Exergy Analysis and Performance Improvement of a Subcritical/Supercritical Organic Rankine Cycle (ORC) for Exhaust Gas Waste Heat Recovery in a Biogas Fuelled Combined Heat and Power (CHP) Engine Through the Use of Regeneration

Abstract

1. Introduction

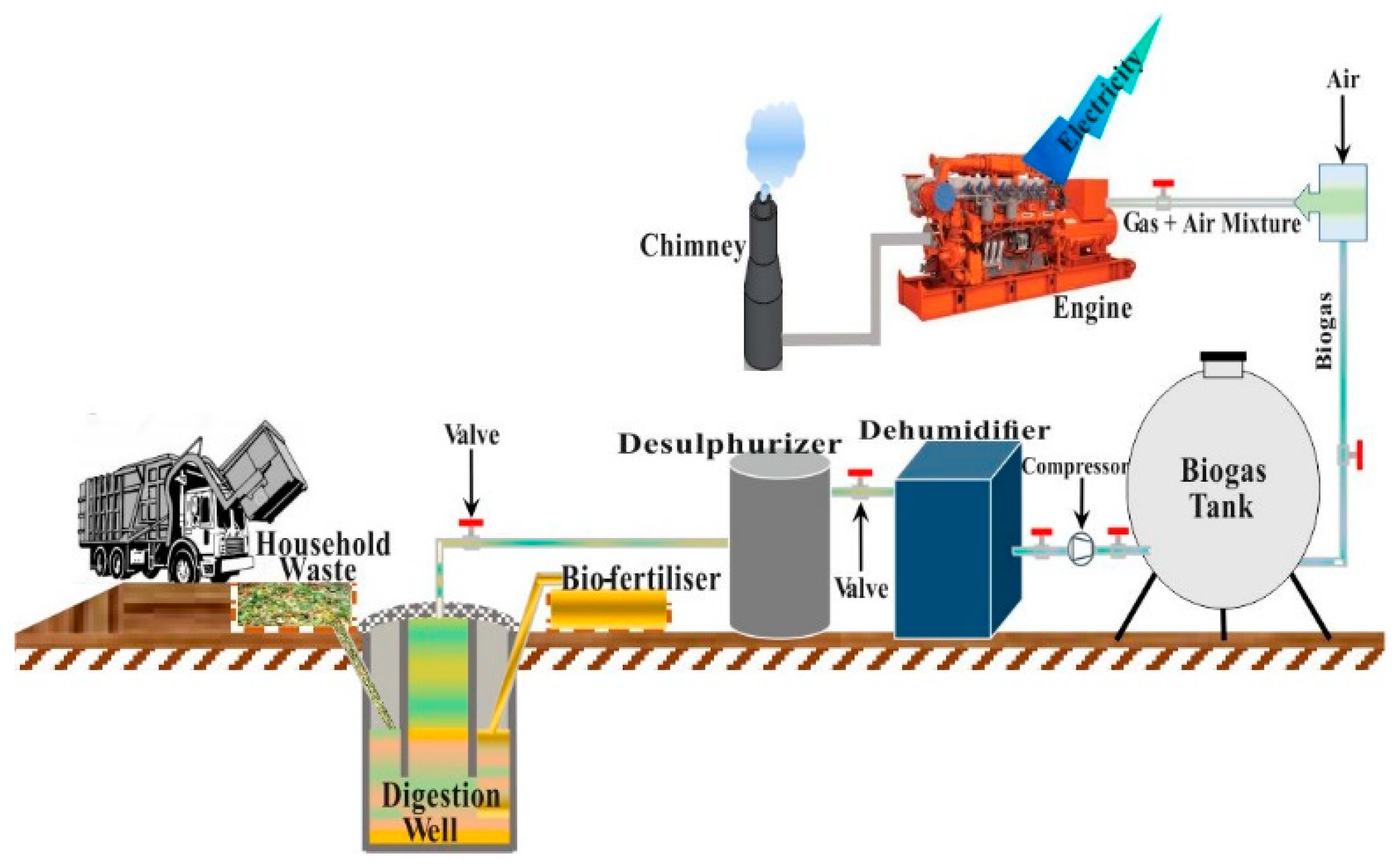

2. Description of the System

2.1. Description of the Biogas Fuelled Power Plant

2.2. Description of the Combined Heat and Power (CHP) Engine

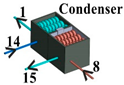

2.3. Description of the rORC

3. Analysis Formulation and Working Fluid

3.1. Energy and Exergy Analysis Equations

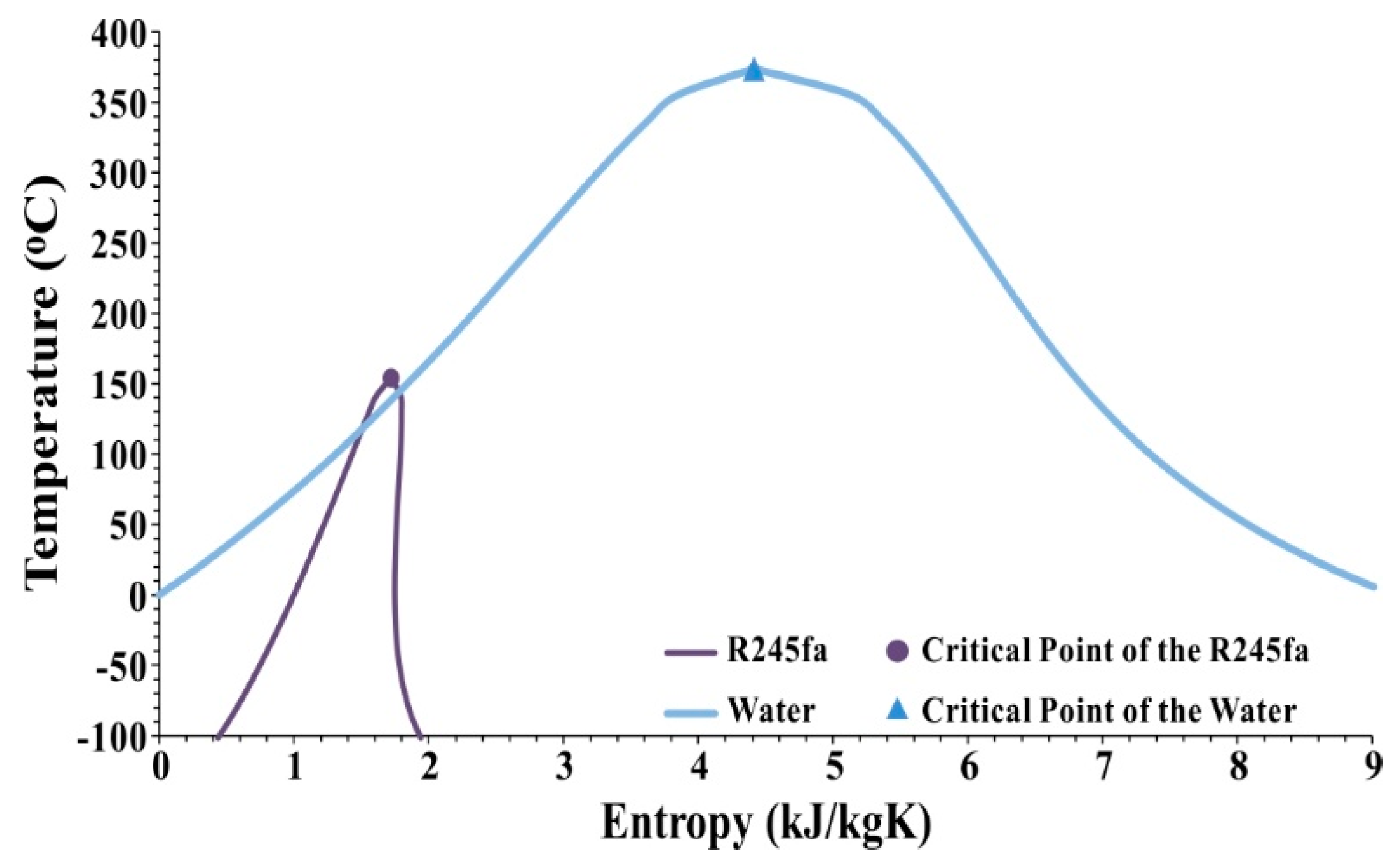

3.2. Working Fluid of the rORC

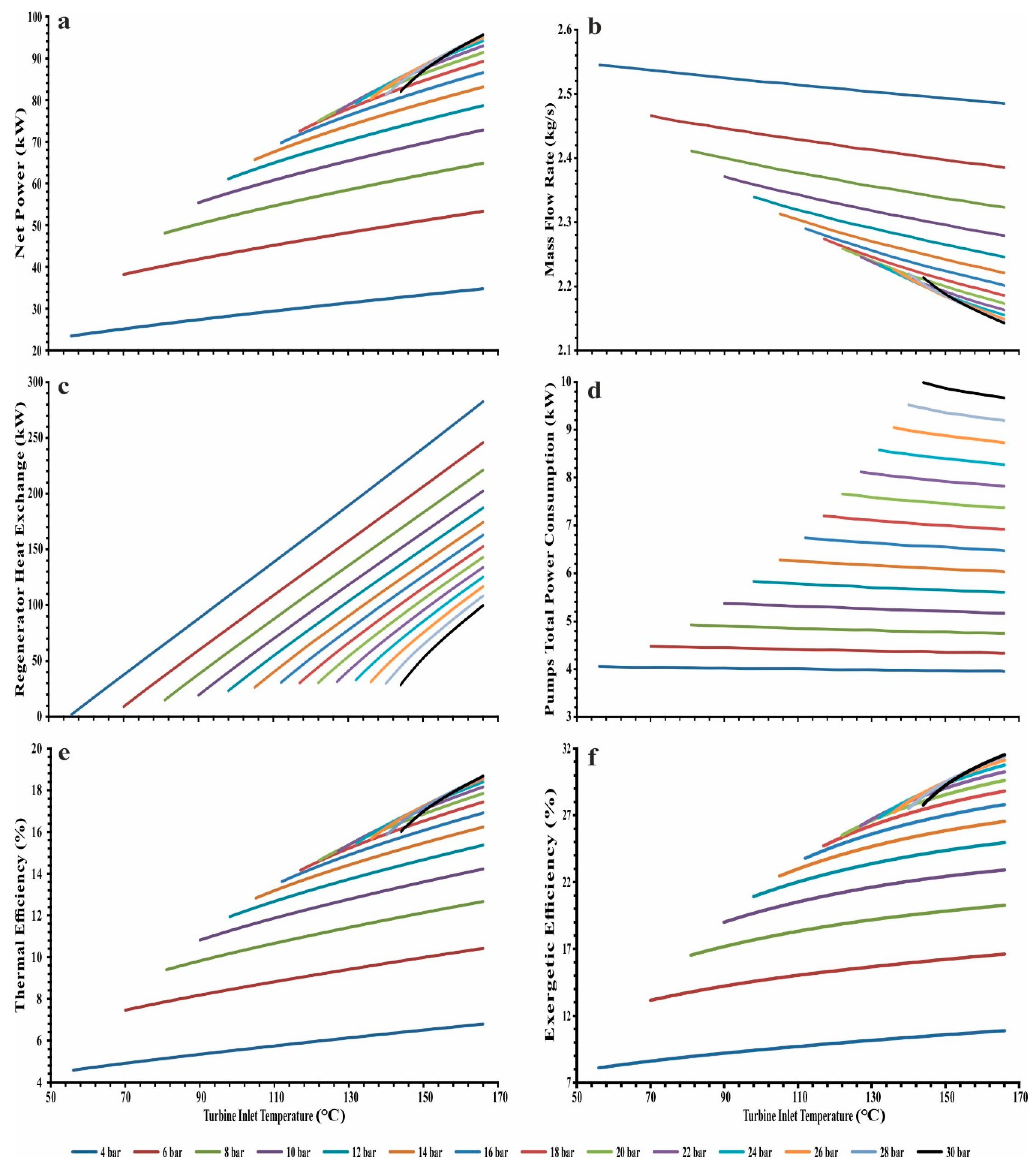

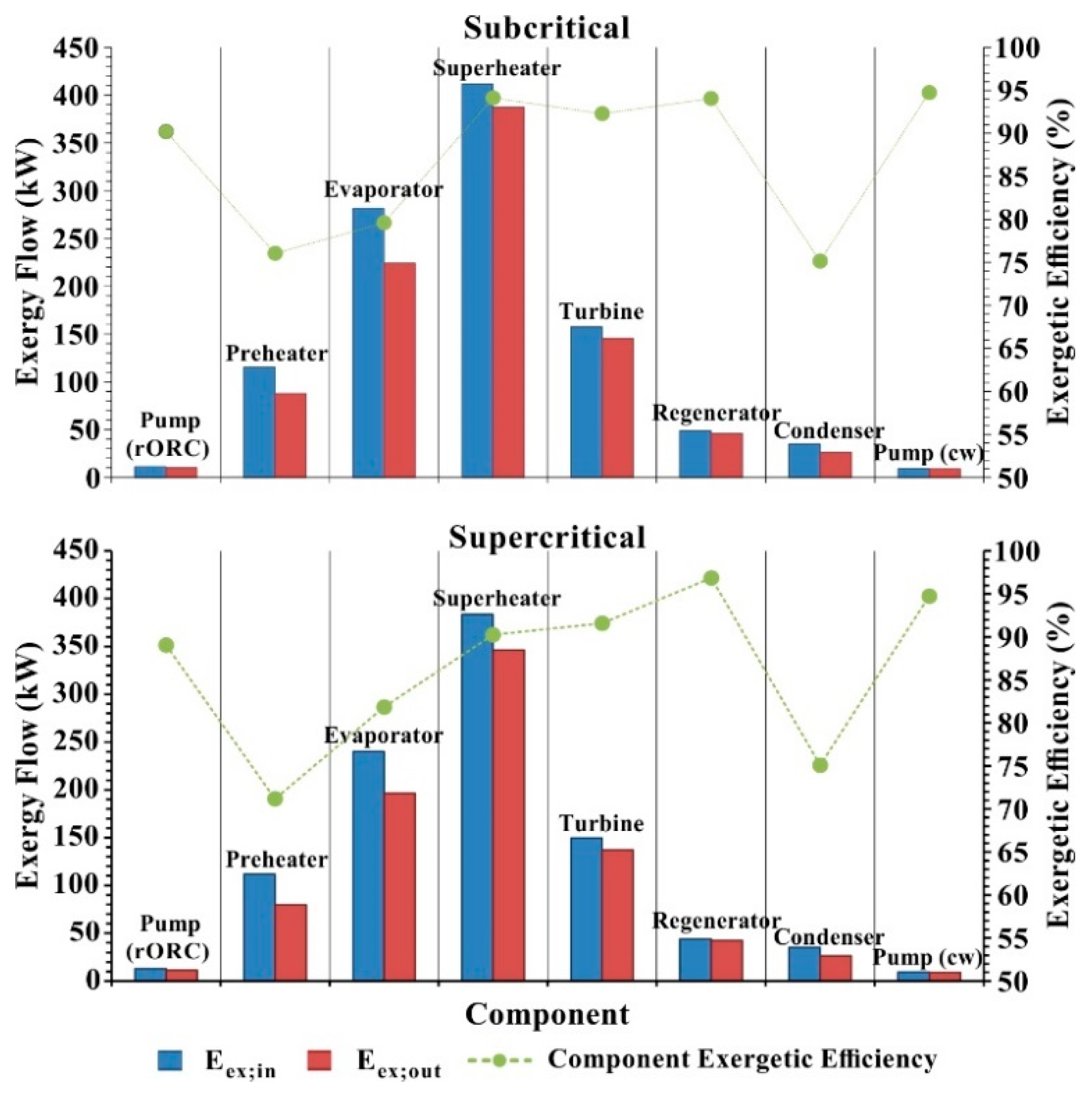

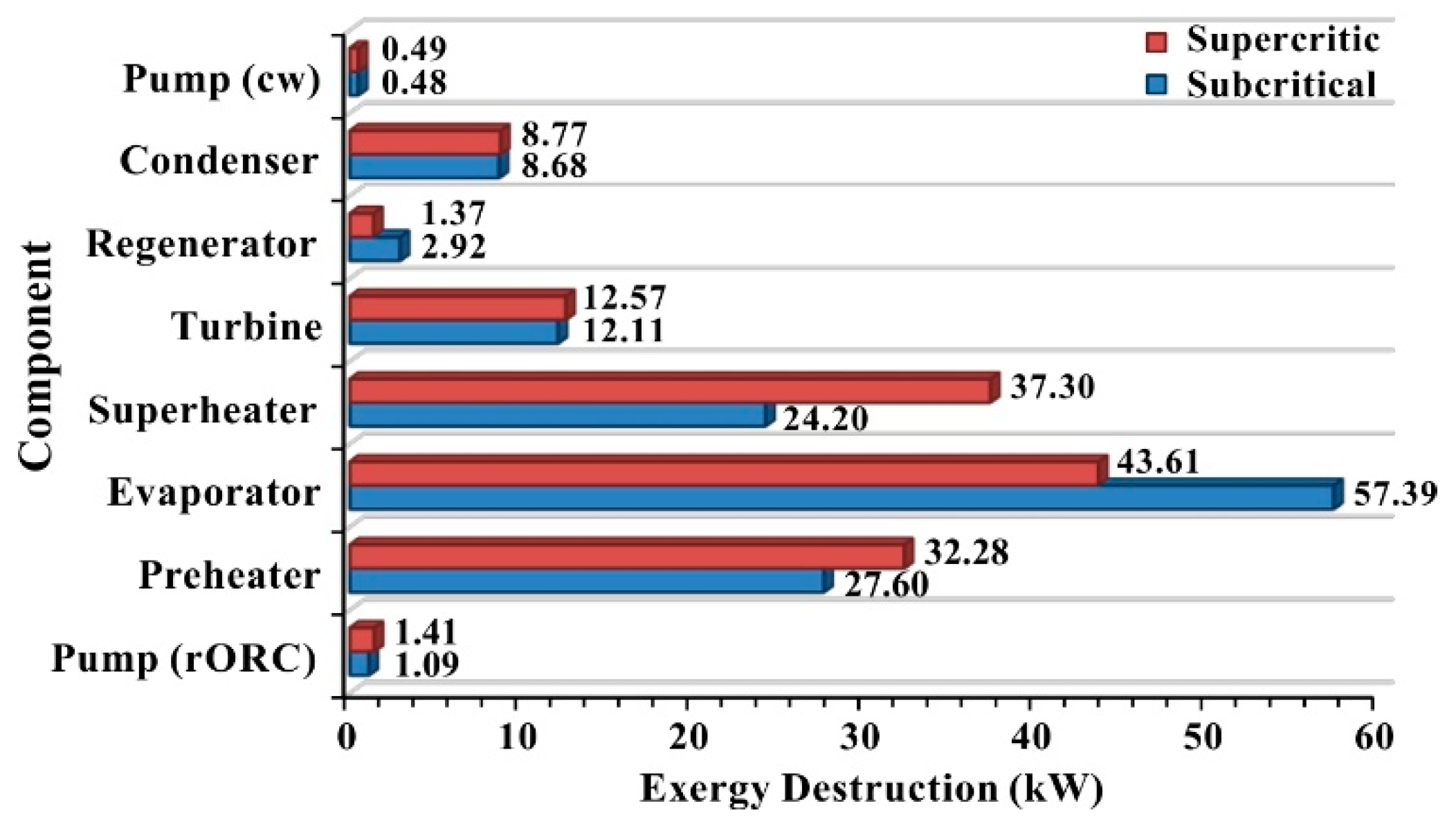

4. Results and Discussion

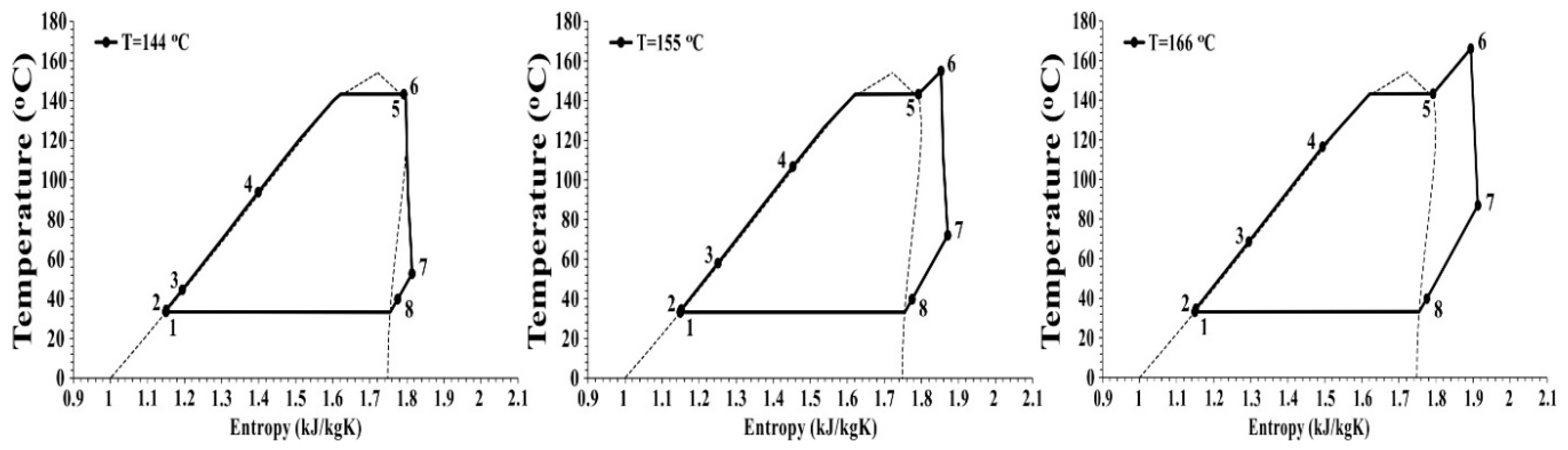

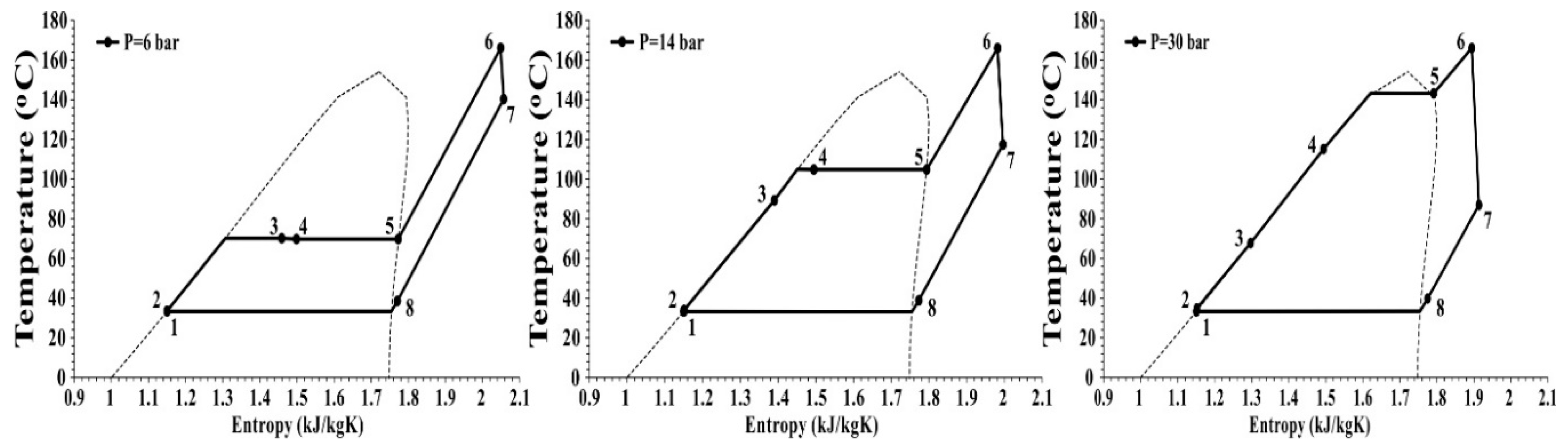

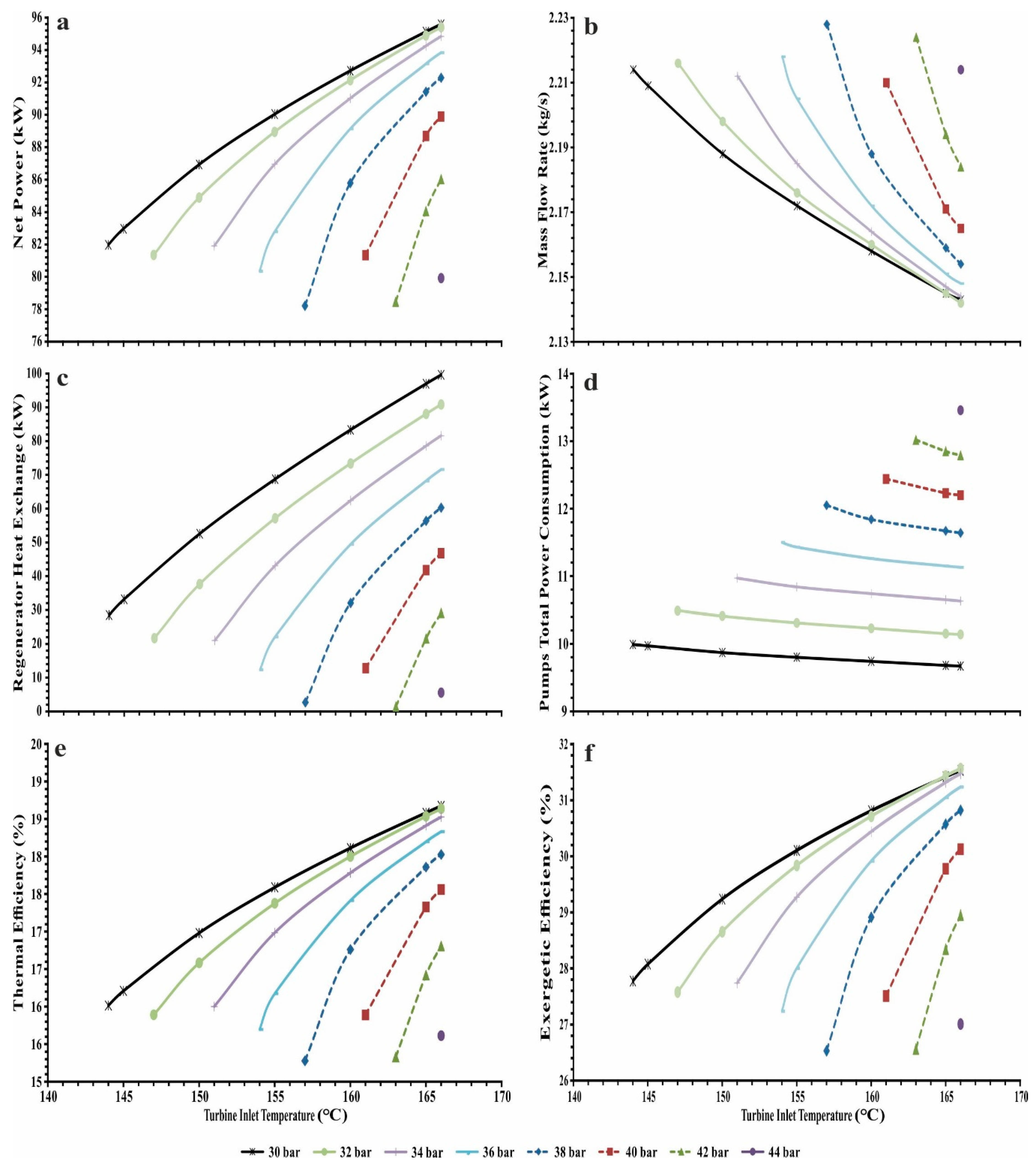

4.1. Subcritical rORC

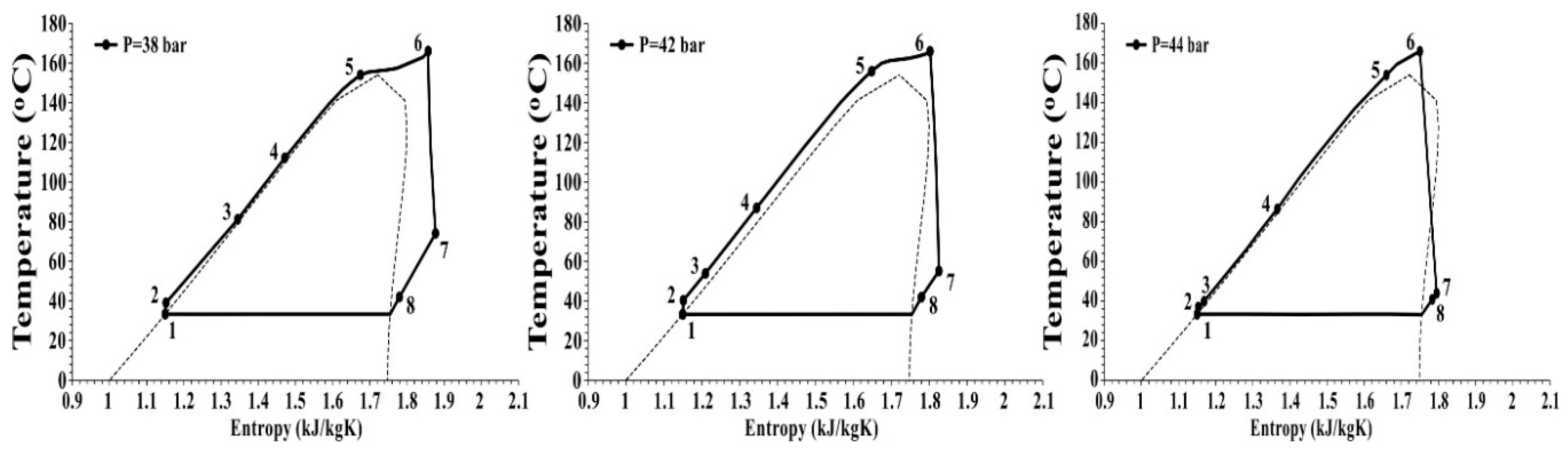

4.2. Supercritical rORC

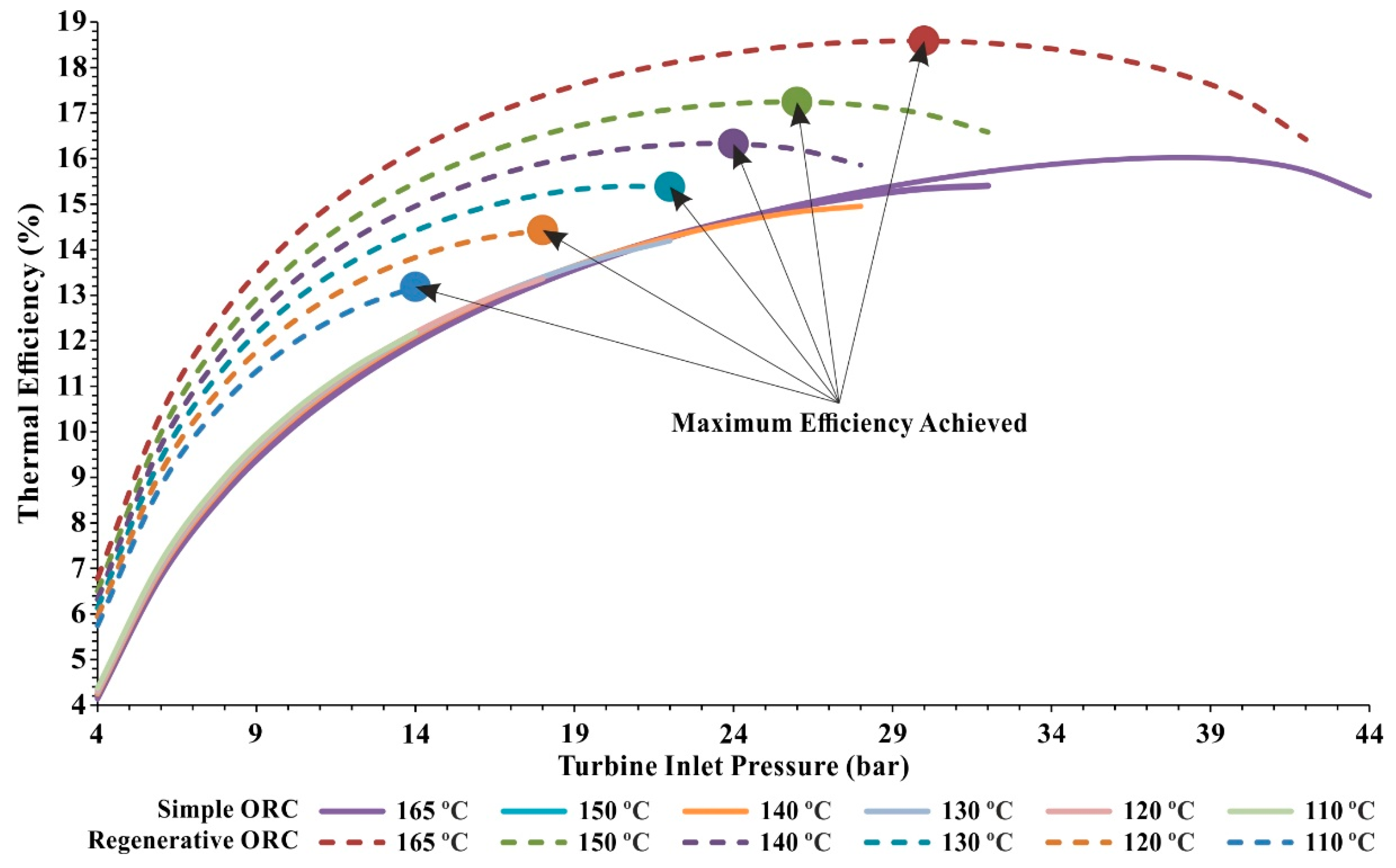

4.3. Effect of the Regenerator

4.4. Comparison of the Exergy Analysis of the Subcritical and Supercritical rORC

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |

| CHP | combined heat and power |

| cw | cooling water |

| exergy flow (kW) | |

| enthalpy (kJ/kg) | |

