Study on Rule of Overburden Failure and Rock Burst Hazard under Repeated Mining in Fully Mechanized Top-Coal Caving Face with Hard Roof

Abstract

1. Introduction

2. Materials and Methods

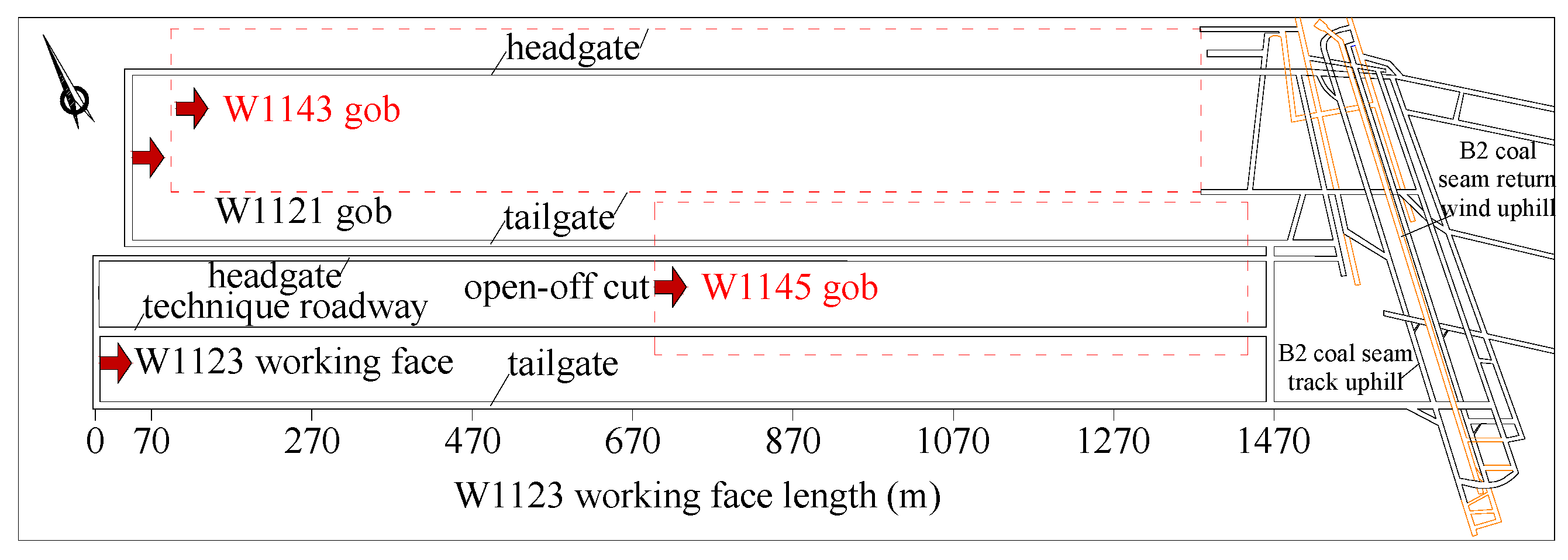

2.1. Engineering Background

2.2. AE Monitoring Principle and Experimental Model Construction

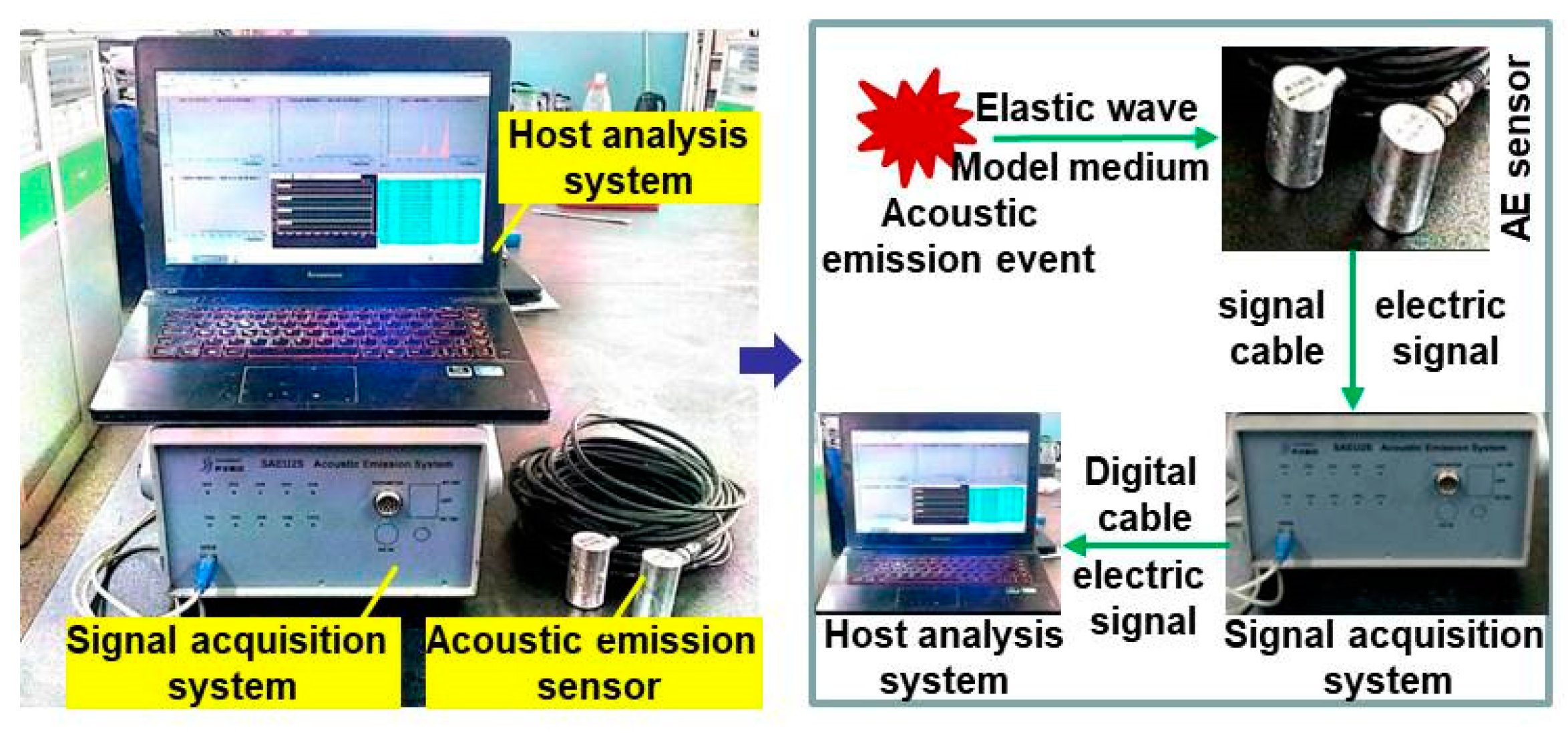

2.2.1. AE Monitoring Principle and Monitoring Device

