A Distributed Generation Hybrid System for Electric Energy Boosting Fueled with Olive Industry Wastes

Abstract

:1. Introduction

2. Materials and Methods

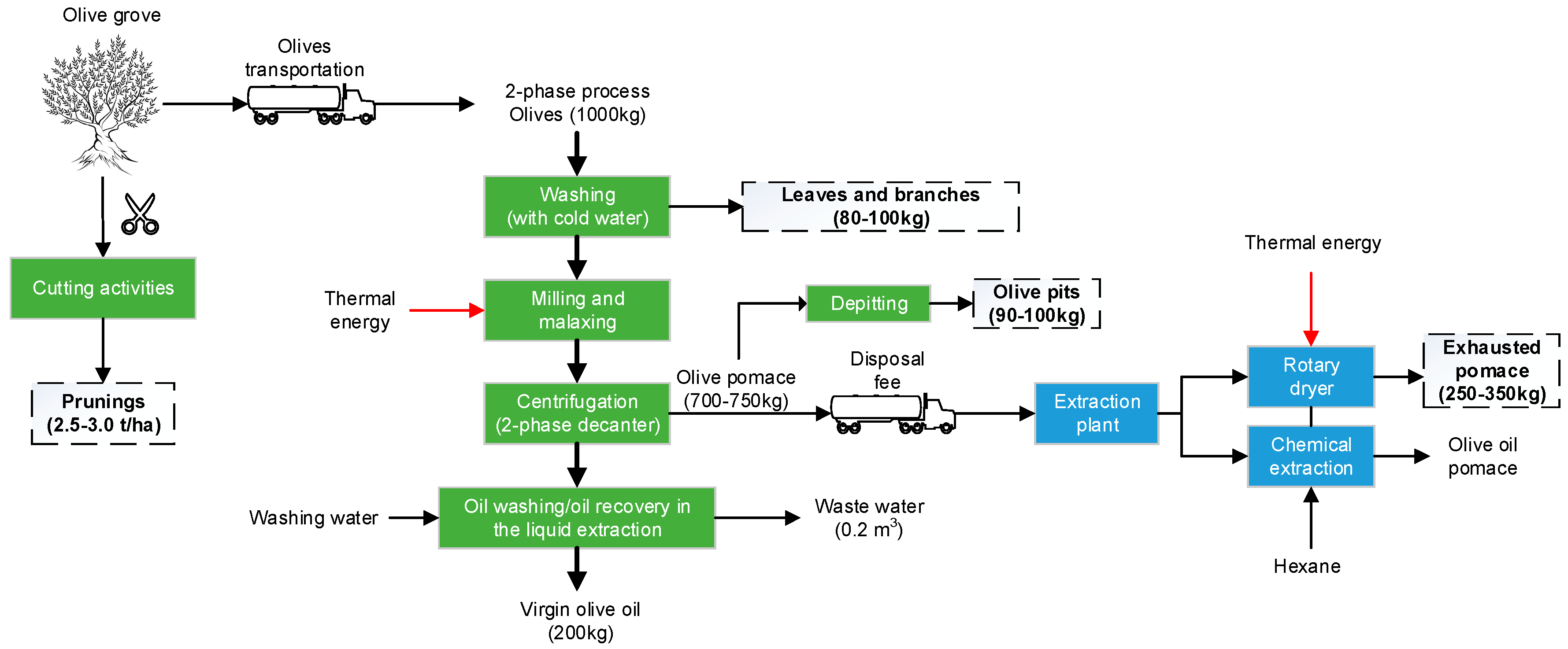

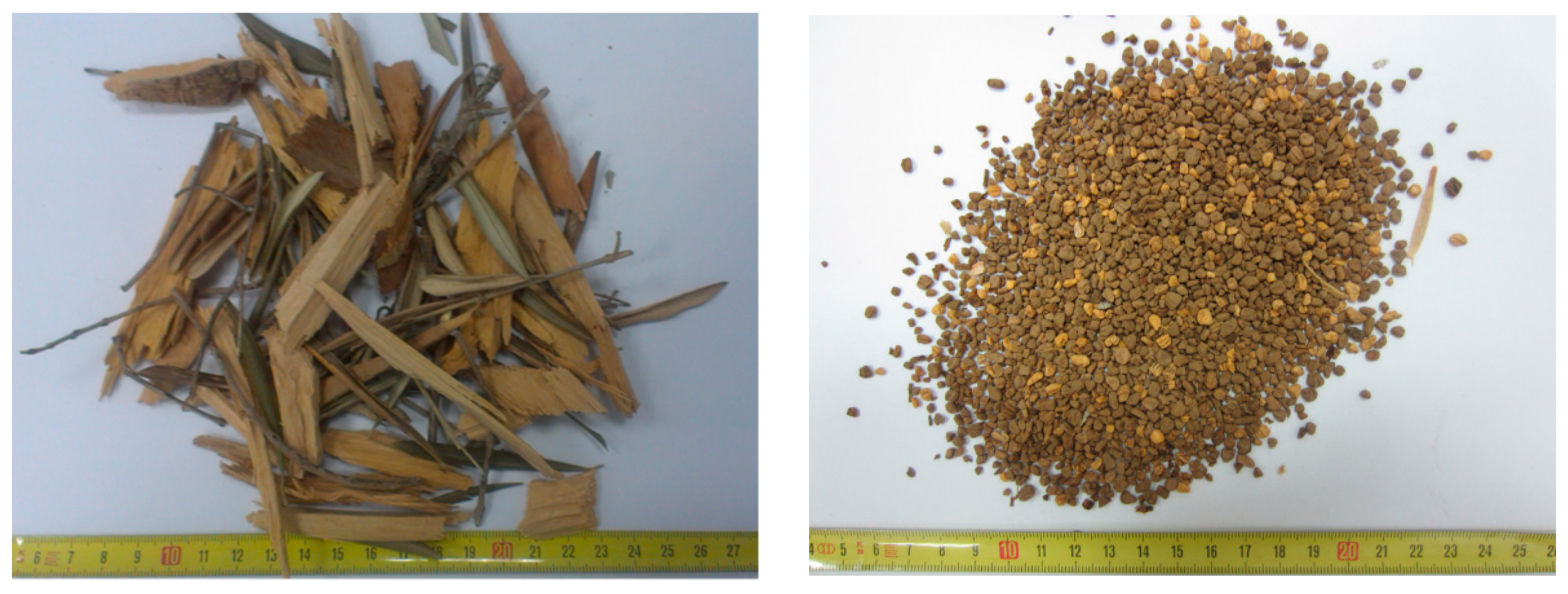

2.1. Olive Industry Wastes

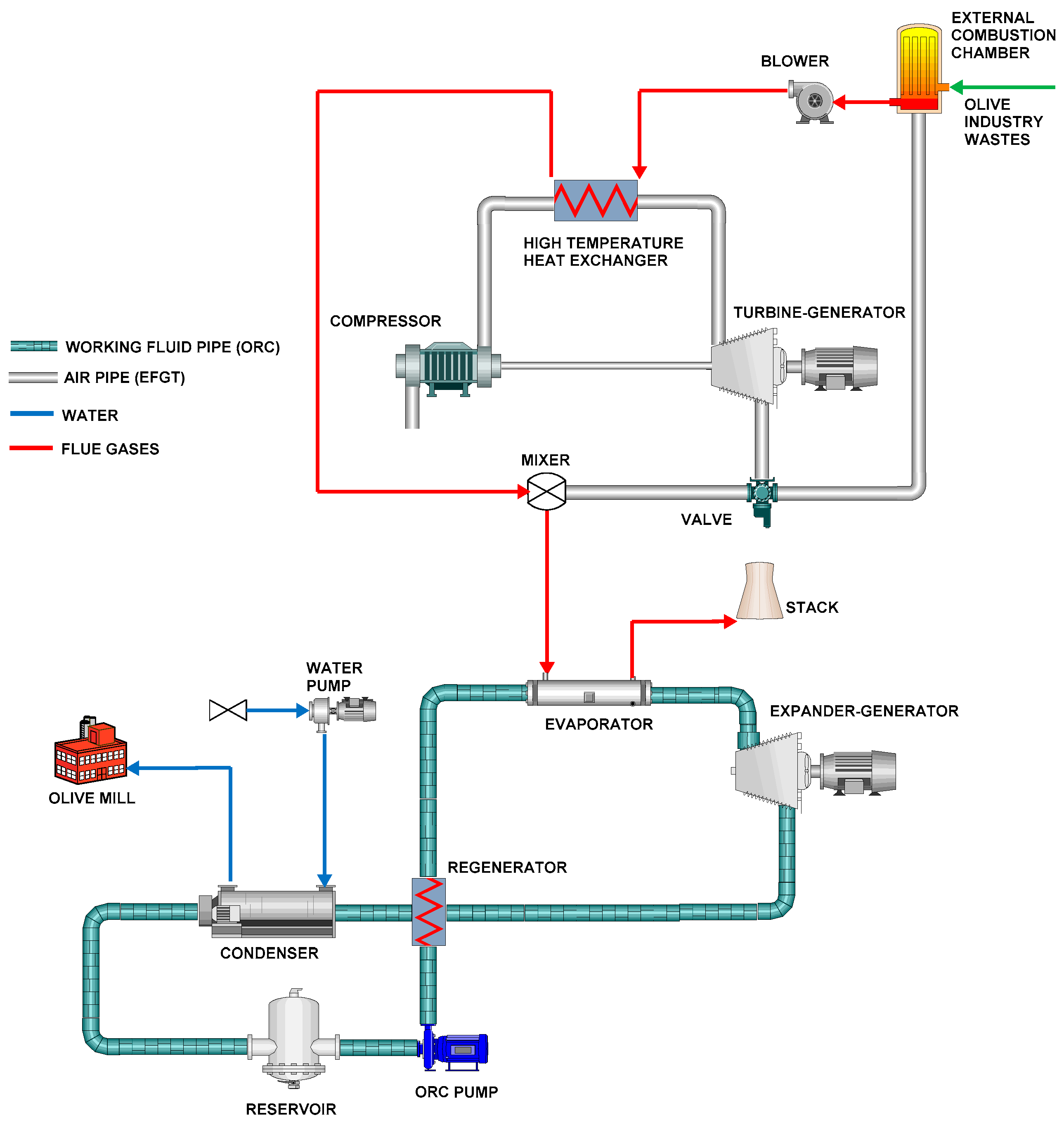

2.2. Plant Description

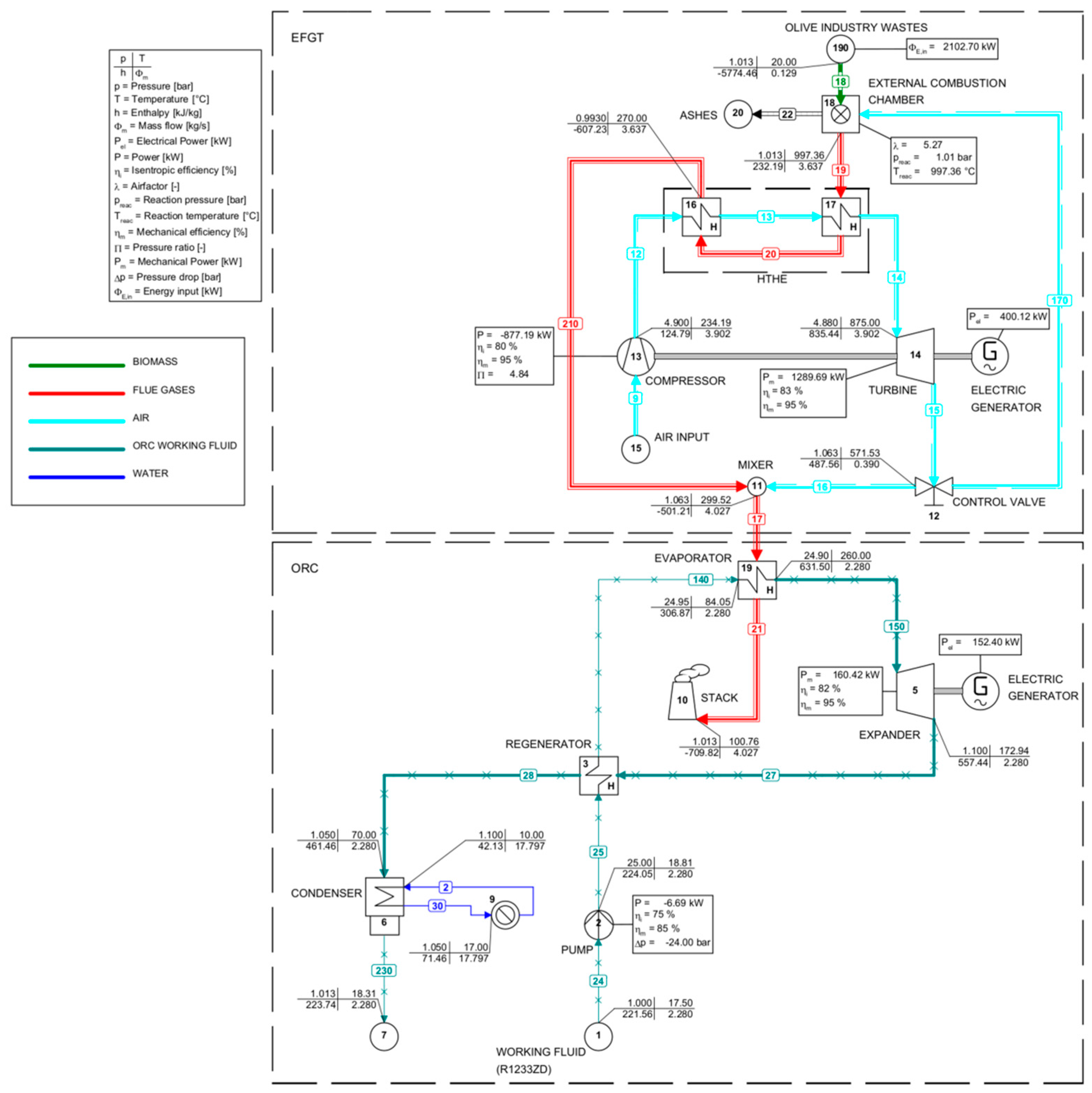

2.2.1. Externally Fired Gas Turbine (EFGT)

2.2.2. Organic Rankine Cycle (ORC)

3. Results and Discussion

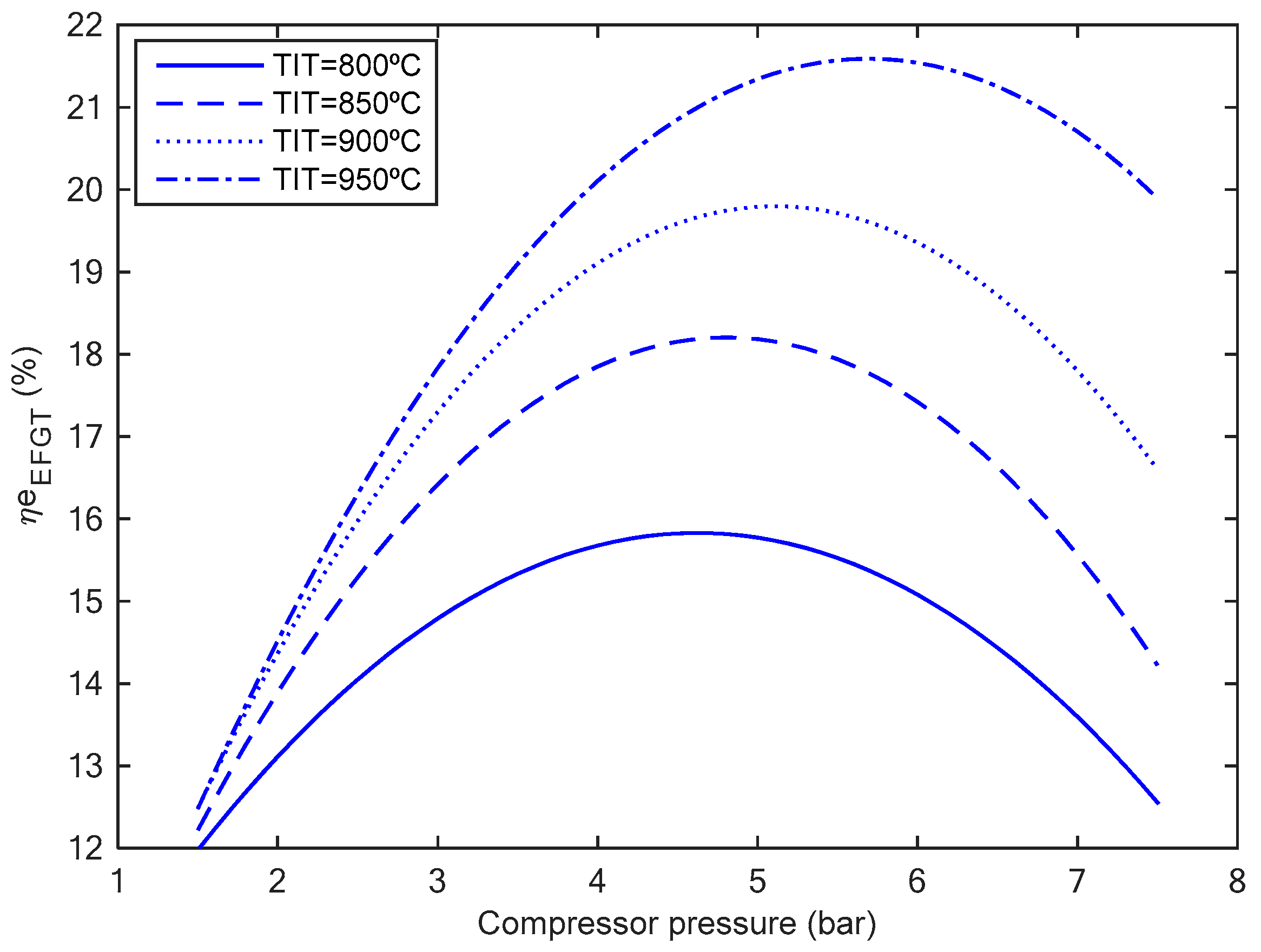

3.1. EFGT Results

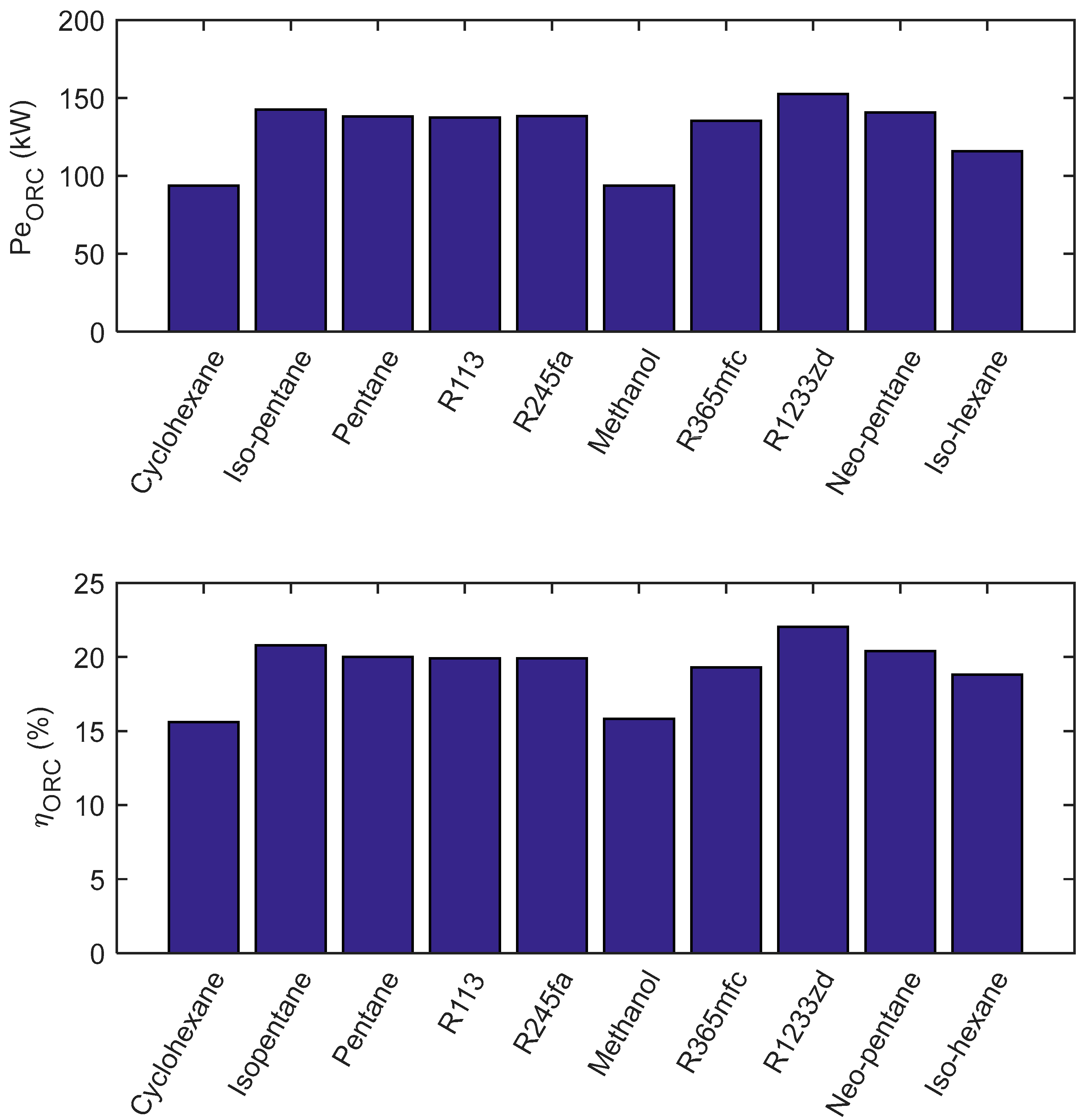

3.2. ORC Results

4. Conclusions

- The olive oil value chain generates a variety of by-products (prunings, stones, pomace, leaves and twigs), particularly during the agricultural and oil production phase, which currently are neglected and dealt with as a waste. This increases the costs for waste treatment of each olive mill, resulting in a heavier economic an environmental burden across the value chain. The development of new biomass conversion technologies as EFGT-ORC presented in this work could be a feasible option for the valorisation of these wastes along the Mediterranean countries.

