High-Efficiency Skutterudite Modules at a Low Temperature Gradient

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials Preparation

2.2. Materials Characterization

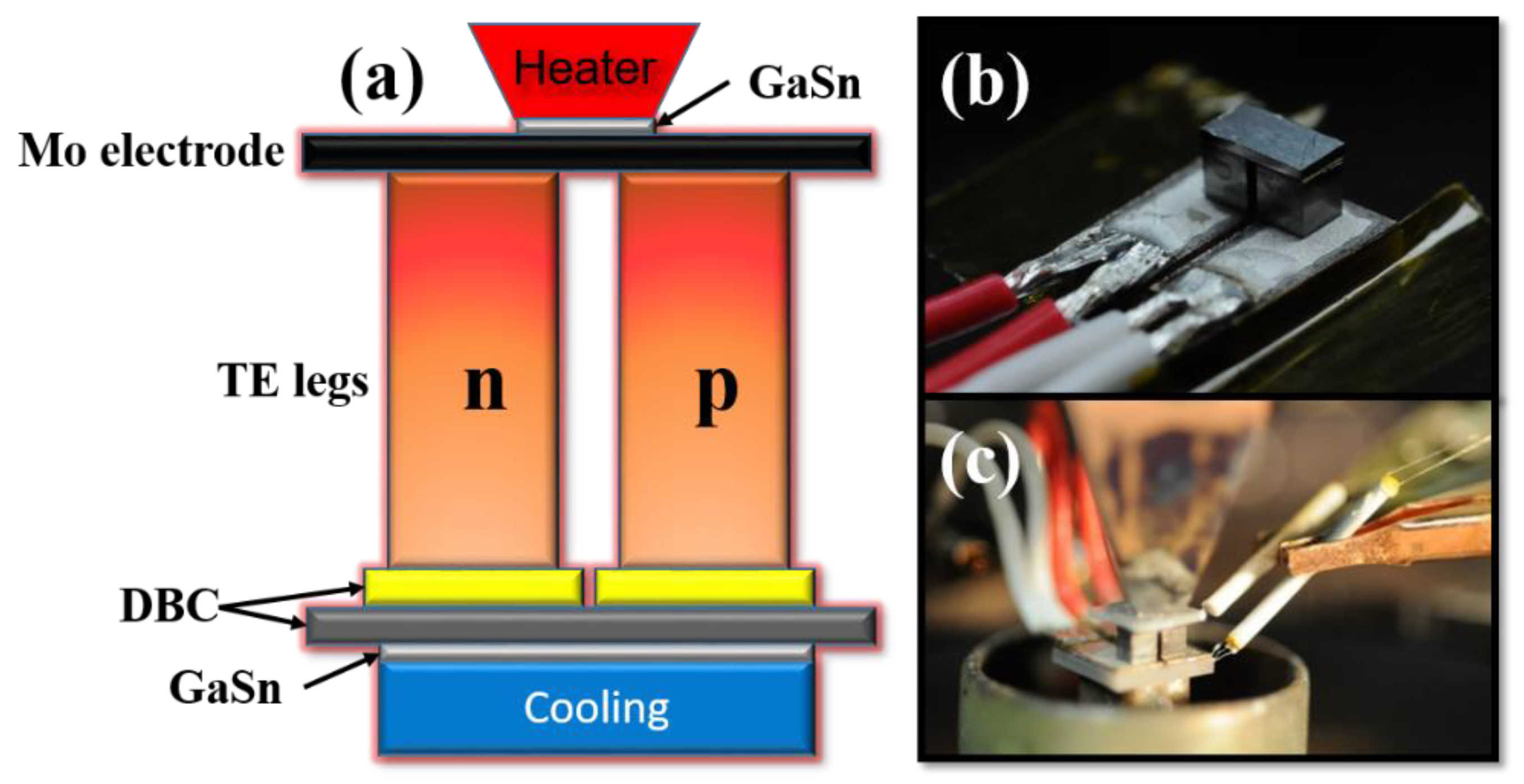

2.3. Module Fabrication and Test

3. Results and Discussion

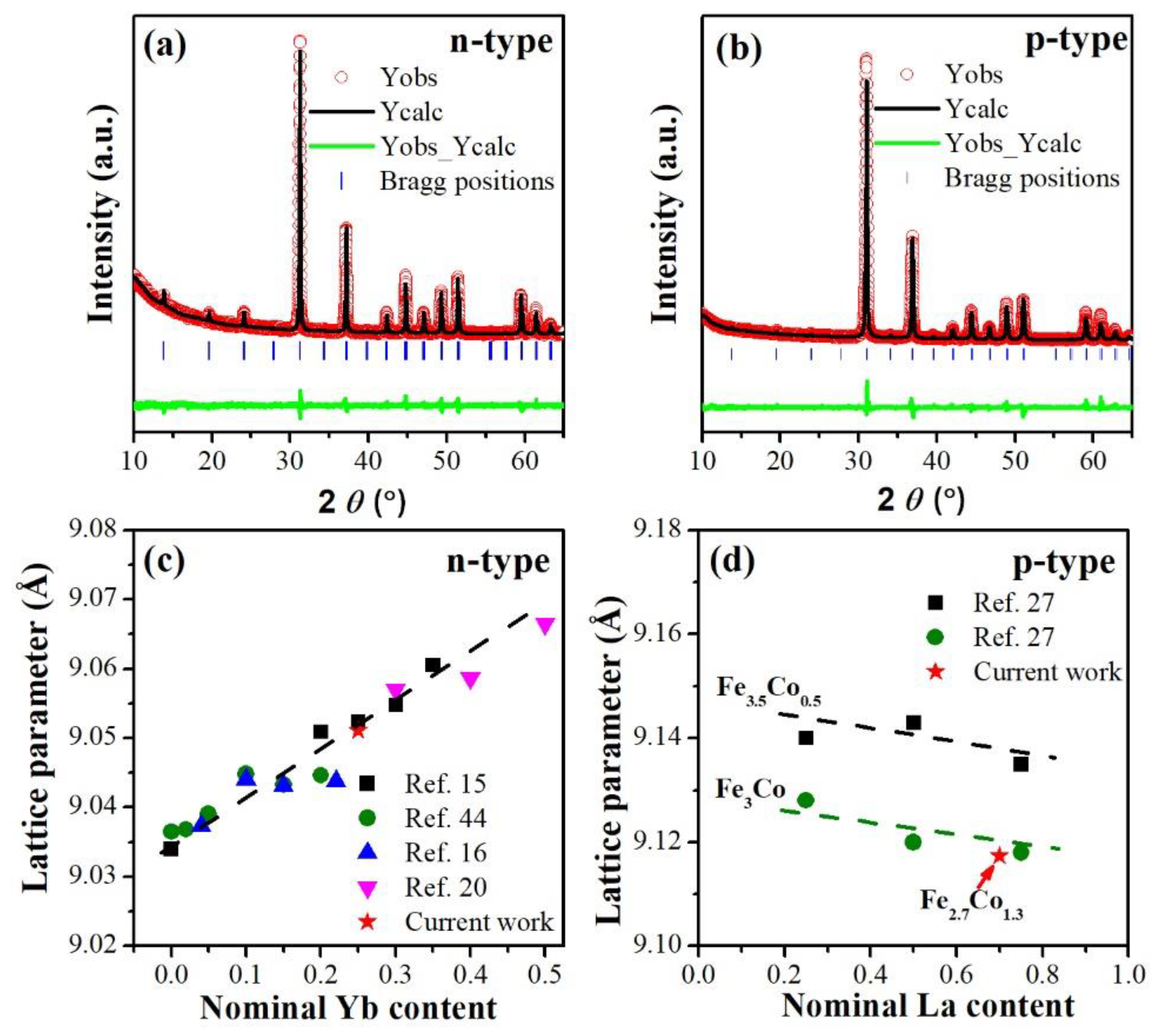

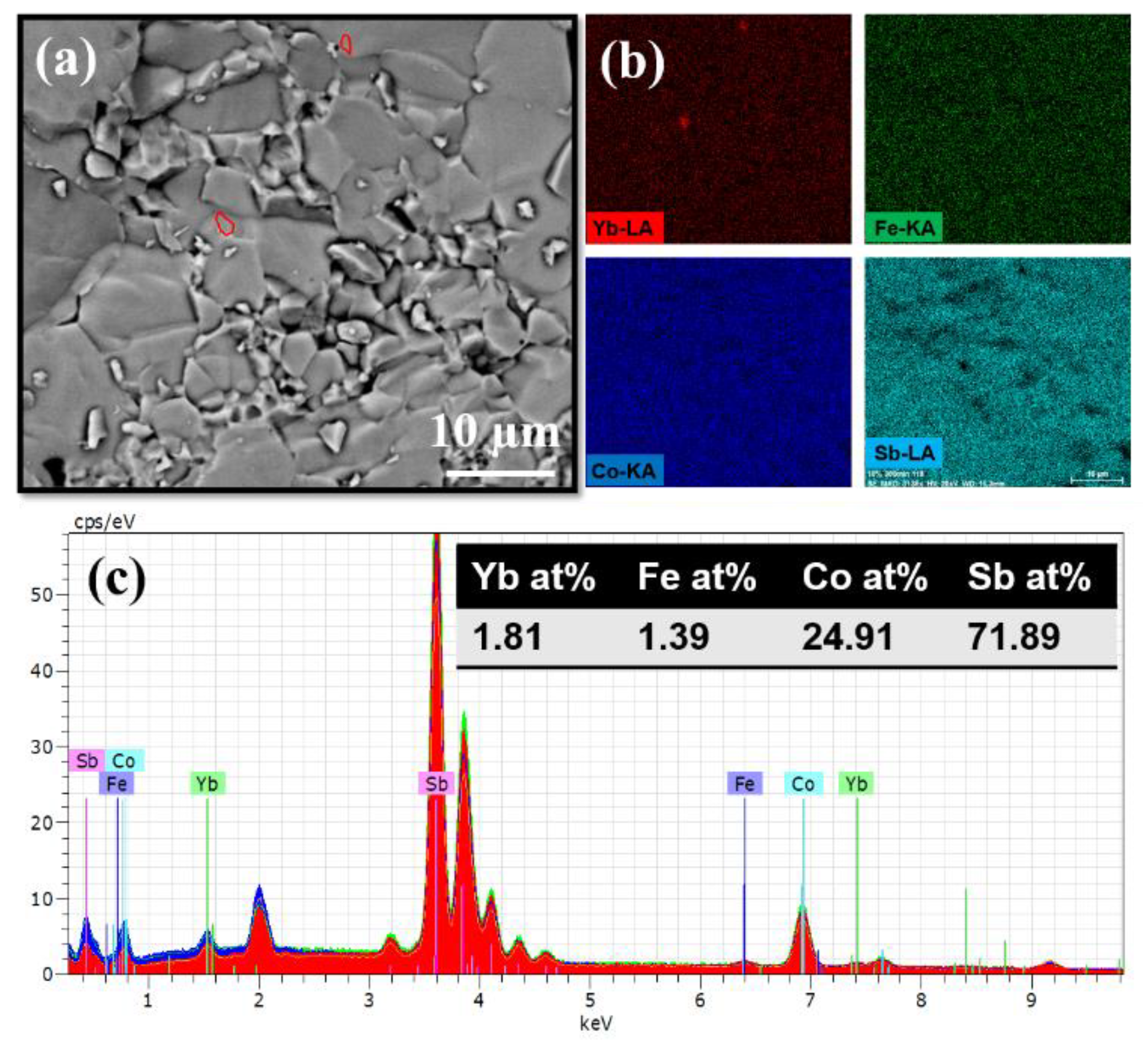

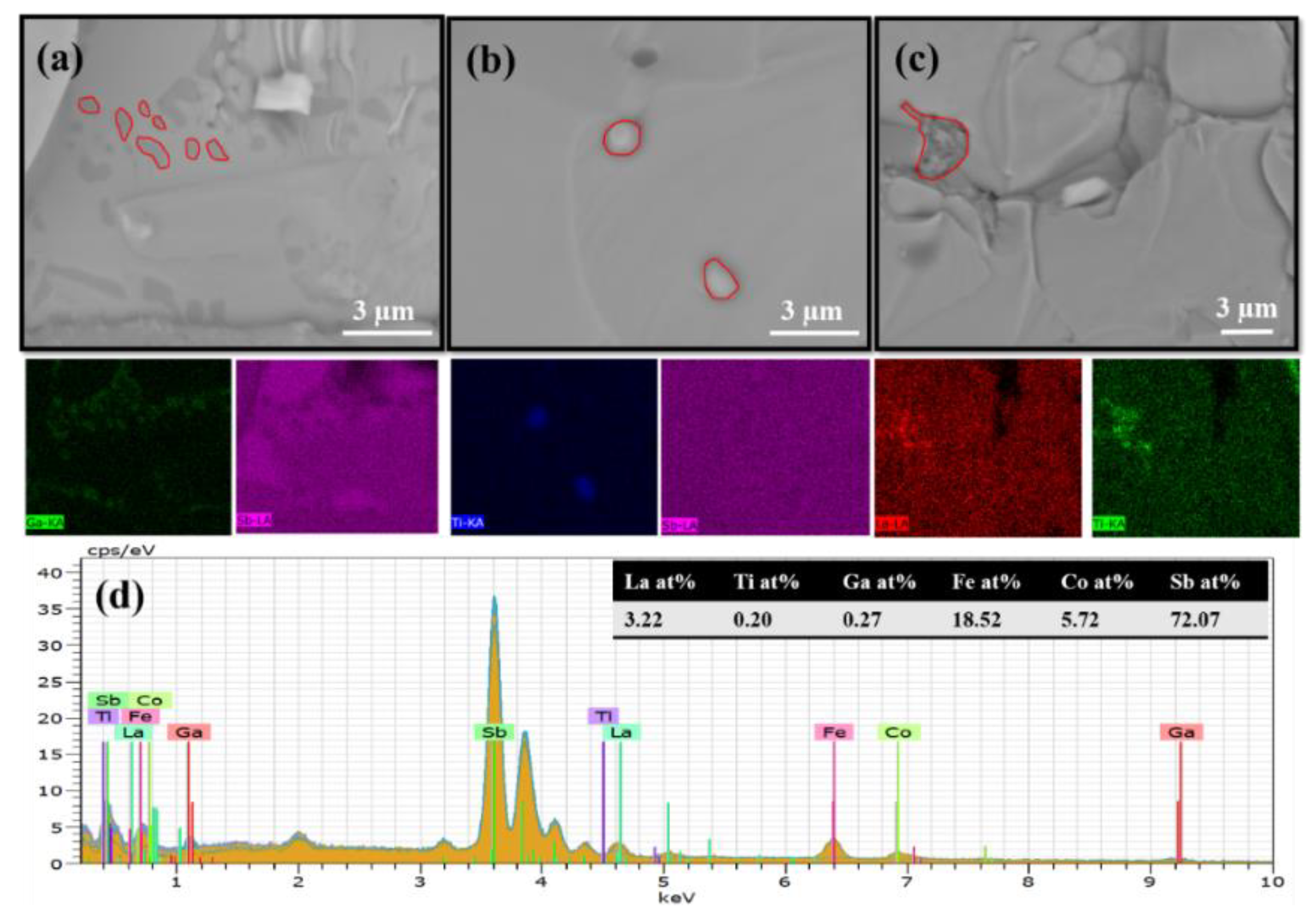

3.1. Materials Phase and Structure Analysis

