Abstract

Biobased liquid fuels are becoming an attractive alternative to replace, totally or partially, fossil ones in the medium term, mainly in aviation and long-distance transportation. In this regard, coprocessing biomass-derived feedstocks in conventional oil refineries might facilitate the transition from the current fossil-based transport to a biobased one. This article addresses the economic and environmental feasibility of such a coprocessing strategy. The biomass-based feedstocks considered include bio-oil and char from the fast pyrolysis of lignocellulosic biomass, which are coprocessed in fluid catalytic cracking (FCC), hydrocracking, and/or cogasification units. The assessment was based on the standardized concept of eco-efficiency, which relates the environmental and economic performances of a system following a life-cycle approach. Data from a complete simulation of the refinery process, from raw materials to products, were used to perform a life cycle costing and eco-efficiency assessment of alternative configurations of the coprocessing strategy, which were benchmarked against the conventional fossil refinery system. Among other relevant results, the eco-efficiency related to the system’s carbon footprint was found to improve when considering coprocessing in the hydrocracking unit, while coprocessing in FCC generally worsens the eco-efficiency score. Overall, it is concluded that coprocessing biomass-based feedstock in conventional crude oil refineries could be an eco-efficient energy solution, which requires a careful choice of the units where biofeedstock is fed.

1. Introduction

The increasing global energy demand and the progressive depletion, supply uncertainty, and environmental issues of fossil fuels have led to a growing interest in alternative and renewable energy sources []. Regardless of the expected upsurge in electromobility [,], the use of liquid fuels in transport will remain important in the medium term [,] since subsectors such as long-distance transportation and aviation cannot yet be effectively powered by electricity. In this sense, liquid biofuels would arise as the most straightforward alternative to fossil fuels, contributing to the global objectives of greenhouse gas (GHG) emission savings [,] without requiring a significant transformation of the existing infrastructure and vehicle fleets. However, the realization of a full biomass-to-fuel concept is still far off due to the huge demand of fuels, the relatively low maturity of the technologies involved, and their high capital and operating costs []. In the short-to-medium term, a realistic scenario could rely on the concept of coprocessing, especially for the production of drop-in fuels [,]. This concept mainly refers to the introduction of biomass-derived feedstock, in addition to conventional fossil sources, in existing petroleum refineries [,]. The transition from the current fossil-based transport to a biobased one would be thereby enabled [].

Currently in the EU, diesel and gasoline are mixed with biobased fatty acid methyl esters (FAME) and ethanol, respectively []. Nevertheless, these fuels are typically related to first-generation biomass and therefore associated with sustainability concerns on land competition with food production []. Hence, second-generation biomass (i.e., biomass from nonfood feedstock, such as lignocellulosic biomass from dedicated energy crops or agricultural and forestry waste) should be used for the production of biobased liquid fuels. In this respect, since raw lignocellulosic biomass could not be easily introduced directly in a refinery, it could be converted into suitable intermediates. In particular, biomass pyrolysis is often seen as the most likely biobased pathway to be integrated into a conventional refinery as a first step before coprocessing []. The raw bio-oil produced through pyrolysis requires a mild hydrodeoxygenation (HDO) process whose product (usually called HDO-oil) can be mixed with the typical feed of some refinery conversion units, for example, fluid catalytic cracking (FCC) and catalytic hydrocracking (HC) units [,,]. In fact, taking into account product yields and operating conditions, coprocessing in these refinery units represents the most likely option [,,,]. Furthermore, biomass pyrolysis also produces gases, used to heat the pyrolysis reactor and satisfy the energy needs of the pyrolysis plant, and char, suitable to produce syngas through gasification [,,,]. Hence, in refineries with dedicated coke gasification processes, char coprocessing could be appropriate [], avoiding the erection of a facility only for char [,,] while increasing hydrogen production (for self-consumption and/or as a net product) [,,,].

Given the growing interest in coprocessing biofeedstock in conventional refineries, several works in the literature have focused on deep experimental studies in different conversion units on a laboratory/pilot scale [,,,,,,,,,,,,,,,]. In addition, previous works by the authors have evaluated the effect that coprocessing could have on an oil refinery from a global perspective. To that end, modelling and simulation of coprocessing units integrated into a refining scheme were performed [,], providing key data to assess and the system’s environmental performance from a life-cycle perspective. Thus, a life-cycle assessment (LCA) of different coprocessing refinery schemes was performed in [], finding that coprocessing strategies could significantly reduce the carbon footprint of the refinery. However, other environmental impacts such as acidification, eutrophication, and abiotic depletion of elements were found to increase, mainly due to the increased use of chemicals (including catalysts) and the need for fertilizers.

To complete the feasibility assessment of coprocessing schemes, their environmental assessment should be complemented with a thorough economic analysis. In this sense, the concept of eco-efficiency matches this need for suitability assessment under economic and environmental aspects. It refers to the delivery of competitively priced goods that fulfil human needs while progressively reducing environmental impacts of products and resource intensity throughout the entire life cycle []. In fact, the standardized eco-efficiency concept incorporates this traditional notion while stressing the life-cycle perspective required for the economic and environmental assessment of product systems []. Even though some eco-efficiency studies have been conducted for energy systems [,,,], there is a lack of this type of study for biobased coprocessing strategies. Hence, this article aims to enrich the feasibility assessment of coprocessing schemes by complementing the previous LCA [] with a life cycle costing (LCC) under the umbrella of an eco-efficiency assessment of the coprocessing of bio-oil and char in conventional refineries.

