Heat Energy and Gas Emissions during Composting of Sewage Sludge

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of Substrates

2.2. Characteristics of Composting Mixtures

2.3. Description of the Experiments

3. Results and Discussion

4. Conclusions

- Maize straw as a carbon-rich substrate improves the C/N ratio and thus enables appropriate composting of sewage sludge.

- Maize straw as a bulking agent increased the porosity of the compost mix accordingly. The free spaces in the mixture promoted the correct flow of oxygen, thus ensuring the occurrence of a thermophilic phase.

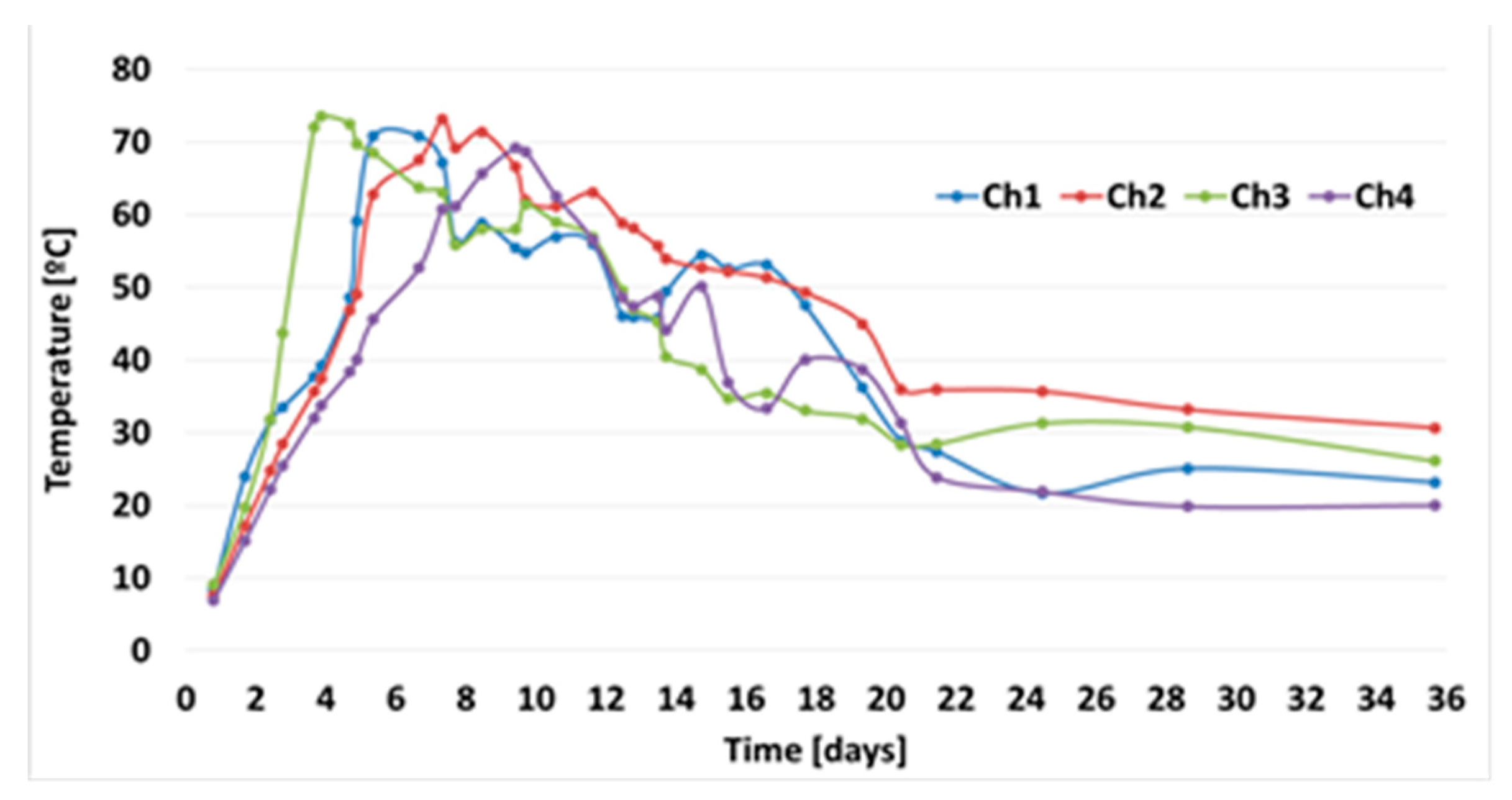

