Life Cycle Assessment of Large-scale Compressed Bio-natural Gas Production in China: A Case Study on Manure Co-digestion with Corn Stover

Abstract

1. Introduction

2. Methodology

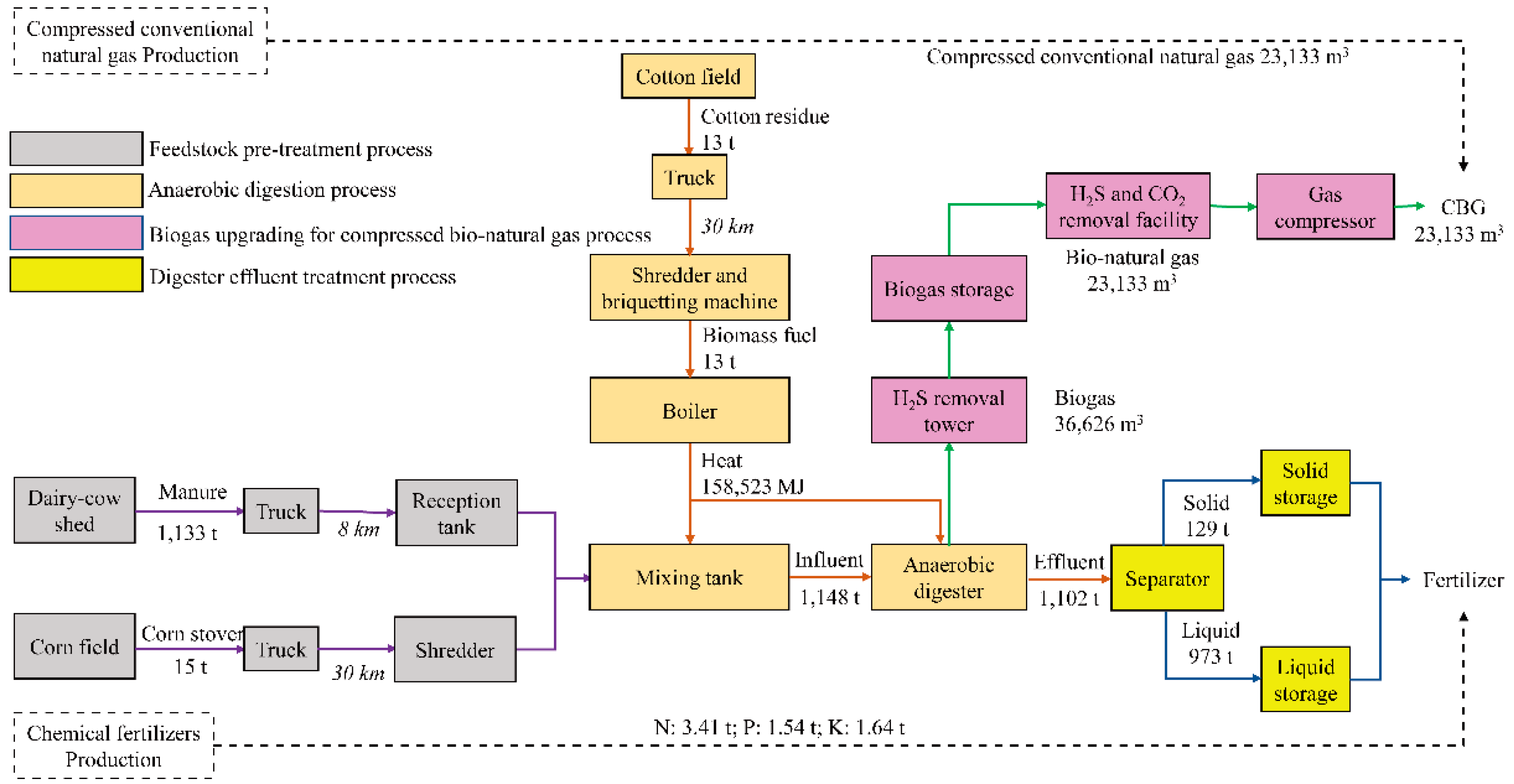

2.1. Goal and Scope

2.2. Software and Database

2.3. Life Cycle Energy Analysis

2.4. Life Cycle Environmental Inventory Analysis

2.4.1. Feedstock Pre-Treatment Process

2.4.2. Anaerobic Digestion Process

2.4.3. Biogas Upgrading for CBG Process

2.4.4. Digester Effluent Treatment Process

2.5. Life Cycle Environmental Impacts Assessment

2.6. Analysis of Emission Credits

2.7. Sensitivity Analysis

3. Results

3.1. Assessment of Energy Efficiency

3.2. Assessment of Environmental Impact

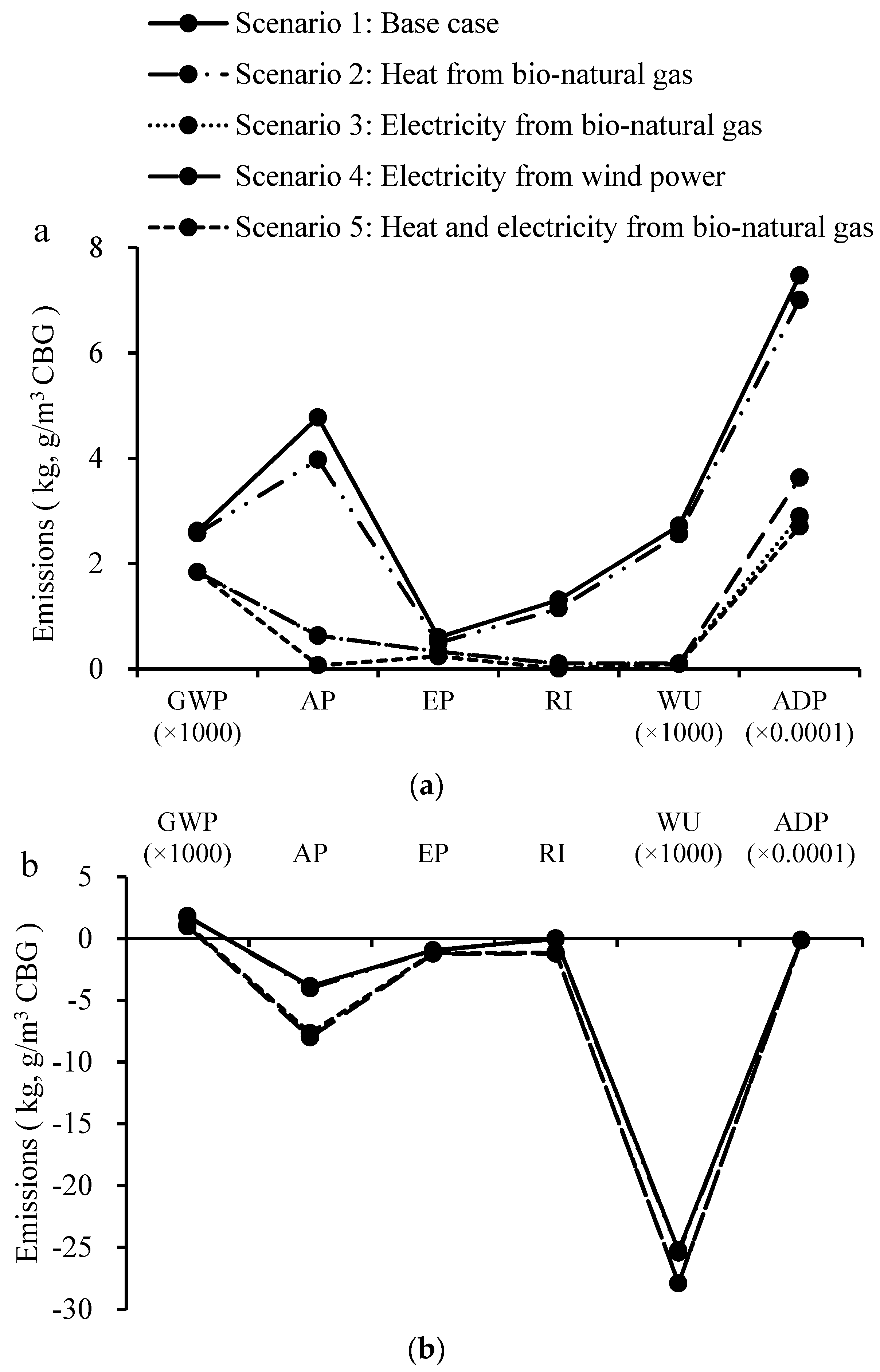

3.3. Emission Credits and Mitigation Potential

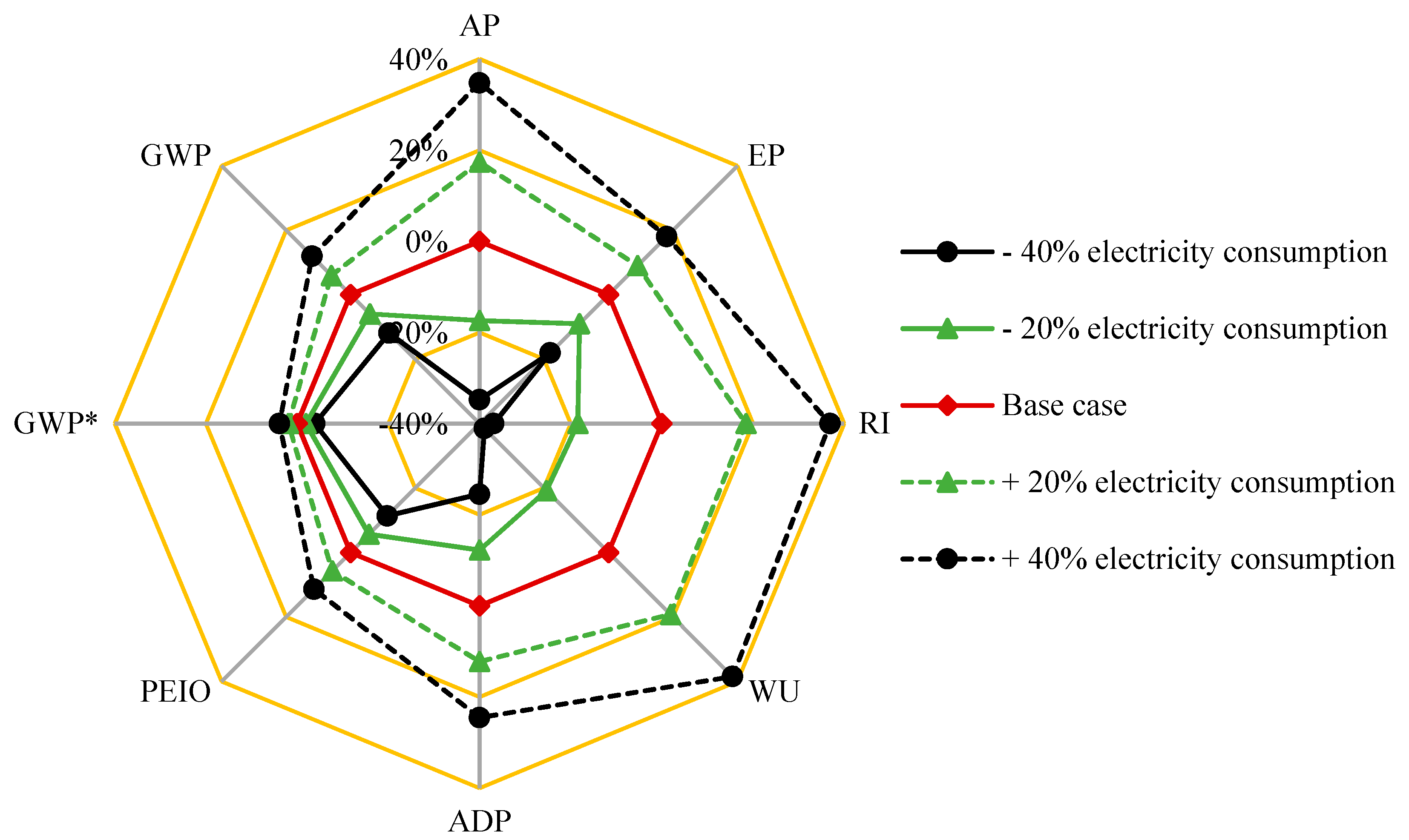

3.4. Sensitivity Analysis

4. Discussion

4.1. Energy Efficiency of Large-Scale CBG System

4.2. Environmental Performance of Large-Scale CBG System

4.3. Development of Large-Scale CBG Systems in China

