in hybrid electric vehicles. J. Power Sources 2013, 229, 159–169. [Google Scholar] [CrossRef]

- Xu, L.; Ouyang, M.; Li, J.; Yang, F.; Lu, L.; Hua, J. Application of Pontryagin’s Minimal Principle to the energy management strategy of plugin fuel cell electric vehicles. Int. J. Hydrog. Energy 2013, 38, 10104–10115. [Google Scholar] [CrossRef]

- Zheng, D.Y.; Wu, X.G.; Chen, H.; Du, J.Y. Construction of driving conditions of Harbin urban passenger cars. J. Highw. Transp. Res. Dev. 2017, 34, 101–107. [Google Scholar] [CrossRef]

- Cheng, S.; Xu, L.; Wu, K.; Fang, C.; Hu, J.; Li, J.; Ouyang, M. Optimal warm-up control strategy of the PEMFC system on a city bus aimed at improving efficiency. Int. J. Hydrog. Energy 2017, 42, 11632–11643. [Google Scholar] [CrossRef]

- Song, Z.; Hofmann, H.; Li, J.; Han, X.; Ouyang, M. Optimization for a hybrid energy storage system in electric vehicles using dynamic programing approach. Appl. Energy 2015, 139, 151–162. [Google Scholar] [CrossRef]

| Driving Cycle | Average Speed (km/h) | Maximum Speed (km/h) | Highest Acceleration (m/s2) | Maximum Deceleration (m/s2) | Average Acceleration (m/s2) |

|---|---|---|---|---|---|

| The CUPDC | 23.138 | 74 | 2.294 | −2.593 | 0.439 |

| The HUPDC | 16.98 | 46 | 1.944 | −2.77 | 0.499 |

| Mass/kg | Wheelbase/m | Frontal Area/m2 | Wheel Radius/m | Centroid Height/m | Front Track/m | Rear Track/m |

|---|---|---|---|---|---|---|

| 1000 | 2.5 | 2.60 | 0.27 | 0.52 | 1.102 | 1.158 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Zheng, D.; Wang, T.; Du, J. Torque Optimal Allocation Strategy of All-Wheel Drive Electric Vehicle Based on Difference of Efficiency Characteristics between Axis Motors. Energies 2019, 12, 1122. https://doi.org/10.3390/en12061122

Wu X, Zheng D, Wang T, Du J. Torque Optimal Allocation Strategy of All-Wheel Drive Electric Vehicle Based on Difference of Efficiency Characteristics between Axis Motors. Energies. 2019; 12(6):1122. https://doi.org/10.3390/en12061122

Chicago/Turabian StyleWu, Xiaogang, Dianyu Zheng, Tianze Wang, and Jiuyu Du. 2019. "Torque Optimal Allocation Strategy of All-Wheel Drive Electric Vehicle Based on Difference of Efficiency Characteristics between Axis Motors" Energies 12, no. 6: 1122. https://doi.org/10.3390/en12061122

APA StyleWu, X., Zheng, D., Wang, T., & Du, J. (2019). Torque Optimal Allocation Strategy of All-Wheel Drive Electric Vehicle Based on Difference of Efficiency Characteristics between Axis Motors. Energies, 12(6), 1122. https://doi.org/10.3390/en12061122