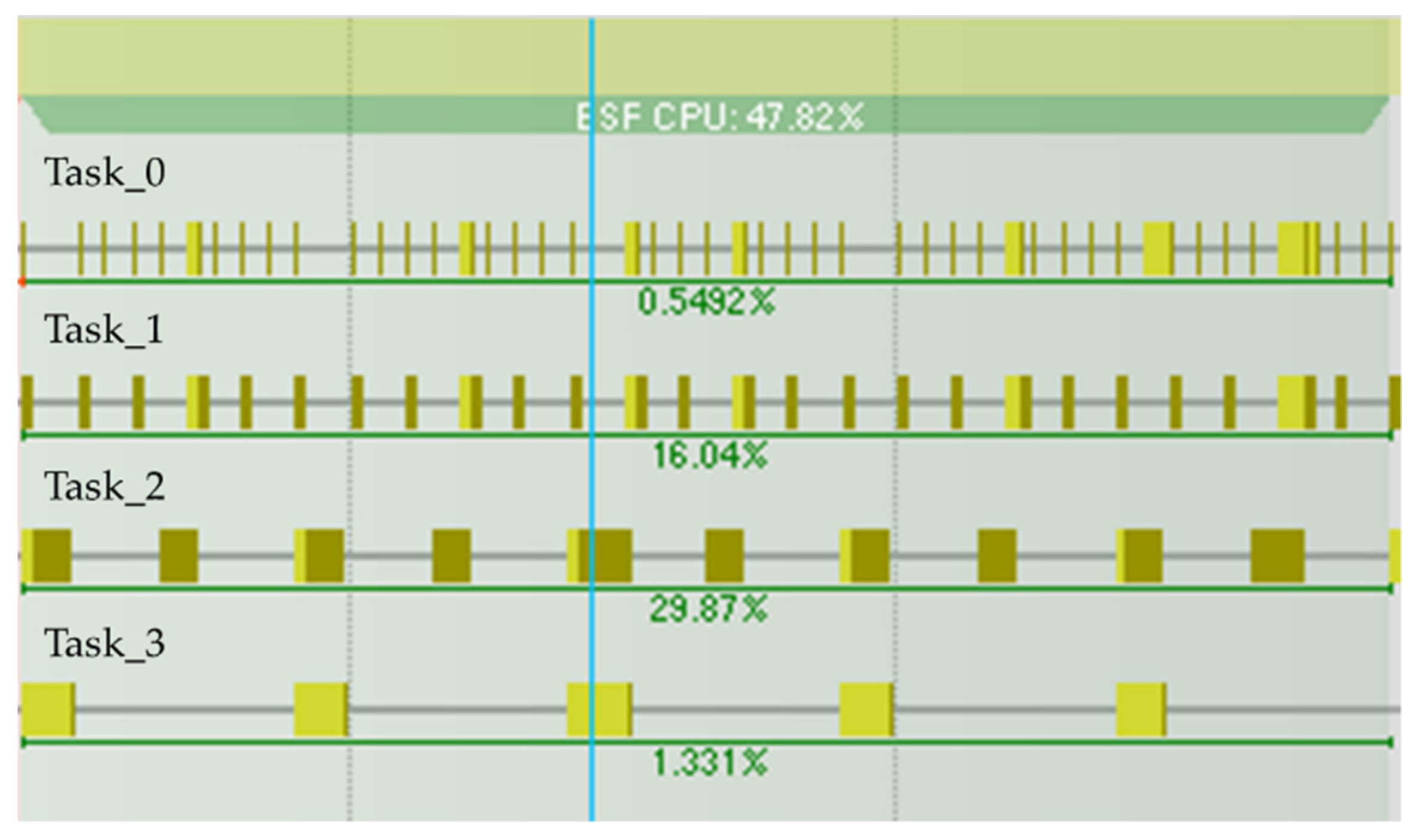

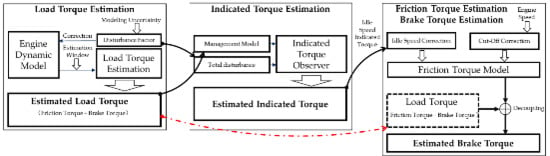

3.1. Engine Dynamic Model

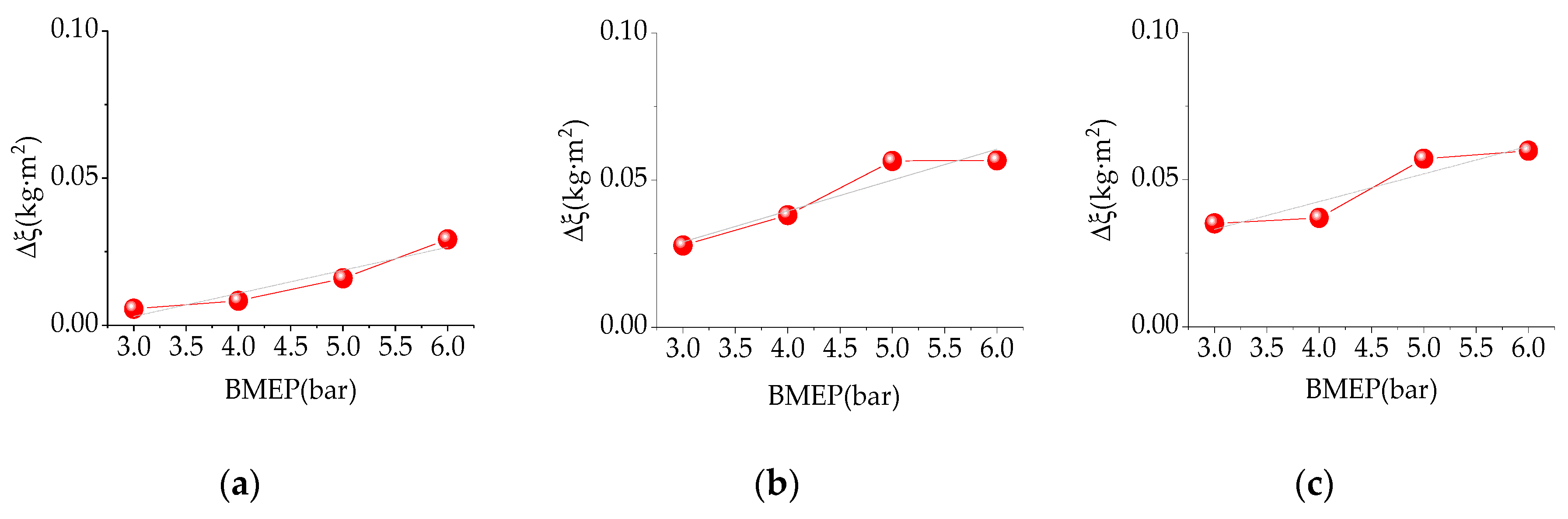

The instantaneous rotational speed of the crankshaft is affected by the torque enforced by the crankshaft following Newton’s law. In the crankshaft dynamics, a combination of the brake torque, the friction torque, the indicated torque, and the reciprocating inertia torque works on the crankshaft, causing engine instantaneous speed to fluctuate. There are two kinds of dynamic model in literature, the elastic model and the rigid-body model. The rigid-body model is simplified from the elastic model. Although the elastic model of the crankshaft has high accuracy, the calculation process needs to consume more computing resources. The rigid-body crankshaft dynamic model needs less computing resources, but it has a lower accuracy. This section proposes a rigid-body crankshaft model with a disturbance factor (1), which is used to compensate the error caused by dynamic model simplification process.

where

is the rotational inertia of the crankshaft,

is the rotation angle of the crankshaft,

is the disturbance factor,

is the angular acceleration of the crankshaft,

is the indicated torque,

is the reciprocating inertia torque,

is the friction torque, and

is the brake torque.

As seen in Equation (1), the angular acceleration is the second-order derivative of the crankshaft rotation angle (), which is very noisy. So, a finite impulse response (FIR) filter is used to process the angular speed signal with a cut-off frequency of 300 Hz. A Kalman filter is used to calculate the angular acceleration.

