Effects of Different Storage Techniques on Round-Baled Orchard-Pruning Residues

Abstract

:1. Introduction

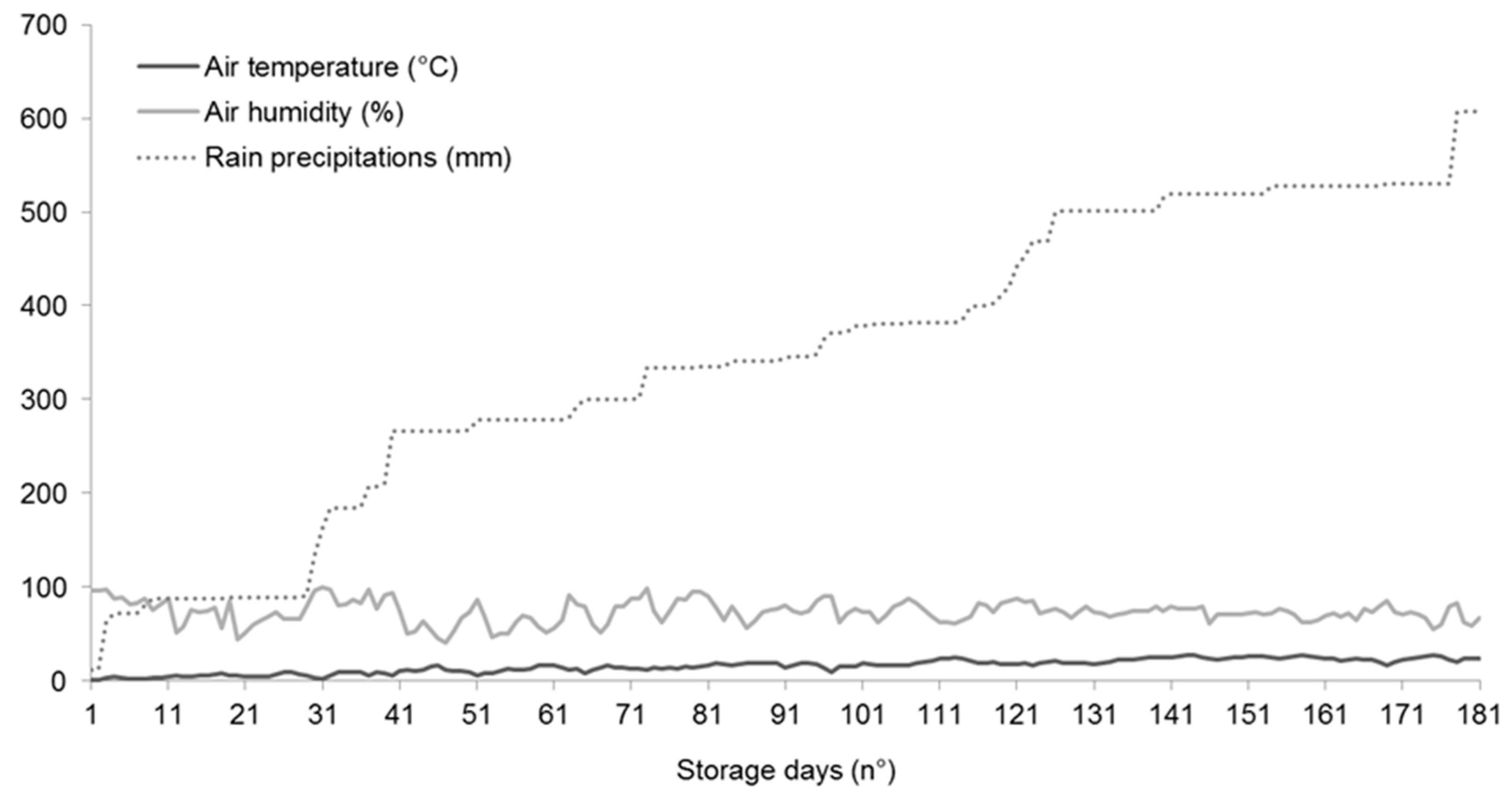

2. Materials and Methods

- LHV = low heating value (MJ kg−1),

- HHV = high heating value (MJ kg−1)

- M = moisture content of the pruning residues,

- K = energy required to evaporate the water in wood (2.447 MJ kg−1).

