An Optimum Enthalpy Approach for Melting and Solidification with Volume Change

Abstract

:1. Introduction

2. Mathematical Model

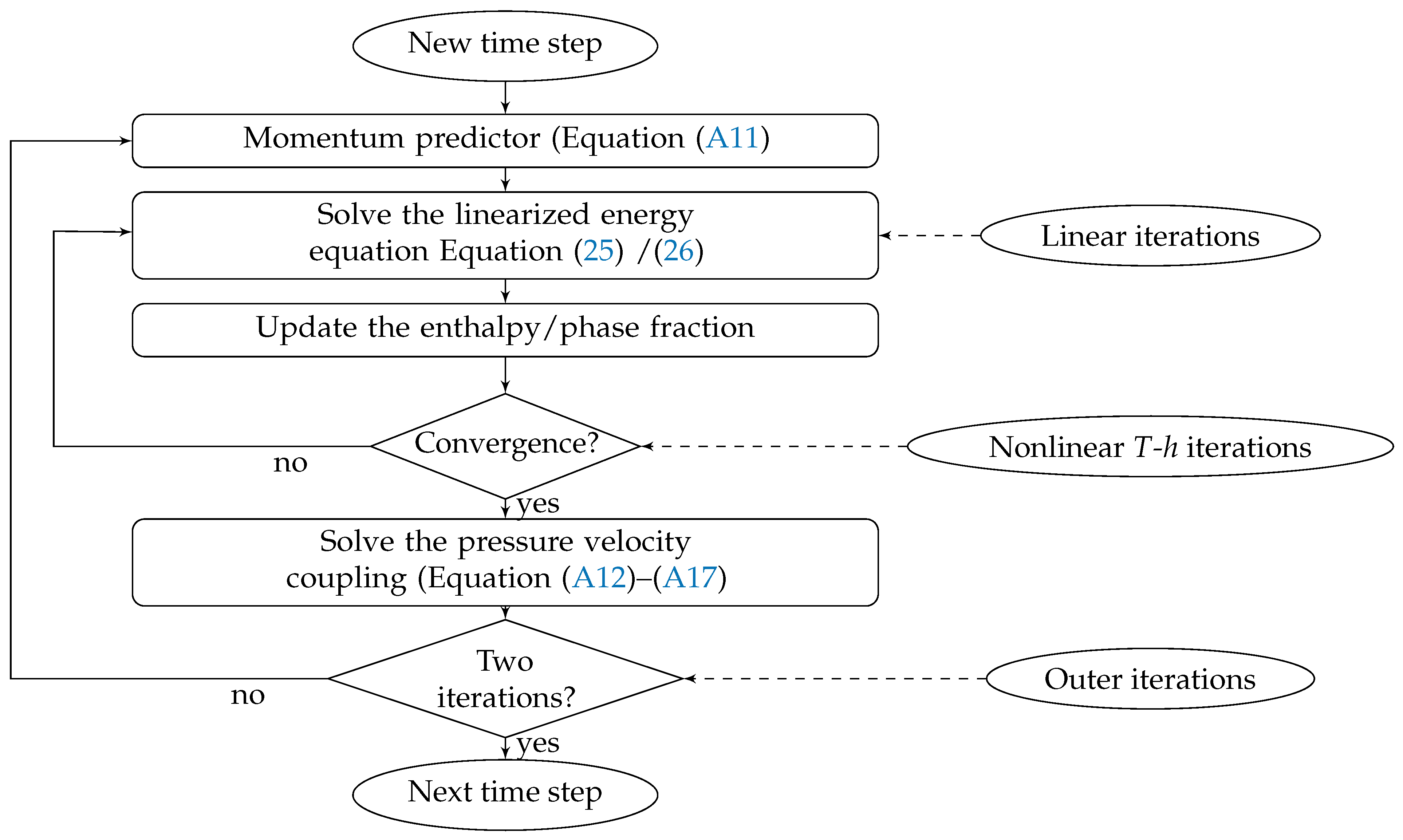

3. Numerical Solution

3.1. Optimum Approach

3.2. Optimum Density Approach

3.3. Source Based Method

3.4. Test Cases

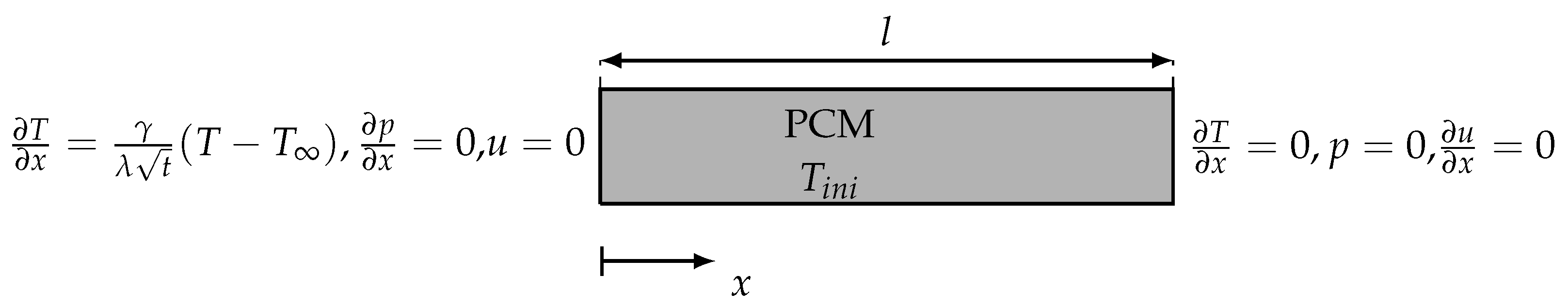

3.4.1. One-Dimensional Solidification

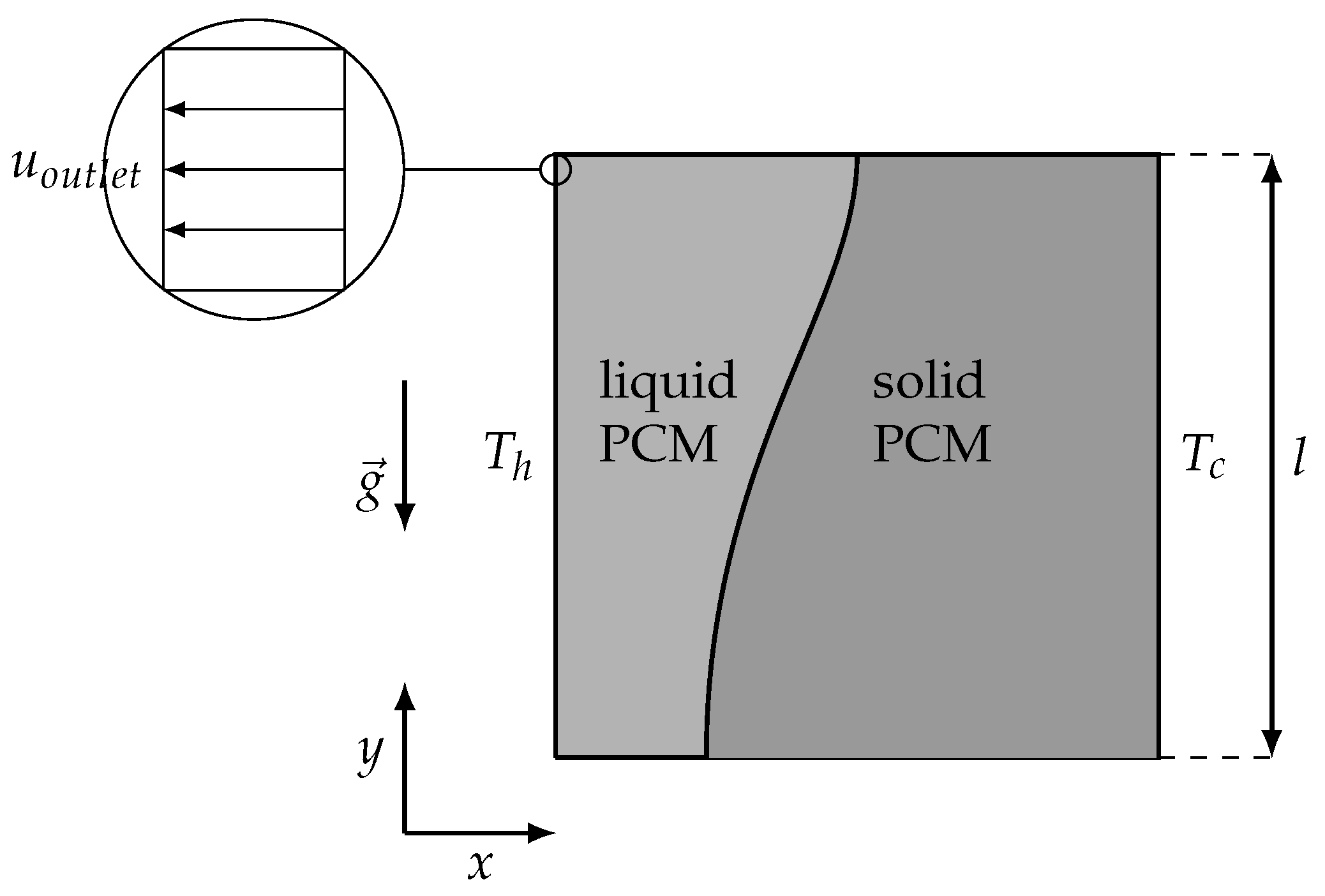

