Production of Carbohydrates from Cardoon Pre-Treated by Acid-Catalyzed Steam Explosion and Enzymatic Hydrolysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characterization of Raw Material, SF, and LF

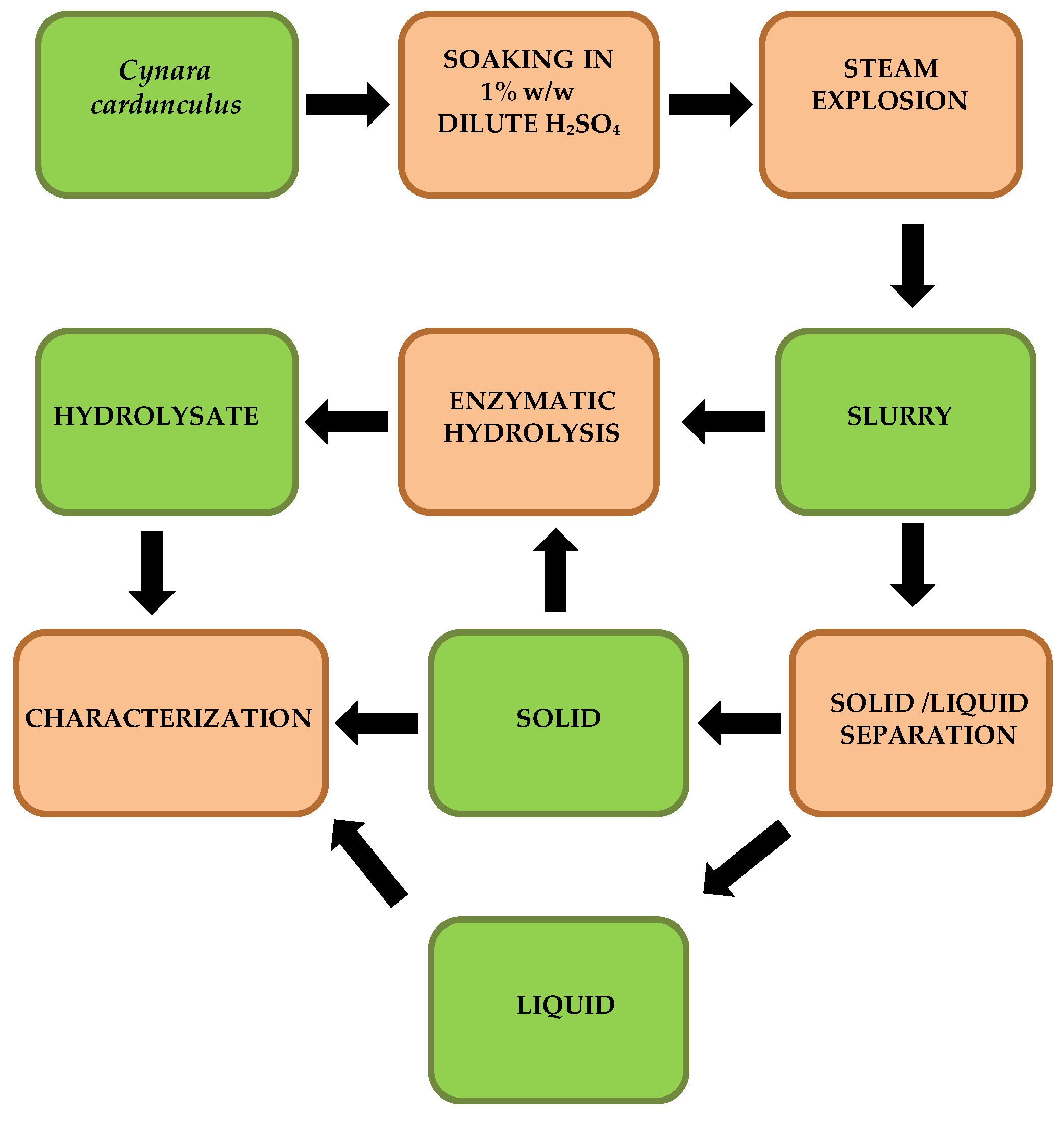

2.2. Process Flowchart

2.3. Steam Explosion

2.4. Enzymatic Hydrolysis

3. Results and Discussion

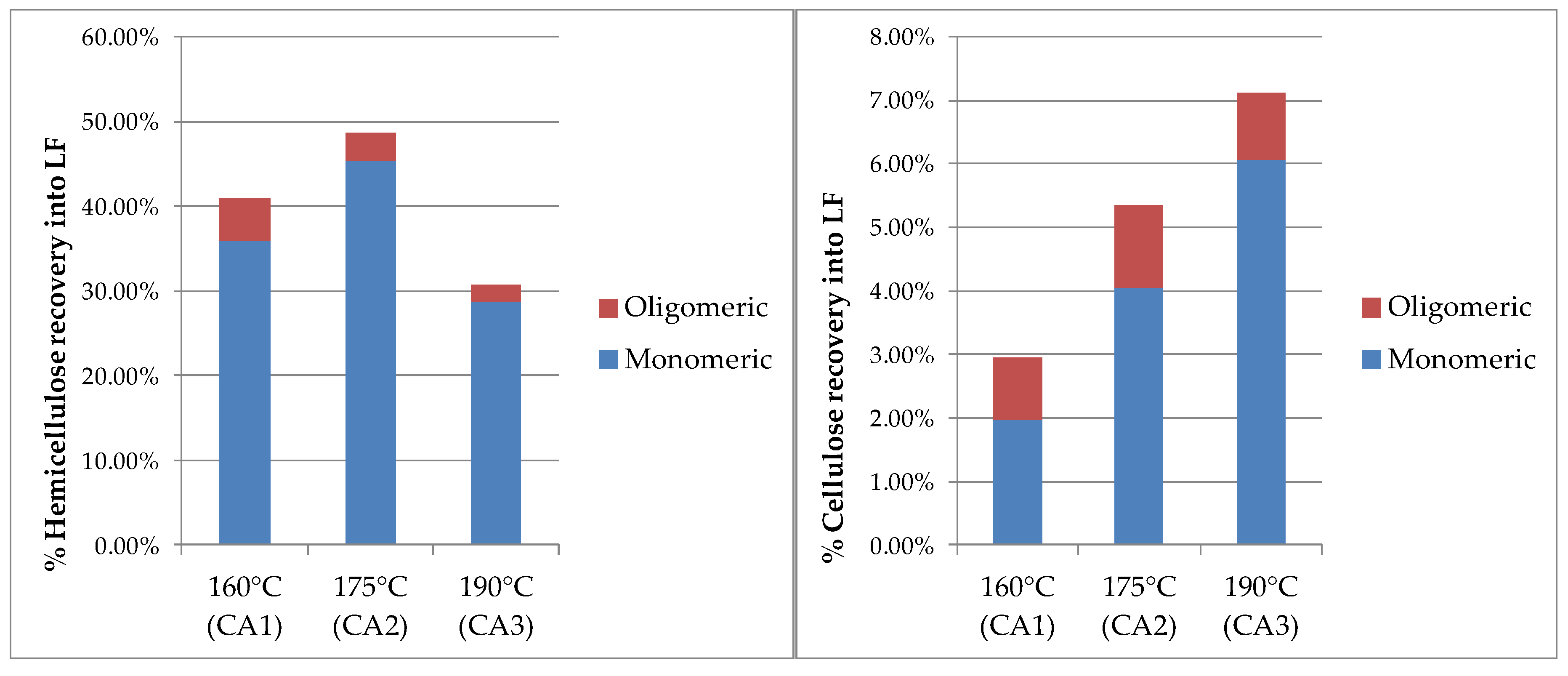

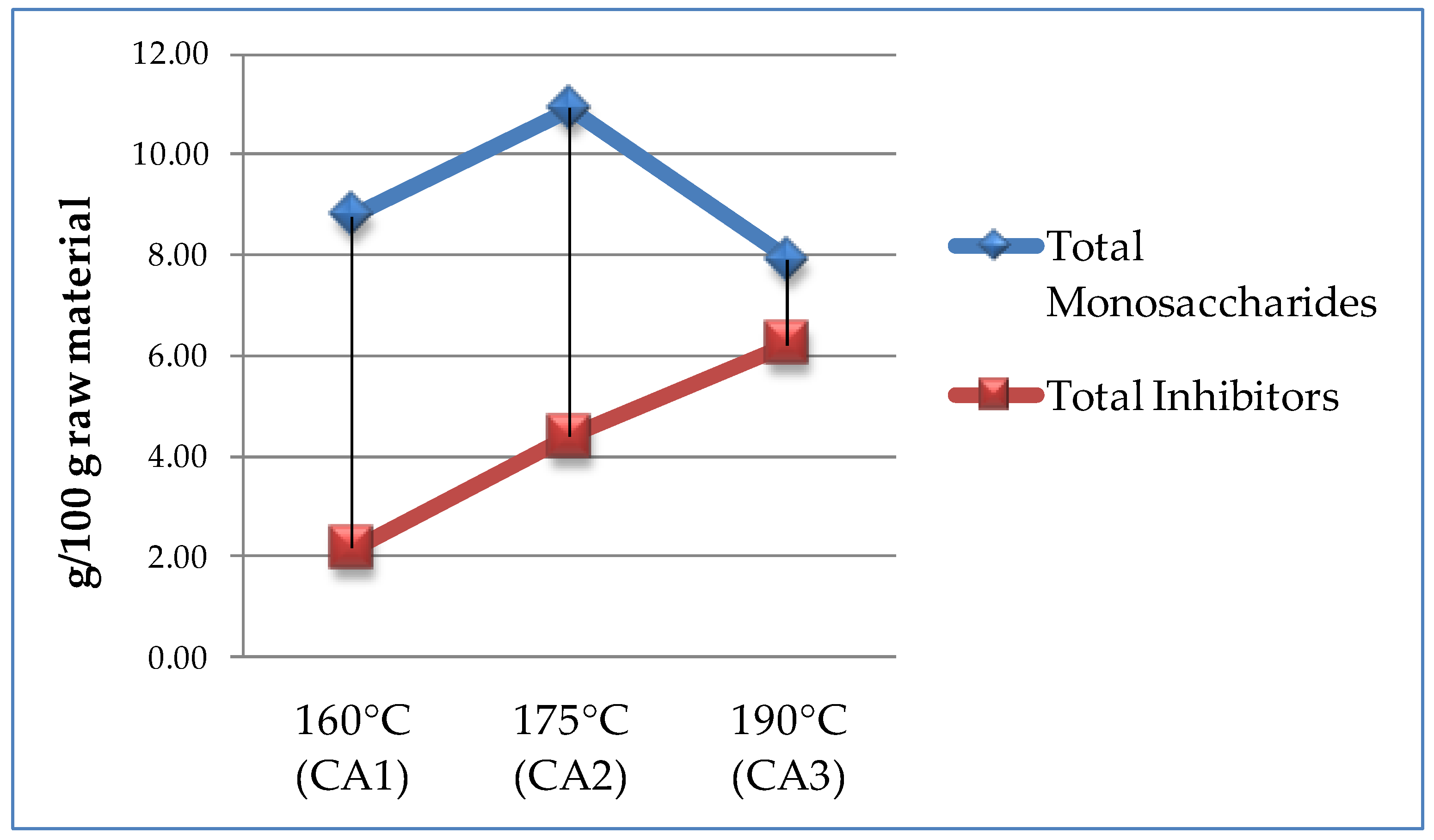