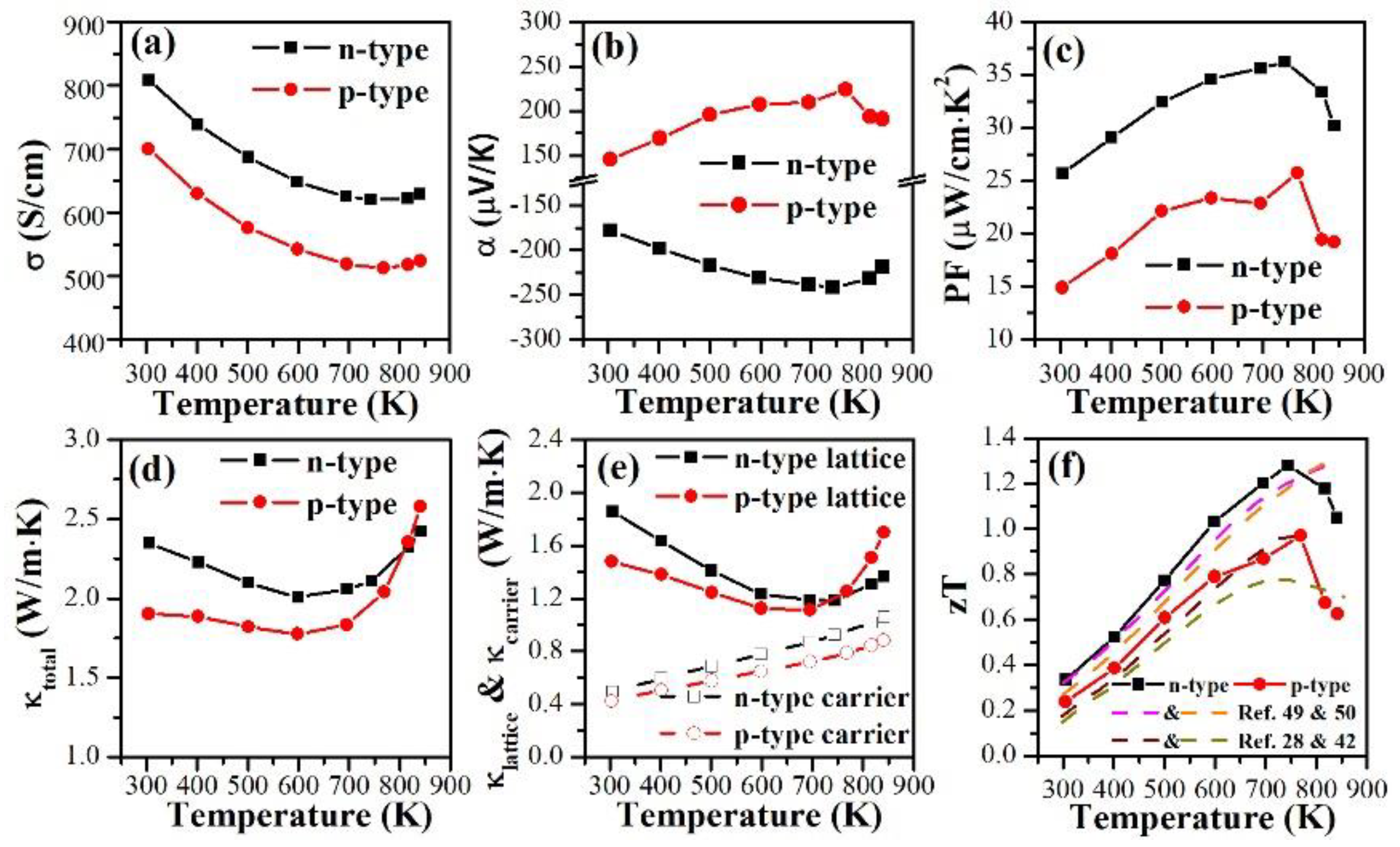

3.2. Material TE Properties

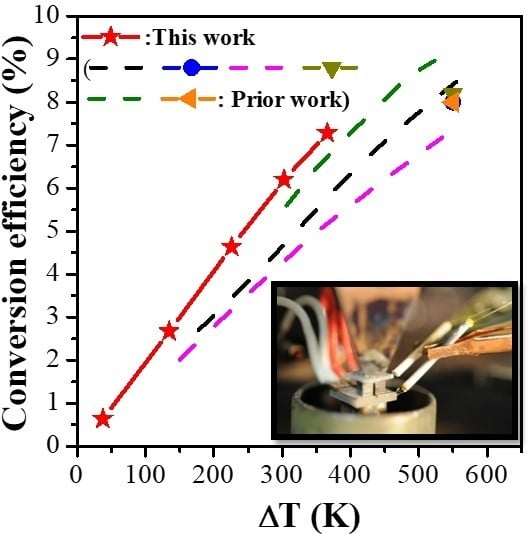

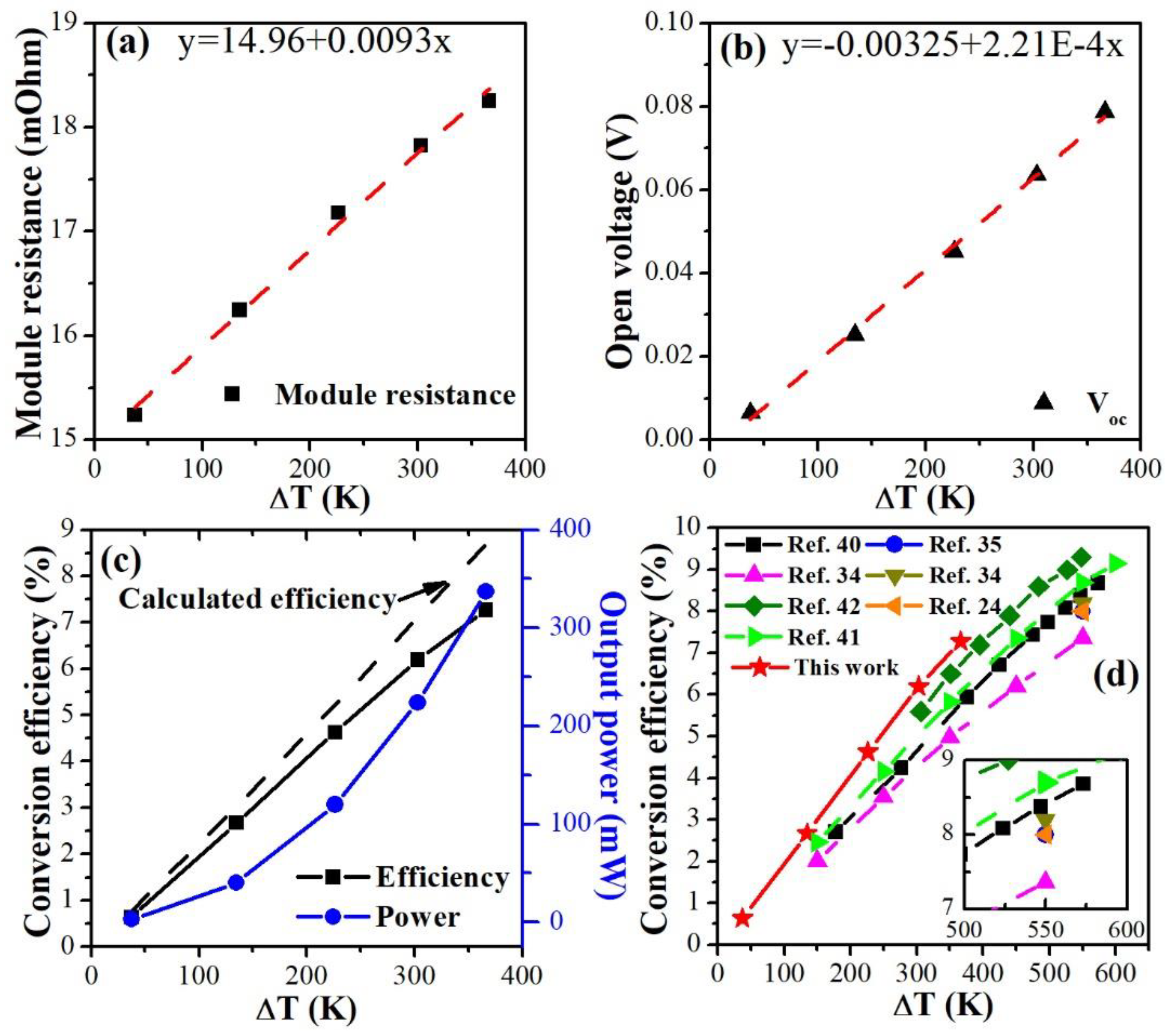

3.3. Module Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zebarjadi, M.; Esfarjani, K.; Dresselhaus, M.S.; Ren, Z.F.; Chen, G. Perspectives on thermoelectrics: From fundamentals to device applications. Energy Environ. Sci. 2012, 5, 5147–5162. [Google Scholar] [CrossRef]

- Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manag. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Fairbanks, J.W. Automotive Thermoelectric Generators and HVAC. In Proceedings of the Directions in Engine-Efficiency and Emissions Research Conference (DEER), Dearborn, MI, USA, 16–19 October 2012. [Google Scholar]

- Sales, B.C.; Mandrus, D.; Williams, R.K. Filled skutterudite antimonides: A new class of thermoelectric materials. Science 1996, 272, 1325–1328. [Google Scholar] [CrossRef] [PubMed]

- Nolas, G.S.; Morelli, D.T.; Tritt, T.M. Skutterudites: A phonon-glass-electron crystal approach to advanced thermoelectric energy conversion applications. Annu. Rev. Mater. Sci. 1999, 29, 89–116. [Google Scholar] [CrossRef]

- Uher, C. Skutterudites: Prospective novel thermoelectrics. In Semiconduct and Semimetals; Elsevier: Amsterdam, The Netherlands, 2001; Volume 69, pp. 139–253. [Google Scholar]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.X.; Krizan, J.W.; Muechler, L.; Haldolaarachchige, N.; Klimczuk, T.; Xie, W.W.; Fuccillo, M.K.; Felser, C.; Cava, R.J. A large family of filled skutterudites stabilized by electron count. Nat. Commun. 2015, 6. [Google Scholar] [CrossRef] [PubMed]

- Rogl, G.; Rogl, P. Skutterudites, a most promising group of thermoelectric materials. Curr. Opin. Green Sustain. Chem. 2017, 4, 50–57. [Google Scholar] [CrossRef]