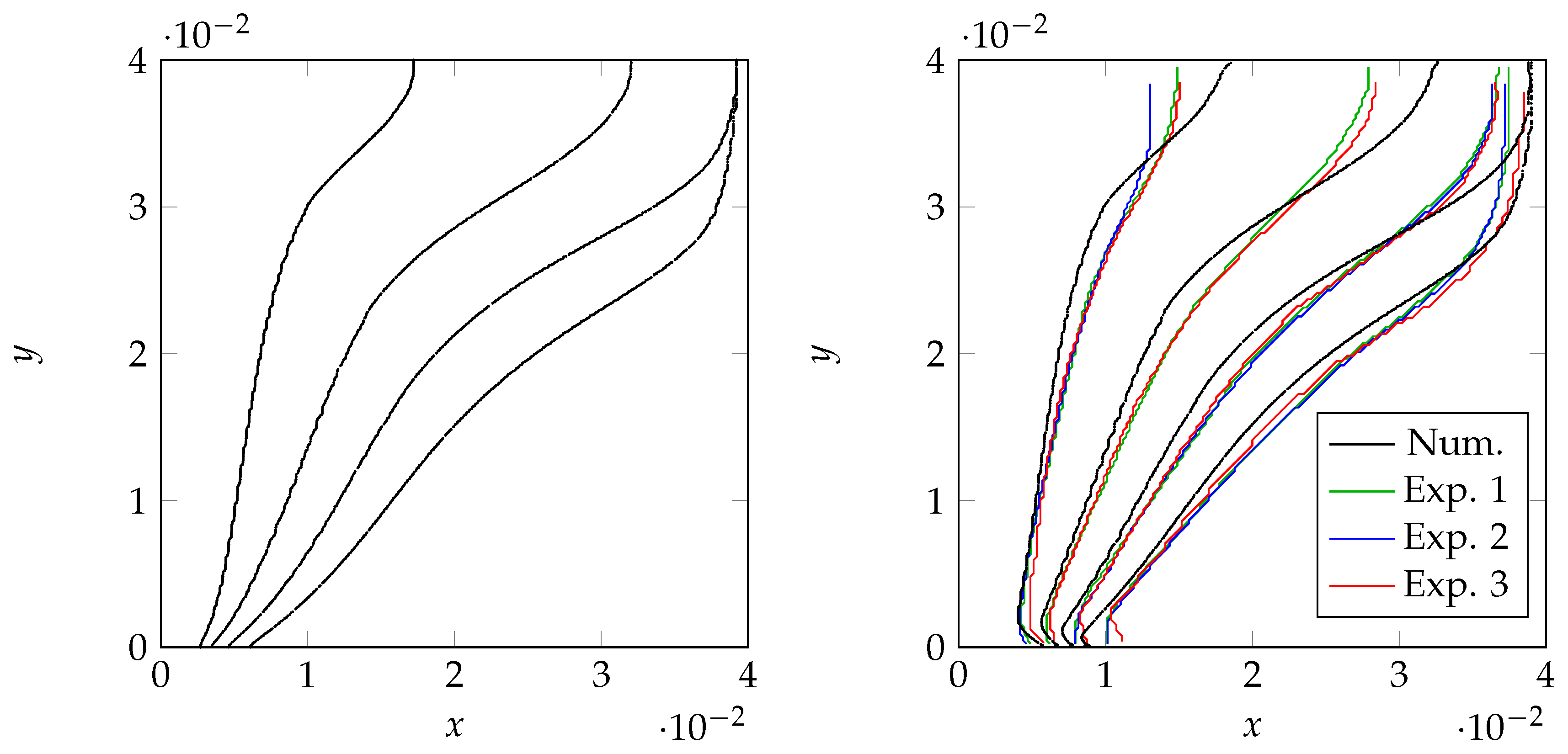

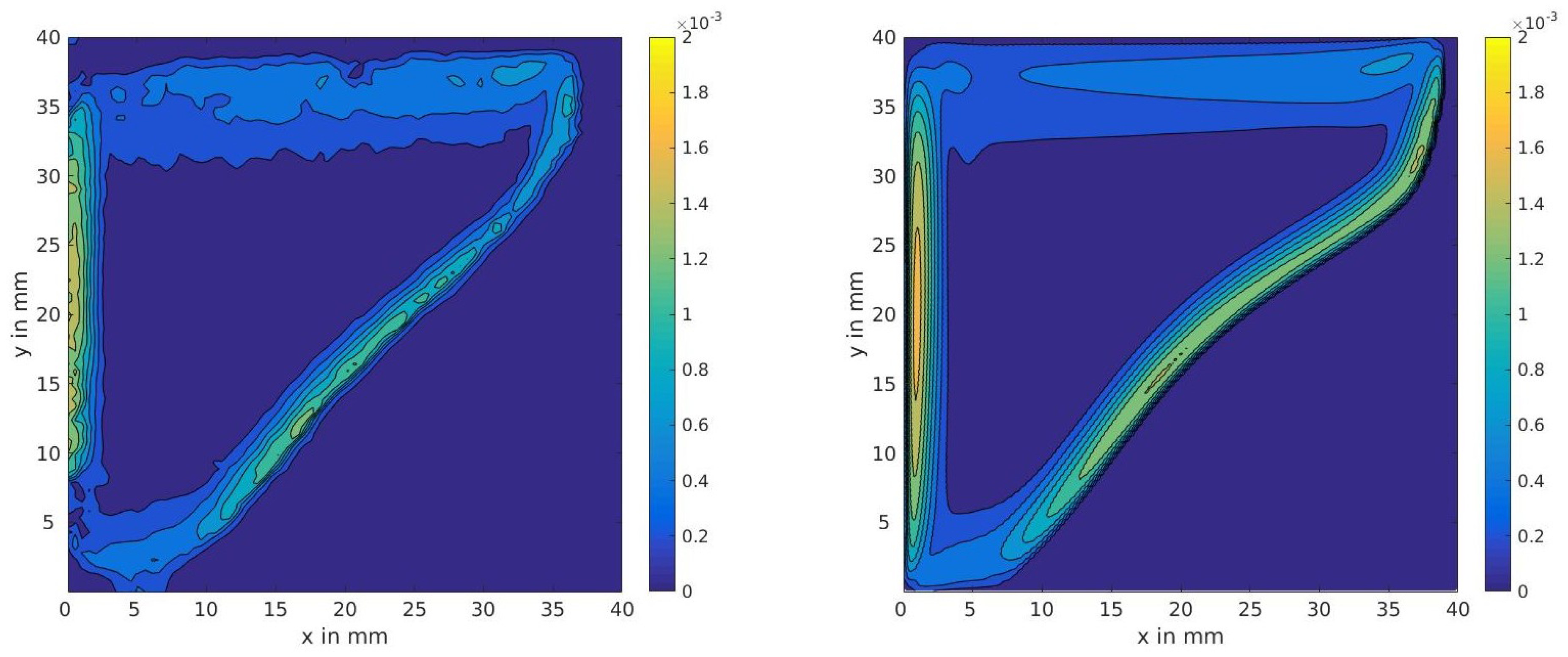

3.4.2. Two-Dimensional Melting with Convection

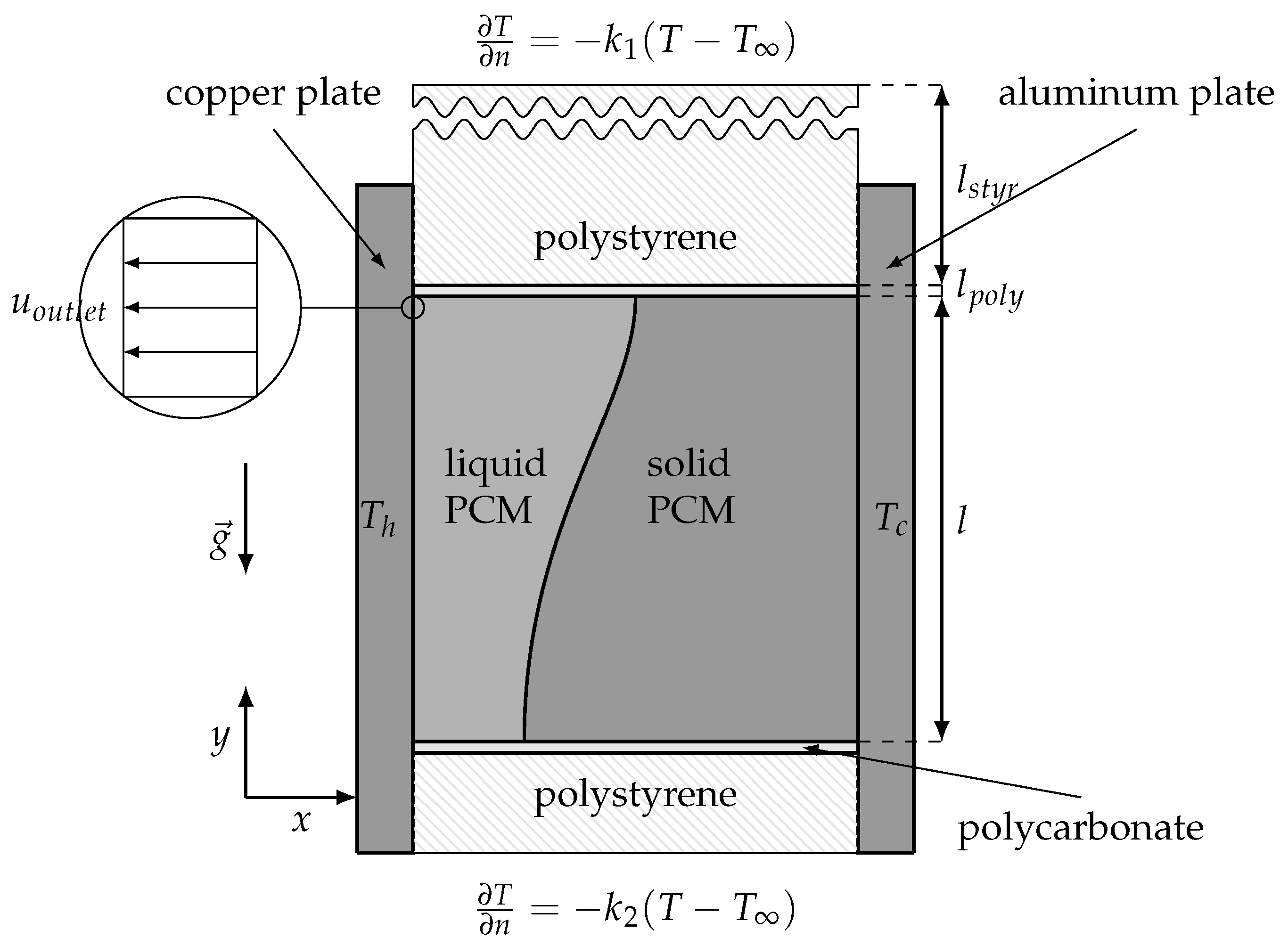

3.5. Validation Case

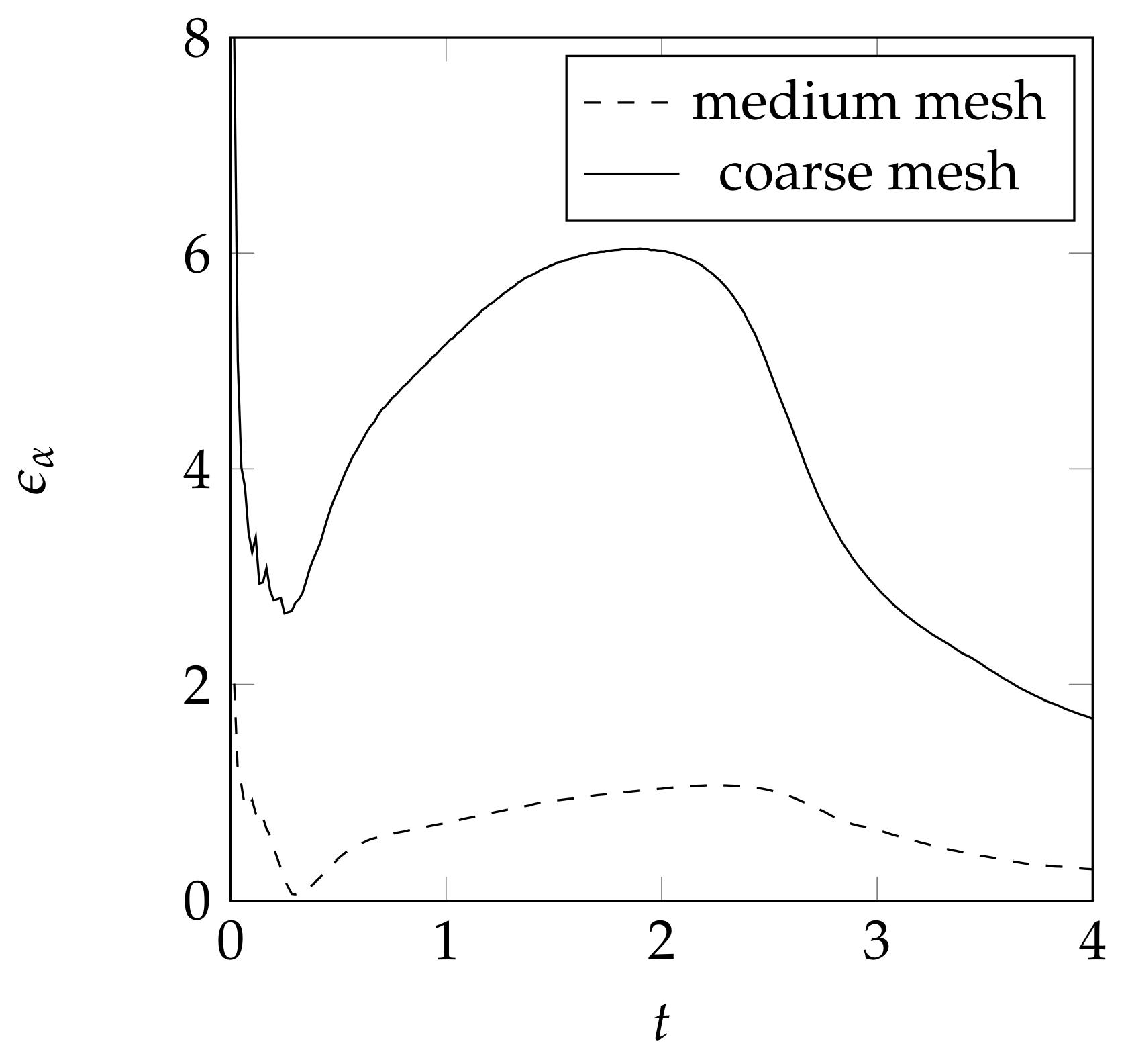

3.6. Mesh Influence for the Convection Test Case

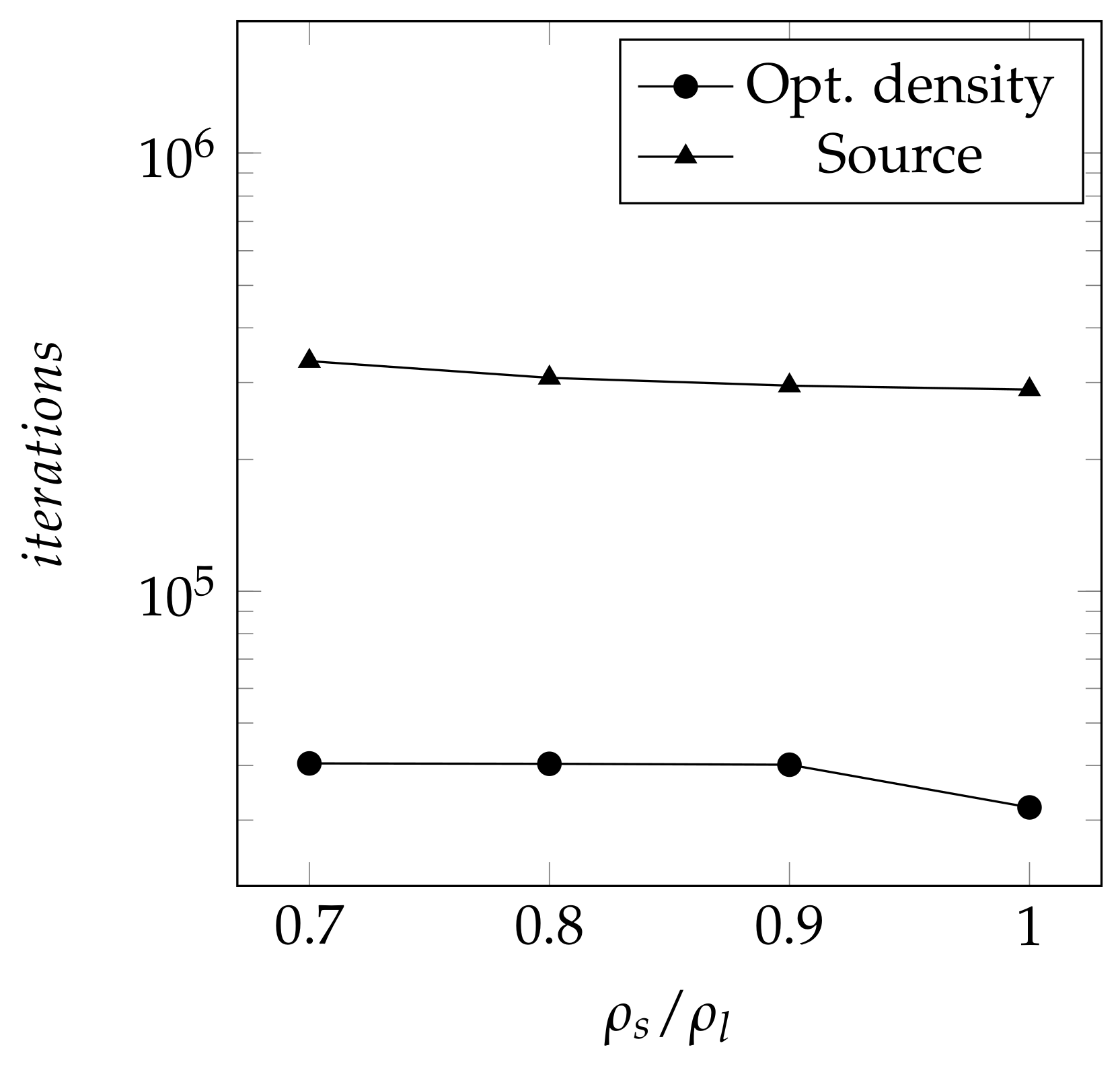

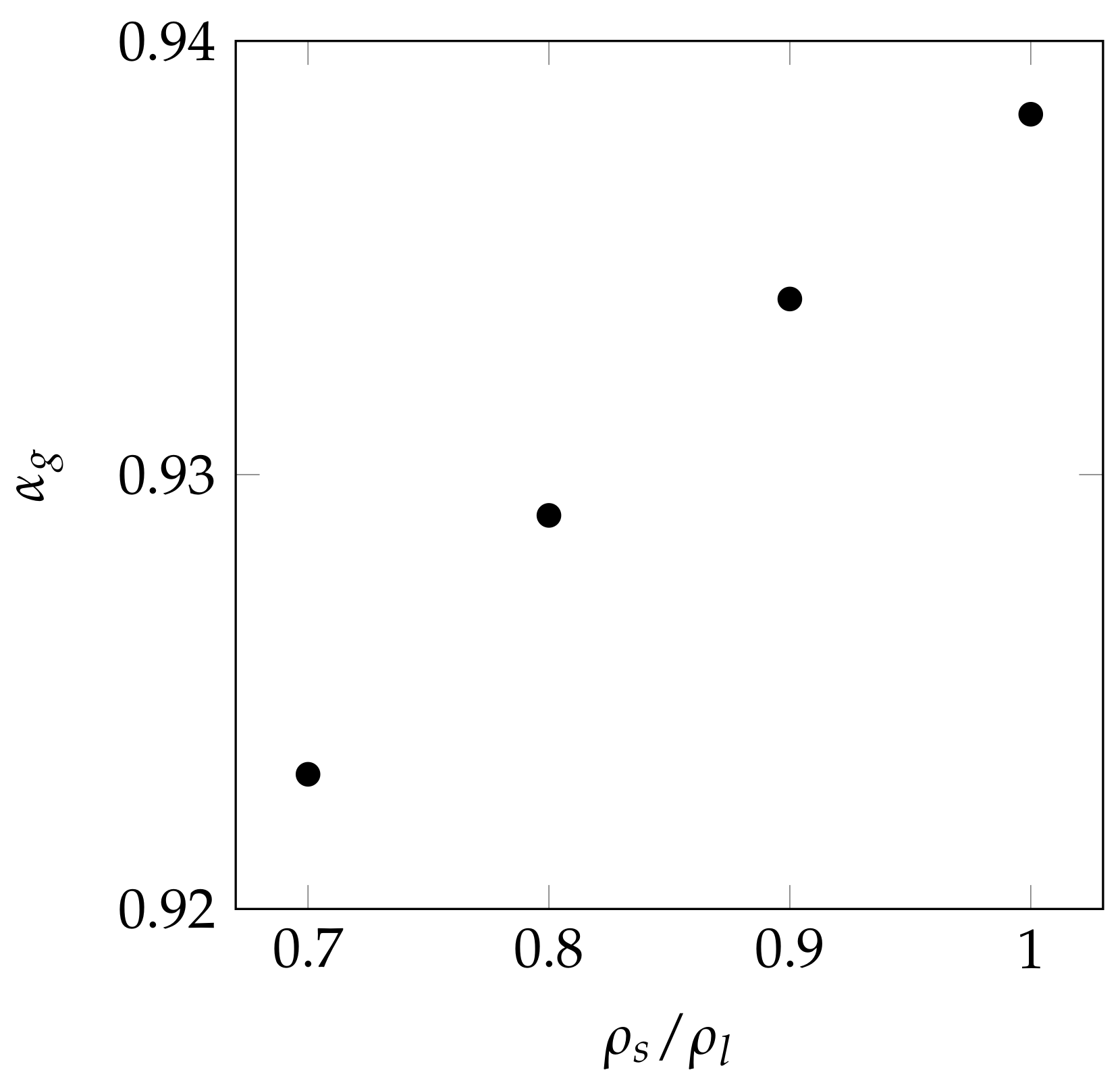

4. Results and Discussion

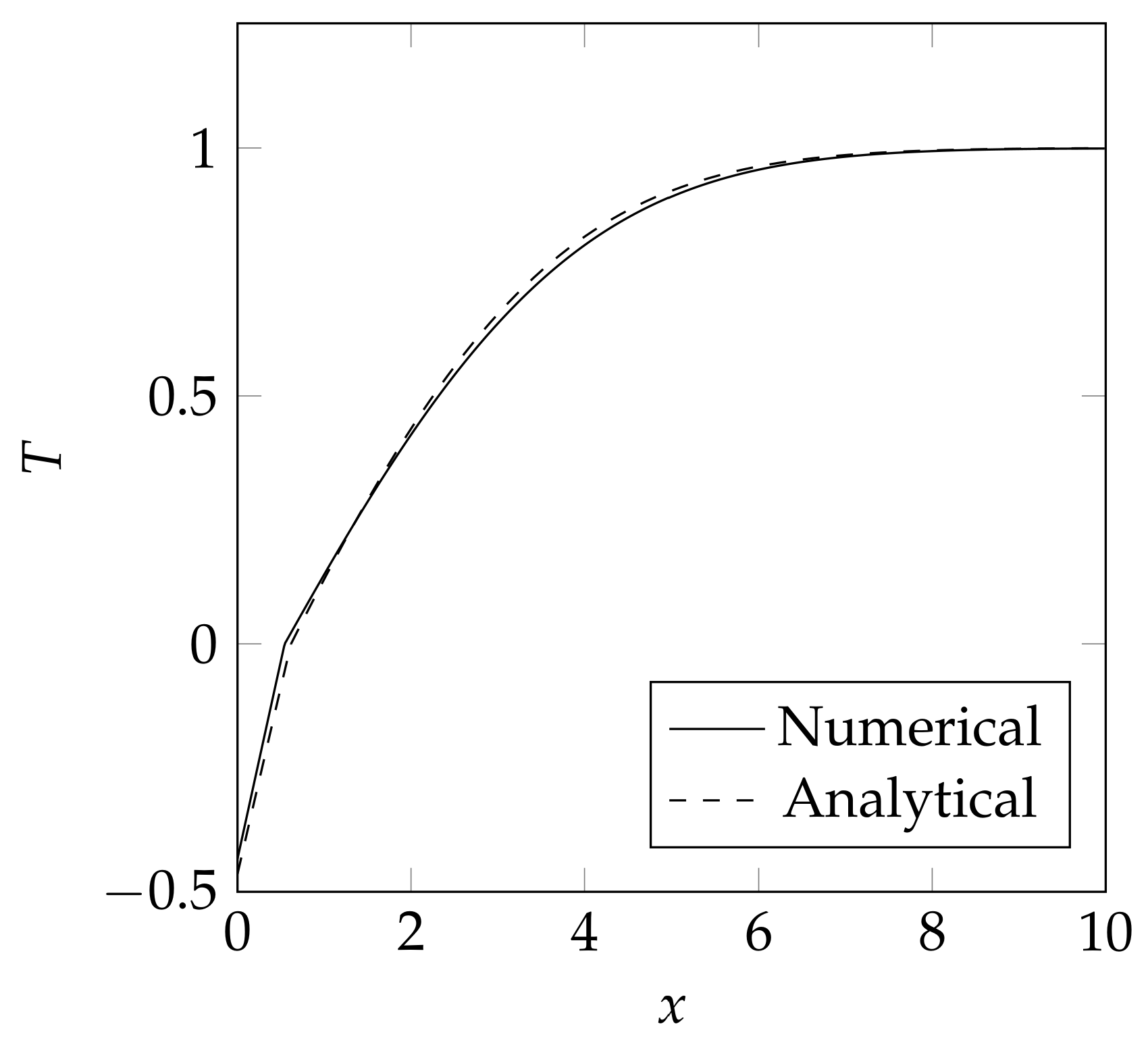

