Weighted-PSO Applied to Tune Sliding Mode Plus PI Controller Applied to a Boost Converter in a PV System

Abstract

:1. Introduction

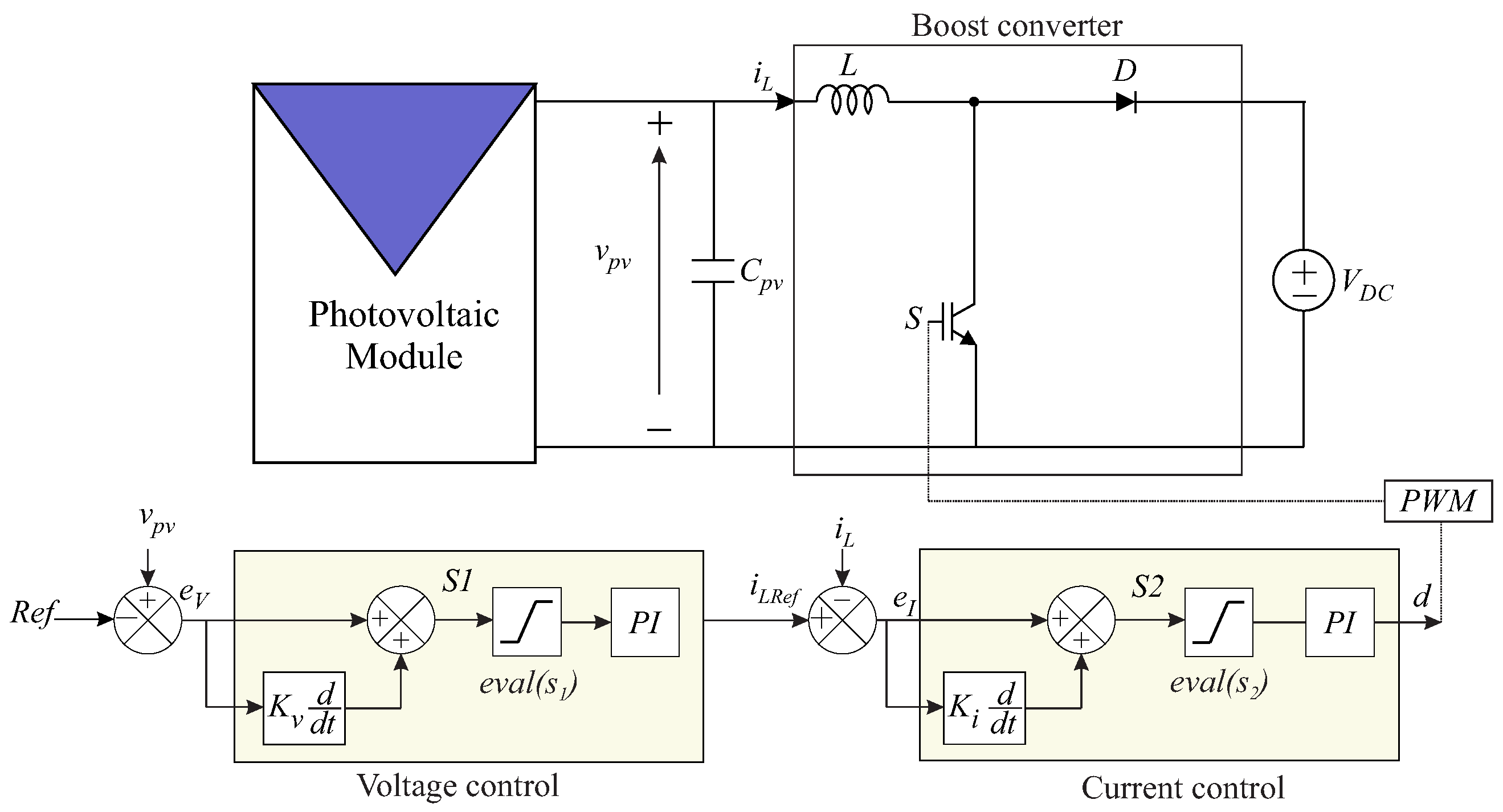

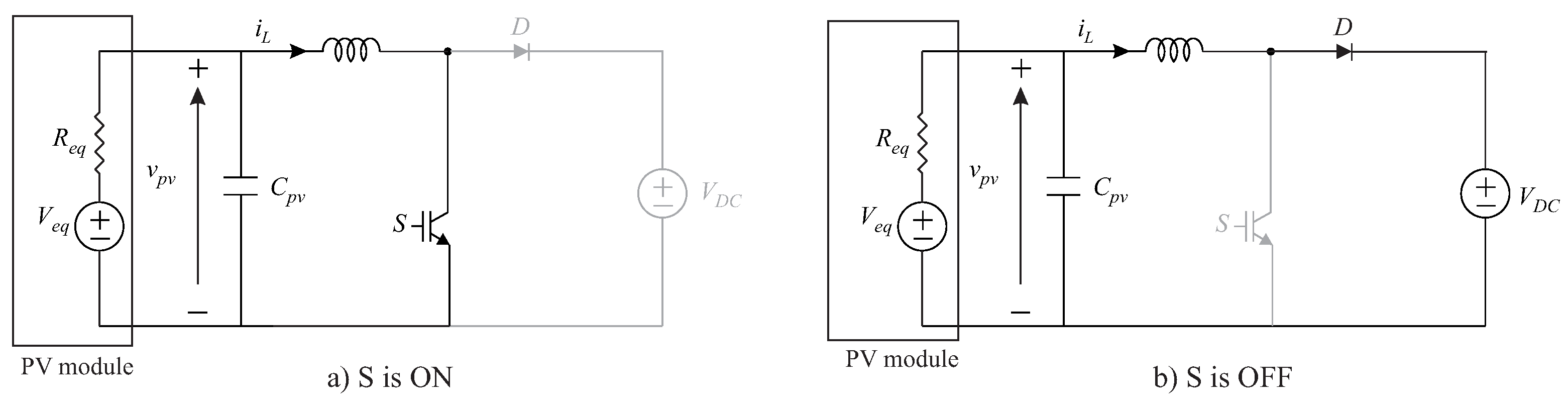

2. System Description

Boost Converter Model

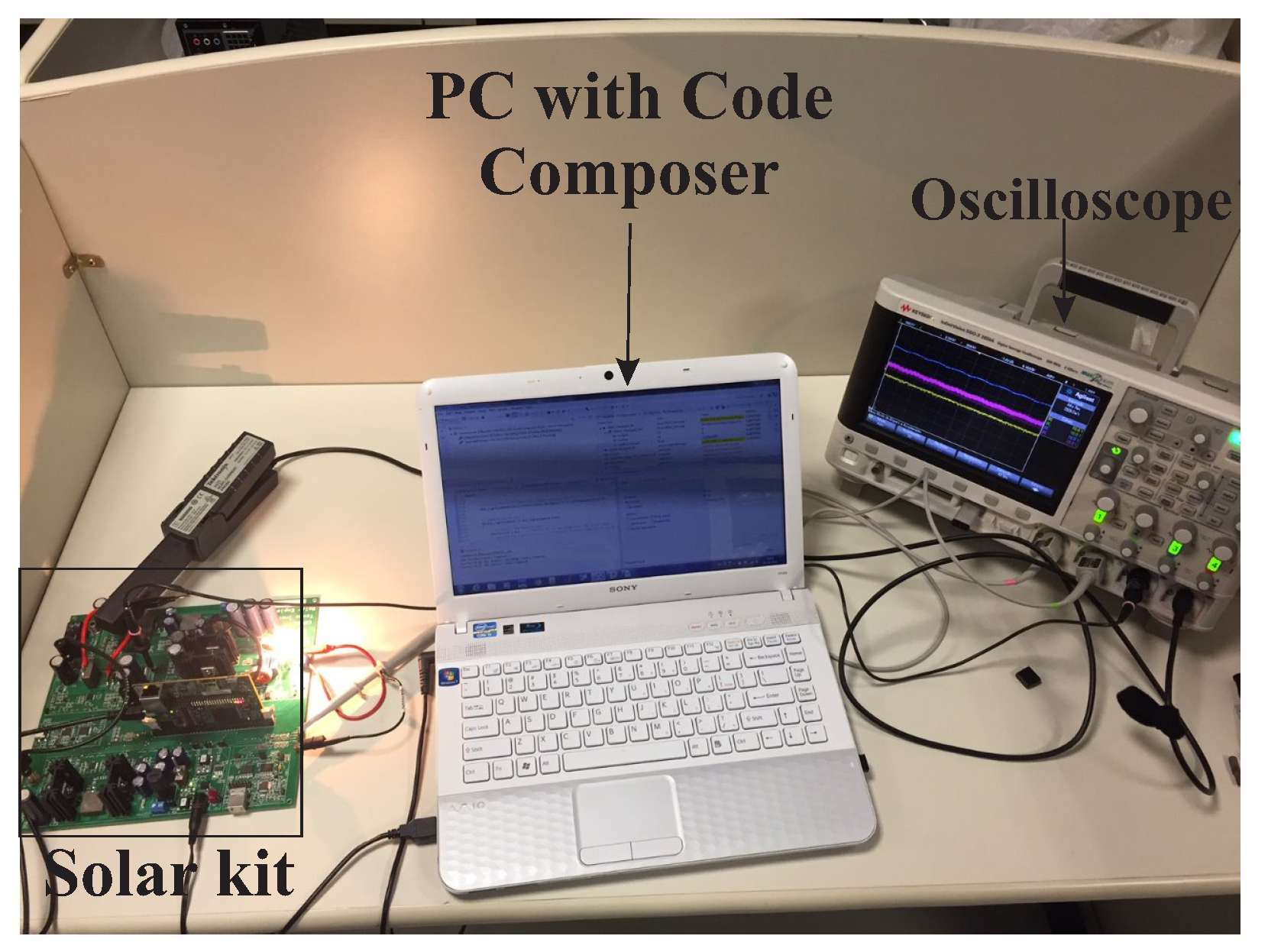

3. Sliding Mode Plus PI Control

3.1. Definition of the Sliding Surface

