Control Strategies of Full-Voltage to Half-Voltage Operation for LCC and Hybrid LCC/MMC based UHVDC Systems

Abstract

1. Introduction

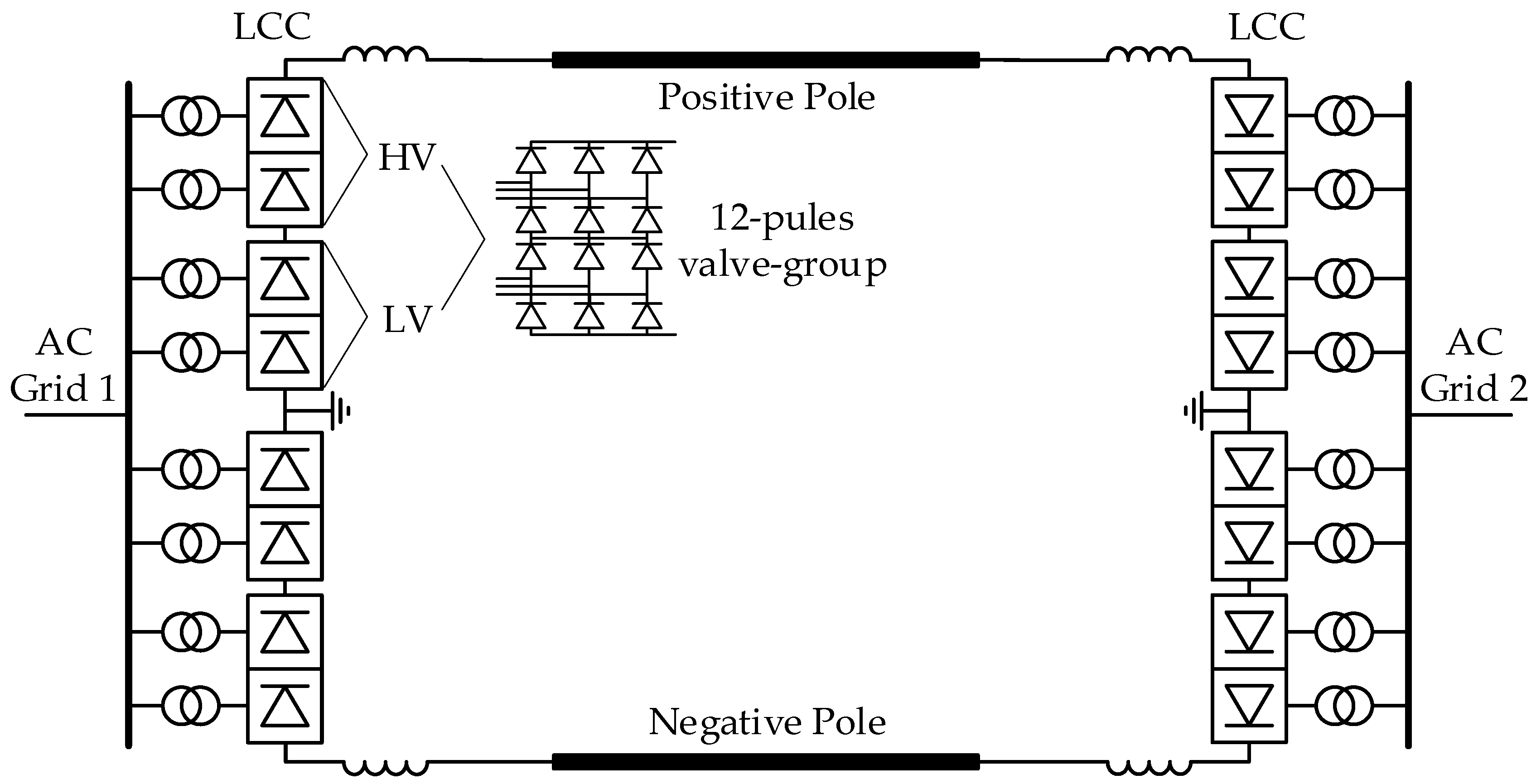

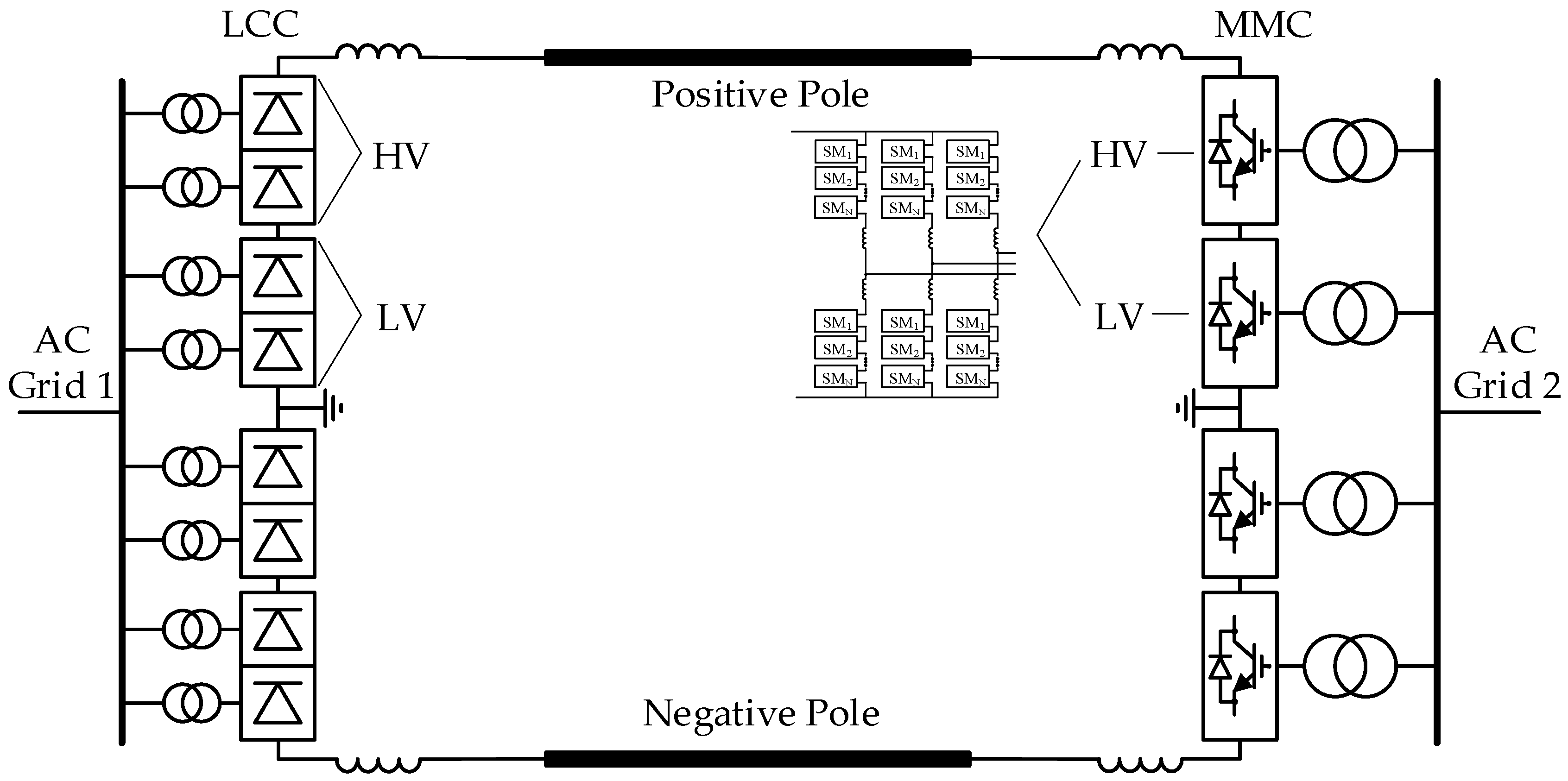

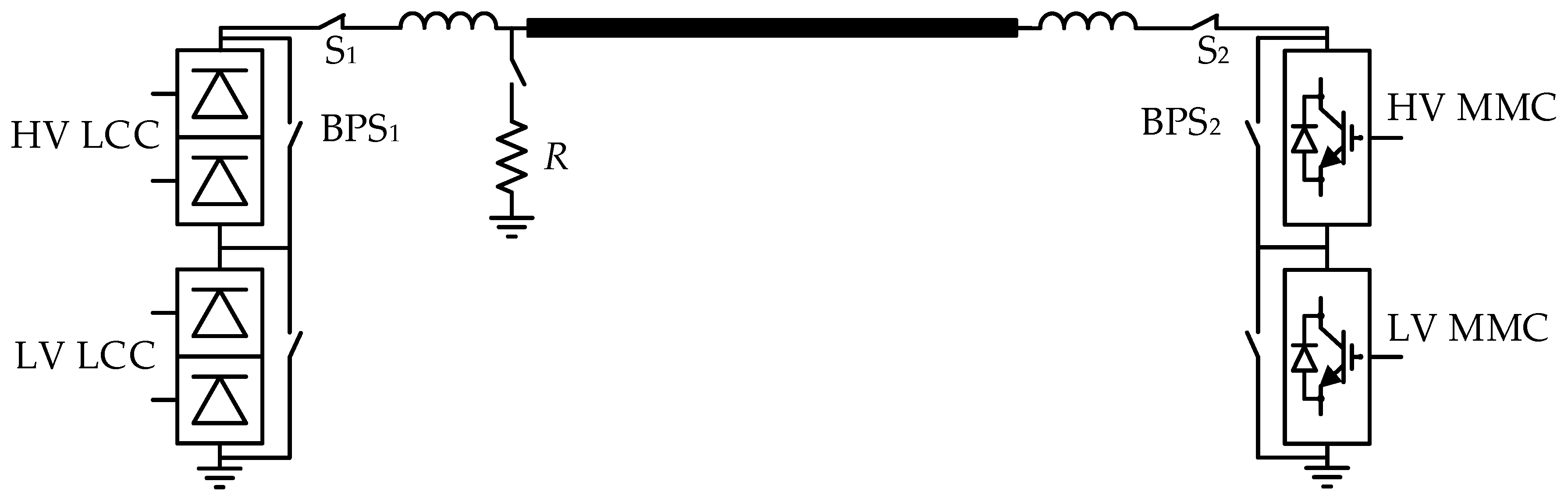

2. Converter Station Configurations of UHVDC Systems

- (1)

- Normal operation: both poles are in full-voltage operation; the whole system power capacity is 100%;

- (2)

- Partial monopole off: one-pole is in full-voltage operation while the other is partially off (25% of the rated capacity); the whole system power capacity is 75%;

- (3)

- Monopole off: one-pole is in full-voltage operation while the other is off; the whole system power capacity is 50%;

- (4)

- Partial bipole off:

- Both poles are in (half-voltage operation) partial monopole off (each pole has 25% of the rated capacity); the whole system power capacity is 50%;

- One-pole is off while the other is (half-voltage operation) partial monopole off (25% of the rated capacity); the whole system power capacity is 25%;

- (5)

- Bipole off: the whole system is shut down; the system power capacity of the whole system is 0.