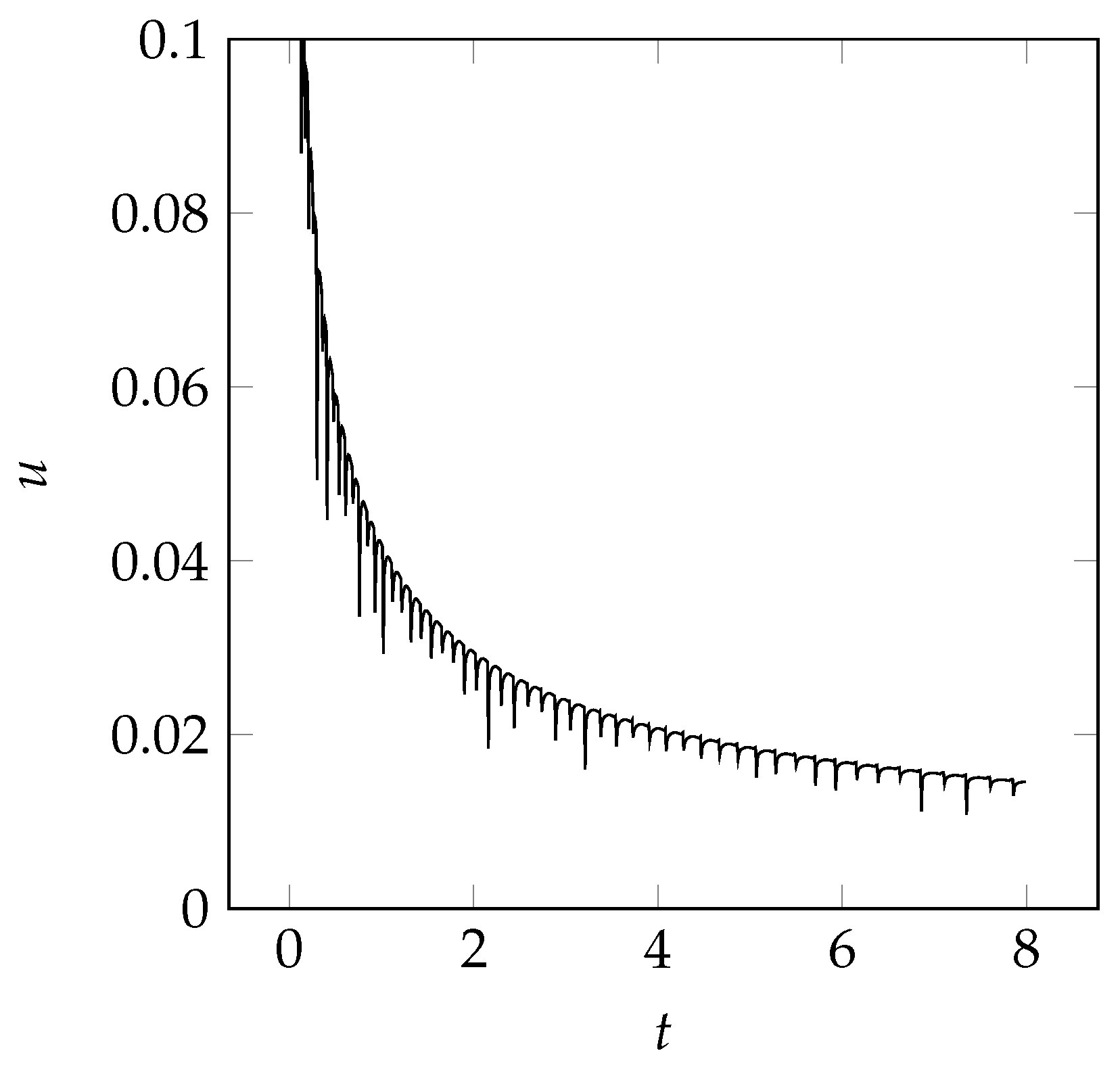

4.1. One-Dimensional Solidification

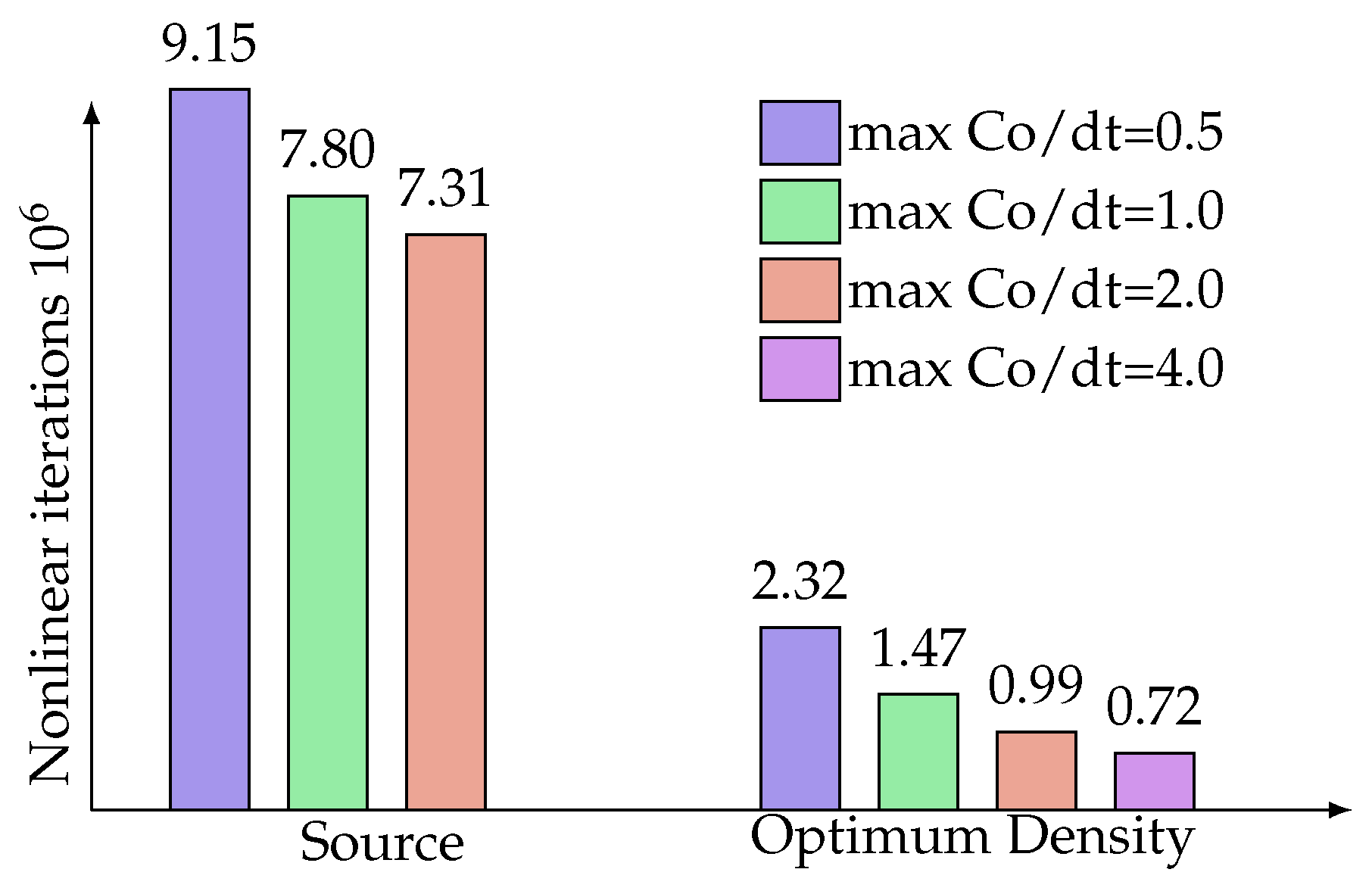

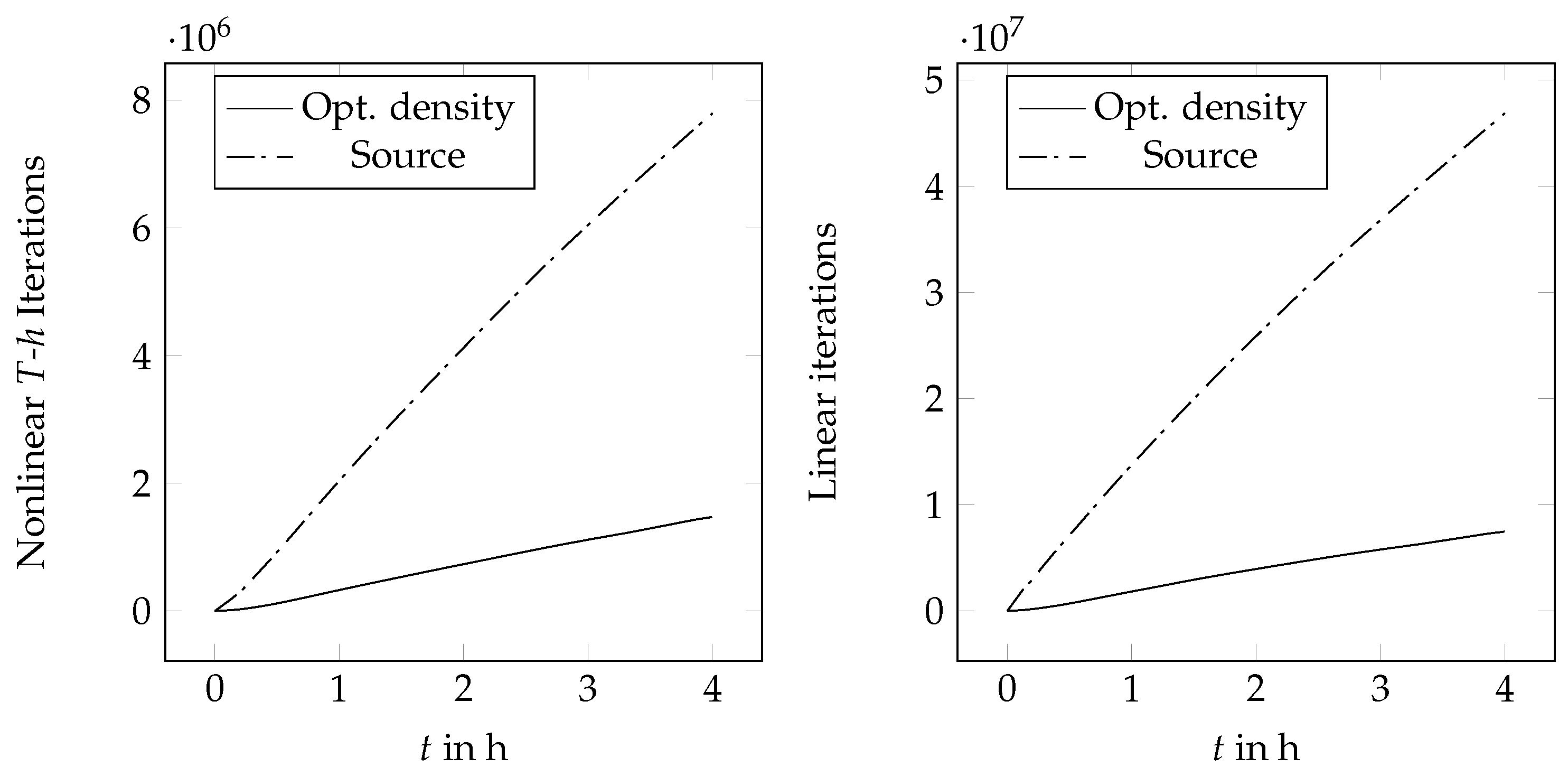

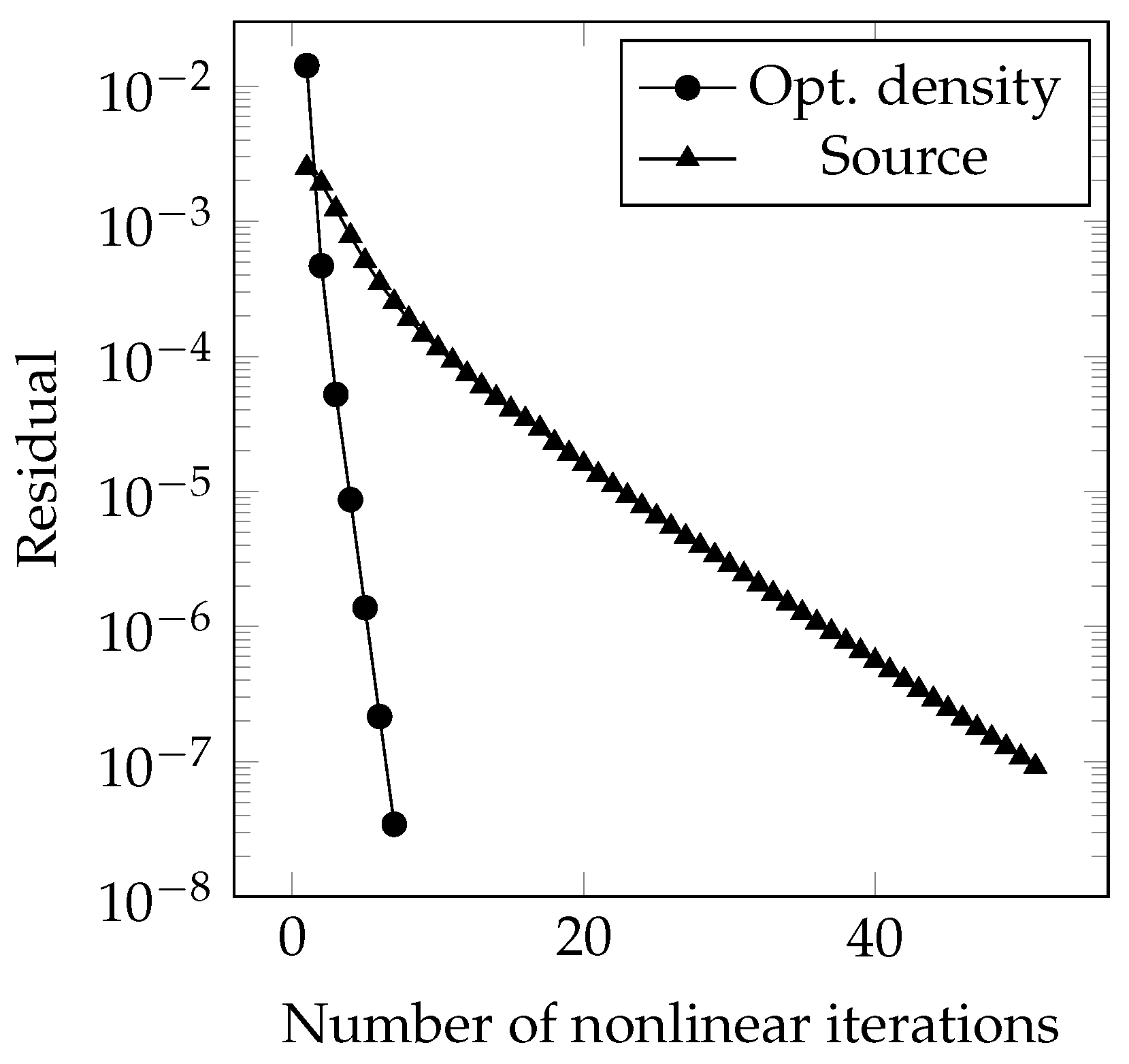

4.2. Two-Dimensional Melting of Octadecane with Natural Convection

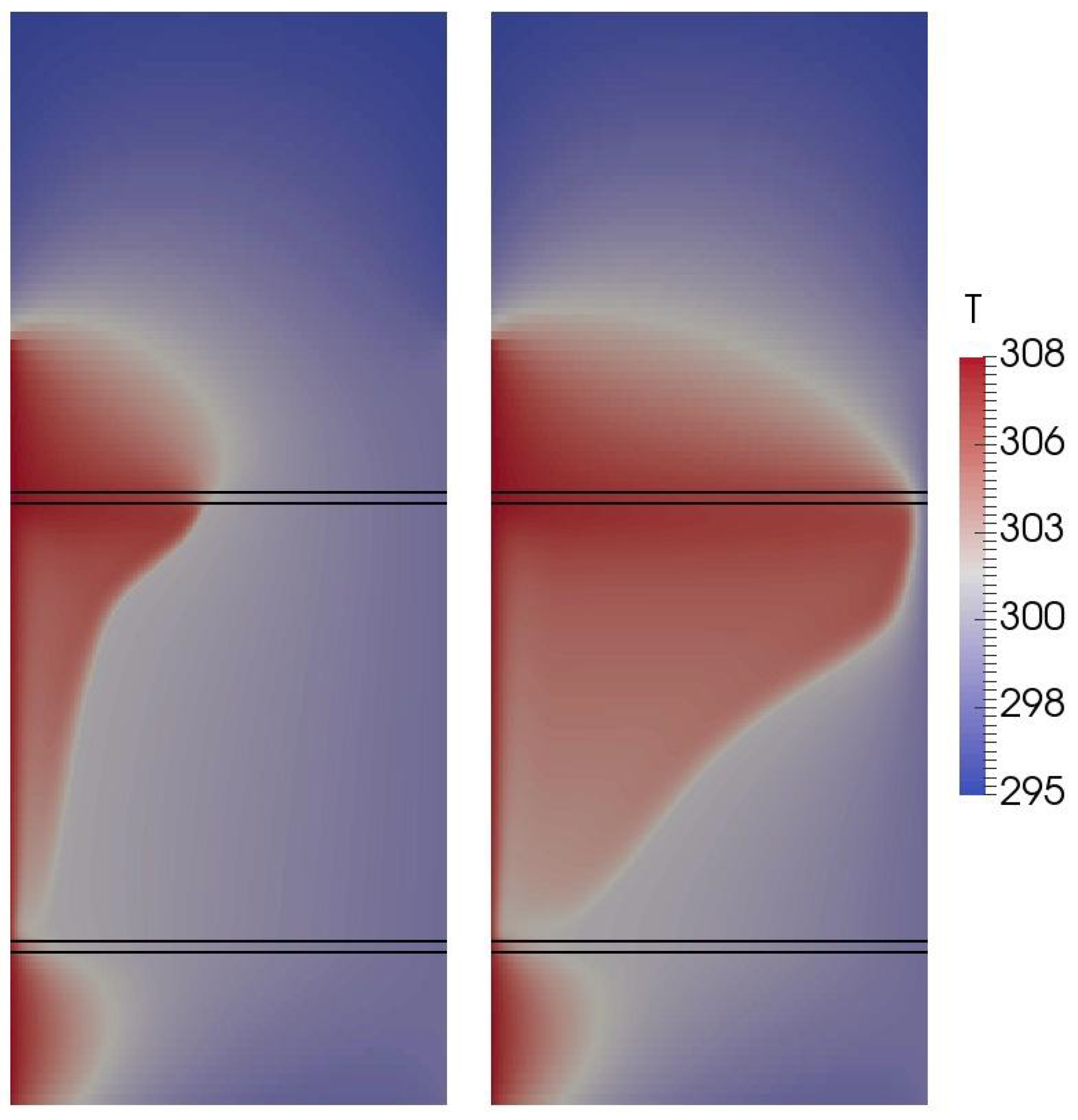

4.3. Validation

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| heat capacity | |

| f | function |