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Muench, S.; Guenther, E. A systematic review of bioenergy life cycle assessments. Appl. Energy 2013, 112, 257–273. [Google Scholar] [CrossRef]

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuel: History, status and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Velazquez-Marti, B.; Fernandez-Gonzales, E.; Lopez-Cortez, I.; Salazar-Hernandez, D.M. Quantification of the residual biomass obtained from pruning of trees on Mediterranean olive groves. Biomass Bioenergy 2001, 35, 3208–3217. [Google Scholar] [CrossRef]

- Scarlat, N.; Blukdea, V.; Dallemand, J.F. Assessment of the availability of agricultural and forest residues for bioenergy production in Romania. Biomass Bioenergy 2011, 35, 1995–2005. [Google Scholar] [CrossRef]

- Bernetti, I.; Fagarazzi, C.; Fratini, R. A methodology to analyze the potential development of biomass energy sector: An application in Tuscany. For. Policy Econ. 2004, 6, 415–432. [Google Scholar] [CrossRef]

- Beccali, M.; Columba, P.; D’Aleberti, V. Assessment of bioenergy potential in Sicily: A GIS-based support methodology. Biomass Bioenergy 2009, 33, 79–87. [Google Scholar] [CrossRef]

- Magagnotti, N.; Pari, L.; Picchi, G.; Spinelli, R. Technology alternatives for tapping the pruning residue resource. Bioresour. Technol. 2013, 128, 697–702. [Google Scholar] [CrossRef]

- Gonzalez-Garcia, S.; Dias, A.C.; Clermidy, S.; Benoist, A.; Maurel, V.B.; Gasol, A.M.; Gabarell, X.; Arroja, L. Comparative environmental and energy profiles of potential bioenergy production chains in Southern Europe. J. Clean. Prod. 2014, 76, 42–54. [Google Scholar] [CrossRef]

- Picchi, G.; Silvestri, S.; Cristoforetti, A. Vineyard residues as a fuel for domestic boilers in Trento province (Italy): Comparison to wood chips and means of polluting emission control. Fuel 2013, 113, 43–49. [Google Scholar] [CrossRef]

- International Organization of Vine. Statistical Report on World Vitiviniculture; International Organization of Vine: Paris, France, 2013. [Google Scholar]

- FAOSTAT. Production—Crops—Area Harvested, 2009 data; Food and Agriculture Organization of the United Nations: Rome, Italy, 2011. [Google Scholar]

- Jones, G.; Joeffler, D.; Calkin, D.; Chung, W. Forest treatment residues for thermal energy compared with disposal by onsite burning: Emissions and energy return. Biomass Bioenergy 2010, 34, 737–746. [Google Scholar] [CrossRef]

- Di Blasi, C.; Tanzi, V.; Lanzetta, M. A study on the production of agricultural residues in Italy. Biomass Bioenergy 1997, 12, 321–331. [Google Scholar] [CrossRef]

- Spinelli, R.; Lombardini, C.; Pari, L.; Sadauskiene, L. An alternative to field burning of pruning residues in mountain vineyards. Ecol. Eng. 2014, 70, 212–216. [Google Scholar] [CrossRef]

- Magagnotti, N.; Nati, C.; Spinelli, R.; Vieri, M. Technical protocol for the utilization of pruning residues from vineyards and olive groves. In The Forest-Wood-Energy Chain: Results from the International Project Woodland Energy; ARSIA di Regione Toscana: Florence, Italy, 2009. [Google Scholar]

- Keshtkar, H.; Ashbaugh, L. Size distribution of polycyclic aromatic hydrocarbon particulate emission factors from agricultural burning. Atmos. Res. 2007, 41, 2729–2739. [Google Scholar] [CrossRef]

- Spinelli, R.; Nati, C.; Pari, L.; Mescalchin, E.; Magagnotti, N. Production and quality of biomass fuels from mechanised collection and processing of vineyard pruning residues. Appl. Energy 2012, 80, 374–379. [Google Scholar] [CrossRef]

- Cavalaglio, G.; Cotana, S. Recovery of wineyard pruning residues in an agroenergetic chain. In Proceedings of the 15th European Biomass Conference and Exhibition, Berlin, Germany, 7–11 May 2007. [Google Scholar]

- Garcia-Maraver, A.; Zamorano, M.; Fernandes, U.; Rabacal, M.; Costa, M. Relationship between fuel quality and gaseous and particulate matter emissions in a domestic pellet-fired boiler. Fuel 2014, 119, 141–152. [Google Scholar] [CrossRef]