- Slack, G.A. CRC Handbook of Thermoelectrics; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Wan, S.; Huang, X.Y.; Qiu, P.F.; Shi, X.; Chen, L.D. Compound Defects and Thermoelectric Properties of Self-Charge Compensated Skutterudites SeyCo4Sb12-xSex. ACS Appl. Mater. Interfaces 2017, 9, 22713–22724. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.R.; Jia, X.P.; Deng, L.; Lv, P.; Guo, X.; Zhang, Y.W.; Sun, B.; Liu, B.W.; Ma, H.G. Effect of HPHT processing on the structure, and thermoelectric properties of Co4Sb12 co-doped with Te and Sn. J. Mater. Chem. A 2015, 3, 4637–4641. [Google Scholar] [CrossRef]

- Xu, C.L.; Duan, B.; Ding, S.J.; Zhai, P.C.; Li, P. Thermoelectric transport properties of nickel-doped Co4-xNixSb11.6Te0.2Se0.2 skutterudites. Phys. B Condens. Matter 2013, 425, 34–37. [Google Scholar] [CrossRef]

- Wojciechowski, K.T.; Tobola, J.; Leszczynski, J. Thermoelectric properties and electronic structure of CoSb3 doped with Se and Te. J. Alloys Compd. 2003, 361, 19–27. [Google Scholar] [CrossRef]

- Wang, S.Y.; Salvador, J.R.; Yang, J.; Wei, P.; Duan, B.; Yang, J.H. High-performance n-type YbxCo4Sb12: From partially filled skutterudites towards composite thermoelectrics. NPG Asia Mater. 2016, 8, e285. [Google Scholar] [CrossRef]

- Shi, X.; Yang, J.; Salvador, J.R.; Chi, M.F.; Cho, J.Y.; Wang, H.; Bai, S.Q.; Yang, J.H.; Zhang, W.Q.; Chen, L.D. Multiple-Filled Skutterudites: High Thermoelectric Figure of Merit through Separately Optimizing Electrical and Thermal Transports. J. Am. Chem. Soc. 2011, 133, 7837–7846. [Google Scholar] [CrossRef] [PubMed]

- Rogl, G.; Grytsiv, A.; Rogl, P.; Peranio, N.; Bauer, E.; Zehetbauer, M.; Eibl, O. n-Type skutterudites (R,Ba,Yb)yCo4Sb12 (R = Sr, La, Mm, DD, SrMm, SrDD) approaching ZT approximate to 2.0. Acta Mater. 2014, 63, 30–43. [Google Scholar] [CrossRef]

- Hanus, R.; Guo, X.Y.; Tang, Y.L.; Li, G.D.; Snyder, G.J.; Zeier, W.G. A Chemical Understanding of the Band Convergence in Thermoelectric CoSb3 Skutterudites: Influence of Electron Population, Local Thermal Expansion, and Bonding Interactions. Chem. Mater. 2017, 29, 1156–1164. [Google Scholar] [CrossRef]

- Zong, P.A.; Chen, X.H.; Zhu, Y.W.; Liu, Z.W.; Zeng, Y.; Chen, L.D. Construction of a 3D-rGO network-wrapping architecture in a YbyCo4Sb12/rGO composite for enhancing the thermoelectric performance. J. Mater. Chem. A 2015, 3, 8643–8649. [Google Scholar] [CrossRef]

- Li, W.; Wang, J.; Xie, Y.; Gray, J.L.; Heremans, J.J.; Kang, H.B.; Poudel, B.; Huxtable, S.T.; Priya, S. Enhanced Thermoelectric Performance of Yb-Single-Filled Skutterudite by Ultralow Thermal Conductivity. Chem. Mater. 2019, 31, 862–872. [Google Scholar] [CrossRef]

- Fairbanks, J.W.V. Thermoelectrics: A New Green Technology in Directions in Engine-Efficiency and Emission Research. Detroit, Michigan. Available online: https://www.energy.gov/eere/vehicles/2011-directions-engine-efficiency-and-emissions-research-deer-conference-presentations (accessed on 9 November 2019).

- Tang, X.F.; Li, H.; Zhang, Q.J.; Niino, M.; Goto, T. Synthesis and thermoelectric properties of double-atom-filled skutterudite compounds CamCenFexCo4-xSb12. J. Appl. Phys. 2006, 100. [Google Scholar] [CrossRef]

- Tan, G.J.; Wang, S.Y.; Tang, X.F.; Li, H.; Uher, C. Preparation and thermoelectric properties of Ga-substituted p-type fully filled skutterudites CeFe4-xGaxSb12. J. Solid State Chem. 2012, 196, 203–208. [Google Scholar] [CrossRef]

- Geng, H.Y.; Ochi, T.; Suzuki, S.; Kikuchi, M.; Ito, S.; Guo, J.Q. Thermoelectric Properties of Multifilled Skutterudites with La as the Main Filler. J. Electron. Mater. 2013, 42, 1999–2005. [Google Scholar] [CrossRef]

- Lu, P.X.; Qu, L.B.; Cheng, Q.H. Enhancement of thermoelectric figure of merit in binary-phased La0.3Ce0.37Fe3CoS12-PbTe materials. J. Alloys Compd. 2013, 558, 50–55. [Google Scholar] [CrossRef]

- Tan, G.J.; Zheng, Y.; Tang, X.F. High thermoelectric performance of nonequilibrium synthesized CeFe4Sb12 composite with multi-scaled nanostructures. Appl. Phys. Lett. 2013, 103. [Google Scholar] [CrossRef]

