Development of an Exergy-Rational Method and Optimum Control Algorithm for the Best Utilization of the Flue Gas Heat in Coal-Fired Power Plant Stacks †

Abstract

1. Introduction

Aims of the Research Work

2. Materials and Methods

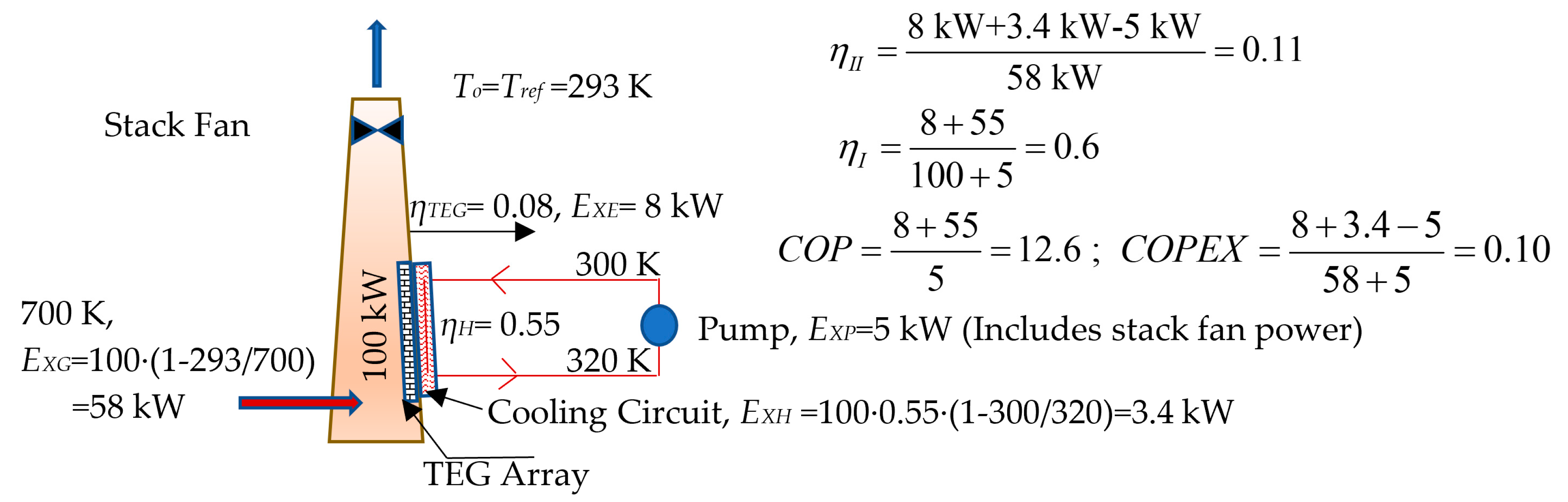

2.1. Method (a): Power and Heat Generation with Thermoelectric Generators

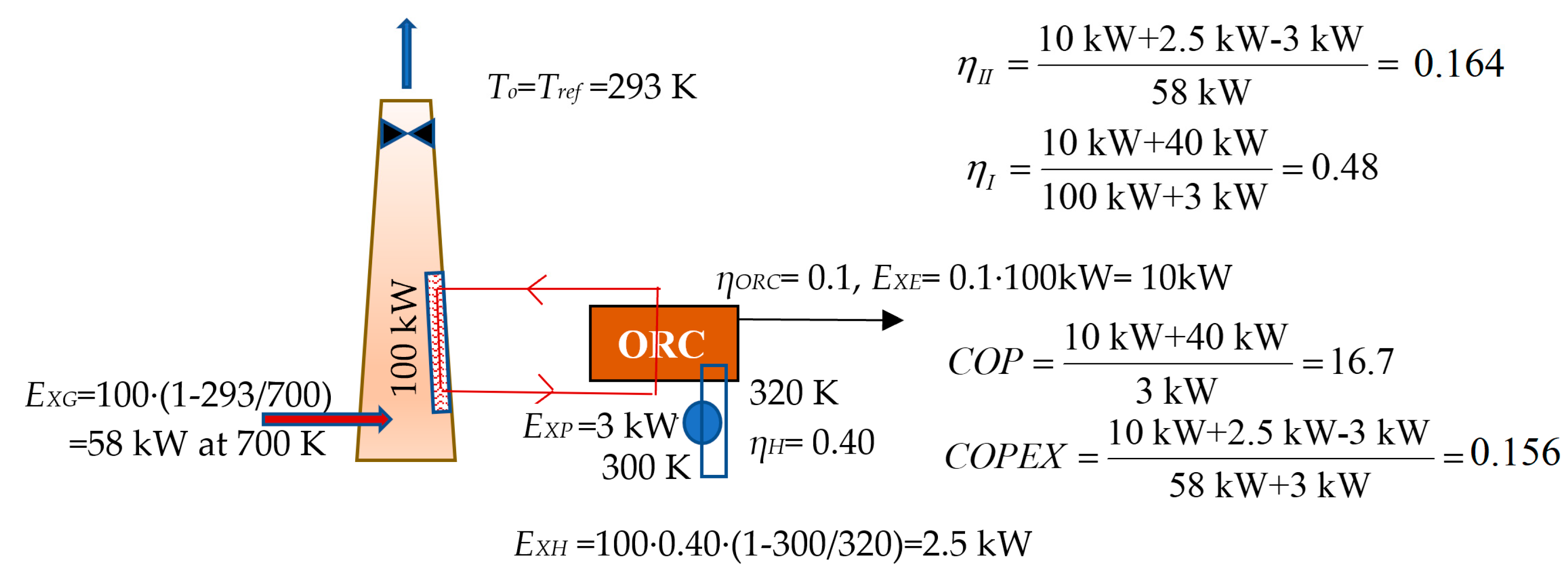

2.2. Method (b): Power Generation with Organic Rankine Cycle Turbines

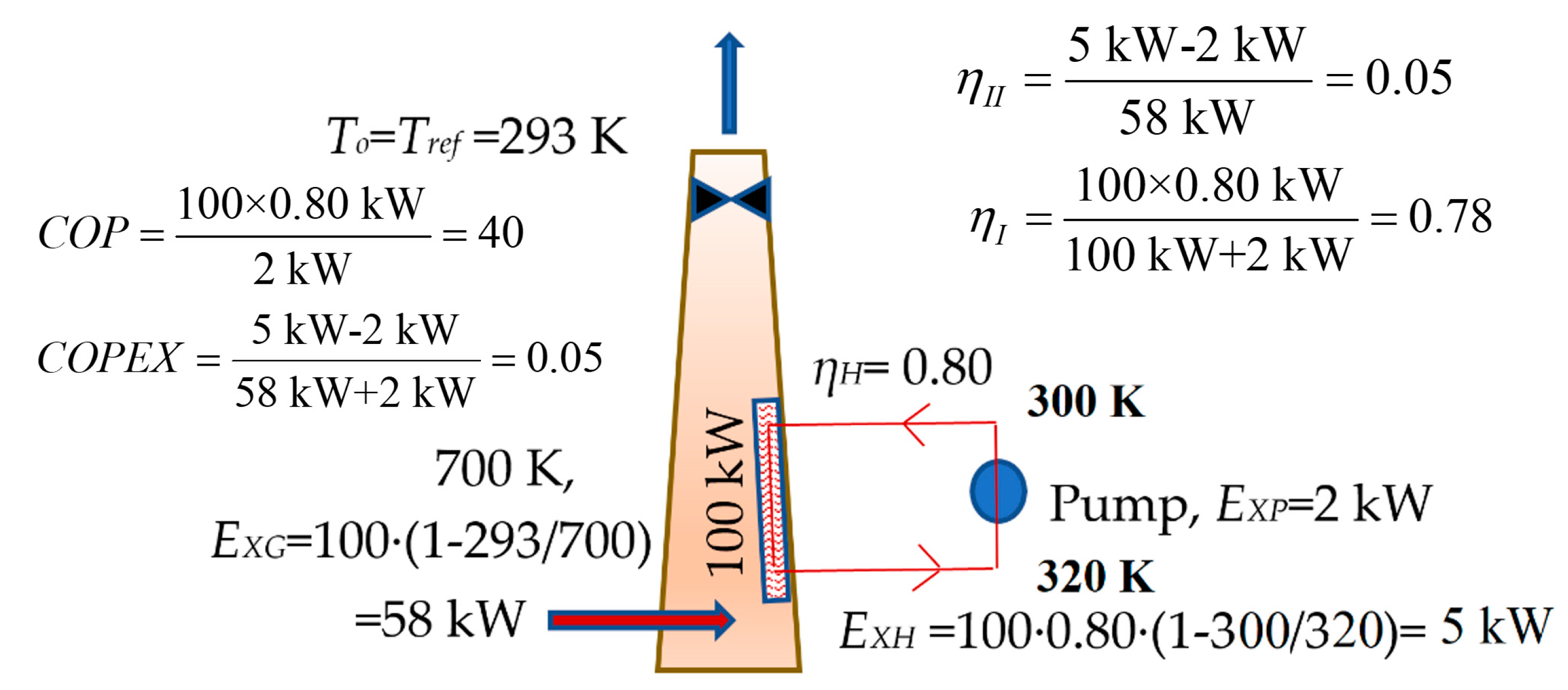

2.3. Method (c): Power Generation with Organic Rankine Cycle and then Converting to Heat by a Heat Pump

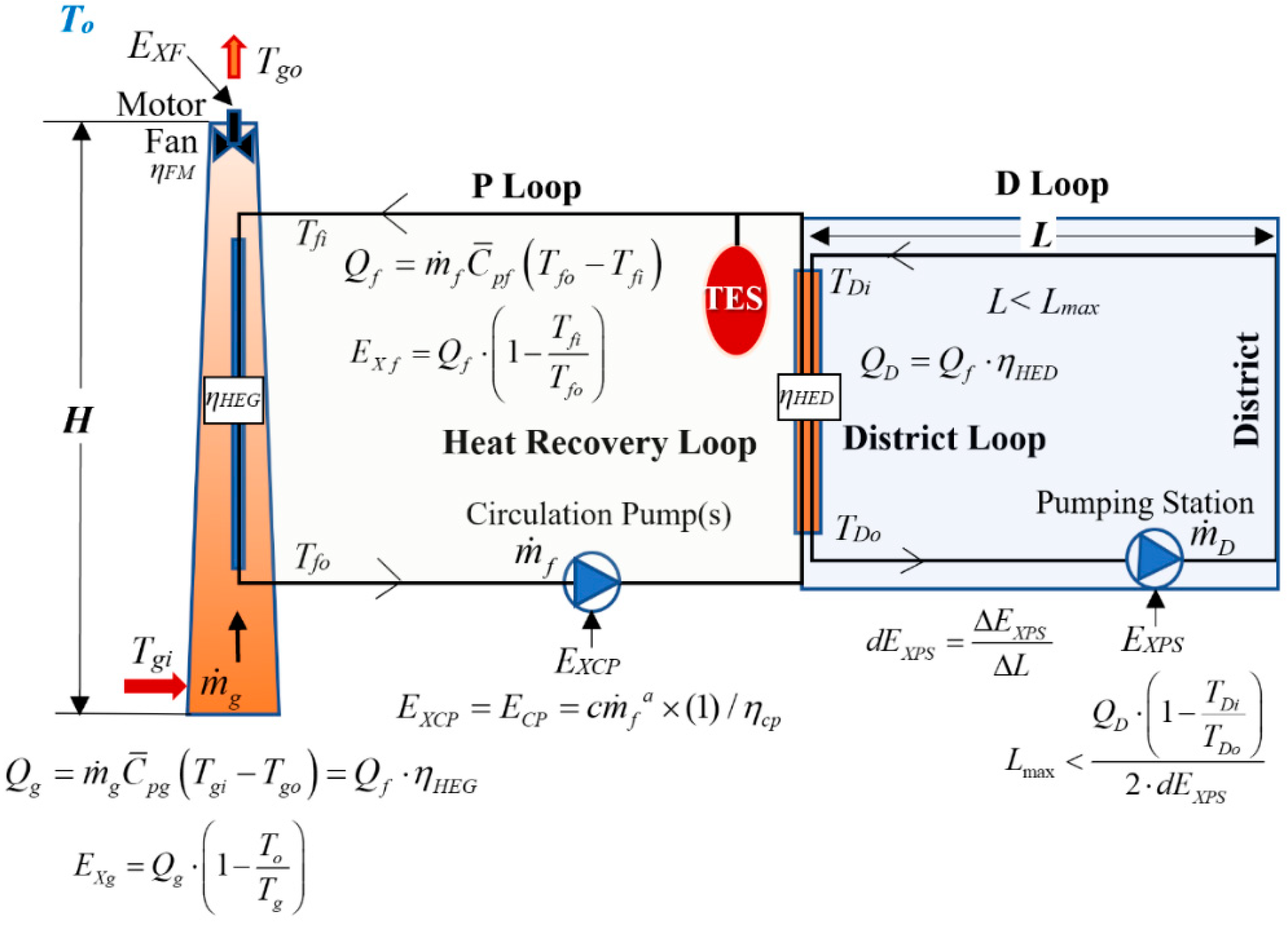

2.4. Method (d): Direct use of the Thermal Exergy in ae District Energy System

2.5. The Necessity for an Exergy-Based Model

2.6. Characterization of the District Energy Model

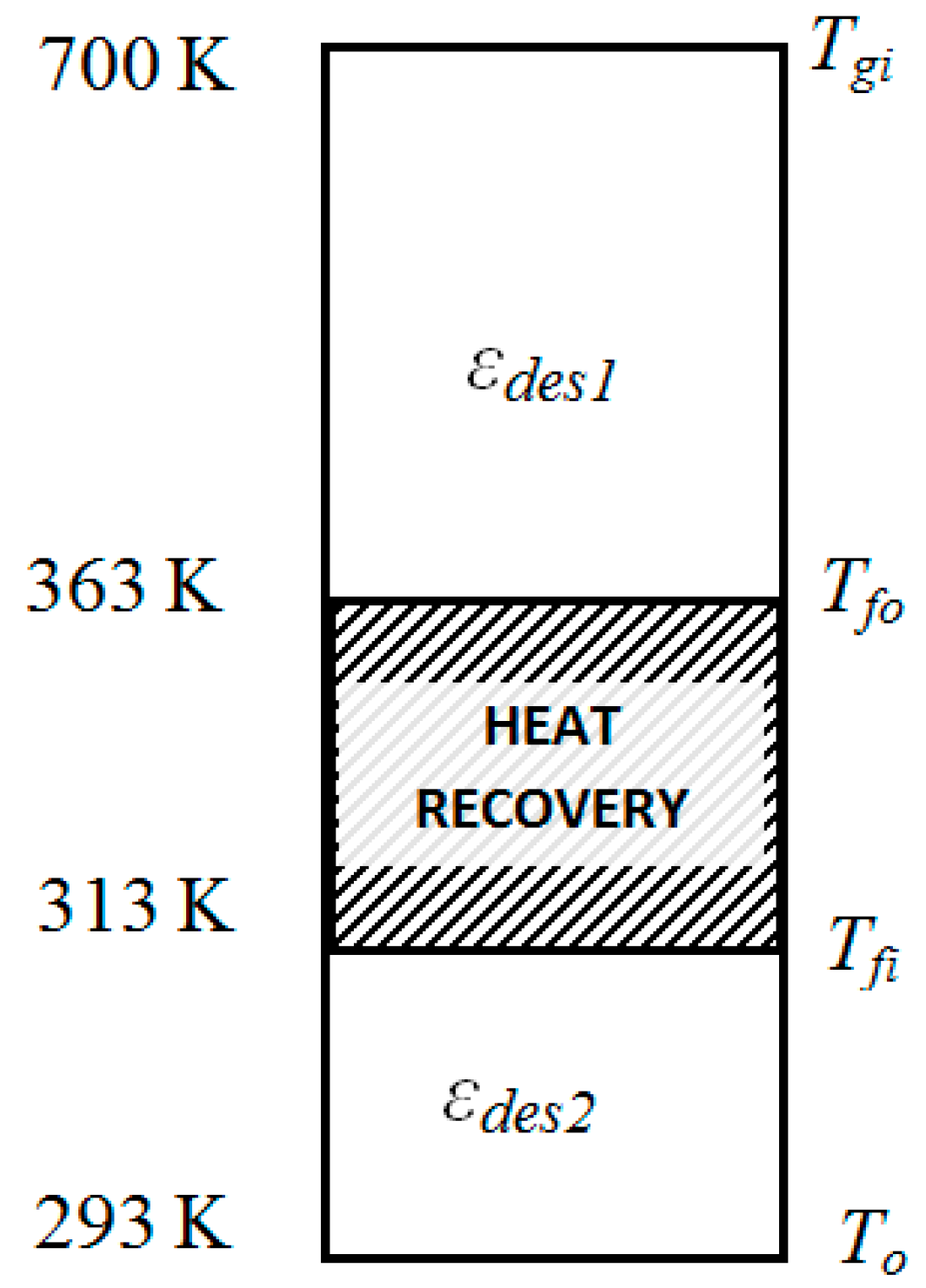

2.6.1. Circuit P Loop: Exergy-based Optimum Heat Recovery Drive Unit for Industrial Stacks

2.6.2. Natural Draught Pressure and EXF