| enthalpy flow (kW) | |

| mass flow (kg/s) | |

| P | pressure (bar) |

| heat flow (kW) | |

| rORC | regenerative organic Rankine cycle |

| entropy (kJ/kgK) | |

| T | temperature (°C) |

| T0 | ambient temperature (°C) |

| power (kW) | |

| Greek letters | |

| ρ | density (kg/m3) |

| specific exergy (kJ/kg) | |

| exergetic efficiency (%) | |

| thermal efficiency (%) | |

| Subscripts | |

| condenser | |

| cooling water | |

| destruction | |

| evaporator | |

| exh | exhaust |

| heat transfer surface | |

| inlet | |

| max | maximum |

| outlet | |

| pump | |

| preheater | |

| regenerator | |

| rev | reversible |

| superheater | |

| turbine |

References

- Kuyumcu, M.E.; Tutumlu, H.; Yumrutaş, R. Performance of a swimming pool heating system by utilizing waste energy rejected from an ice rink with an energy storage tank. Energy Convers. Manag. 2016, 121, 349–357. [Google Scholar] [CrossRef]

- Tutumlu, H.; Yumrutaş, R.; Yildirim, M. Investigating thermal performance of an ice rink cooling system with an underground thermal storage tank. Energy Explor. Exploit. 2018, 36, 314–334. [Google Scholar] [CrossRef]

- Tanç, B.; Arat, H.T.; Baltacıoğlu, E.; Aydın, K. Overview of the next quarter century vision of hydrogen fuel cell electric vehicles. Int. J. Hydrog. Energy 2018. [Google Scholar] [CrossRef]