2. Materials and Methods

2.1. Definition of Case Studies

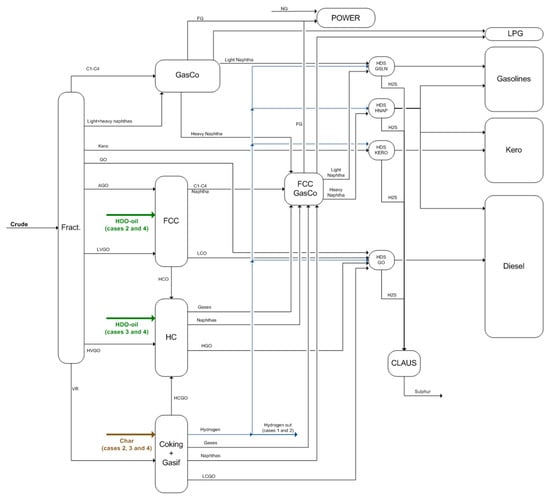

The refinery considered to include biofeedstock coprocessing follows a deep conversion scheme with the aim of reducing low-value byproducts such as fuel oils and asphalts and promoting the production of the most demanded fractions (gasoline, diesel, and kerosene) []. As shown in Figure 1, it includes fractionation at atmospheric and vacuum conditions, FCC, HC, coking, and coke gasification, hydrotreatment, sulfur recovery, steam production, and product blending. For the sake of simplicity, catalytic reforming, isomerization, alkylation and further product upgrading were not considered since they are not especially affected by biofeedstock coprocessing. On the other hand, the system does include the biomass pyrolysis plant and the HDO process to produce HDO-oil for coprocessing. The products of the refinery comprise liquefied petroleum gas (LPG), gasoline, kerosene, diesel, and hydrogen (self-consumed within the refinery and a net output in some cases).

Figure 1.

Refining process scheme and case studies of biofeedstock coprocessing (based on []).

As done in the LCA study of coprocessing schemes in conventional refineries [], four case studies were investigated to explore the feasibility of different combinations of biomass feedstock coprocessing in terms of eco-efficiency:

- Case 1: This is the base case, where the refinery only processes petroleum crude (100 Mbbl/day). Angolan CLOV (Cravo-Lirio-Orquidea-Violeta oilfields) was considered, which is an intermediate-to-heavy sweet crude that may represent the future of refining according to the trend towards deep conversion from heavy crudes [].

- Case 2: The refinery coprocesses crude oil (100 Mbbl/day) and HDO-oil in the FCC unit, and char in the cogasification section. HDO-oil accounts for 20 wt% of the riser feed (value reported as the maximum for cofeeding [,]). HDO-oil and char are produced in a dedicated pyrolysis plant from poplar biomass, and the amount of char corresponds to that coproduced along with the bio-oil in the pyrolysis plant [].

- Case 3: The refinery coprocesses crude oil (100 Mbbl/day) and HDO-oil in the HC unit, and char in the cogasification section. As in Case 2, the amount of HDO-oil corresponds to 20 wt% of the hydrocracker feed and the amount of char is that coproduced with the bio-oil.

- Case 4: It represents a combination of Cases 2 and 3, increasing the amount of HDO-oil coprocessed in the refinery. Crude oil (100 Mbbl/day) is fed into the refinery together with HDO-oil in the FCC and HC units and char in the cogasification section. The amount of HDO-oil corresponds to 20 wt% of the riser feed plus 20 wt% of the hydrocracker feed. The amount of char corresponds to that coproduced with the bio-oil in the pyrolysis section.

The validated models and process simulation of these coprocessing cases were directly retrieved from previous works [,,], where further details can be found, and used to obtain key data to perform the eco-efficiency assessment. In fact, the environmental component of the eco-efficiency assessment was directly based on the LCA results from [], whereas the economic component was specifically addressed in this article along with the joint economic–environmental interpretation in terms of eco-efficiency. For the life-cycle evaluations, a cradle-to-gate approach was followed, covering from crude oil extraction and biomass cultivation to fuel production at the refinery. Most of the inventory data were obtained from process simulation, while additional inventory data were taken from Iribarren et al. [] for HDO-oil and char as well as from well-established databases []. According to the original LCA study [], the environmental component of the study includes six life-cycle indicators evaluated with the CML method (Institute of Environmental Sciences of Leiden University []): abiotic depletion of elements (ADPe), abiotic depletion of fossil fuels (ADPf), global warming (GWP), ozone layer depletion (ODP), acidification (AP), and eutrophication (EP). ADPe is related to the extraction of mineral resources and expressed in kg Sb eq, while ADPf is associated with the extraction of fossil fuels and expressed in energy units (e.g., kJ). ODP refers to stratospheric ozone depletion and is expressed in kg CFC-11 eq. AP, which is expressed in kg SO2 eq, is related to the emission of acidifying substances to the air, while EP, which is expressed in kg PO43− eq, refers to nutrification because of emissions of nutrients to air, water, and soil. GWP, expressed in kg CO2 eq, is associated with greenhouse gas emissions to the air over a 100-year time horizon. In this respect, it should be noted that CO2 uptake during biomass growth was quantified at the biomass plantation stage, thus avoiding the need for a distinction between the biogenic and non-biogenic origin of subsequent emissions []. Finally, the economic and eco-efficiency components of the study are detailed in Section 2.2 and Section 2.3, respectively.

2.2. Economic Component

Life cycle costing (LCC) is a methodology for the analysis of the total cost of a system along its entire life cycle. Net present value (NPV) is among the most common life-cycle economic indicators. It represents the difference between the present value of cash inflows and the present value of cash outflows over the lifetime of the system. In order to calculate the NPV of each of the four case studies, the following steps were addressed:

- Cost estimation for standard equipment through size dimensioning and well-established correlations.

- Cost estimation for specific equipment through literature correlations and rescaling.

- Estimation of direct, indirect, and other costs to calculate the total investment cost (TIC). These costs were estimated as a function of the cost of equipment.

- Estimation of annual variable costs.

- Evaluation of annual cash flows over lifetime and NPV calculation.

