Mechanisms and Influence of Casing Shear Deformation near the Casing Shoe, Based on MFC Surveys during Multistage Fracturing in Shale Gas Wells in Canada

Abstract

:1. Introduction

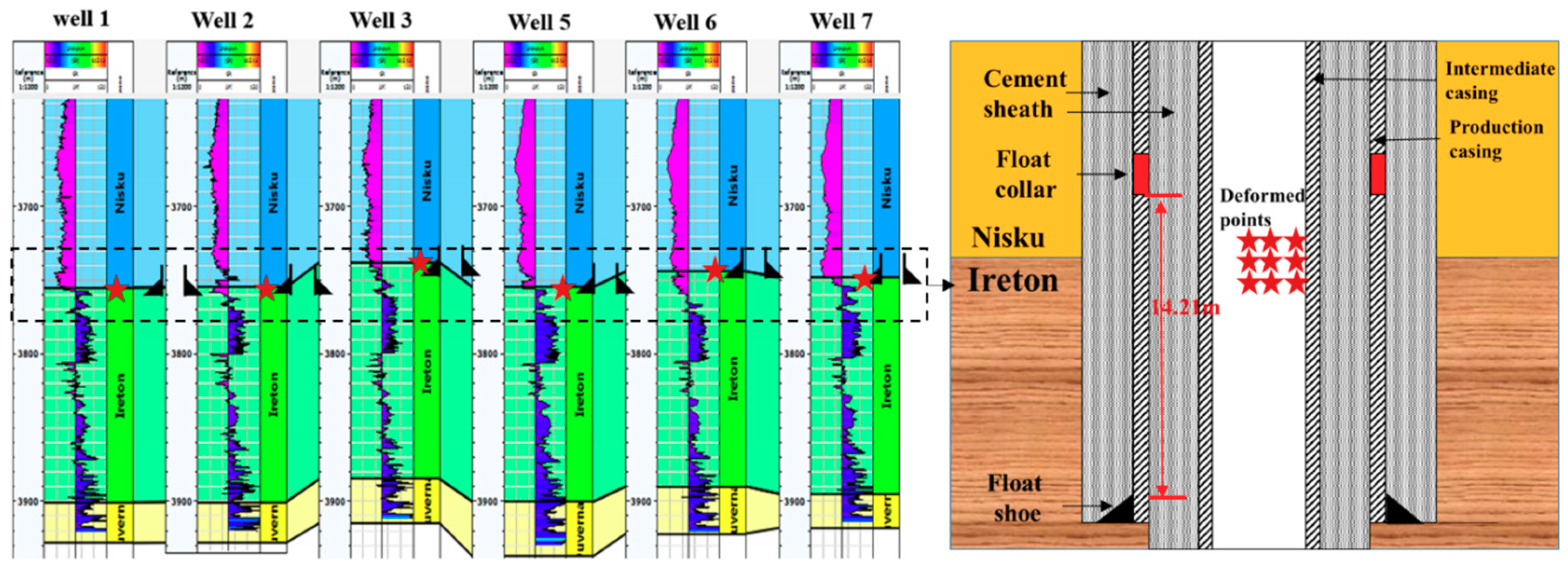

2. Overview of Casing Shear Deformation in Simonette

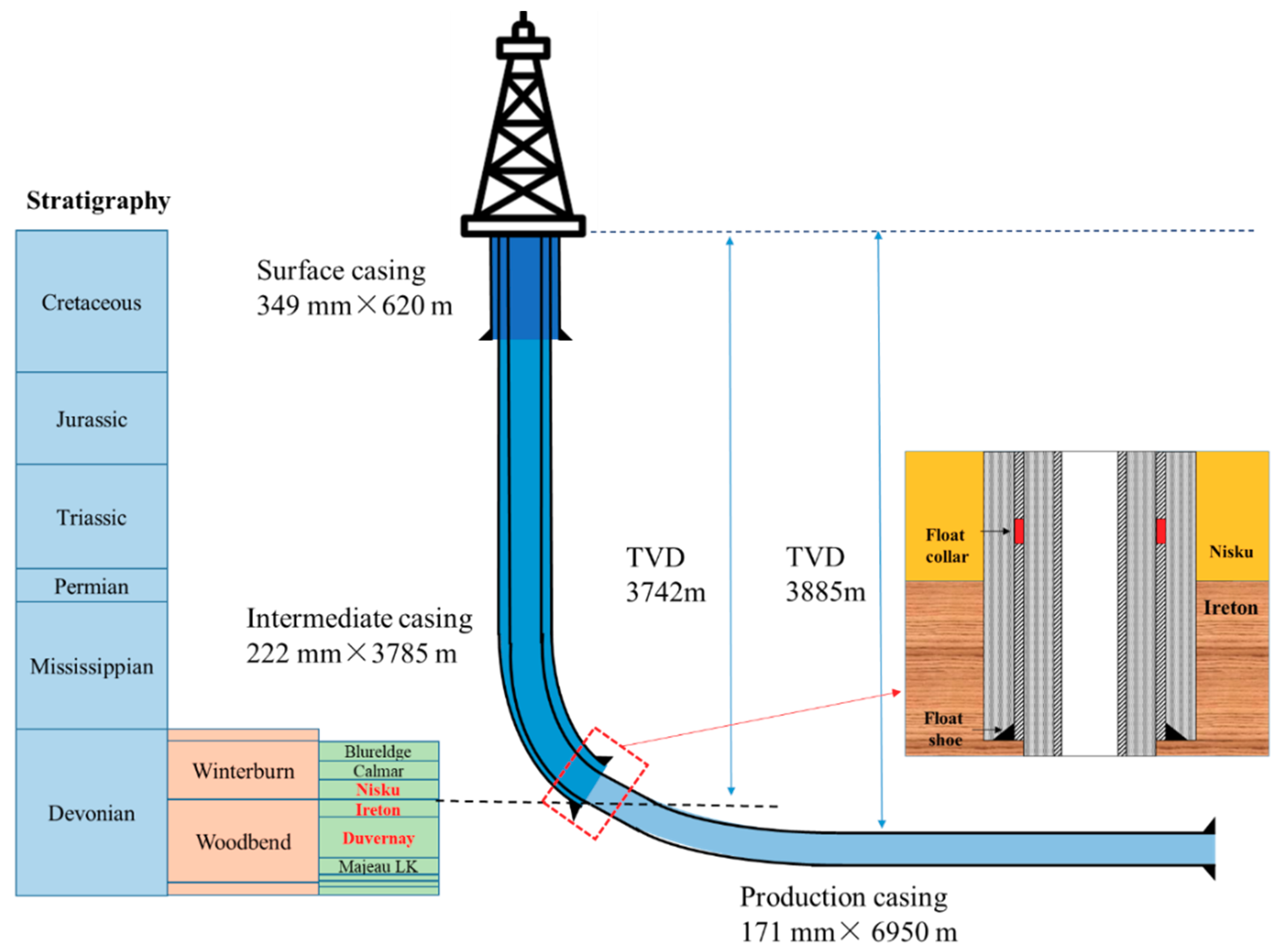

2.1. Field Description