- Koç, A.; Yağlı, H.; Koç, Y.; Uğurlu, İ. Dünyada ve Türkiye’de Enerji Görünümünün Genel Değerlendirilmesi. Eng. Mach. Mag. 2018, 59, 86–114. [Google Scholar]

- Lund, H. Renewable Heating Strategies and their Consequences for Storage and Grid Infrastructures Comparing a Smart Grid to a Smart Energy Systems Approach. Energy 2018, 151, 94–102. [Google Scholar] [CrossRef]

- Mert, İ.; Karakuş, C.; Üneş, F. Estimating the energy production of the wind turbine using artificial neural network. Neural Comput. Appl. 2016, 27, 1231–1244. [Google Scholar] [CrossRef]

- Öksel, C.; Koç, A.; Koç, Y.; Yağlı, H. Antakya körfezi deniz üstü rüzgâr enerjisi potansiyel araştirilmasi. Selçuk Üniversitesi Mühendislik Bilim Ve Teknoloji Dergisi 2016, 4, 18–29. [Google Scholar]

- Tempesti, D.; Manfrida, G.; Fiaschi, D. Thermodynamic analysis of two micro CHP systems operating with geothermal and solar energy. Appl. Energy 2012, 97, 609–617. [Google Scholar] [CrossRef]

- Theo, W.L.; Lim, J.S.; Ho, W.S.; Hashim, H.; Lee, C.T.; Muis, Z.A. Optimisation of oil palm biomass and palm oil mill effluent (POME) utilisation pathway for palm oil mill cluster with consideration of BioCNG distribution network. Energy 2017, 121, 865–883. [Google Scholar] [CrossRef]

- Kim, S.; Sung, T.; Kim, K.C. Thermodynamic Performance Analysis of a Biogas-Fuelled Micro-Gas Turbine with a Bottoming Organic Rankine Cycle for Sewage Sludge and Food Waste Treatment Plants. Energies 2016, 10, 275. [Google Scholar] [CrossRef]