| h | enthalpy |

| gravitational acceleration | |

| k | heat transfer coefficient |

| l | length |

| m | mass |

| normalized gradient | |

| p | pressure |

| t | time |

| velocity vector | |

| x | coordinate |

| y | coordinate |

| Darcy term | |

| A | area |

| D | Darcy constant |

| E | identity matrix |

| L | latent heat of fusion |

| T | temperature |

| V | volume |

| phase fraction | |

| volumetric coefficient of thermal expansion | |

| abbreviation | |

| small numerical constant | |

| thermal conductivity | |

| viscosity | |

| density | |

| stress tensor | |

| underrelaxation factor | |

| c | cold |

| g | global |

| h | hot |

| i | index |

| initial | |

| k | index |

| l | liquid |

| m | index |

| o | old |

| reference | |

| residuum | |

| s | solid |

| y | y component |

| L | liquidus |

| S | solidus |

| T | transpose |

Appendix A

Appendix A.1. Derivation of the Pressure Equation

Appendix A.2. PISO-Algorithm

References

- Kuboth, S.; König-Haagen, A.; Brüggemann, D. Numerical analysis of shell-and-tube type latent thermal energy storage performance with different arrangements of circular fins. Energies 2017, 10, 274. [Google Scholar] [CrossRef]

- Kozak, Y.; Rozenfeld, T.; Ziskind, G. Close-contact melting in vertical annular enclosures with a non-isothermal base: Theoretical modeling and application to thermal storage. Int. J. Heat Mass Transf. 2014, 72, 114–127. [Google Scholar] [CrossRef]

- Brent, A.D.; Voller, V.R.; Reid, K.J. Enthalpy-Porosity Technique for Modeling Convection-Diffusion Phase Change: Application To the Melting of a Pure Metal. Numer. Heat Transf. 1988, 13, 297–318. [Google Scholar] [CrossRef]