- Olive industry wastes were burnt in an EFGT producing 400 kW of electric power and heat in the way of exhaust gases. The high temperature heat exchanger (HTHE) was the decisive component of this sub-system, and the optimum compressor pressure and TIT was achieved at 5 bars and 875 °C, respectively. The electric efficiency of the EFGT was 19% operating without the ORC generator.

- For increasing the low electric efficiency of the EFGT, the flue gases at EFGT outlet were used in an ORC generator. The behavior of the ORC subsystem directly depended on the working fluid, pump pressure and TIT. A new working fluid, R1233zd, was selected as the optimum for the electric power maximization, producing 152.4 kW and 22.1% of ORC thermal efficiency. From environmental point of view, R1233zd presented the lowest global warming potential index (GWP = 2), very suitable compared with typical organic fluids as R245fa (GWP = 1030) and R113 (GWP = 6130). Moreover, R1233zd showed suitable safety information (no flammability and instability). As drawback, R1233zd was not able to produce thermal power due to its lower condensation temperature (18.3 °C according to Table 4), being only suitable for electric distributed generation.

- Finally, despite R113 gave minor electricity production (137.5 kW) and ORC thermal efficiency (19.9%), this allowed generating thermal power for CHP applications (506.8 kW) in the way of hot water at 45 °C. Notice that in the concrete case of this work, the olive oil industry, this water flow can be very suitable for the olive oil production process. In contrast, R113 was not an eco-friendly organic fluid, presenting the highest GWP index among ten working fluids evaluated.

Author Contributions

Funding

Conflicts of Interest

References

- IOC World Olive Oil Figures. Available online: http://www.internationaloliveoil.org/estaticos/view/131-world-olive-oil-figures (accessed on 20 May 2016).

