Cooling Benefits of an Extensive Green Roof and Sensitivity Analysis of Its Parameters in Subtropical Areas

Abstract

1. Introduction

2. Methods

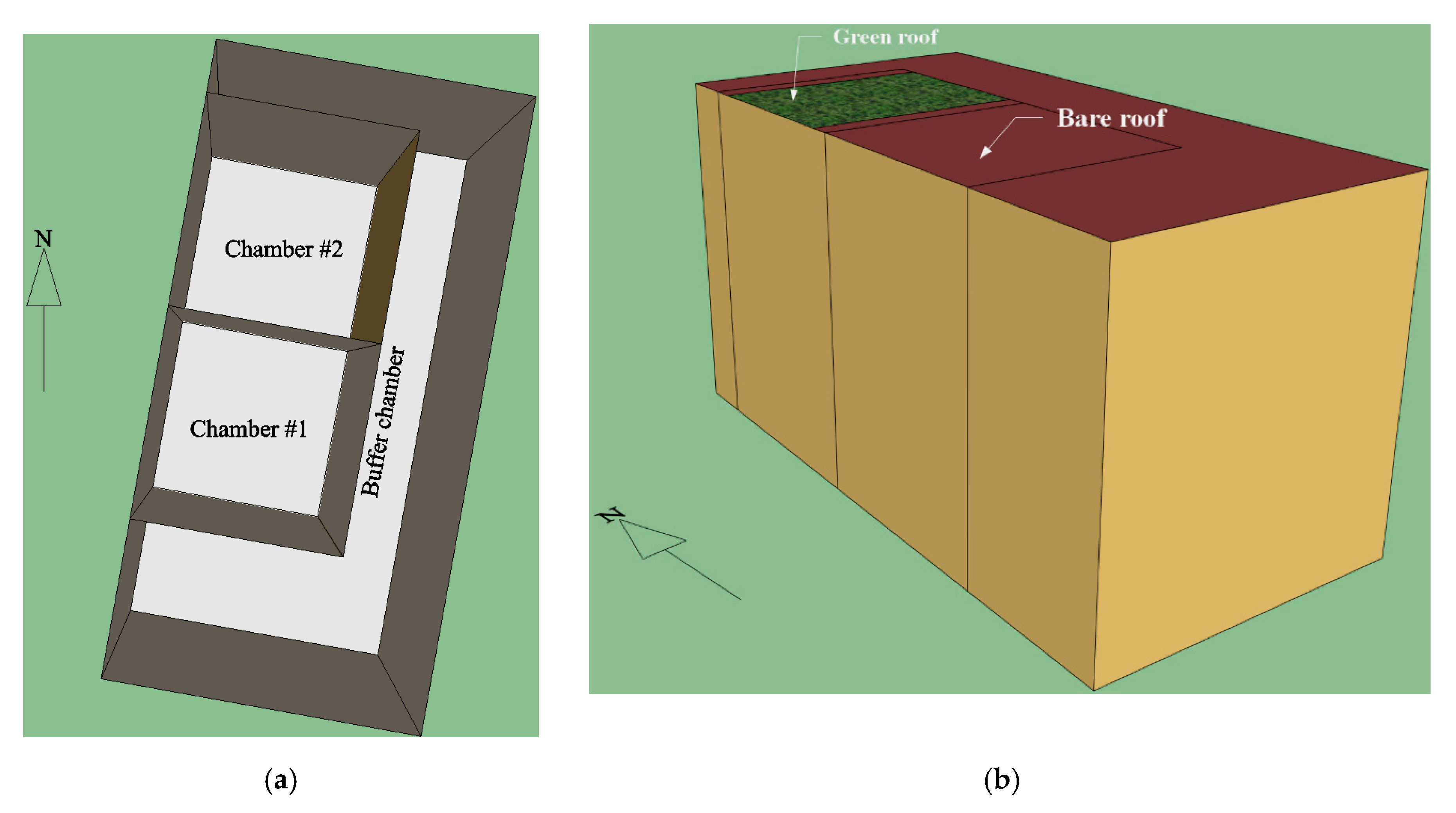