- Velazquez-Marti, B.; Fernandez-Gonzales, E.; Lopez-Cortez, I.; Salazar-Hernandez, D.M. Quantification of the residual biomass obtained from pruning of vineyards in Mediterranean area. Biomass Bioenergy 2011, 35, 3453–3464. [Google Scholar] [CrossRef]

- Nord-Larsen, T.; Talbot, B. Assessment of forest-fuel resources in Denmark: Technical and economic availability. Biomass Bioenergy 2004, 27, 97–109. [Google Scholar] [CrossRef]

- Kanzian, C.; Holzleitner, F.; Stampfer, K.; Ashton, S. Regional energy wood logistics—Optimizing local fuel supply. Silva Fenn. 2009, 43, 113–128. [Google Scholar] [CrossRef]

- Jirijs, R. Effects of particle size and pile height on storage and fuel quality of comminuted Salix viminalis. Biomass Bioenergy 2005, 28, 193–201. [Google Scholar] [CrossRef]

- Barontini, M.; Scarfone, A.; Spinelli, R.; Gallucci, F.; Santagelo, E.; Acampora, A.; Jirjis, R.; Civitarese, V.; Pari, L. Storage dynamics and fuel quality of poplar chips. Biomass Bioenergy 2014, 62, 17–25. [Google Scholar] [CrossRef]

- Manzone, M. Loader performance during woodchip loading. Biomass Bioenergy 2017, 98, 80–84. [Google Scholar] [CrossRef]

- Manzone, M.; Balsari, P. The energy consumption and economic costs of different vehicles used in transporting woodchips. Fuel 2015, 139, 511–515. [Google Scholar] [CrossRef]

- Manzone, M.; Balsari, P.; Spinelli, R. Small-scale storage techniques for fuel chips from short rotation forestry. Fuel 2013, 109, 687–692. [Google Scholar] [CrossRef]

- Manzone, M.; Balsari, P. Poplar woodchip storage in small and medium piles with different forms, densities and volumes. Biomass Bioenergy 2016, 87, 162–168. [Google Scholar] [CrossRef] [Green Version]

- National Statistical Institute of Italy (INSTAT). 2010. Available online: https://www.iaos-isi.org/papers/CS_9_1_Consalvi.doc (accessed on 15 November 2017).

- Manzone, M.; Gioelli, F.; Balsari, P. Kiwi clear-cut: First evaluation of recovered biomass for energy production. Energies 2017, 10, 1837. [Google Scholar] [CrossRef]

- Lorensi do Canto, J.; Klepac, J.; Rummer, B.; Savoie, P.; Seixas, F. Evaluation of two round baling systems for harvesting understory biomass. Biomass Bioenergy 2011, 35, 2163–2170. [Google Scholar] [CrossRef]

- Fuller, W. Chip pile storage – a review of practices to avoid deterioration and economic losses. Tappi J. 1985, 68, 48–52. [Google Scholar]

- National Standards Authority of Ireland. Solid Biofuels, Determination of Moisture Content—Oven Dry Method, Part 2: Total Moisture—Simplified Method; UNI EN 14774-2; National Standards Authority of Ireland: Dublin, Ireland, 2010. [Google Scholar]

- National Standards Authority of Ireland. Solid Biofuels, Determination of Calorific Value; UNI EN 14918; National Standards Authority of Ireland: Dublin, Ireland, 2010. [Google Scholar]

- Magagnotti, N.; Spinelli, R. COST Action FP0902—Good Practice Guideline for Biomass Production Studies; CNR IVALSA: Florence, Italy, 2012; p. 41. ISBN 978-88-901660-4-4. [Google Scholar]

- Keppel, G.; Wickens, T.D. Design and Analysis: A Researchers Handbook, 4th ed.; Pearson: London, UK, 2004; p. 624. [Google Scholar]

- Tukey, J. Comparing individual means in the analysis of variance. Biometrics 1949, 5, 99–114. [Google Scholar] [CrossRef]

- Gigler, J.K.; Van Loon, W.K.P.; Van den Berg, J.V.; Sonneveld, C.; Meerdink, G. Natural wind drying of willow stems. Biomass Bioenergy 2000, 19, 153–163. [Google Scholar] [CrossRef]