- Barati, M.R.; Aghbashlo, M.; Ghanavati, H.; Tabatabaei, M.; Sharifi, M.; Javadirad, G.; Dadak, A.; Soufiyan, M.M. Comprehensive exergy analysis of a gas engine-equipped anaerobic digestion plant producing electricity and biofertilizer from organic fraction of municipal solid waste. Energy Convers. Manag. 2017, 151, 753–763. [Google Scholar] [CrossRef]

- Dumont, O.; Dickes, R.; De Rosa, M.; Douglas, R.; Lemort, V. Technical and economic optimization of subcritical, wet expansion and transcritical Organic Rankine Cycle (ORC) systems coupled with a biogas power plant. Energy Convers. Manag. 2018, 157, 294–306. [Google Scholar] [CrossRef]

- Akgul, D.; Cella, M.A.; Eskicioglu, C. Influences of low-energy input microwave and ultrasonic pretreatments on single-stage and temperature-phased anaerobic digestion (TPAD) of municipal wastewater sludge. Energy 2017, 123, 271–282. [Google Scholar] [CrossRef]

- Itodo, I.N.; Agyo, G.E.; Yusuf, P. Performance evaluation of a biogas stove for cooking in Nigeria. J. Energy South. Afr. 2017, 18, 14–18. [Google Scholar]

- Hakawati, R.; Smyth, B.M.; McCullough, G.; De Rosa, F.; Rooney, D. What is the most energy efficient route for biogas utilization: Heat, electricity or transport? Appl. Energy 2017, 206, 1076–1087. [Google Scholar] [CrossRef]