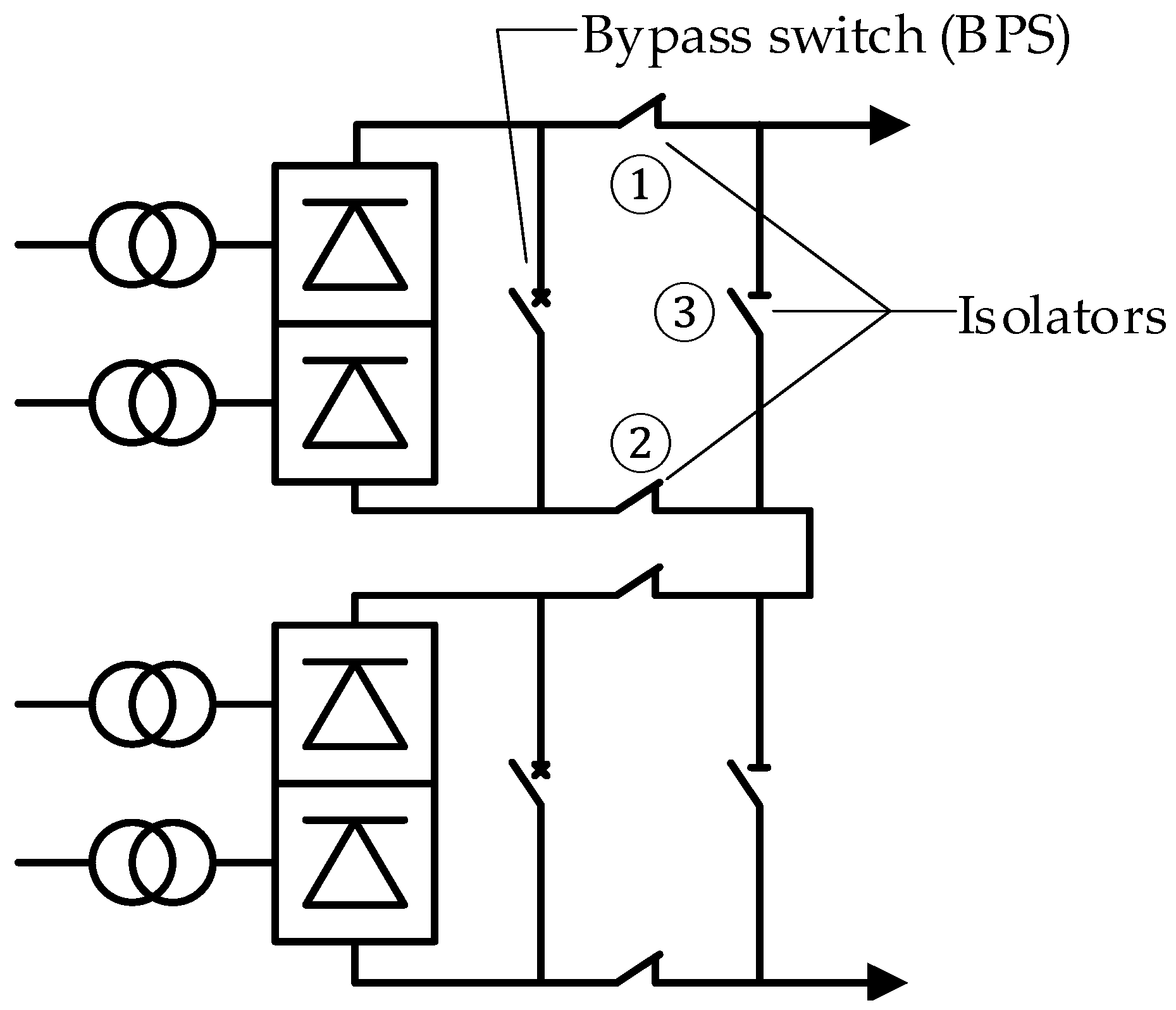

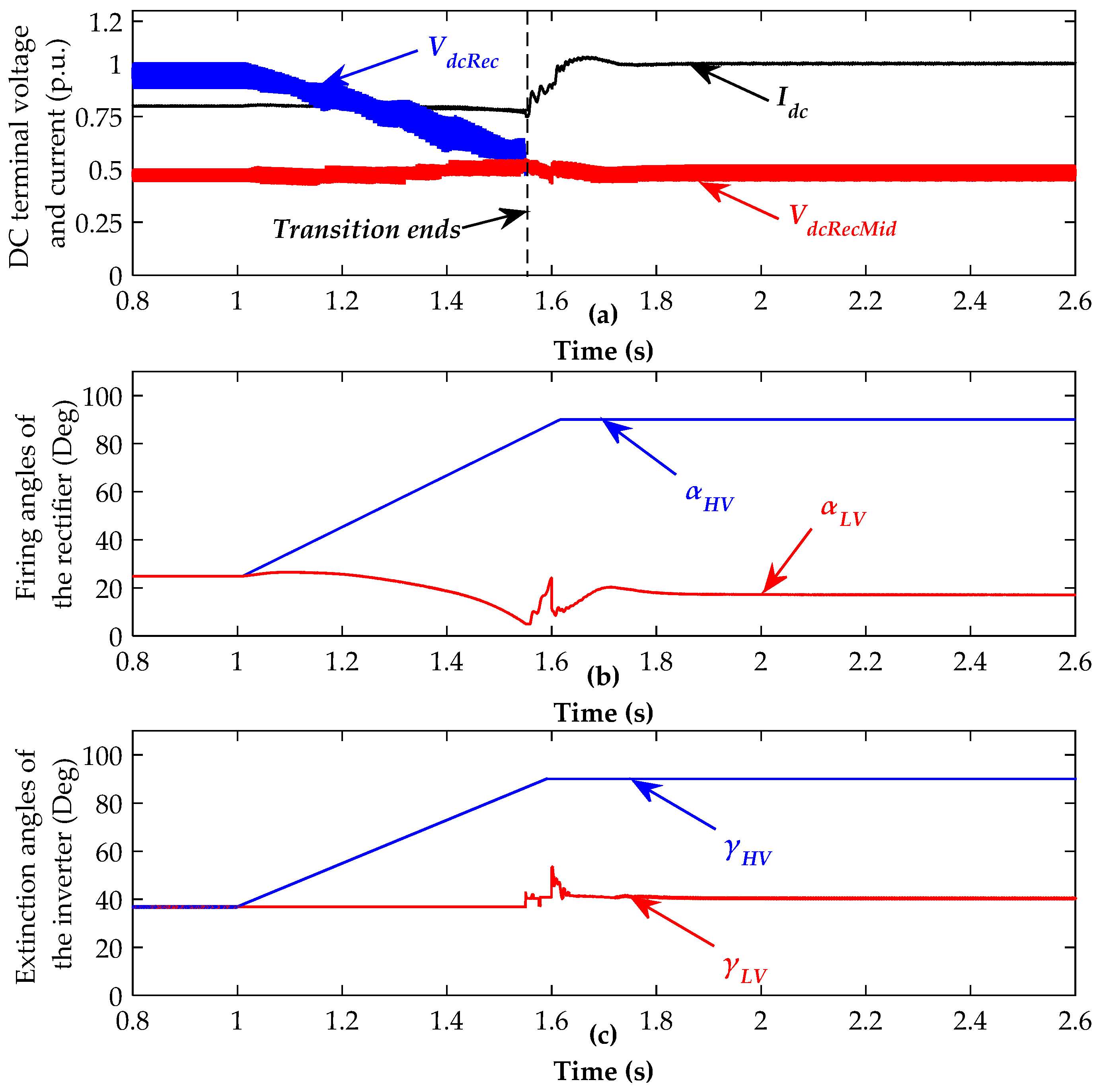

3. Valve-Group Bypassing Strategy for LCC-UHVDC

- (1)

- The extinction angle γ of the HV valve-group in the inverter will be ramped up to 90˚ once a bypassing order is received from the system upper level control. At the same time, the bypassing order will be transmitted to the rectifier;

- (2)

- The firing angle α of the HV valve-group in the rectifier will be ramped up to 90˚ once the bypassing order is received;

- (3)

- When the voltage of the HV valve-groups decrease to 0.1 p.u., the BPS is closed. Then, the valve-groups are blocked. At the same time, the bypass isolator will be closed;

- (4)

- The BPS is opened once the bypass isolator is fully closed;

- (5)

- The valve-group isolators are opened once the BPS is fully opened;

- (6)

- The full-voltage to half-voltage process completes after the above process.

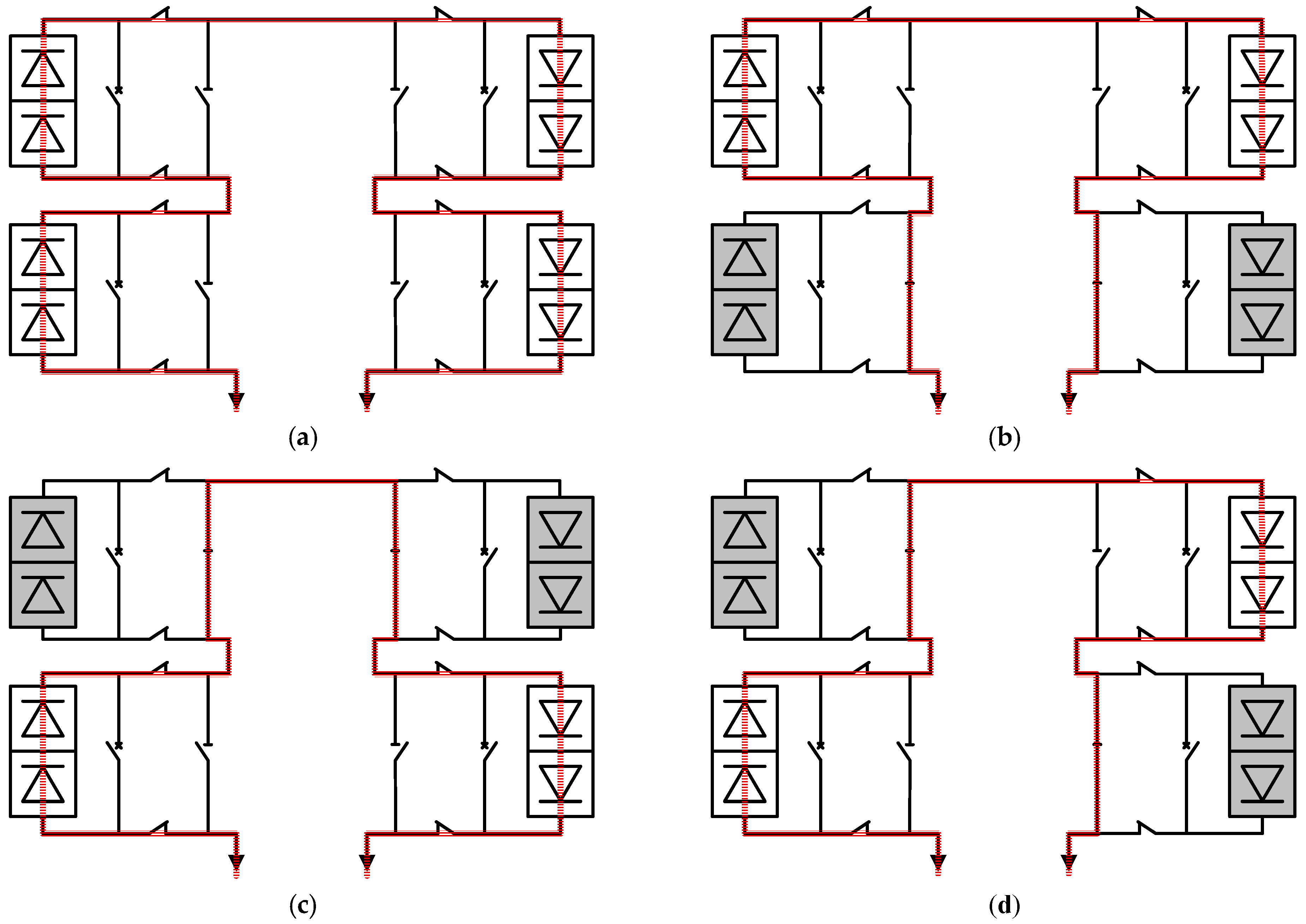

4. Valve-Group Bypassing Strategy for Hybrid LCC/VSC UHVDC

4.1. The VSC in the Hybrid System is Half-Bridge Modular Multilevel Converter (HB-MMC)

- (1)

- Reduce the DC current to a minimum value (0.1 p.u.) once a bypassing order is received from the system upper level control;

- (2)

- Block the HV and LV LCCs and the HV MMC valve-groups once the DC current is reduced to the target value;

- (3)