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature and Abbreviations

| ADP | Abiotic depletion potential |

| AP | Acidification potential |

| CBG | Compressed Bio-natural Gas |

| CH4 | Methane |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| COD | Chemical oxygen demand |

| EP | Eutrophication potential |

| H2S | Hydrogen sulfide |

| IPCC | Intergovernmental panel on climate change |

| K | Potassium |

| LCA | Life cycle assessment |

| MCF | Methane conversion factor |

| N | Nitrogen |

| NH3 | Ammonia |

| NOx | Nitrogen oxides |

| N2O | Nitrous oxide |

| P | Phosphorus |

| PEIO | Primary Energy Input to Output |

| PM2.5 | Particulate matter 2.5 |

| PM10 | Particulate matter 10 |

| RI | Respiratory inorganics |

| Sb | Antimony |

| SO2 | Sulfur dioxide |

| VOC | Volatile organic compounds |

| VS | Volatile solid |

| WU | Water use |

References

- National Development and Reform Commission, Ministry of Agriculture and Rural Affairs of the People’s Republic of China (NDRC). The 13th Five-Year National Plan for Rural Biogas Development. 2017. Available online: http://www.gov.cn/xinwen/2017-02/10/5167076/files/797001c427eb47b680c0cd77daad 4327. pdf (accessed on 25 January 2017).