| C | A constant for coal-fired plant stacks, 0.0342 K·m−1 |

| C′ | C·Patm·H |

| Patm | Atmospheric pressure at the given elevation at the given time, kPa |

| H | Stack height, m |

| Tg | Average flue gas temperature in the stack, K |

| Tgi | Hot flue gas entry temperature to the stack, K |

| Tgo | Flue gas exit temperature from the stack, K. |

2.7. Rating Metrics

2.7.1. Performance Coefficients

2.7.2. Fuel Savings

2.7.3. Carbon Dioxide Emissions Replacement

2.7.4. Thermal Efficiencies

3. Results

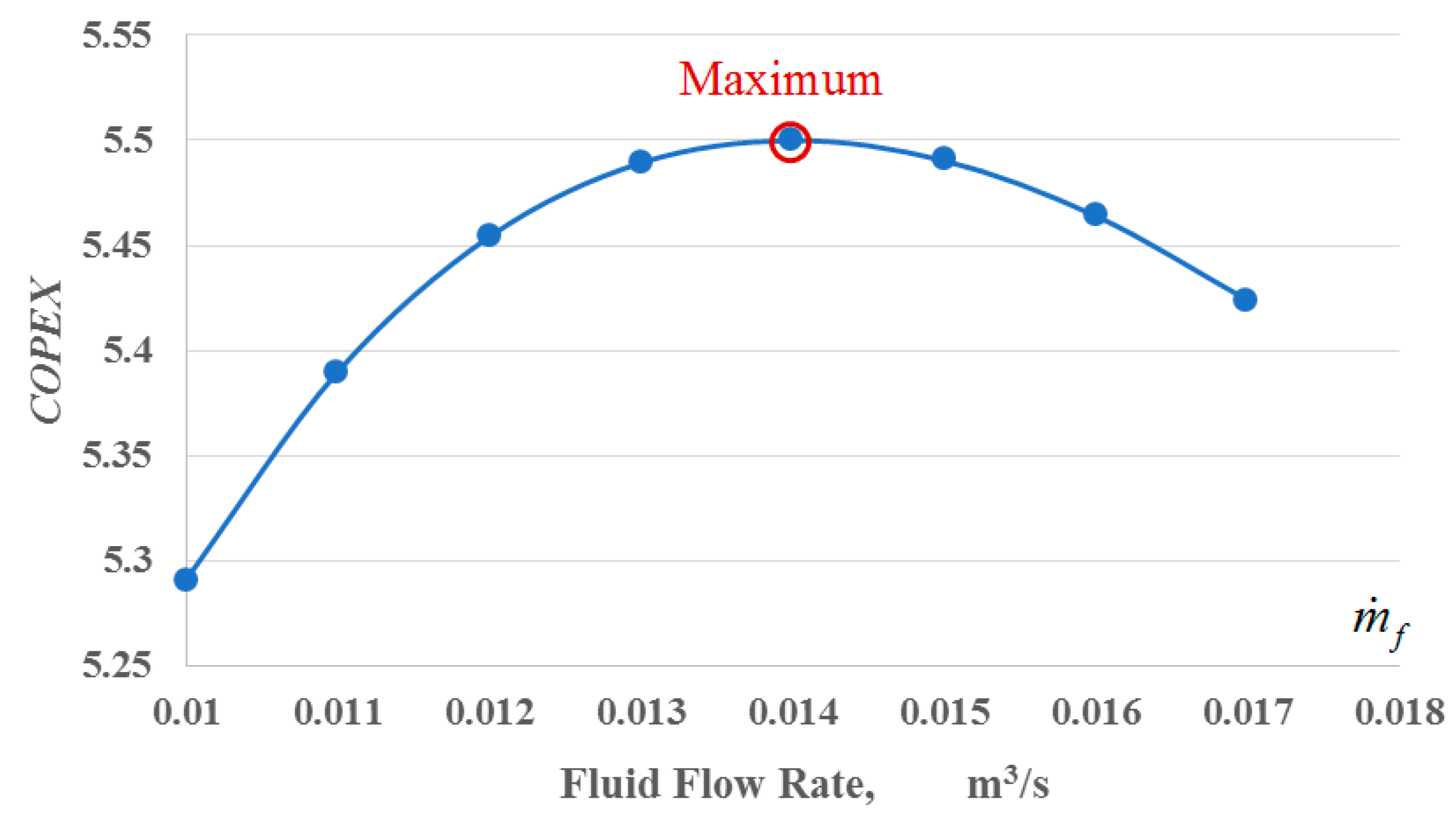

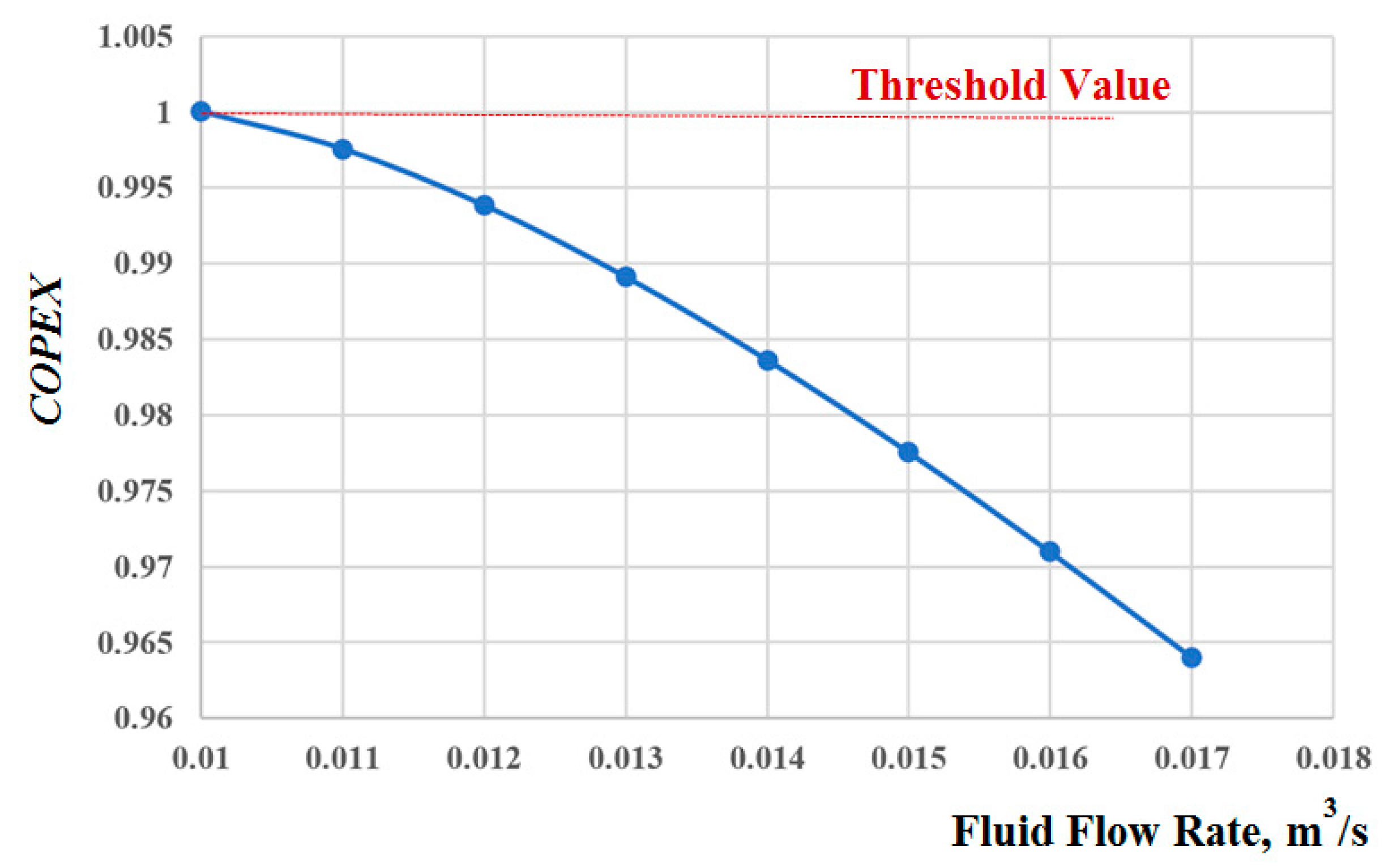

3.1. Results of the Analysis of the P Loop-Case Sdudy

3.2. Implications of the Analysis for the D Loop

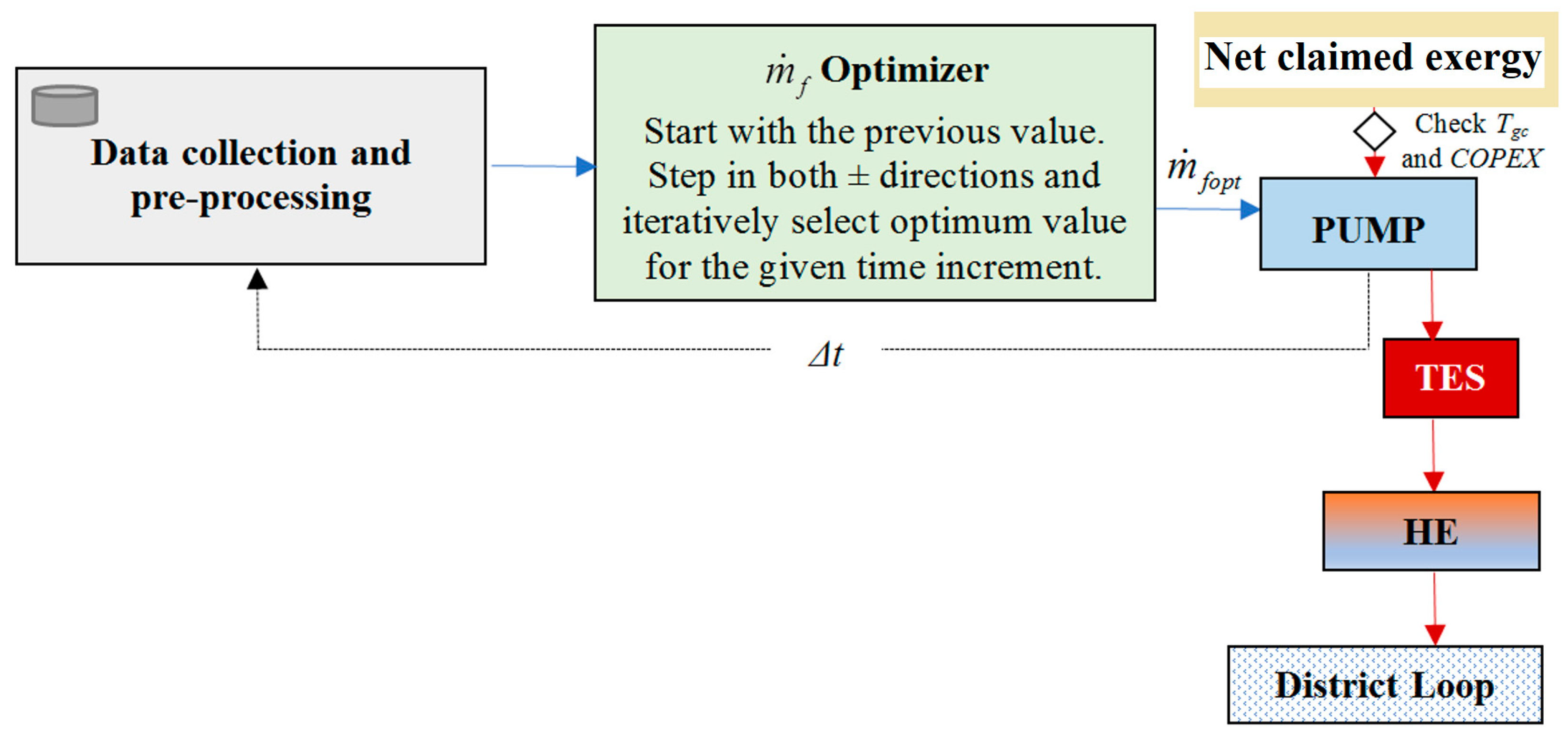

3.3. Development of the Control Unit to Maximize the Exergy Gain

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Average cross-sectional area of the stack, m2 | |

| ao | Constant distance in Lmax equation, km |

| a, c | Performance constants of the circulating pump |