Equations for cost estimation from the literature usually involve different currencies and years. In this regard, all monetary values were converted into €2019. Spain was assumed as the reference location for the estimation of other costs, for example, feedstock, electricity, services, and land. The industrial price index (IPRI) and USD/€ exchange rates from the Spanish National Statistics Institute [] were used to express data in €2019.

2.2.1. Cost Estimation for Standard and Specific Equipment

Cost estimation for standard equipment was mainly based on the principal dimensioning and design parameters from the simulation. On the other hand, some estimations were made by rescaling from data reported for similar equipment, assuming a Williams scaling exponent of 0.7. Table 1 summarizes the cost estimation method used for general and specific equipment.

Table 1.

Cost estimation method for general and specific equipment.

2.2.2. Estimation of the Total Investment Cost

TIC involves the sum of the design, construction, and installation costs of the system. It is composed of ISBL (inside battery limits), OSBL (outside battery limits), contingencies, and EPC (engineering, procurement, and construction) costs [], which were calculated as a function of the total purchased equipment cost (TPEC) as shown in Table 2. ISBL investment represents the purchasing and installation costs of all the equipment of the process. It includes materials, catalysts, engineering, construction, and supervision costs. On the other hand, OSBL investment represents costs associated with general services, interconnections, and commissioning. Moreover, contingencies represent likely variations in the investment estimation, while EPC costs are those estimated for crude distillation unit (CDU), vacuum distillation unit (VDU), FCC, HC, coking, hydrodesulfurization (HDS), pyrolysis and Claus units as final installed ones according to Table 1. Finally, some installed units involve the duty to pay royalties, and thus paid-up royalties were also considered as a cost contributing to TIC [].

Table 2.

Method for the total investment cost (TIC) calculation. TPEC: total purchased equipment cost; ISBL: inside battery limits; OSBL: outside battery limits; EPC: engineering, procurement, and construction.

2.2.3. Estimation of Annual Variable Costs

The operation of the refinery involves costs related to the consumption of feedstock, general services, pyrolysis plant operation, and others. In this sense, the main annual variable costs of the system are those detailed in Table 3, which include:

Table 3.

Main operating costs of the system.

- Materials: crude oil, natural gas, process water, monoethanolamine (aq.), oxygen, air, and catalyst replacement. It should be noted that the biomass consumed in the pyrolysis plant was not included in this group but within the pyrolysis costs.

- General services: also known as utilities, including cooling water, heating steams, and electricity.

- Pyrolysis costs: biomass consumption, electricity, waste disposal, catalysts, and cooling water according to Peters [].

- Other costs: staff, depreciation, insurance, and running royalties. Staff was assumed to be 300 people in the refinery, and 15 people in the pyrolysis plant (assuming a 5% increment in the original staff), with a mean gross salary of 40,000 €/year. Linear depreciation over 15 years was considered (6.67% of TIC each year). Insurance was considered to be 1% of TIC. Running royalties were considered for FCC, HC, and HDS according to [].

2.2.4. Net Present Value Calculation

The net present value (NPV) is the difference between the present value of cash inflows and the present value of outflows over a period of time. This economic indicator represents the profitability and economic potential of an investment, taking into account inflation and discount rates, annual variable costs, and inflows from selling products. It was calculated using Equation (1):

where Ct is the net cash flow in the year t, r is the discount rate, and T stands for the total number of years assumed for the project investment. Selling prices (without taxes) of products were assumed to be 450 €/t for propane and butane; 0.39, 0.30, and 0.40 €/l for gasoline, kerosene, and diesel, respectively; and 550 €/t for hydrogen []. Other general assumptions in the LCC study were 8000 annual operating hours, 3 years of construction, and 30 years of operation, 10% discount rate, and 1% linear inflation.

2.3. Eco-Efficiency Framework

The eco-efficiency indicator (or eco-efficiency score) was calculated according to Equation (2), using the selected life-cycle economic indicator (NPV) in the numerator, monetizing the system’s functional value, and a life-cycle environmental indicator (ADPe, ADPf, GWP, ODP, AP, or EP) in the denominator. This definition of the system’s eco-efficiency means that the most favorable scores should involve a high NPV and a low impact (under the specific environmental indicator considered). This definition of eco-efficiency is in line with the standardized concept [] as well as with other related works [,,].

where EEi,j represents the eco-efficiency indicator for the case study i (i.e., 1, 2, 3, or 4) and the life-cycle environmental indicator j (ADPe, ADPf, GWP, ODP, AP, or EP for the whole lifetime of the refinery). Furthermore, the benchmarking of each case study against the base case (i.e., case study 1) was performed through the ratio of the corresponding eco-efficiency scores. This ratio, known as factor-X according to [], quantifies the relative level of eco-efficiency improvement or decline with respect to the conventional refinery (Equation (3)):

where FXi,j represents the factor-X of the case study i for the environmental indicator j.

3. Results and Discussion

3.1. LCC Results

3.1.1. Cost of Standard and Specific Equipment and Total Investment Cost

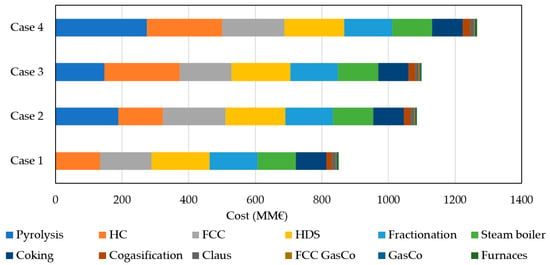

The costs of standard and specific equipment were estimated following the methodology detailed in Section 2.2.1. Figure 2 shows the breakdown of costs by relevant section of the refinery. When compared to the base case (case study 1, i.e., conventional refinery without biofeedstock coprocessing), the introduction of HDO-oil in the refinery (case studies 2–4) increases the cost of HC (cases 3 and 4) and FCC (cases 2 and 4) and adds the cost of the pyrolysis plant. The contribution of these three sections means approximately half of the equipment costs in all the coprocessing cases. The rest of equipment remains similar, only showing slight changes due to capacity increments.