- Ministry of Agriculture and Rural Affairs of the People’s Republic of China (MARAC). Classification of Scale for Biogas Engineering. 2011. Available online: http://www.jsagri.gov.cn/attachement/5980.doc (accessed on 2 September 2011).

- Xu, C.; Zongjun, C.; Wanbin, Z. The upcoming bio-natural gas in China: A strategic emerging industry. Nat. Gas Ind. 2013, 33, 141–148. [Google Scholar]

- Budzianowski, W.M.; Wylock, C.E.; Marciniak, P.A. Power requirements of biogas upgrading by water scrubbing and biomethane compression: Comparative analysis of various plant configurations. Energy Convers. Manag. 2017, 141, 2–19. [Google Scholar] [CrossRef]

- De Vries, J.W.; Vinken, T.M.; Hamelin, L.; De Boer, I.J. Comparing environmental consequences of anaerobic mono- and co-digestion of pig manure to produce bio-energy—A life cycle perspective. Bioresour. Technol. 2012, 125, 239–248. [Google Scholar] [CrossRef] [PubMed]

- Pehme, S.; Veromann, E.; Hamelin, L. Environmental performance of manure co-digestion with natural and cultivated grass: A consequential life cycle assessment. J. Clean. Prod. 2017, 162, 1135–1143. [Google Scholar] [CrossRef]

- Croxatto Vega, G.C.; ten Hoeve, M.; Birkved, M.; Sommer, S.G.; Bruun, S. Choosing co-substrates to supplement biogas production from animal slurry—A life cycle assessment of the environmental consequences. Bioresour. Technol. 2014, 171, 410–420. [Google Scholar] [CrossRef]

- Hamelin, L.; Naroznova, I.; Wenzel, H. Environmental consequences of different carbon alternatives for increased manure-based biogas. Appl. Energy 2014, 114, 774–782. [Google Scholar] [CrossRef]

- Fuchsz, M.; Kohlheb, N. Comparison of the environmental effects of manure- and crop-based agricultural biogas plants using life cycle analysis. J. Clean. Prod. 2015, 86, 60–66. [Google Scholar] [CrossRef]

- ISO. Environmental Management—Life Cycle Assessment—Principles and Framework. 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 1 July 2006).