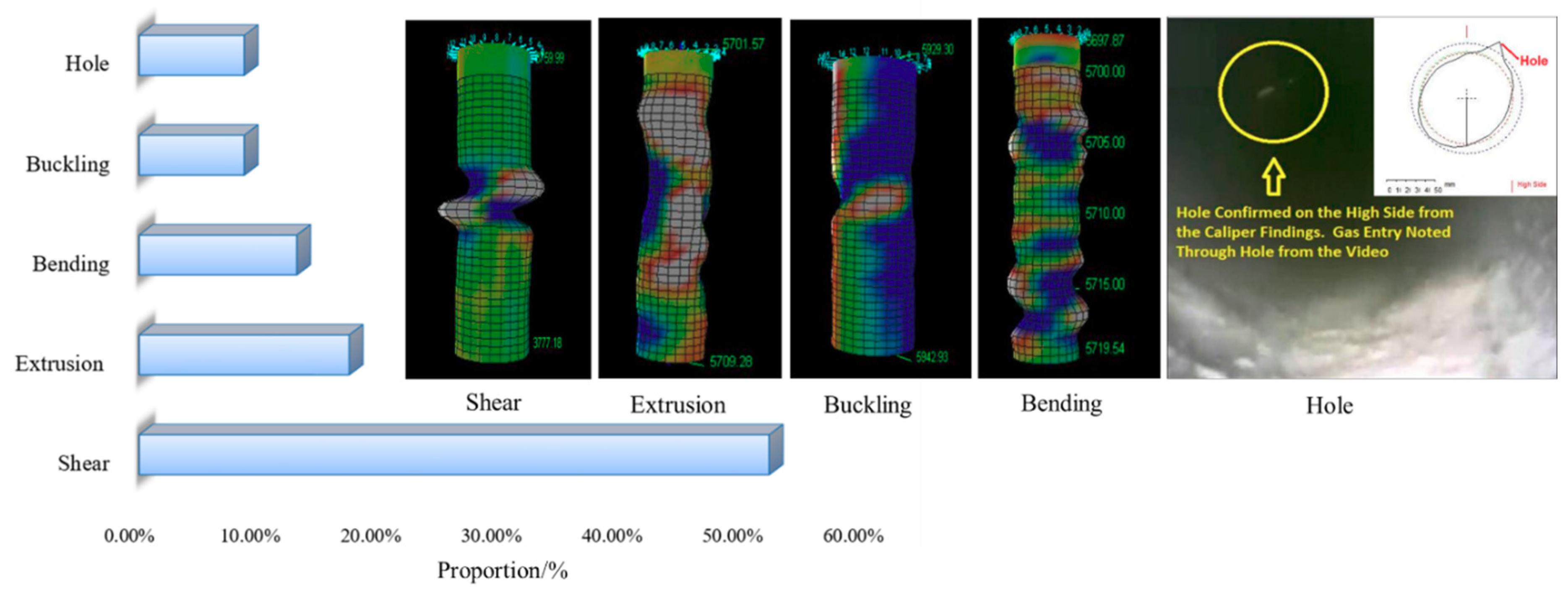

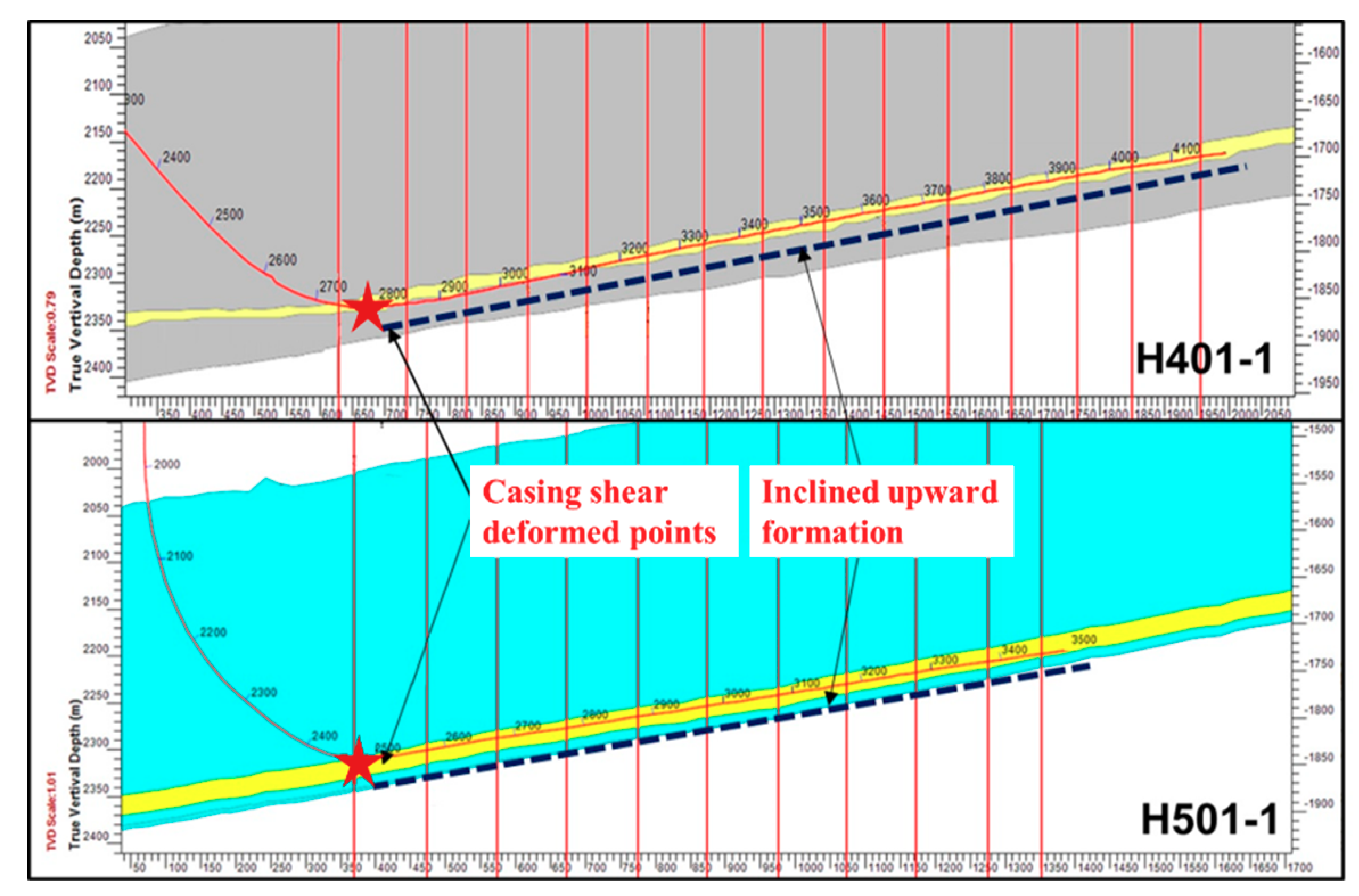

2.2. Casing Shear Deformation

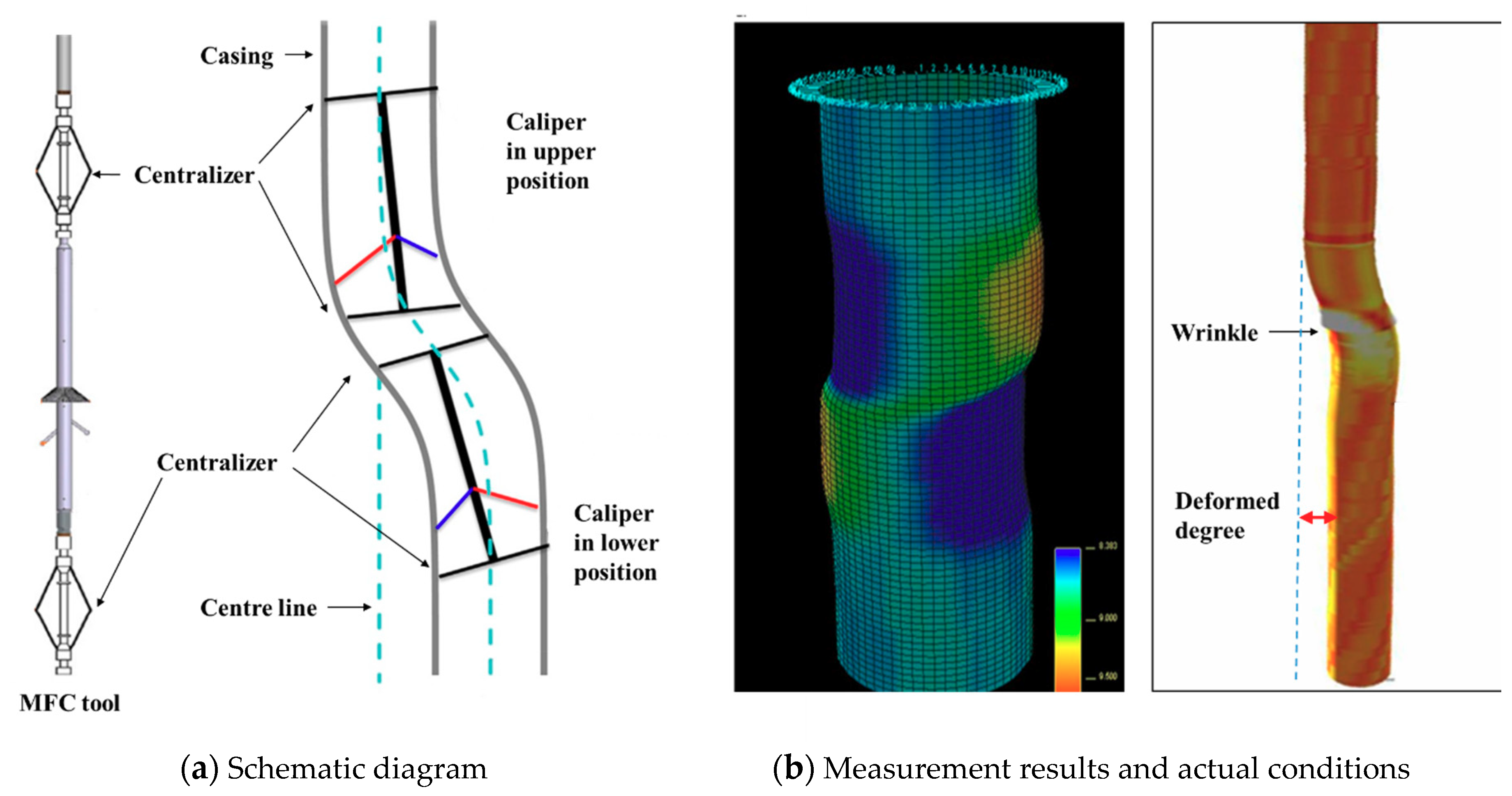

2.3. Difference Between Measurement Results and Actual Shear Deformation

3. Mechanisms of Casing Shear Deformation induced by Multistage Fracturing