| C | A constant for the coal-fired plant stack height, 0.0342 K·m−1 |

| Cp | Specific heat, kJ/kg·K |

| CHPEη | Partial first-law efficiency of electric power generation, dimensionless |

| COP | Coefficient of performance, dimensionless |

| COPEX | Exergetic coefficient of performance, dimensionless |

| H | Stack height, m |

| L | Distance between the district heating system and the power plant (one way), m |

| E, Q | Thermal power, kW |

| EX | Exergy, kW |

| F | Hourly coal consumption, kg/h |

| Gas flow rate, m3/s | |

| Heat transfer fluid flow rate, m3/s | |

| n | power in Lmax equation |

| P | Pressure, kPa |

| PD | Natural draught pressure, kPa |

| PES | Primary energy savings ratio, % |

| PESR | Exergy-based primary energy savings ratio, % |

| S | Sulphur content, % |

| T | Temperature, K |

| Greek Symbols | |

| ε | Unit exergy, kW/kW |

| Δε | Unit exergy gain, kW/kW |

| η | Efficiency, dimensionless |

| ψR | REMM efficiency, dimensionless |

| Δ | Difference |

| ρ | Density, kg/m3 |

| Subscripts | |

| atm | Atmospheric |

| CP | Circulating pump |

| D | District, draught |

| dem | Demand |

| des | Destroyed |

| Di | Return from the district loop |

| Do | To the district loop |

| I | First-law |

| II | Second-law |

| F | Stack fan |

| FM | Fan motor |

| f | Fluid (water in P Loop) |

| fi | Inlet fluid (water) |

| fo | Outlet (supply) fluid |

| g, G | flue gas (to/at the stack) |

| gc | Gas condensation |

| gi | Inlet gas (to the stack) |

| go | Outlet gas (from the stack) |

| H | Stack heat exchanger |

| max | Maximum |

| NET | Net |

| o | Outdoor |

| PS | Pumping station |

| R | Rational exergy management related |

| ref | Reference |

| sup | Supply |

| X | Exergy |

| Acronyms | |

| CFPP | Coal-fired power plant |

| CHP | Combined heat and power |

| DE | District energy |

| EC | European commission |

| EU | European union |

| EC | European council |

| GSHP | Ground-source heat pump |

| HE | Heat exchanger |

| ORC | Organic-Rankine cycle |