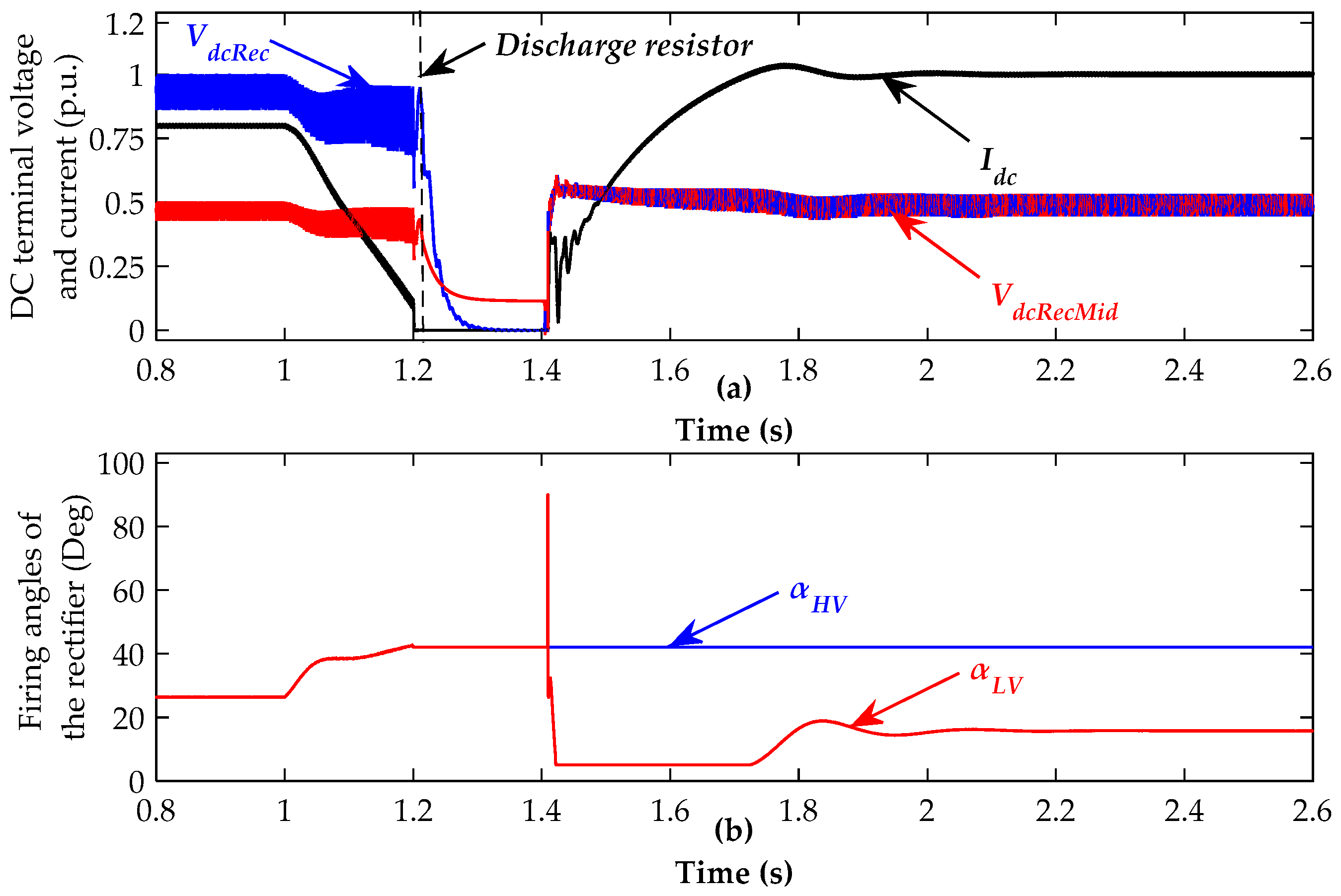

- The DC terminal switches are tripped to isolate the converters from the DC line; Then, the discharging resistor is inserted; The HV valve-groups are bypassed during this process;

- (4)

- The discharging resistor is removed once the DC line is fully de-energized;

- (5)

- The LV LCC is deblocked to charge the DC line once its DC side switch is re-closed;

- (6)

- The LV MMC’s DC side switch is closed once the DC line voltage reaches to its DC terminal voltage;

- (7)

- The full-voltage to half-voltage process completes after the above process.