- García-Maraver, A.; Zamorano, M.; Ramos-Ridao, A.; Díaz, L.F. Analysis of olive grove residual biomass potential for electric and thermal energy generation in Andalusia (Spain). Renew. Sustain. Energy Rev. 2012, 16, 745–751. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Margaritis, N.K.; Grammelis, P. Experimental and economic study of a gasification plant fuelled with olive industry wastes. Energy Sustain. Dev. 2014, 23, 247–257. [Google Scholar] [CrossRef]

- Malheiro, R.; Rodrigues, N.; Manzke, G.; Bento, A.; Pereira, J.A.; Casal, S. The use of olive leaves and tea extracts as effective antioxidants against the oxidation of soybean oil under microwave heating. Ind. Crop. Prod. 2013, 44, 37–43. [Google Scholar] [CrossRef]

- de Mena, B.; Vera, D.; Jurado, F.; Ortega, M. Updraft gasifier and ORC system for high ash content biomass: A modelling and simulation study. Fuel Process. Technol. 2017, 156, 394–406. [Google Scholar] [CrossRef]

- Pesta, G.; Mayer Pittroff, R.W. Utilization of By-Products and Treatment of Wast in the Food Industry; Springer: Luxemburg, 2007; ISBN 9780387335117. [Google Scholar]

- Evans, R. Optimization of a wood-waste-fuelled, indirectly fired gas turbine cogeneration plant. Bioresour. Technol. 1996, 57, 117–126. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; de Mena, B.; Schories, G. Comparison between externally fired gas turbine and gasifier-gas turbine system for the olive oil industry. Energy 2011, 36, 6720–6730. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Carpio, J. Study of a downdraft gasifier and externally fired gas turbine for olive industry wastes. Fuel Process. Technol. 2011, 92, 1970–1979. [Google Scholar] [CrossRef]

- Al-attab, K.A.; Zainal, Z.A. Turbine startup methods for externally fired micro gas turbine (EFMGT) system using biomass fuels. Appl. Energy 2010, 87, 1336–1341. [Google Scholar] [CrossRef]

- Al-attab, K.A.; Zainal, Z.A. Performance of high-temperature heat exchangers in biomass fuel powered externally fired gas turbine systems. Renew. Energy 2010, 35, 913–920. [Google Scholar] [CrossRef]

- Al-attab, K.A.; Zainal, Z.A. Externally fired gas turbine technology: A review. Appl. Energy 2015, 138, 474–487. [Google Scholar] [CrossRef]