Figure 2.

Distribution of equipment costs by section of the refinery (HC: hydrocracking; FCC: fluid catalytic cracking; HDS: hydrodesulfurization; GasCo: gas concentration unit).

As a consequence of the increase in the cost of equipment, and according to the methodology detailed in Section 2.2.2, the implementation of coprocessing involves an increased TIC (Table 4). This increase with respect to the base case is +20%, +21%, and +35% for cases 2, 3, and 4, respectively. TIC also increases when expressed per installed capacity (MW and MWhannual), mainly due to the erection of the pyrolysis plant. When compared to the base case (24.17 €/MWhannual), coprocessing adds 3.21, 3.71, and 5.17 € to the TIC per annual MWh of products in cases 2, 3, and 4, respectively.

Table 4.

Results of the TIC (€) estimation for each case study.

3.1.2. Annual Variable Costs and Inflows

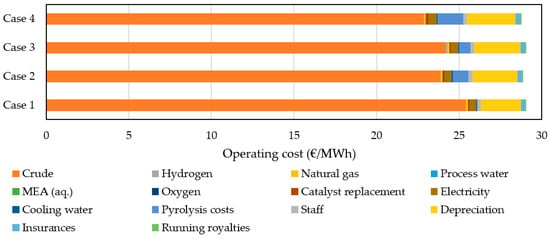

Annual variable (operating) costs account for 1521, 1609, 1598, and 1675 MM€ for cases 1, 2, 3, and 4, respectively. Figure 3 shows the contribution of each variable cost per MWh of product. It should be noted that these costs refer to a normalized year, while inflation was considered for cash-flow calculation in the specific years. Furthermore, although catalyst replacement in some reactors (gasifier, tar reformer, water–gas shift (WGS)) occurs in different years, the value considered in the analysis was annualized and added to the rest of the annual costs for catalyst replacement. Nevertheless, the replacement costs were considered in the expected replacement years for NPV calculation (Section 3.1.3).

Figure 3.

Distribution of annual variable costs in the refinery.

As shown in Figure 3, crude oil, the main feedstock of the refinery, was identified as the main contributor to variable costs, representing 79–87% (1331 MM€/year and 22.9–25.4 €/MWh) depending on the case study. It is distantly followed by depreciation (8–10%) and electricity (around 1.5%). Hence, the fluctuation in the price of crude oil has an important impact on the system’s economic performance. Even though the absolute annual costs increase due to coprocessing, annual unit costs slightly decrease (Figure 3): Case 4 shows the lowest annual unit cost (28.77 €/MWh), followed by case 2 (28.89 €/MWh) and case 3 (29.06 €/MWh). The relatively low price of the biomass feedstock and, consequently, the low cost of the pyrolysis plant operation, in addition to the change in the fuel yields of the refinery, are behind this finding. Thus, the costs associated with the increase in amortization due to the increased capacity of the refinery and the operation of the pyrolysis plant are offset.

Regarding the inflows of the refinery, Table 5 presents the economic values attributed to the products. In the conventional refinery (case 1), diesel represents 47.3% of the monetary incomes, followed by gasoline (26.4%) and kerosene (23.9%), whereas the remaining products only represent 2.4%. When compared to the base case, the coprocessing scheme in case 2 (characterized by the use of HDO-oil in FCC) involves an increase in gasoline (+8%) and kerosene (+57%) revenues, which respectively represent 27.6% and 36.6% of the total incomes in case 2. The monetary inflow associated with hydrogen also increases (+39%) due to char cogasification. However, diesel revenues decrease (−27%) as a consequence of the changes in product distribution. Alternatively, the coprocessing scheme in case 3 (characterized by the use of HDO-oil in hydrocracking) was found to lead to an increase in the incomes related to both gasoline (+42%) and diesel (+8%) with respect to the base case, but at the expense of reducing kerosene revenues (−27%). In this case, hydrogen production does not fully meet the system’s hydrogen demand, and therefore hydrogen does not constitute an inflow but a net operating cost. Finally, case 4, as a combination of cases 2 and 3, shows increased revenues for gasoline (+42%) and kerosene (+45%) at the expense of reduced revenues for diesel (−25%), with gasoline, kerosene, and diesel representing 33.8%, 31.3%, and 32.2% of the total incomes, respectively.

Table 5.

Annual inflows (€) for each case study.

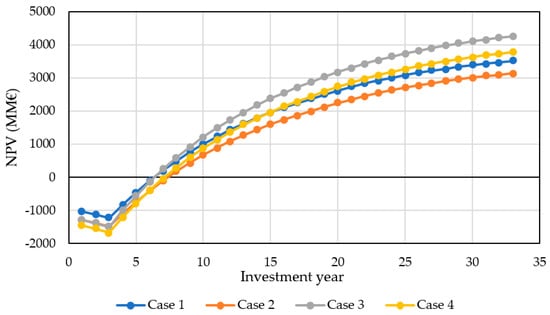

3.1.3. Net Present Value

In order to estimate the NPV, the cash flows over the refinery lifetime were calculated in each case study considering costs, inflows, inflation, and discount rate. The resultant NPVs are 3512, 3134, 4258, and 3776 MM€ for cases 1, 2, 3, and 4, respectively. Figure 4 shows the NPV evolution over the refinery lifetime. The NPV was found to follow the same trend in all the case studies considered. As stated in Section 2.2.4, a lifetime of 33 years was considered, with 3 years for design and construction and 30 years for operation. The following TIC payment distribution was considered during the first three years: year 1 for costs related to EPCs, TPEC, materials, engineering, services, interconnections, paid-up royalties, and 1/3 of contingencies; year 2 for 1/2 of construction and 1/3 of contingencies; and year 3 for commissioning, 1/2 of construction, and 1/3 of contingencies. Hence, as shown in Figure 4, the first years are associated with negative values, and afterwards, once operative, the system starts to recover the investment.