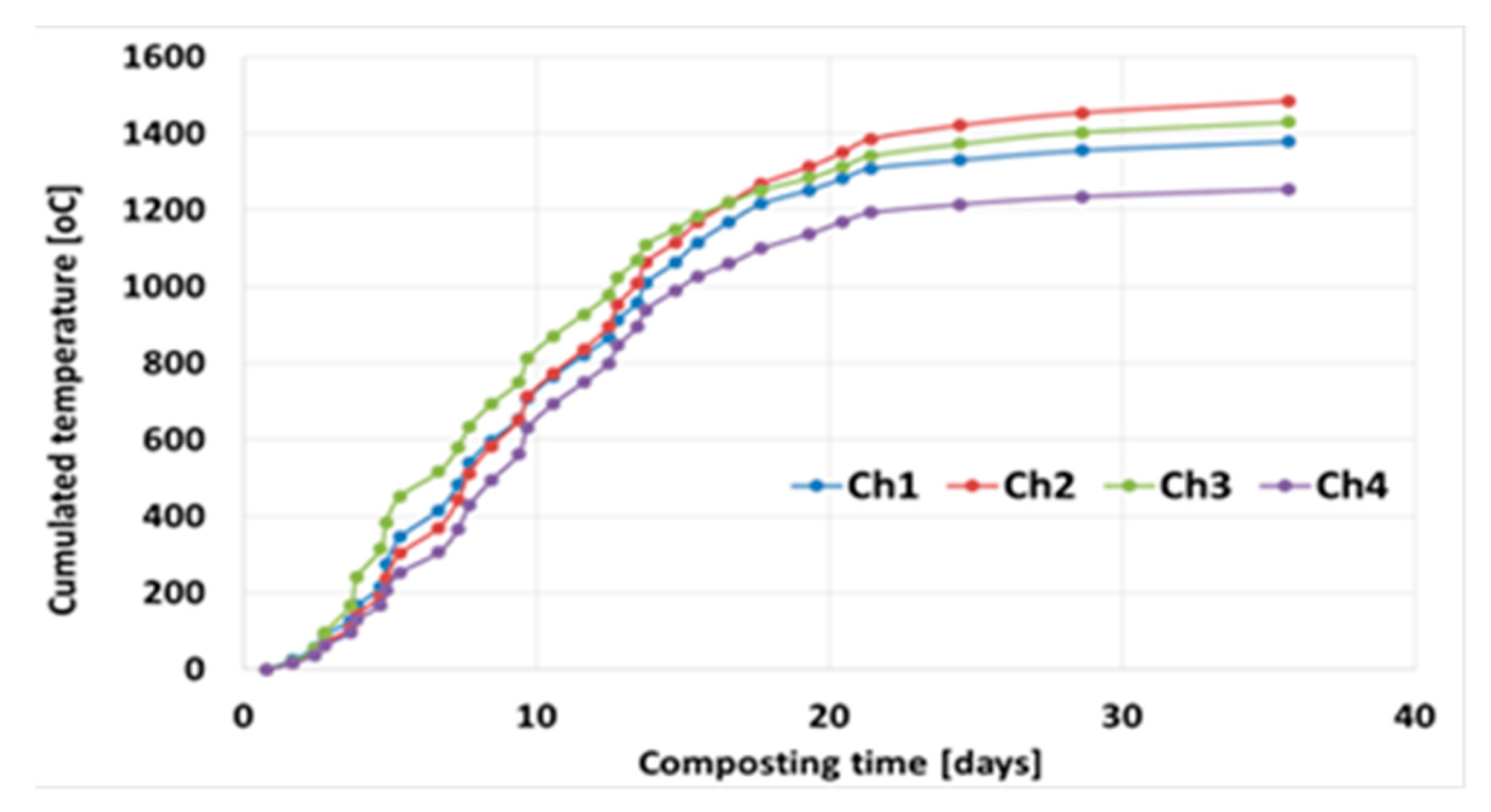

- All the examined mixtures reached a strong thermophilic phase of composting; however, the lowest dynamics of temperature growth were observed in the highest sewage sludge content (Ch4, 60% of sewage sludge).

- The mixture designated as Ch1 was characterized by a high C/N ratio at almost 20, with a high OM content over 86%, but in terms of CO2 and NH3 gas emissions (intermediate values between the tested samples) and in terms of economic considerations, the highest cumulative temperature was found and a relatively moderate demand for the carbon source (C/N = 11.6), and so the Ch3 mixture seems to be the most advantageous.