- Peris, B.; Navarro-Esbrí, J.; Molés, F.; Collado, R.; Mota-Babiloni, A. Performance evaluation of an Organic Rankine Cycle (ORC) for power applications from low grade heat sources. Appl. Therm. Eng. 2015, 75, 763–769. [Google Scholar] [CrossRef]

- Peris, B.; Navarro-Esbrí, J.; Molés, F.; Mota-Babiloni, A. Experimental study of an ORC (organic Rankine cycle) for low grade waste heat recovery in a ceramic industry. Energy 2015, 85, 534–542. [Google Scholar] [CrossRef]

- Huang, B.S.; Chen, H.Y.; Kuo, J.H.; Chang, C.H.; Wey, M.Y. Catalytic upgrading of syngas from fluidized bed air gasification of sawdust. Bioresour. Technol. 2012, 110, 670–675. [Google Scholar] [CrossRef] [PubMed]

- Invernizzi, C.; Iora, P.; Silva, P. Bottoming micro-Rankine cycles for micro-gas turbines. Appl. Therm. Eng. 2007, 27, 100–110. [Google Scholar] [CrossRef]

- Camporeale, S.M.; Pantaleo, A.M.; Ciliberti, P.D.; Fortunato, B. Cycle configuration analysis and techno-economic sensitivity of biomass externally fired gas turbine with bottoming ORC. Energy Convers. Manag. 2015, 105, 1239–1250. [Google Scholar] [CrossRef]

- Iora, P.; Silva, P. Innovative combined heat and power system based on a double shaft intercooled externally fired gas cycle. Appl. Energy 2013, 105, 108–115. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Carpio, J.; Kamel, S. Biomass gasification coupled to an EFGT-ORC combined system to maximize the electrical energy generation: A case applied to the olive oil industry. Energy 2018, 144, 41–53. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Panopoulos, K.D.; Grammelis, P. Modelling of biomass gasifier and microturbine for the olive oil industry. Int. J. Energy Res. 2012, 36, 355–367. [Google Scholar] [CrossRef]

- De Mello, P.E.B.; Monteiro, D.B. Thermodynamic study of an EFGT (externally fired gas turbine) cycle with one detailed model for the ceramic heat exchanger. Energy 2012, 45, 497–502. [Google Scholar] [CrossRef]

- Cocco, D.; Deiana, P.; Cau, G. Performance evaluation of small size externally fired gas turbine (EFGT) power plants integrated with direct biomass dryers. Energy 2006, 31, 1459–1471. [Google Scholar] [CrossRef]

- Bao, J.; Zhao, L. A review of working fluid and expander selections for organic Rankine cycle. Renew. Sustain. Energy Rev. 2013, 24, 325–342. [Google Scholar] [CrossRef]

- Rahbar, K.; Mahmoud, S.; Al-Dadah, R.K.; Moazami, N.; Mirhadizadeh, S.A. Review of organic Rankine cycle for small-scale applications. Energy Convers. Manag. 2017, 134, 135–155. [Google Scholar] [CrossRef]

- Drescher, U.; Brüggemann, D. Fluid selection for the Organic Rankine Cycle (ORC) in biomass power and heat plants. Appl. Therm. Eng. 2007, 27, 223–228. [Google Scholar] [CrossRef]

- Macchi, E. 1 – Theoretical basis of the Organic Rankine Cycle. In Organic Rankine Cycle (ORC) Power Systems; Woodhead Publ. Ltd.: Cambridge, UK; Abington Hall: Abington, PA, USA, 2017; pp. 3–24. ISBN 9780081005101. [Google Scholar]

- Astolfi, M.; Martelli, E.; Pierobon, L. 7 – Thermodynamic and technoeconomic optimization of Organic Rankine Cycle systems. In Organic Rankine Cycle (ORC) Power Systems; Woodhead Publ. Ltd.: Cambridge, UK; Abington Hall: Abington, PA, USA, 2017; pp. 173–249. ISBN 9780081005101. [Google Scholar]

- Mohammadi, A.; Kasaeian, A.; Pourfayaz, F.; Ahmadi, M.H. Thermodynamic analysis of a combined gas turbine, ORC cycle and absorption refrigeration for a CCHP system. Appl. Therm. Eng. 2017, 111, 397–406. [Google Scholar] [CrossRef]

- Branchini, L.; De Pascale, A.; Peretto, A. Systematic comparison of ORC configurations by means of comprehensive performance indexes. Appl. Therm. Eng. 2013, 61, 129–140. [Google Scholar] [CrossRef]

- Eksi, G.; Karaosmanoglu, F. Combined bioheat and biopower: A technology review and an assessment for Turkey. Renew. Sustain. Energy Rev. 2017, 73, 1313–1332. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Biomass in the generation of electricity in Portugal: A review. Renew. Sustain. Energy Rev. 2017, 71, 373–378. [Google Scholar] [CrossRef]

- Datta, A.; Ganguly, R.; Sarkar, L. Energy and exergy analyses of an externally fired gas turbine (EFGT) cycle integrated with biomass gasifier for distributed power generation. Energy 2010, 35, 341–350. [Google Scholar] [CrossRef]