- ISO. Environmental Management—Life Cycle Assessment—Requirements and Guidelines. 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 1 July 2017).

- Chen, S.; Chen, B.; Song, D. Life-cycle energy production and emissions mitigation by comprehensive biogas-digestate utilization. Bioresour. Technol. 2012, 114, 357–364. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, W.F.; Wang, P.; Dou, Z.X.; Gao, L.W.; Styles, D. Greenhouse Gas Mitigation of Rural Household Biogas Systems in China: A Life Cycle Assessment. Energies 2017, 10, 239. [Google Scholar] [CrossRef]

- Ren, C.; Wang, W.; Mao, Y.; Yuan, X.; Song, Z.; Sun, J.; Zhao, X. Comparative life cycle assessment of sulfoaluminate clinker production derived from industrial solid wastes and conventional raw materials. J. Clean. Prod. 2017, 167, 1314–1324. [Google Scholar] [CrossRef]

- Tian, X.; Wu, Y.; Hou, P.; Liang, S.; Qu, S.; Xu, M.; Zuo, T. Environmental impact and economic assessment of secondary lead production: Comparison of main spent lead-acid battery recycling processes in China. J. Clean. Prod. 2017, 144, 142–148. [Google Scholar] [CrossRef]

- Yu, Z.; Ma, W.; Xie, K.; Lv, G.; Chen, Z.; Wu, J.; Yu, J. Life cycle assessment of grid-connected power generation from metallurgical route multi-crystalline silicon photovoltaic system in China. Appl. Energy 2017, 185, 68–81. [Google Scholar] [CrossRef]

- Wang, J.; Wang, R.; Zhu, Y.; Li, J. Life cycle assessment and environmental cost accounting of coal-fired power generation in China. Energy Policy 2018, 115, 374–384. [Google Scholar] [CrossRef]

- Yang, X.; Hu, M.; Wu, J.; Zhao, B. Building-information-modeling enabled life cycle assessment, a case study on carbon footprint accounting for a residential building in China. J. Clean. Prod. 2018, 183, 729–743. [Google Scholar] [CrossRef]

- Wang, M.; Elgowainy, A.; Han, J.; Benavides, P.T.; Burnham, A.; Cai, H.; Canter, C.; Chen, R.; Dai, Q.; Kelly, J.; et al. Summary of Expansions, Updates, and Results in GREET 2017 Suite of Models. 2017. Available online: https://www.osti.gov/biblio/1414291 (accessed on 1 November 2017).

- Jin, Y.Y.; Chen, T.; Chen, X.; Yu, Z.X. Life-cycle assessment of energy consumption and environmental impact of an integrated food waste-based biogas plant. Appl. Energy 2015, 151, 227–236. [Google Scholar] [CrossRef]

- Wang, Q.-L.; Li, W.; Gao, X.; Li, S.-J. Life cycle assessment on biogas production from straw and its sensitivity analysis. Bioresour. Technol. 2016, 201, 208–214. [Google Scholar] [CrossRef] [PubMed]

- Pöschl, M.; Ward, S.; Owende, P. Evaluation of energy efficiency of various biogas production and utilization pathways. Appl. Energy 2010, 87, 3305–3321. [Google Scholar] [CrossRef]

- Thelen, K. Corn Fields Help Clean Up and Protect the Environment. 2007. Available online: https://www.canr.msu.edu/news/corn_fields_help_clean_up_and_protect_the_environment (accessed on 7 June 2007).

- IPCC. Chapter 10: Emissions from Livestock and Manure Management. In IPCC Guidelines for National Greenhouse Gas Inventories, Prepared by the National Greenhouse Gas Inventories Programme; Cambridge University Press: Cambridge, UK, 2006; pp. 10.1–10.87. [Google Scholar]

- Liebetrau, J.; Reinelt, T.; Agostini, A.; Linke, B. Methane Emissions from Biogas Plants; IEA Bioenergy: Golden, CO, USA, 2017; ISBN 978-1-910154-35-9. [Google Scholar]

- Golsteijn, L. Characterisation: New Developments for Toxicity. 2014. Available online: https://www.pre-sustainability.com/news/characterisation-new-developments-for-toxicity (accessed on 7 July2014).