- Steele, P.H.; Mitchell, B.K.; Cooper, J.E.; Arora, S. Bundled slash: A potential new biomass resource for fuels and chemicals. Appl. Biochem. Biotechnol. 2008, 148, 1–13. [Google Scholar] [CrossRef]

- Casal, M.D.; Gil, M.V.; Pevida, C.; Rubiera, F.; Pis, J.J. Influence of storage time on the quality and combustion behaviour of pine woodchips. Energy 2010, 35, 3066–3071. [Google Scholar] [CrossRef] [Green Version]

- Le Lostec, B.; Galanis, N.; Baribeault, J.; Millette, J. Wood chip drying with an adsorption heat pump. Energy 2008, 33, 500–512. [Google Scholar] [CrossRef]

- Jirjis, R. Storage and drying of wood fuel. Biomass Bioenergy 1995, 9, 181–190. [Google Scholar] [CrossRef]

- Jirjis, R.; Thelander, O. The effect of seasonal storage on the chemical composition of forest residue chips. Scand. J. Res. 1990, 5, 437–448. [Google Scholar] [CrossRef]

- Nord-Larsen, T.; Bergstedt, A.; Farver, O.; Heding, N. Drying of firewood—The effect of harvesting time, tree species and shelter of stacked wood. Biomass Bioenergy 2011, 35, 2993–2998. [Google Scholar] [CrossRef]

- Manzone, M. Energy and moisture losses during poplar and black locust logwood storage. Fuel Process. Technol. 2015, 138, 194–201. [Google Scholar] [CrossRef] [Green Version]

- Carmona, R.; Nuñez, T.; Alonso, M.F. Biomass yield and quality of an energy dedicated crop of poplar (Populus spp.) clones in the Mediterranean zone of Chile. Biomass Bioenergy 2015, 74, 96–102. [Google Scholar] [CrossRef]

- Gautam, S.; Pulkki, R.; Shahi, C.; Leitch, M. Fuel quality changes in full tree logging residue during storage in roadside slash piles in Northwestern Ontario. Biomass Bioenergy 2012, 42, 43–50. [Google Scholar] [CrossRef]

- Lin, Y.; Pan, F. Effect of in-wood storage of unprocessed logging residue on biomass feedstock quality. For. Prod. J. 2013, 63, 119–124. [Google Scholar]

- Brand, M.A.; Bolzon de Muniz, G.I.; Quirino, W.F.; Brito, J.O. Storage as a tool to improve wood fuel quality. Biomass Bioenergy 2011, 35, 2581–2588. [Google Scholar] [CrossRef]

- Nurmi, J. The effect of whole-tree storage on the fuelwood properties of short-rotation Salix crops. Biomass Bioenergy 1995, 8, 245–249. [Google Scholar] [CrossRef]

- Hakkila, P. Utilization of Residual Forest Biomass, 1st ed.; Springer: Berlin, Germany, 1989. [Google Scholar]

- Manzone, M. Performances of woodchips stored in pressed bales. Fuel Process. Technol. 2017, 157, 59–64. [Google Scholar] [CrossRef]

| Bales Storage | Orchard Tree | Storage (Days) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 5 | 10 | 15 | 30 | 60 | 90 | 180 | |||

| Air | mean | 1.4a,a | 5.3a,d | 2.8a,b | 4.5a,c | 6.0a,e | 2.8a,b | 16.3a,f | 14.4a,g | 24.3a,h | |

| Covered | Apple | mean | 1.4a,a | 4.9a,d | 2.9a,b | 4.7a,c | 6.1a,e | 3.2a,b | 15.8a,f | 14.5a,g | 24.1a,h |

| SD | 0.25 | 0.34 | 0.29 | 0.42 | 0.15 | 0.29 | 0.18 | 0.23 | 0.21 | ||

| Peach | mean | 1.6a,a | 5.2a,d | 3.1a,b | 4.6a,c | 6.4a,e | 3.1a,b | 16.5a,f | 14.6a,g | 23.9a,h | |

| SD | 0.43 | 0.32 | 0.31 | 0.28 | 0.21 | 0.43 | 0.35 | 0.29 | 0.34 | ||

| Kiwi | mean | 1.5a,a | 5.0a,d | 2.8a,b | 4.5a,c | 5.9a,e | 2.8a,b | 16.7a,f | 14.1a,g | 24.3a,h | |