- García-Maraver, A.; Terron, L.C.; Ramos-Ridao, A.; Zamorano, M. Effects of mineral contamination on the ash content of olive tree residual biomass. Biosyst. Eng. 2014, 118, 167–173. [Google Scholar] [CrossRef]

| By-Product | Olive Tree Pruning | Olive Pits | Olive Pomace (2-Phases) | Leaves, Twigs |

|---|---|---|---|---|

| Location | Olive grove | Olive mill | Olive mill | Olive mill |

| Production rate | 2.5–3.0 t/ha | 90–100 kg/t of olives | 650–750 kg/t of olives | 80–100 kg/t of olives |

| Ash (%, ar) | 3–5 | 0.5–2 | 2–5 | 8–10 |

| Moisture (%, ar) | 10–20 | 20–35 | 65–70 | 5–10 |

| Lower Calorific Value, LHV (MJ/kg, db) | 16–18 | 17–19 | 16–18 | 10–14 |

| Selling price (€/kg) | Free | 0.08 (wet) | Disposal fee | Free |

| Current valorization | None (burn or scattered in the field) | Sold to biomass traders | Pomace oil, extractor companies | None |

| Proximate Analysis (% Weight) | Stones | Leaves and Twigs | Olive Tree Pruning | Pomace (2 Phases) |

| Moisture (ar) | 25–30 | 8.5 | 10–15 | 65–70 |

| Ashes (db) | 1–2 | 8.71 | 3–5 | 2–5 |

| Volatiles (db) | 76.36 | 71.41 | 78.18 | 77.38 |

| Fixed carbon (db) | 21.58 | 19.88 | 17.13 | 17.60 |

| Elemental analysis (% weight, dry basis) | ||||

| C | 50.08 | 45.08 | 47.10 | 51.31 |

| H | 5.90 | 5.89 | 6.18 | 6.40 |

| N | 0.64 | 0.52 | 0.55 | 2.00 |

| S | 0.02 | 0.09 | 0.10 | 0.26 |

| O (difference) | 41.03 | 39.70 | 41.66 | 35.01 |

| Other properties | ||||

| LHV (MJ/kg) | 17.9 | 12.3 | 16.3 | 17.0 |

| Ash melting point (°C) | >1200 | >1200 | >1200 | >1200 |

| Bulk density (kg/m3) Average particle size (mm) | 709 2–5 | 108 20–40 | 195 20–60 | 780 5–10 |

| Parameter | Unit | Value |

|---|---|---|

| Combustion chamber pressure | bar | 1.013 |

| Combustion chamber efficiency | % | 94 |

| Combustion chamber pressure drop | % | 1 |

| Maximum flue gases temperature | °C | 1000 |

| HTHE thermal efficiency | % | 85 |

| HTHE pressure drop | % | 2 |

| Hot side temperature difference for HTHE | °C | 125 |

| Maximum turbine inlet temperature (TIT) | °C | 875 |

| Turbine isentropic efficiency | % | 83 |

| Compressor isentropic efficiency | % | 80 |

| Turbine and compressor mechanical efficiency | % | 95 |

| Electric generator efficiency | % | 96 |

| Exhaust gases temperature | °C | 300 |

| Working Fluid | Molar Mass (kg/kmol) | Critical Pressure (Bar) | Critical Temp. (°C) | Maximum Operative Temp. (°C) | Condensation Temperature (°C) | Environmental Issues b | |||

|---|---|---|---|---|---|---|---|---|---|

| GWP a | H | F | I | ||||||

| Cyclohexane | 84.16 | 40.7 | 280 | 426.9 | 80.3 | 4–6 | 1 | 3 | 0 |

| Isohexane | 86.18 | 30.4 | 225 | 277 | 60.2 | 4–6 | 2 | 3 | 0 |

| Pentane | 72.15 | 33.7 | 197 | 400 | 36.2 | 4–6 | 1 | 4 | 0 |

| Isopentane | 72.15 | 33.8 | 187 | 227 | 26.8 | 4–6 | 1 | 4 | 0 |

| Neopentane | 72.15 | 32.0 | 161 | 277 | 9.5 | 4–6 | 1 | 4 | 0 |

| R113 | 187.38 | 33.8 | 214 | 251 | 47.4 | 6130 | 1 | 1 | 0 |

| R245fa | 134.05 | 36.5 | 154 | 226 | 14.8 | 1030 | 2 | 1 | 0 |

| R365mfc | 148.07 | 32.7 | 187 | 226 | 40.2 | 794 | 0 | 4 | 1 |

| R1233zd | 130.50 | 36.2 | 166.45 | 277 | 18.3 | 1 | 2 | 0 | 0 |

| Methanol | 32.04 | 82.2 | 240 | 350 | 78.2 | 4–6 | 1 | 3 | 0 |

| Performance Parameter | Unit | Value |

| Turbine isentropic efficiency | % | 80 |

| Turbine mechanical efficiency | % | 95 |

| Pump isentropic efficiency | % | 75 |

| Pump electro-mechanical efficiency | % | 85 |

| Regenerator and evaporator efficiency | % | 85 |

| Condenser efficiency | % | 87 |

| Electric generator efficiency | % | 97 |

| Pressure drop in evaporator | % | 2 |

| Pressure drop in regenerator | % | 1 |

| Technical constraints | Unit | Value |

| Minimum stack temperature | °C | 100 |

| Minimum evaporator pinch point temperature, ΔTpinch | °C | 10 |

| Heat source temperature | °C | 300 |

| Maximum pump operating pressure | bar | 25 |

| Olive Industry Waste | Exhaust Gases Mass Flow mfg (kg/s) | Exhaust Gases Temperature (°C) | Biomass Mass Flow mb (kg/h) | (%) |