- Sung, T.; Kim, S.; Kim, K.C. Thermoeconomic analysis of a biogas-fueled micro-gas turbine with a bottoming organic Rankine cycle for a sewage sludge and food waste treatment plant in the Republic of Korea. Appl. Therm. Eng. 2017, 127, 963–974. [Google Scholar] [CrossRef]

- Madeira, J.G.F.; Boloy, R.A.M.; Delgado, A.R.S.; Lima, F.R.; Coutinho, E.R.; de Castro Pereira Filho, R. Ecological analysis of hydrogen production via biogas steam reforming from cassava flour processing wastewater. J. Clean. Prod. 2017, 162, 709–716. [Google Scholar] [CrossRef]

- Barzegaravval, H.; Hosseini, S.E.; Wahid, M.A.; Saat, A. Effects of fuel composition on the economic performance of biogas-based power generation systems. Appl. Therm. Eng. 2018, 128, 1543–1554. [Google Scholar] [CrossRef]

- Liu, W.H.; Hashim, H.; Lim, J.S.; Ho, C.S.; Klemeš, J.J.; Zamhuri, M.I.; Ho, W.S. Techno-Economic Assessment of Different Cooling Systems for Office Buildings in Tropical Large City Considering On-site Biogas Utilization. J. Clean. Prod. 2018, 184, 774–787. [Google Scholar] [CrossRef]

- Chatzopoulou, M.A.; Christos, N. Markides Modelling of Advanced Combined Heat and Power Systems in Building Applications. Available online: http://dl.astfe.org/conferences/tfec2017,5303da2e708371c8,220146de273cf89f.html (accessed on 14 January 2019).