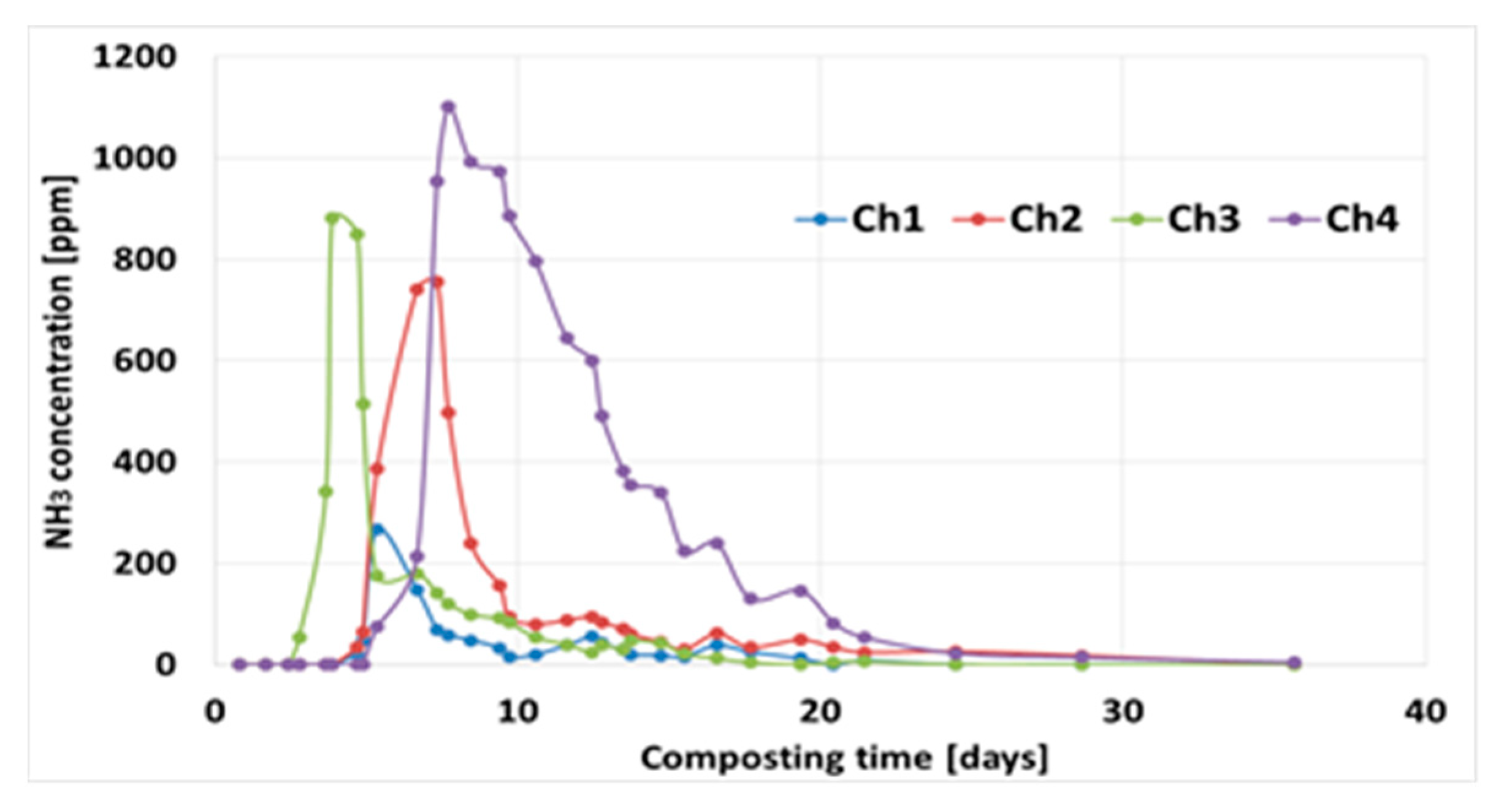

- An excessively high content of sewage sludge strongly influenced the C/N ratio and losses through ammonia emissions.

- The concentration of ammonia in the bioreactor chambers was directly related to the content of sewage sludge in the composted mixture. A two-fold increase in the content of sewage sludge in the composted mixture from 30% to 60% resulted in more than a six-times lower ammonia concentration.