|---|---|---|---|---|

| Pruning | 4.03 | 299.5 | 464.4 | 19.03 |

| Dry pomace | 4.07 | 300.7 | 450.0 | 19.05 |

| Stones | 4.03 | 300.3 | 428.4 | 18.95 |

| Leaves and twins | 4.06 | 303.6 | 633.6 | 18.48 |

| Working Fluid | TIT (°C) | (%) | |||||

|---|---|---|---|---|---|---|---|

| Cyclohexane | 13 | 200 | 1.3 | 3.2 | 93.6 | 475.7 a | 15.60 |

| Isohexane | 25 | 240 | 1.24 | 7.6 | 115.8 | 423.4 b | 18.82 |

| Pentane | 25 | 240 | 1.21 | 7.2 | 138.2 | - | 20.02 |

| Isopentane | 25 | 177 | 1.55 | 9.0 | 142.4 | - | 20.80 |

| Neopentane | 25 | 240 | 1.19 | 7.4 | 140.7 | - | 20.41 |

| R113 | 25 | 230 | 3.35 | 7.9 | 137.5 | 506.8 c | 19.92 |

| R245fa | 25 | 216 | 2.34 | 6.3 | 138.3 | - | 19.90 |

| R365mfc | 25 | 216 | 2.57 | 7.9 | 135.4 | 481.4 d | 19.30 |

| R1233zd | 25 | 260 | 2.28 | 6.7 | 152.4 | - | 22.05 |

| Methanol | 25 | 210 | 0.62 | 3.4 | 93.6 | 461.2 a | 15.82 |

| Hot Source Working Fluid | Present Work | Branchini et al. [29] | |||||

|---|---|---|---|---|---|---|---|

| THOT = 300 °C | THOT = 400 °C | THOT = 200 °C | |||||

| R1233zd | R113 | Isopentane | MDM | Toluene | R245fa | Butane | |

| Type of cycle | REC + SH | REC | sC | REC + SH | SH | ||

| Pv (bar) | 25.0 | 25.0 | 25.0 | 13.7 | 39.0 | 27.3 | 30.3 |

| ηORC (%) | 22.1 | 19.9 | 20.8 | 22.2 | 24.5 | 16.3 | 14.4 |

| WORC (kJ/kg) | 67 | 41 | 92 | 69 | 184 | 38 | 75 |

| VER (-) | 21.4 | 26.1 | 30.0 | 624.0 | 1199.0 | 20.0 | 15.0 |

| MFR (-) | 0.566 | 0.831 | 0.385 | 0.716 | 0.488 | 0.539 | 0.289 |

| ∑UA (kJ/kg °C) | 35.4 | 17.8 | 15.0 | 13.6 | 18.1 | 14.8 | 13.2 |

| UAREC | 0.7 | 0.9 | 1.9 | 3.8 | - | 1.3 | - |

| UACON | 27.8 | 10.5 | 10.3 | 4.2 | 5.1 | 5.9 | 4.0 |

| UAEVA | 6.9 | 6.4 | 2.8 | 0.2 | 0.4 | 1.9 | 1.9 |

| UAECO | - | - | - | 5.4 | 12.5 | 5.5 | 7.1 |

| UASH | - | - | - | - | - | 0.2 | 0.2 |

| Performance Parameters | Unit | Present Work | Vera et al. [19] | Camporeale et al. [17] |

|---|---|---|---|---|

| Biomass conversion technology | - | External combustion | Downdraft gasifier | Furnace |

| Type of biomass | - | Olive industry wastes | Olive tree pruning | n.a. |

| Biomass consumption | Kg/h | 430–460 | 217 | 3600 |

| EFGT electric power | kW | 400.0 | 150.2 | 1383.0 |

| ORC electric power | kW | 152.4 (R1233zd) 137.5 (R113) | 57.1 (isopentane) 49.1 (R113) | 700 |

| Thermal power available | kW | 506.8 (R113) | 199.8 (R113) | 963 |

| Waste source temperature | °C | 300 | 290 | 400 |

| Optimum ORC working fluids | - | R1233zd (electricity) R113 (CHP) | Isopentane (electricity) R113 (CHP) | Toluene (CHP) |

| ORC thermal efficiency | % | 22.1 (R1233zd) 19.9 (R113) | 20.5 (isopentane) 17.6 (R113) | 19.0 |

| Net electric efficiency | % | 26.0 (R1233zd) 25.2 (R113) | 20.7 (isopentane) 20.0 (R113) | 23.0 |

| Percentage of electric power increased | % | 38.1 | 38.0 | 50.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vera, D.; Jurado, F.; de Mena, B.; C. Hernández, J. A Distributed Generation Hybrid System for Electric Energy Boosting Fueled with Olive Industry Wastes. Energies 2019, 12, 500. https://doi.org/10.3390/en12030500

Vera D, Jurado F, de Mena B, C. Hernández J. A Distributed Generation Hybrid System for Electric Energy Boosting Fueled with Olive Industry Wastes. Energies. 2019; 12(3):500. https://doi.org/10.3390/en12030500

Chicago/Turabian StyleVera, David, Francisco Jurado, Bárbara de Mena, and Jesús C. Hernández. 2019. "A Distributed Generation Hybrid System for Electric Energy Boosting Fueled with Olive Industry Wastes" Energies 12, no. 3: 500. https://doi.org/10.3390/en12030500

APA StyleVera, D., Jurado, F., de Mena, B., & C. Hernández, J. (2019). A Distributed Generation Hybrid System for Electric Energy Boosting Fueled with Olive Industry Wastes. Energies, 12(3), 500. https://doi.org/10.3390/en12030500