| REMM | Rational exergy management model |

| TEG | Thermo-electric generator |

| TES | Thermal energy storage |

| TPG | Thermal to electric power conversion |

References

- The Economic Times. The Badarpur Plant’s Effect on Air Pollution and Why it Needs to be Shut Down. 2015. Available online: https://economictimes.indiatimes.com/the-badarpur-plants-effect-on-air-pollution-and-why-it-needs-to-be-shut-down/changetheair_show/53669369.cms (accessed on 16 February 2019).

- Irfan, U.; Vox. How Delhi Became the Most Polluted City on Earth. Available online: https://www.vox.com/energy-and-environment/2017/11/22/16666808/india-air-pollution-new-delhi (accessed on 25 November 2017).

- Kilkis, B.I.; Gungor, C. Effective Use of Low-Enthalpy Renewable Energy Resources in District Heating and Cooling. In Proceedings of the National Clean Energy Symposium, Istanbul, Turkey, 15–17 November 2000; pp. 731–738. (In Turkish). [Google Scholar]

- Kilkis, I.B. Ein aus verschiedenen Kreislaufen zusammengesetztes, geotermisches Energiesystem für die Stadt Denizli, Geothermie-Energie der Zukunft, Geeste. In Proceedings of the Tagusband der 4. Geothermischen Fachtagung in Konstanz, Germany, 18–20 September 1997; pp. 413–424. [Google Scholar]

- Saghafifar, M.; Omar, A.; Mohammadi, K.; Alashkar, A.; Gadalla, M. A review of unconventional bottoming cycles for waste heat recovery: Part I—Analysis, design, and optimization. Energy Convers. Manag. in press. [CrossRef]

- Wang, D.; Bao AKunc, W.; Liss, W. Coal power plant flue gas waste heat and water recovery. Appl. Energy 2012, 91, 341–348. [Google Scholar] [CrossRef]

- Suresh, M.V.J.J.; Reddy, K.S.; Kolar, A.K. Thermodynamic analysis of a coal-fired power plant repowered with pressurized pulverized coal combustion. J. Power Energy 2011. [Google Scholar] [CrossRef]

- Lu, V.; Sun, F.; Shi, Y. Exergy Analysis of Advanced Boiler Flue Gas Heat Recovery System in Power Plant. In Proceedings of the CSEE, Cluj-Napoca, Romania, 2–5 May 2012. [Google Scholar]