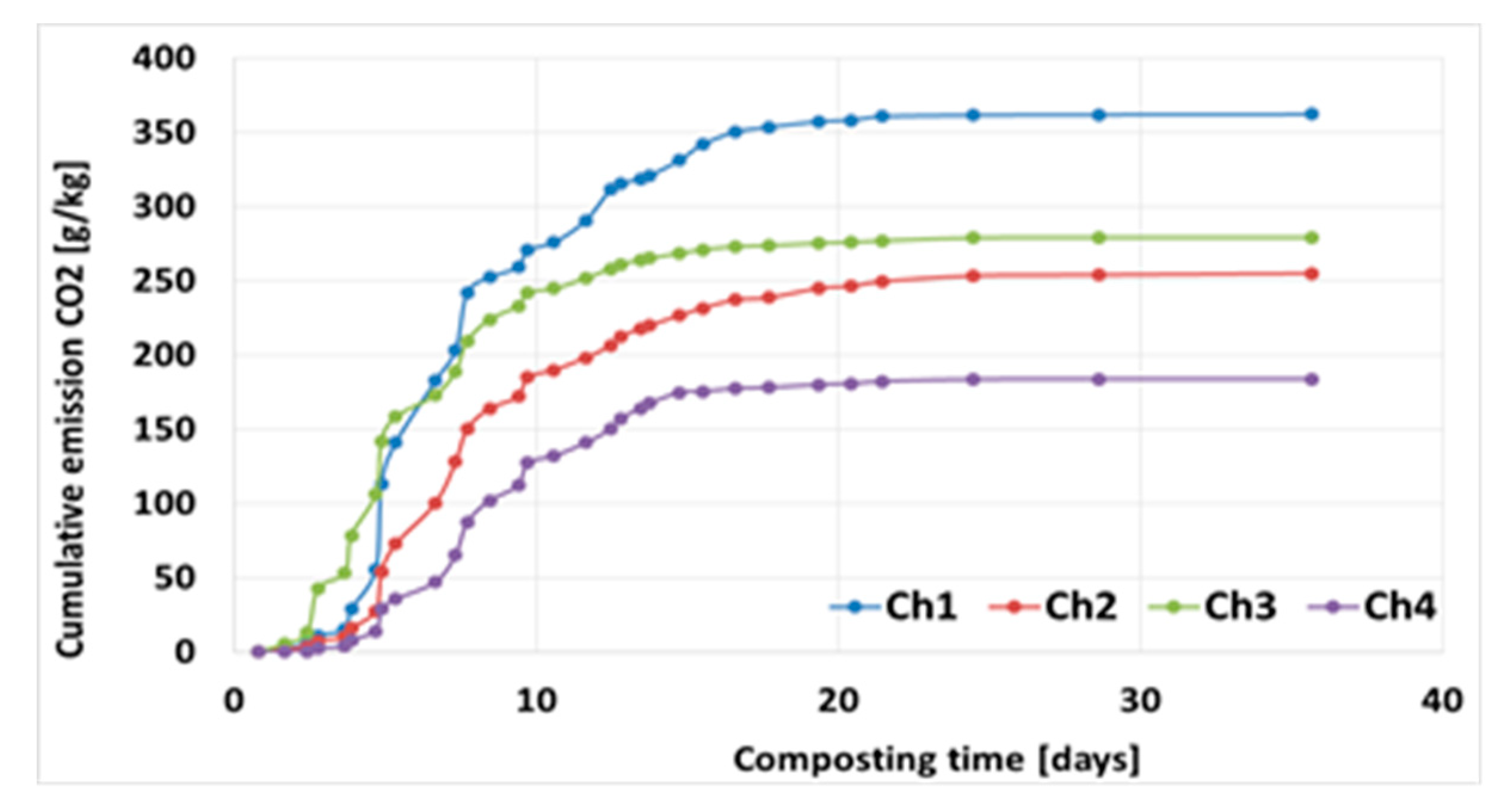

- Cumulative emissions of CO2 showed the greatest dynamics of substrate mixture decomposition with the highest content of organic matter and C/N ratio. However, its value decreased along with the increase in the content of sewage sludge in the mixture (the mixture with the lowest sewage sludge content).

- The results of the analyzed parameters showed that the composting process worked properly and that composting maize straw may be a cheap solution in sewage sludge management.

- It was found that, even with very low air-flow (average air-flow of 2.5 dm3·min−1), but with a regular bottom-up aeration system (by not very high bulk density), ongoing monitoring of exhaust gas concentrations enabled the proper composting of all mix variants.

Author Contributions

Funding

Conflicts of Interest

References

- Nayak, A.K.; Kalamdhad, A.S. Sewage sludge composting in a rotary drum reactor: Stability and kinetic analysis. Int. J. Recycl. Org. Waste Agric. 2015, 4, 249–259. [Google Scholar] [CrossRef]

- Uçaroğlu, S.; Alkan, U. Composting of wastewater treatment sludge with different bulking agents. J. Air Waste Manag. Assoc. 2016, 66, 288–295. [Google Scholar] [CrossRef] [PubMed]

- Meng, L.; Zhang, S.; Gong, H.; Zhang, X.; Wu, C.; Li, W. Improving sewage sludge composting by addition of spent mushroom substrate and sucrose. Bioresour. Technol. 2018, 253, 197–203. [Google Scholar] [CrossRef] [PubMed]

- Mateo-Sagasta, J.; Raschid-Sally, L.; Thebo, A. Global Wastewater and Sludge Production, Treatment and Use. In Wastewater: Economic Asset in an Urbanizing World; Drechsel, P., Qadir, M., Wichelns, D., Eds.; Springer: Dordrecht, The Netherlands, 2015; pp. 15–38. ISBN 978-94-017-9545-6. [Google Scholar]

- Sewage Sludge Production and Disposal—Eurostat. Available online: https://ec.europa.eu/eurostat/web/products-datasets/product?code=env_ww_spd (accessed on 23 August 2019).

- FWR Reviews of Common Knowledge. Available online: http://www.fwr.org/rocks.htm (accessed on 23 August 2019).

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Sludge Quantities and Characteristics. In Wastewater Sludge Processing; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2005; pp. 30–59. ISBN 978-0-471-79161-4.

- Kosicka-Dziechciarek, D.; Mazurkiewicz, J.; Mazur, R. Composting of municipal and onside wastewater treatment plant sewage sludge in Poland. Water Technol. 2016, 46, 56–62. Available online: http://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-caba0b72-8e2c-4041-9c86-c529d3a7e296 (accessed on 23 August 2019).