- Forster, P.; Ramaswamy, V.; Artaxo, P.; Berntsen, T.; Betts, R.; Fahey, D.W.; Haywood, J.; Lean, J.; Lowe, D.C.; Myhre, G.; et al. Climate Change 2007: The Physical Science Basis—Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007; pp. 129–234. [Google Scholar]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; Koning, A.D.; Oers, L.V.; Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; et al. Handbook on Life Cycle Assessment. Operational Guide to the ISO standards. I: LCA in Perspective; Guinée, J., Ed.; Kluwer Academic: Dordrecht, The Netherlands, 2002; p. 692. [Google Scholar]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324. [Google Scholar] [CrossRef]

- IKE Environmental Technology Co., Ltd. eBalance 4.7. 2018. Available online: www.ike-global.com (accessed on 15 May 2014).

- Yi, R.; Zhang, W.; Zhou, J.; Li, W.; Wu, S.; Dong, R. Environmental impact analysis on the production and utilization of digestate based on LCA method. Renew. Energy Resour. 2015, 33, 301–307. [Google Scholar]

- Xu, Y.; Tian, X.; Li, D.; Tian, W.; Xu, X. The nutrient content compare of different raw biogas fermentation residues. Bull. Agric. Sci. Technol. 2012, 5, 100–102. [Google Scholar]

- You, Y.; Dong, H.; Zhu, Z.; Tao, X.; Chen, Y. Experiments on influencing factors of methane emissions from beef cattle manure stack. Trans. CSAE 2008, 24, 168–172. [Google Scholar]

- Wang, O.; Ye, F.; Li, K. Problems and solutions of cows manure treatment in Chongqing. China Dairy Cattle 2006, 10, 38–40. [Google Scholar]

- Li, X.; Wang, S.; Duan, L.; Hao, J.; Li, C.; Chen, Y.; Yang, L. Particulate and trace gas emissions from open burning of wheat straw and corn stover in China. Environ. Sci. Technol 2007, 41, 6052–6058. [Google Scholar] [CrossRef] [PubMed]

- Berglund, M.; Börjesson, P. Assessment of energy performance in the life-cycle of biogas production. Biomass Bioenergy 2006, 30, 254–266. [Google Scholar] [CrossRef]

- Becker, C.; Döhler, H.; Eckel, H.; Fröba, N.; Georgieva, T.; Grube, J. Empirical Values for Biogas; Springer Nature: Darmstadt, Germany, 2007. [Google Scholar]

- Aguirre-Villegas, H.A.; Larson, R.A. Evaluating greenhouse gas emissions from dairy manure management practices using survey data and lifecycle tools. J. Clean. Prod. 2017, 143, 169–179. [Google Scholar] [CrossRef]

- Hamelin, L.; Wesnaes, M.; Wenzel, H.; Petersen, B.M. Environmental consequences of future biogas technologies based on separated slurry. Environ. Sci. Technol. 2011, 45, 5869–5877. [Google Scholar] [CrossRef]

- Han, J.; Mintz, M.; Wang, M. Waste-to-Wheel Analysis of Anaerobic-Digestion-Based Renewable Natural Gas Pathways with the GREET Model. 2011. Available online: file:///C:/Users/1234/Downloads/ ANL _ESD _11-6.pdf (accessed on 30 September 2011).

- Wang, X.; Wang, L. Environmental Protection Departments about the Fog Haze in Harbin: Straw Is a Important Factor. 2013. Available online: http://www.chinanews.com/gn/2013/10-21/5403825.shtml (accessed on 21 October 2013).