3.1. Characterization of Raw Material, SF, and LF

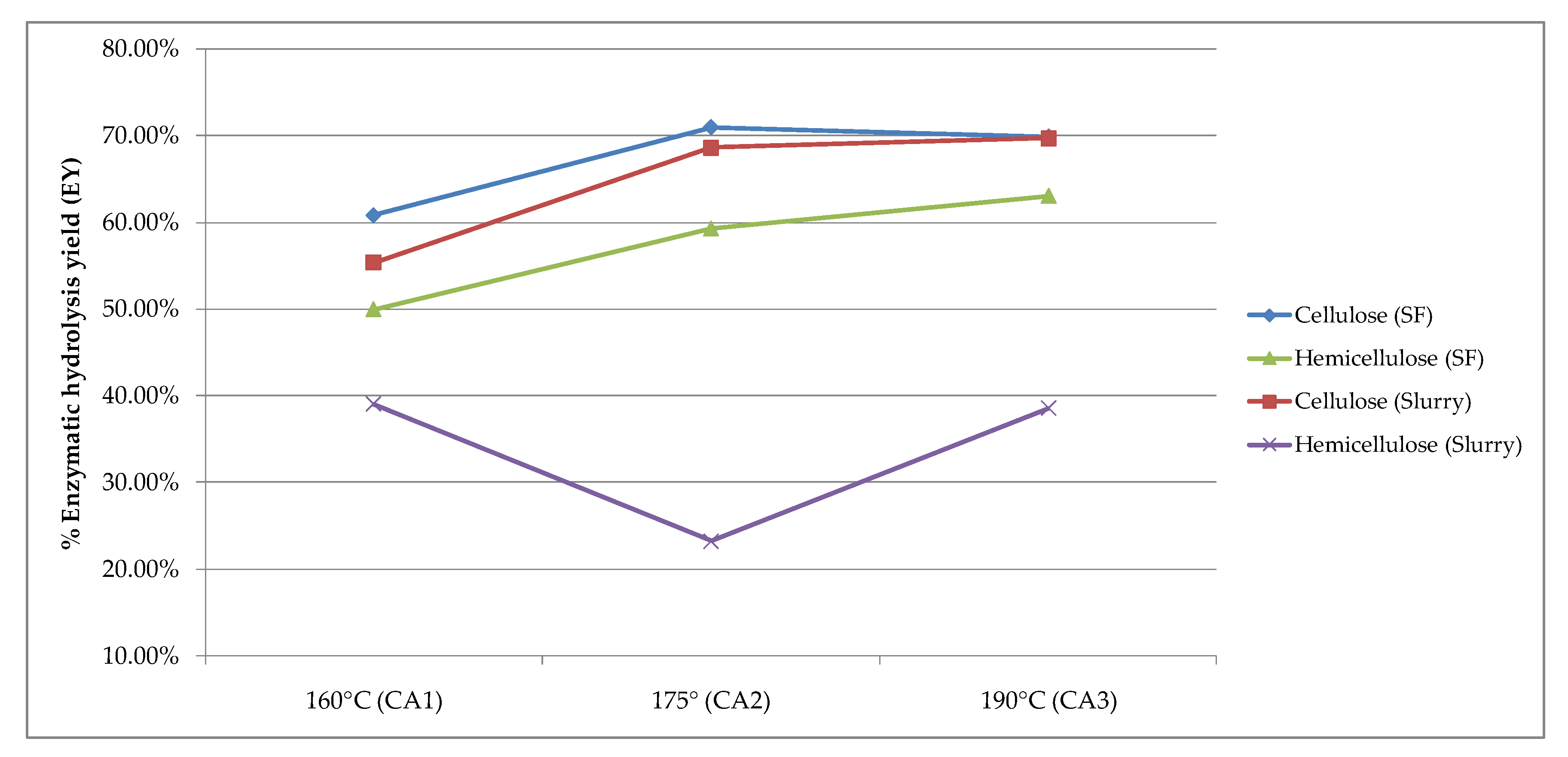

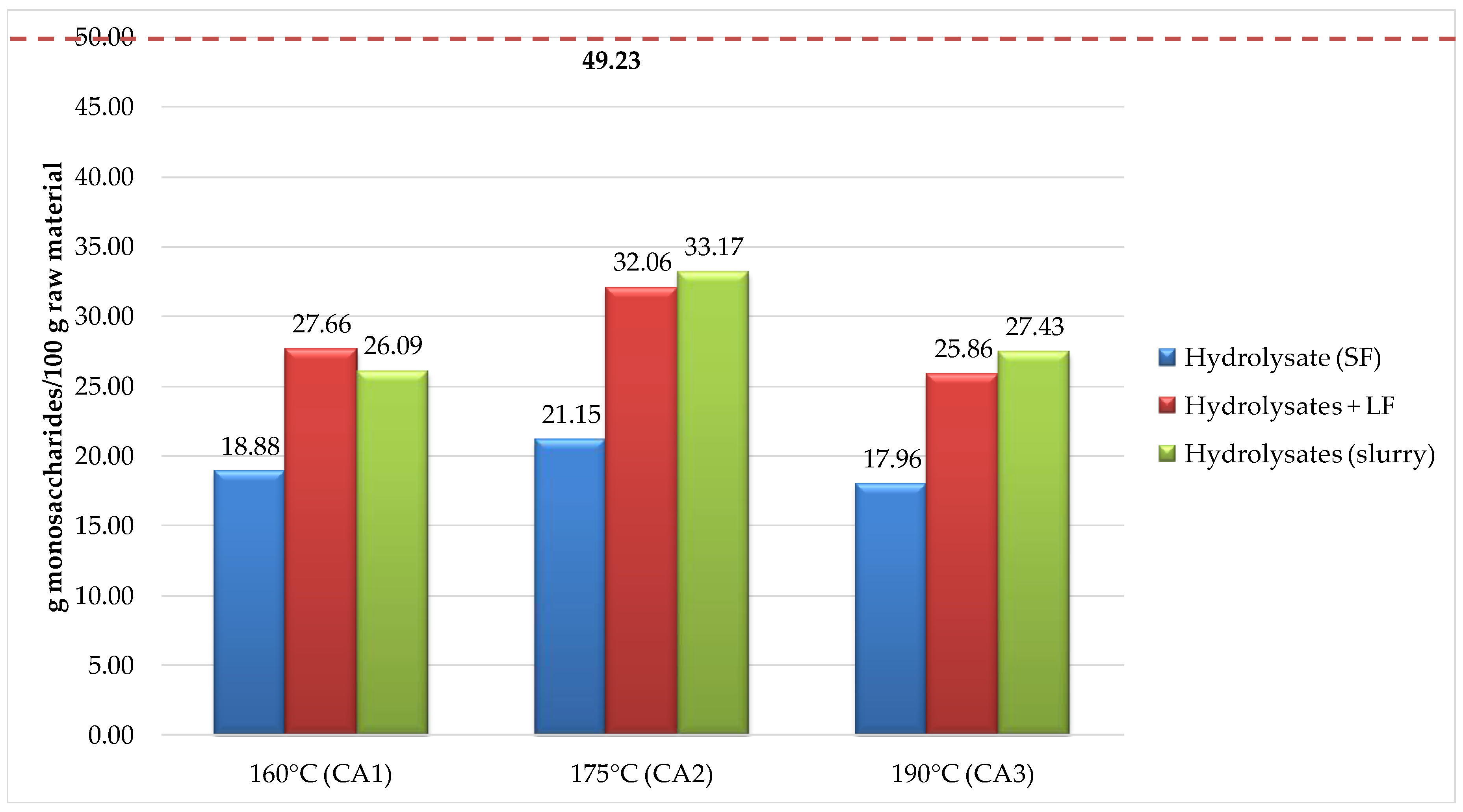

3.2. Enzymatic Hydrolysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cajarville, C.; González, J.; Repetto, J.; Alvir, M.; Rodrı́guez, C. Nutritional evaluation of cardoon (cynara cardunculus) seed for ruminants. Anim. Feed Sci. Technol. 2000, 87, 203–213. [Google Scholar] [CrossRef]