- Joo, G.S.; Shin, D.K.; Kim, I.H. Thermoelectric Properties of Double-Filled p-Type La1-zYbzFe4-xCoxSb12 Skutterudites. J. Electron. Mater. 2015, 44, 1383–1387. [Google Scholar] [CrossRef]

- Fu, L.W.; Jiang, Q.H.; Yang, J.Y.; Peng, J.Y.; Xiao, Y.; Luo, Y.B.; Zhou, Z.W.; Zhang, D. Enhancement of thermoelectric properties of Ce0.9Fe3.75Ni0.25Sb12 p-type skutterudite by tellurium addition. J. Mater. Chem. A 2016, 4, 16499–16506. [Google Scholar] [CrossRef]

- Ortiz, B.R.; Crawford, C.M.; McKinney, R.W.; Parilla, P.A.; Toberer, E.S. Thermoelectric properties of bromine filled CoSb3 skutterudite. J. Mater. Chem. A 2016, 4, 8444–8450. [Google Scholar] [CrossRef]

- Kim, J.; Kurosaki, K.; Choi, S.; Ohishi, Y.; Muta, H.; Yamanaka, S.; Takahashi, M.; Tanaka, J. Thermoelectric Properties of InxFeCo3Sb12 Consisting Mainly of In-Filled p-Type Skutterudites. Mater. Trans. 2017, 58, 1207–1211. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, W.; Bai, S.Q.; Mei, Z.; Chen, L.D. Dual-frequency resonant phonon scattering in BaxRyCo4Sb12 (R=La, Ce, and Sr). Appl. Phys. Lett. 2007, 90. [Google Scholar] [CrossRef]

- Ballikaya, S.; Uzar, N.; Yildirim, S.; Salvador, J.R.; Uher, C. High thermoelectric performance of In, Yb, Ce multiple filled CoSb3 based skutterudite compounds. J. Solid State Chem. 2012, 193, 31–35. [Google Scholar] [CrossRef]

- Ren, W.; Geng, H.Y.; Zhang, L.X.; Liu, X.P.; He, T.H.; Feng, J.C. Simultaneous blocking of minority carrier and high energy phonon in p-type skutterudites. Nano Energy 2018, 46, 249–256. [Google Scholar] [CrossRef]

- Nie, G.; Suzuki, S.; Tomida, T.; Sumiyoshi, A.; Ochi, T.; Mukaiyama, K.; Kikuchi, M.; Guo, J.Q.; Yamamoto, A.; Obara, H. Performance of Skutterudite-Based Modules. J. Electron. Mater. 2017, 46, 2640–2644. [Google Scholar] [CrossRef]

- Guo, J.Q.; Geng, H.Y.; Ochi, T.; Suzuki, S.; Kikuchi, M.; Yamaguchi, Y.; Ito, S. Development of Skutterudite Thermoelectric Materials and Modules. J. Electron. Mater. 2012, 41, 1036–1042. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Rogl, P.; Bauer, E.; Zehetbauer, M. A new generation of p-type didymium skutterudites with high ZT. Intermetallics 2011, 19, 546–555. [Google Scholar] [CrossRef]

- Prado-Gonjal, J.; Phillips, M.; Vaqueiro, P.; Min, G.; Powell, A.V. Skutterudite Thermoelectric Modules with High Volume-Power Density: Scalability and Reproducibility. ACS Appl. Energy Mater. 2018, 1, 6609–6618. [Google Scholar] [CrossRef]

- Park, S.H.; Jin, Y.; Cha, J.; Hong, K.; Kim, Y.; Yoon, H.; Yoo, C.Y.; Chung, I. High-Power-Density Skutterudite-Based Thermoelectric Modules with Ultralow Contact Resistivity Using Fe-Ni Metallization Layers. ACS Appl. Energy Mater. 2018, 1, 1603–1611. [Google Scholar] [CrossRef]

- Salvador, J.R.; Cho, J.Y.; Ye, Z.X.; Moczygemba, J.E.; Thompson, A.J.; Sharp, J.W.; Koenig, J.D.; Maloney, R.; Thompson, T.; Sakamoto, J.; et al. Conversion efficiency of skutterudite-based thermoelectric modules. Phys. Chem. Chem. Phys. 2014, 16, 12510–12520. [Google Scholar] [CrossRef] [PubMed]

- Zong, P.A.; Hanus, R.; Dylla, M.; Tang, Y.S.; Liao, J.C.; Zhang, Q.H.; Snyder, G.J.; Chen, L.D. Skutterudite with graphene-modified grain-boundary complexion enhances zT enabling high-efficiency thermoelectric device. Energy Environ. Sci. 2017, 10, 183–191. [Google Scholar] [CrossRef]

- Nie, G.; Li, W.; Guo, J.; Ymamoto, A.; Kimura, K.; Zhang, X.; Isaacs, E.B.; Dravid, V.; Wolverton, C.; Kanatzidis, M.G.; et al. High performance thermoelectric module through isotype bulk heterojunction engineering of skutterudite materials. Nano Energy 2019. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Zhou, Z.X.; Dylla, M.; Agne, M.T.; Pei, Y.Z.; Wang, L.J.; Tang, Y.S.; Liao, J.C.; Li, J.; Bai, S.Q.; et al. Realizing high-performance thermoelectric power generation through grain boundary engineering of skutterudite-based nanocomposites. Nano Energy 2017, 41, 501–510. [Google Scholar] [CrossRef]