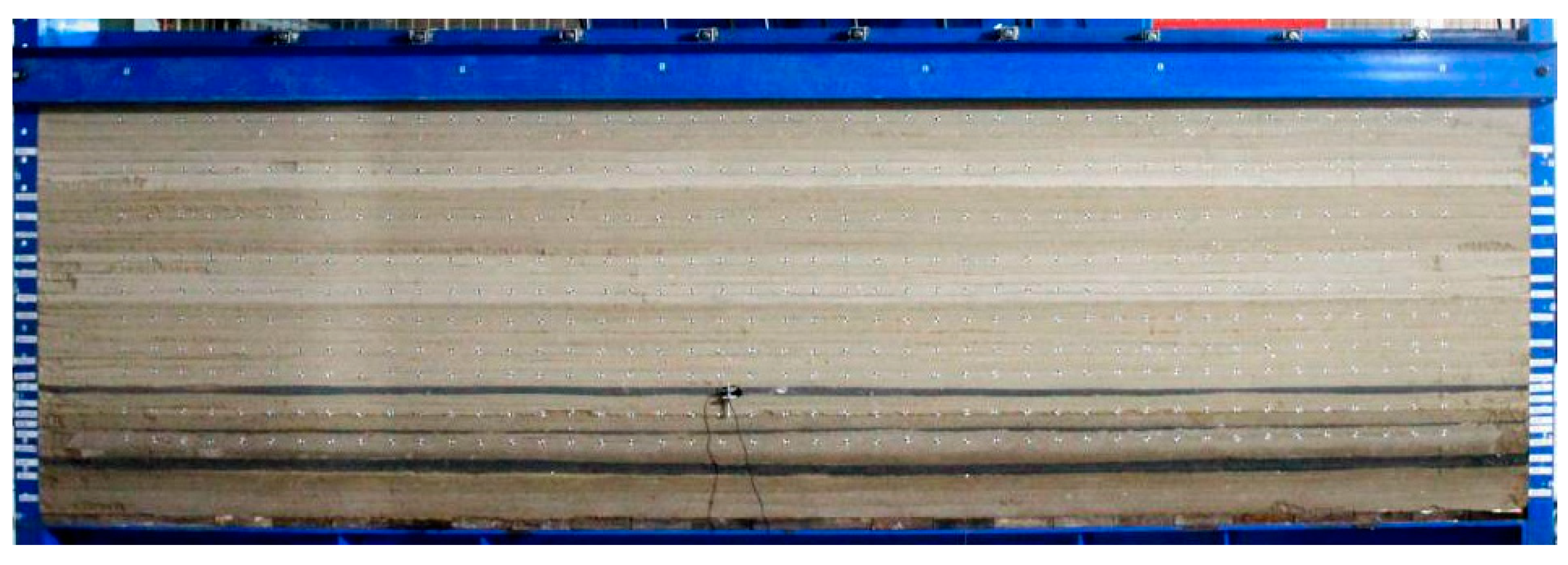

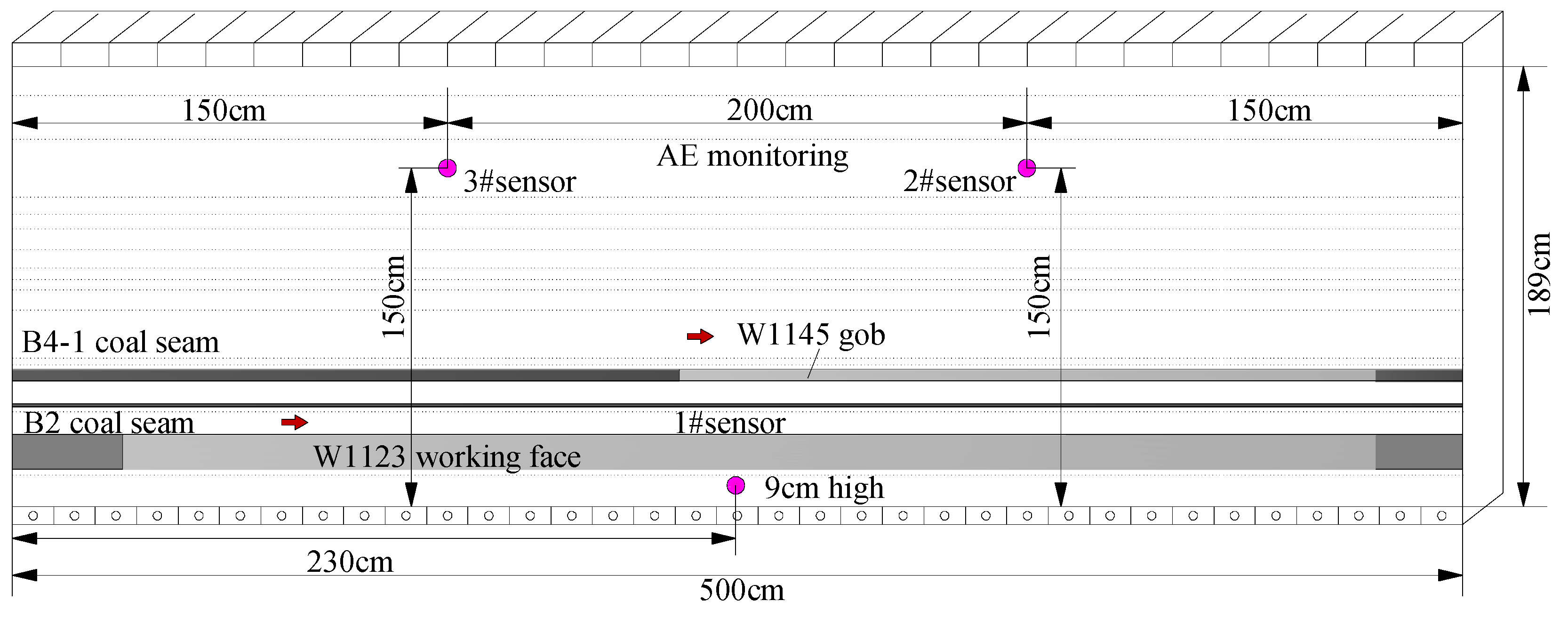

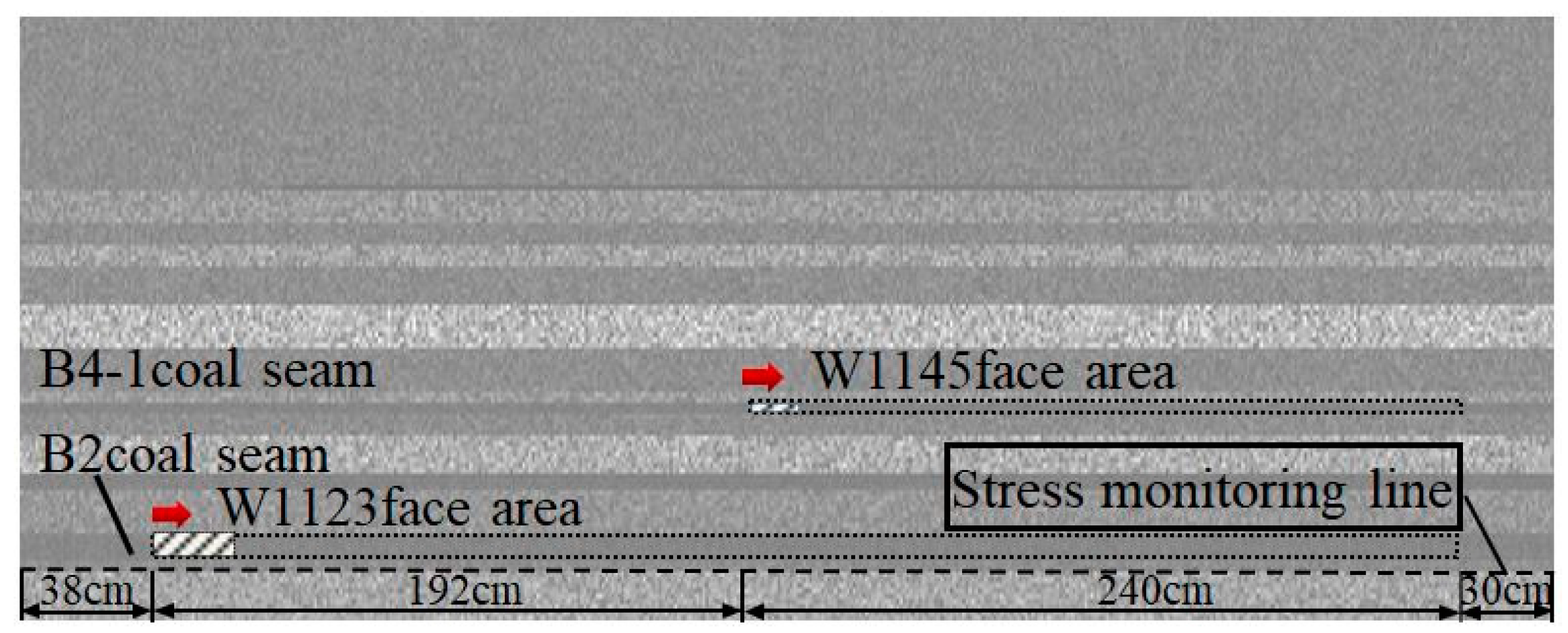

2.2.2. Construction of Similar Model and Layout of AE Monitoring

2.3. Definition of AE Large Energy Event

3. Results and Discussions

3.1. Simulation of Overburden Breakage Based on AE Monitoring

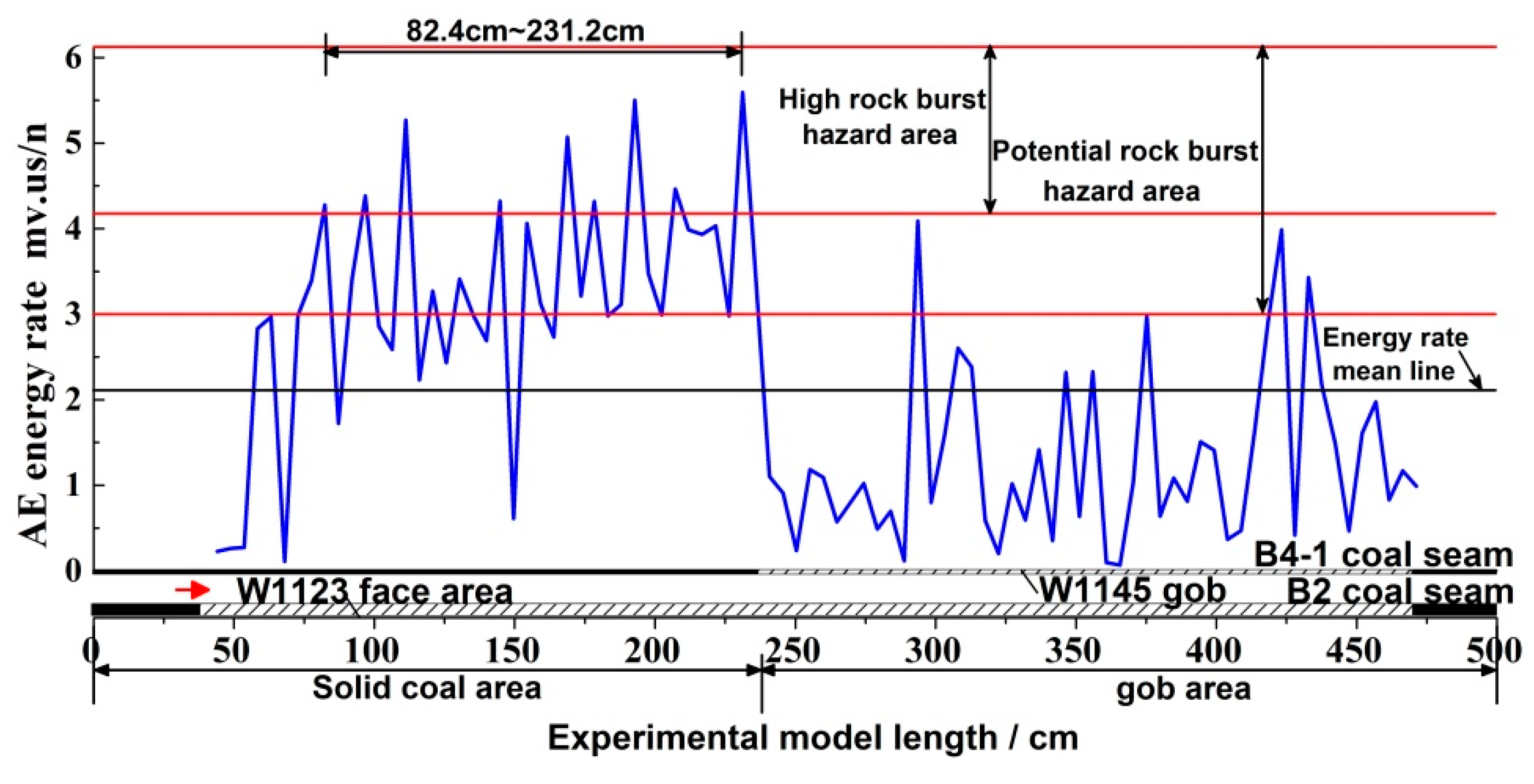

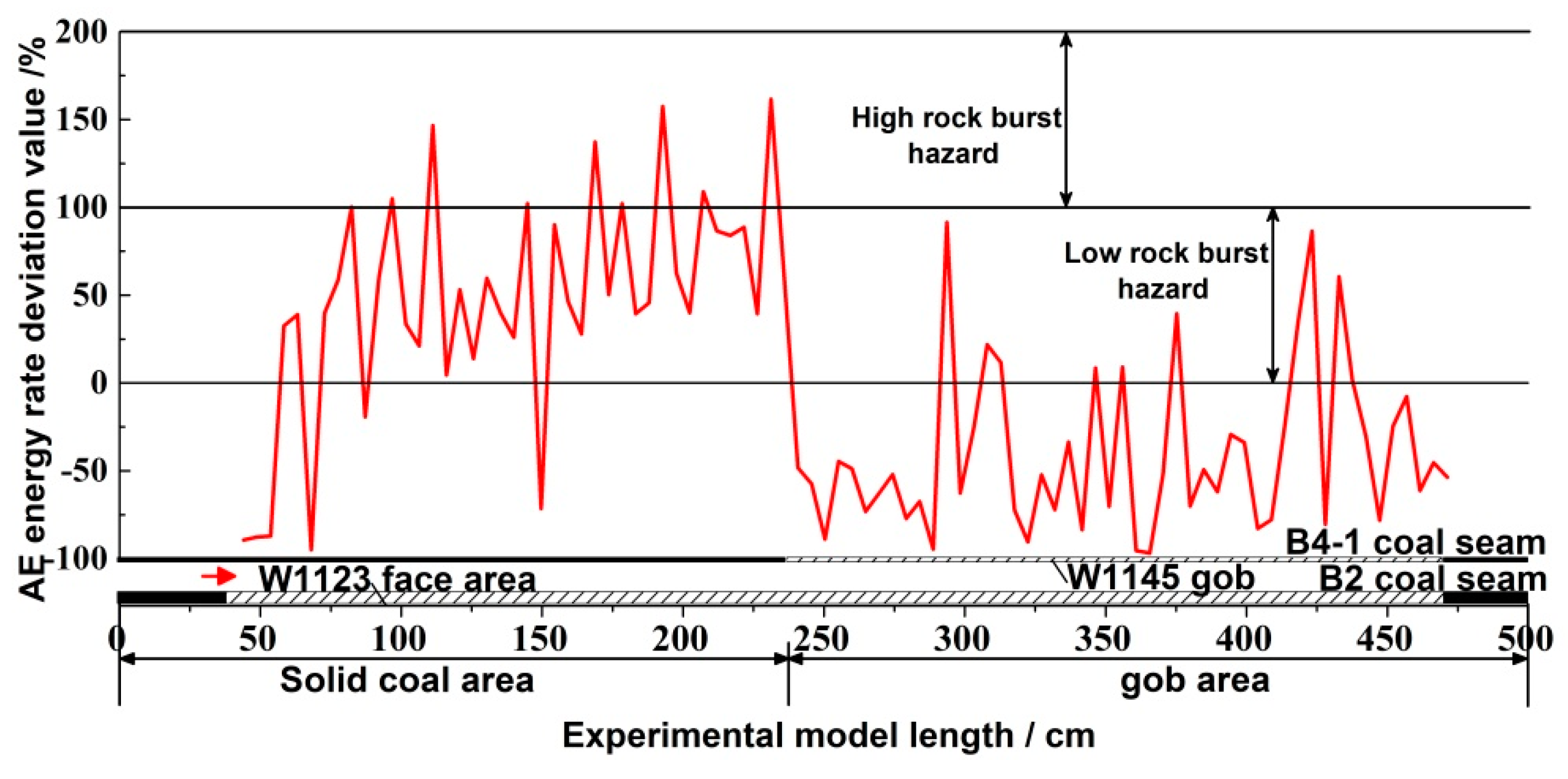