3.2. Design of the Control Law

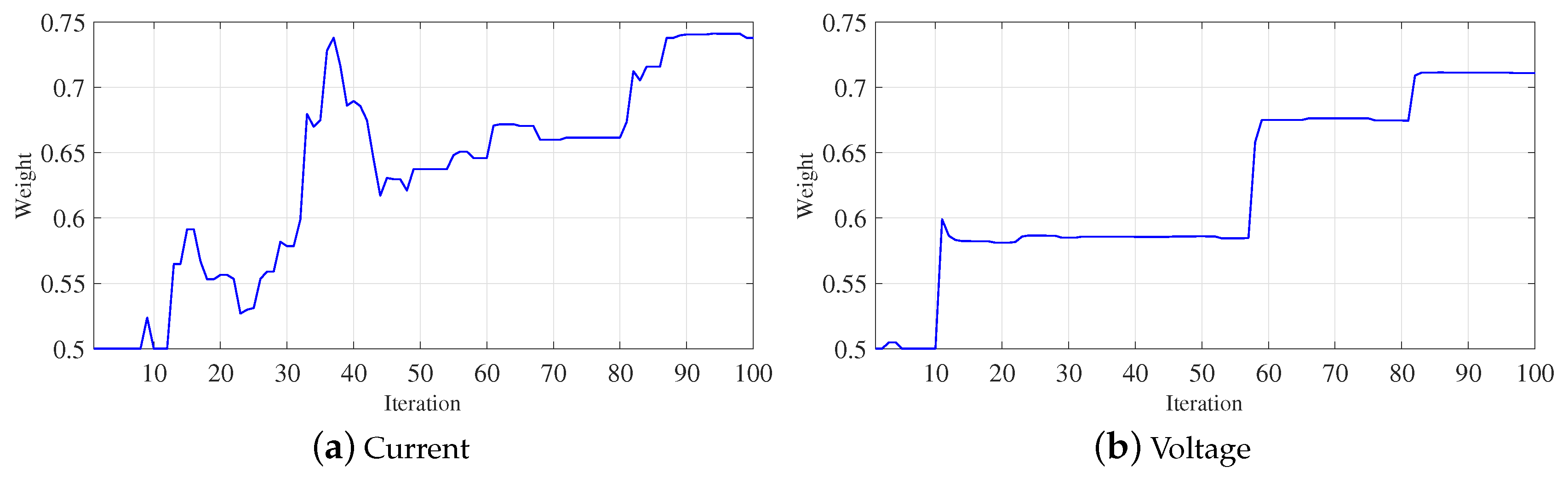

4. w-PSO

5. Results Using Solar Kit

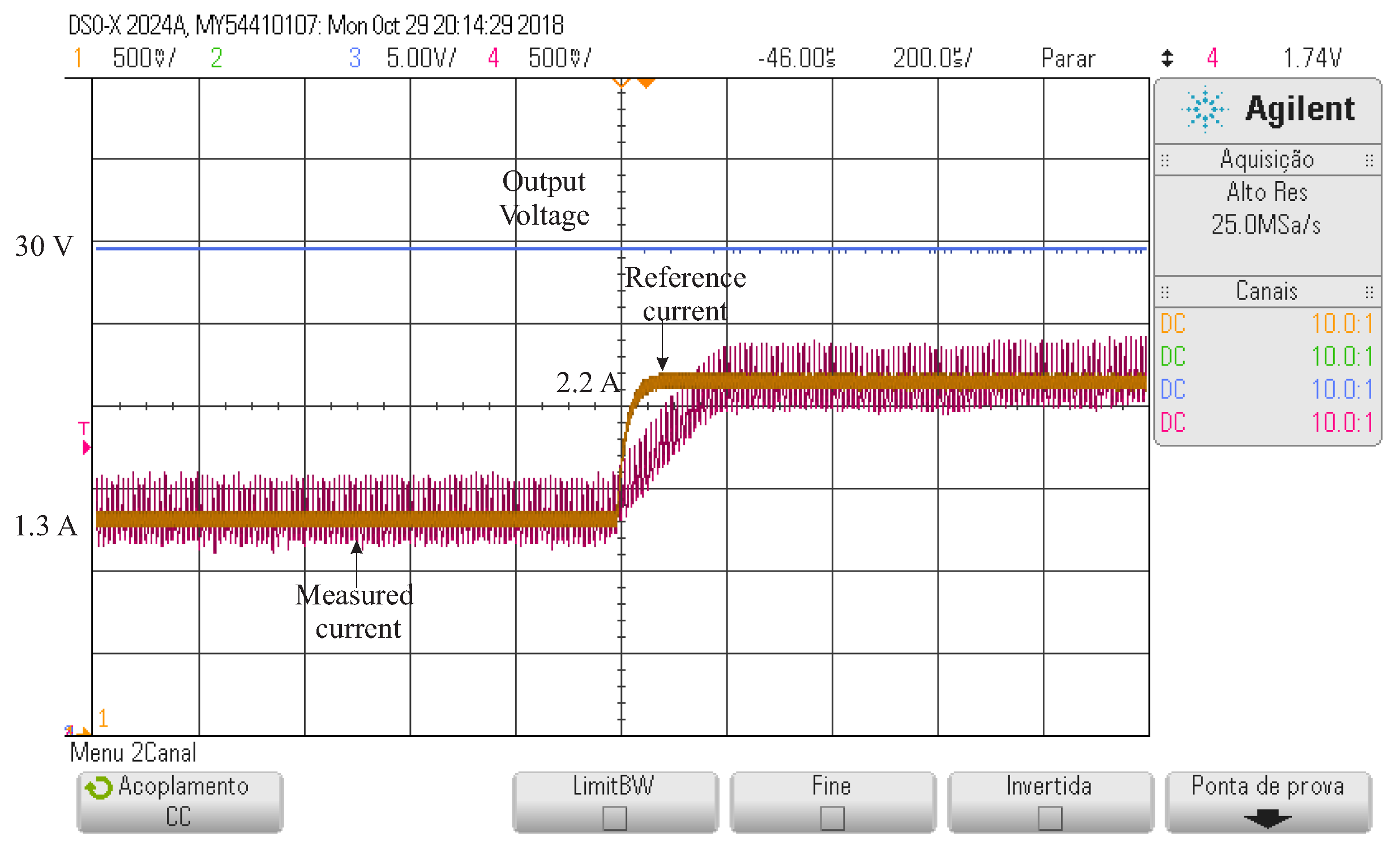

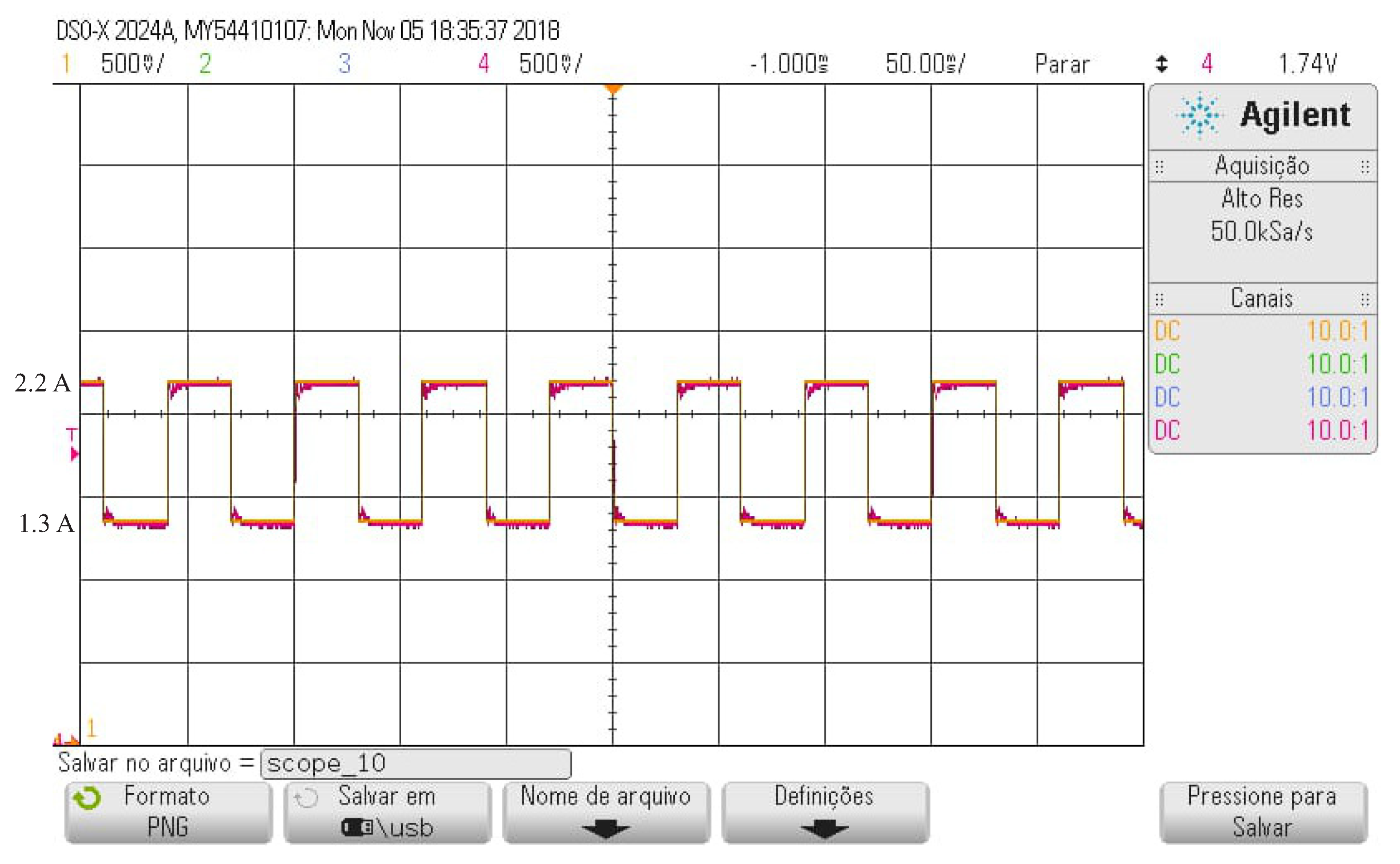

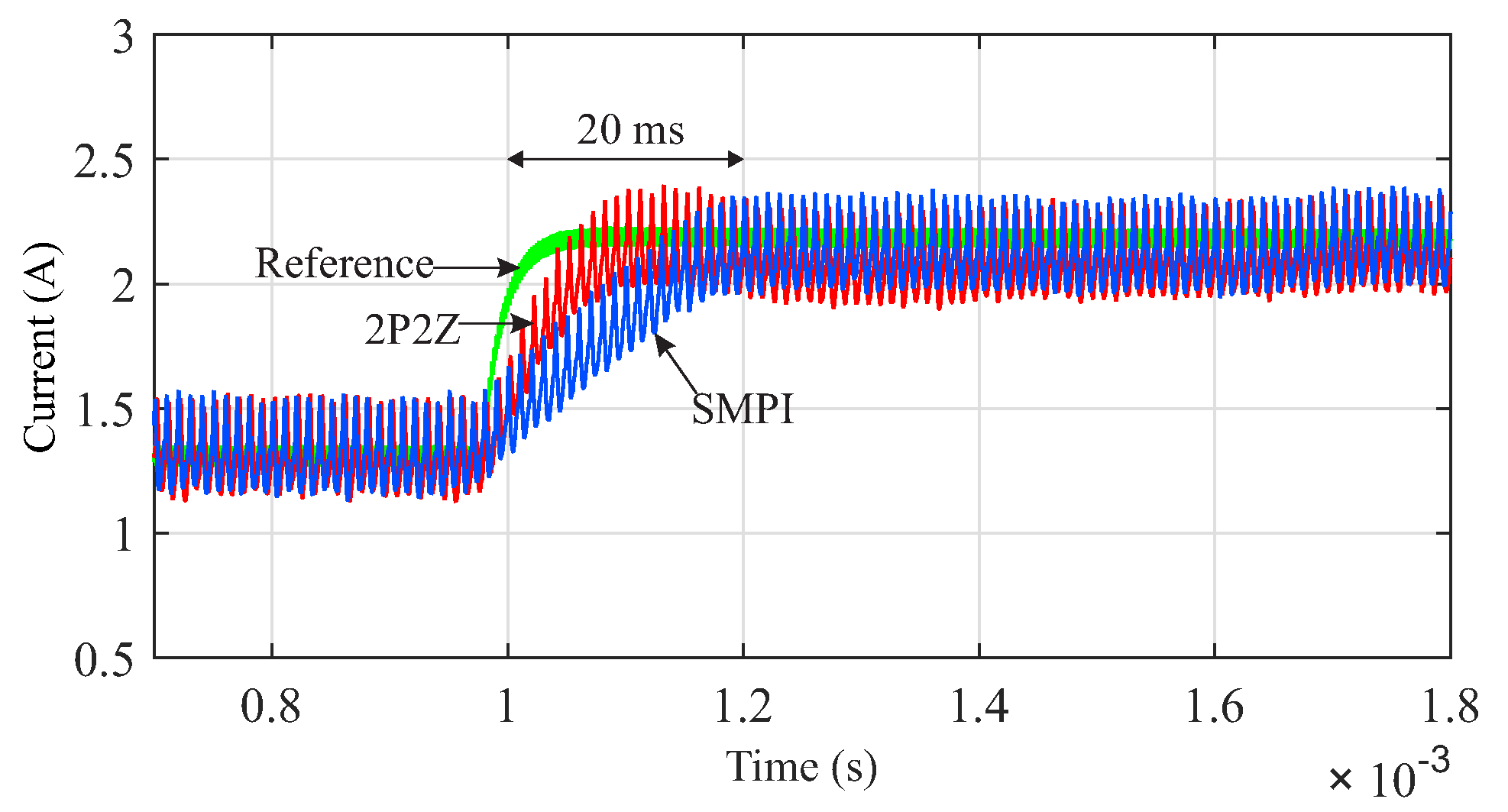

5.1. Current Control

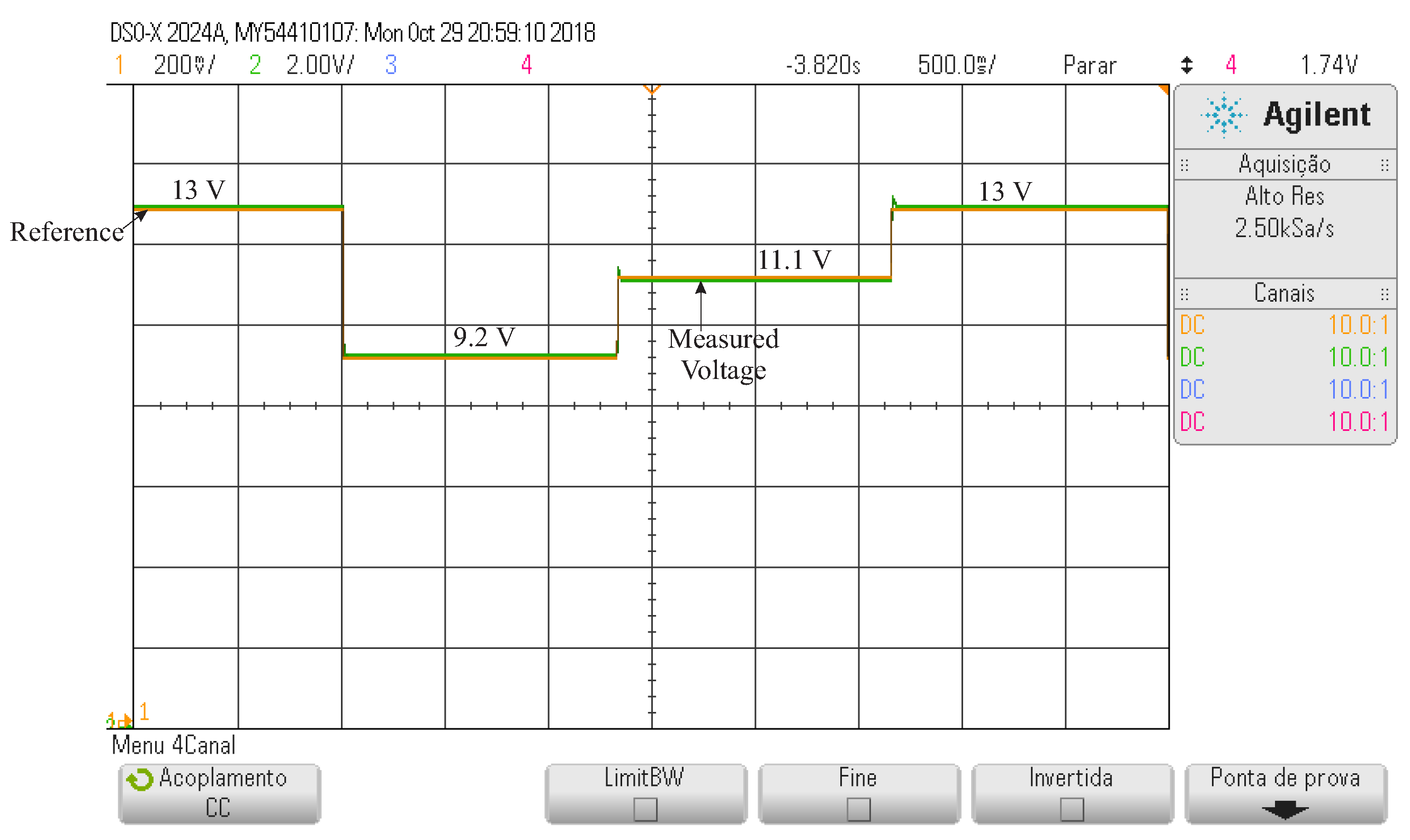

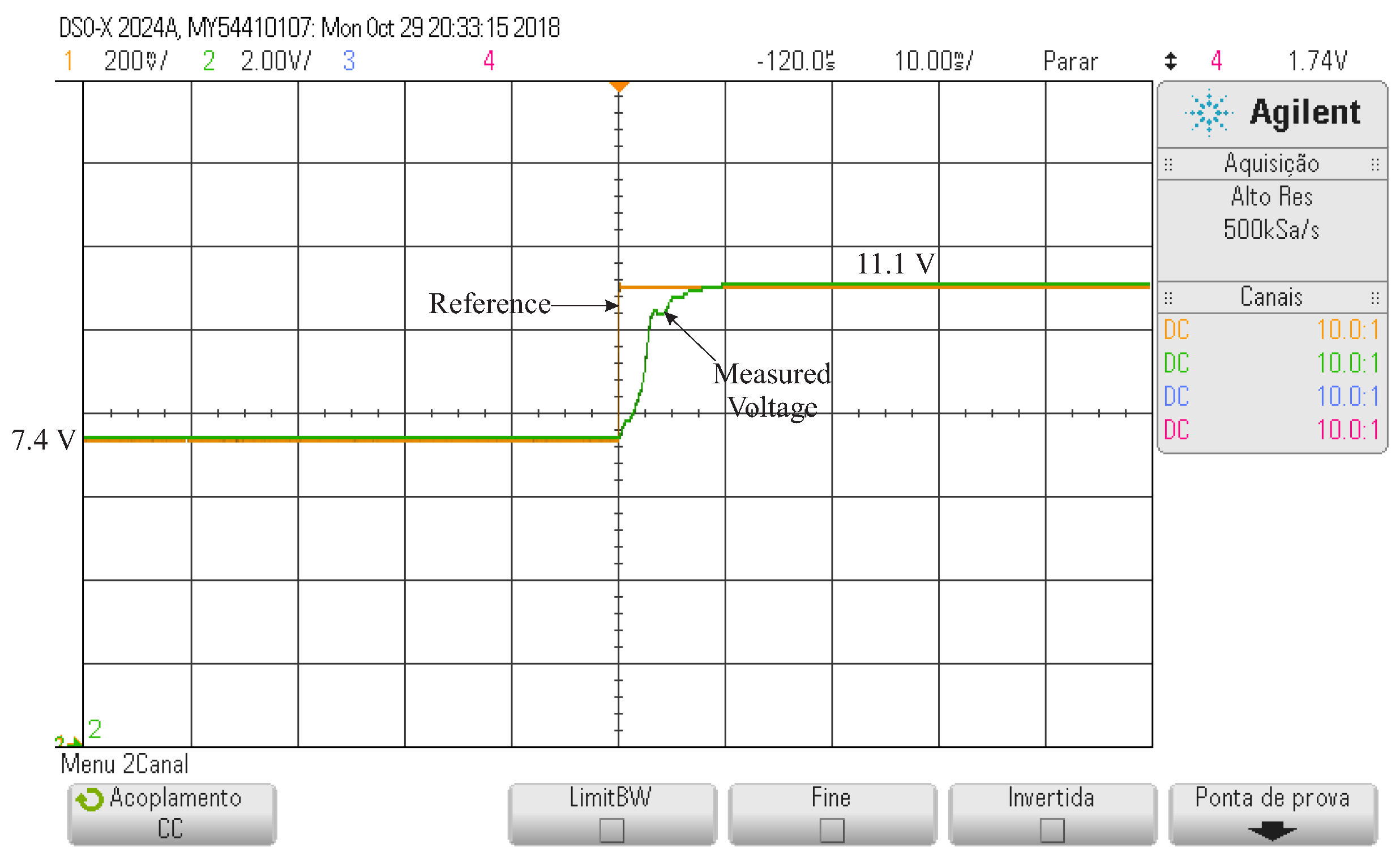

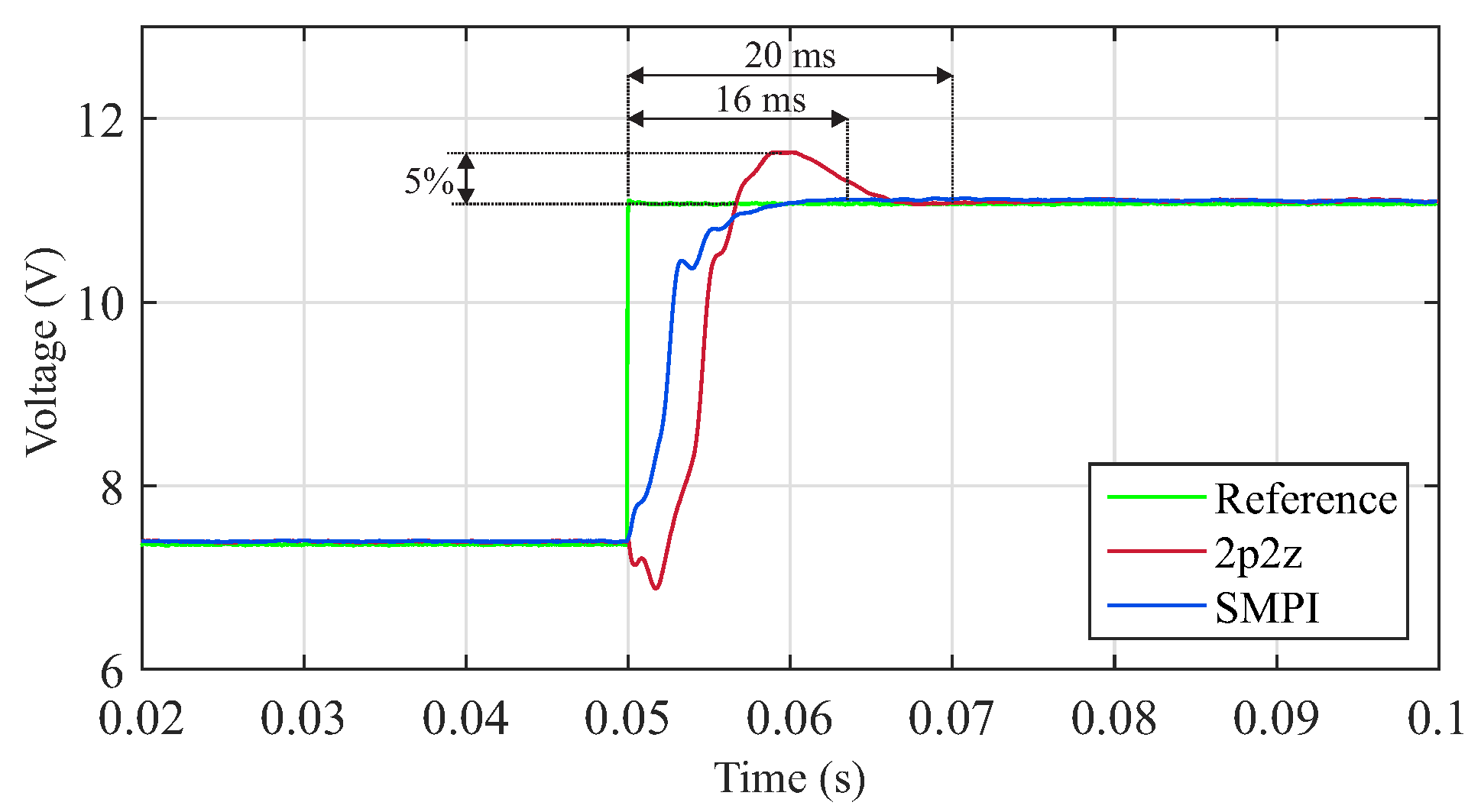