- Callegari, A.; Capodaglio, A.G. Properties and Beneficial Uses of (Bio)Chars, with Special Attention to Products from Sewage Sludge Pyrolysis. Resources 2018, 7, 20. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Callegari, A.; Dondi, D. Microwave-Induced Pyrolysis for Production of Sustainable Biodiesel from Waste Sludges. Waste Biomass Valorizat. 2016, 7, 703–709. [Google Scholar] [CrossRef]

- Daneshgar, S.; Buttafava, A.; Callegari, A.; Capodaglio, A.G. Simulations and Laboratory Tests for Assessing Phosphorus Recovery Efficiency from Sewage Sludge. Resources 2018, 7, 54. [Google Scholar] [CrossRef]

- Kirchmann, H.; Börjesson, G.; Kätterer, T.; Cohen, Y. From agricultural use of sewage sludge to nutrient extraction: A soil science outlook. Ambio 2017, 46, 143–154. [Google Scholar] [CrossRef]

- Duan, B.; Zhang, W.; Zheng, H.; Wu, C.; Zhang, Q.; Bu, Y. Comparison of Health Risk Assessments of Heavy Metals and As in Sewage Sludge from Wastewater Treatment Plants (WWTPs) for Adults and Children in the Urban District of Taiyuan, China. Int. J. Environ. Res. Public. Health 2017, 14, 1194. [Google Scholar] [CrossRef]

- Peltre, C.; Nyord, T.; Bruun, S.; Jensen, L.S.; Magid, J. Repeated soil application of organic waste amendments reduces draught force and fuel consumption for soil tillage. Agric. Ecosyst. Environ. 2015, 211, 94–101. [Google Scholar] [CrossRef]

- Kosicka-Dziechciarek, D.; Wolna-Maruwka, A.; Mazurkiewicz, J. The danger of pathogenic organisms in sewage sludge and methods of their reduction. Arch. Waste Manag. Environ. Prot. 2015, 17, 127–138. [Google Scholar]

- Yan, L.; Li, Z.; Bao, J.; Wang, G.; Wang, C.; Wang, W. Diversity of ammonia-oxidizing bacteria and ammonia-oxidizing archaea during composting of municipal sludge. Ann. Microbiol. 2015, 65, 1729–1739. [Google Scholar] [CrossRef]

- Malamis, D.; Moustakas, K.; Haralambous, K.-J. Evaluating in-vessel composting in treating sewage sludge and agricultural waste by examining and determining the kinetic reactions of the process. Clean Technol. Environ. Policy 2016, 18, 2493–2502. Available online: https://link.springer.com/article/10.1007/s10098-016-1230-z (accessed on 26 August 2019). [CrossRef]

- Wang, K.; Mao, H.; Li, X. Functional characteristics and influence factors of microbial community in sewage sludge composting with inorganic bulking agent. Bioresour. Technol. 2018, 249, 527–535. [Google Scholar] [CrossRef]

- Diaz, L.F.; Savage, G.M.; Eggerth, L.L.; Chiumenti, A. Chapter 5—Systems used in composting. In Waste Management Series; Diaz, L.F., de Bertoldi, M., Bidlingmaier, W., Stentiford, E., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; Volume 8, pp. 67–87, ISSN 1478-7482. [Google Scholar]

- Kosobucki, P.; Chmarzyński, A.; Buszewski, B. Sewage Sludge Composting. Pol. J. Environ. Stud. 2000, 9, 243–248. [Google Scholar]

- Nayak, A.K.; Kalamdhad, A.S. Feasibility of Composting Combinations of Sewage Sludge, Cattle Manure, and Sawdust in a Rotary Drum Reactor. Environ. Eng. Res. 2014, 19, 47–57. [Google Scholar] [CrossRef]

- Chen, Y. Sewage Sludge Aerobic Composting Technology Research Progress. AASRI Procedia 2012, 1, 339–343. [Google Scholar] [CrossRef]

- Epstein, E. Industrial Composting: Environmental Engineering and Facilities Management; CRC Press: Boca Raton, FL, USA, 2011; ISBN 9781439845318. [Google Scholar]

- Sun, Q.H.; Zhang, J.K.; Zhang, H.F. Research on Sewage Sludge Composting Experimental. Adv. Mater. Res. 2014, 1030–1032, 313–316. [Google Scholar] [CrossRef]

- Sullivan, T.S.; Stromberger, M.E.; Paschke, M.W.; Ippolito, J.A. Long-term impacts of infrequent biosolids applications on chemical and microbial properties of a semi-arid rangeland soil. Biol. Fertil. Soils 2006, 42, 258–266. [Google Scholar] [CrossRef]

- Jezierska-Tys, S.; Frac, M. Investigation of the influence of dairy sewage sludge on microbiological and biochemical activity of soil. Acta Agrophys. Rozpr. Monogr. 2008. Available online: http://www.old.acta-agrophysica.org/artykuly/acta_agrophysica/ActaAgr_160_2008_0_3_0.pdf (accessed on 23 August 2019).