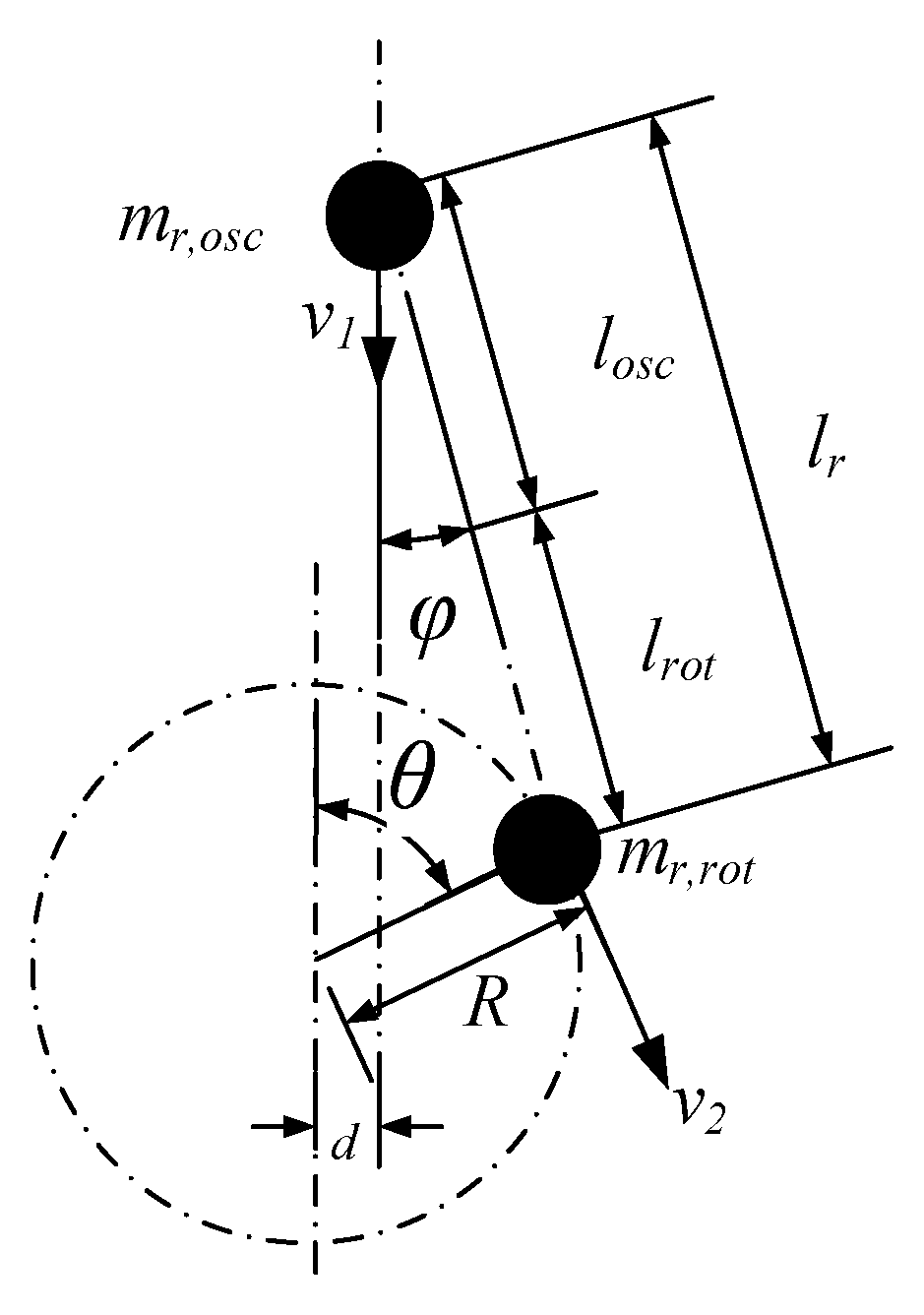

3.1.1. Reciprocating Torque

The reciprocating torque is generated by the reciprocating part of the connecting rod system. The schematic diagram of the movement of the connecting rod system is as follows in

Figure 3.

is the reciprocating mass of the system, including the piston group and the reciprocating part of the connecting rod. is the length of the reciprocating part of crank connecting rod mechanism. is the rotation mass of the system, including the crankshaft and the rotation part of the connecting rod mechanism, and is the length of the rotating part of the connecting rod. denotes the length of the connecting rod. is radius of the crank. is the crankshaft rotation angle. denotes the connecting rod angle. is the velocity of the piston. is the linear velocity of the crank. denotes the piston pin offset, which is neglected in this research.

According to the law of conservation of energy, the system’s kinetic energy consists of the kinetic energy of the reciprocating mass and the rotation mass, which can be expressed as Equation (2) [

23].

The velocities of the reciprocating mass and the rotation mass can be expressed as:

where

denotes the crank radius to connecting rod length ratio [

23].

So, according to Equations (2) and (3), the moment of inertia of the system can be expressed as:

denotes the reciprocating torque [

23].

where:

The total reciprocating torque can be written as:

where:

is the number of cylinders, in this case

.

(

) denotes the phase of the

th cylinder [

13].