5.2. Voltage Control

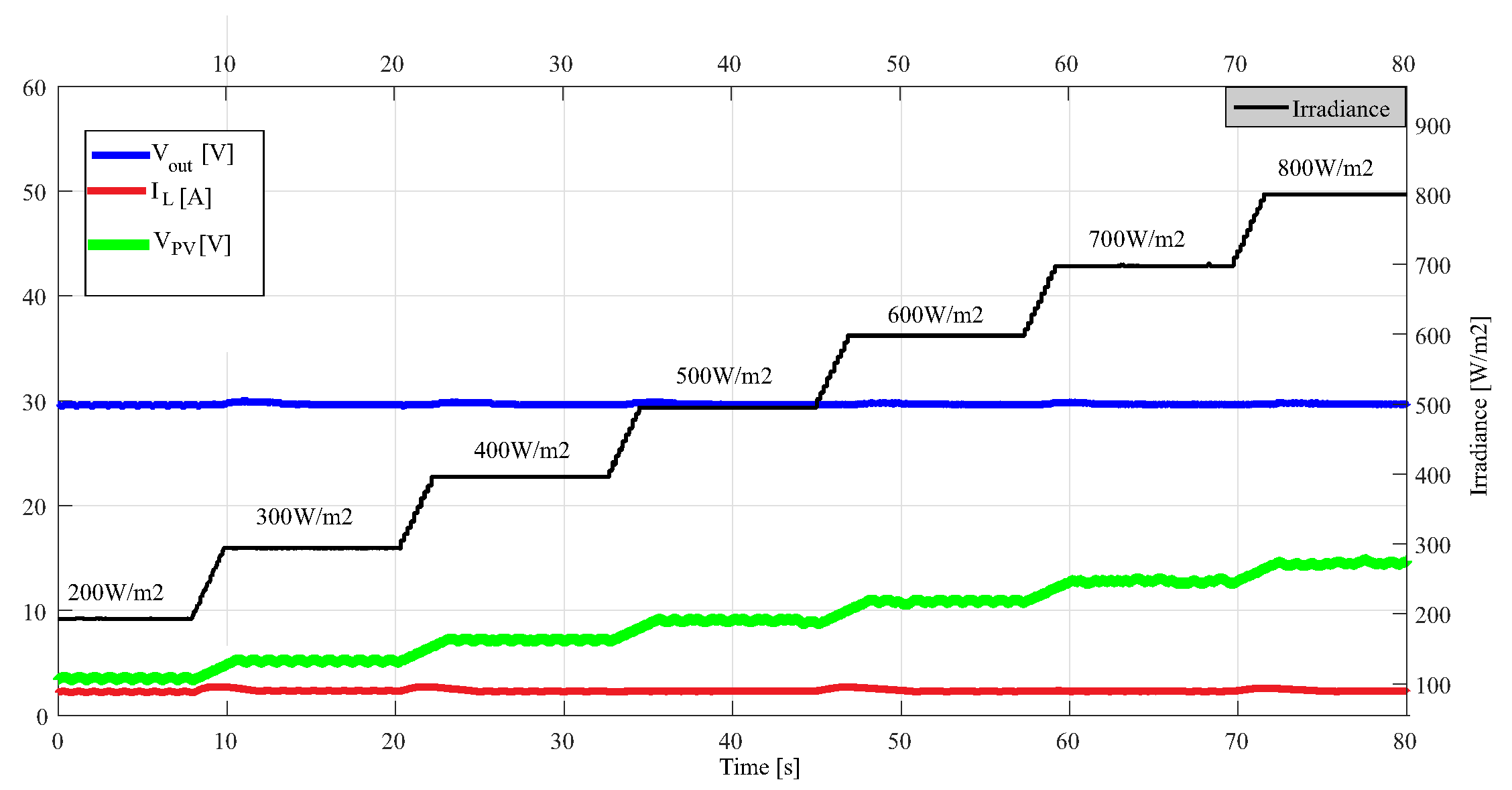

5.3. Comparison Performance Tests

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| MPPT | Maximum Power Point Tracker |

| PI | Proportional-Integral Controller |

| 2p2z | Two-pole two-zero controller |

| SMPI | Sliding Mode plus PI Controller |

| PSO | Particle Swarm Optimization |