- Singh, R.P.; Singh, P.; Ibrahim, M.H.; Hashim, R. Land application of sewage sludge: Physicochemical and microbial response. Rev. Environ. Contam. Toxicol. 2011, 214, 41–61. [Google Scholar]

- Bai, Y.; Zang, C.; Gu, M.; Gu, C.; Shao, H.; Guan, Y.; Wang, X.; Zhou, X.; Shan, Y.; Feng, K. Sewage sludge as an initial fertility driver for rapid improvement of mudflat salt-soils. Sci. Total Environ. 2017, 578, 47–55. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zeng, G.; Dong, H.; Chen, Y.; Zhang, J.; Yan, M.; Zhu, Y.; Yuan, Y.; Xie, Y.; Huang, Z. The impact of silver nanoparticles on the co-composting of sewage sludge and agricultural waste: Evolutions of organic matter and nitrogen. Bioresour. Technol. 2017, 230, 132–139. [Google Scholar] [CrossRef] [PubMed]

- Merrington, G.; Oliver, I.; Smernik, R.J.; McLaughlin, M.J. The influence of sewage sludge properties on sludge-borne metal availability. Adv. Environ. Res. 2003, 8, 21–36. [Google Scholar] [CrossRef]

- Niemiec, W.; Zdeb, M. Plantation of energetic willow fertilizing by municipal sewage sludge. J. Civ. Eng. Environ. Archit. 2013, 67–78. [Google Scholar] [CrossRef]

- Kujawa, S.; Nowakowski, K.; Tomczak, R.J.; Dach, J.; Boniecki, P.; Weres, J.; Mueller, W.; Raba, B.; Piechota, T.; Rodríguez Carmona, P.C. Neural image analysis for maturity classification of sewage sludge composted with maize straw. Comput. Electron. Agric. 2014, 109, 302–310. [Google Scholar] [CrossRef]

- Malińska, K. Biochar—A response to current environmental issues. Eng. Prot. Environ. Ochr. Śr. 2012, 15, 387–403. [Google Scholar]

- Stylianou, M.A.; Inglezakis, V.J.; Moustakas, K.G.; Loizidou, M.D. Improvement of the quality of sewage sludge compost by adding natural clinoptilolite. Desalination 2008, 224, 240–249. [Google Scholar] [CrossRef]

- Berggren, I.; Albihn, A.; Johansson, M. The effect of the temperature on the survival of pathogenic bacteria and Ascaris suum in stored sewagesludge. Sustain. Org. Waste Manag. Environ. Prot. Food Saf. 2004, 2, 53–56. [Google Scholar]

- Cotxarrera, L.; Trillas-Gay, M.I.; Steinberg, C.; Alabouvette, C. Use of sewage sludge compost and Trichoderma asperellum isolates to suppress Fusarium wilt of tomato. Soil Biol. Biochem. 2002, 34, 467–476. [Google Scholar] [CrossRef]

- Dach, J. Influence of C:N level on ammonia emission from composted sewage sludge. J. Res. Appl. Agric. Eng. 2010, 55, 14–18. [Google Scholar]

- Czekała, W.; Dach, J.; Ludwiczak, A.; Przybylak, A.; Boniecki, P.; Koszela, K.; Zaborowicz, M.; Przybył, K.; Wojcieszak, D.; Witaszek, K. The use of image analysis to investigate C:N ratio in the mixture of chicken manure and straw. In Proceedings of the Seventh International Conference on Digital Image Processing (ICDIP 2015), Los Angeles, CA, USA, 9–10 April 2015; Volume 9631, p. 963117. [Google Scholar]

- Czekała, W.; Malińska, K.; Cáceres, R.; Janczak, D.; Dach, J.; Lewicki, A. Co-composting of poultry manure mixtures amended with biochar—The effect of biochar on temperature and C-CO2 emission. Bioresour. Technol. 2016, 200, 921–927. [Google Scholar] [CrossRef] [PubMed]

- Janczak, D.; Malińska, K.; Czekała, W.; Cáceres, R.; Lewicki, A.; Dach, J. Biochar to reduce ammonia emissions in gaseous and liquid phase during composting of poultry manure with wheat straw. Waste Manag. 2017, 66, 36–45. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Liu, E.; Zhu, X.; Wang, H.; Liu, H.; Liu, X.; Dong, W. Impact of Composting Methods on Nitrogen Retention and Losses during Dairy Manure Composting. Int. J. Environ. Res. Public Health 2019, 16, 3324. [Google Scholar] [CrossRef] [PubMed]

- Zuokaitė, E.; Zigmontienė, A. Application of a Natural Cover during Sewage Sludge Composting to Reduce Gaseous Emissions. Pol. J. Environ. Stud. 2013, 22, 621–626. [Google Scholar]