Figure 4.

Net present value (NPV) evolution in each case study.

Regarding the effect of coprocessing with respect to the base case, case 2 (use of HDO-oil in FCC) was found to lead to a decrease in the profit (−11%). On the other hand, case 3 (use of HDO-oil in hydrocracking) results in a 21% NPV increase. In this case, despite the costs related to the pyrolysis plant and other additional costs such as catalyst replacement, the enhanced amount and distribution of products leads to significantly high inflows. Finally, case 4 shows an intermediate behavior, with a 7% NPV increase in year 33.

3.1.4. LCC Summary

The analysis of TIC, variable costs, and NPV proved that coprocessing could be economically feasible. Nevertheless, coprocessing can be performed under different layouts and, therefore, different consequences compared to a conventional refinery. Coprocessing in FCC (case 2) involves an increase in the investment, mainly related to the FCC unit and the addition of the pyrolysis plant. Consequently, the operational costs associated with the pyrolysis plant, FCC catalyst replacement, and services grow. Nevertheless, the operating unit cost (per MWh of produced fuel) decreases since the production rate increases. Product revenues also increase due to the higher production (mainly gasoline and kerosene). However, the NPV of case 2 result is lower than that of the conventional refinery (case 1), implying less profit throughout the operation of the process.

Coprocessing in hydrocracking (case 3) also increases the investment cost because of the HC unit and the pyrolysis plant, as well as the operating costs due to hydrogen consumption, HC catalyst replacement, services, and the pyrolysis plant. On the other hand, the rise in gasoline and diesel production involves an increase in inflows. In fact, the NPV of case 3 result is higher than that of the conventional refinery, which means an enhancement of the profit on the investment.

Coprocessing in both FCC and HC (case 4) shows an intermediate behavior between cases 2 and 3. It involves a growth of the investment, closely linked to the pyrolysis plant and the FCC and HC units, as well as of the operating costs related to catalyst replacement, services, and hydrogen consumption. Due to the product distribution achieved, gasoline and kerosene inflows increase, while the diesel inflow decreases. The NPV of this case is higher than that of the base case, but lower than that of case 3.

It is important to remark that changes in the crude oil selected and/or in the quality of the coprocessed HDO-oil and char, strongly dependent on biomass composition and pyrolysis conditions, could significantly affect relevant aspects such as product distribution, and thus economic and environmental results. However, regardless of specific implications, the conclusion on the potential feasibility of coprocessing is not altered, given the validity of the data used in the study.

Finally, it should be noted that no economic penalty or externality was assumed according to the origin of the fuels (fossil or biobased). If taxes were implemented by policy-makers, for example, on fossil greenhouse gas emissions, coprocessing could, to a certain extent, contribute to keeping the existing refineries profitable.

3.2. Eco-Efficiency Results

Based on the NPV results (Section 3.1.3) as well as on the LCA results retrieved from [], the eco-efficiency scores of each case study were calculated for each environmental indicator according to Equation (2). The corresponding results are presented in Table 6. The higher the scores in each category, the better the eco-efficiency performance achieved. Except for the ADPe-related eco-efficiency, where case 1 involves the highest score, the most favorable eco-efficiency scores were found to be associated with case studies coprocessing biomass-based feedstock. In particular, four of the six highest eco-efficiency scores refer to case 3, while case 4 involves the most favorable result for the carbon footprint-related eco-efficiency. A straightforward identification of the most eco-efficient case study is not possible due to the dependence on the specific life-cycle environmental indicator considered.

Table 6.

Eco-efficiency scores of each case study.

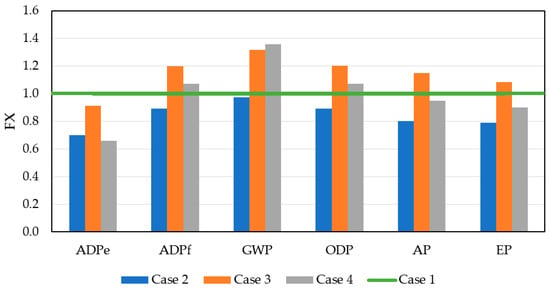

Given the common difficulty in understanding the dimensions and units of the eco-efficiency indicators, the factor-X calculation (Equation (3)) was used since it facilitates the report of eco-efficiency results and the benchmarking of the different case studies against the reference case (i.e., case 1) [,]. Factor-X values above 1 indicate an improvement in eco-efficiency with respect to the conventional refinery, whereas values below 1 point to a decline in eco-efficiency.

As shown in Figure 5, the coprocessing of HDO-oil in FCC (case 2) was found to involve a generalized decline in eco-efficiency when compared to the base case, which is closely linked to the reduced NPV. On the other hand, coprocessing in HC (case 3) was found to lead to an improvement in eco-efficiency for all the environmental categories considered, except for ADPe. For instance, coprocessing biomass-based feedstock in hydrocracking shows a 32% improvement in the carbon footprint-related eco-efficiency. The favorable (i.e., generally eco-efficient) behavior of case 3 is linked to the enhanced NPV, which keeps the favorable ADPf, GWP, and ODP results of case 3 while counterbalancing its environmental deterioration in terms of AP and EP (but not sufficiently to overcome the environmental decline in ADPe).

Figure 5.

Factor-X for each case study.

Finally, since case 4 was defined as a combination of cases 2 and 3, it shows an eco-efficiency improvement for three environmental indicators (ADPf, GWP, and ODP), but an eco-efficiency decline for the remaining environmental indicators (ADPe, AP, and EP). In other words, the moderate NPV increase when coprocessing biobased feedstock in both FCC and HC does not compensate for the environmental penalty in several categories.