| ISE | Integral of the Squared Error |

| ITAE | Integral of Time multiplied by the Absolute value of Error |

| DOCHM | Dynamic Objetive Constraint Handling Method |

References

- Chatrenour, N.; Razmi, H.; Doagou-Mojarrad, H. Improved double integral sliding mode MPPT controller based parameter estimation for a stand-alone photovoltaic system. Energy Convers. Manag. 2017, 139, 97–109. [Google Scholar] [CrossRef]

- Karami, N.; Moubayed, N.; Outbib, R. General review and classification of different MPPT Techniques. Renew. Sustain. Energy Rev. 2017, 68, 1–18. [Google Scholar] [CrossRef]

- De Brito, M.A.G.; Galotto, L.; Sampaio, L.P.; de Azevedo e Melo, G.; Canesin, C.A. Evaluation of the Main MPPT Techniques for Photovoltaic Applications. IEEE Trans. Ind. Electron. 2013, 60, 1156–1167. [Google Scholar] [CrossRef]

- Adly, M.; El-Sherif, H.; Ibrahim, M. Maximum power point tracker for a PV cell using a fuzzy agent adapted by the fractional open circuit voltage technique. In Proceedings of the 2011 IEEE International Conference on Fuzzy Systems (FUZZ-IEEE 2011), Taipei, Taiwan, 27–30 June 2011; pp. 1918–1922. [Google Scholar] [CrossRef]