- Angelini, L.G.; Ceccarini, L.; o Di Nasso, N.N.; Bonari, E. Long-term evaluation of biomass production and quality of two cardoon (Cynara cardunculus L.) cultivars for energy use. Biomass Bioenergy 2009, 33, 810–816. [Google Scholar] [CrossRef]

- Ciancolini, A.; Alignan, M.; Pagnotta, M.A.; Vilarem, G.; Crinò, P. Selection of italian cardoon genotypes as industrial crop for biomass and polyphenol production. Ind. Crops Prod. 2013, 51, 145–151. [Google Scholar] [CrossRef]

- Fernández, J.; Curt, M.D.; Aguado, P.L. Industrial applications of Cynara cardunculus L. For energy and other uses. Ind. Crops Prod. 2006, 24, 222–229. [Google Scholar] [CrossRef]

- Francaviglia, R.; Bruno, A.; Falcucci, M.; Farina, R.; Renzi, G.; Russo, D.E.; Sepe, L.; Neri, U. Yields and quality of Cynara cardunculus L. Wild and cultivated cardoon genotypes. A case study from a marginal land in central Italy. Eur. J. Agron. 2016, 72, 10–19. [Google Scholar] [CrossRef]

- Fernandes, M.C.; Ferro, M.D.; Paulino, A.F.C.; Chaves, H.T.; Evtuguin, D.V.; Xavier, A.M.R.B. Comparative study on hydrolysis and bioethanol production from cardoon and rockrose pretreated by dilute acid hydrolysis. Ind. Crops Prod. 2018, 111, 633–641. [Google Scholar] [CrossRef]