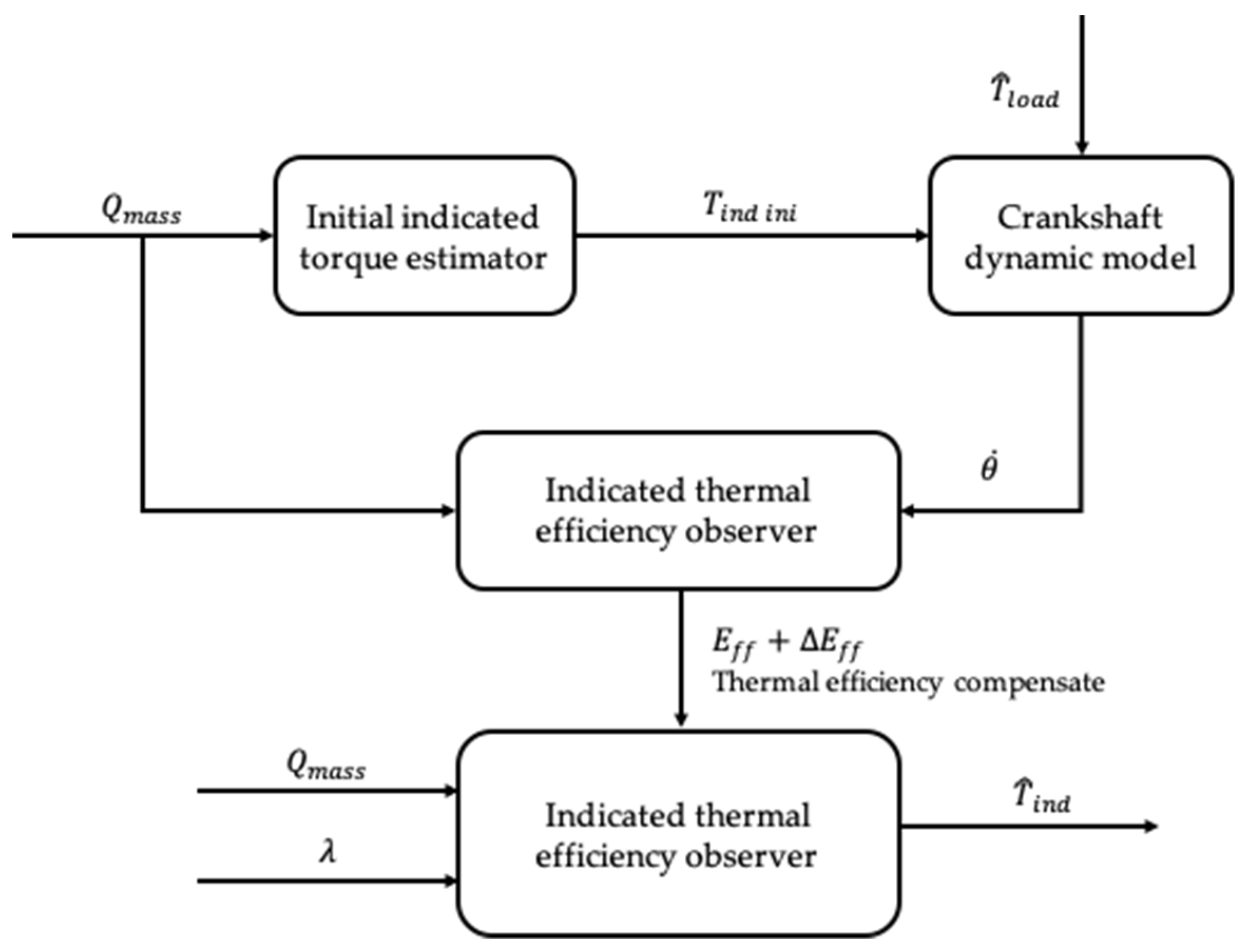

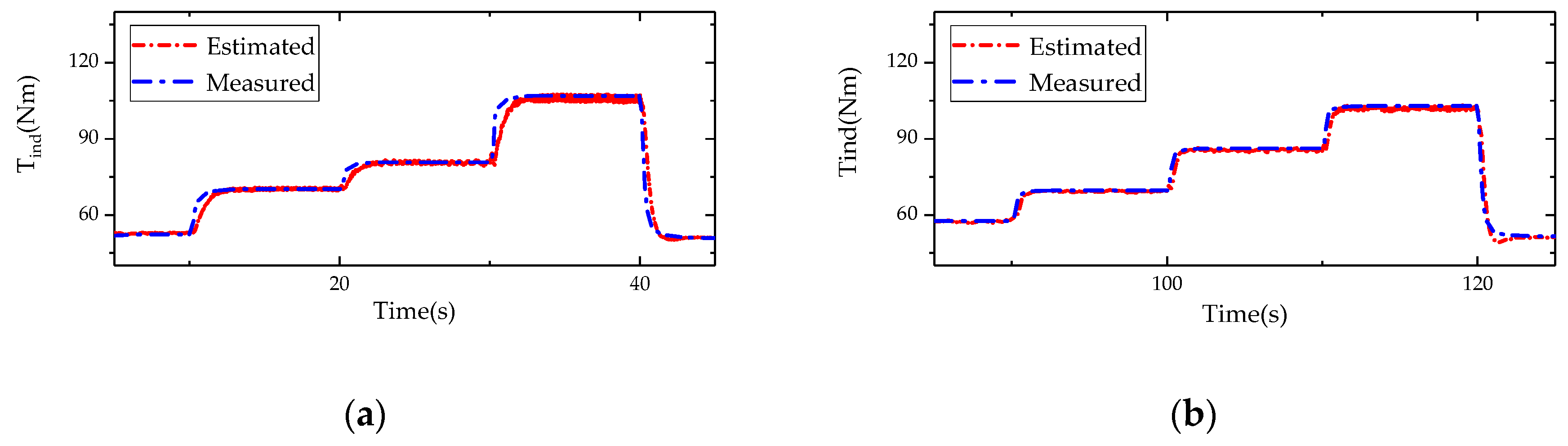

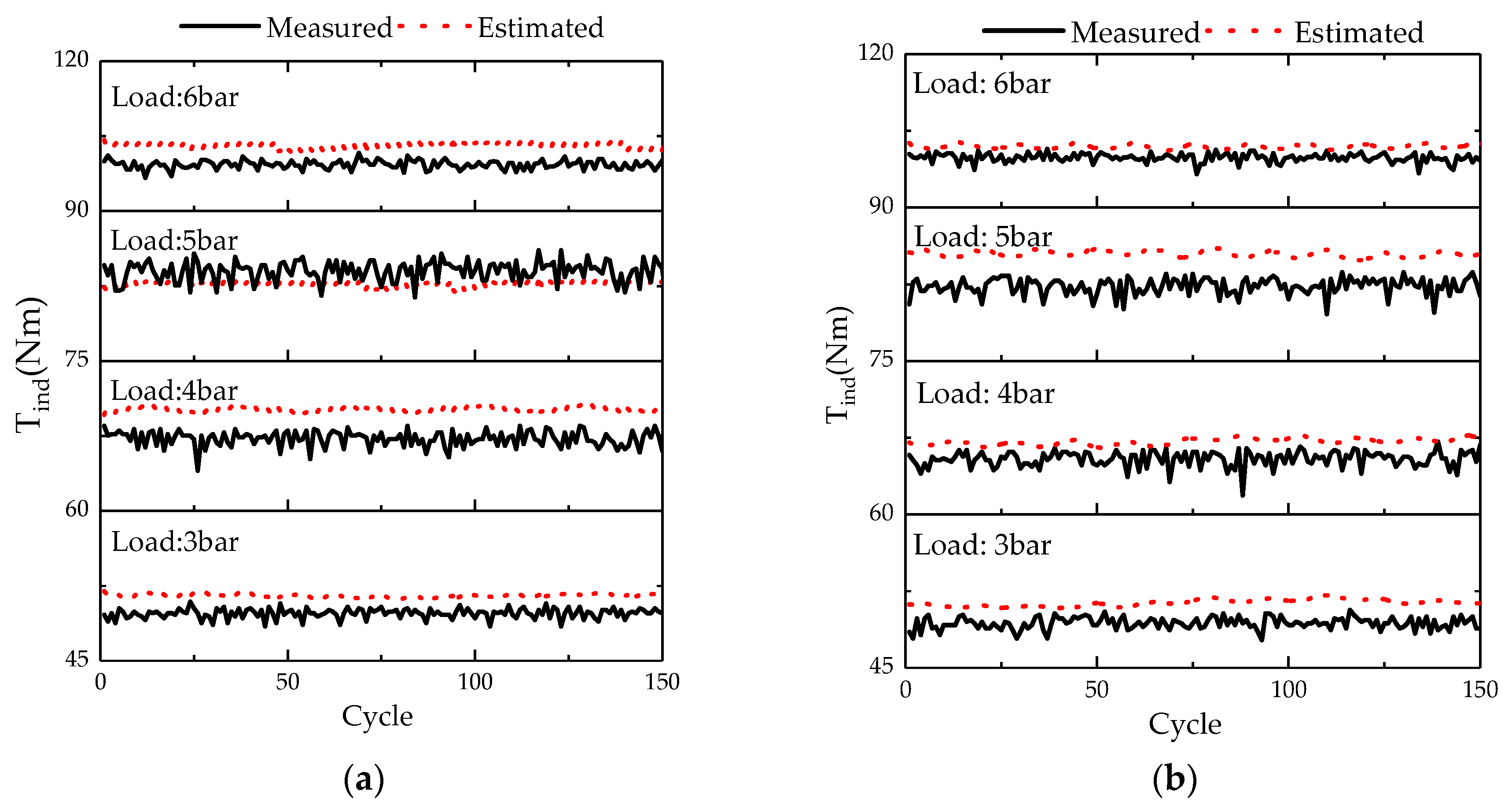

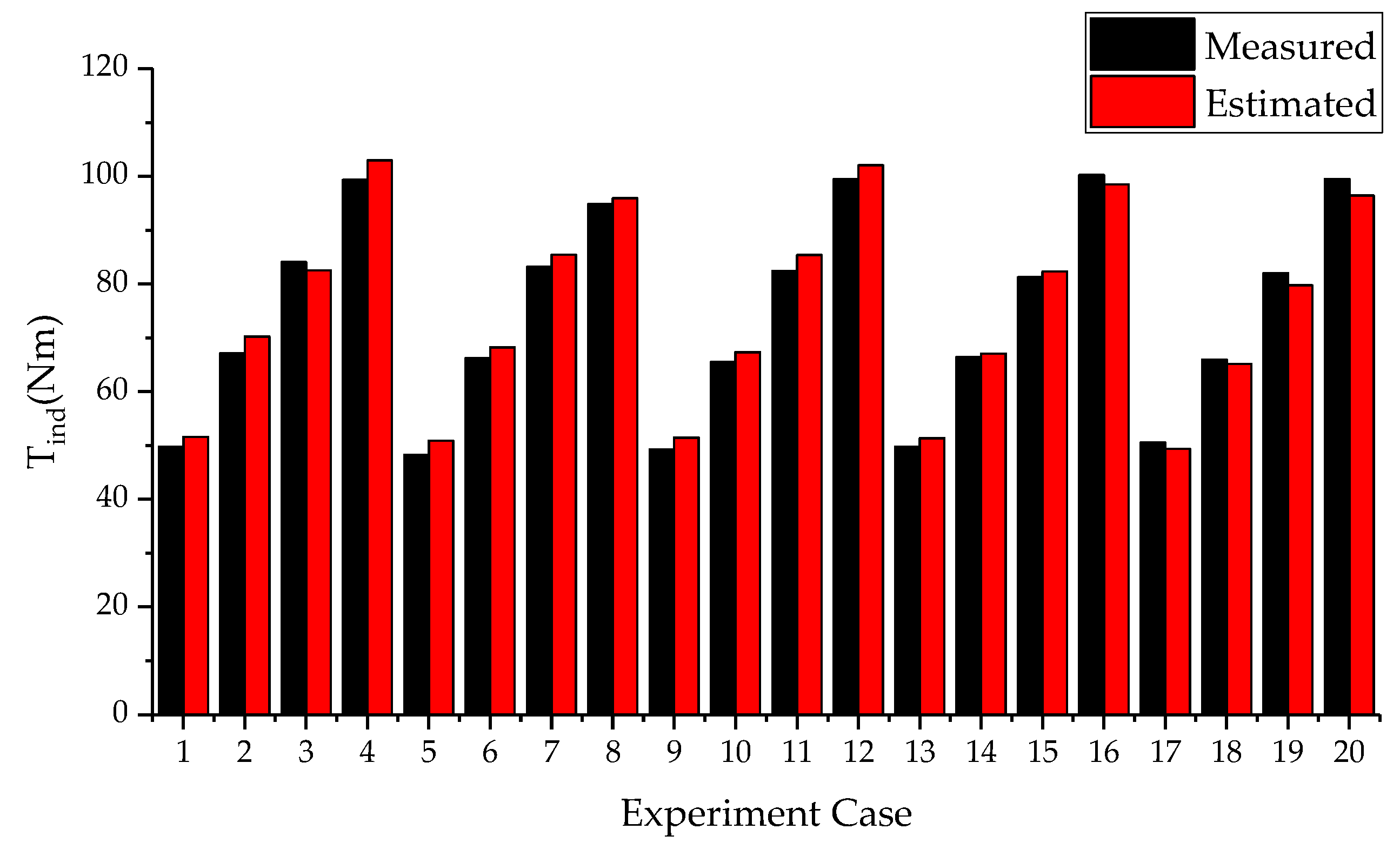

3.1.2. Indicated Torque Estimation

Indicated torque is generated at two process, the compression process and the combustion process. The indicated torque during combustion process is difficult to estimate. However, the compression process can be considered as a polytropic process, the in-cylinder pressure can be estimated using the manifold absolute pressure (MAP) sensor and the intake air temperature (IAT) sensor, assuming that the in-cylinder pressure can be approximated by MAP at the timing of intake valve closing and corrected by volumetric efficiency. The MAP sensor and IAT sensor are already standard sensors equipped in stock engines. The estimated pressure then can be used to calculate the indicated torque during compression process, shown in

Figure 4.

where

denotes the in-cylinder pressure;

denotes the gas volume; and

is the polytropic process factor, which is taken to be 1.3 in this research within the compression stoke [

21].

where

is the combustion chamber volume, and

is the cylinder diameter [

22].

The total indicated torque is:

3.1.3. Load Torque Estimation

For an internal combustion engine, the load torque (

) involves two parts: The brake torque (

) and the friction torque (

).

a slow-varying variable compared to the combustion process, so

can be considered approximately as a constant in one cycle. In the crankshaft dynamic model, both

and

are unknown variables, which makes