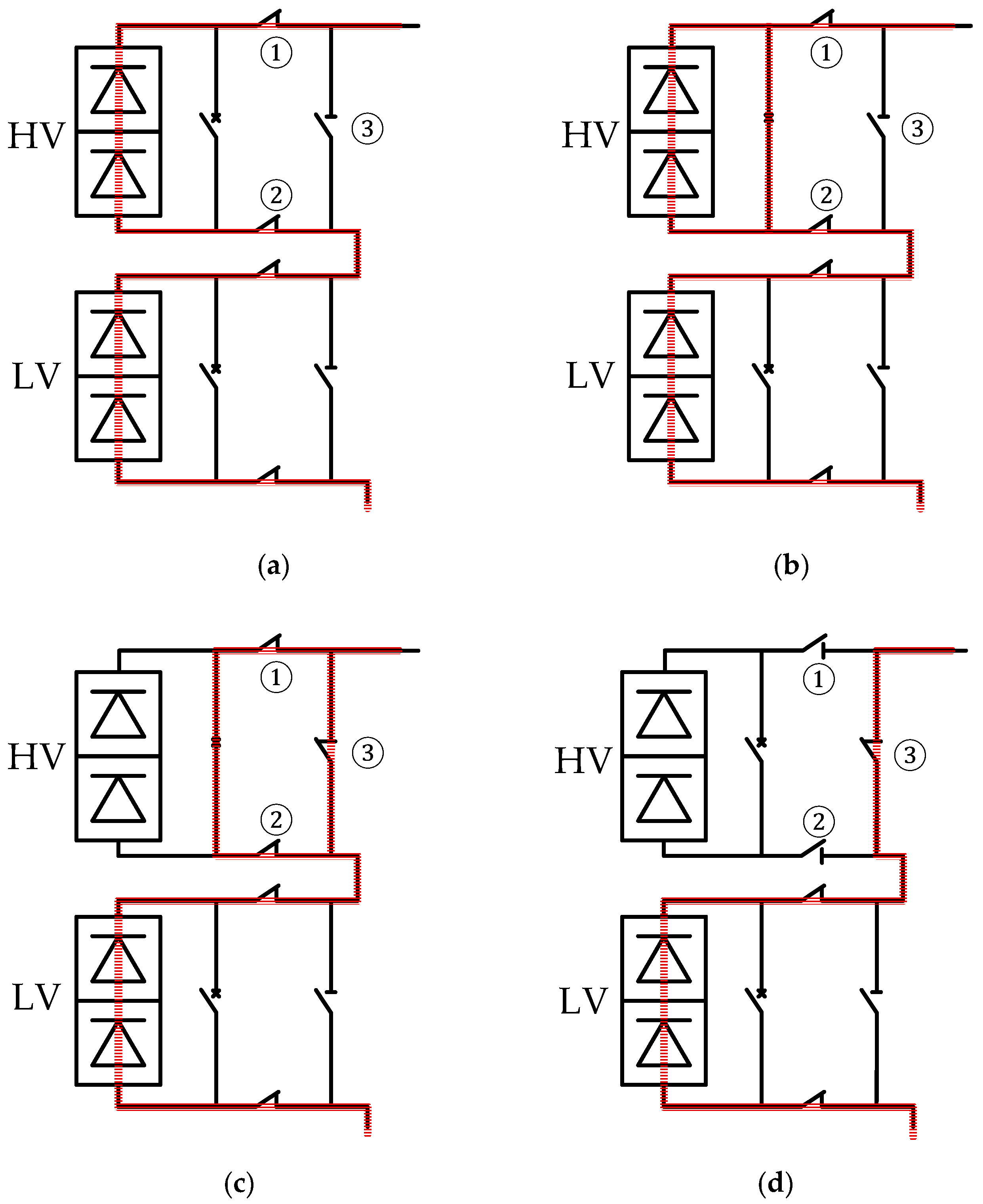

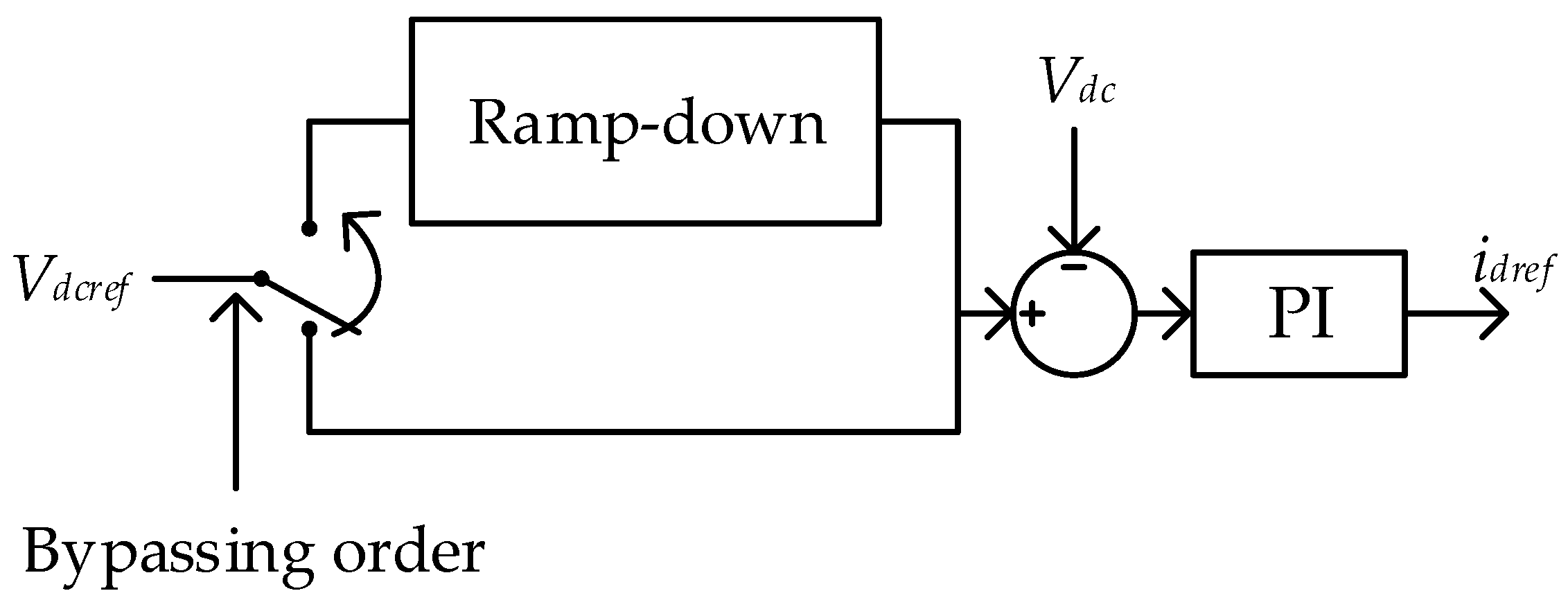

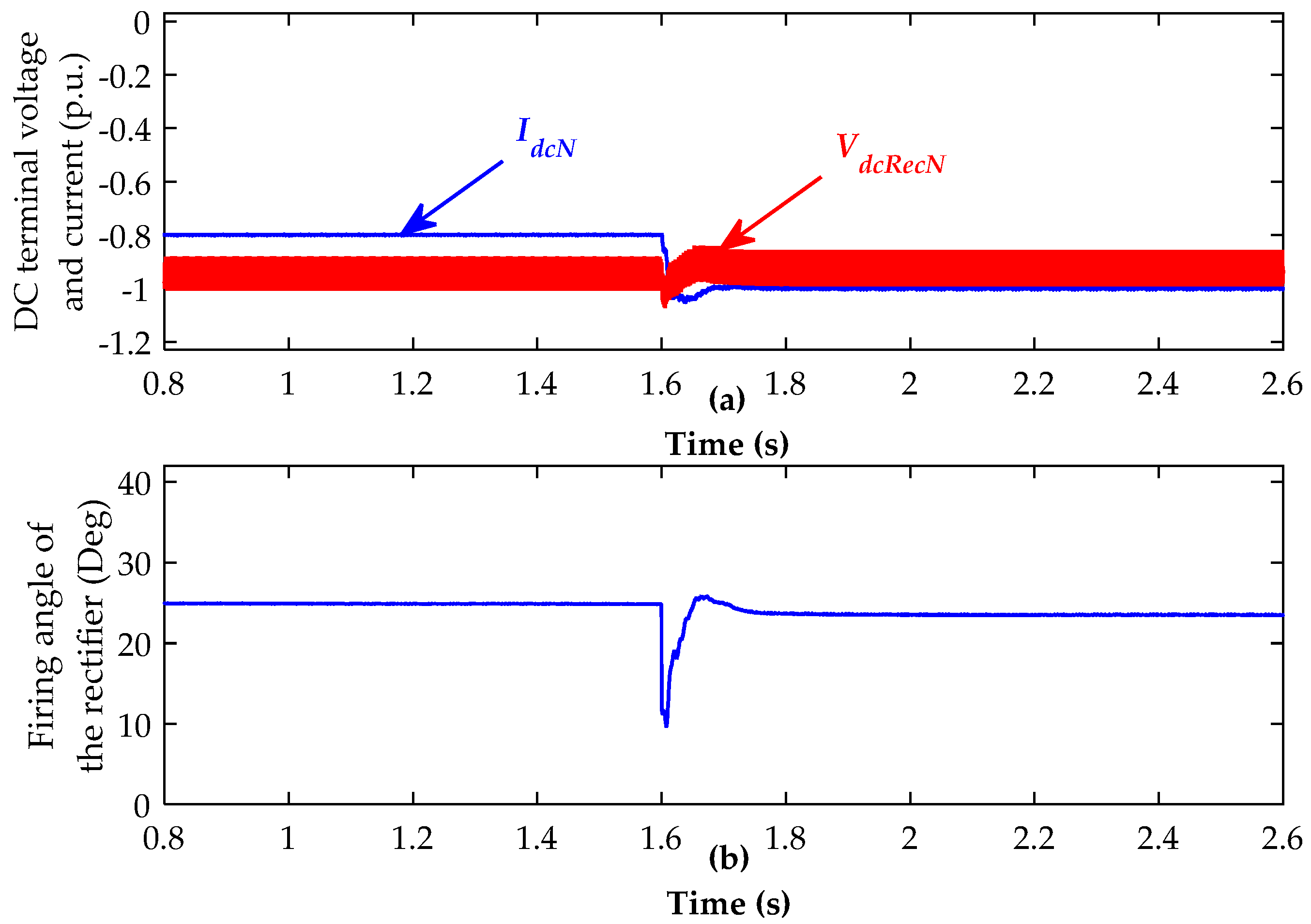

4.2. The VSC in the Hybrid System is Full-Bridge Modular Multilevel Converter (FB-MMC)

- (1)