- Nedumgatt, J.J.; Jayakrishnan, K.B.; Umashankar, S.; Vijayakumar, D.; Kothari, D.P. Perturb and observe MPPT algorithm for solar PV systems-modeling and simulation. In Proceedings of the 2011 Annual IEEE India Conference, Hyderabad, India, 16–18 December 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Tey, K.S.; Mekhilef, S. Modified incremental conductance MPPT algorithm to mitigate inaccurate responses under fast-changing solar irradiation level. Sol. Energy 2014, 101, 333–342. [Google Scholar] [CrossRef]

- Algazar, M.M.; L-monier, H.A.; L-halim, H.A.E.; Salem, E.E.K. Maximum power point tracking using fuzzy logic control. Int. J. Electr. Power Energy Syst. 2012, 39, 21–28. [Google Scholar] [CrossRef]

- Messalti, S.; Harrag, A.; Loukriz, A. A new variable step size neural networks MPPT controller: Review, simulation and hardware implementation. Renew. Sustain. Energy Rev. 2017, 68, 221–233. [Google Scholar] [CrossRef]

- Villalva, M.G.; Siqueira, T.G.D.; Ruppert, E. Voltage regulation of photovoltaic arrays: Small-signal analysis and control design. IET Power Electron. 2010, 3, 869–880. [Google Scholar] [CrossRef]

- Gil, G.M.V.; Catata, E.O.H.; Ccarita, J.C.C.; Cardoso, J.G.; Filho, A.J.S.; Azcue-Puma, J.L. Digital controller design for interleaved boost converter in photovoltaic system. In Proceedings of the 2016 12th IEEE International Conference on Industry Applications (INDUSCON), Curitiba, Brazil, 20–23 November 2016; pp. 1–8. [Google Scholar]

- Elgendy, M.A.; Zahawi, B.; Atkinson, D.J. Assessment of Perturb and Observe MPPT Algorithm Implementation Techniques for PV Pumping Applications. IEEE Trans. Sustain. Energy 2012, 3, 21–33. [Google Scholar] [CrossRef]

- Mohamed, H.A.; Khattab, H.A.; Mobarka, A.; Morsy, G.A. Design, control and performance analysis of DC-DC boost converter for stand-alone PV system. In Proceedings of the 2016 Eighteenth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 27–29 December 2016; pp. 101–106. [Google Scholar]

- Li, C.-H.; Zhu, X.-J.; Cao, G.-Y.; Hu, W.-Q.; Sui, S.; Hu, M.-R. A maximum power point tracker for photovoltaic energy systems based on fuzzy neural networks. J. Zhejiang Univ.-Sci. A 2009, 10, 263–270. [Google Scholar] [CrossRef]

- Kumar, N.; Saha, T.K.; Dey, J. Sliding-Mode Control of PWM Dual Inverter-Based Grid-Connected PV System: Modeling and Performance Analysis. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 435–444. [Google Scholar] [CrossRef]

- Pradhan, R.; Subudhi, B. Double Integral Sliding Mode MPPT Control of a Photovoltaic System. IEEE Trans. Control Syst. Technol. 2016, 24, 285–292. [Google Scholar] [CrossRef]

- Mamarelis, E.; Petrone, G.; Spagnuolo, G. Design of a Sliding-Mode-Controlled SEPIC for PV MPPT Applications. IEEE Trans. Ind. Electron. 2014, 61, 3387–3398. [Google Scholar] [CrossRef]

- Montoya, D.G.; Ramos-Paja, C.A.; Giral, R. Improved Design of Sliding-Mode Controllers Based on the Requirements of MPPT Techniques. IEEE Trans. Power Electron. 2016, 31, 235–247. [Google Scholar] [CrossRef]

- Dahech, K.; Allouche, M.; Damak, T.; Tadeo, F. Backstepping sliding mode control for maximum power point tracking of a photovoltaic system. Electric Power Syst. Res. 2017, 143, 182–188. [Google Scholar] [CrossRef]

- Trindade, F.S.; Filho, A.J.S.; Jacomini, R.V.; Ruppert, E. Experimental results of sliding-mode power control for doubly-fed induction generator. In Proceedings of the 2013 Brazilian Power Electronics Conference, Gramado, Brazil, 27–31 October 2013; pp. 686–691. [Google Scholar]

- Lascu, C.; Boldea, I.; Blaabjerg, F. Direct torque control of sensorless induction motor drives: A sliding-mode approach. IEEE Trans. Ind. Appl. 2004, 40, 582–590. [Google Scholar] [CrossRef]

- Anantwar, H.; Lakshmikantha, D.B.R.; Sundar, S. Fuzzy self tuning PI controller based inverter control for voltage regulation in off-grid hybrid power system. Energy Procedia 2017, 117, 409–416. [Google Scholar] [CrossRef]

- Kihal, A.; Krim, F.; Laib, A.; Talbi, B.; Afghoul, H. An improved MPPT scheme employing adaptive integral derivative sliding mode control for photovoltaic systems under fast irradiation changes. ISA Trans. 2018. [Google Scholar] [CrossRef] [PubMed]

- Khazane, J.E.; Tissir, E.H. Achievement of MPPT by finite time convergence sliding mode control for photovoltaic pumping system. Sol. Energy 2018, 166, 13–20. [Google Scholar] [CrossRef]

- Kchaou, A.; Naamane, A.; Koubaa, Y.; M’sirdi, N. Second order sliding mode-based MPPT control for photovoltaic applications. Sol. Energy 2017, 155, 758–769. [Google Scholar] [CrossRef]

- Bounar, N.; Labdai, S.; Boulkroune, A. PSO-GSA based fuzzy sliding mode controller for DFIG-based wind turbine. ISA Trans. 2018, 85, 177–188. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Sung, W.; Yao, W. Computer, Intelligent Computing and Education Technology; CRC Press: Hong Kong, China, 2014; Volume 1. [Google Scholar]

- Gavhane, P.S.; Krishnamurthy, S.; Dixit, R.; Ram, J.P.; Rajasekar, N. EL-PSO based MPPT for Solar PV under Partial Shaded Condition. Energy Procedia 2017, 117, 1047–1053. [Google Scholar] [CrossRef]

- Eswaran, T.; Kumar, V.S. Particle swarm optimization (PSO)-based tuning technique for PI controller for management of a distributed static synchronous compensator (DSTATCOM) for improved dynamic response and power quality. J. Appl. Res. Technol. 2017, 15, 173–189. [Google Scholar] [CrossRef]

- Ruiz-Cruz, R.; Sanchez, E.N.; Ornelas-Tellez, F.; Loukianov, A.G.; Harley, R.G. Particle Swarm Optimization for Discrete-Time Inverse Optimal Control of a Doubly Fed Induction Generator. Energies 2014, 7, 1706–1720. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.-H.; Yau, H.-T.; Hung, W. Design and study on sliding mode extremum seeking control of thechaos embedded particle swarm optimization for maximum power point tracking in wind power systems. IEEE Trans. Cybern. 2013, 43, 1698–1709. [Google Scholar]