4. Conclusions

This article used the LCC methodology and the standardized eco-efficiency concept to discuss the feasibility of coprocessing biomass-based feedstock in conventional petroleum refineries. From the LCC results, the economic feasibility of coprocessing was proven. In particular, coprocessing in hydrocracking and cogasification units was found to significantly improve the economic performance of the refinery. In contrast, coprocessing in FCC and cogasification involves a reduction in the net present value of the refinery. In between, coprocessing in FCC, hydrocracking, and cogasification units involve a moderate increase in the net present value of the refinery, supporting the effect of coprocessing in hydrocracking over the effect of coprocessing in FCC.

The eco-efficiency assessment showed that coprocessing in hydrocracking and cogasification units generally improves the eco-efficiency of the refinery, for example, 32% improvement in the carbon footprint-related eco-efficiency score. However, opposite findings arose when coprocessing in FCC, while the eco-efficiency of coprocessing in FCC, hydrocracking, and cogasification units was found to be highly dependent on the specific life-cycle environmental indicator considered. Overall, it is concluded that coprocessing biomass-based feedstock in conventional crude oil refineries could be an eco-efficient energy solution, which requires a careful choice of the units where biofeedstock is fed.

Author Contributions

P.L.C. performed the economic assessment; P.L.C. and D.I. performed the environmental and eco-efficiency assessment; all authors conceived the study, analyzed the data, and contributed to writing the article.

Funding

This research has been partly supported by the Spanish Ministry of Economy, Industry and Competitiveness (ENE 2015-74607-JIN AEI/FEDER/UE).

Acknowledgments

The authors thank Antonio Valente (IMDEA Energy) for valuable scientific exchange.

Conflicts of Interest

The authors declare no conflict of interest.

References

- BP. BP Energy Outlook 2018; BP: London, UK, 2018. [Google Scholar]

- A portfolio of power-trains for Europe: A fact-based analysis. The role of Battery Electric Vehicles, Plug-in Hybrids and Fuel Cell Electric Vehicle. Available online: https://www.fch.europa.eu/sites/default/files/Power_trains_for_Europe_0.pdf (accessed on 7 December 2019).

- European Environment Agency. Electric Vehicles in Europe; European Environment Agency: Copenhagen, Denmark, 2016; ISBN 9789292138042.

- European Commission. In Biofuels in the European Union—A Vision for 2030 and Beyond; European Commission: Brussels, Belgium, 2006.

- International Energy Agency. World Energy Outlook 2016. Executive Summary; International Energy Agency: Paris, France, 2016. [Google Scholar]

- United Nations/Framework Convention on Climate Change Paris Agreement. In Proceedings of the 21st Conference of Parties of the United Nations Framework Convention on Climate Change, Paris, France, 30 November–11 December 2015.

- European Union Directive 2009/30/EC of the European Parliament and of the Council of 23 April 2009 amending Directive 98/70/EC as regards the specification of petrol, diesel and gas-oil and introducing a mechanism to monitor and reduce greenhouse gas emissions and amend. Off. J. Eur. Union 2009, L140, 88–113.

- U.S. Energy Information Administration. Short-Term Energy Outlook; U.S. Energy Information Administration: Washington, DC, USA, 2018.

- Melero, J.A.; Iglesias, J.; Garcia, A. Biomass as renewable feedstock in standard refinery units. Feasibility, opportunities and challenges. Energy Environ. Sci. 2012, 5, 7393. [Google Scholar] [CrossRef]

- Fogassy, G.; Thegarid, N.; Schuurman, Y.; Mirodatos, C. From biomass to bio-gasoline by FCC co-processing: Effect of feed composition and catalyst structure on product quality. Energy Environ. Sci. 2011, 4, 5068–5076. [Google Scholar] [CrossRef]

- Huber, G.W.; Corma, A. Synergies between Bio- and Oil Refineries for the Production of Fuels from Biomass. Angew. Chem. Int. Ed. 2007, 46, 7184–7201. [Google Scholar] [CrossRef]

- Fogassy, G.; Thegarid, N.; Toussaint, G.; van Veen, A.C.; Schuurman, Y.; Mirodatos, C. Biomass derived feedstock co-processing with vacuum gas oil for second-generation fuel production in FCC units. Appl. Catal. B Environ. 2010, 96, 476–485. [Google Scholar] [CrossRef]

- EU Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC. Off. J. Eur. Union 2009. [CrossRef]

- Fischer, G.; Hizsnyik, E.; Prieler, S.; Shah, M.; van Velthuizen, H.T. Biofuels and Food Security. Final Report to Sponsor: The OPEC Fund for International Development (OFID); International Food Policy Research Institute (IFPRI): Vienna, Austria, 2009. [Google Scholar]

- De Miguel Mercader, F. Pyrolysis Oil Upgrading for Co-Processing in Standard Refinery Units; University of Twente: Enschede, The Nertherlands, 2010. [Google Scholar]

- Solantausta, Y. BIOCOUP: Co-Processing of Upgraded Bio-Liquids in Standard Refinery Units; VTT: Espoo, Finland, 2011. [Google Scholar]

- Cruz, P.L.; Montero, E.; Dufour, J. Modelling of co-processing of HDO-oil with VGO in a FCC unit. Fuel 2017, 196, 362–370. [Google Scholar] [CrossRef]

- Lappas, A.A.; Bezergianni, S.; Vasalos, I.A. Production of biofuels via co-processing in conventional refining processes. Catal. Today 2009, 145, 55–62. [Google Scholar] [CrossRef]

- Leprince, P. Petroleum Refining. Vol. 3 Conversion Processes; Leprince, P., Ed.; Editions Technip: Paris, France, 2001; ISBN 9782710807797. [Google Scholar]

- Guizani, C.; Jeguirim, M.; Gadiou, R.; Escudero Sanz, F.J.; Salvador, S. Biomass char gasification by H2O, CO2 and their mixture: Evolution of chemical, textural and structural properties of the chars. Energy 2016, 112, 133–145. [Google Scholar] [CrossRef]