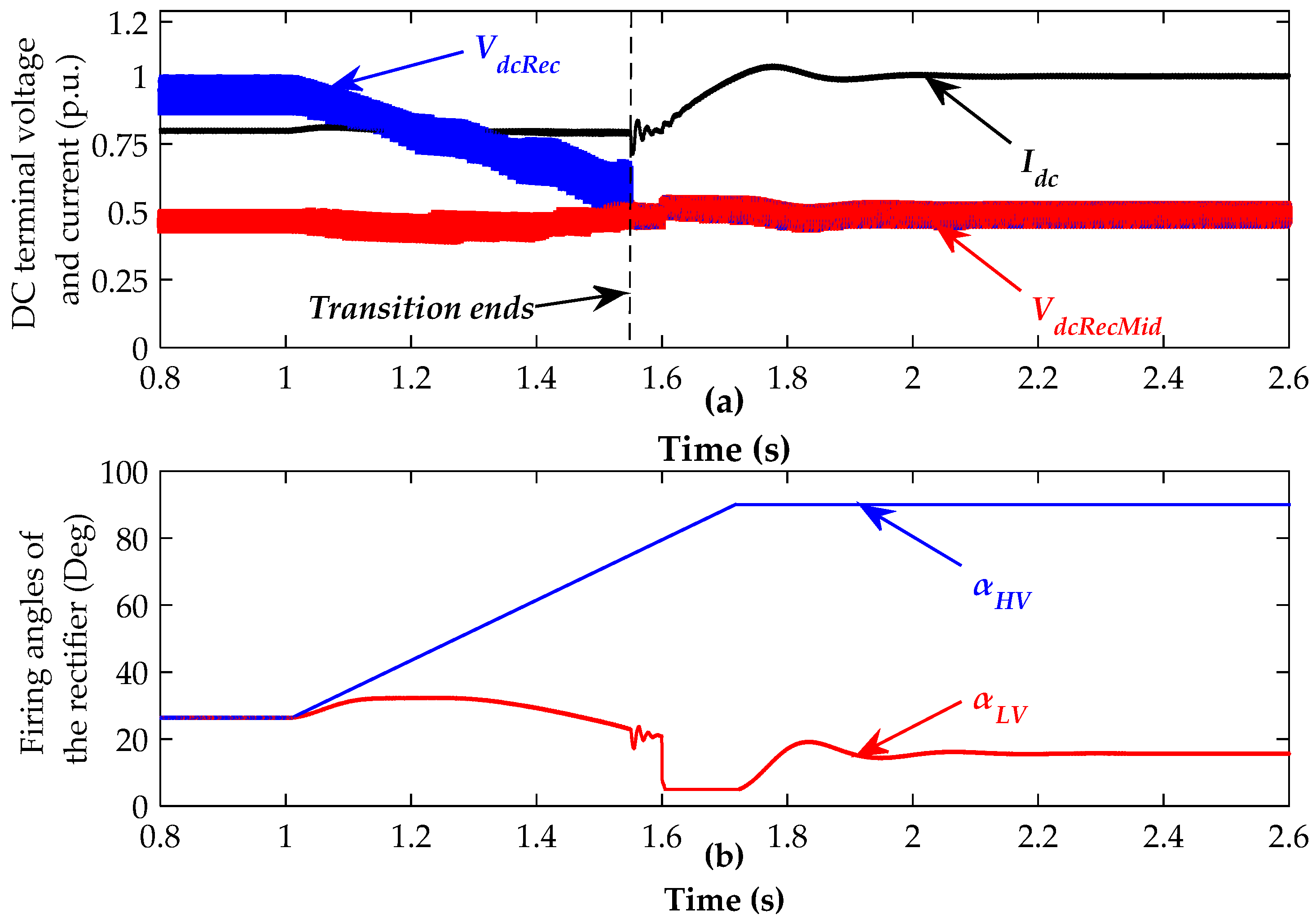

- The DC voltage of the HV valve-group of the FB-MMC will be controlled to ramp down to a minimum value (0.1 p.u.) once a bypassing order is received from the system upper level control. At the same time, the bypassing order will be transmitted to the rectifier;

- (2)

- The firing angle α of the HV valve-group in the rectifier will be ramped up to follow the voltage decrease controlled by the FB-MMC;

- (3)

- When the voltage of the HV valve-groups decrease to 0.1 p.u., the BPS is closed. Then, the valve-groups are blocked. At the same time, the bypass isolator will be closed;

- (4)

- The BPS is opened once the bypass isolator is fully closed;

- (5)

- The valve-group isolators are opened once the BPS is fully opened;

- (6)

- The full-voltage to half-voltage process completes after the above process.

5. Power Rescheduling Strategy for Full-Voltage to Half-Voltage Operation

- (1)

- If P0 ≤ ½Prated, the new power reference for the half-voltage operating valve-group will be set as 2P0. The power reference for the full-voltage operating pole is not changed. In this case, there is no power loss.

- (2)

- If ½Prated < P0 ≤ ¾Prated, the new power reference for the half-voltage operating valve-group will be set as Prated. In this case, the increased power of the half-voltage valve-group is (Prated ‒P0), the lost power is P0 ‒ (Prated ‒ P0) = (2P0 ‒ Prated) which can be undertaken by the full-voltage operating pole. It is known the original power in the full-voltage operating pole is 2P0. As P0 ≤ ¾Prated, therefore (2P0 ‒ Prated) + 2P0 = (4P0 ‒ Prated) ≤ 2Prated. Therefore, the new power reference for the full-voltage operating pole is set to (4P0 ‒ Prated). In this case, power loss of the system is 0.

- (3)

- If ¾Prated < P0 ≤ Prated, the new power reference for the half-voltage operating valve-group will be set as Prated. The power reference for the full-voltage operating valve-group will be set as 2Prated. In this case, the power loss in the system is (4P0 ‒ 3Prated).