- Ameri, M.; Mokhtari, H. Simulation of a New Hybrid Solar and Organic Cycle as a Combined Cooling, Heat and Power (CCHP) Unit in Off Design Condition. Environ. Energy Econ. Res. 2017, 1, 183–194. [Google Scholar]

- Uris, M.; Linares, J.I.; Arenas, E. Feasibility assessment of an Organic Rankine Cycle (ORC) cogeneration plant (CHP/CCHP) fueled by biomass for a district network in mainland Spain. Energy 2017, 133, 969–985. [Google Scholar] [CrossRef]

- Chintala, V.; Subramanian, K.A. Assessment of maximum available work of a hydrogen fueled compression ignition engine using exergy analysis. Energy 2014, 67, 162–175. [Google Scholar] [CrossRef]

- Saidur, R.; BoroumandJazi, G.; Mekhilef, S.; Mohammed, H.A. A review on exergy analysis of biomass based fuels. Renew. Sustain. Energy Rev. 2012, 16, 1217–1222. [Google Scholar] [CrossRef]

- Abedin, M.J.; Masjuki, H.H.; Kalam, M.A.; Sanjid, A.; Rahman, S.A.; Masum, B.M. Energy balance of internal combustion engines using alternative fuels. Renew. Sustain. Energy Rev. 2013, 26, 20–33. [Google Scholar] [CrossRef]

- Chintala, V.; Kumar, S.; Pandey, J.K. A technical review on waste heat recovery from compression ignition engines using organic Rankine cycle. Renew. Sustain. Energy Rev. 2018, 81, 493–509. [Google Scholar] [CrossRef]

- Pandiyarajan, V.; Pandian, M.C.; Malan, E.; Velraj, R.; Seeniraj, R.V. Experimental investigation on heat recovery from diesel engine exhaust using finned shell and tube heat exchanger and thermal storage system. Appl. Energy 2011, 88, 77–87. [Google Scholar] [CrossRef]

- Galindo, J.; Ruiz, S.; Dolz, V.; Royo-Pascual, L.; Haller, R.; Nicolas, B.; Glavatskaya, Y. Experimental and thermodynamic analysis of a bottoming Organic Rankine Cycle (ORC) of gasoline engine using swash-plate expander. Energy Convers. Manag. 2015, 103, 519–532. [Google Scholar] [CrossRef]

- Kim, D.K.; Lee, J.S.; Kim, J.; Kim, M.S.; Kim, M.S. Parametric study and performance evaluation of an organic Rankine cycle (ORC) system using low-grade heat at temperatures below 80 °C. Appl. Energy 2017, 189, 55–65. [Google Scholar] [CrossRef]

- Fiaschi, D.; Manfrida, G.; Rogai, E.; Talluri, L. Exergoeconomic analysis and comparison between ORC and Kalina cycles to exploit low and medium-high temperature heat from two different geothermal sites. Energy Convers. Manag. 2017, 154, 503–516. [Google Scholar] [CrossRef]

- Preißinger, M.; Schatz, S.; Vogl, A.; König-Haagen, A.; Brüggemann, D. Thermoeconomic analysis of configuration methods for modular Organic Rankine Cycle units in low-temperature applications. Energy Convers. Manag. 2016, 127, 25–34. [Google Scholar] [CrossRef]

- Chen, H.; Goswami, D.Y.; Rahman, M.M.; Stefanakos, E.K. A supercritical Rankine cycle using zeotropic mixture working fluids for the conversion of low-grade heat into power. Energy 2016, 36, 549–555. [Google Scholar] [CrossRef]

- Manfrida, G.; Secchi, R.; Stańczyk, K. Modelling and simulation of phase change material latent heat storages applied to a solar-powered Organic Rankine Cycle. Appl. Energy 2016, 179, 378–388. [Google Scholar] [CrossRef]

- Hettiarachchi, H.M.; Golubovic, M.; Worek, W.M.; Ikegami, Y. Optimum design criteria for an organic Rankine cycle using low-temperature geothermal heat sources. Energy 2007, 32, 1698–1706. [Google Scholar] [CrossRef]

- Yagli, H.; Koc, A.; Karakus, C.; Koc, Y. Comparison of toluene and cyclohexane as a working fluid of an organic Rankine cycle used for reheat furnace waste heat recovery. Int. J. Exergy 2016, 19, 420–438. [Google Scholar] [CrossRef]

- Lai, N.A.; Wendland, M.; Fischer, J. Working fluids for high-temperature organic Rankine cycles. Energy 2011, 36, 199–211. [Google Scholar] [CrossRef]

- Algieri, A.; Morrone, P. Comparative energetic analysis of high-temperature subcritical and transcritical Organic Rankine Cycle (ORC). A biomass application in the Sibari district. Appl. Therm. Eng. 2012, 36, 236–244. [Google Scholar] [CrossRef]

- Vaja, I.; Gambarotta, A. Internal combustion engine (ICE) bottoming with organic Rankine cycles (ORCs). Energy 2010, 35, 1084–1093. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Y.; Peng, Z.; Shu, G. A review of researches on thermal exhaust heat recovery with Rankine cycle. Renew. Sustain. Energy Rev. 2011, 15, 2862–2871. [Google Scholar] [CrossRef]

- Wang, E.H.; Zhang, H.G.; Fan, B.Y.; Ouyang, M.G.; Zhao, Y.; Mu, Q.H. Study of working fluid selection of organic Rankine cycle (ORC) for engine waste heat recovery. Energy 2011, 36, 3406–3418. [Google Scholar] [CrossRef]

- Benato, A.; Macor, A. Biogas engine waste heat recovery using organic Rankine cycle. Energies 2017, 10, 327. [Google Scholar] [CrossRef]

- Glover, S.; Douglas, R.; De Rosa, M.; Zhang, X.; Glover, L. Simulation of a multiple heat source supercritical ORC (Organic Rankine Cycle) for vehicle waste heat recovery. Energy 2015, 93, 1568–1580. [Google Scholar] [CrossRef]

- Dong, B.; Xu, G.; Luo, X.; Zhuang, L.; Quan, Y. Analysis of the supercritical organic Rankine cycle and the radial turbine design for high temperature applications. Appl. Therm. Eng. 2017, 123, 1523–1530. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, J.; Zhao, L.; Deng, S.; Zhang, Y. Novel experimental research on the compression process in organic Rankine cycle (ORC). Energy Convers. Manag. 2017, 137, 1–11. [Google Scholar] [CrossRef]

- Fiaschi, D.; Innocenti, G.; Manfrida, G.; Maraschiello, F. Design of micro radial turboexpanders for ORC power cycles: From 0D to 3D. Appl. Therm. Eng. 2016, 99, 402–410. [Google Scholar] [CrossRef]

- Braimakis, K.; Karellas, S. Energetic optimization of regenerative Organic Rankine Cycle (ORC) configurations. Energy Convers. Manag. 2018, 159, 353–370. [Google Scholar] [CrossRef]

- Yu, H.; Eason, J.; Biegler, L.T.; Feng, X. Simultaneous heat integration and techno-economic optimization of Organic Rankine Cycle (ORC) for multiple waste heat stream recovery. Energy 2017, 119, 322–333. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, H.; Yu, Z.; Wang, E.; Meng, F.; Liu, H.; Wang, J. Parametric optimization and heat transfer analysis of a dual loop ORC (organic Rankine cycle) system for CNG engine waste heat recovery. Energy 2017, 118, 753–775. [Google Scholar] [CrossRef]