- Kaushik, S.C.; Reddy, V.S.; Tyagi, S.K. Energy and exergy analyses of thermal power plants: A review. Renew. Sustain. Energy Rev. 2011, 15, 1857–1872. [Google Scholar] [CrossRef]

- Woudstra, N.; Woudstra, T.; Pirone, A.; van der Stelt, T. Thermodynamic evaluation of combined cycle plants. Energy Convers. Manag. 2010, 51, 1099–1110. [Google Scholar] [CrossRef]

- Kilkis, B. Analysis of cogeneration systems and their environmental benefits. TTMD J. 2007, 48/26, 15. [Google Scholar]

- Kilkis, Ş.; Kilkis, B. Integrated circular economy and education model to address aspects of an energy-water-food nexus in a dairy facility and local contexts. J. Clean. Prod. 2017, 167, 1084–1098. [Google Scholar] [CrossRef]

- EU; The European Parliament; Council of the European Union. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the energy performance of buildings. Off. J. Eur. Union 2010, 53, 13–55. [Google Scholar]

- Ando, O.H., Jr.; Calderon, N.H.; De Souza, S.S. Characterization of a Thermoelectric Generator (TEG) system for waste heat recovery. Energies 2018, 11, 1555. [Google Scholar] [CrossRef]

- Memon, S.; Khawaja, N.T. Experimental and analytical simulation analyses on the electrical performance of thermoelectric generator modules for direct and concentrated quartz-halogen heat harvesting. Energies 2018, 11, 3315. [Google Scholar] [CrossRef]

- Oyewunmi, O.; Markides, C.; Lazova, M.; Kaya, A.; van den Broek, M.; De Paepe, M. Case study of an Organic Rankine Cycle (ORC) for waste heat recovery from an Electric Arc Furnace (EAF). Energies 2017, 10, 649. [Google Scholar] [CrossRef]

- Markus, P.; Dieter, B. Thermo-economic evaluation of modular organic rankine cycles for waste heat recovery over a broad range of heat source temperatures and capacities. Energies 2017, 10, 269. [Google Scholar] [CrossRef]

- He, T.; Shi, R.; Peng, J.; Zhuge, W.; Zhang, Y. Waste heat recovery of a PEMFC system by using organic rankine cycle. Energies 2016, 9, 267. [Google Scholar] [CrossRef]

- Ayachi, F.; Ksayer, E.B.; Neveu, P. Exergy assessment of recovery solutions from dry and moist gas available at medium temperature. Energies 2012, 5, 718–730. [Google Scholar] [CrossRef]

- Xu, C.; Gao, Y.; Zhang, Q.; Zhang, G.; Xu, G. Thermodynamic, economic and environmental evaluation of an improved ventilation air methane-based hot air power cycle integrated with a de-carbonization oxy-coal combustion power plant. Energies 2018, 11, 1434. [Google Scholar] [CrossRef]

- Erguvan, M.; MacPhee, D.W. Energy and exergy analyses of tube banks in waste heat recovery applications. Energies 2018, 11, 2094. [Google Scholar] [CrossRef]

- Kılkış, Ş. A Rational Exergy Management Model to Curb CO2 Emissions in the Exergy-Aware Built Environments of the Future. Doctoral Thesis, Division of Building Technology School of Architecture and the Built Environment KTH Royal Institute of Technology, Stockholm, Sweden, 2011. [Google Scholar]

- Bingöl, E.; Kilkis, B.; Eralp, C. Exergy based performance analysis of high-efficiency poly-generation systems for sustainable building applications. Energy Build. 2011, 43, 3074–3081. [Google Scholar] [CrossRef]

- PPIC. Power Plants Information Center, Flue Gas Stack. 2018. Available online: http://powerplantstechnology.blogspot.com/2010/08/flue-gas-stack.html (accessed on 16 February 2019).

- Kilkis, B. An Exergy-Rational Model for Rating Sensible Air-to-Air Heat Recovery Systems in Sustainable Buildings. In Proceedings of the 3rd SEE SDEWES Conference, Novi Sad, Serbia, 30 June–4 July 2018. [Google Scholar]

- Kılkış, B.; Kılkış, Ş. Hydrogen economy model for nearly net-zero cities with exergy rationale and energy-water nexus. Energies 2018, 11, 1226. [Google Scholar] [CrossRef]

- Kilkis, B.; Kilkis, S. Exergetic Optimization of Generated Electric Power Split in a Heat Pump Coupled Poly-Generation System. In Proceedings of the Energy Sustainability Conference, Long Beach, CA, USA, 27–30 July 2007; pp. 211–218. [Google Scholar] [CrossRef]

- Pershing, D.W.; Wendt, J.O.L. Relative Contributions of volatile nitrogen and char nitrogen to NOx emissions from pulverized coal flames. Ind. Eng. Chem. Process Des. Dev. 1979, 18, 60–66. [Google Scholar] [CrossRef]

- Hong, B.D.; Slatic, E.R. Energy Information Administration, Carbon Dioxide Emission Factors for Coal; Quarterly Coal Report, DOE/EIA-0121(94/Q1); DOE/EIA: Washington, DC, USA, 1994; pp. 1–8. Available online: https://www.eia.gov/coal/production/quarterly/co2_article/co2.html.

- Cheng, M.T.; Zeng, T.H. Calculation and Analysis of Acid Dew-Point Temperature in Coal-Fired Boiler Gas. In Proceedings of the 5th International Conference on Advanced Design and Manufacturing Engineering (ICADME), Shenzhen, China, 19–20 September 2015; pp. 615–617. [Google Scholar]

- Kılkış, B. Sustainability and Decarbonization Efforts of the EU: Potential Benefits of Joining Energy Quality (Exergy) and Energy Quantity (Energy) in EU Directives, A State of-the-Art Survey and Recommendations; Exclusive EU Position Report of TTMD; TTMD: Ankara, Turkey, 2017. [Google Scholar]

- Lu, P.C.; Fu, T.T.; Garg, S.C.; Novakowski, G. Boiler Stack Gas Heat Recovery; NCEL Technical Note, N-1776; Defence Technical Information Centre: Fort Belvoir, VA, USA, 1987; Available online: http://www.dtic.mil/dtic/tr/fulltext/u2/a187419.pdf.