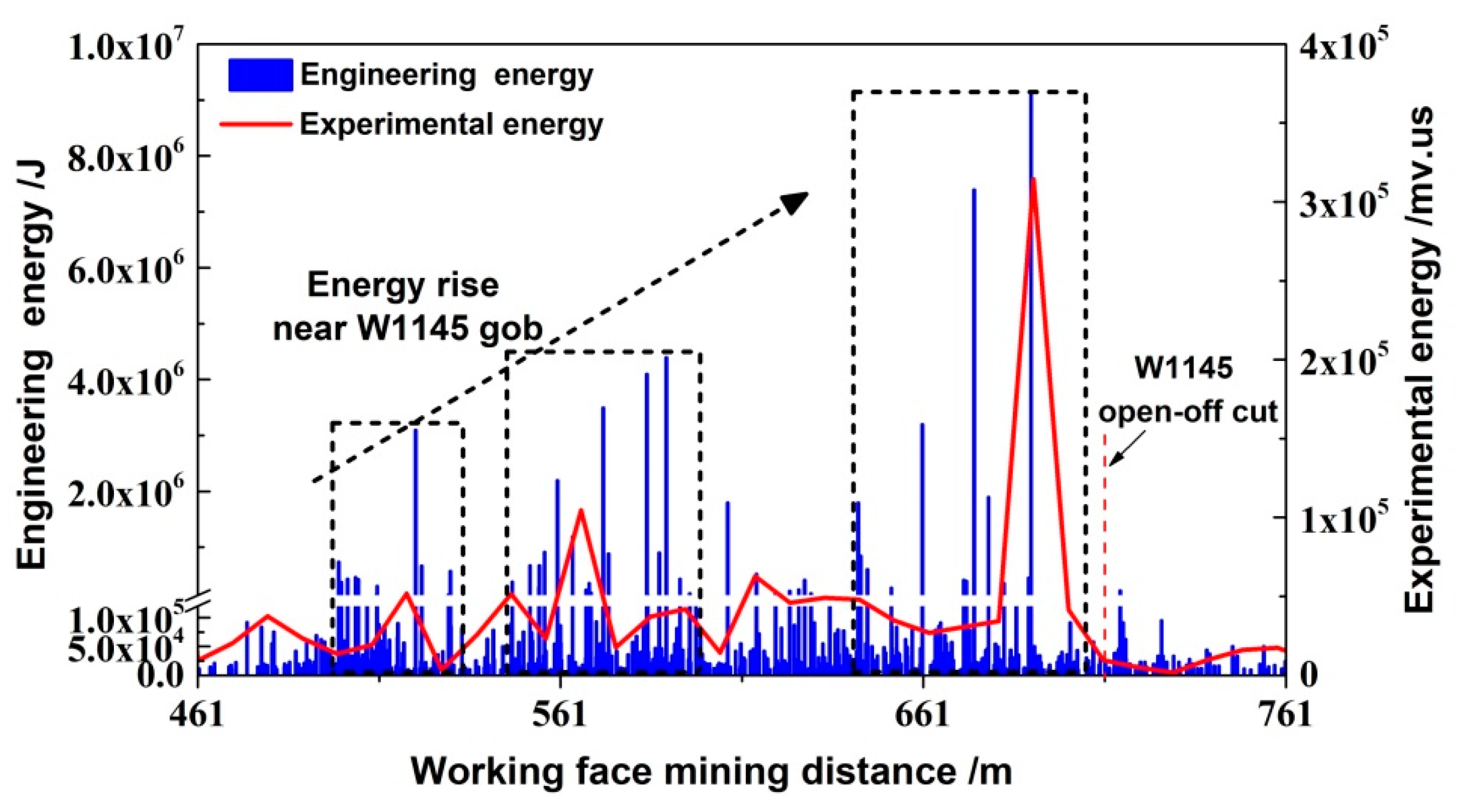

3.1.1. Distribution Characteristics of AE Large Energy Event in W1123

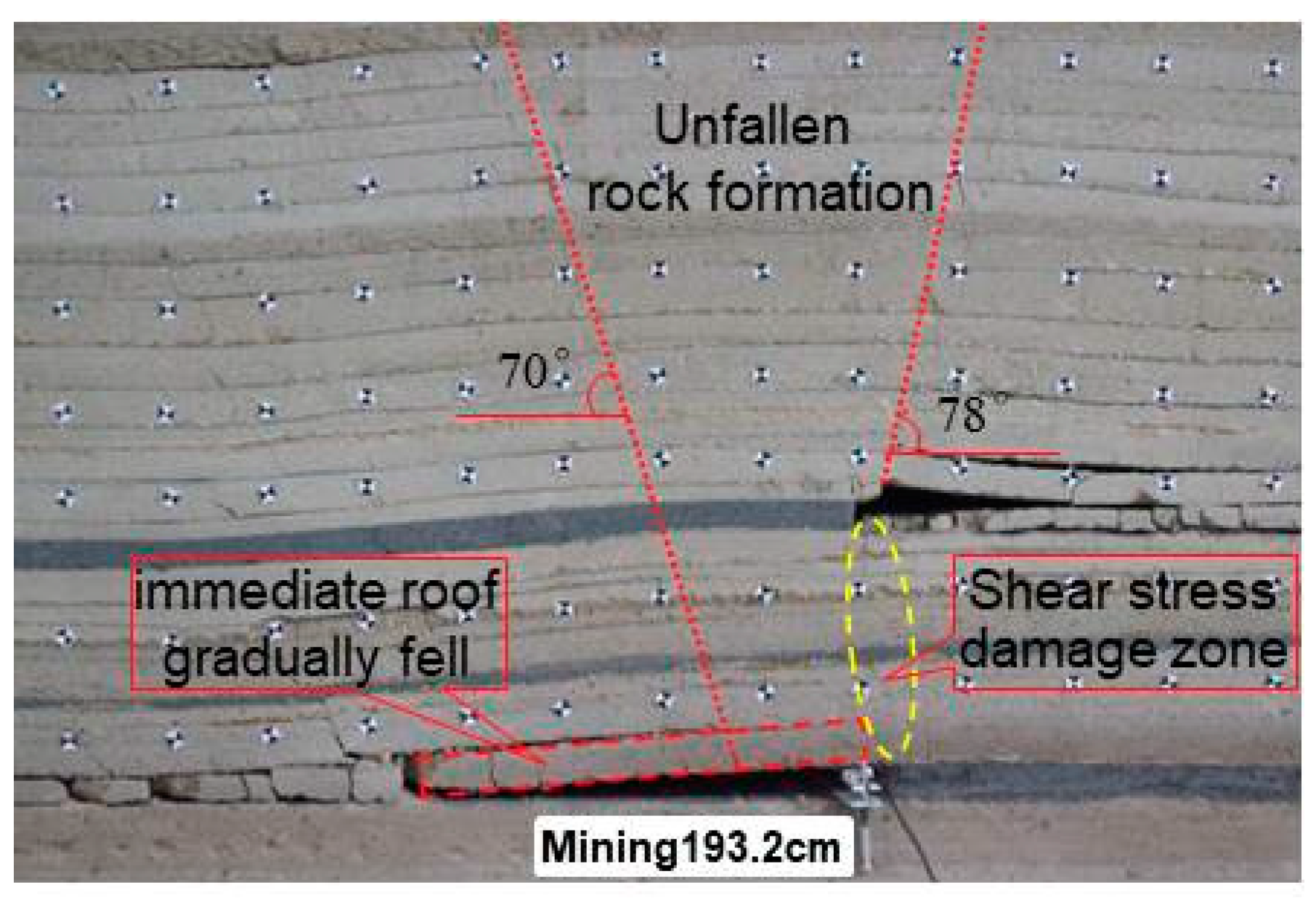

3.1.2. Rule of Overburden Breakage and Characteristics of AE in W1123 Working Face

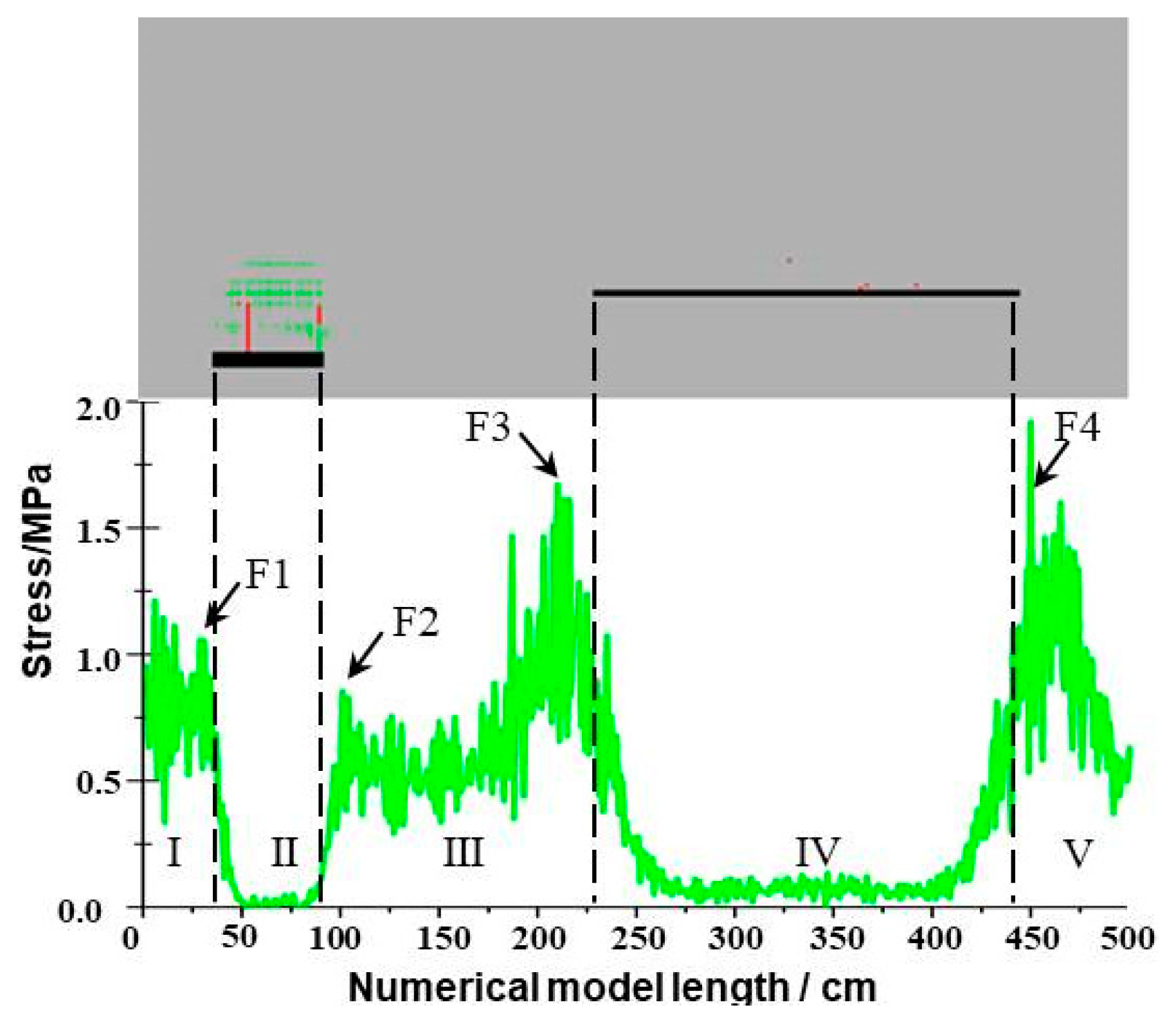

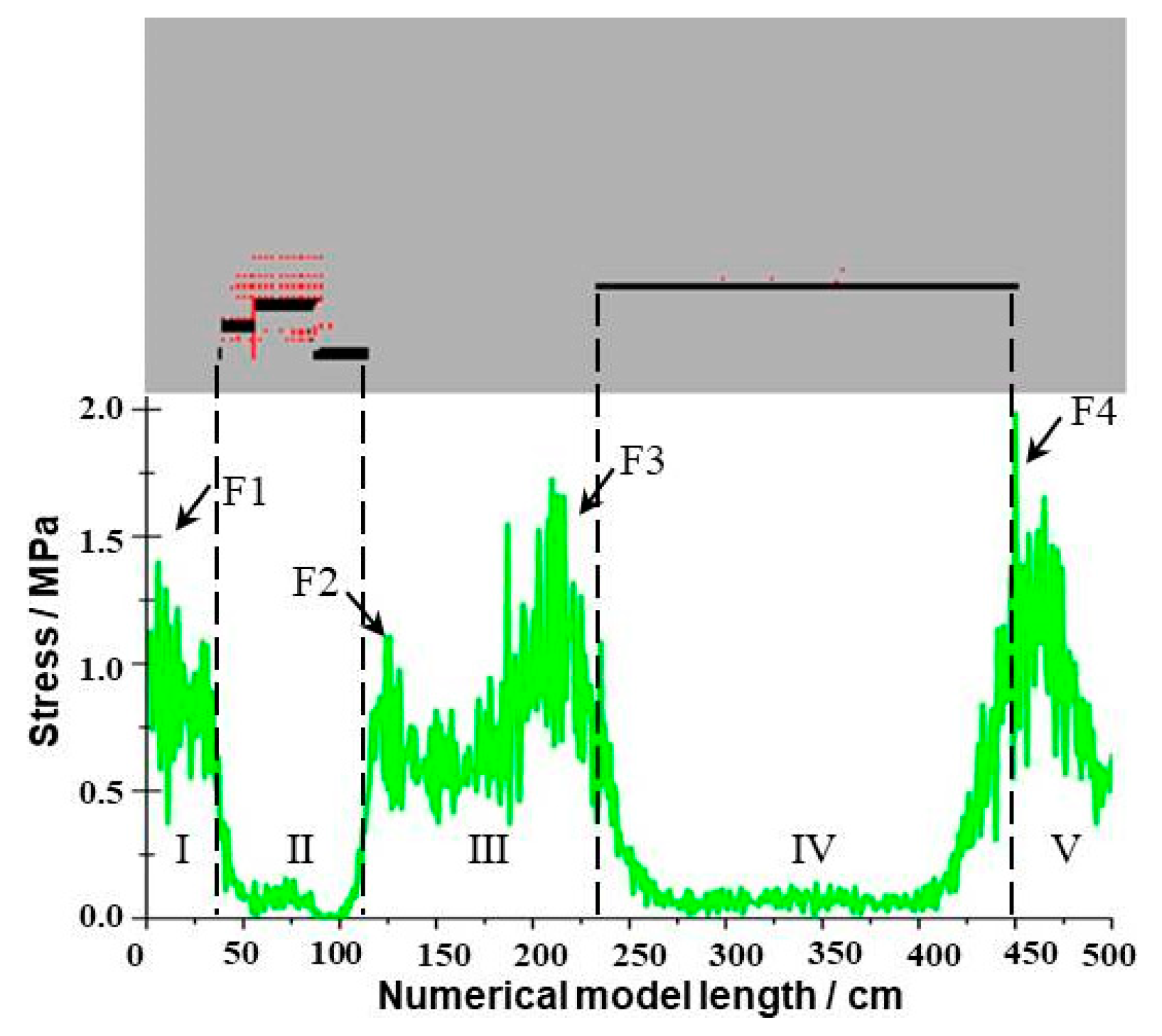

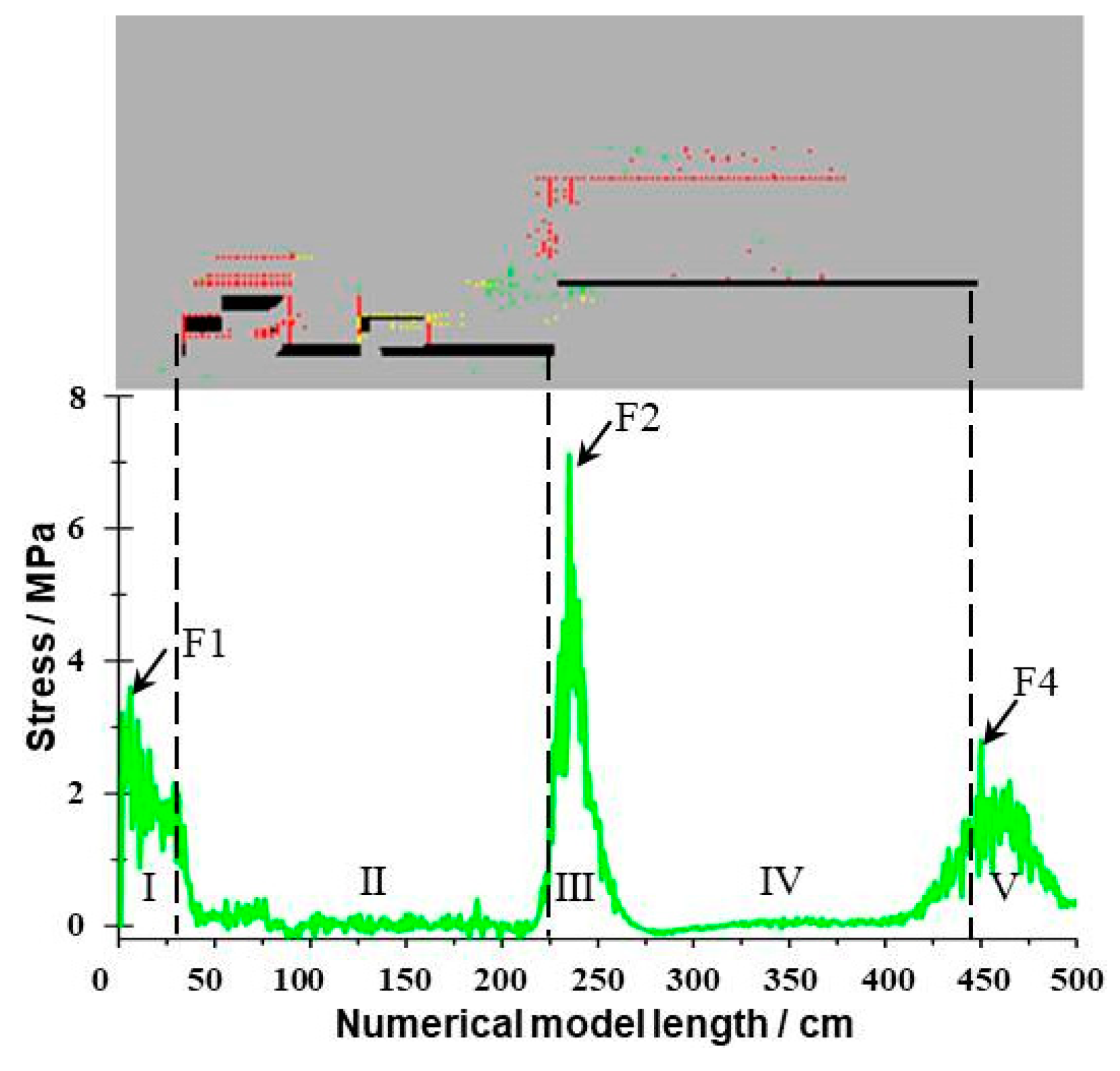

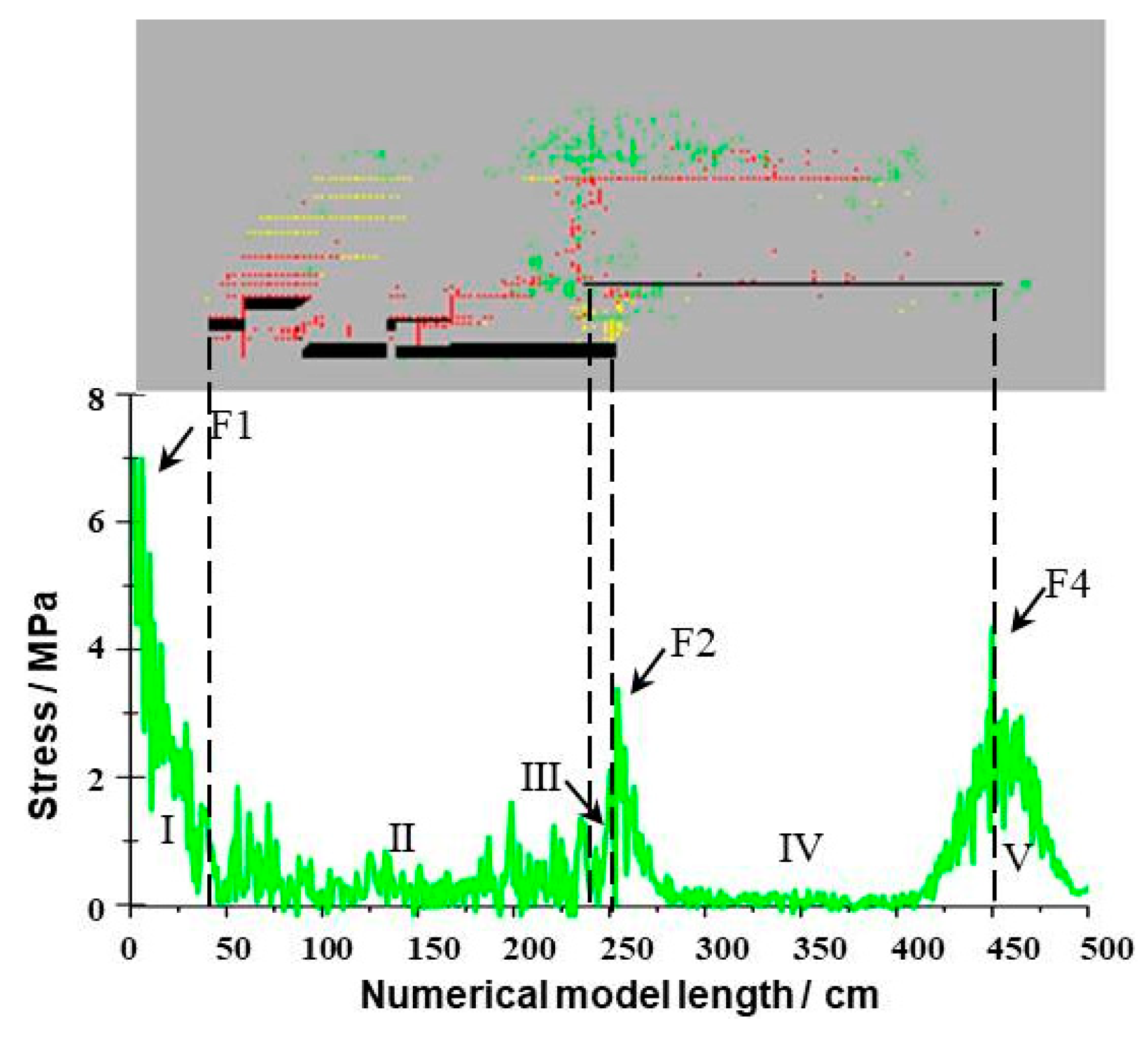