- Kim, H.S.; Liu, W.S.; Chen, G.; Chua, C.W.; Ren, Z.F. Relationship between thermoelectric figure of merit and energy conversion efficiency. Proc. Natl. Acad. Sci. USA 2015, 112, 8205–8210. [Google Scholar] [CrossRef] [PubMed]

- Dilley, N.R.; Bauer, E.D.; Maple, M.B.; Sales, B.C. Thermoelectric properties of chemically substituted skutterudites YbyCo4SnxSb12-x. J. Appl. Phys. 2000, 88, 1948–1951. [Google Scholar] [CrossRef]

- Tan, G.J.; Liu, W.; Wang, S.Y.; Yan, Y.G.; Li, H.; Tang, X.F.; Uher, C. Rapid preparation of CeFe4Sb12 skutterudite by melt spinning: Rich nanostructures and high thermoelectric performance. J. Mater. Chem. A 2013, 1, 12657–12668. [Google Scholar] [CrossRef]

- Fu, L.W.; Yang, J.Y.; Peng, J.Y.; Jiang, Q.H.; Xiao, Y.; Luo, Y.B.; Zhang, D.; Zhou, Z.W.; Zhang, M.Y.; Cheng, Y.D.; et al. Enhancement of thermoelectric properties of Yb-filled skutterudites by an Ni-Induced “core-shell” structure. J. Mater. Chem. A 2015, 3, 1010–1016. [Google Scholar] [CrossRef]

- Li, Y.L.; Qiu, P.F.; Duan, H.Z.; Chen, J.K.; Snyder, G.J.; Shi, X.; Iversen, B.B.; Chen, L.D. Enhanced thermoelectric performance in rare-earth filled-skutterudites. J. Mater. Chem. C 2016, 4, 4374–4379. [Google Scholar] [CrossRef]

- Meng, X.F.; Liu, Z.H.; Cui, B.; Qin, D.D.; Geng, H.Y.; Cai, W.; Fu, L.W.; He, J.Q.; Ren, Z.; Sui, J.H. Grain Boundary Engineering for Achieving High Thermoelectric Performance in n-Type Skutterudites. Adv. Energy Mater. 2017, 7. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, S.-W.; Snyder, G.J. Temperature dependent solubility of Yb in Yb–CoSb3 skutterudite and its effect on preparation, optimization and lifetime of thermoelectrics. J. Mater. 2015, 1, 75–84. [Google Scholar] [CrossRef]

- Tang, Y.L.; Hanus, R.; Chen, S.W.; Snyder, G.J. Solubility design leading to high figure of merit in low-cost Ce-CoSb3 skutterudites. Nat. Commun. 2015, 6. [Google Scholar] [CrossRef] [PubMed]

- Rogl, G.; Zhang, L.; Rogl, P.; Grytsiv, A.; Falmbigl, M.; Rajs, D.; Kriegisch, M.; Muller, H.; Bauer, E.; Koppensteiner, J.; et al. Thermal expansion of skutterudites. J. Appl. Phys. 2010, 107, 043507. [Google Scholar] [CrossRef]

| Samples | Lattice Parameters | R-Factors | |||

|---|---|---|---|---|---|

| a = b = c (Å) | Vol (Å3) | Density (g/cm3) | Rp (%) | Rwp (%) | |

| n-Yb0.25Fe0.25Co3.75Sb12 | 9.0511 | 741.487 | 7.567 | 3.55 | 3.53 |

| p-La0.7Ti0.1Ga0.1Fe2.7Co1.3Sb12 | 9.1173 | 757.869 | 7.866 | 4.69 | 3.28 |

| Nominal Composition | Measured Composition | ρ (g/cm3) | σ (S/cm) | α (µV/K) | κtotal (W/m·K) |

|---|---|---|---|---|---|

| Yb0.25Fe0.25Co3.75Sb12 | Yb0.29Fe0.22Co3.78Sb11.68 | 7.54 | 808 | −178.25 | 2.34 |

| La0.7Ti0.1Ga0.1Fe2.7Co1.3Sb12 | La0.54Ti0.04Ga0.05Fe3.03Co0.97Sb11.4 | 7.86 | 700 | 145.80 | 1.90 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Stokes, D.; Poudel, B.; Saparamadu, U.; Nozariasbmarz, A.; Kang, H.B.; Priya, S. High-Efficiency Skutterudite Modules at a Low Temperature Gradient. Energies 2019, 12, 4292. https://doi.org/10.3390/en12224292

Li W, Stokes D, Poudel B, Saparamadu U, Nozariasbmarz A, Kang HB, Priya S. High-Efficiency Skutterudite Modules at a Low Temperature Gradient. Energies. 2019; 12(22):4292. https://doi.org/10.3390/en12224292

Chicago/Turabian StyleLi, Wenjie, David Stokes, Bed Poudel, Udara Saparamadu, Amin Nozariasbmarz, Han Byul Kang, and Shashank Priya. 2019. "High-Efficiency Skutterudite Modules at a Low Temperature Gradient" Energies 12, no. 22: 4292. https://doi.org/10.3390/en12224292

APA StyleLi, W., Stokes, D., Poudel, B., Saparamadu, U., Nozariasbmarz, A., Kang, H. B., & Priya, S. (2019). High-Efficiency Skutterudite Modules at a Low Temperature Gradient. Energies, 12(22), 4292. https://doi.org/10.3390/en12224292