- Ligero, P.; Villaverde, J.J.; Vega, A.; Bao, M. Pulping cardoon (Cynara cardunculus) with peroxyformic acid (milox) in one single stage. Bioresour. Technol. 2008, 99, 5687–5693. [Google Scholar] [CrossRef] [PubMed]

- Foti, S.; Mauromicale, G.; Raccuia, S.A.; Fallico, B.; Fanella, F.; Maccarone, E. Possible alternative utilization of Cynara spp.: I. Biomass, grain yield and chemical composition of grain. Ind. Crops Prod. 1999, 10, 219–228. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, S.; Singh, O.V. Bioconversion of lignocellulosic biomass: Biochemical and molecular perspectives. J. Ind. Microbiol. Biotechnol. 2008, 35, 377–391. [Google Scholar] [CrossRef] [PubMed]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.; Holtzapple, M.; Ladisch, M. Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef] [PubMed]

- Hendriks, A.; Zeeman, G. Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour. Technol. 2009, 100, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Jacquet, N.; Maniet, G.; Vanderghem, C.; Delvigne, F.; Richel, A. Application of steam explosion as pretreatment on lignocellulosic material: A review. Ind. Eng. Chem. Res. 2015, 54, 2593–2598. [Google Scholar] [CrossRef]

- Palmqvist, E.; Hahn-Hägerdal, B. Fermentation of lignocellulosic hydrolysates. II: Inhibitors and mechanisms of inhibition. Bioresour. Technol. 2000, 74, 25–33. [Google Scholar] [CrossRef]

- Ballesteros, M.; Negro, M.J.; Manzanares, P.; Ballesteros, I.; Sáez, F.; Oliva, J.M. Fractionation of cynara cardunculus (cardoon) biomass by dilute-acid pretreatment. In Applied Biochemistry and Biotecnology; Springer: Berlin, Germany, 2007; pp. 239–252. [Google Scholar]

- Schell, D.; Torget, R.; Power, A.; Walter, P.; Grohmann, K.; Hinman, N. A technical and economic analysis of acid-catalyzed steam explosion and dilute sulfuric acid pretreatments using wheat straw or aspen wood chips. Appl. Biochem. Biotechnol. 1991, 28, 87. [Google Scholar] [CrossRef]

- Bondesson, P.M.; Galbe, M.; Zacchi, G. Ethanol and biogas production after steam pretreatment of corn stover with or without the addition of sulphuric acid. Biotechnol. Biofuels 2013, 6, 11. [Google Scholar] [CrossRef] [PubMed]

- Duarte, G.C.; Moreira, L.R.S.; Jaramillo, P.M.D.; Filho, E.X.F. Biomass-derived inhibitors of holocellulases. BioEnergy Res. 2012, 5, 768–777. [Google Scholar] [CrossRef]

- Jing, X.; Zhang, X.; Bao, J. Inhibition performance of lignocellulose degradation products on industrial cellulase enzymes during cellulose hydrolysis. Appl. Biochem. Biotechnol. 2009, 159, 696. [Google Scholar] [CrossRef] [PubMed]

- Sluiter, J.; Sluiter, A. Summative Mass Closure; NREL NREL/TP-510-48087; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2010; pp. 1–10.

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of structural carbohydrates and lignin in biomass. Labor. Anal. Proced. 2008, 1617, 1–16. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Sugars, Byproducts, and Degradation Products in Liquid Fraction Process Samples; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2006.

- Tao, L.; Schell, D.; Davis, R.; Tan, E.; Elander, R.; Bratis, A. Nrel 2012 Achievement of Ethanol Cost Targets: Biochemical Ethanol Fermentation via Dilute-Acid Pretreatment and Enzymatic Hydrolysis of Corn Stover; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2014.

