A Novel Dual-Structure Parallel Hybrid Excitation Machine for Electric Vehicle Propulsion

Abstract

:1. Introduction

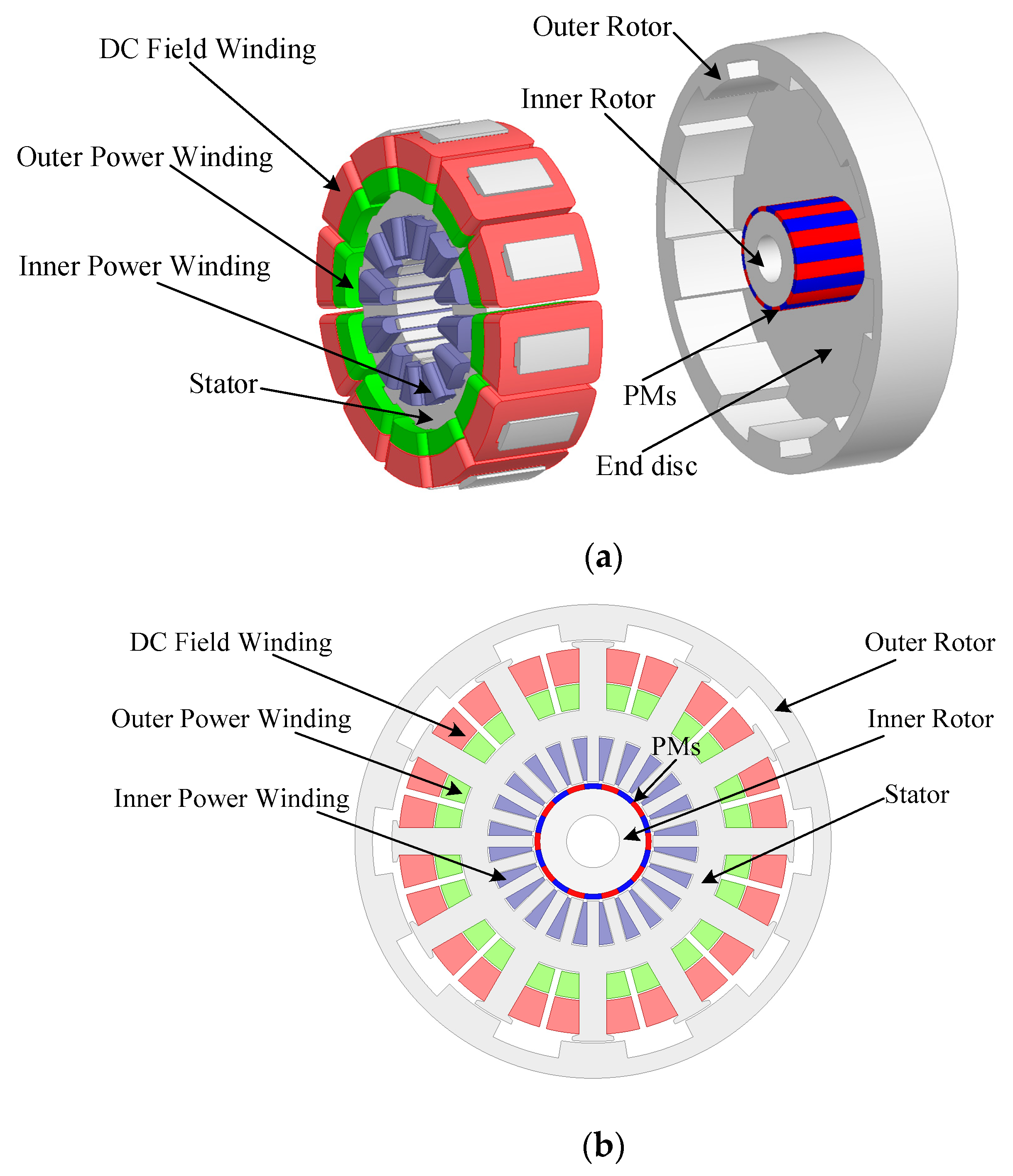

2. The Proposed DS-PHEM

2.1. Machine Structure

- A brushless structure is achieved since DC field winding is located at the stationary body, which ensures simple DC field current regulation and high reliability.

- Two machine structures are integrated into a compact design, leading to a torque boost effect.

- Two machine structures share a common stator yoke, which contributes to a decoupled and parallel magnetic circuit, thus, no demagnetization risk exists during DC field current regulation.

- The power of two machine structures can be flexibly designed and combined, which can provide a theoretically unlimited constant power range at both motor and generator modes.