difficult to estimate. In

Section 3.1.2,

during the compression process can be estimated, which can be defined as gas torque (

). For four-cylinder engines and engines with less than four cylinders, there is a unique crankshaft angle window, where the sum of the other three cylinders can be neglected [

21]. Within this particular crankshaft angle window, the total indicated torque can be calculated from the cylinder in the compression phase. A

estimator can be designed in this window, where there is no combustion, even for all cylinders. A bench test was done to locate this angle window, and experimental result shows that 50 crank angle before TDC to 20 crank angle before TDC is the unique angle window to estimate the total gas torque for all cylinders. Meanwhile, this angle window can be used to estimate

and

.

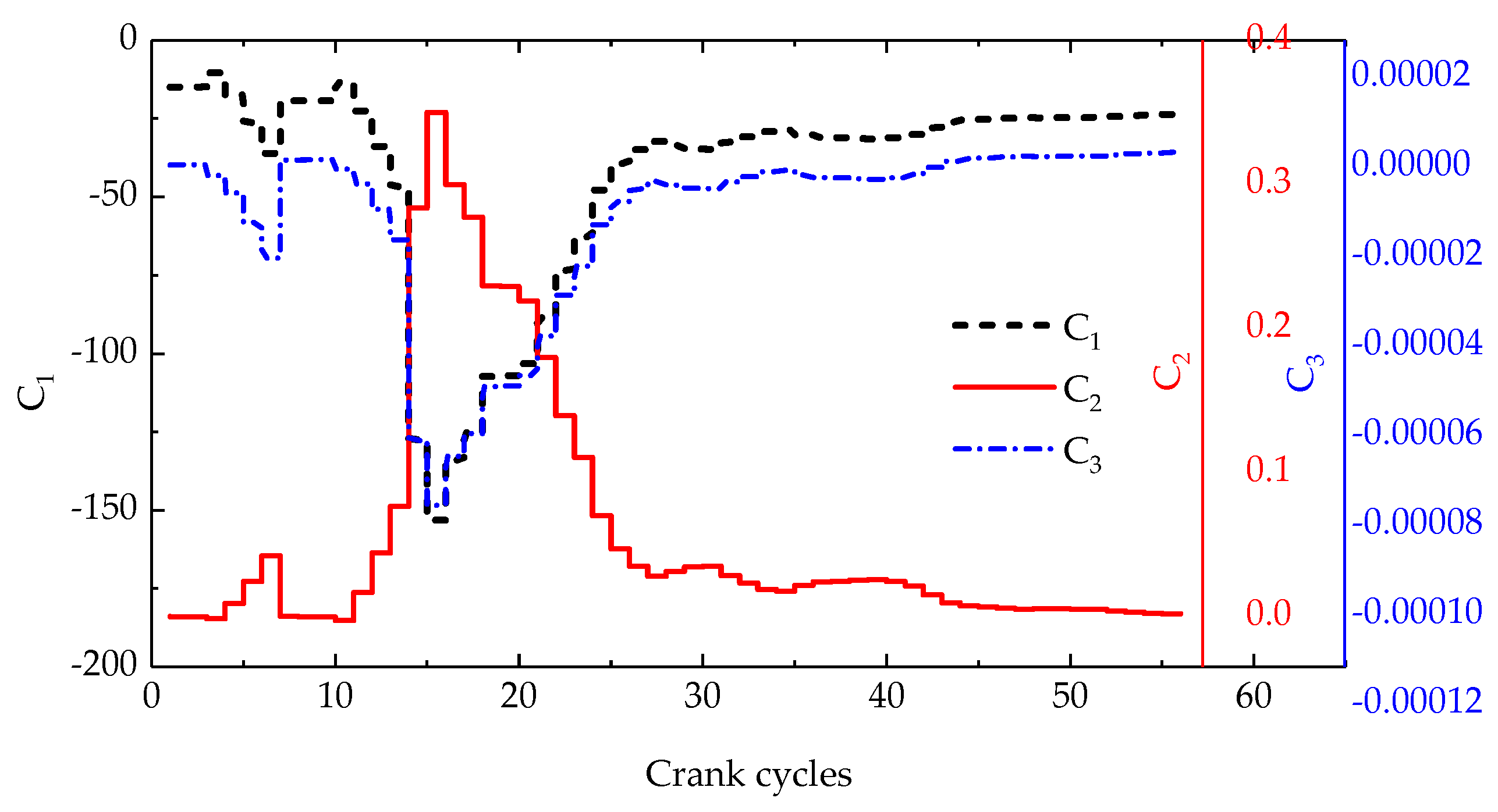

In the unique crankshaft angle window from 50° before TDC to 20° before TDC, the only unknown variables are and . So the estimation issue can be regarded as a system parameter estimation issue. The least-squares method is a method for identifying system parameters. However, there are few sampling points in the unique window, and the least-squares method is challenging for online applications. So estimation algorithm using the recursive least-squares method is proposed, and the algorithm can process the sampling data in multiple cycles. The estimated load torque () at the end of last cycle will be set as the initial load torque into the engine load torque estimator. and are key variables for observer in the next section.