- Cherubini, E.; Zanghelini, G.M.; Alvarenga, R.A.F.; Franco, D.; Soares, S.R. Life cycle assessment of swine production in Brazil: A comparison of four manure management systems. J. Clean. Prod. 2015, 87, 68–77. [Google Scholar] [CrossRef]

- Bunus FT. Phosphoric acid by wet process: Radioactive components in phosphoric acid and their removal. In Hodge CH, Popovici NP (eds) Pollution Control in Fertilizer Production; Marcel Dekker, Inc.: New York, NY, USA, 1994. [Google Scholar]

- ZCG. The Natural Gas Industry Report of In-Depth Market Research and Future Development Trent from 2018–2024 in China; Zhiyan Grail Research Group: Beijing, China, 2018. [Google Scholar]

- SC. The Rate of China’s Natural Gas Dependence on Importation in 2017. 2018. Available online: http://www.china-nengyuan.com/news/120546.html (accessed on 2 February 2018).

| Characterization Categories | Reference Method | Normalization Factor d |

|---|---|---|

| Global warming potential (GWP) | IPCC 2007 a | 1.05 × 1013 |

| Acidification potential (AP) | CML2002 b | 0.36 × 1011 |

| Eutrophication potential (EP) | CML2002 b | 0.38 × 1010 |

| Respiratory inorganics (RI) | IMPACT2002+ c | 1.88 × 1010 |

| Water use (WU) | - | 6.06 × 1014 |

| Abiotic depletion potential (ADP) | CML2002 b | 0.75 × 107 |

| Inventory | Emissions from Manure Storage in Lagoons without any Treatment | Emissions from Corn Stover Burning in Field | ||

|---|---|---|---|---|

| Value (g kg−1) | Reference | Value (g kg−1) | Reference | |

| Methane (CH4) | 4.45 | [33] | 4.40 | [35] |

| Ammonia (NH3) | 0.02 | [34] | - | - |

| Chemical oxygen demand (COD) | 1.91 | [31] | - | - |

| Total phosphorus (TP) | 0.07 | [31] | - | - |

| Total nitrogen (TN) | 0.25 | [31] | - | - |

| Nitrous oxide (N2O) | - | - | 0.14 | [35] |

| Carbon monoxide (CO) | - | - | 4.60 | [31] |

| Nitrogen oxide (NOX) | - | - | 0.13 | [31] |

| Volatile organic compounds (VOC) | - | - | 0.79 | [31] |

| Sulfur dioxide (SO2) | - | - | 0.02 | [31] |

| Particulate matter 2.5 (PM2.5) | - | - | 11.7 | [35] |

| Particulate matter 10 (PM10) | - | - | 0.29 | [31] |

| Item | Value | Percent of Total Energy (%) |

|---|---|---|

| Total energy input | 245,413 MJ d−1 | 100 |

| Feedstock pre-treatment process | 16,043 MJ d−1 | 6.54 |

| Feedstock transportation (diesel) | 376 kg d−1 | 6.49 |

| Feedstock pretreatment | 33 kwh d−1 | 0.05 |

| Anaerobic digestion process | 186,430 MJ d−1 | 75.97 |

| Homogenate | 1,240 kwh d−1 | 1.82 |

| Cotton residue transportation (diesel) | 28 kg d−1 | 0.47 |

| Cotton residue treatment for heat | 1,166 kwh d−1 | 1.71 |

| Anaerobic digestion | 5,022 kwh d−1 | 7.37 |

| Heat consumption | 158,523 MJ d−1 | 64.59 |

| Biogas for CBG production process | 42,359 MJ d−1 | 17.26 |

| H2S removal | 1,248 kwh d−1 | 1.83 |

| Final H2S removal, CO2 removal and gas compression | 10,518 kwh d−1 | 15.43 |

| Digester effluent treatment process | 582 MJ d−1 | 0.24 |

| Solid and liquid separation | 162 kwh d−1 | 0.24 |

| Total energy output | 1,243,467 MJ d−1 | 100 |

| CBG | 855,921 MJ d−1 | 69.00 |

| Energy savings from chemical fertilizer production | 387,546 MJ d−1 | 31.00 |

| Primary Energy Input to Output (PEIO) ratio | 20 % | - |

| Process | GWP | AP | EP | RI | WU | ADP | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg (CO2-eq) | % | g (SO2-eq) | % | g (PO43−-eq) | % | g (PM2.5-eq) | % | kg | % | 10−4 g (Sb-eq) | % | |