- Nasini, L.; De Luca, G.; Ricci, A.; Ortolani, F.; Caselli, A.; Massaccesi, L.; Regni, L.; Gigliotti, G.; Proietti, P. Gas emissions during olive mill waste composting under static pile conditions. Int. Biodeterior. Biodegrad. 2016, 107, 70–76. [Google Scholar] [CrossRef]

- He, Y.; Inamori, Y.; Mizuochi, M.; Kong, H.; Iwami, N.; Sun, T. Nitrous Oxide Emissions from Aerated Composting of Organic Waste. Environ. Sci. Technol. 2001, 35, 2347–2351. [Google Scholar] [CrossRef]

- Bajko, J.; Fišer, J.; Jícha, M. Condenser-Type Heat Exchanger for Compost Heat Recovery Systems. Energies 2019, 12, 1583. [Google Scholar] [CrossRef]

- Proietti, P.; Calisti, R.; Gigliotti, G.; Nasini, L.; Regni, L.; Marchini, A. Composting optimization: Integrating cost analysis with the physical-chemical properties of materials to be composted. J. Clean. Prod. 2016, 137, 1086–1099. [Google Scholar] [CrossRef]

- Xiong, Z.Q.; Wang, G.X.; Huo, Z.C.; Yan, L.; Gao, Y.M.; Wang, Y.J.; Gu, J.D.; Wang, W.D. Effect of aeration rates on the composting processes and Nitrogen loss during composting. Appl. Environ. Biotechnol. 2017, 2, 2. [Google Scholar]

- Wolna-Maruwka, A.; Dach, J. Effect of type and proportion of different structure-creating additions on the inactivation rate of pathogenic bacteria in sewage sludge composting in a cybernetic bioreactor. Arch. Environ. Prot. 2009, 35, 87–100. [Google Scholar]

- Waszkielis, K.M.; Wronowski, R.; Chlebus, W.; Białobrzewski, I.; Dach, J.; Pilarski, K.; Janczak, D. The effect of temperature, composition and phase of the composting process on the thermal conductivity of the substrate. Ecol. Eng. 2013, 61, 354–357. [Google Scholar] [CrossRef]

- Piotrowska-Cyplik, A.; Olejnik, A.; Cyplik, P.; Dach, J.; Czarnecki, Z. The kinetics of nicotine degradation, enzyme activities and genotoxic potential in the characterization of tobacco waste composting. Bioresour. Technol. 2009, 100, 5037–5044. [Google Scholar] [CrossRef] [PubMed]

- Czekała, W.; Dach, J.; Dong, R.; Janczak, D.; Malińska, K.; Jóźwiakowski, K.; Smurzyńska, A.; Cieślik, M. Composting potential of the solid fraction of digested pulp produced by a biogas plant. Biosyst. Eng. 2017, 160, 25–29. [Google Scholar] [CrossRef]

- Czekała, W.; Dach, J.; Janczak, D.; Smurzyńska, A.; Kwiatkowska, A.; Kozłowski, K. Influence of maize straw content with sewage sludge on composting process. J. Water Land Dev. 2016, 30, 43–49. [Google Scholar] [CrossRef]

- Makan, A.; Assobhei, O.; Mountadar, M. Effect of initial moisture content on the in-vessel composting under air pressure of organic fraction of municipal solid waste in Morocco. Iran. J. Environ. Health Sci. Eng. 2013, 10, 3. [Google Scholar] [CrossRef] [PubMed]

- Eftoda, G.; McCartney, D. Determining the Critical Bulking Agent Requirement for Municipal Biosolids Composting. Compost Sci. Util. 2013, 12, 208–218. [Google Scholar] [CrossRef]

- Barthod, J.; Rumpel, C.; Dignac, M.F. Composting with additives to improve organic amendments. A review. Agron. Sustain. Dev. 2018, 38, 17. [Google Scholar] [CrossRef]

- McGuckin, R.L.; Eiteman, M.A.; Das, K. Pressure Drop through Raw Food Waste Compost containing Synthetic Bulking Agents. J. Agric. Eng. Res. 1999, 72, 375–384. [Google Scholar] [CrossRef]

- Poulsen, T.G.; Moldrup, P. Air permeability of compost as related to bulk density and volumetric air content. Waste Manag. Res. 2007, 25, 343–351. [Google Scholar] [CrossRef]

- Hemmat, A.; Aghilinategh, N.; Rezainejad, Y.; Sadeghi, M. Long-term impacts of municipal solid waste compost, sewage sludge and farmyard manure application on organic carbon, bulk density and consistency limits of a calcareous soil in central Iran. Soil Tillage Res. 2010, 108, 43–50. [Google Scholar] [CrossRef]

- Khater, E.-S.G. Some Physical and Chemical Properties of Compost. Int. J. Waste Resour. 2015, 5, 1. [Google Scholar] [CrossRef]