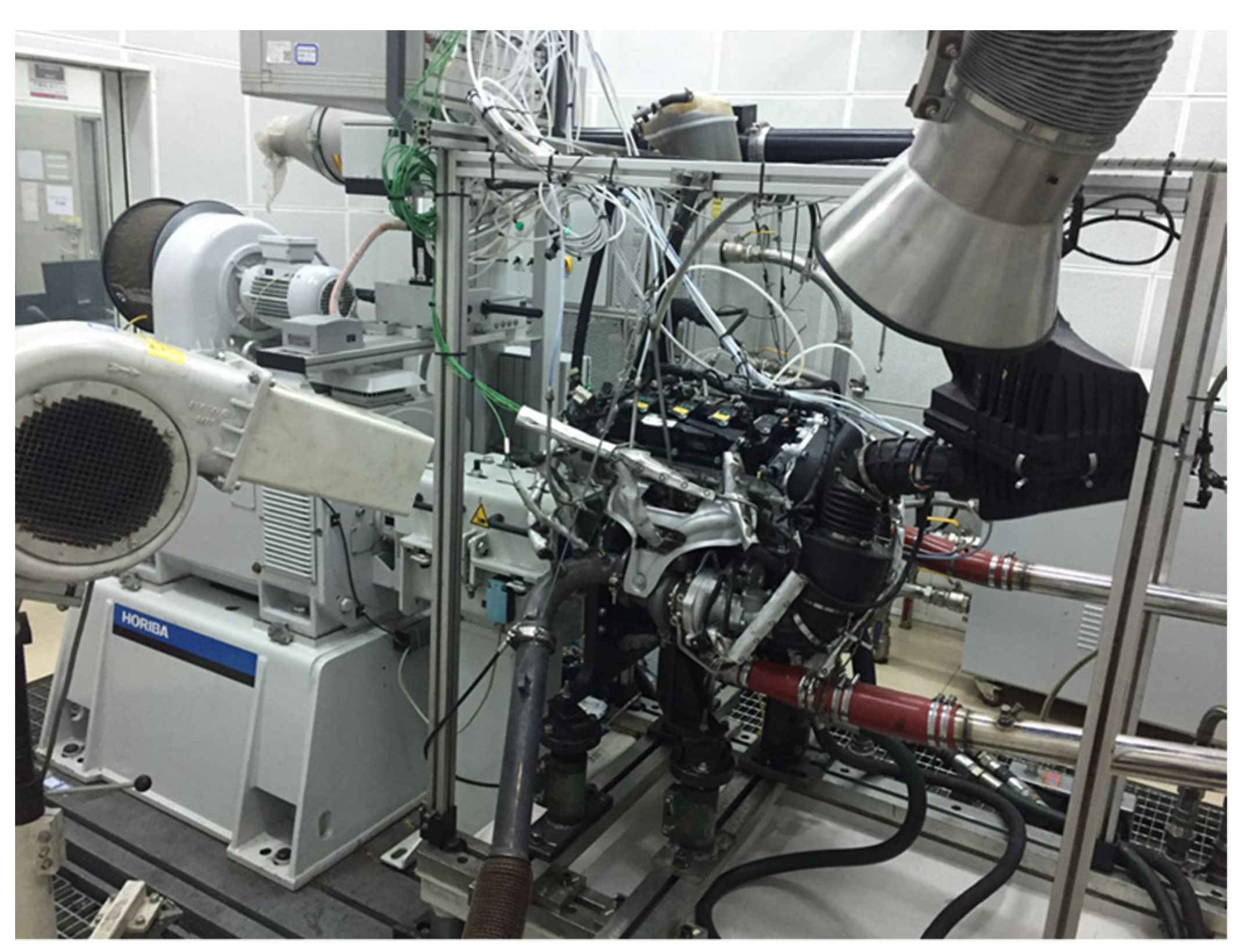

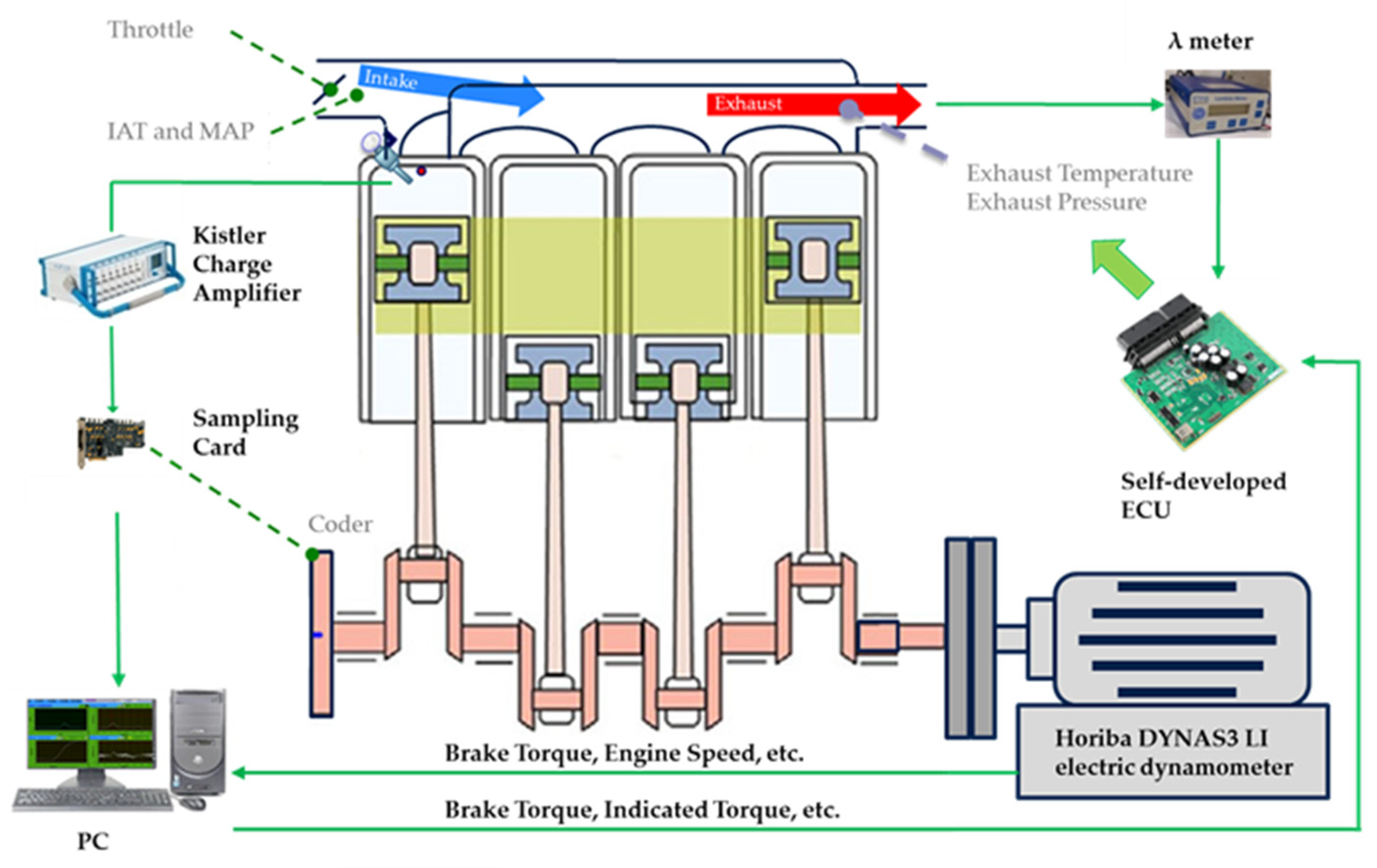

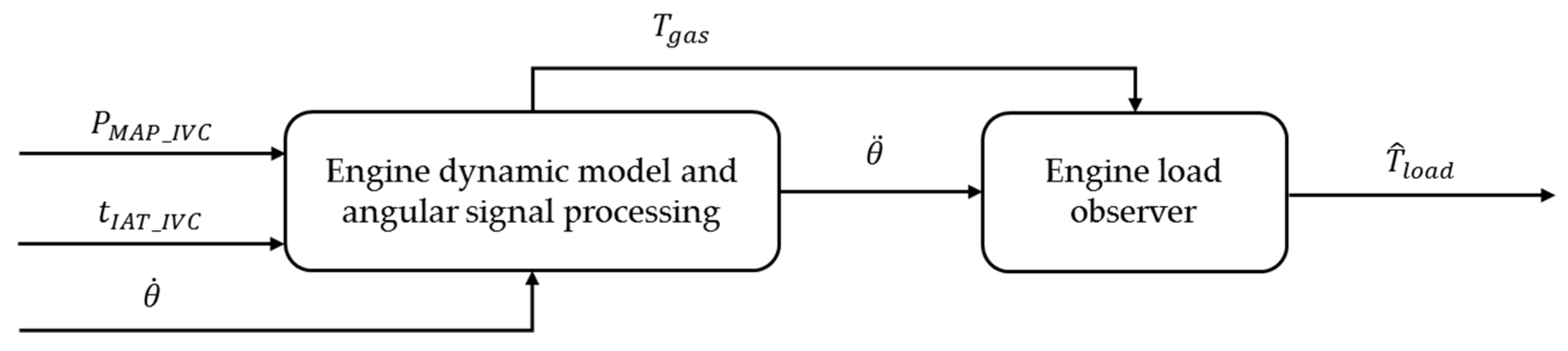

The specific algorithm is shown in

Figure 5. The manifold absolute pressure at intake valve close (IVC)

is used to calculate

.