3.2. Numerical Simulation of Stress and AE Distribution Characteristics During Overburden Failure

3.2.1. Election of Numerical Simulation Software and Establishment of Model

3.2.2. Analysis of Numerical Simulation Results

3.3. Discussions

3.3.1. Analysis of Rock Burst Hazard in Working Face

3.3.2. Engineering Practice Verification and Suggestions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, G.F.; Gong, S.Y.; Dou, L.M.; Cai, W.; Yuan, X.Y.; Fan, C.J. Rock burst mechanism and control in coal seam with both syncline and hard strata. Saf. Sci. 2019, 115, 320–328. [Google Scholar] [CrossRef]

- Wang, P.; Jiang, L.S.; Zheng, P.Q.; Qin, G.P.; Zhang, G.P. Inducing mode analysis of rock burst in fault-affected zone with a hard–thick stratum occurrence. Environ. Earth Sci. 2019, 78, 467. [Google Scholar] [CrossRef]

- Feng, X.J.; Wang, E.Y.; Shen, R.X.; Wei, M.Y.; Chen, Y.; Cao, X.Q. The dynamic impact of rock burst induced by the fracture of the thick and hard key stratum. Procedia Eng. 2011, 26, 457–465. [Google Scholar]

- Shen, W.L.; Wang, M.; Cao, J.; Su, F.Q.; Nan, H.; Li, X.L. Mining-Induced Failure Criteria of Interactional Hard Roof Structures: A Case Study. Energies 2019, 12, 3016. [Google Scholar] [CrossRef]

- Zhao, T.B.; Guo, W.Y.; Tan, Y.L.; Yin, Y.C.; Cai, L.S.; Pan, J.F. Case Studies of Rock Bursts Under Complicated Geological Conditions During Multi-seam Mining at a Depth of 800 m. Rock Mech. Rock Eng. 2018, 51, 1539–1564. [Google Scholar] [CrossRef]

- Sun, S.G.; Gong, Z.Q.; Wei, S.Y. The Study of Rock Burst Induced by Underground Mining Excavation. DEStech Trans. Environ. Energy Earth Sci. 2017, 7857. [Google Scholar] [CrossRef]