- Shen, Y.; Ren, L.; Li, G.; Chen, T.; Guo, R. Influence of aeration on CH4, N2O and NH3 emissions during aerobic composting of a chicken manure and high C/N waste mixture. Waste Manag. 2011, 31, 33–38. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Zheng, G.; Gao, D.; Chen, T.; Wu, F.; Niu, M.; Zou, K. Odor composition analysis and odor indicator selection during sewage sludge composting. J. Air Waste Manag. Assoc. 2016, 66, 930–940. [Google Scholar] [CrossRef] [PubMed]

- Pagans, E.; Barrena, R.; Font, X.; Sánchez, A. Ammonia emissions from the composting of different organic wastes. Dependency on process temperature. Chemosphere 2006, 62, 1534–1542. [Google Scholar] [CrossRef] [PubMed]

- Sołowiej, P.; Neugebauera, M.; Dach, J.; Czekała, W.; Janczak, D. The influence of substrate C: N ratios on heat generation during the composting process of sewage sludge. Int. J. Smart Grid Clean Energy 2017, 6, 61–66. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Wu, C.; Wang, K. New insights into the interactions between carbon dioxide and ammonia emissions during sewage sludge composting. Bioresour. Technol. 2013, 136, 385–393. [Google Scholar] [CrossRef]

- Santos, A.; Bustamante, M.A.; Tortosa, G.; Moral, R.; Bernal, M.P. Gaseous emissions and process development during composting of pig slurry: The influence of the proportion of cotton gin waste. J. Clean. Prod. 2016, 112, 81–90. [Google Scholar] [CrossRef]

- Nakasaki, K.; Tran, L.T.H.; Idemoto, Y.; Abe, M.; Rollon, A.P. Comparison of organic matter degradation and microbial community during thermophilic composting of two different types of anaerobic sludge. Bioresour. Technol. 2009, 100, 676–682. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Przybył, J.; Dach, J.; Zaborowicz, M.; Staszak, Ż. Economic Assessment of the Technology Harvesting Maize Straw for Biogas Production. BIO Web Conf. 2018, 10, 01017. [Google Scholar] [CrossRef][Green Version]

- Wojcieszak, D.; Przybył, J.; Mazurkiewicz, J.; Janczak, D.; Zaborowicz, M. Increasing the energy value of corn stover used in biogas plant without pre-processing. Sect. Mod. Energy Power Sources 2018, 18, 495–502. [Google Scholar]

| Composting Mixture Numbers | Composting Mixture | |||

|---|---|---|---|---|

| Weight, FM | Mixture’s Proportion (Calculated in TS) | |||

| SS, kg | MS, kg | SS, % | MS, % | |

| Ch1 | 20.0 | 16.0 | 30 | 70 |

| Ch2 | 33.0 | 14.5 | 44 | 56 |

| Ch3 | 26.3 | 7.5 | 55 | 45 |

| Ch4 | 40.0 | 9.1 | 60 | 40 |

| Substrates | Parameters | ||||

|---|---|---|---|---|---|

| TS % | OM % TS | Corg % | Ntot % | C/N | |

| Sewage sludge | 15.9 | 68.3 | 38.5 | 6.3 | 6.2 |

| Maize straw | 45.8 | 94.0 | 48.5 | 0.6 | 80.9 |

| Parameters | Composting Mixture Numbers | |||

|---|---|---|---|---|

| Ch1 | Ch2 | Ch3 | Ch4 | |

| MC, % | 70.81 | 74.97 | 77.47 | 78.56 |

| OM, % TS | 86.22 | 82.66 | 79.89 | 78.48 |

| C/N | 19.7 | 14.3 | 11.6 | 10.6 |

| TS, kg | 10.51 | 11.89 | 7.62 | 10.53 |

| AAF, dm3 min−1·kg−1 | 0.24 | 0.21 | 0.33 | 0.24 |

| BD, kg·m−3 | 257 | 350 | 349 | 362 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żukowska, G.; Mazurkiewicz, J.; Myszura, M.; Czekała, W. Heat Energy and Gas Emissions during Composting of Sewage Sludge. Energies 2019, 12, 4782. https://doi.org/10.3390/en12244782

Żukowska G, Mazurkiewicz J, Myszura M, Czekała W. Heat Energy and Gas Emissions during Composting of Sewage Sludge. Energies. 2019; 12(24):4782. https://doi.org/10.3390/en12244782

Chicago/Turabian StyleŻukowska, Grażyna, Jakub Mazurkiewicz, Magdalena Myszura, and Wojciech Czekała. 2019. "Heat Energy and Gas Emissions during Composting of Sewage Sludge" Energies 12, no. 24: 4782. https://doi.org/10.3390/en12244782

APA StyleŻukowska, G., Mazurkiewicz, J., Myszura, M., & Czekała, W. (2019). Heat Energy and Gas Emissions during Composting of Sewage Sludge. Energies, 12(24), 4782. https://doi.org/10.3390/en12244782