- Bates, R.B.; Altantzis, C.; Ghoniem, A.F. Modeling of Biomass Char Gasification, Combustion, and Attrition Kinetics in Fluidized Beds. Energy Fuels 2016, 30, 360–376. [Google Scholar] [CrossRef]

- Ephraim, A.; Pozzobon, V.; Louisnard, O.; Minh, D.P.; Nzihou, A.; Sharrock, P. Simulation of biomass char gasification in a downdraft reactor for syngas production. AIChE J. 2016, 62, 1079–1091. [Google Scholar] [CrossRef]

- Kramb, J.; Konttinen, J.; Gómez-Barea, A.; Moilanen, A.; Umeki, K. Modeling biomass char gasification kinetics for improving prediction of carbon conversion in a fluidized bed gasifier. Fuel 2014, 132, 107–115. [Google Scholar] [CrossRef]

- Nemanova, V.; Abedini, A.; Liliedahl, T.; Engvall, K. Co-gasification of petroleum coke and biomass. Fuel 2014, 117, 870–875. [Google Scholar] [CrossRef]

- Edreis, E.M.A.; Luo, G.; Li, A.; Xu, C.; Yao, H. Synergistic effects and kinetics thermal behaviour of petroleum coke/biomass blends during H2O co-gasification. Energy Convers. Manag. 2014, 79, 355–366. [Google Scholar] [CrossRef]

- Fermoso, J.; Arias, B.; Plaza, M.G.; Pevida, C.; Rubiera, F.; Pis, J.J.; García-Peña, F.; Casero, P. High-pressure co-gasification of coal with biomass and petroleum coke. Fuel Process. Technol. 2009, 90, 926–932. [Google Scholar] [CrossRef]

- Fermoso, J.; Arias, B.; Gil, M.V.; Plaza, M.G.; Pevida, C.; Pis, J.J.; Rubiera, F. Co-gasification of different rank coals with biomass and petroleum coke in a high-pressure reactor for H2-rich gas production. Bioresour. Technol. 2010, 101, 3230–3235. [Google Scholar] [CrossRef]

- Hernández, J.J.; Aranda-Almansa, G.; Serrano, C. Co-Gasification of Biomass Wastes and Coal−Coke Blends in an Entrained Flow Gasifier: An Experimental Study. Energy Fuels 2010, 24, 2479–2488. [Google Scholar] [CrossRef]

- Li, K.; Zhang, R.; Bi, J. Experimental study on syngas production by co-gasification of coal and biomass in a fluidized bed. Int. J. Hydrog. Energy 2010, 35, 2722–2726. [Google Scholar] [CrossRef]

- Emami-Taba, L.; Irfan, M.F.; Wan Daud, W.M.A.; Chakrabarti, M.H. Fuel blending effects on the co-gasification of coal and biomass—A review. Biomass Bioenergy 2013, 57, 249–263. [Google Scholar] [CrossRef]

- De Figueiredo Portilho, M.; Duarte Santiago, F.A.; Gomes Soares, G.M.; Goncalves, N.J.; Marins Pala, D.; Araujo Saraiva De, A.P.; Rangel Bastos, A.; Da Costa Barros, F.C.; Monteiro Da, R.D.; Taparo, M.; et al. Process for Production of Bio-Oil by Coprocessing of Biomass in A Delayed Coking Unit 2010. U.S. Patent Application No. 12/533/074, 29 January 2010. [Google Scholar]

- Marker, T.L.; Petri, J.A. Gasoline and Diesel Production from Pyrolytic Lignin Produced from Pyrolysis of Cellulosic Waste 2009. U.S. Patent No. 7/578/927, 25 August 2009. [Google Scholar]

- Schinski, W.L. Hybrid Refinery for Co-Processing Biomass with Conventional Refinery Streams 2014. U.S. Patent No. 8/641/991, 4 February 2014. [Google Scholar]

- Siskin, M.; Phillips, G.E.; Kelemen, S.R.; Weissman, W. Biomass Oil Conversion Process 2011. U.S. Patent No. 8/480/765, 9 July 2013. [Google Scholar]

- Yanik, S.; O’Connor, P.; Bartek, R. Co-Processing Solid Biomass in A Conventional Petroleum Refining Process Unit 2012. U.S. Patent No. 8/288/599, 16 October 2012. [Google Scholar]

- Castello, D.; Rosendahl, L. 9. Coprocessing of pyrolysis oil in refineries. In Direct Thermochemical Liquefaction for Energy Applications; Woodhead Publishing: Cambridge, UK, 2018; pp. 293–317. ISBN 9780081010297. [Google Scholar]

- Holmgren, J.; Gosling, C.; Marinangeli, R.; Marker, T. New developments in renewable fuels offer more choices. Hydrocarb. Process. 2007, 86, 67–71. [Google Scholar]

- Holmgren, J.; Marinangeli, R.; Marker, T.; Petri, J.; Czernik, S. Opportunities for Biorenewables. Hydrocarb. Eng. 2007, 12, 75–80. [Google Scholar]

- Huber, G.W.; O’Connor, P.; Corma, A. Processing biomass in conventional oil refineries: Production of high quality diesel by hydrotreating vegetable oils in heavy vacuum oil mixtures. Appl. Catal. A Gen. 2007, 329, 120–129. [Google Scholar] [CrossRef]

- Samolada, M.C.; Baldauf, W.; Vasalos, I.A. Production of a bio-gasoline by upgrading biomass flash pyrolysis liquids via hydrogen processing and catalytic cracking. Fuel 1998, 77, 1667–1675. [Google Scholar] [CrossRef]

- Al-Sabawi, M.; Chen, J.; Ng, S. Fluid Catalytic Cracking of Biomass-Derived Oils and Their Blends with Petroleum Feedstocks: A Review. Energy Fuels 2012, 26, 5355–5372. [Google Scholar] [CrossRef]