| Feedstock pre-treatment process | 13.43 | 0.51 | 0.07 | 1.45 | 0.01 | 1.63 | 0.01 | 0.90 | 103.76 | 3.81 | 2.71 | 36.32 |

| Manure transport and pre-treatment | 11.22 | 0.43 | 0.06 | 1.21 | 0.01 | 1.44 | 0.01 | 0.69 | 92.03 | 3.38 | 2.51 | 33.57 |

| Corn stover transport and pre-treatment | 2.22 | 0.08 | 0.01 | 0.24 | 0.00 | 0.19 | 0.00 | 0.21 | 11.72 | 0.43 | 0.21 | 2.75 |

| Anaerobic digestion process | 553.80 | 21.13 | 2.14 | 44.92 | 0.19 | 32.30 | 0.56 | 42.39 | 1007.09 | 37.00 | 1.94 | 25.99 |

| Homogenate | 50.02 | 1.91 | 0.27 | 5.56 | 0.02 | 2.88 | 0.08 | 5.90 | 167.47 | 6.15 | 0.29 | 3.92 |

| Cotton residue for heat | 46.95 | 1.79 | 0.80 | 16.85 | 0.11 | 17.75 | 0.17 | 12.61 | 161.37 | 5.93 | 0.46 | 6.21 |

| Anaerobic digestion | 456.84 | 17.43 | 1.08 | 22.51 | 0.07 | 11.67 | 0.31 | 23.88 | 678.25 | 24.92 | 1.18 | 15.87 |

| Biogas upgrading for CBG process | 474.69 | 18.11 | 2.53 | 52.91 | 0.16 | 27.35 | 0.74 | 55.95 | 1589.07 | 58.38 | 2.78 | 37.18 |

| H2S removal | 50.36 | 1.92 | 0.27 | 5.59 | 0.02 | 2.90 | 0.08 | 5.94 | 168.59 | 6.19 | 0.29 | 3.94 |

| Final H2S removal, CO2 removal and gas compression | 424.33 | 16.19 | 2.26 | 47.32 | 0.15 | 24.44 | 0.66 | 50.01 | 1420.48 | 52.19 | 2.48 | 33.23 |

| Digester effluent treatment process | 1578.70 | 60.24 | 0.03 | 0.72 | 0.23 | 38.73 | 0.01 | 0.77 | 21.83 | 0.80 | 0.04 | 0.51 |

| Solid and liquid separation | 6.52 | 0.25 | 0.03 | 0.72 | 0.00 | 0.38 | 0.01 | 0.77 | 21.83 | 0.80 | 0.04 | 0.51 |

| Solid and liquid storage | 1572.21 | 59.99 | 0.00 | 0.00 | 0.23 | 38.35 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Total | 2,620.62 | 100 | 4.78 | 100 | 0.60 | 100 | 1.31 | 100 | 2,721.74 | 100 | 7.47 | 100 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Ni, J.-Q.; Zhu, W.; Xie, G. Life Cycle Assessment of Large-scale Compressed Bio-natural Gas Production in China: A Case Study on Manure Co-digestion with Corn Stover. Energies 2019, 12, 429. https://doi.org/10.3390/en12030429

Yang Y, Ni J-Q, Zhu W, Xie G. Life Cycle Assessment of Large-scale Compressed Bio-natural Gas Production in China: A Case Study on Manure Co-digestion with Corn Stover. Energies. 2019; 12(3):429. https://doi.org/10.3390/en12030429

Chicago/Turabian StyleYang, Yang, Ji-Qin Ni, Wanbin Zhu, and Guanghui Xie. 2019. "Life Cycle Assessment of Large-scale Compressed Bio-natural Gas Production in China: A Case Study on Manure Co-digestion with Corn Stover" Energies 12, no. 3: 429. https://doi.org/10.3390/en12030429

APA StyleYang, Y., Ni, J.-Q., Zhu, W., & Xie, G. (2019). Life Cycle Assessment of Large-scale Compressed Bio-natural Gas Production in China: A Case Study on Manure Co-digestion with Corn Stover. Energies, 12(3), 429. https://doi.org/10.3390/en12030429