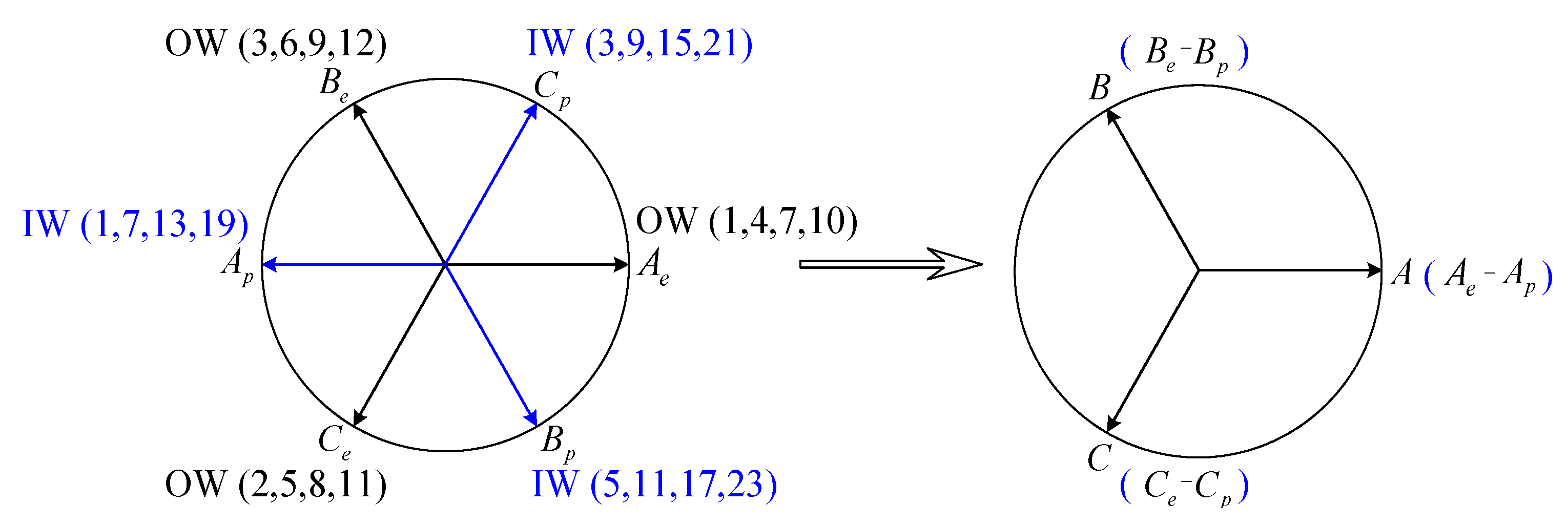

2.2. Electromagnetic Integration of Two Structures

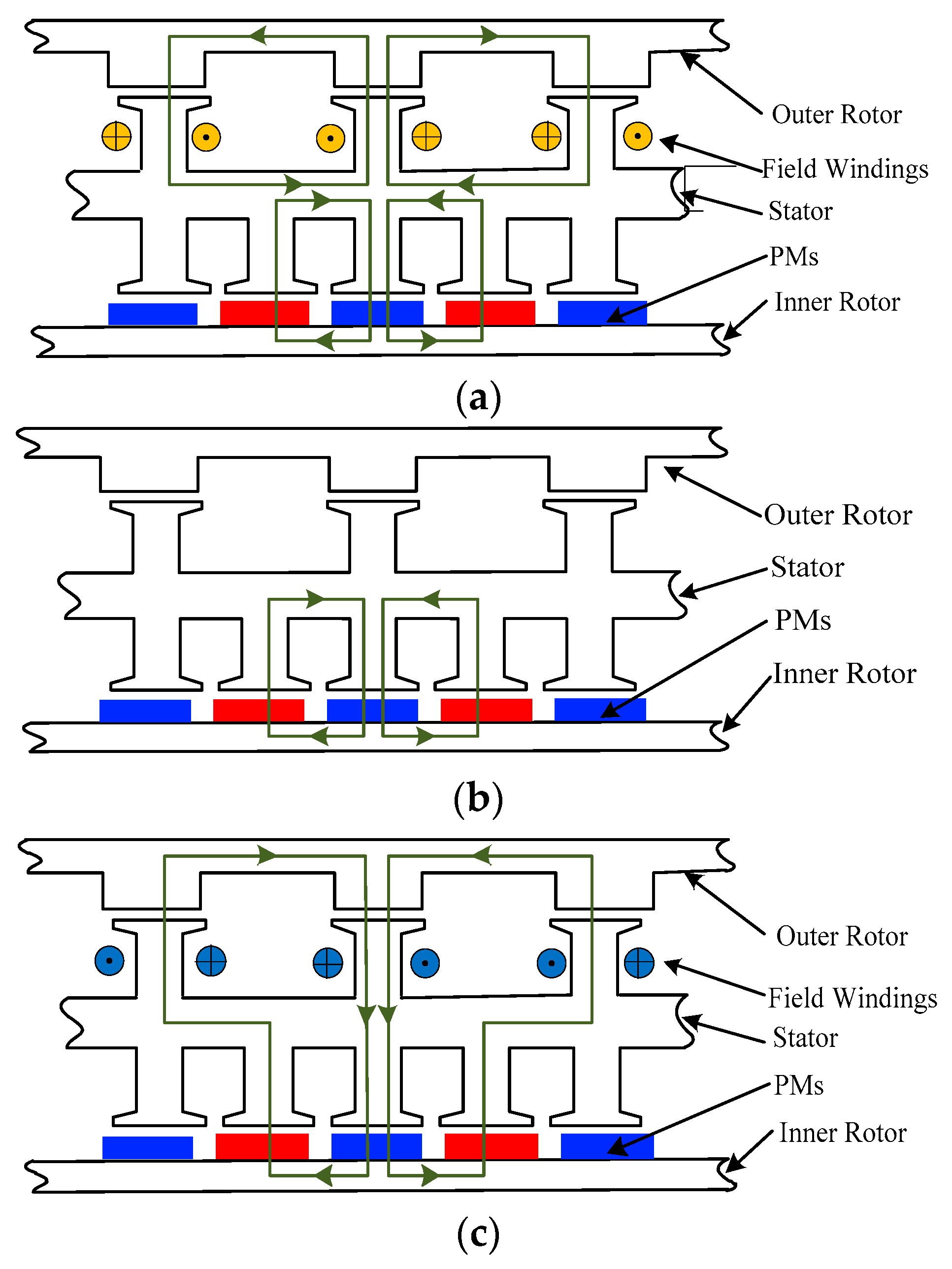

2.3. Operation Principle of Flux Control

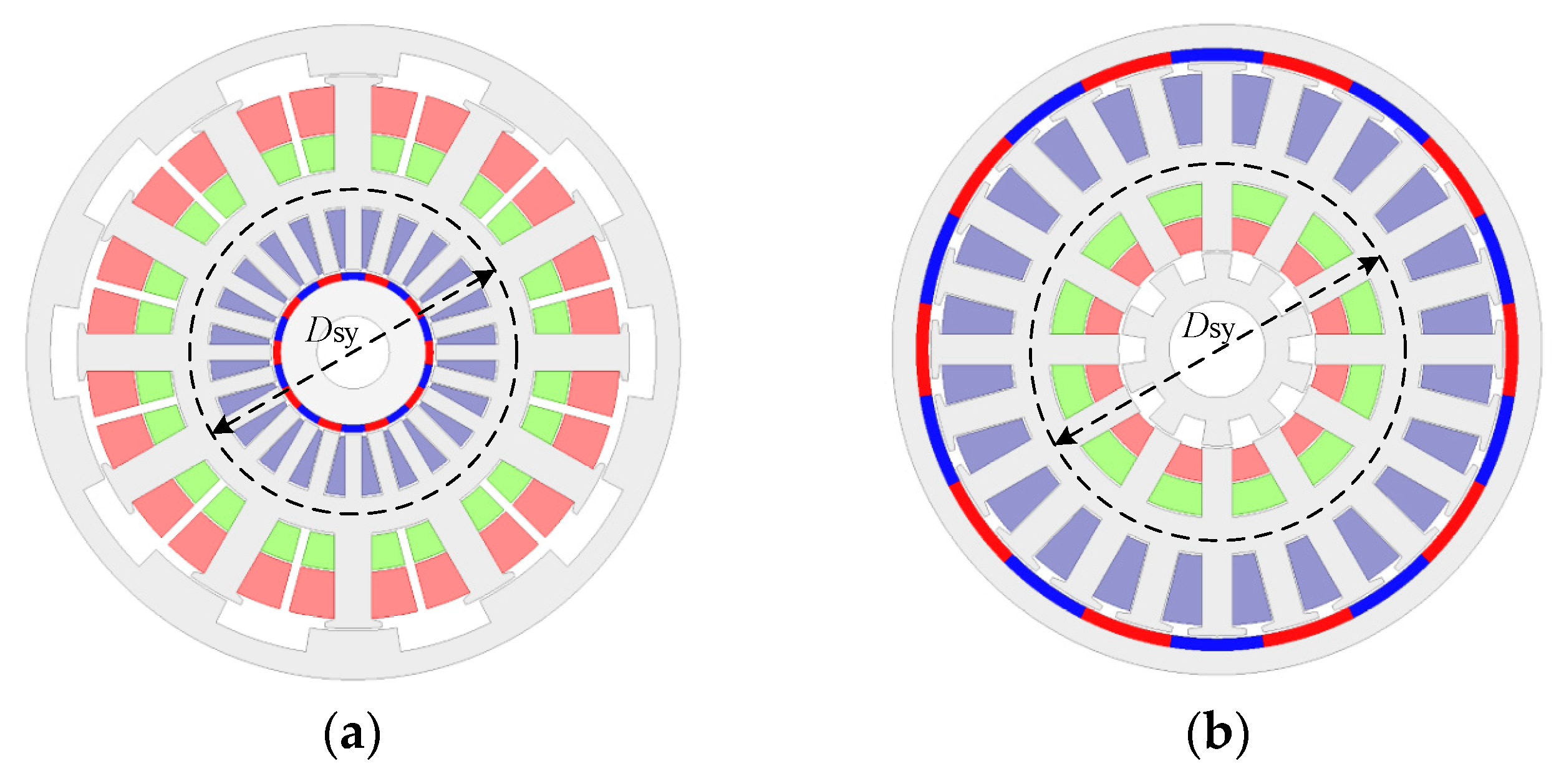

2.4. Design Considerations

3. Finite Element Analysis

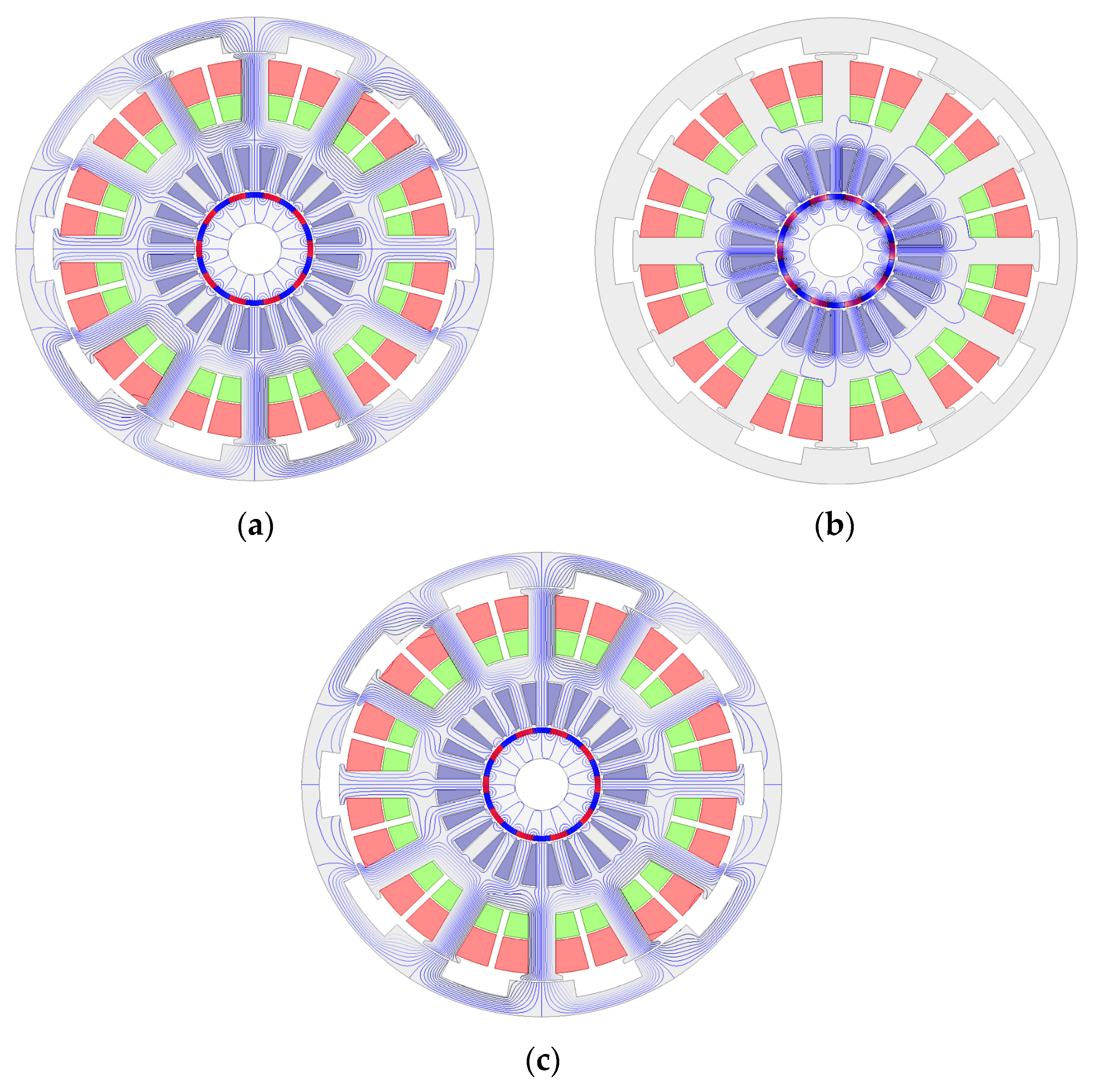

3.1. Flux Distribution

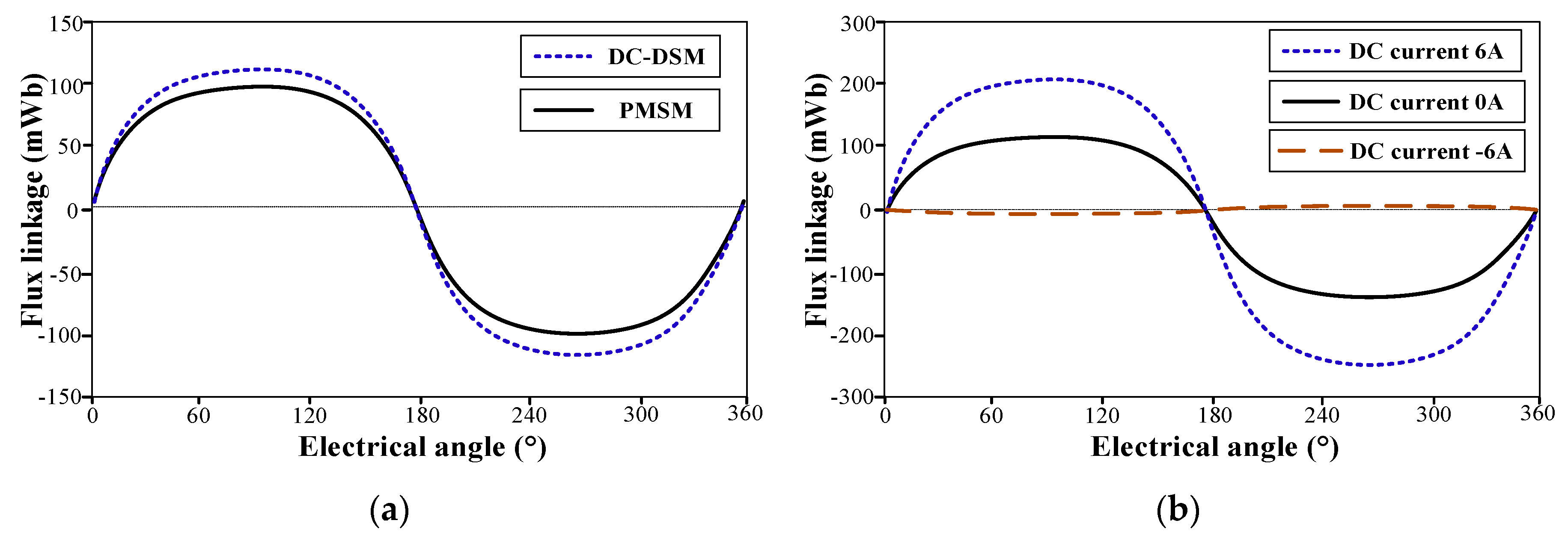

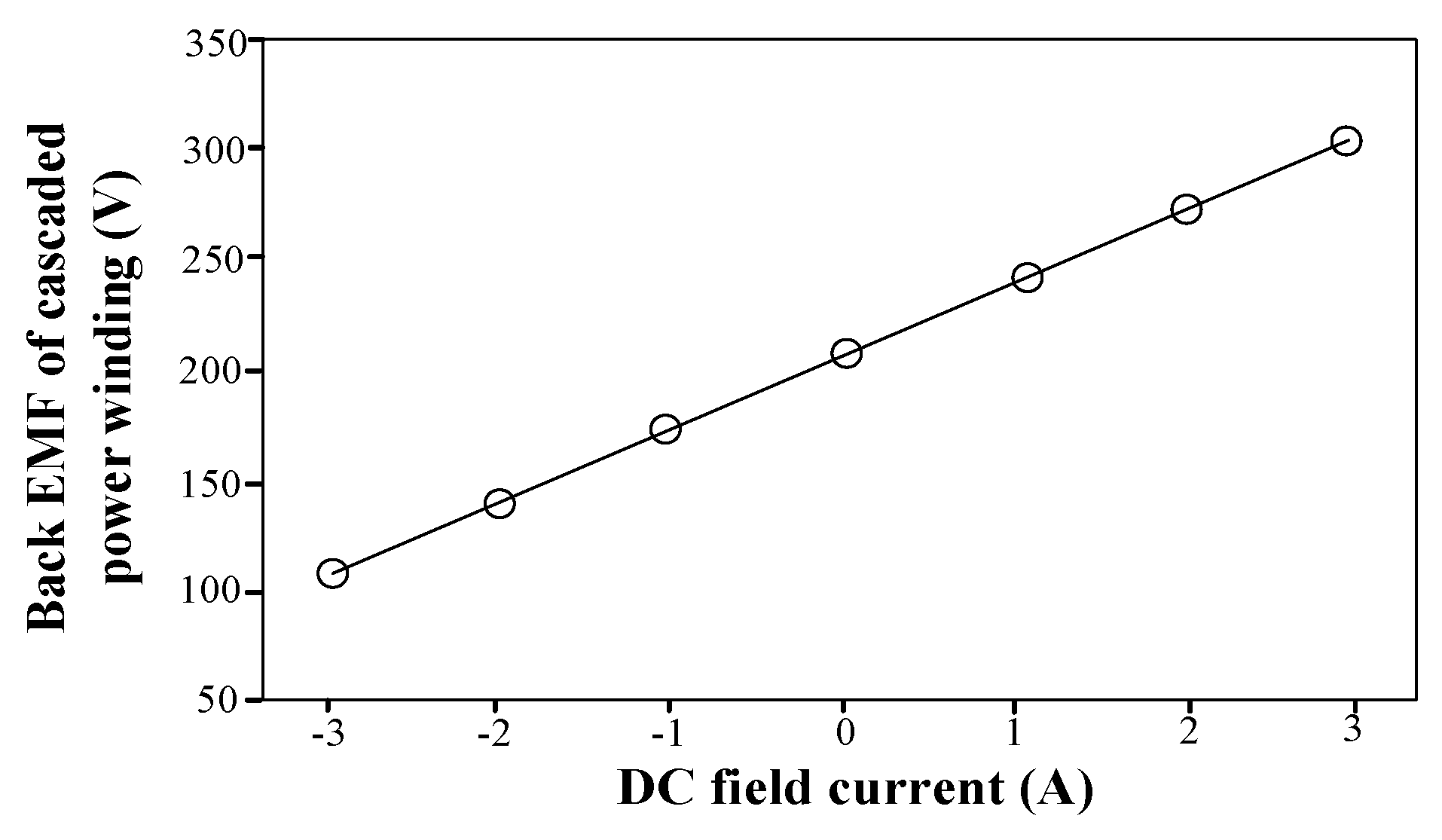

3.2. Flux Linkage and Back EMF

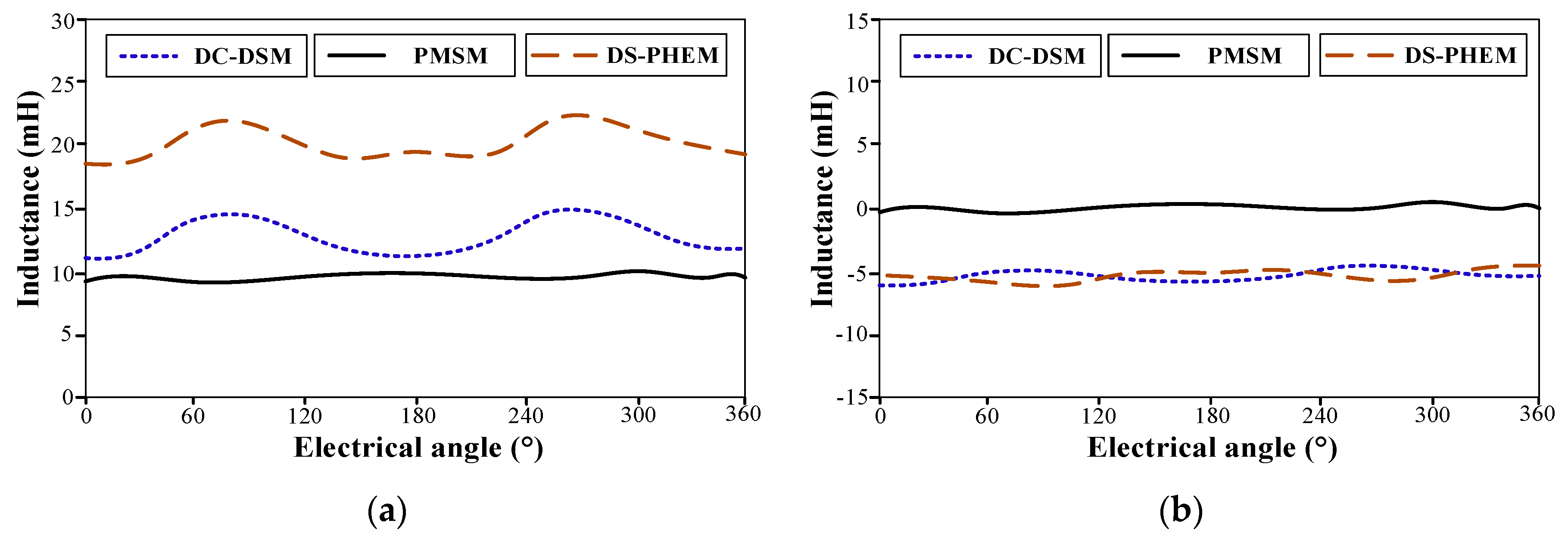

3.3. Inductance Characteristics

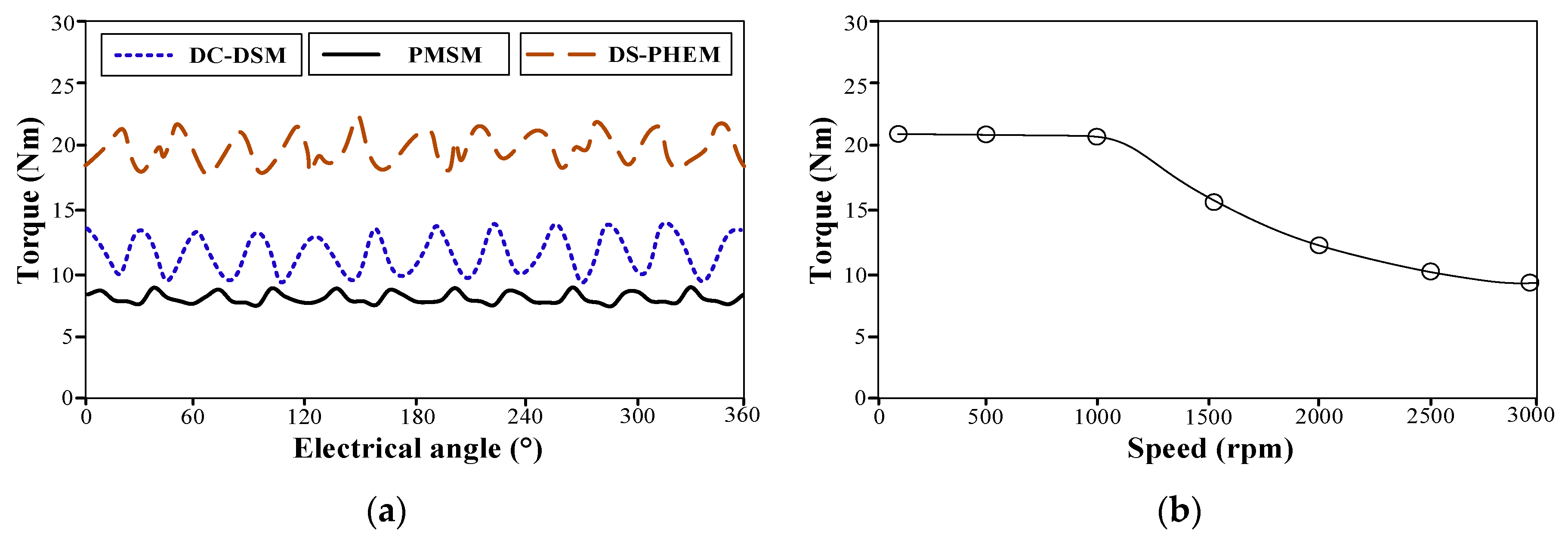