During the unique crankshaft angle window, Equation (1) can be transformed as:

where:

For the

K times of successive sampling, Equation (10) can be:

where

is white noise with mean value 0.

So Equation (11) can be described as:

According to the recursive least-squares method:

For

+1, when a new

and

are calculated, we define

, so:

Then the

can be estimated using recursive least-squares method:

The convergence of requires a certain amount of and . Therefore, the recursive process is expanded to multiple cycles, that is, the initial value of the estimated parameter , including and , is the result of the last estimated value from the previous cycle.

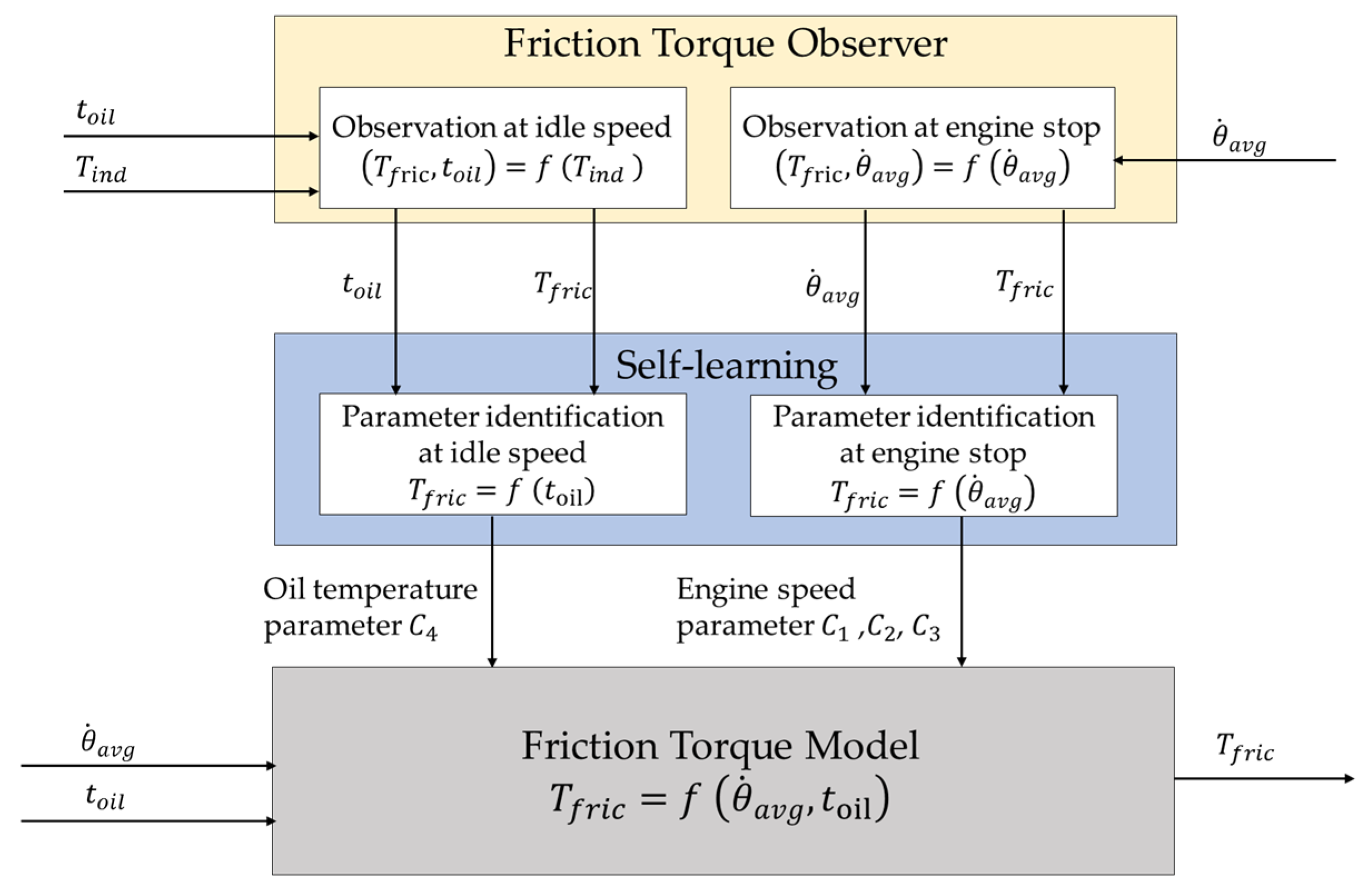

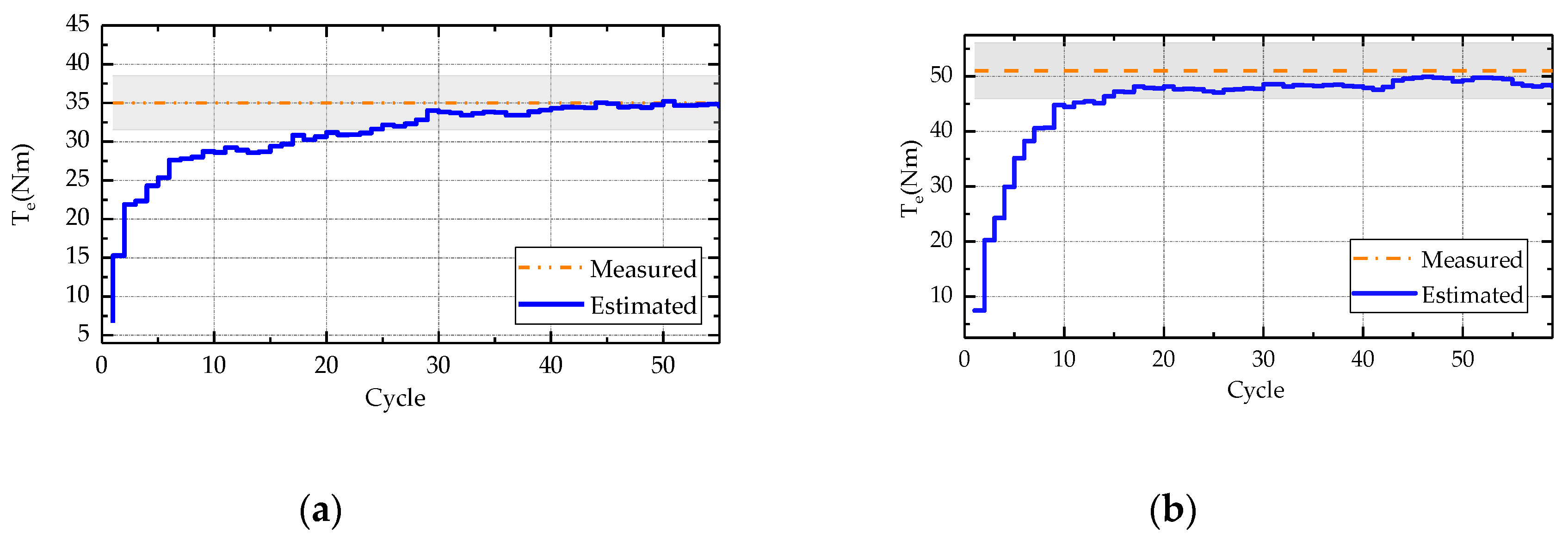

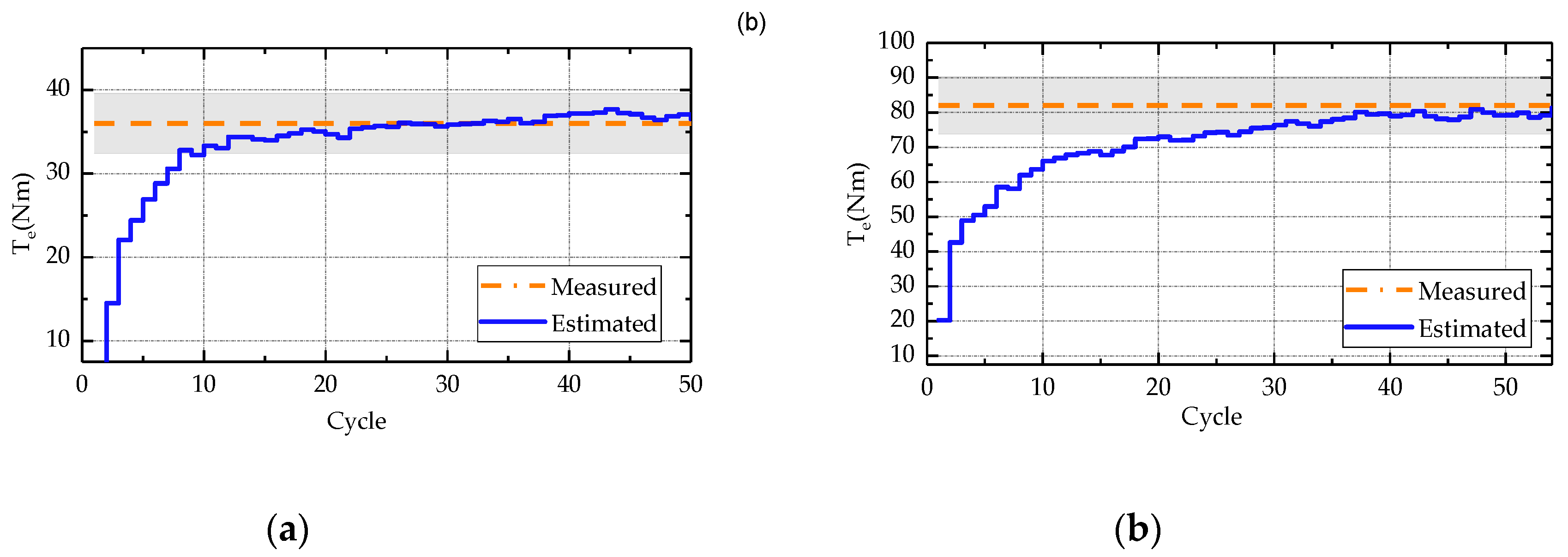