| SD | 0.26 | 0.16 | 0.40 | 0.18 | 0.33 | 0.26 | 0.51 | 0.32 | 0.26 | ||

| Kiwi (Wrapped) | mean | 1.7a,a | 5.2a,d | 3.2a,b | 4.6a,c | 5.8a,e | 3.3a,b | 15.8a,f | 13.9a,g | 24.9a,h | |

| SD | 0.33 | 0.25 | 0.48 | 0.16 | 0.24 | 0.21 | 0.38 | 0.14 | 0.34 | ||

| Uncovered | Apple | mean | 1.4a,a | 5.1a,d | 2.8a,b | 4.5a,c | 5.8a,e | 3.0a,b | 16.1a,f | 14.1a,g | 24.4a,h |

| SD | 0.29 | 0.34 | 0.28 | 0.31 | 0.43 | 0.34 | 0.33 | 0.42 | 0.28 | ||

| Peach | mean | 1.3a,a | 5.3a,d | 2.9a,b | 4.6a,c | 5.8a,e | 2.9a,b | 15.9a,f | 14.3a,g | 23.8a,h | |

| SD | 0.45 | 0.19 | 0.35 | 0.42 | 0.23 | 0.38 | 0.19 | 0.31 | 0.27 | ||

| Kiwi | mean | 1.5a,a | 4.9a,d | 3.0a,b | 4.4a,c | 6.2a,e | 2.9a,b | 16.4a,f | 14.1a,g | 24.2a,h | |

| SD | 0.38 | 0.29 | 0.18 | 0.43 | 0.31 | 0.25 | 0.41 | 0.42 | 0.39 | ||

| Kiwi (Wrapped) | mean | 1.6a,a | 5.3a,d | 2.6a,b | 4.8a,c | 5.7a,e | 3.2a,b | 16.8a,f | 14.1a,g | 24.8a,h | |

| SD | 0.51 | 0.18 | 0.16 | 0.36 | 0.31 | 0.26 | 0.42 | 0.15 | 0.42 | ||

| Bales Storage | Orchard Tree | Storage (days) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 5 | 10 | 15 | 30 | 60 | 90 | 180 | |||

| Air | mean | 96d,f | 88d,e | 82e,d | 88e,e | 75e,c | 100e,g | 56c,a | 81c,d | 67c,b | |

| Covered | Apple | mean | 46b,d | 46b,d | 45b,d | 43b,c | 41c,c | 39c,c | 22a,b | 18a,a | 19a,a |

| SD | 0.57 | 1.52 | 0.57 | 0.57 | 1.52 | 1.52 | 1.00 | 0.57 | 0.57 | ||

| Peach | mean | 42a,d | 42a,d | 41a,d | 39a,d | 36a,c | 31a,c | 21a,b | 18a,a | 18a,a | |

| SD | 1.52 | 1.52 | 0.57 | 0.57 | 0.57 | 1.00 | 0.57 | 0.57 | 0.57 | ||

| Kiwi | mean | 51c,f | 50c,f | 48c,e | 46c,e | 39b,d | 34b,c | 23a,b | 19a,a | 18a,a | |

| SD | 0.57 | 0.57 | 1.52 | 1.52 | 0.57 | 1.00 | 0.57 | 1.52 | 0.57 | ||

| Kiwi (Wrapped) | mean | 51c,a | 51c,a | 50d,a | 51d,a | 51d,a | 50d,a | 51b,a | 51b,a | 50b,a | |

| SD | 0.57 | 0.57 | 0.57 | 0.57 | 0.57 | 0.57 | 0 | 0.57 | 0.57 | ||

| Uncovered | Apple | mean | 45b,d | 46b,d | 44b,d | 43b,d | 41b,c | 44b,d | 29a,b | 22a,a | 21a,a |

| SD | 1.52 | 0.57 | 0.28 | 0.31 | 0.43 | 0.34 | 0.33 | 0.42 | 0.28 | ||

| Peach | mean | 41a,e | 42a,e | 42a,e | 40a,e | 37a,d | 41a,e | 27a,c | 22a,a | 20a,a | |

| SD | 1.00 | 1.52 | 0.35 | 0.42 | 0.23 | 0.38 | 0.19 | 0.31 | 0.27 | ||

| Kiwi | mean | 51c,e | 51c,e | 48a,d | 49c,d | 46c,c | 48c,d | 30a,b | 22a,a | 22a,a | |