3.1. Mechanisms of Casing Shear Deformation

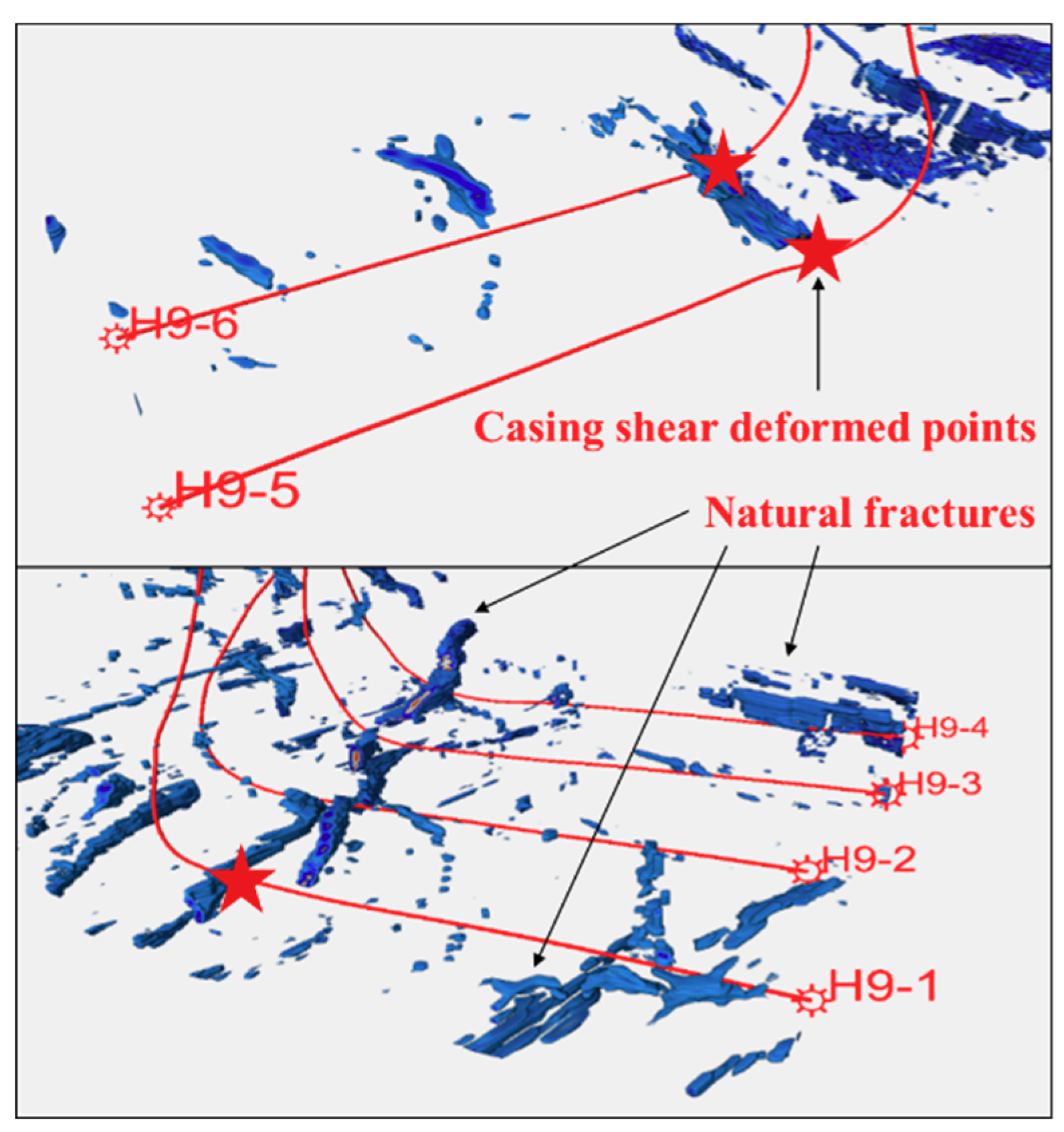

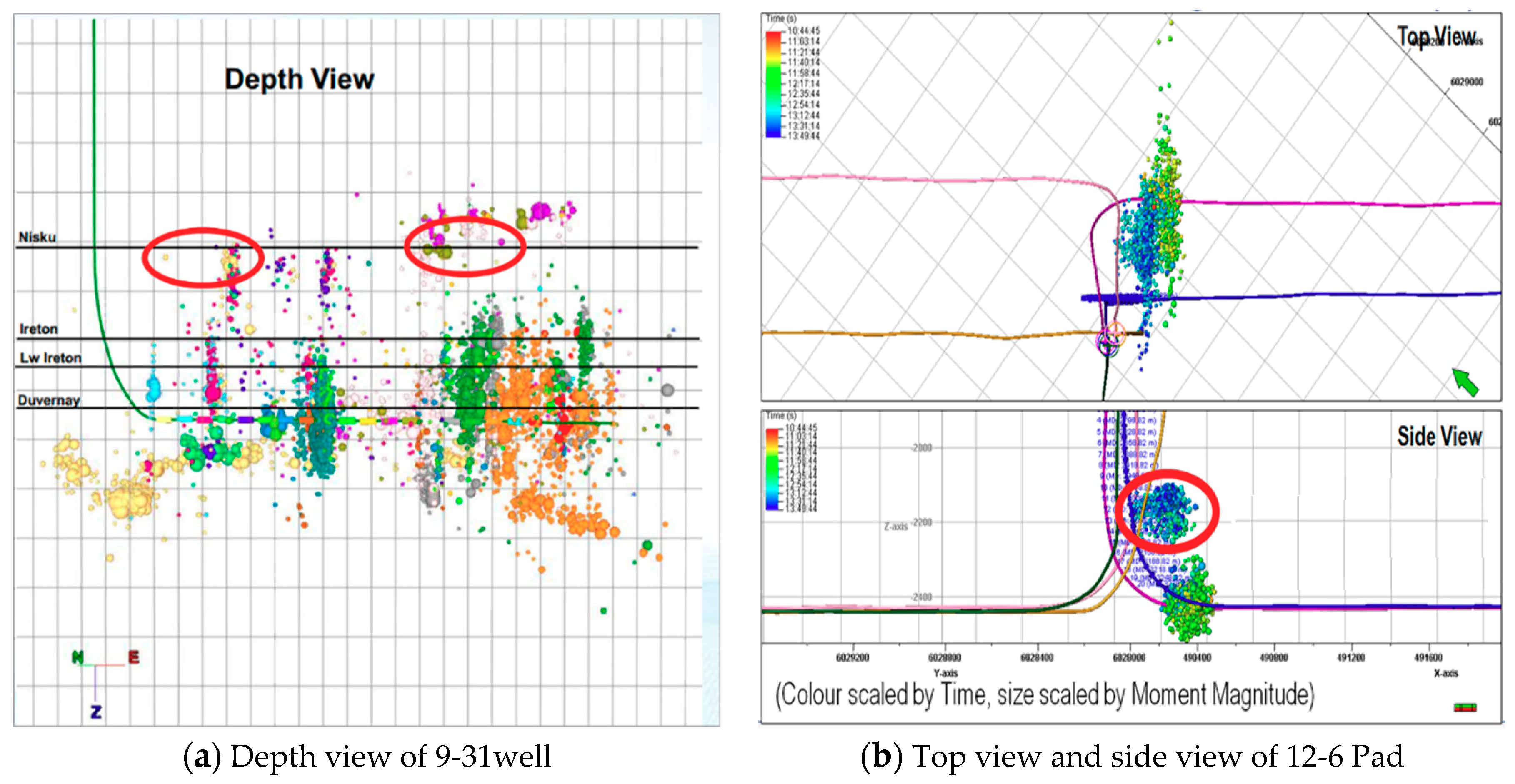

3.2. Verification of Fault Slipping

4. Numerical Simulation

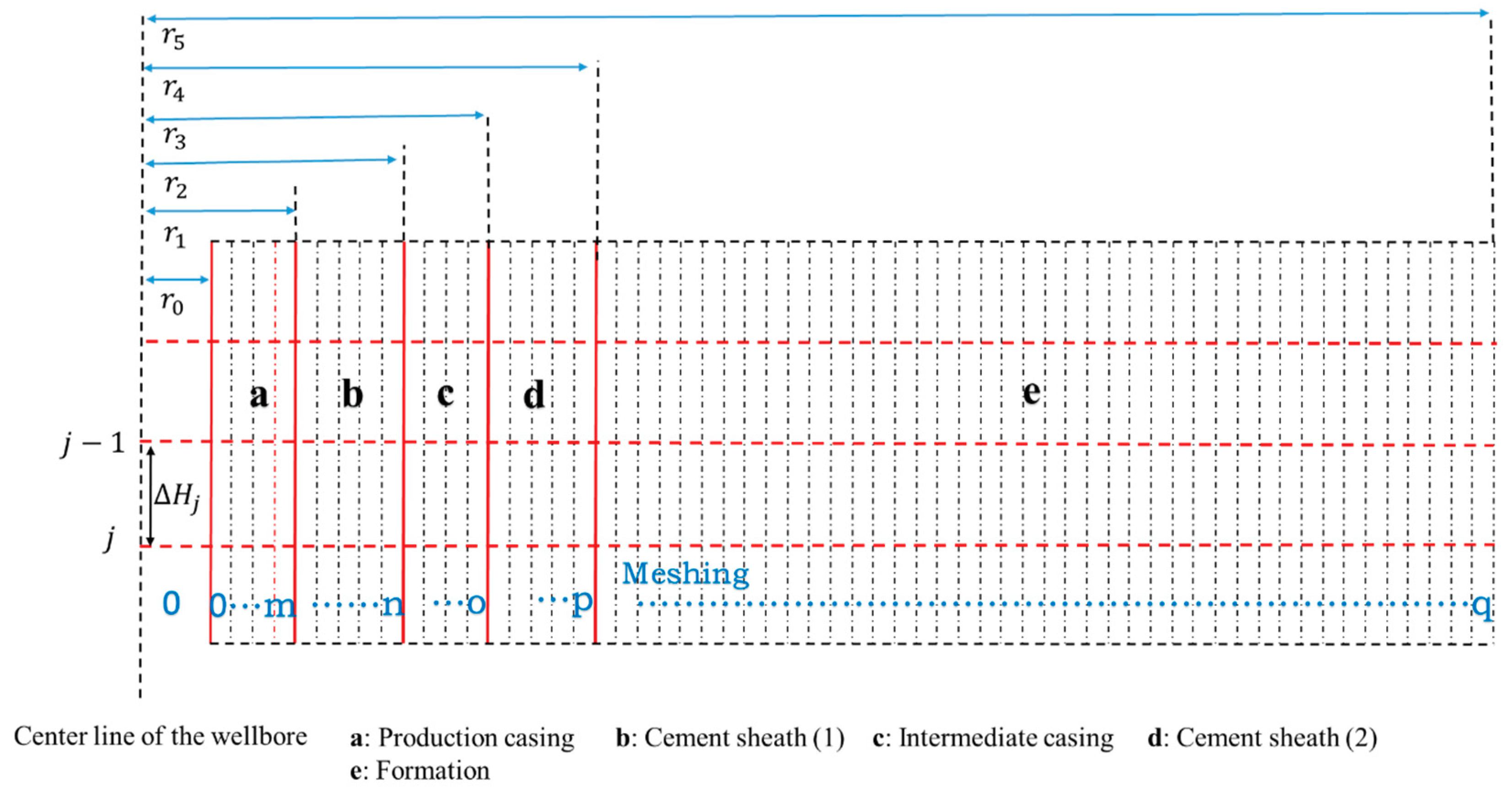

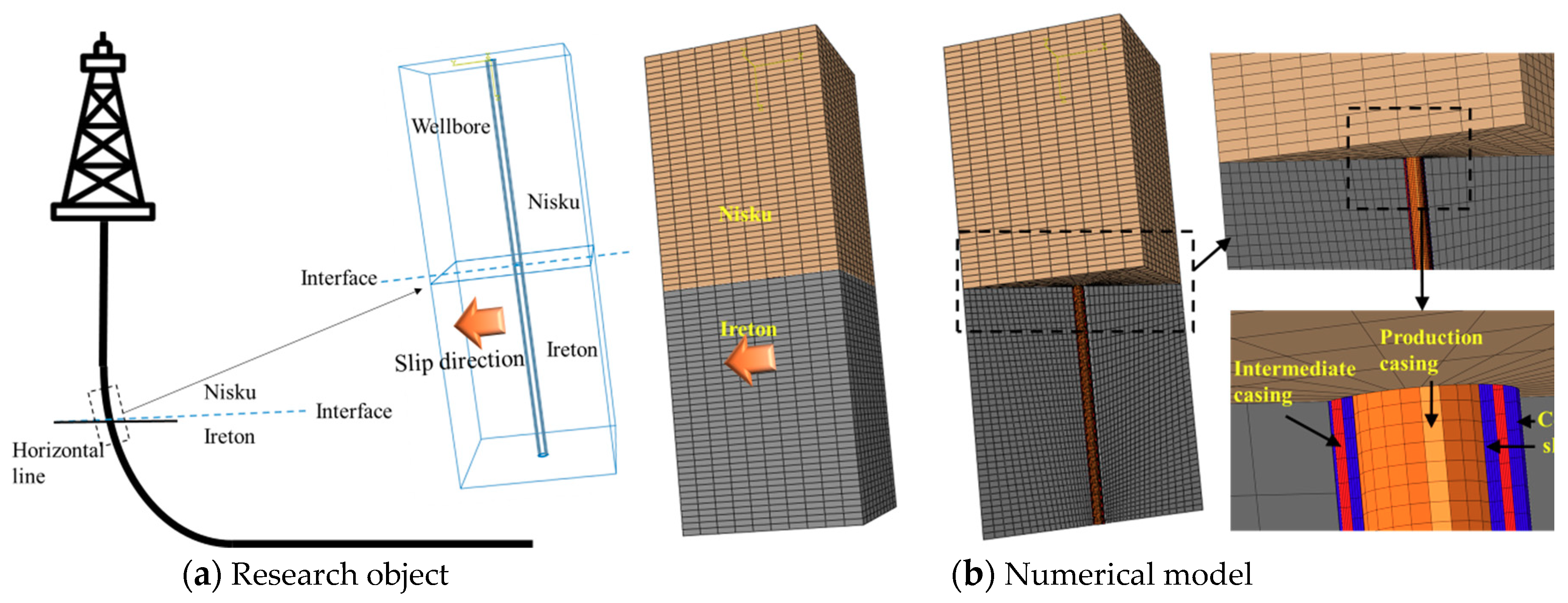

4.1. Model Geometry and Discretization

4.2. Boundary Conditions and Simulation Steps