- Kessentini, S.; Barchies, D. Particle swarm optimization with adaptive inertia weight. Int. J. Mach. Learn. Comput. 2015, 5, 368–373. [Google Scholar] [CrossRef]

- Villalva, M.G.; Ruppert, F.E. Analysis and simulation of the P&O MPPT algorithm using a linearized PV array model. In Proceedings of the 2009 35th Annual Conference of IEEE Industrial Electronics, Porto, Portugal, 3–5 November 2009; pp. 231–236. [Google Scholar]

- Sahu, P.; Verma, D.; Nema, S. Physical design and modelling of boost converter for maximum power point tracking in solar PV systems. In Proceedings of the 2016 International Conference on Electrical Power and Energy Systems (ICEPES), Bhopal, India, 14–16 December 2016; pp. 10–15. [Google Scholar]

- Ayop, R.; Tan, C.W. Design of boost converter based on maximum power point resistance for photovoltaic applications. Sol. Energy 2018, 160, 322–335. [Google Scholar] [CrossRef]

- Cucuzzella, M.; Lazzari, R.; Trip, S.; Rosti, S.; Sandroni, C.; Ferrara, A. Sliding mode voltage control of boost converters in DC microgrids. Control Eng. Pract. 2018, 73, 161–170. [Google Scholar] [CrossRef]

- Yatimi, H.; Aroudam, E. Assessment and control of a photovoltaic energy storage system based on the robust sliding mode MPPT controller. Sol. Energy 2016, 139, 557–568. [Google Scholar] [CrossRef]

- Mojallizadeh, M.R.; Badamchizadeh, M.; Khanmohammadi, S.; Sabahi, M. Designing a new robust sliding mode controller for maximum power point tracking of photovoltaic cells. Sol. Energy 2016, 132, 538–546. [Google Scholar] [CrossRef]

- Levant, A. Chattering Analysis. IEEE Trans. Autom. Control 2010, 55, 1380–1389. [Google Scholar] [CrossRef]

- CSoon, C.; Ghazali, R.; Jaafar, H.I.; Hussien, S.Y.S. Sliding Mode Controller Design with Optimized PID Sliding Surface Using Particle Swarm Algorithm. Procedia Comput. Sci. 2017, 105, 235–239. [Google Scholar] [CrossRef]

- Vargas-Gil, G.M.; Colque, C.J.C.; Sguarezi, A.J.; Monaro, R.M. Sliding mode plus PI control applied in PV systems control. In Proceedings of the 2017 IEEE 6th International Conference on Renewable Energy Research and Applications (ICRERA), San Diego, CA, USA, 5–8 Nocember 2017; pp. 562–567. [Google Scholar]

- Yang, M.; Zhang, S. PSO-based PID controller design for unwinding tension system of web press. In Proceedings of the 2018 13th IEEE Conference on Industrial Electronics and Applications (ICIEA), Wuhan, China, 31 May–2 June 2018; pp. 1399–1403. [Google Scholar]

- Sánchez, J.A. Instrumentación y Control Avanzado de Procesos; Ediciones Díaz de Santos: Madrid, Spain, 2013. [Google Scholar]

- Lu, H.; Chen, W. Dynamic-objective particle swarm optimization for constrained optimization problems. J. Comb. Optim. 2006, 12, 409–419. [Google Scholar] [CrossRef]

- Segura, C.; Coello, C.A.; Miranda, G.; León, C. Using multi-objective evolutionary algorithms for single-objective constrained and unconstrained optimization. Ann. Oper. Res. 2016, 240, 217–250. [Google Scholar] [CrossRef]

- He, F.; Liu, C. Particle Swarm Optimization Applied to a Stochastic Optimization Problem. In Proceedings of the 2010 2nd International Workshop on Database Technology and Applications, Wuhan, China, 27–28 November 2010; pp. 1–4. [Google Scholar]

- Thangaraj, R.; Pant, M.; Bouvry, P.; Abraham, A. Evolutionary Algorithms for Solving Stochastic Programming Problems. In Proceedings of the 2010 International Conference on Computational Intelligence and Communication Networks, Bhopal, India, 26–28 November 2010; pp. 628–632. [Google Scholar]

- Žilinskas, A.; Fraga, E.; Mackutė, A. Data analysis and visualisation for robust multi-criteria process optimization. Comput. Chem. Eng. 2006, 30, 1061–1071. [Google Scholar] [CrossRef]

- Bhardwaj, M.; Subharmanya, B. PV Inverter Design Using Solar Explorer Kit; Texas Instruments: Dallas, TX, USA, 2013. [Google Scholar]

- Neuman, C.P. The two-pole two-zero root locus. IEEE Trans. Educ. 1994, 37, 369–371. [Google Scholar] [CrossRef]

- Elgendy, M.A.; Zahawi, B.; Atkinson, D.J. Assessment of the Incremental Conductance Maximum Power Point Tracking Algorithm. IEEE Trans. Sustain. Energy 2013, 4, 108–117. [Google Scholar] [CrossRef]

| Irradiance | |||

|---|---|---|---|

| 1000 W/m | W | V | A |

| 900 W/m | W | V | A |

| 800 W/m | W | V | A |

| 700 W/m | W | V | A |

| 600 W/m | W | V | A |

| 500 W/m | W | V | A |

| 400 W/m | W | V | A |

| 300 W/m | W | V | A |

| 200 W/m | W | V | A |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vargas Gil, G.M.; Lima Rodrigues, L.; Inomoto, R.S.; Sguarezi, A.J.; Machado Monaro, R. Weighted-PSO Applied to Tune Sliding Mode Plus PI Controller Applied to a Boost Converter in a PV System. Energies 2019, 12, 864. https://doi.org/10.3390/en12050864

Vargas Gil GM, Lima Rodrigues L, Inomoto RS, Sguarezi AJ, Machado Monaro R. Weighted-PSO Applied to Tune Sliding Mode Plus PI Controller Applied to a Boost Converter in a PV System. Energies. 2019; 12(5):864. https://doi.org/10.3390/en12050864

Chicago/Turabian StyleVargas Gil, Gloria Milena, Lucas Lima Rodrigues, Roberto S. Inomoto, Alfeu J. Sguarezi, and Renato Machado Monaro. 2019. "Weighted-PSO Applied to Tune Sliding Mode Plus PI Controller Applied to a Boost Converter in a PV System" Energies 12, no. 5: 864. https://doi.org/10.3390/en12050864

APA StyleVargas Gil, G. M., Lima Rodrigues, L., Inomoto, R. S., Sguarezi, A. J., & Machado Monaro, R. (2019). Weighted-PSO Applied to Tune Sliding Mode Plus PI Controller Applied to a Boost Converter in a PV System. Energies, 12(5), 864. https://doi.org/10.3390/en12050864