- Habibi, H.; Chitsaz, A.; Javaherdeh, K.; Zoghi, M.; Ayazpour, M. Thermo-economic analysis and optimization of a solar-driven ammonia-water regenerative Rankine cycle and LNG cold energy. Energy 2018, 149, 147–160. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, Y.; Li, B.; Yang, J.; Shi, Y. Comparison between regenerative organic Rankine cycle (RORC) and basic organic Rankine cycle (BORC) based on thermoeconomic multi-objective optimization considering exergy efficiency and levelized energy cost (LEC). Energy Convers. Manag. 2015, 96, 58–71. [Google Scholar] [CrossRef]

- Bilgiç, H.H.; Yağli, H.; Koç, A.; Yapici, A. Deneysel bir organik rankine çevriminde yapay sinir ağları (YSA) yardımıyla güç tahmini. Selcuk Univ. J. Eng. Sci. Technol. 2016, 4. [Google Scholar] [CrossRef]

- Yağlı, H.; Koç, Y.; Koç, A.; Görgülü, A.; Tandiroğlu, A. Parametric optimization and exergetic analysis comparison of subcritical and supercritical organic Rankine cycle (ORC) for biogas fuelled combined heat and power (CHP) engine exhaust gas waste heat. Energy 2016, 111, 923–932. [Google Scholar] [CrossRef]

- Cengel, Y.A.; Boles, M.A. Thermodynamics: An Engineering Approach, 6th ed.; McGraw-Hill Inc.: New York, NY, USA, 2008. [Google Scholar]

- Bejan, A.; Tsatsaronis, G.; Moran, M. Thermal Design and Optimization; John Wiley: New York, NY, USA, 1996. [Google Scholar]

- Dincer, I.; Rosen, M.A. Exergy: Energy, Environment and Sustainable Development, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Kotas, T.J. The Exergy Method of Thermal Plant Analysis; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Abuşoğlu, A.; Özahi, E.; Kutlar, A.İ.; Demir, S. Exergy analyses of green hydrogen production methods from biogas-based electricity and sewage sludge. Int. J. Hydrog. Energy 2017, 42, 10986–10996. [Google Scholar] [CrossRef]

- Yağlı, H.; Karakuş, C.; Koç, Y.; Çevik, M.; Uğurlu, İ.; Koç, A. Designing and exergetic analysis of a solar power tower system for Iskenderun region. Int. J. Exergy 2019, 28, 96–112. [Google Scholar] [CrossRef]

- NIST. Reference Fluid Thermodynamic and Transport Properties (REFPROP); Version 9.0; NIST: Gaithersburg, MD, USA, 2009. [Google Scholar]

- Zhai, H.; An, Q.; Shi, L.; Lemort, V.; Quoilin, S. Categorization and analysis of heat sources for organic Rankine cycle systems. Renew. Sustain. Energy Rev. 2016, 64, 790–805. [Google Scholar] [CrossRef]

- Tchanche, B.F.; Lambrinos, G.; Frangoudakis, A.; Papadakis, G. Low-grade heat conversion into power using organic Rankine cycles—A review of various applications. Renew. Sustain. Energy Rev. 2011, 15, 3963–3979. [Google Scholar] [CrossRef]

- Chatzopoulou, M.A.; Markides, C.N. Thermodynamic optimisation of a high-electrical efficiency integrated internal combustion engine–Organic Rankine cycle combined heat and power system. Appl. Energy 2018, 226, 1229–1251. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, H.; Yang, K.; Yang, F.; Wang, Z.; Zhao, G.; Liu, H.; Wang, E.; Yao, B. Performance analysis of regenerative organic Rankine cycle (RORC) using the pure working fluid and the zeotropic mixture over the whole operating range of a diesel engine. Energy Convers. Manag. 2014, 84, 282–294. [Google Scholar] [CrossRef]

- Xi, H.; Li, M.J.; Xu, C.; He, Y.L. Parametric optimization of regenerative organic Rankine cycle (ORC) for low grade waste heat recovery using genetic algorithm. Energy 2013, 58, 473–482. [Google Scholar] [CrossRef]

- Fernández, F.J.; Prieto, M.M.; Suárez, I. Thermodynamic analysis of high-temperature regenerative organic Rankine cycles using siloxanes as working fluids. Energy 2011, 36, 5239–5249. [Google Scholar] [CrossRef]

- Wang, E.; Yu, Z.; Zhang, H.; Yang, F. A regenerative supercritical-subcritical dual-loop organic Rankine cycle system for energy recovery from the waste heat of internal combustion engines. Appl. Energy 2017, 190, 574–590. [Google Scholar] [CrossRef]

- Kemp, R.; Schot, J.; Hoogma, R. Regime shifts to sustainability through processes of niche formation: The approach of strategic niche management. Technol. Anal. Strateg. Manag. 1998, 10, 175–198. [Google Scholar] [CrossRef]

- Oyewunmi, O.A.; Ferré-Serres, S.; Lecompte, S.; van den Broek, M.; De Paepe, M.; Markides, C.N. An assessment of subcritical and trans-critical organic Rankine cycles for waste-heat recovery. Energy Procedia 2017, 105, 1870–1876. [Google Scholar] [CrossRef]

- Latz, G.; Andersson, S.; Munch, K. Comparison of Working Fluids in Both Subcritical and Supercritical Rankine Cycles for Waste-Heat Recovery Systems in Heavy-Duty Vehicles (No. 2012-01-1200); SAE Technical Paper; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Chowdhury, J.; Nguyen, B.K.; Thornhill, D.; Hu, Y.; Soulatiantork, P.; Balta-Ozkan, N.; Varga, L. Fuzzy Nonlinear Dynamic Evaporator Model in Supercritical Organic Rankine Cycle Waste Heat Recovery Systems. Energies 2018, 11, 901. [Google Scholar] [CrossRef]

- Mago, P.J.; Chamra, L.M.; Srinivasan, K.; Somayaji, C. An examination of regenerative organic Rankine cycles using dry fluids. Appl. Therm. Eng. 2008, 28, 998–1007. [Google Scholar] [CrossRef]

- Mosaffa, A.H.; Mokarram, N.H.; Farshi, L.G. Thermo-economic analysis of combined different ORCs geothermal power plants and LNG cold energy. Geothermics 2017, 65, 113–125. [Google Scholar] [CrossRef]

- Reis, M.M.L.; Gallo, W.L. Study of waste heat recovery potential and optimization of the power production by an organic Rankine cycle in an FPSO unit. Energy Convers. Manag. 2018, 157, 409–422. [Google Scholar] [CrossRef]

- Javanshir, A.; Sarunac, N.; Razzaghpanah, Z. Thermodynamic Analysis of ORC and Its Application for Waste Heat Recovery. Sustainability 2017, 9, 1974. [Google Scholar] [CrossRef]

- Yasa, T. Thermodynamic evaluation of energy recovery system for heavy duty diesel engine by using organic rankine cycle. Anadolu Univ. Sci. Technol. A Appl. Sci. Eng. 2017, 18. [Google Scholar] [CrossRef]

- Ayub, A.; Sheikh, N.A.; Tariq, R.; Khan, M.M.; Invernizzi, C.M. Exergetic optimization and comparison of combined gas turbine supercritical CO2 power cycles. J. Renew. Sustain. Energy 2018, 10, 044703. [Google Scholar] [CrossRef]

- Abam, F.I.; Ekwe, E.B.; Effiom, S.O.; Ndukwu, M.C. A comparative performance analysis and thermo-sustainability indicators of modified low-heat organic Rankine cycles (ORCs): An exergy-based procedure. Energy Rep. 2018, 4, 110–118. [Google Scholar] [CrossRef]