3.4. Torque Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Han, K.J.; Cho, D.H.; Jung, H.K. Optimal core shape design for cogging torque reduction of BLDC motor using genetic algorithm. In Proceedings of the International Conference on Electric Machines and Drives, Sapporo, Japan, 9–12 May 1999; pp. 332–333. [Google Scholar]

- Zhao, X.; Niu, S. Design of a novel consequent-pole transverse-flux machine with improved permanent magnet utilization. IEEE Trans. Magn. 2017, 53, 1–5. [Google Scholar] [CrossRef]

- Potgieter, J.H.J.; Kamper, M.J. Torque and voltage quality in design optimization of low-cost non-overlap single layer winding permanent magnet wind generator. IEEE Trans. Ind. Electron. 2012, 59, 2147–2156. [Google Scholar] [CrossRef]

- Song, W.L.; Miller, T.J. Field-weakening performance of brushless synchronous AC motor drives. IEE Proc. Electr. Power Appl. 1994, 141, 331–340. [Google Scholar] [CrossRef]

- Zhao, X.; Niu, S. Investigation of a new hybrid excitation machine with auxiliary winding for energy recycling. IEEE Trans. Magn. 2017, 53, 1–5. [Google Scholar] [CrossRef]

- Wang, Q.; Niu, S. Overview of flux-controllable machines: Electrically excited machines, hybrid excited machines and memory machines. Renew. Sustain. Energy Rev. 2017, 68, 475–491. [Google Scholar] [CrossRef]