- Liang, P.; Zhang, Y.B.; Tian, B.Z.; Yao, X.L.; Sun, L.; Liu, X.X. Experimental study on energy evolution characteristics in the process of tunnel rock burst. Chin. J. Rock Mech. Eng. 2019, 38, 736–746. [Google Scholar]

- He, J.; Dou, L.M.; Wang, S.W.; Shan, C.H. Study on mechanism and type of hard roof inducing rock burst. J. Min. Saf. Eng. 2017, 34, 1122–1127. [Google Scholar]

- Pan, Y.S.; Li, Z.H.; Zhang, M.T. Distribution, type, mechanism and prevention of rock burst in China. Chin. J. Rock Mech. Eng. 2003, 22, 1844–1851. [Google Scholar]

- Lan, H.; Du, T.T.; Peng, Y.W.; Zhang, C.J. Rock-burst mechanism and prevention in working face of shallow buried coal-seam. J. China Coal Soc. 2012, 7, 1618–1623. [Google Scholar]

- Lu, J.G.; Jiang, Y.D.; Li, S.G. Characteristics and mechanism research of coal bumps induced by faults based on extra thick and hard roof. J. China Coal Soc. 2014, 39, 1961–1969. [Google Scholar]

- Pang, X.F. Study on the Mechanism and Prevention Technology of Rock Burst in Isolated Island Face with Hard Roof; China University of Mining and Technology: Beijing, China, 2013. [Google Scholar]

- Li, X.H.; Zhang, X.D. Mechanism and prevention of rock-burst by immediate roof breakage in shallow-buried coal seam. J. China Coal Soc. 2017, 42, 510–517. [Google Scholar]

- Li, H.G.; Li, H.M. Mechanical properties and AE characteristics of thick hard roof sandstone in Shendong coal field. Int. J. Coal Sci. Technol. 2017, 4, 147–158. [Google Scholar] [CrossRef]

- Rasskazov, I.Y.; Migunov, D.S.; Anikin, P.A.; Gladyr’, A.V.; Tereshkin, A.A.; Zhelnin, D.O. New-generation portable geoacoustic instrument for rock burst hazard assessment. J. Min. Sci. 2015, 51, 614–623. [Google Scholar] [CrossRef]

- Li, N.; Wang, E.Y.; Ge, M.C.; Liu, J. The fracture mechanism and AE analysis of hard roof: A physical modeling study. Arab. J. Geosci. 2015, 8, 1895–1902. [Google Scholar] [CrossRef]

- Dou, L.M.; Chen, T.J.; Gong, S.Y.; He, H.; Zhang, S.B. Rock burst hazard determination by using computed tomography technology in deep workface. Saf. Sci. 2012, 50, 736–740. [Google Scholar] [CrossRef]

- Lu, C.P.; Liu, G.J.; Liu, Y.; Zhang, N.; Xue, J.H.; Zhang, L. Microseismic multi-parameter characteristics of rock burst hazard induced by hard roof fall and high stress concentration. Int. J. Rock Mech. Min. Sci. 2015, 76, 18–32. [Google Scholar] [CrossRef]

- XU, J.; Ma, F.H.; Han, J. Rock burst hazard assessment based on electromagnetic emission in Xingfu Mine. J. Coal Sci. Eng. 2012, 18, 25–28. [Google Scholar] [CrossRef]

- Dou, L.M.; Cai, W.; Cao, A.Y.; Guo, W.H. Comprehensive early warning of rock burst utilizing microseismic multi-parameter indices. Int. J. Min. Sci. Technol. 2018, 28, 767–774. [Google Scholar] [CrossRef]

- Wang, S.H.; Liu, J.X.; Tang, C.N. Study on generation and numerical simulation of impact pressure in coal layer mining process. Chin. J. Rock Mech. Eng. 2002, 21, 2480–2483. [Google Scholar]

- Xiong, Z.Q.; He, H.J. Numerical Simulation of Rock Burst Stress and Its Control by Stress-Relief. J. Min. Saf. Eng. 2006, 32, 489–493. [Google Scholar]

- Shan, P.F.; Lai, X.P. Numerical Simulation of the Fluid-Solid Coupling Process During the Failure of a Fractured Coal-Rock Mass Based on the Regional Geostress Characteristics. Transp. Porous Media 2018, 124, 1061–1079. [Google Scholar] [CrossRef]

- Shan, P.F.; Lai, X.P. Influence of CT scanning parameters on rock and soil images. J. Vis Commun. Image Represent 2019, 58, 642–650. [Google Scholar] [CrossRef]

- Liu, Z.G. Research and Application of Monitoring Equipment Based on the AE Principle Rock Burst; Shandong University of Science and Technology: Qingdao, China, 2011. [Google Scholar]

- Li, X.W. AE Mode and Application of Working Face Impact Ground Pressure; Shandong University of Science and Technology: Qingdao, China, 2004. [Google Scholar]

- Yang, G.Y.; Jiang, F.X.; Qu, X.C.; Li, L.; Wei, Q.D.; Li, N.L. Study on comprehensive monitoring and early warning technology of rock burst in ultra-thick coal seam heading face. Chin. J. Geotech. Eng. 2019, 41, 1949–1958. [Google Scholar]

| Distance (cm) | Energy Rate (Er, mv·us/n) | Energy Rate Deviation (Xi, %) |

|---|---|---|

| 82.4 | 4.28 | 109.8 |

| 96.8 | 4.38 | 114.71 |

| 111.2 | 5.27 | 158.33 |

| 144.8 | 4.32 | 111.76 |

| 168.8 | 5.07 | 148.53 |

| 178.4 | 4.32 | 111.76 |

| 192.8 | 5.50 | 169.61 |

| 207.2 | 4.46 | 118.63 |

| 231.2 | 5.59 | 174.02 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, F.; Dong, S.; Lai, X.; Chen, J.; Cao, J.; Shan, P. Study on Rule of Overburden Failure and Rock Burst Hazard under Repeated Mining in Fully Mechanized Top-Coal Caving Face with Hard Roof. Energies 2019, 12, 4780. https://doi.org/10.3390/en12244780

Cui F, Dong S, Lai X, Chen J, Cao J, Shan P. Study on Rule of Overburden Failure and Rock Burst Hazard under Repeated Mining in Fully Mechanized Top-Coal Caving Face with Hard Roof. Energies. 2019; 12(24):4780. https://doi.org/10.3390/en12244780

Chicago/Turabian StyleCui, Feng, Shuai Dong, Xingping Lai, Jianqiang Chen, Jiantao Cao, and Pengfei Shan. 2019. "Study on Rule of Overburden Failure and Rock Burst Hazard under Repeated Mining in Fully Mechanized Top-Coal Caving Face with Hard Roof" Energies 12, no. 24: 4780. https://doi.org/10.3390/en12244780

APA StyleCui, F., Dong, S., Lai, X., Chen, J., Cao, J., & Shan, P. (2019). Study on Rule of Overburden Failure and Rock Burst Hazard under Repeated Mining in Fully Mechanized Top-Coal Caving Face with Hard Roof. Energies, 12(24), 4780. https://doi.org/10.3390/en12244780