| SD | 0.57 | 0.57 | 0.18 | 0.43 | 0.31 | 0.25 | 0.41 | 0.42 | 0.39 | ||

| Kiwi (Wrapped) | mean | 51c,a | 52c,a | 51d,a | 51d,a | 52d,a | 51d,a | 51b,a | 51b,a | 51b,a | |

| SD | 1.52 | 1.52 | 0.57 | 0 | 0.57 | 0.57 | 1.52 | 0.57 | 0.57 | ||

| Bales Storage | Orchard Tree | Initial Values (MJ kg−1) | Final Values (MJ kg−1) | Δ Value | ||||

|---|---|---|---|---|---|---|---|---|

| HHV | LHV | HHV | LHV | HHV | LHV | |||

| Covered | Apple | mean | 18.74a | 8.94b | 18.73a | 14.85a | −0.01 | 5.91 |

| SD | 0.057 | 0.134 | 0.08 | 0.078 | - | - | ||

| Peach | mean | 18.66ab | 9.94a | 18.68ab | 14.74a | 0.02 | 4.80 | |

| SD | 0.044 | 0.097 | 0.089 | 0.193 | - | - | ||

| Kiwi | mean | 18.68ab | 7.96c | 18.74a | 14.78a | 0.04 | 6.82 | |

| SD | 0.067 | 0.139 | 0.095 | 0.163 | - | - | ||

| Kiwi (wrapped) | mean | 18.73a | 8.00c | 18.77a | 8.02b | 0.04 | 0.02 | |

| SD | 0.075 | 0.156 | 0.055 | 0.147 | - | - | ||

| Uncovered | Apple | mean | 18.73a | 9.06b | 18.73a | 14.29a | 0.00 | 5.23 |

| SD | 0.08 | 0.16 | 0.075 | 0.187 | - | - | ||

| Peach | mean | 18.68ab | 10.09a | 18.74a | 14.36a | 0.06 | 4.27 | |

| SD | 0.089 | 0.174 | 0.095 | 0.162 | - | - | ||

| Kiwi | mean | 18.74a | 7.86c | 18.66ab | 14.16a | −0.08 | 6.30 | |

| SD | 0.095 | 0.167 | 0.044 | 0.088 | - | - | ||

| Kiwi (wrapped) | mean | 18.73a | 7.86c | 18.68ab | 7.81b | −0.05 | −0.05 | |

| SD | 0.040 | 0.121 | 0.094 | 0.117 | - | - | ||

| Bales Storage | Orchard Tree | Fresh Matter (kg) | Total (*) Dry Matter (kg) | |||

|---|---|---|---|---|---|---|

| Bale | Total (*) | Beginning | End | |||

| Mean | SD | |||||

| Covered | Apple | 449.1b | 7.00 | 1347.4 | 723.0ns | 721.8ns |

| Peach | 431.1a | 4.42 | 1293.2 | 758.7ns | 754.8ns | |

| Kiwi | 486.8c | 6.81 | 1460.4 | 710.7ns | 707.0ns | |

| Kiwi (Wrapped) | 485.9c | 6.94 | 1457.6 | 719.2ns | 719.1ns | |

| Uncovered | Apple | 460.5b | 8.66 | 1381.4 | 750.6ns | 747.2ns |

| Peach | 437.5a | 2.84 | 1312.6 | 778.8ns | 775.6ns | |

| Kiwi | 488.1c | 3.40 | 1464.2 | 712.6ns | 709.9ns | |

| Kiwi (Wrapped) | 490.0c | 7.69 | 1470.0 | 715.4ans | 715.3ns | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manzone, M.; Gioelli, F.; Balsari, P. Effects of Different Storage Techniques on Round-Baled Orchard-Pruning Residues. Energies 2019, 12, 1044. https://doi.org/10.3390/en12061044

Manzone M, Gioelli F, Balsari P. Effects of Different Storage Techniques on Round-Baled Orchard-Pruning Residues. Energies. 2019; 12(6):1044. https://doi.org/10.3390/en12061044

Chicago/Turabian StyleManzone, Marco, Fabrizio Gioelli, and Paolo Balsari. 2019. "Effects of Different Storage Techniques on Round-Baled Orchard-Pruning Residues" Energies 12, no. 6: 1044. https://doi.org/10.3390/en12061044

APA StyleManzone, M., Gioelli, F., & Balsari, P. (2019). Effects of Different Storage Techniques on Round-Baled Orchard-Pruning Residues. Energies, 12(6), 1044. https://doi.org/10.3390/en12061044