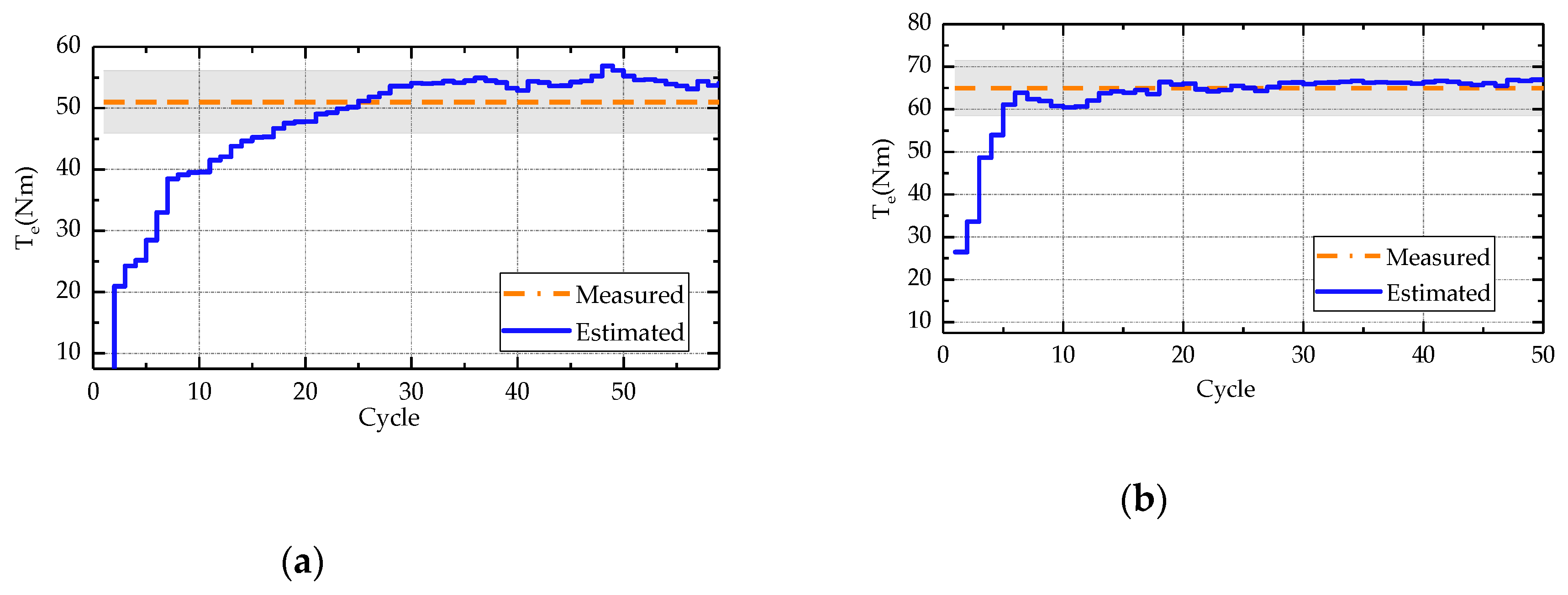

3.3. A Self-Learning Observer for Brake Torque Estimation

The

of a GDI engine (the total torque of the brake torque and friction torque) was estimated. In order to calculate the brake torque (

), the engine friction torque (

) must be calculated first. An empirical engine friction model is established to change the look-up tables in traditional control algorithms. The engine friction model’s parameters could be identified during certain operation points of the engine, such as in idle and fuel cut-off operating conditions, which do not only save a large amount of calibration work, but can also update the friction torque, along with the engine operations. Finally, both

and

can be calculated from load torque (as in

Section 3.1.3).