- Anvari, S.; Jafarmadar, S.; Khalilarya, S. Proposal of a combined heat and power plant hybridized with regeneration organic Rankine cycle: Energy-Exergy evaluation. Energy Convers. Manag. 2016, 122, 357–365. [Google Scholar] [CrossRef]

| Value | Unit | |

|---|---|---|

| Engine number | 2 | - |

| Plant electricity production capacity | 1068 | kWe |

| Engine electrical efficiency | 39.3% | - |

| Engine mechanical efficiency | 40.6% | - |

| Engine thermal efficiency * | 37.2% | - |

| Exhaust gas mass flow rate (wet) | 2981 | kg/h |

| Exhaust gas temperature range | 450–500 | °C |

| Exhaust gas power content * | 285 | kW |

| Parameter | Value | Unit |

|---|---|---|

| Isentropic efficiency of the pumps | 80% | - |

| Isentropic efficiency of the turbine | 88% | - |

| Electrical efficiency of the generator | 98.5% | - |

| Condensing pressure | 2 | bar |

| Hot side pressure drop in the regenerator | 0.001 | bar |

| Cold side pressure drop in the regenerator | 0.05 | bar |

| Hot side pressure drop in the condenser | 0 | bar |

| Cold side pressure drop in the condenser | 0.5 | bar |

| Exhaust gas inlet temperature | 450 | °C |

| Exhaust gas outlet temperature | 150 | °C |

| Cooling water temperature at condenser inlet | 25 | °C |

| Component | Energy Analysing Equations | Exergy Analysing Equations |

|---|---|---|

| ||

| ||

| ||

| ||

| ||

| ||

| ||

|

| Parameter | R245fa | Water | Unit |

|---|---|---|---|

| Fluid type (chemical basis) | organic | inorganic | - |

| Fluid type (thermodynamic basis) | isentropic | wet | - |

| Boiling point * | 14.81 | 99.60 | °C |

| Critical temperature | 154.01 | 373.94 | °C |

| Critical Pressure | 36.51 | 220.64 | bar |

| Maximum temperature | 166.85 | 2000 | °C |

| Enthalpy of evaporation * | 196.23 | 2257.50 | kJ/kg |

| Subcritical (30 bar, 165 °C) | ||||||||

| Pipe No * | P | T | ρ | |||||

| bar | °C | kJ/kg | kg/s | kg/m3 | kJ/kgK | kJ/kg | kW | |

| 1 | 2.00 | 33.35 | 243.587 | 2.15 | 1315.5 | 1.1501 | 2.5365 | 522.57 |

| 2 | 30.15 | 34.78 | 246.254 | 2.15 | 1321.2 | 1.1518 | 4.6995 | 528.30 |

| 3 | 30.10 | 67.71 | 291.471 | 2.15 | 1225.5 | 1.2913 | 9.3159 | 625.30 |

| 4 | 30.05 | 115.71 | 364.131 | 2.15 | 1042.1 | 1.4904 | 24.0025 | 781.18 |

| 5 | 30.05 | 143.29 | 487.900 | 2.15 | 232.3 | 1.7917 | 60.0493 | 1046.71 |

| 6 | 30.00 | 165.00 | 530.077 | 2.15 | 163.2 | 1.8907 | 73.3897 | 1137.19 |

| 7 | 2.00 | 85.64 | 480.407 | 2.15 | 9.3 | 1.9098 | 18.1715 | 1030.63 |

| 8 | 2.00 | 39.78 | 435.191 | 2.15 | 11.1 | 1.7750 | 12.1937 | 933.63 |

| 9 | 1.00 | 450.00 | 465.445 | 1.63 | 0.5 | 7.7817 | 173.4936 | 758.68 |

| 10 | 1.00 | 398.35 | 409.934 | 1.63 | 0.5 | 7.7023 | 141.0851 | 668.19 |

| 11 | 1.00 | 243.29 | 247.034 | 1.63 | 0.7 | 7.4267 | 58.4350 | 402.67 |

| 12 | 1.00 | 150.00 | 151.403 | 1.63 | 0.8 | 7.2228 | 22.1667 | 246.79 |

| 13 | 1.00 | 25.00 | 104.928 | 19.71 | 997.0 | 0.3672 | 0.3452 | 2067.90 |

| 14 | 2.00 | 25.01 | 105.053 | 19.71 | 997.1 | 0.3673 | 0.4460 | 2070.37 |

| 15 | 1.50 | 30.01 | 125.911 | 19.71 | 995.7 | 0.4369 | 1.0566 | 2481.42 |

| Supercritical (38 bar, 165 °C) | ||||||||

| Pipe No * | P | T | ρ | |||||

| bar | °C | kJ/kg | kg/s | kg/m3 | kJ/kgK | kJ/kg | kW | |

| 1 | 2.00 | 33.35 | 243.587 | 2.16 | 1315.5 | 1.1501 | 2.5365 | 525.84 |

| 2 | 38.15 | 35.17 | 247.010 | 2.16 | 1322.8 | 1.1523 | 5.3129 | 533.23 |

| 3 | 38.10 | 54.49 | 273.132 | 2.16 | 1269.1 | 1.2345 | 7.5100 | 589.62 |

| 4 | 38.05 | 104.57 | 345.901 | 2.16 | 1101.2 | 1.4409 | 20.1850 | 746.71 |

| 5 | 38.05 | 154.01 | 440.548 | 2.16 | 726.6 | 1.6748 | 46.7240 | 951.03 |

| 6 | 38.00 | 165.00 | 510.254 | 2.16 | 268.2 | 1.8366 | 69.3346 | 1101.51 |

| 7 | 2.00 | 66.82 | 461.703 | 2.16 | 9.9 | 1.8563 | 15.0565 | 996.70 |

| 8 | 2.00 | 40.17 | 435.581 | 2.16 | 11.0 | 1.7763 | 12.2211 | 940.31 |

| 9 | 1.00 | 450.00 | 465.445 | 1.63 | 0.5 | 7.7817 | 173.4936 | 758.68 |

| 10 | 1.00 | 363.77 | 373.128 | 1.63 | 0.5 | 7.6460 | 120.6624 | 608.20 |

| 11 | 1.00 | 244.01 | 247.778 | 1.63 | 0.7 | 7.4281 | 58.7598 | 403.88 |

| 12 | 1.00 | 150.00 | 151.404 | 1.63 | 0.8 | 7.2228 | 22.1669 | 246.79 |

| 13 | 1.00 | 25.00 | 104.928 | 19.87 | 997.0 | 0.3672 | 0.3452 | 2085.07 |

| 14 | 2.00 | 25.01 | 105.053 | 19.87 | 997.1 | 0.3673 | 0.4460 | 2087.56 |

| 15 | 1.50 | 30.01 | 125.911 | 19.87 | 995.7 | 0.4369 | 1.0566 | 2502.03 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koç, Y.; Yağlı, H.; Koç, A. Exergy Analysis and Performance Improvement of a Subcritical/Supercritical Organic Rankine Cycle (ORC) for Exhaust Gas Waste Heat Recovery in a Biogas Fuelled Combined Heat and Power (CHP) Engine Through the Use of Regeneration. Energies 2019, 12, 575. https://doi.org/10.3390/en12040575

Koç Y, Yağlı H, Koç A. Exergy Analysis and Performance Improvement of a Subcritical/Supercritical Organic Rankine Cycle (ORC) for Exhaust Gas Waste Heat Recovery in a Biogas Fuelled Combined Heat and Power (CHP) Engine Through the Use of Regeneration. Energies. 2019; 12(4):575. https://doi.org/10.3390/en12040575

Chicago/Turabian StyleKoç, Yıldız, Hüseyin Yağlı, and Ali Koç. 2019. "Exergy Analysis and Performance Improvement of a Subcritical/Supercritical Organic Rankine Cycle (ORC) for Exhaust Gas Waste Heat Recovery in a Biogas Fuelled Combined Heat and Power (CHP) Engine Through the Use of Regeneration" Energies 12, no. 4: 575. https://doi.org/10.3390/en12040575

APA StyleKoç, Y., Yağlı, H., & Koç, A. (2019). Exergy Analysis and Performance Improvement of a Subcritical/Supercritical Organic Rankine Cycle (ORC) for Exhaust Gas Waste Heat Recovery in a Biogas Fuelled Combined Heat and Power (CHP) Engine Through the Use of Regeneration. Energies, 12(4), 575. https://doi.org/10.3390/en12040575