- Zhao, X.; Niu, S. Design and optimization of a novel slot-PM-assisted variable flux reluctance generator for hybrid electric vehicles. IEEE Trans. Energy Convers. 2018, 33, 2–11. [Google Scholar]

- Nasr, A.; Hlioui, S.; Gabsi, M.; Mairie, M.; Lalevee, D. Design optimization of a hybrid-excited flux-switching machine for aircraft safe DC power generation using a diode bridge rectifier. IEEE Trans. Ind. Electron. 2017, 64, 9896–9904. [Google Scholar] [CrossRef]

- Amara, Y.; Vido, L.; Gabsi, M. Hybrid excitation synchronous machines: Energy-efficient solution for vehicles propulsion. IEEE Trans. Veh. Technol. 2009, 58, 2137–2149. [Google Scholar] [CrossRef]

- Zhao, X.; Niu., S.; Fu, W. A new modular Relieving-DC-Saturation Vernier reluctance machine excited by zero sequence current for electric vehicle. IEEE Trans. Magn. 2019. [Google Scholar]

- Chau, K.T.; Chan, C.C.; Liu, C. Overview of permanent-magnet brushless drives for electric and hybrid electric vehicles. IEEE Trans. Ind. Electron. 2008, 55, 2246–2257. [Google Scholar] [CrossRef]

- Cheng, M.; Hua, W.; Zhang, J.; Zhao, W. Overview of stator-permanent magnet brushless machines. IEEE Trans. Ind. Electron. 2011, 58, 5087–5101. [Google Scholar] [CrossRef]

- Jian, L.; Shi, Y.; Liu, C.; Xu, G.; Chan, C.C. A novel dual-permanent-magnet-excited machine for low-speed large-torque applications. IEEE Trans. Magn. 2013, 49, 2381–2384. [Google Scholar] [CrossRef]

- Niu, S.; Ho, S.L.; Fu, W.N. A novel stator and rotor dual PM Vernier motor with space vector pulse width modulation. IEEE Trans. Magn. 2014, 50, 805–808. [Google Scholar] [CrossRef]

- Fodorean, D.; Djerdir, A. A double excited synchronous machine for direct drive application—Design and prototype tests. IEEE Trans. Energy Convers. 2007, 22, 656–665. [Google Scholar] [CrossRef]

- FCapponi, G.; de Donato, G.; Borocci, G.; Caricchi, F. Axial-flux hybrid-excitation synchronous machine: analysis design and experimental evaluation. IEEE Trans. Ind. Appl. 2014, 50, 31. [Google Scholar]