4.3. Geological and Mechanical Parameters

5. Results

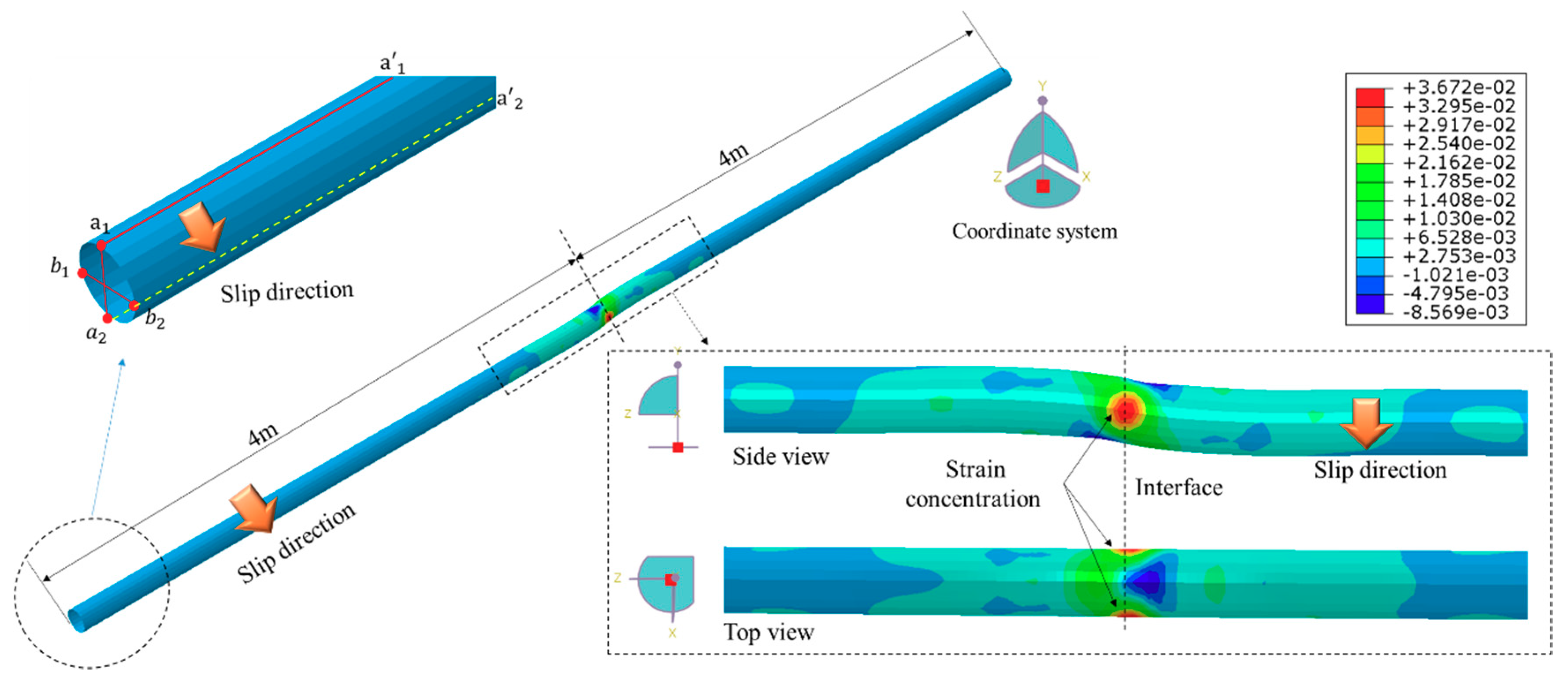

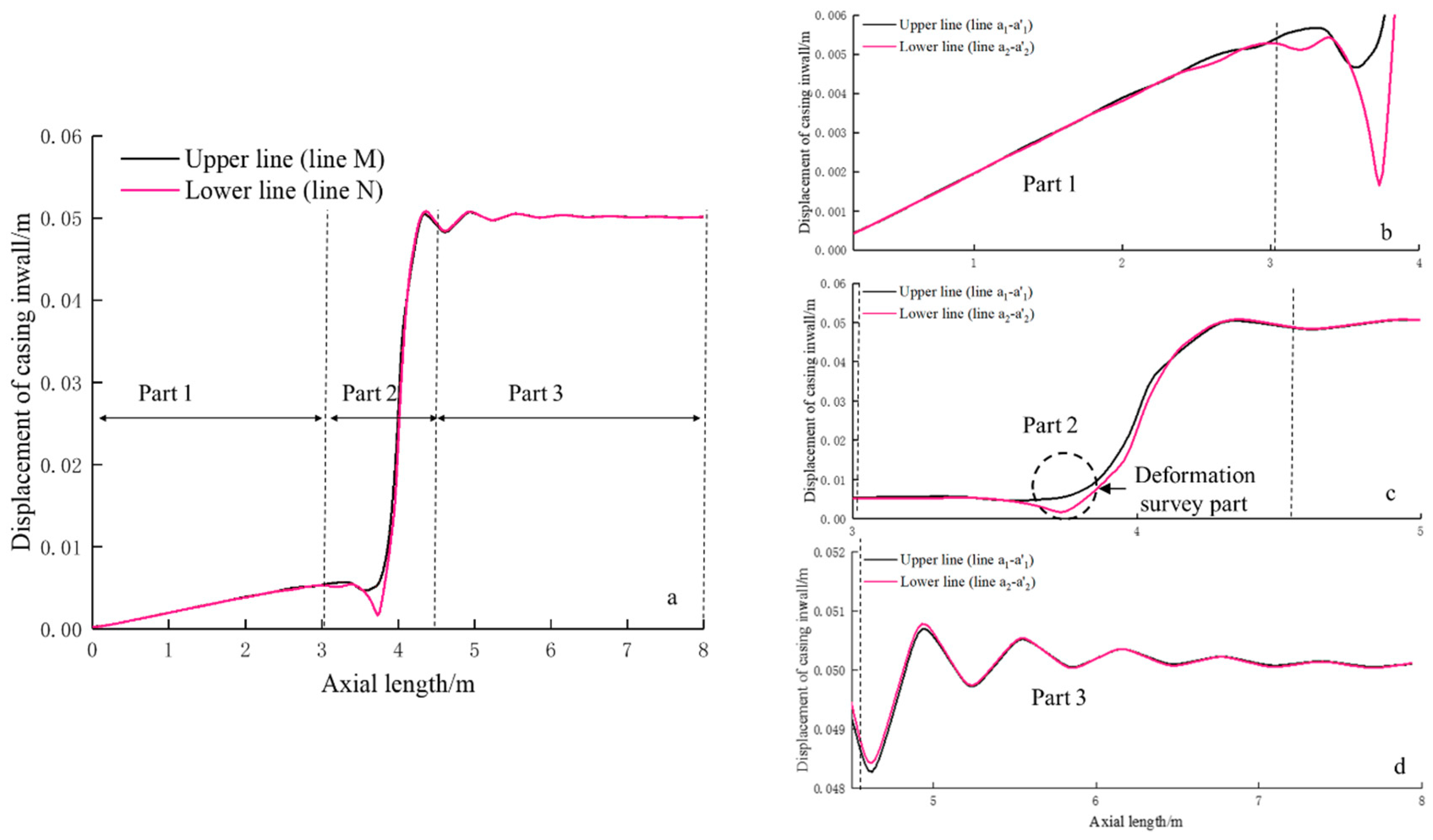

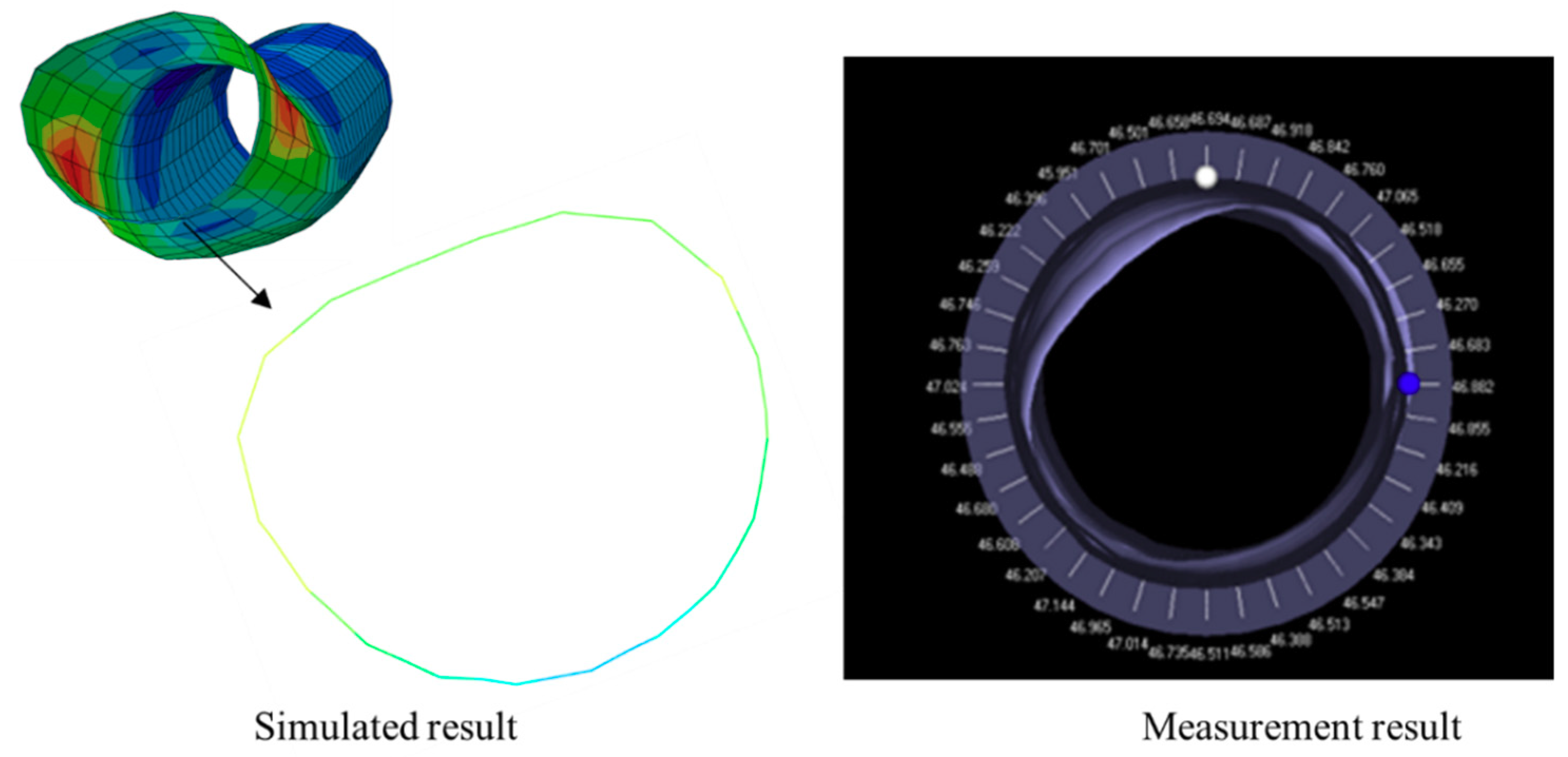

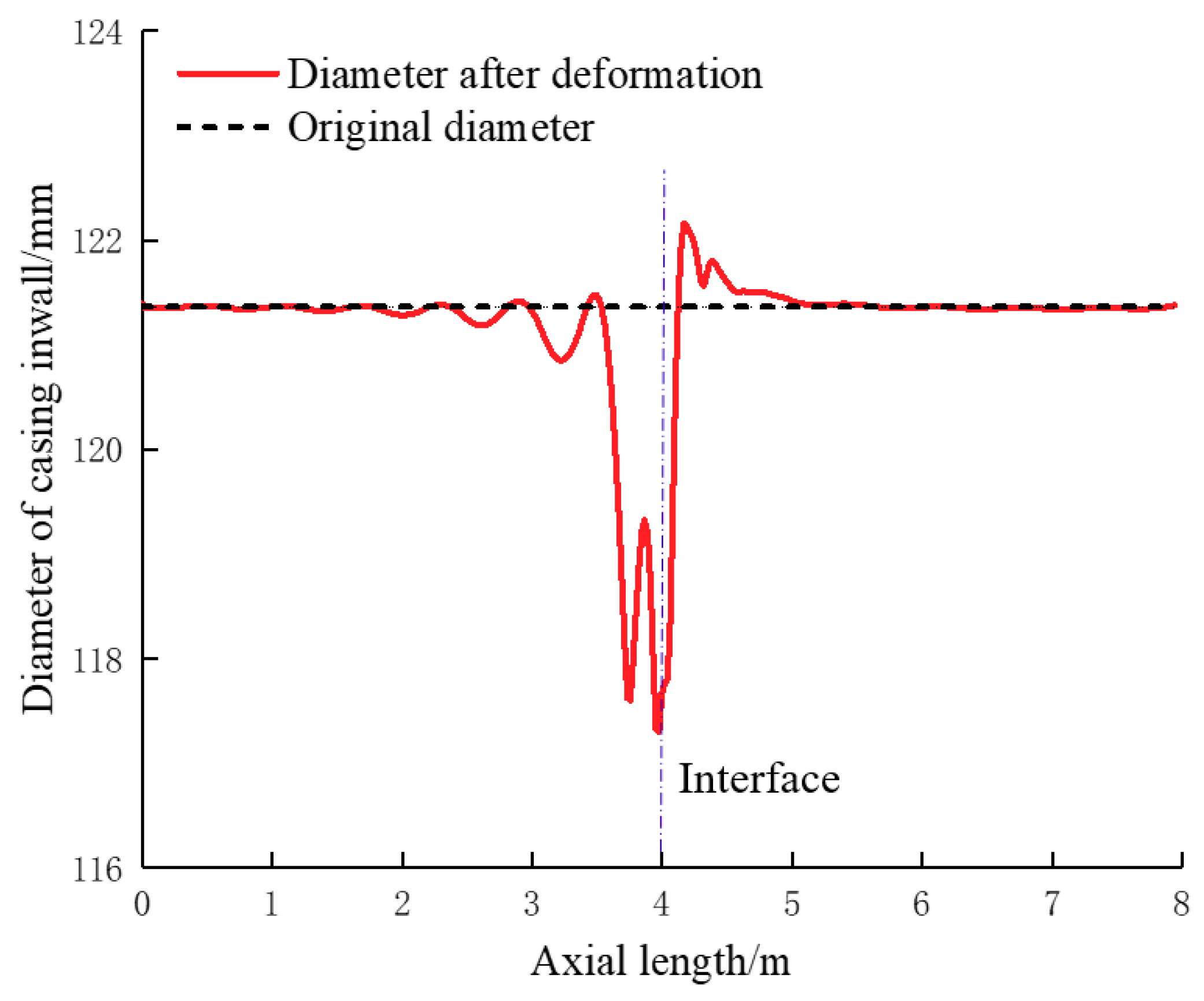

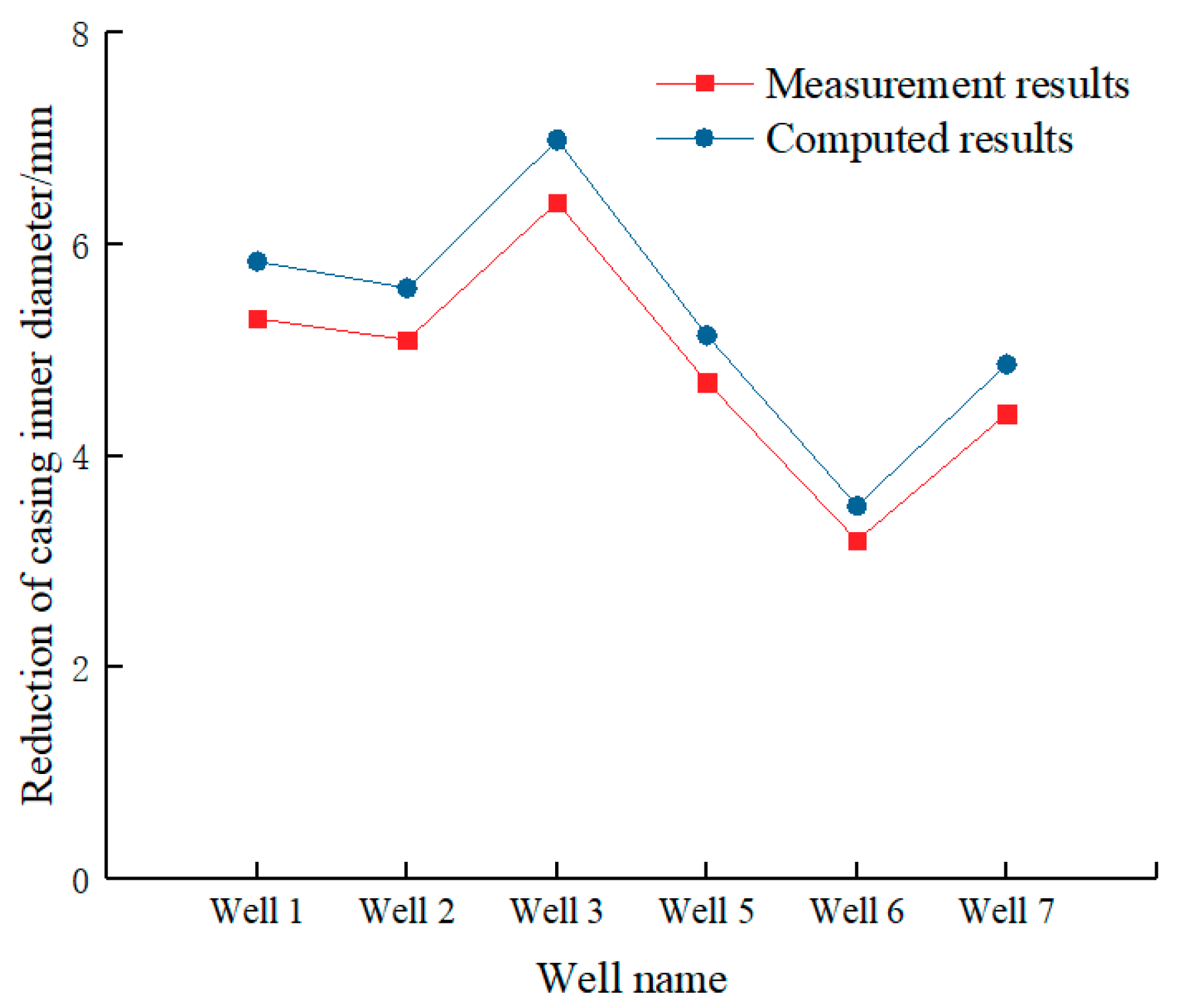

5.1. Engineering Verification of the Numerical Simulation