- Alhajri, I.; Alper, E.; Is, G.; Fung, J.; Lo, J.; Yanez, K.; Elkamel, A. Optimization Model for the Integration of Biomass into a Conventional Oil Refinery. In Proceedings of the 2014 International Conference on Industrial Engineering and Operations Management, Bali, Indonesia, 7–9 January 2014; pp. 1115–1125. [Google Scholar]

- Cruz, P.L. Modelling, Simulation and Analysis of the Coprocessing of Biomass-Based Feedstocks in Crude Oil Refineries. Ph.D. Thesis, Universidad Rey Juan Carlos, Madrid, Spain, 2018. [Google Scholar]

- Cruz, P.L.; Iribarren, D.; Dufour, J. Modeling, simulation and life-cycle assessment of the use of bio-oil and char in conventional refineries. Biofuels Bioprod. Biorefin. 2019. [Google Scholar] [CrossRef]

- Schmidheiny, S. Changing Course. A Global Business Perspective on Development and the Environment; MIT Press: Cambridge, UK, 1992. [Google Scholar]

- International Organization for Standardization ISO 14045. Environmental Management—Eco-Efficiency Assessment of Product Systems—Principles, Requirements and Guidelines 2012; International Organization for Standardization, ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Korhonen, J.; Snäkin, J.-P. Quantifying the relationship of resilience and eco-efficiency in complex adaptive energy systems. Ecol. Econ. 2015, 120, 83–92. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, W.; Tian, J.; He, R.; Chen, L. Eco-efficiency assessment of coal-fired combined heat and power plants in Chinese eco-industrial parks. J. Clean. Prod. 2017, 168, 963–972. [Google Scholar] [CrossRef]

- Martín-Gamboa, M.; Iribarren, D.; Dufour, J. Environmental impact efficiency of natural gas combined cycle power plants: A combined life cycle assessment and dynamic data envelopment analysis approach. Sci. Total Environ. 2018, 615, 29–37. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Gálvez-Martos, J.-L.; Dufour, J. Robust eco-efficiency assessment of hydrogen from biomass gasification as an alternative to conventional hydrogen: A life-cycle study with and without external costs. Sci. Total Environ. 2019, 650, 1465–1475. [Google Scholar] [CrossRef]

- Asociación Española de Operadores de Productos Petrolíferos. La Industria del Refino en España; Asociación Española de Operadores de Productos Petrolíferos: Madrid, Spain, 2010. [Google Scholar]

- Van Swaaij, W.; Van Rossum, G.; Kersten, S. Feeding Biomass into a Mineral Oil Refinery. Process Routes and Feedstock Preparation. Termotehnika 2012, 38, 281–290. [Google Scholar]

- De Miguel Mercader, F.; Groeneveld, M.J.; Kersten, S.R.A.; Way, N.W.J.; Schaverien, C.J.; Hogendoorn, J.A. Production of advanced biofuels: Co-processing of upgraded pyrolysis oil in standard refinery units. Appl. Catal. B Environ. 2010, 96, 57–66. [Google Scholar] [CrossRef]

- Peters, J.F. Pyrolysis for Biofuels or Biochar? A Thermodynamic, Environmental and Economic Assessment. Ph.D. Thesis, Universidad Rey Juan Carlos, Madrid, Spain, 2015. [Google Scholar]

- Iribarren, D.; Peters, J.F.; Dufour, J. Life cycle assessment of transportation fuels from biomass pyrolysis. Fuel 2012, 97, 812–821. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; Oers, L.; Wegener Sleeswijk, A.; Suh, S.; Haes, H.A.; Bruijn, H.; et al. Life Cycle Assessment—An Operational Guide to the ISO Standards; Centre of Environmental Science: Leiden, The Netherlands, 2001.

- INE—Instituto Nacional de Estadística. (Spanish Statistical Office). Available online: https://www.ine.es/en/prensa/ipri_prensa_en.htm (accessed on 19 January 2019).

- Gary, J.H.; Handwerk, G.E.; Kaiser, M.J. Petroleum Refining. Technology and Economics; CRC Press: Boca Raton, FL, USA, 2003; ISBN 978-0-8493-7038-0. [Google Scholar]

- Worley, M.; Yale, J. Biomass Gasification Technology Assessment—Consolidated Report; NREL: Golden, CO, USA, 2012.

- Nexant Inc. Equipment Design and Cost Estimation for Small Modular Biomass Systems, Synthesis Gas Cleanup and Oxygen Separation Equipment; NREL: San Francisco, CA, USA, 2006.

- Ratnasamy, C.; Wagner, J.P. Water Gas Shift Catalysis. Catal. Rev. 2009, 51, 325–440. [Google Scholar] [CrossRef]

- Spath, P.; Aden, A.; Eggeman, T.; Ringer, M.; Wallace, B.; Jechura, J. Biomass to Hydrogen Production Detailed Design and Economics Utilizing the Battelle Colombus Laboratory Indirectly-Heated Gasifier; National Renewable Energy Laboratory: Golden, CO, USA, 2005.

- Bejan, A.; Tsatsaronis, G.; Moran, M. Thermal Design & Optimization; John Wiley: New York, NY, USA, 1996; ISBN 978-0-471-58467-4. [Google Scholar]

- Sinnott, R.; Towler, G. Diseño en Ingeniería Química, 5th ed.; Reverté: Barcelona, Spain, 2012; ISBN 978-84-291-7199-0. [Google Scholar]

- BP. BP Statistical Review of World Energy 2017; BP: London, UK, 2017. [Google Scholar]

- Oxygen Element Facts. Available online: http://www.chemicool.com/elements/oxygen.html (accessed on 20 March 2018).

- Huppes, G.; Ishikawa, M. Eco-efficiency and Its xsTerminology. J. Ind. Ecol. 2005, 9, 43–46. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).