- Tapia, J.A.; Leonardi, F.; Lipo, T.A. Consequent-pole permanent magnet machine with extended field-weakening capability. IEEE Trans. Ind. Appl. 2003, 39, 1704–1709. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, Y.; Yang, S.; Bo, Z. Principle of operation and feature investigation of a new topology of hybrid excitation synchronous machine. IEEE Trans. Magn. 2008, 44, 2174–2180. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Zhang, X. Design and optimization of hybrid excitation synchronous machines with magnetic shunting rotor for electric vehicle traction applications. IEEE Trans. Ind. Appl. 2017, 53, 5252–5261. [Google Scholar] [CrossRef]

- Liu, C.; Chau, K.T.; Jiang, J.Z. A permanent-magnet hybrid brushless integrated starter–generator for hybrid electric vehicles. IEEE Trans. Ind. Electron. 2010, 57, 4055–4064. [Google Scholar] [CrossRef]

- Zhao, X.; Niu, S. Design of a novel parallel-hybrid-excited Vernier reluctance machine with improved utilization of redundant winding harmonics. IEEE Trans. Ind. Electron. 2018, 65, 9056–9067. [Google Scholar] [CrossRef]

- Owen, R.L.; Zhu, Z.Q.; Jewell, G.W. Hybrid-excited flux-switching permanent-magnet machines with iron flux bridges. IEEE Trans. Magn. 2010, 46, 1726–1729. [Google Scholar] [CrossRef]

- Zhao, X.; Niu, S.; Ching, T.W. Design and analysis of a new brushless electrically excited claw-pole generator for hybrid electric vehicle. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Hua, H.; Zhu, Z.Q. Novel parallel hybrid excited machines with separate stators. IEEE Trans. Energy Convers. 2016, 31, 1212–1220. [Google Scholar] [CrossRef]

- Zhao, X.; Niu, S. Design and optimization of a new magnetic-geared pole-changing hybrid excitation machine. IEEE Trans. Ind. Electron. 2017, 64, 9943–9952. [Google Scholar] [CrossRef]

- Jang, D.K.; Chang, J.H. Design of a Vernier machine with PM on both sides of rotor and stator. IEEE Trans. Magn. 2014, 50, 877–880. [Google Scholar] [CrossRef]

- Wang, Q.; Niu, S.; Yang, L. Design optimization and comparative study of novel dual-PM excited machines. IEEE Trans. Ind. Electron. 2017, 64, 9924–9933. [Google Scholar] [CrossRef]

- Zhao, X.; Niu, S.; Fu, W. Design of a novel parallel-hybrid-excited dual-PM machine based on armature harmonics diversity for electric vehicle propulsion. IEEE Trans. Ind. Electron. 2018. [Google Scholar] [CrossRef]

- Wang, Q.; Niu, S. A novel hybrid-excited dual-PM machine with bidirectional flux modulation. IEEE Trans. Energy Convers. 2017, 32, 424–435. [Google Scholar] [CrossRef]

- Shi, Y.; Jian, L. A novel dual-permanent-magnet-excited machine with flux strengthening effect for low-speed large-torque applications. Energies 2018, 11, 153. [Google Scholar] [CrossRef]

| Parameter | Unit | Value | Parameter | Unit | Value |

|---|---|---|---|---|---|

| Outer diameter of outer rotor | mm | 270 | Outer diameter of stator yoke | mm | 152 |

| Inner diameter of outer rotor | mm | 230 | Inner diameter of stator yoke | mm | 118 |

| Number of rotor salient poles | - | 10 | Outer diameter of stator inner teeth | mm | 68 |

| Arc of rotor salient poles | ° | 7 | Number of stator inner teeth | - | 24 |

| Length of outer air gap | mm | 1 | Coil number of inner power winding | - | 80 |

| Outer diameter of stator outer teeth | mm | 228 | Length of inner air gap | mm | 1 |

| Number of stator outer teeth | mm | 12 | Outer diameter of inner rotor | mm | 66 |

| Coil number of outer power winding | - | 120 | Inner diameter of inner rotor | mm | 30 |

| Coil number of outer field winding | - | 250 | Number of PM pole pairs | - | 10 |

| PM | Material | NdFeB35 |

| Remanence | 1.2 T | |

| Coercive force | 915 kA/m | |

| Steel | Material | MG19_24 |

| Saturated flux density | 1.8 T | |

| Mass density | 7650 kg/m3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhao, X.; Niu, S. A Novel Dual-Structure Parallel Hybrid Excitation Machine for Electric Vehicle Propulsion. Energies 2019, 12, 338. https://doi.org/10.3390/en12030338

Zhang X, Zhao X, Niu S. A Novel Dual-Structure Parallel Hybrid Excitation Machine for Electric Vehicle Propulsion. Energies. 2019; 12(3):338. https://doi.org/10.3390/en12030338

Chicago/Turabian StyleZhang, Xiaodong, Xing Zhao, and Shuangxia Niu. 2019. "A Novel Dual-Structure Parallel Hybrid Excitation Machine for Electric Vehicle Propulsion" Energies 12, no. 3: 338. https://doi.org/10.3390/en12030338

APA StyleZhang, X., Zhao, X., & Niu, S. (2019). A Novel Dual-Structure Parallel Hybrid Excitation Machine for Electric Vehicle Propulsion. Energies, 12(3), 338. https://doi.org/10.3390/en12030338