6. Case Studies

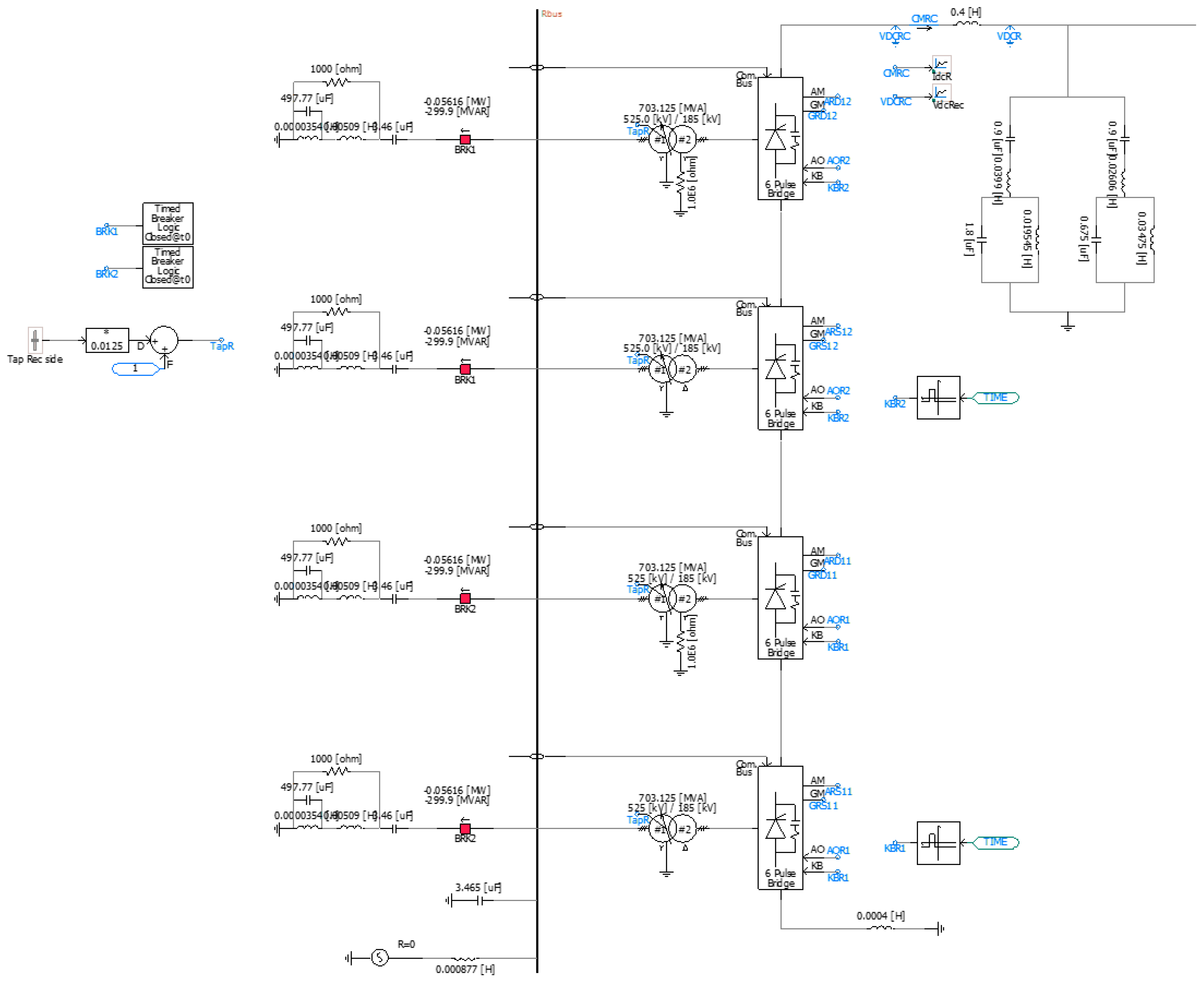

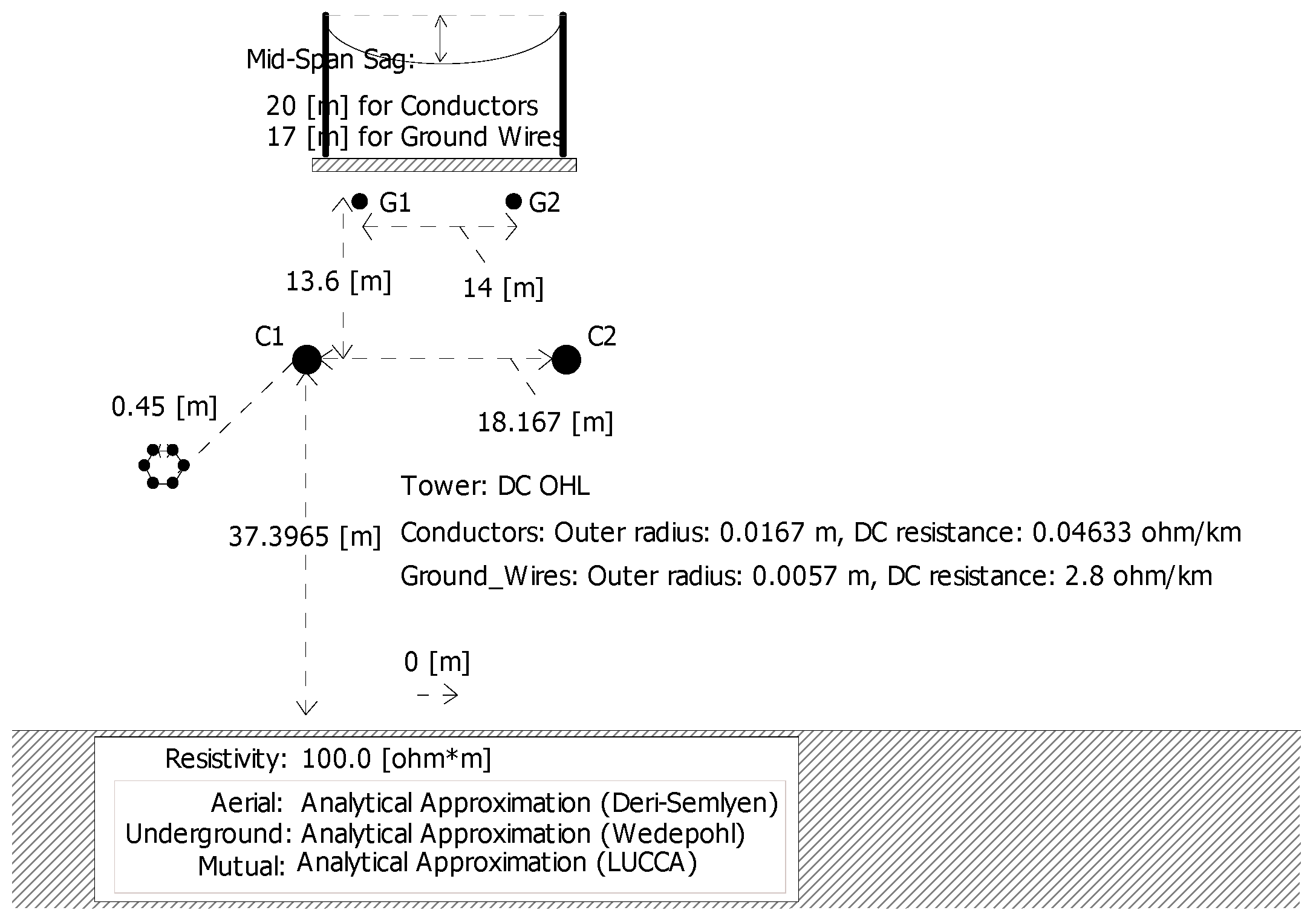

6.1. LCC-UHVDC Point-to-Point Link

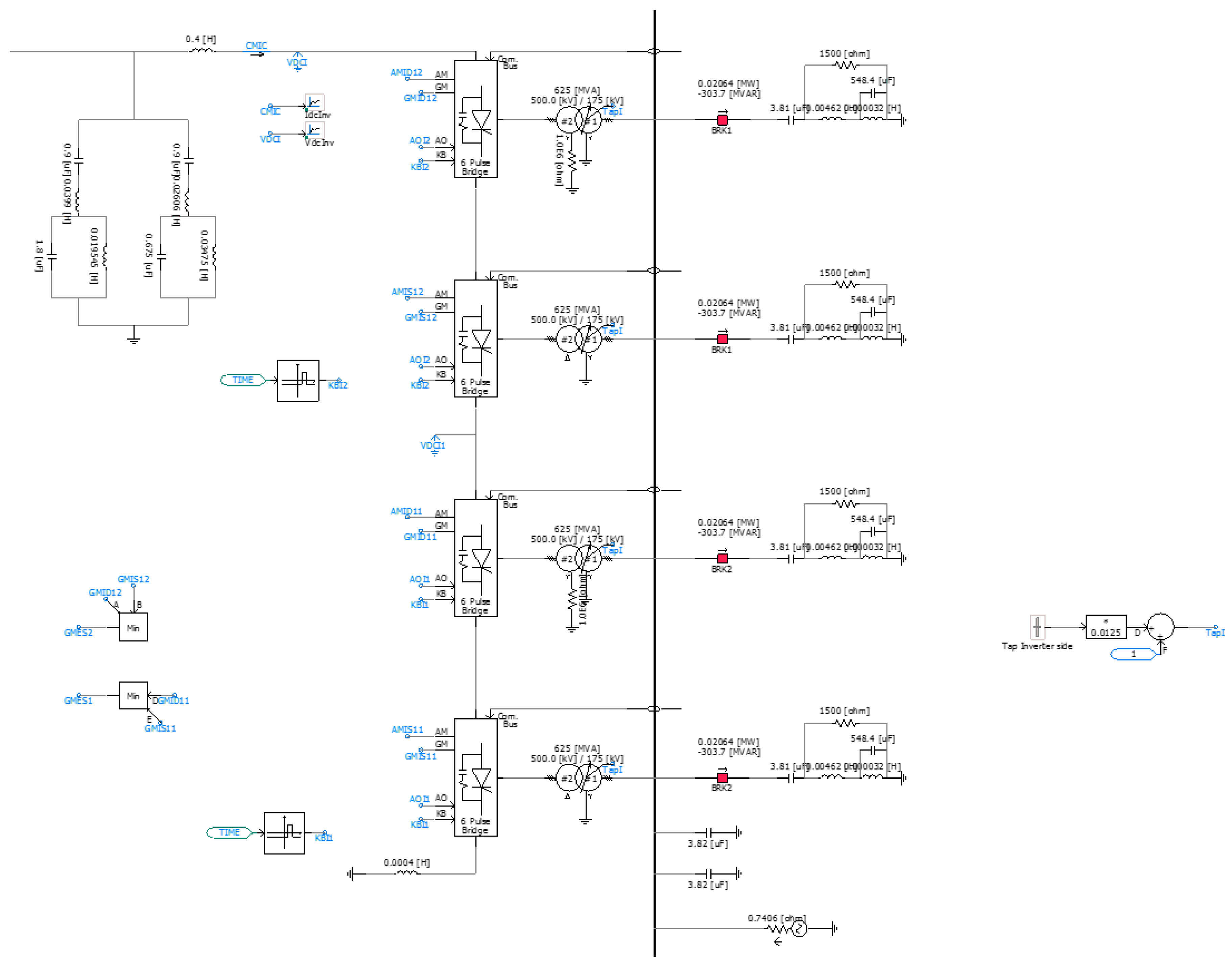

6.2. Hybrid LCC/HB-MMC UHVDC Point-to-Point Link

6.3. Hybrid LCC/FB-MMC UHVDC Point-to-Point Link

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Wang, Y.; Wen, W.; Wang, C.; Liu, H.; Zhan, X.; Xiao, X. Adaptive Voltage Droop Control of Multiterminal VSC-HVDC Systems for DC Voltage Deviation and Power Sharing. IEEE Trans. Power Del. 2019, 34, 169–176. [Google Scholar] [CrossRef]

- Li, G.; Liang, J.; Ugalde-Loo, C.E.; Coventry, P.; Rimez, J. Dynamic interactions of DC and AC grids subject to DC faults. In Proceedings of the 2016 IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Hefei, China, 22–26 May 2016; pp. 2627–2633. [Google Scholar]

- Bucher, M.K.; Franck, C.M. Contribution of Fault Current Sources in Multiterminal HVDC Cable Networks. IEEE Trans. Power Del. 2013, 28, 1796–1803. [Google Scholar] [CrossRef]

- Li, G.; Li, C.; van Hertem, D. HVDC technology overview. In HVDC Grid: For Offshore and Supergrid of the Future; Wiley-IEEE: Piscataway, NJ, USA, 2016; Chapter 3; pp. 45–78. [Google Scholar]

- Joseph, T.; Ugalde-Loo, C.E.; Liang, J.; Coventry, P.F. Asset Management Strategies for Power Electronic Converters in Transmission Networks: Application to Hvdc and FACTS Devices. IEEE Access 2018, 6, 21084–21102. [Google Scholar] [CrossRef]

- Barnes, M.; van Hertem, D.; Teeuwsen, S.P.; Callavik, M. HVDC Systems in Smart Grids. Proc. IEEE 2017, 105, 2082–2098. [Google Scholar] [CrossRef]

- World’s Biggest Ultra-High Voltage Line Powers Up Across China. Available online: https://www.bloomberg.com/news/articles/2019-01-02/world-s-biggest-ultra-high-voltage-line-powers-up-across-china (accessed on 15 January 2019).