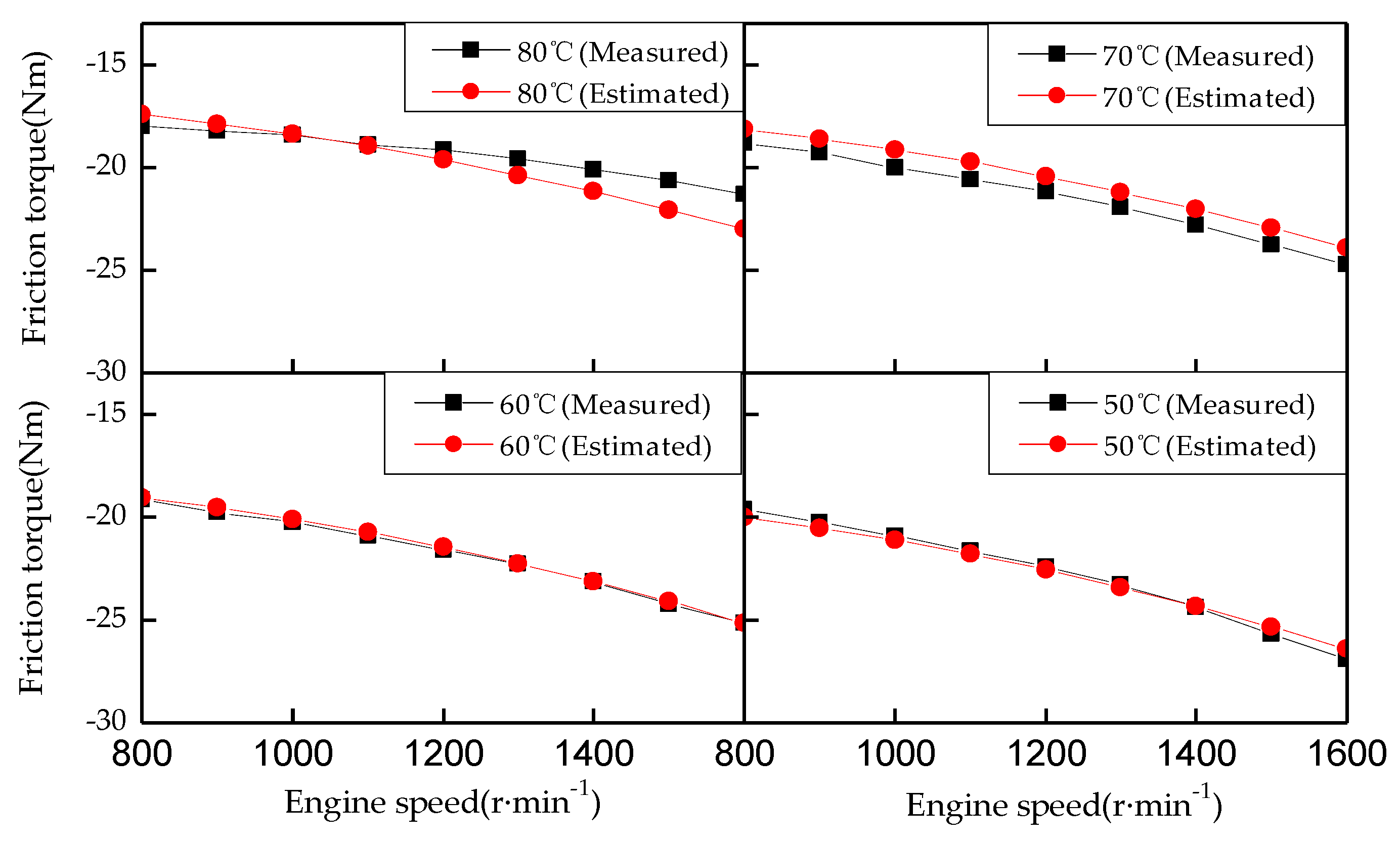

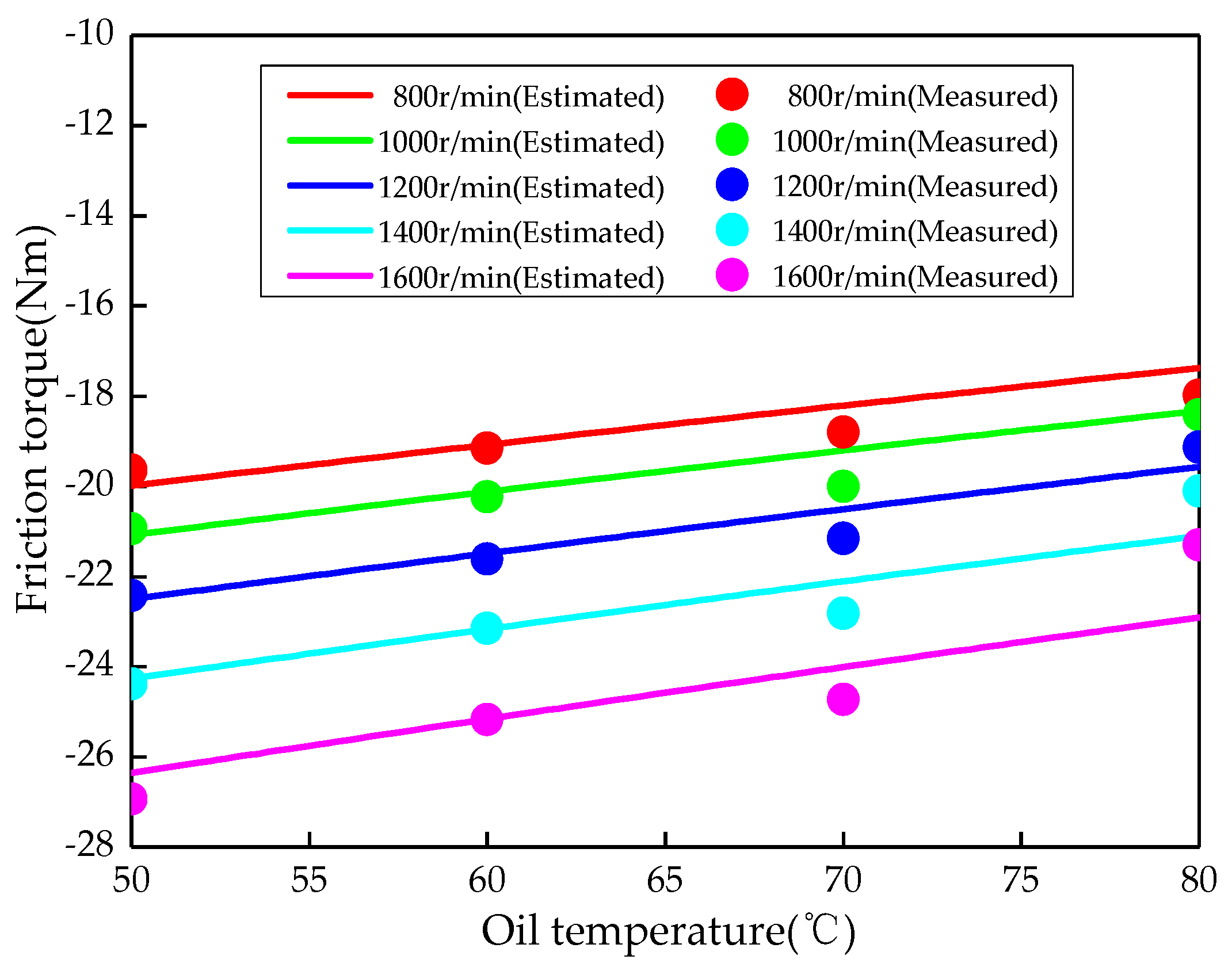

Engine friction torque includes the friction loss of accessories in mechanical systems, the friction loss of crankshaft bushings, piston liners and piston rings, the friction loss of valve trains, etc. A detailed engine friction torque model could better describe the relationship between and engine working characteristics, but this model would be too complicated and unsuitable for online applications. In traditional applications, a look-up table is used to describe friction torque. Thus, it requires a large amount of calibration work and is not easy to be corrected online. Therefore, a friction torque mean value model is proposed.

According to [

32],

increases with an increase in engine speed. This relationship can be described as in Equation (24):

where

is the engine’s average speed; and

,

, and

are the model’s parameters.

is also related to oil temperature. The reference friction torque is calculated as

at the oil viscosity of

; then, regardless of the initial oil viscosity, after an initial period of transient behavior, the

can be expressed with an oil viscosity of

[

33], as follows:

where

is the model’s parameter.

generally is taken within the range of 0.29 to 0.35.

In this study, the correction of the oil viscosity is simplified as follows:

where

is the oil temperature of the engine, and the reference temperature is 0 °C.

Base on the reference model at a temperature of 0 °C, an engine friction model is proposed as:

A friction torque look-up table requires a large amount of calibration work and cannot describe the aging issues as the engine operates. Thus, an engine friction model parameter self-learning algorithm is proposed (shown as

Figure 7). The parameters are estimated based on engine idle and fuel cut-off operating conditions. Once the engine starts, it will retain idle speed operations. In this working condition, the engine’s average speed will remain stable as the temperature of the cooling water and oil start to rise. In this process, the temperature parameter

can be identified. During engine stop operations, the engine stops supplying fuel so the crankshaft rotation speed decreases over a few seconds. During this process, the temperature of the cooling water and oil barely change, so the engine speed parameters

,

, and

can be identified.

In engine idle speed working conditions, the crankshaft average speed remains stable and engine indicated torque is used to overcome friction loss.

during idle speed operations is estimated in

Section 3 using the engine management model and crankshaft instantaneous speed. Thus, the friction torque can be expressed as:

In fuel cut-off operating conditions, the crankshaft dynamic system is only affected by friction. Thus, the process can be described as:

During the idle and fuel cut-off operating conditions, the friction torque of the two working conditions can be estimated. However, this only covers a small part of the whole engine operation range. Once the parameters in the model are identified, the friction torque model can be expanded to cover a larger working range. While the friction torque model is a nonlinear model, it is very challenging to directly identify the speed parameter and oil temperature parameter at the same time in online applications. Therefore, it is necessary to combine the two working conditions—idle and fuel cut-off operating conditions—to identify the model parameters.

In idle speed working conditions, the relation between friction torque and oil temperature can be rendered as:

or

In fuel cut-off operating conditions, the oil temperature barely changes. The friction torque model can be described as:

By combining the particularity of the specific operating conditions of the engine, the nonlinear coefficients in the model are temporarily eliminated, and the linearization of the model’s coefficients is realized. During this process, the structure and parameters of the model do not change, and the relationship between the friction torque described in the model and the speed and oil temperature is not affected, so the accuracy of the model is not affected.

The parameters of the model are identified by the recursive least squares method. The description of the friction torque model can be abstracted into the following formula:

where

is the mode input,

is the model’s output, and

stands for the parameters of the model.

The parameters’ identification process using the recursive least squares method can be expressed as:

In engine idle speed working conditions, the system can be described as:

and for fuel cut-off process as:

After the friction model’s parameters are identified, a friction torque model can be acquired. On the basis of the identified friction torque, can then be calculated from the aforementioned .