- Voller, V.R. An overview of numerical methods for solving phase change problems. Adv. Numer. Heat Transf. 1996, 1, 341–380. [Google Scholar]

- Crank, J. Free and Moving Boundary Problems; Oxford Science Publications: New York, NY, USA, 1984. [Google Scholar]

- König-Haagen, A.; Franquet, E.; Pernot, E.; Brüggemann, D. A comprehensive benchmark of fixed-grid methods for the modeling of melting. Int. J. Therm. Sci. 2017, 118, 69–103. [Google Scholar] [CrossRef]

- Faden, M.; König-Haagen, A.; Höhlein, S.; Brüggemann, D. An implicit algorithm for melting and settling of phase change material inside macrocapsules. Int. J. Heat Mass Transf. 2018, 117, 757–767. [Google Scholar] [CrossRef]

- Rose, M.E. A Method for Calculating Solutions of Parabolic Equations with a Free Boundary. Math. Comput. 1960, 14, 249–256. [Google Scholar] [CrossRef]

- Solomon, A.D. Some Remarks on the Stefan Problem. Math. Comput. 1966, 20, 347–360. [Google Scholar] [CrossRef]

- Morgan, K. A numerical analysis of freezing and melting with convection. Comput. Methods Appl. Mech. Eng. 1981, 28, 275–284. [Google Scholar] [CrossRef]

- Gartling, D.K. Finite element analysis of convective heat transfer problems with change of phase. Comput. Methods Fluids 1980, 257–284. [Google Scholar]

- Voller, V.R.; Prakash, C. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int. J. Heat Mass Transf. 1987, 30, 1709–1719. [Google Scholar] [CrossRef]

- Swaminathan, C.R.; Voller, V.R. A general enthalpy method for modeling solidification processes. Metall. Trans. B 1992, 23, 651–664. [Google Scholar] [CrossRef]

- Swaminathan, C.R.; Voller, V.R. On the enthalpy method. Int. J. Numer. Methods Heat Fluid Flow 1993, 3, 233–244. [Google Scholar] [CrossRef]

- Danaila, I.; Moglan, R.; Hecht, F.; Le Masson, S. A Newton method with adaptive finite elements for solving phase-change problems with natural convection. J. Comput. Phys. 2014, 274, 826–840. [Google Scholar] [CrossRef]

- Assis, E.; Katsman, L.; Ziskind, G.; Letan, R. Numerical and experimental study of melting in a spherical shell. Int. J. Heat Mass Transf. 2007, 50, 1790–1804. [Google Scholar] [CrossRef]

- Assis, E.; Ziskind, G.; Letan, R. Numerical and Experimental Study of Solidification in a Spherical Shell. J. Heat Transf. 2009, 131, 24502–24506. [Google Scholar] [CrossRef]

- Galione, P.A.; Lehmkuhl, O.; Rigola, J.; Oliva, A. Fixed-grid numerical modeling of melting and solidification using variable thermo-physical properties - Application to the melting of n-Octadecane inside a spherical capsule. Int. J. Heat Mass Transf. 2015, 86, 721–743. [Google Scholar] [CrossRef]

- Hassab, M.A.; Sorour, M.M.; Khamis Mansour, M.; Zaytoun, M.M. Effect of volume expansion on the melting process’s thermal behavior. Appl. Therm. Eng. 2017, 115, 350–362. [Google Scholar] [CrossRef]

- Dallaire, J.; Gosselin, L. Numerical modeling of solid-liquid phase change in a closed 2D cavity with density change, elastic wall and natural convection. Int. J. Heat Mass Transf. 2017, 114, 903–914. [Google Scholar] [CrossRef]

- Faden, M.; Linhardt, C.; Höhlein, S.; König-Haagen, A.; Brüggemann, D. Velocity field and phase boundary measurements during melting of n-octadecane in a cubical test cell. Int. J. Heat Mass Transf. 2019, 135, 104–114. [Google Scholar] [CrossRef]

- Alexiades, V.; Drake, J.B. A weak formulation for phase-change problems with bulk movement due to unequal densities. In Free Boundary Problems Involving Solids; Longman: Harlow, UK, 1993; pp. 82–87. [Google Scholar]

- OpenFOAM Ltd. OpenFOAM 2.2.2, The OpenFOAM Foundation Ltd.: London, UK, 2013.

- Tarzia, D.A. Exact Solution for a Stefan Problem with Convective Boundary Condition and Density Jump; PAMM Wiley: Hoboken, NJ, USA, 2007; Volume 7, pp. 1040307–1040308. [Google Scholar]

- Zhang, P.; Ma, Z.W.; Wang, R.Z. An overview of phase change material slurries: MPCS and CHS. Renew. Sustain. Energy Rev. 2010, 14, 598–614. [Google Scholar] [CrossRef]

- Vélez, C.; Khayet, M.; Ortiz De Zárate, J.M. Temperature-dependent thermal properties of solid/liquid phase change even-numbered n-alkanes: N-Hexadecane, n-octadecane and n-eicosane. Appl. Energy 2015, 143, 383–394. [Google Scholar] [CrossRef]

- Klan, H.; Thess, A. F2 Wärmeübertragung durch freie Konvektion: Außenströmung. In VDI-Wärmeatlas; Springer Vieweg: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Rhie, C.M.; Chow, W.L. Numerical study of the turbulent flow past an airfoil with trailing edge separation. AIAA J. 1983, 21, 1525–1532. [Google Scholar] [CrossRef]

- Issa, R.I. Solution of the implicitly discretised fluid flow equations by operator-splitting. J. Comput. Phys. 1986, 62, 40–65. [Google Scholar] [CrossRef]

- Jasak, H. Error Analysis and Estimation for the Finite Volume Method with Applications to Fluid Flows. Ph.D. Thesis, Imperial College of Science, Technology and Medicine, London, UK, 1996. [Google Scholar]

- Damián, S.M. An Extended Mixture Model for the Simultaneous Treatment of Short and Long Scale Interfaces. Ph.D. Thesis, Universidad Nacional Del Litoral, Santa Fe, Argentina, 2013. [Google Scholar]

| Property | Unit | Value |

|---|---|---|

| Melting temperature | K | 301.15 [25] |

| Melting Range (-) | K | 0.05 |

| Latent heat of fusion | kJ/kg | 243.68 [26] |

| Density (solid) | kg/m3 | 867.00 |

| Density (liquid) | kg/m3 | 775.60 [26] |

| Volumetric thermal expansion coefficient | 1/K | 8.36 × [26] |

| Specific heat capacity (solid) | kJ/(kg K) | 1.90 [26] |

| Specific heat capacity (liquid) | kJ/(kg K) | 2.24 [26] |

| Thermal conductivity (solid) | W/(m K) | 0.32 [26] |

| Thermal conductivity (liquid) | W/(m K) | 0.15 [26] |

| Dynamic viscosity () | mPas | 3.75 |

| Darcy constant | kg/(m3s) |

| Property | Unit | Value |

|---|---|---|

| Density PC | kg/m3 | 1200.0 |

| Density PS | kg/m3 | 40.0 |

| Specific heat capacity PC | kJ/(kg K) | 1170.0 |

| Specific heat capacity PS | kJ/(kg K) | 1500.0 |

| Thermal conductivity PC | W/(m K) | 0.21 |

| Thermal conductivity PS | W/(m K) | 0.04 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faden, M.; König-Haagen, A.; Brüggemann, D. An Optimum Enthalpy Approach for Melting and Solidification with Volume Change. Energies 2019, 12, 868. https://doi.org/10.3390/en12050868

Faden M, König-Haagen A, Brüggemann D. An Optimum Enthalpy Approach for Melting and Solidification with Volume Change. Energies. 2019; 12(5):868. https://doi.org/10.3390/en12050868

Chicago/Turabian StyleFaden, Moritz, Andreas König-Haagen, and Dieter Brüggemann. 2019. "An Optimum Enthalpy Approach for Melting and Solidification with Volume Change" Energies 12, no. 5: 868. https://doi.org/10.3390/en12050868

APA StyleFaden, M., König-Haagen, A., & Brüggemann, D. (2019). An Optimum Enthalpy Approach for Melting and Solidification with Volume Change. Energies, 12(5), 868. https://doi.org/10.3390/en12050868