- Perez, M.A.; Bernet, S.; Rodriguez, J.; Kouro, S.; Lizana, R. Circuit Topologies, Modeling, Control Schemes, and Applications of Modular Multilevel Converters. IEEE Trans. Power Electron. 2015, 30, 4–17. [Google Scholar] [CrossRef]

- Li, G.; Liang, J.; Ma, F.; Ugalde-Loo, C.E.; Liang, H. Analysis of Single-Phase-to-Ground Faults at the Valve-Side of HB-MMCs in HVDC Systems. IEEE Trans. Ind. Electron. 2019, 66, 2444–2453. [Google Scholar] [CrossRef]

- Kouro, S.; Malinowski, M.; Gopakumar, K.; Pou, J.; Franquelo, L.G.; Wu, B.; Rodriguez, J.; Perez, M.A.; Leon, J.I. Recent Advances and Industrial Applications of Multilevel Converters. IEEE Trans. Ind. Electron. 2010, 57, 2553–2580. [Google Scholar] [CrossRef]

- TBEA. The World’s First-ever ±800kV Modular Multilevel Converter Valve has been Developed. Available online: http://en.tbeaenergy.com/content/details144_1804.html (accessed on 15 January 2018).

- RXPE. RXHK Awarded World’s Largest VSC HVDC Converter Contract. Available online: http://www.rxpe.co.uk/corporate/news/worlds-largest-vsc-hvdc-converter-order/ (accessed on 15 January 2018).

- Song, J. Analysis of Hybrid LCC-VSC HVDC Transmission Systems. Master’s Thesis, Universitat Politècnica de Catalunya UPC, Barcelona, Spain, 2018. [Google Scholar]

- Lebre, J.R.; Portugal, P.M.M.; Watanabe, E.H. Hybrid HVDC (H2VDC) System Using Current and Voltage Source Converters. Energies 2018, 11, 1323. [Google Scholar] [CrossRef]

- Li, G.; Liang, J.; Joseph, T.; An, T.; Szechtman, M.; Andersen, B.; Zhuang, Q. Start-up and Shut-down Strategies of Hybrid LCC/VSC DC Grids. In Proceedings of the 2018 2nd IEEE Conference on Energy Internet and Energy System Integration (EI2), Beijing, China, 20–22 October 2018; pp. 1–5. [Google Scholar]

- Mohamed Haleem, N.; Rajapakse, A.D.; Gole, A.M.; Fernando, I.T. Investigation of Fault Ride-Through Capability of Hybrid VSC-LCC Multi-Terminal HVDC Transmission Systems. IEEE Trans. Power Del. 2019, 34, 241–250. [Google Scholar] [CrossRef]

- Li, G.; Liang, J.; Joseph, T.; An, T. Feasibility and Reliability Analysis of LCC DC Grids and LCC/VSC Hybrid DC Grids. IEEE Access 2019. [CrossRef]

- Ying, H.; Weihuang, H.; Ming, L.; Tao, L. Steady-state control strategy of multi-terminal hybrid UHVDC. In Proceedings of the 2017 19th European Conference on Power Electronics and Applications (EPE’17 ECCE Europe), Warsaw, Poland, 11–14 September 2017; pp. 1–10. [Google Scholar]

- Liu, Z.; Yu, J.; Guo, X.; Sun, T.; Zhang, J. Survey of technologies of line commutated converter based high voltage direct current transmission in China. CSEE J. Power Energy Syst. 2015, 1, 1–8. [Google Scholar] [CrossRef]

- Rao, H.; Xu, S.; Zhou, Y.; Zhu, Z. Research on Main Circuit Scheme of VSC-UHVDC. Southern Power Syst. Technol. 2017, 11, 1–4. [Google Scholar]

- Xie, K.; Hu, B.; Singh, C. Reliability Evaluation of Double 12-Pulse Ultra HVDC Transmission Systems. IEEE Trans. Power Del. 2016, 31, 210–218. [Google Scholar]

- Vithayathil, J.J. Bypass operation in bridge convertors for high-voltage d.c. transmission. Proc. IEEE 1965, 112, 359–365. [Google Scholar]

- Machida, T.; Yoshida, Y.; Fujii, N.; Yokoyama, K. Bypass control system for high-voltage dc converter using semiconductor control rectifiers. U.S. Patent 3,636,431, 18 January 1972. [Google Scholar]

- Li, Y.; Huang, L.; Hong, C.; Li, X. Analysis on the Strategy of Block/Deblock Dual 12-Pulse Valve Groups in ±800 kV DC Transmission System. Southern Power Syst. Technol. 2010, 4, 21–25. [Google Scholar]

- Li, D.; Wang, Y.; Ding, L.; Li, X.; Dai, H.; Su, G. Blocking and deblocking strategy of single UHVDC converter group under joint control mode of dual 12-pulse converter groups. Electr. Power Autom. Equip. 2014, 34, 148–154. [Google Scholar]

- Yu, L.; Guo, C.; Zhao, C.; Xu, J.; An, N.; Hu, X. Power Reversal of Hybrid HVDC System. In Proceedings of the 11th IET International Conference on AC and DC Power Transmission, Birmingham, UK, 10–12 February 2015; pp. 1–6. [Google Scholar]

| Initial Power of Each Valve-Group | Power Reference for Half-Voltage Pole | Power Reference for Full-Voltage Pole | System Power Loss |

|---|---|---|---|

| P0 ≤ ½Prated | 2P0 | 2P0 | 0 |

| ½Prated < P0 ≤ ¾Prated | Prated | 4P0 ‒ Prated | 0 |

| ¾Prated < P0 ≤ Prated | Prated | 2Prated | 4P0 ‒ 3Prated |

| Parameters | Real Value |

|---|---|

| Capacity (MVA) | 5000 |

| Rated DC voltage (kV) | ±800 |

| AC grid frequency (Hz) | 50 |

| Rated AC voltages (kV) | 525 (Rec) |

| 500 (Inv) | |

| Transformer ratios (kV/kV) | 525/185 (Rec) |

| 500/175 (Inv) | |

| Transformer capacity per valve (MVA) | 703.125 (Rec) |

| 625 (Inv) | |

| Transformer leakage inductance (p.u.) | 0.14 |

| Parameters | Real Value |

|---|---|

| Capacity (MVA) | 5000 |

| Rated DC voltage (kV) | ± 800 |

| AC grid frequency (Hz) | 50 |

| Rated AC voltages (kV) | 500 |

| Transformer ratios (kV/kV) | 500/260 |

| Transformer capacity per valve (MVA) | 1250 |

| Transformer leakage inductance (p.u.) | 0.14 |

| Number of SM | 167 |

| SM capacitor (mF) | 18 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Liu, W.; Joseph, T.; Liang, J.; An, T.; Lu, J.; Szechtman, M.; Andersen, B.; Zhuang, Q. Control Strategies of Full-Voltage to Half-Voltage Operation for LCC and Hybrid LCC/MMC based UHVDC Systems. Energies 2019, 12, 742. https://doi.org/10.3390/en12040742

Li G, Liu W, Joseph T, Liang J, An T, Lu J, Szechtman M, Andersen B, Zhuang Q. Control Strategies of Full-Voltage to Half-Voltage Operation for LCC and Hybrid LCC/MMC based UHVDC Systems. Energies. 2019; 12(4):742. https://doi.org/10.3390/en12040742

Chicago/Turabian StyleLi, Gen, Wei Liu, Tibin Joseph, Jun Liang, Ting An, Jingjing Lu, Marcio Szechtman, Bjarne Andersen, and Qikai Zhuang. 2019. "Control Strategies of Full-Voltage to Half-Voltage Operation for LCC and Hybrid LCC/MMC based UHVDC Systems" Energies 12, no. 4: 742. https://doi.org/10.3390/en12040742

APA StyleLi, G., Liu, W., Joseph, T., Liang, J., An, T., Lu, J., Szechtman, M., Andersen, B., & Zhuang, Q. (2019). Control Strategies of Full-Voltage to Half-Voltage Operation for LCC and Hybrid LCC/MMC based UHVDC Systems. Energies, 12(4), 742. https://doi.org/10.3390/en12040742