- Karaoglu, C.; Ozbek, A. District heating and power generation-based flue gas waste heat recovery. Eur. Mech. Sci. 2017, 1, 63–68. [Google Scholar]

- Franco, A.; Villani, M. Optimal design of binary cycle power plants for water-dominated, medium-temperature geothermal fields. Geothermics 2009, 38, 379–391. [Google Scholar] [CrossRef]

| Method | Claimed Exergy, kW | ηII | Exergy Input, kW | ηI | COP | COPEX (Colum 3/Colum 5) (Including Source Exergy) | ||

|---|---|---|---|---|---|---|---|---|

| Net Electrical Exergy, kW | Net Thermal Exergy, kW | Total Net Exergy, kW | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||

| a | 3 | 3.4 | 6.4 | 0.11 | 5 + 58 | 0.60 | 12.6 | 0.10 |

| b | 7 | 2.5 | 9.5 | 0.164 | 3 + 58 | 0.48 | 16.7 | 0.156 |

| c | 0 | 0.6 | 0.6 | 0.01 | 5 + 58 | 0.68 | 8.62 | 0.009 |

| d | −2 | 5 | 3 | 0.15 | 2 + 58 | 0.78 | 40 | 0.05 |

| Variable | Value | Unit and Comments |

|---|---|---|

| To | 293 | K (Outdoor temperature) |

| Tgi | 600 | K (Flue gas inlet temperature, constant) |

| Tgo | 600 | K (Initial value, varies with heat recovery) |

| Tg | 600 | K (Initial value, varies with heat recovery) |

| mg | 86.154 | m3/s (Design value, varies with heat recovery) |

| Cpg | 1.151 | kJ/kg·K at 750 K |

| Cpf | 4.187 | kJ/kg·K at 300 K |

| Eg | 15982.64 | kW |

| Exg | 8177.783 | kW |

| Ag | 5 | m2 (Average cross-sectional stack area) |

| H | 79 | m (Stack height) |

| h | 860 | m (Altitude from sea level) |

| Patm | 91.41271 | kPa (Corrected with altitude) |

| Tfo | 363 | K (Design input) |

| Tfi | 345 | K (Design output) |

| ΔTf | 18 | K (Tfo − Tfi) |

| Tfav | 354 | K (Tfi + ΔTf/2) |

| ηHE | 0.85 | Assumed constant |

| ηFM | 0.8 | Assumed constant |

| ρf | 986.1687 | kg/m3 (Corrected for temperature) |

| ρg | 0.525 | kg/m3 (To be corrected for temperature and gas composition) |

| ηcp | 0.75 | Assumed constant |

| mf | mg | Δmg | Tgo | ΔTg | ΔTf | Exf | ΔPD | EXF | EXCP | COPEX |

|---|---|---|---|---|---|---|---|---|---|---|

| (m3/s) | (m3/s) | (m3/s) | (K) | (K) | (K) | (kW) | (Pa) | (kW) | (kW) | (Dimensionless) |

| 0.01 | 85.73 | 0.42 | 587.87 | 6.07 | 18 | 36.85 | 3.69 | 1.94 | 5.024 | 5.291502 |

| 0.011 | 85.69 | 0.46 | 586.65 | 6.67 | 18 | 40.54 | 4.06 | 2.35 | 5.169 | 5.390105 |

| 0.012 | 85.65 | 0.51 | 585.44 | 7.28 | 18 | 44.23 | 4.43 | 2.80 | 5.306 | 5.454215 |

| 0.013 | 85.60 | 0.55 | 584.22 | 7.89 | 18 | 47.91 | 4.79 | 3.29 | 5.435 | 5.489238 |

| 0.014 | 85.56 | 0.59 | 583.01 | 8.49 | 18 | 51.60 | 5.16 | 3.82 | 5.557 | 5.499905 |

| 0.015 | 85.52 | 0.64 | 581.80 | 9.10 | 18 | 55.28 | 5.53 | 4.40 | 5.674 | 5.490328 |

| 0.016 | 85.48 | 0.68 | 580.58 | 9.71 | 18 | 58.97 | 5.90 | 5.01 | 5.785 | 5.464054 |

| 0.017 | 85.43 | 0.72 | 579.37 | 10.31 | 18 | 62.65 | 6.27 | 5.66 | 5.891 | 5.424127 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kılkış, B. Development of an Exergy-Rational Method and Optimum Control Algorithm for the Best Utilization of the Flue Gas Heat in Coal-Fired Power Plant Stacks. Energies 2019, 12, 760. https://doi.org/10.3390/en12040760

Kılkış B. Development of an Exergy-Rational Method and Optimum Control Algorithm for the Best Utilization of the Flue Gas Heat in Coal-Fired Power Plant Stacks. Energies. 2019; 12(4):760. https://doi.org/10.3390/en12040760

Chicago/Turabian StyleKılkış, Birol. 2019. "Development of an Exergy-Rational Method and Optimum Control Algorithm for the Best Utilization of the Flue Gas Heat in Coal-Fired Power Plant Stacks" Energies 12, no. 4: 760. https://doi.org/10.3390/en12040760

APA StyleKılkış, B. (2019). Development of an Exergy-Rational Method and Optimum Control Algorithm for the Best Utilization of the Flue Gas Heat in Coal-Fired Power Plant Stacks. Energies, 12(4), 760. https://doi.org/10.3390/en12040760