- Ballesteros, I.; Negro, M.J.; Oliva, J.M.; Cabañas, A.; Manzanares, P.; Ballesteros, M. Ethanol Production from Steam-Explosion Pretreated Wheat Straw. In Proceedings of the Twenty-Seventh Symposium on Biotechnology for Fuels and Chemicals, Denver, CO, USA, 1–4 May 2005; Springer: Berlin, Germany, 2006; pp. 496–508. [Google Scholar]

- Cotana, F.; Cavalaglio, G.; Gelosia, M.; Coccia, V.; Petrozzi, A.; Ingles, D.; Pompili, E. A comparison between shf and sssf processes from cardoon for ethanol production. Ind. Crops Prod. 2015, 69, 424–432. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Chen, H. Formation kinetics of potential fermentation inhibitors in a steam explosion process of corn straw. Appl. Biochem. Biotechnol. 2013, 169, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Takagi, M. Inhibition of cellulase by fermentation products. Biotechnol. Bioeng. (U. S.) 1984, 26, 1506-7. [Google Scholar] [CrossRef] [PubMed]

- Qing, Q.; Yang, B.; Wyman, C.E. Xylooligomers are strong inhibitors of cellulose hydrolysis by enzymes. Bioresour. Technol. 2010, 101, 9624–9630. [Google Scholar] [CrossRef] [PubMed]

- Ballesteros, I.; Ballesteros, M.; Manzanares, P.; Negro, M.J.; Oliva, J.M.; Sáez, F. Dilute sulfuric acid pretreatment of cardoon for ethanol production. Biochem. Eng. J. 2008, 42, 84–91. [Google Scholar] [CrossRef]

| Sample Name | Temperature (°C) | Time (min) |

|---|---|---|

| CA1 | 160 | 35 |

| CA2 | 175 | 35 |

| CA3 | 190 | 35 |

| Sample Name | Solid Dry Weight (g) | Water Content (g) | Buffer Solution (g) | Enzyme (g) |

|---|---|---|---|---|

| CA1SF | 2.5 | 10.25 | 38.90 | 0.42 |

| CA2SF | 2.5 | 8.91 | 40.19 | 0.43 |

| CA3SF | 2.5 | 8.81 | 40.29 | 0.42 |

| CA1 slurry | 2.5 | 46.25 | 0.83 | 0.42 |

| CA2 slurry | 2.5 | 39.41 | 7.66 | 0.43 |

| CA3 slurry | 2.5 | 40.91 | 6.17 | 0.42 |

| CA1LF | 0 | 36 | 13.58 | 0.42 |

| CA2LF | 0 | 30.5 | 19.07 | 0.43 |

| CA3LF | 0 | 32.1 | 17.48 | 0.42 |

| Hemicellulose | Cellulose | Acetyls | Pectin | Lignin | Extractives | Ash | Total |

|---|---|---|---|---|---|---|---|

| 15.81% | 28.11% | 4.62% | 4.38% | 13.08% | 7.64% | 8.79% | 82.43% |

| Sample | Hsolid | Csolid | Lsolid | HRsolid | CRsolid | HRliquid | CRliquid | HRtotal | CRtotal |

|---|---|---|---|---|---|---|---|---|---|

| CA1 | 9.44% | 55.43% | 24.99% | 26.33% | 86.93% | 41.02% | 2.95% | 67.34% | 89.88% |

| CA2 | 5.46% | 57.27% | 30.41% | 16.49% | 87.56% | 48.80% | 4.28% | 65.29% | 91.84% |

| CA3 | 3.61% | 56.25% | 36.41% | 8.87% | 77.71% | 30.69% | 7.14% | 39.56% | 84.85% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bertini, A.; Gelosia, M.; Cavalaglio, G.; Barbanera, M.; Giannoni, T.; Tasselli, G.; Nicolini, A.; Cotana, F. Production of Carbohydrates from Cardoon Pre-Treated by Acid-Catalyzed Steam Explosion and Enzymatic Hydrolysis. Energies 2019, 12, 4288. https://doi.org/10.3390/en12224288

Bertini A, Gelosia M, Cavalaglio G, Barbanera M, Giannoni T, Tasselli G, Nicolini A, Cotana F. Production of Carbohydrates from Cardoon Pre-Treated by Acid-Catalyzed Steam Explosion and Enzymatic Hydrolysis. Energies. 2019; 12(22):4288. https://doi.org/10.3390/en12224288

Chicago/Turabian StyleBertini, Alessandro, Mattia Gelosia, Gianluca Cavalaglio, Marco Barbanera, Tommaso Giannoni, Giorgia Tasselli, Andrea Nicolini, and Franco Cotana. 2019. "Production of Carbohydrates from Cardoon Pre-Treated by Acid-Catalyzed Steam Explosion and Enzymatic Hydrolysis" Energies 12, no. 22: 4288. https://doi.org/10.3390/en12224288