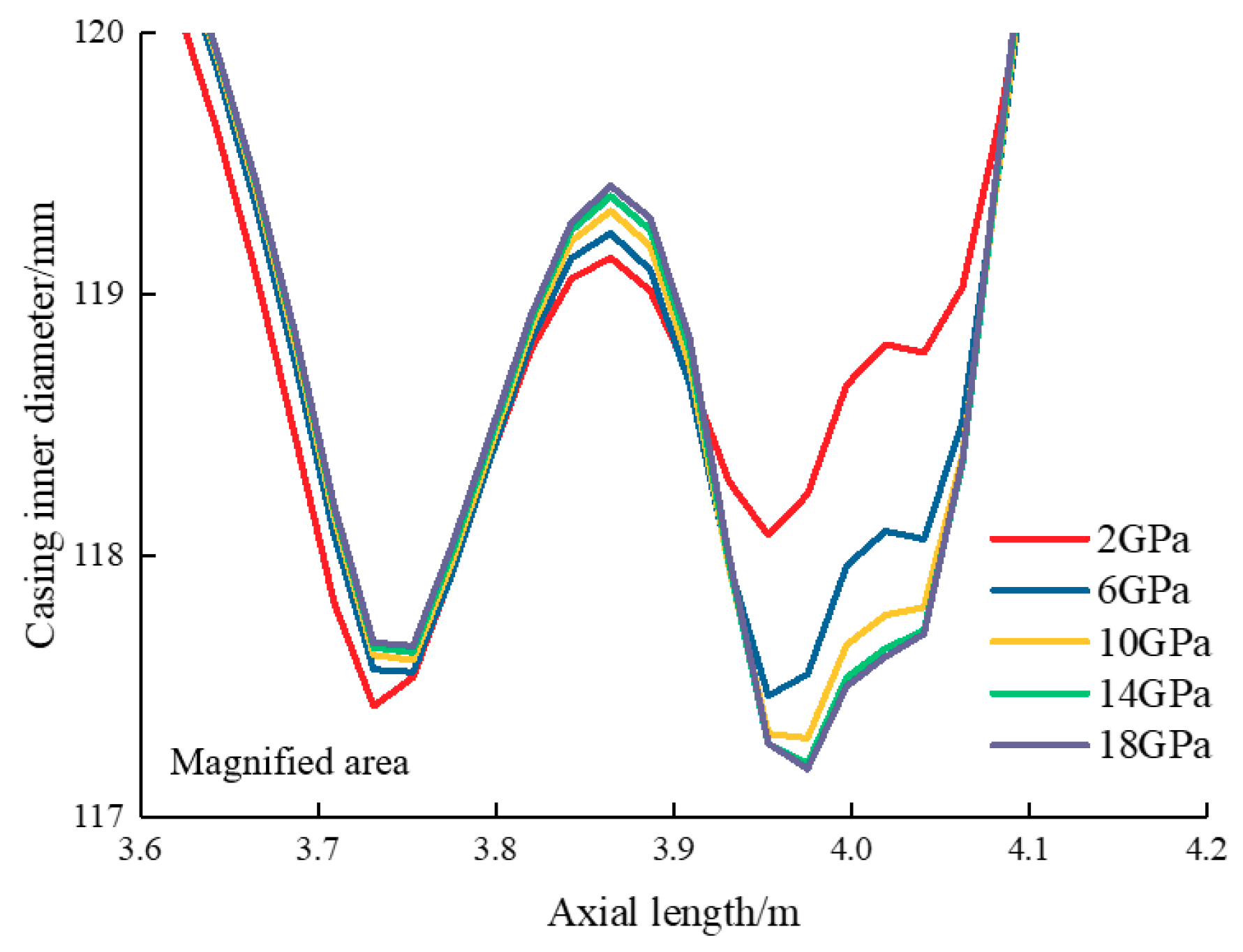

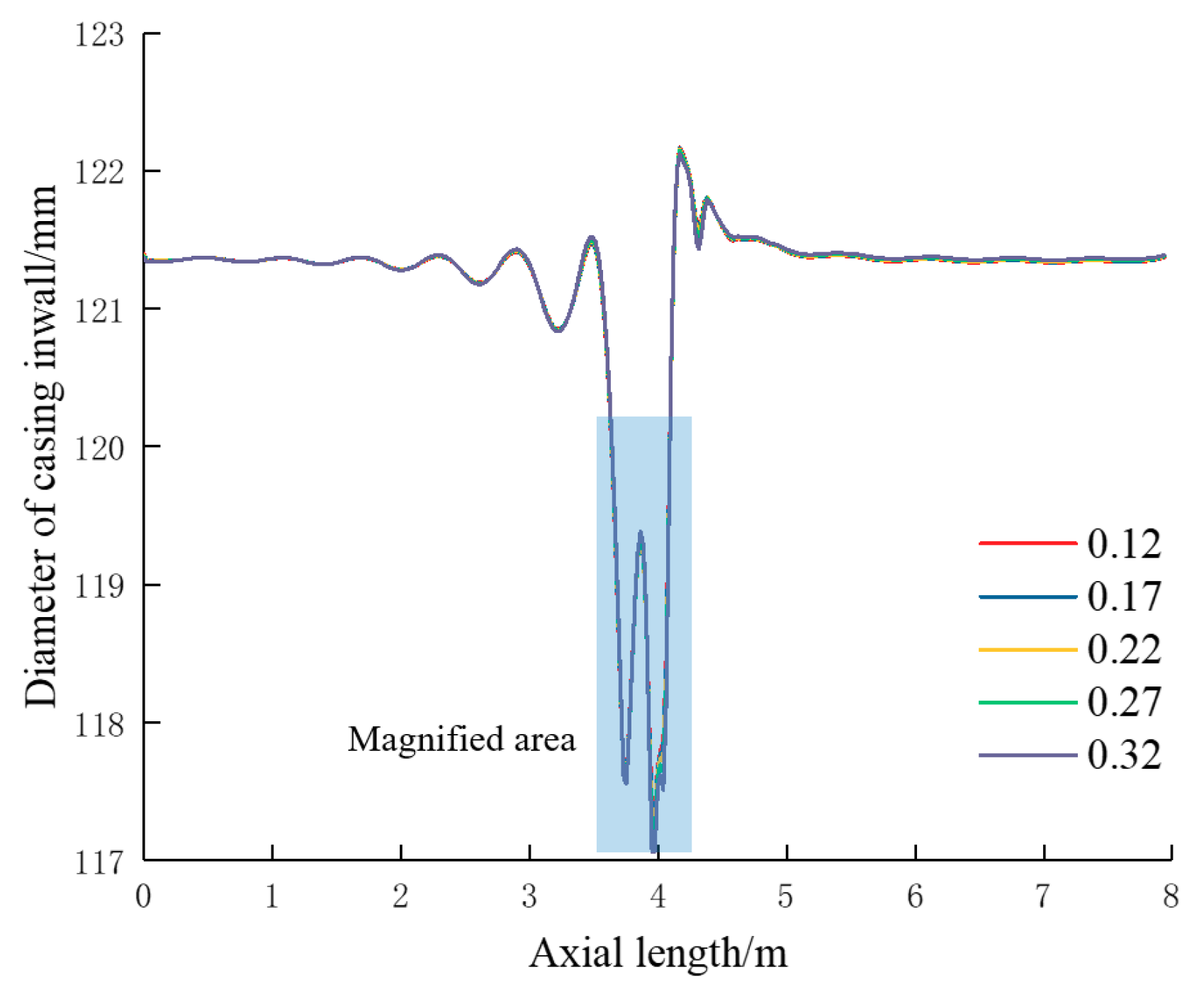

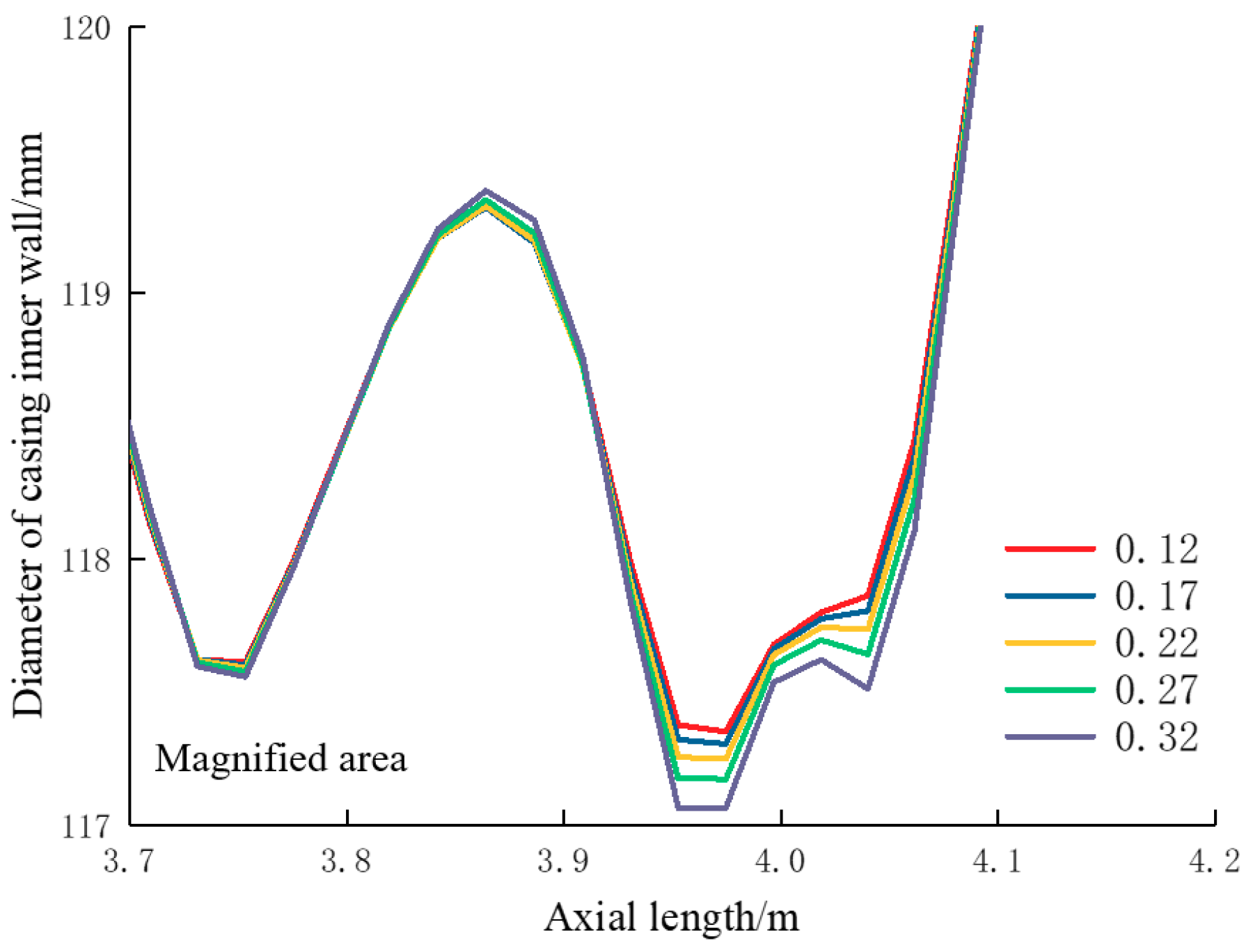

5.2. Sensitivity Analysis of Casing Shear Deformation

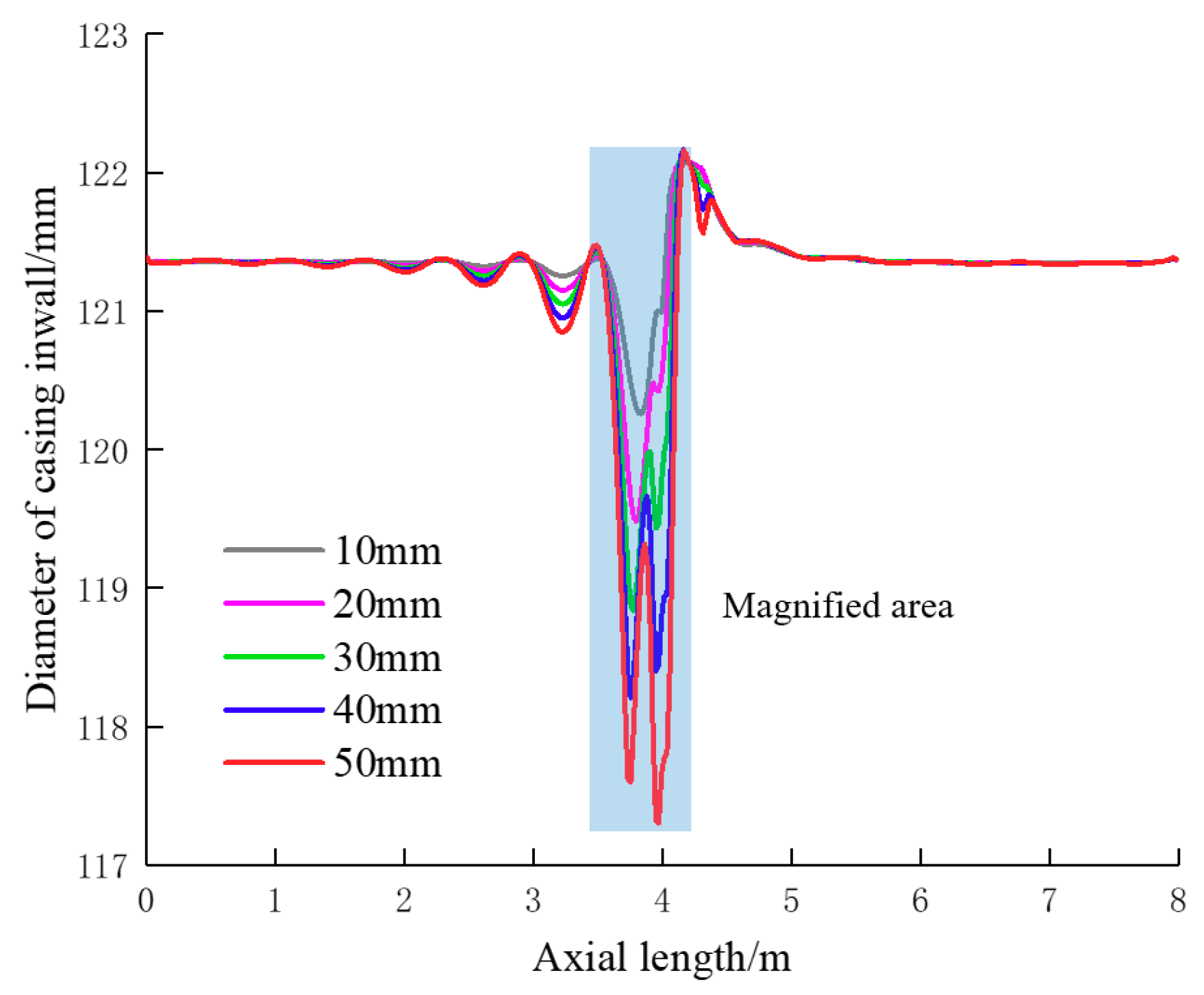

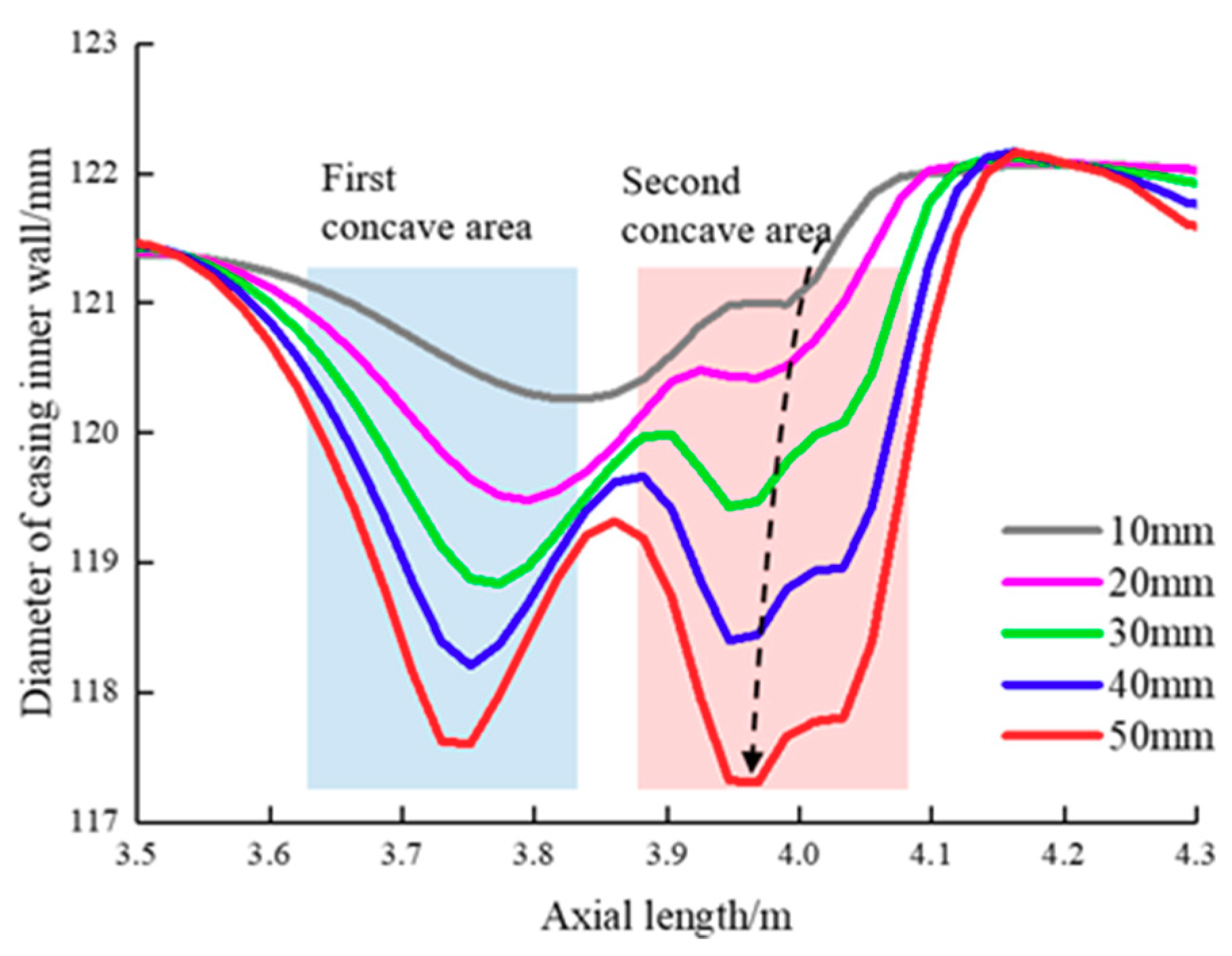

5.2.1. Influence of Slip Distance

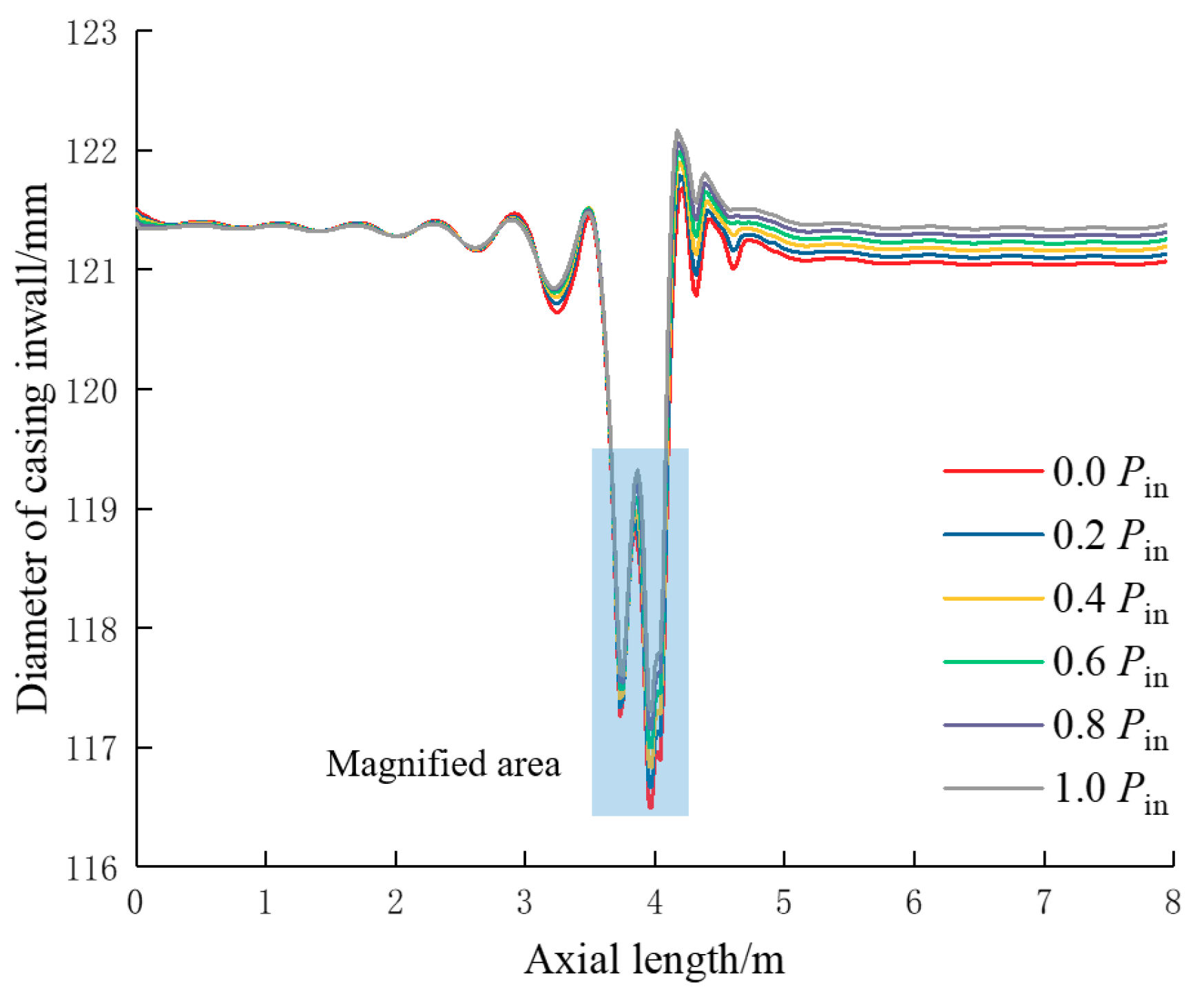

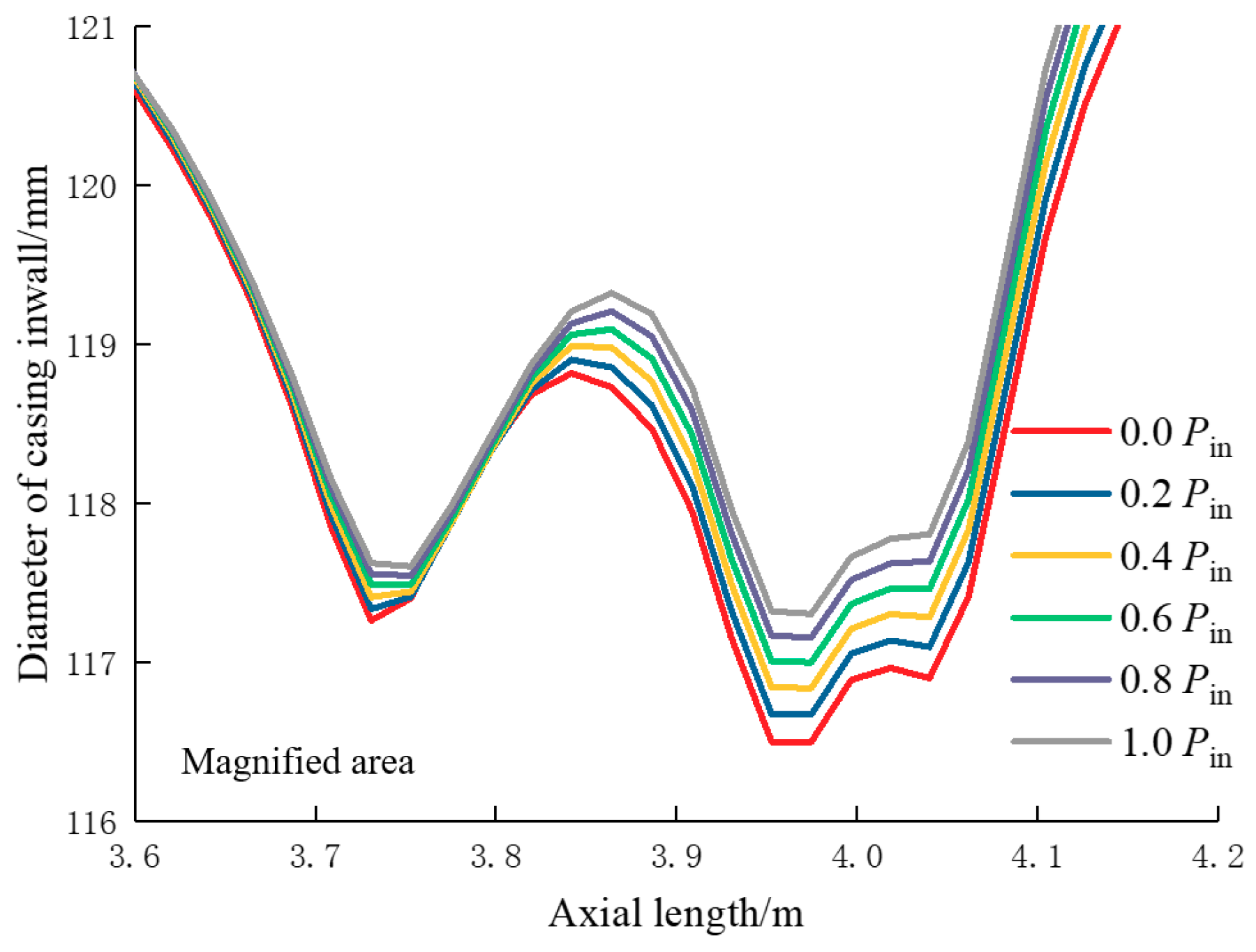

5.2.2. Influence of Casing Inner Pressure

5.2.3. Influence of Casing Thickness

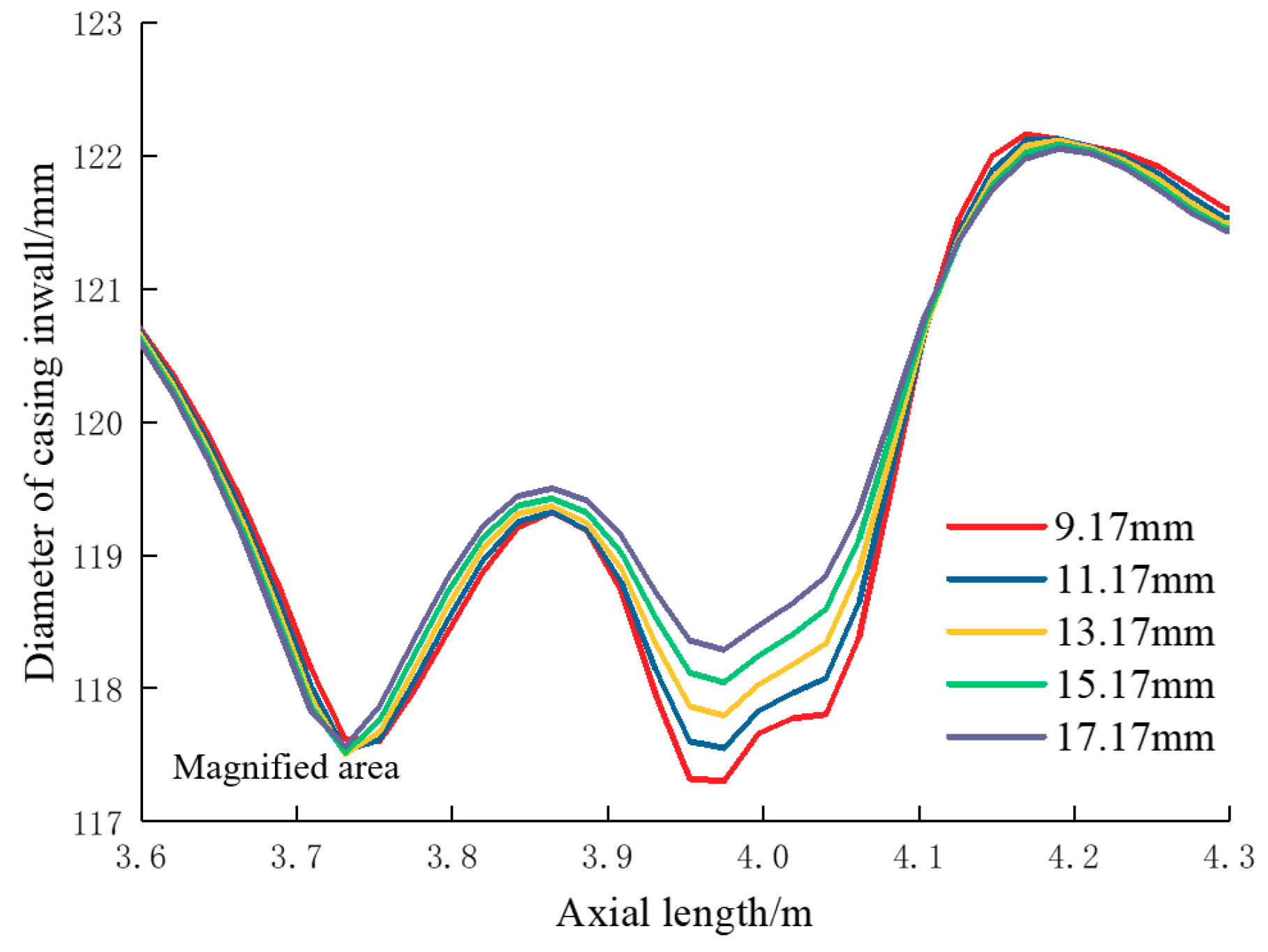

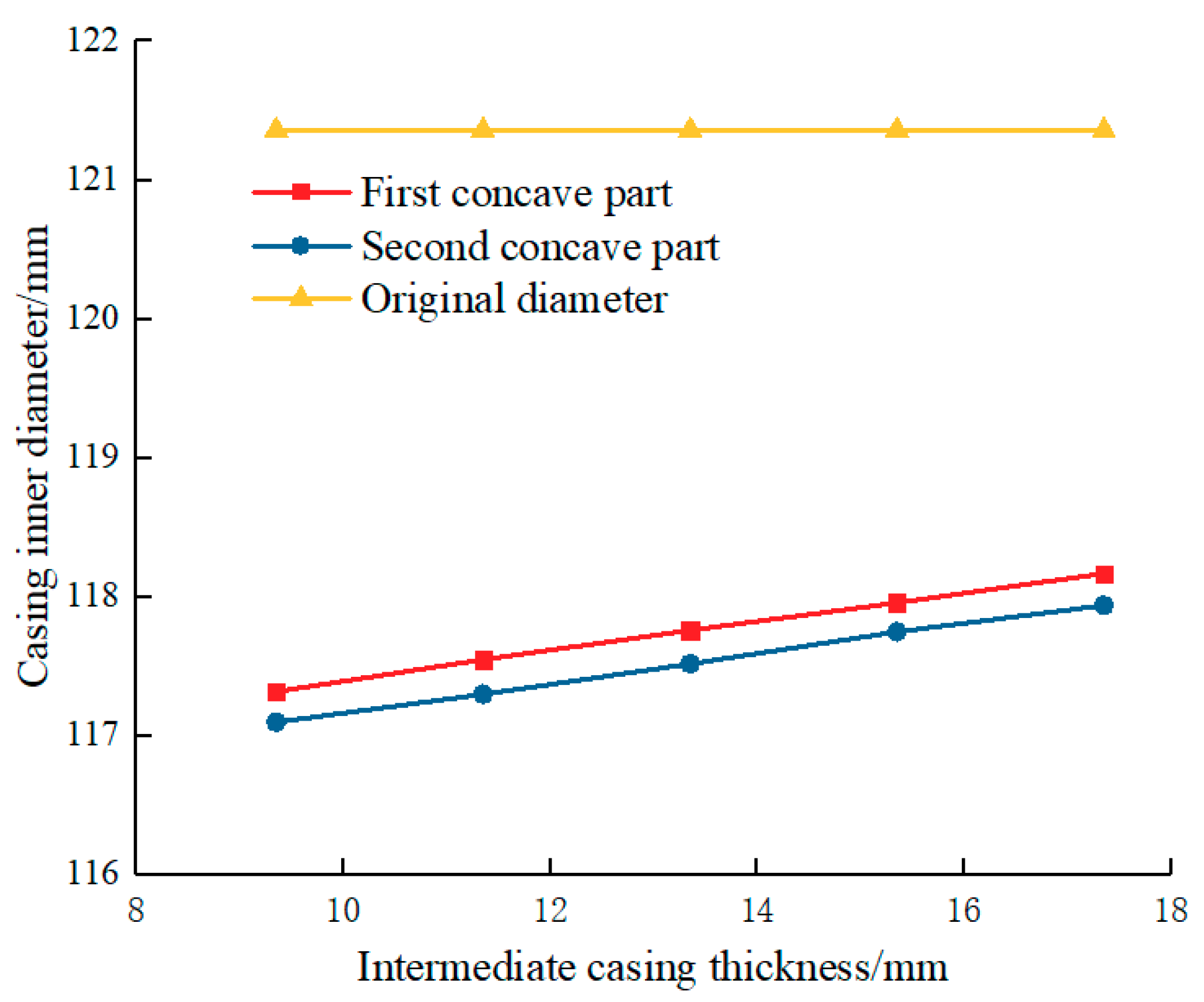

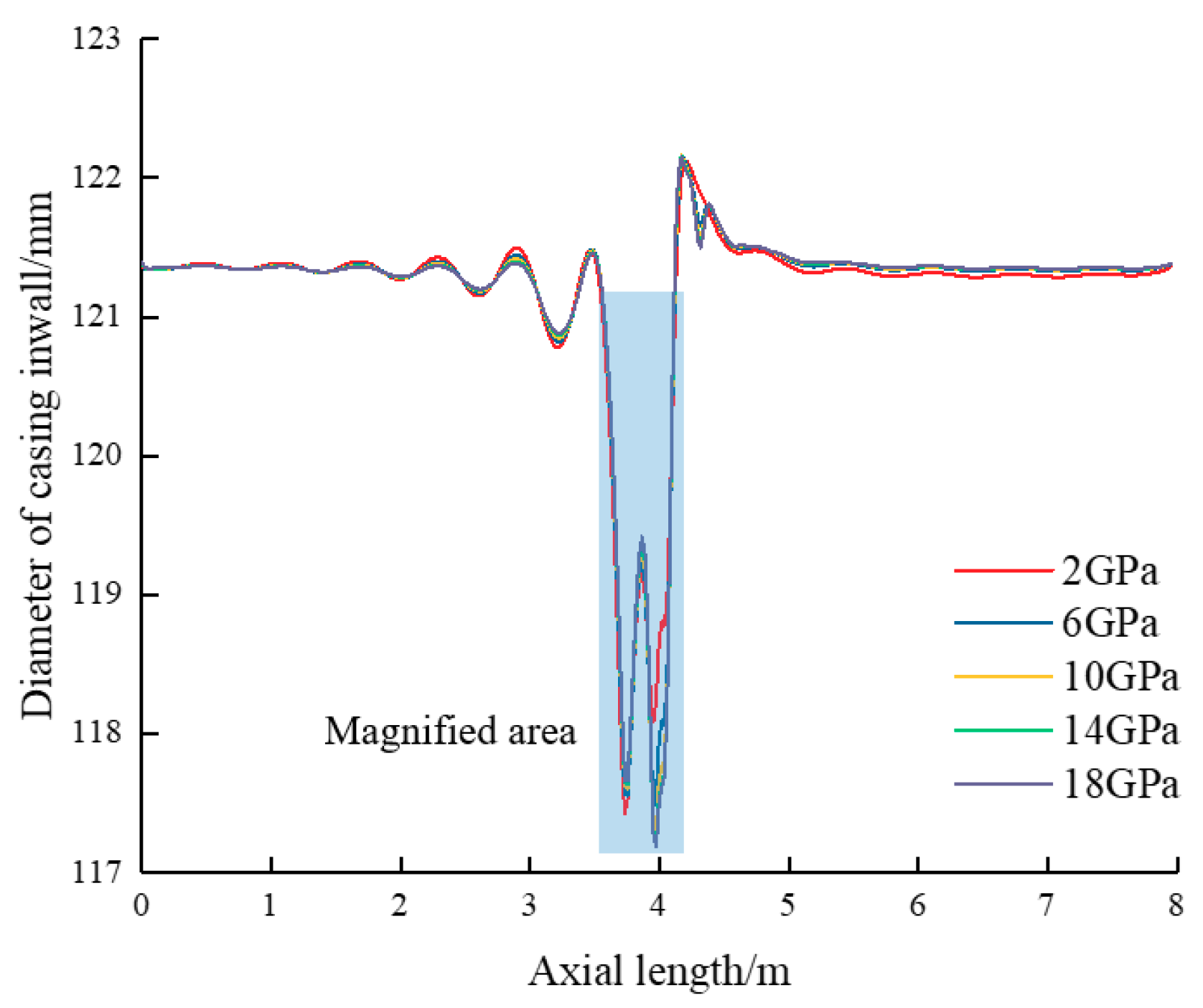

5.2.4. Influence of Cement Sheath Mechanical Parameters

6. Results Comparison and Mitigation Method

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

References

- Meyer, B.R.; Bazan, L.W. A Discrete Fracture Network Model for Hydraulically Induced Fractures-Theory, Parametric and Case Studies. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, Woodlands, TX, USA, 24–26 January 2011. [Google Scholar]

- Wu, Q.; Xu, Y.; Zhang, S.; Wang, T.; Guan, B.; Wu, G.; Wang, X. The Core Theories and Key Optimization Design of Volume Simulation Technology for Unconventional Reservoirs. Acta Petrolei Sin. 2014, 35, 706–714. [Google Scholar]

- Zhou, D.; Zheng, P.; He, P.; Peng, J. Hydraulic Fracture Propagation Direction during Volume Fracturing in Unconventional Reservoirs. J. Petrol. Sci. Eng. 2016, 141, 82–89. [Google Scholar] [CrossRef]

- Wang, F.; Li, B.; Zhang, Y.; Zhang, S. Coupled Thermo-Hydro-Mechanical-Chemical Modeling of Water Leak-Off Process during Hydraulic Fracturing in Shale Gas Reservoirs. Energies 2017, 10, 1960. [Google Scholar] [CrossRef]

- Tao, H.; Zhang, L.; Liu, Q.; Qi, D.; Luo, M.; Zhao, Y. An Analytical Flow Model for Heterogeneous Multi-Fractured Systems in Shale Gas Reservoirs. Energies 2018, 11, 3422. [Google Scholar] [CrossRef]

- Bao, X.; David, W.E. Fault Activation by Hydraulic Fracturing in Western Canada. Science 2016, 17, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Nagel, N.B.; Garcia, X.; Sanchez Nagel, M.A.; Lee, B. Understanding “SRV”: A Numerical Investigation of “Wet” vs. “Dry” Microseismicity during Hydraulic Fracturing. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- Lian, Z.; Yu, H.; Lin, T.; Guo, J. A Study on Casing Deformation Failure during Multi-Stage Hydraulic Fracturing for the Stimulated Reservoir Volume of Horizontal Shale Wells. J. Nat. Gas Sci. Eng. 2015, 23, 538–546. [Google Scholar] [CrossRef]

- Jalali, H.H.; Rofooei, F.R.; Attarin, N.K.A.; Samadianc, M. Experimental and Finite Element Study of the Reverse Faulting Effects on Buried Continuous Steel Gas Pipelines. Soil Dyn. Earthq. Eng. 2016, 86, 1–14. [Google Scholar] [CrossRef]

- Adams, N.J.; Mitchell, R.F.; Eustes, A.W.; Sampaio, J.H.; Antonio, A.O. A Causation Investigation for Observed Casing Failures Occurring during Fracturing Operations. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Woodlands, TX, USA, 24–26 January 2017. [Google Scholar]

- Meyer, J.J.; Gallop, J.; Chen, A.; Reynods, S.; Mildren, S. Can Seismic Inversion Be Used for Geomechanics? A Casing Deformation Example. In Proceedings of the Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. [Google Scholar]

- Saada, M.; Ismail, M.; Lu, Y.; Zhang, W.; Moula, M. Measure The Effectiveness of Frac Sleeves Integrity in Multi-Stage Completions Using Multi-Finger Caliper and Acoustic Flow-Analyzer. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Damman, Saudi Arbia, 23–26 April 2018. [Google Scholar]

- Simon, S.; Husam, A.R.; Basant, K.S.; Graeme, D. OCTG Corrosion Status Monitoring in Wells Completed with Challenging High Ni CRA Non-Magnetic OCTG in Gas Well Environment with Higher Temperature, Extreme Hydrogen Sulphide and Reservoir Conditions–A Case Study. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, 12–15 November 2018. [Google Scholar]

- Yan, W.; Zou, L.; Li, H.; Deng, J.; Ge, H.; Wang, H. Investigation of Casing Deformation During Hydraulic Fracturing in High Geo-Stress Shale Gas Play. J. Petrol. Sci. Eng. 2017, 150, 22–29. [Google Scholar] [CrossRef]

- Xi, Y.; Li, J.; Liu, G.; Cha, C.; Fu, Y. Numerical Investigation for Different Casing Deformation Reasons in Weiyuan-Changning Shale Gas Field During Multistage Hydraulic Fracturing. J. Petrol. Sci. Eng. 2018, 163, 691–702. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, P.; Xiang, D. Analysis of Casing Deformation in the Changning-Weiyuan Block Based on Focal Mechanism. Petrol. Drill. Tech. 2017, 45, 110–114. [Google Scholar]

- Noshi, C.I.; Noynaert, S.F.; Schubert, J.J. Casing Failure Data Analytics: A Novel Data Mining Approach in Predicting Casing Failures for Improved Drilling Performance and Production Optimization. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24–26 September 2018. [Google Scholar]

- Chen, Z.; Shi, L.; Xiang, D. Mechanism of Casing Deformation in the Changning–Weiyuan National Shale Gas Project Demonstration Area and Countermeasures. Nature Gas Ind. 2016, 36, 70–75. [Google Scholar]

- Yin, F.; Deng, Y.; He, Y.; Gao, D.; Hou, B. Mechanical Behavior of Casing Crossing Slip Formation in Water Flooding Oilfields. J. Petrol. Sci. Eng. 2018, 167, 796–802. [Google Scholar] [CrossRef]

- Qian, B.; Yin, C.; Li, Y.; Xu, B.; Qin, G. Diagnostics of Casing Deformation in Multi-Stage Hydraulic Fracturing Stimulation in Lower Silurian Marine Shale Play In Southwestern, China. In Proceedings of the Unconventional Resources Technology Conference, San Antonio, TX, USA, 20–22 July 2015. [Google Scholar]

- Zoback, M.D.; Snee, J.E.L. Predicted and observed shear on pre-existing faults during hydraulic fracture stimulation. In Proceedings of the SEG International Exposition and 88th Annual Meeting, Anaheim, CA, USA, 14–19 October 2018. [Google Scholar]

- Marc, M. Monitoring Shear Deformations above Compacting High-Pressure High-Temperature Reservoirs With Calliper Surveys. Int. J. Rock Mech. Min. Sci. 2016, 86, 292–302. [Google Scholar]

- Gao, L.; Qiao, L.; Liu, Z.; Zhuang, Z.; Yang, H. Numerical Modeling and Cementing Countermeasure Analysis of Casing Shear Damage in Shale Reservoir. China Petrol. Mach. 2016, 44, 6–10. [Google Scholar]

- Guo, X.; Li, J.; Liu, G.; Zeng, Y.; He, M.; Yan, H. Numerical Simulation of Casing Deformation During Volume Fracturing of Horizontal Shale Gas Wells. J. Petrol. Sci. Eng. 2019, 172, 731–742. [Google Scholar] [CrossRef]

- Davis, M.; Karlen, G.A. Regional Assessment of the Duvernay Formation; A World-Class Liquids-Rich Shale Play. In Proceedings of the GeoConvention 2013: Integration, Calgary, AB, Canada, 6–10 May 2013. [Google Scholar]

- Rodgers, B. Declining Costs Enhance Duvernay Shale Economics. Oil Gas J. 2014, 112, 70. [Google Scholar]

- Fox, A. A Regional Geomechanical Study of the Duvernay Formation in Alberta, Canada. In Proceedings of the GeoConvention 2015: New Horizon, Calgary, AB, Canada, 4–8 May 2015. [Google Scholar]

- Zoback, M.D. Reservoir Geomichanics, 2nd ed.; Cambridge University Press: London, UK, 2010; pp. 43–95. [Google Scholar]

- Biot, M.A. General Theory of three-dimensional consolidation. J. Appl. Phys. 1941, 12, 155–164. [Google Scholar] [CrossRef]

- Goodman, R.E. Introduction to rock mechanics., 2nd ed.; Wiley: Chichester, UK, 1989; pp. 21–78. [Google Scholar]

- Brune, J. Tectonic Stress and the Spectra of Shear Waves from Earthquakes. J. Geophys. Res. 1970, 75, 4997–5009. [Google Scholar] [CrossRef]

- Hanks, T.C.; Kanamori, H. A Moment Magnitude Scale. J. Geophys. Res. 1979, 84, 2348–2350. [Google Scholar] [CrossRef]

- Cipolla, C.L.; Mack, M.G.; Maxwell, S.C.; Downie, R.C. A Practical Guide to Interpreting Microseismic Measurements. In Proceedings of the North American Unconventional Gas Conference and Exhibition, Woodlands, TX, USA, 14–16 June 2011. [Google Scholar]

- Marshall, D.W.; Bentsen, R.G. A computer model to determine the temperature distributions in a wellbore. J. Can. Petrol. Technol. 1982, 21, 63–75. [Google Scholar] [CrossRef]

| Component | Outer Diameter (mm) | Young Modulus (GPa) | Poisson’s Ratio | Cohesive Strength (MPa) | Internal Friction Angle(°) |

|---|---|---|---|---|---|

| Production Casing | 139.7 | 210 | 0.3 | \ | \ |

| Cement Sheath (2) | 171 | 10 | 0.17 | 8 | 27 |

| Intermediate Casing | 193.7 | 210 | 0.3 | \ | \ |

| Cement Sheath (1) | 222 | 10 | 0.17 | 8 | 27 |

| Formation | \ | 22 | 0.23 | 5 | 39 |

| Materials | Coefficient of Heat Conduction (W·(m·°C)−1) | Specific Heat (J·(kg·°C)−1) | Density (kg·m−3) | Coefficient of Thermal Expansion (10−6·°C−1) |

|---|---|---|---|---|

| Casing | 45 | 461 | 7800 | 13 |

| Cement sheath | 0.98 | 837 | 3100 | 11 |

| Formation | 1.59 | 1256 | 2600 | 10.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, Y.; Li, J.; Liu, G.; Li, J.; Jiang, J. Mechanisms and Influence of Casing Shear Deformation near the Casing Shoe, Based on MFC Surveys during Multistage Fracturing in Shale Gas Wells in Canada. Energies 2019, 12, 372. https://doi.org/10.3390/en12030372

Xi Y, Li J, Liu G, Li J, Jiang J. Mechanisms and Influence of Casing Shear Deformation near the Casing Shoe, Based on MFC Surveys during Multistage Fracturing in Shale Gas Wells in Canada. Energies. 2019; 12(3):372. https://doi.org/10.3390/en12030372

Chicago/Turabian StyleXi, Yan, Jun Li, Gonghui Liu, Jianping Li, and Jiwei Jiang. 2019. "Mechanisms and Influence of Casing Shear Deformation near the Casing Shoe, Based on MFC Surveys during Multistage Fracturing in Shale Gas Wells in Canada" Energies 12, no. 3: 372. https://doi.org/10.3390/en12030372

APA StyleXi, Y., Li, J., Liu, G., Li, J., & Jiang, J. (2019). Mechanisms and Influence of Casing Shear Deformation near the Casing Shoe, Based on MFC Surveys during Multistage Fracturing in Shale Gas Wells in Canada. Energies, 12(3), 372. https://doi.org/10.3390/en12030372