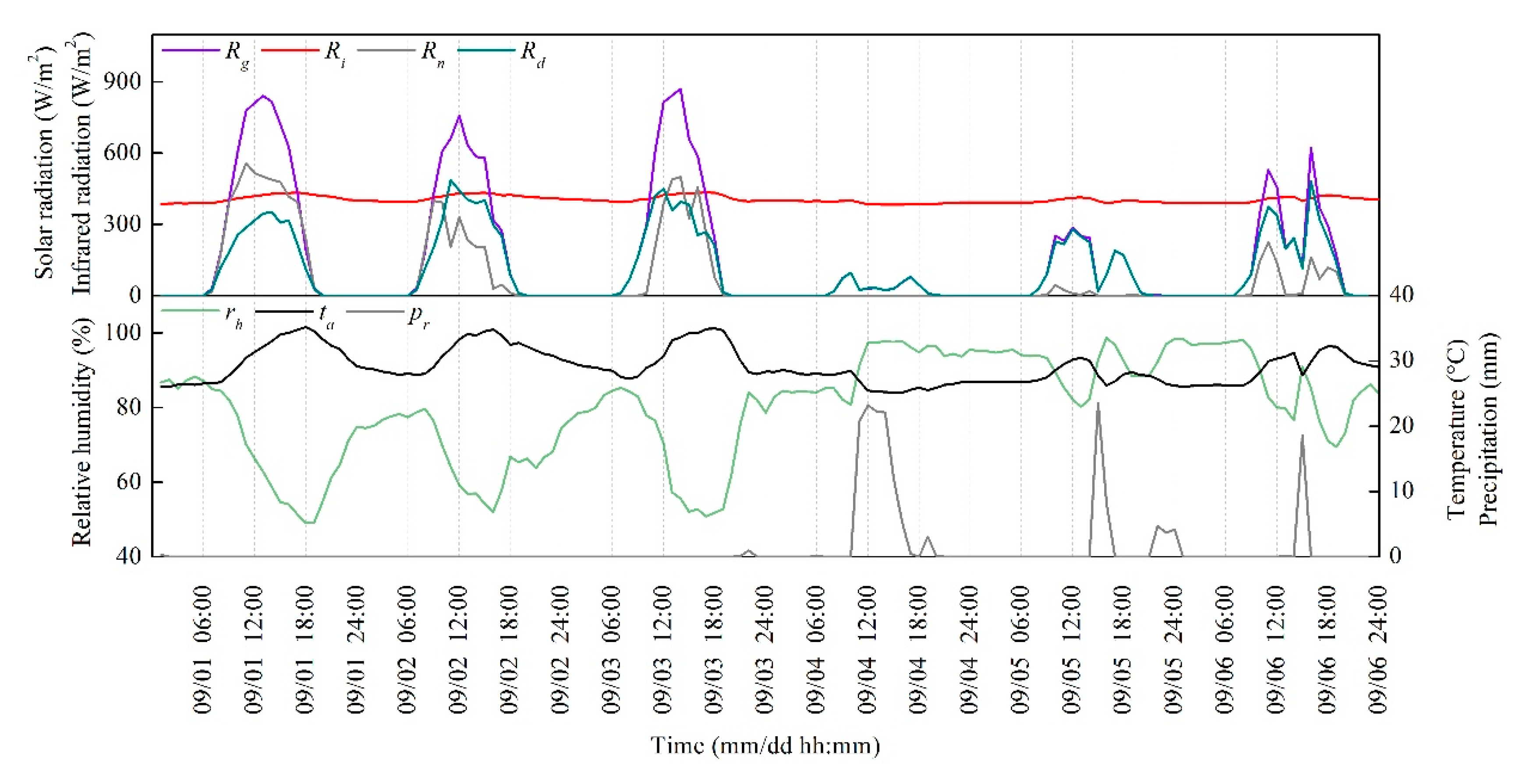

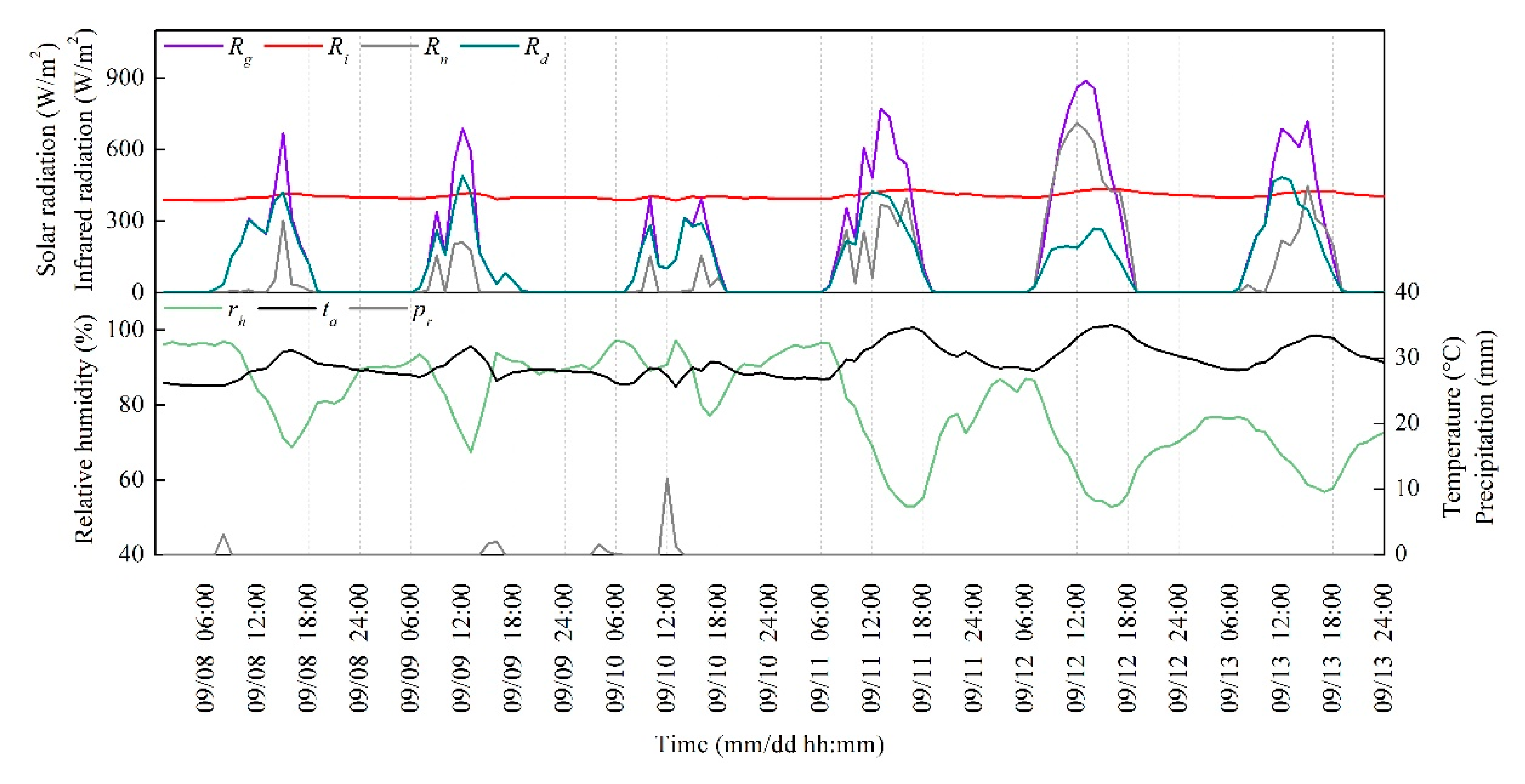

2.1. Onsite Measurements

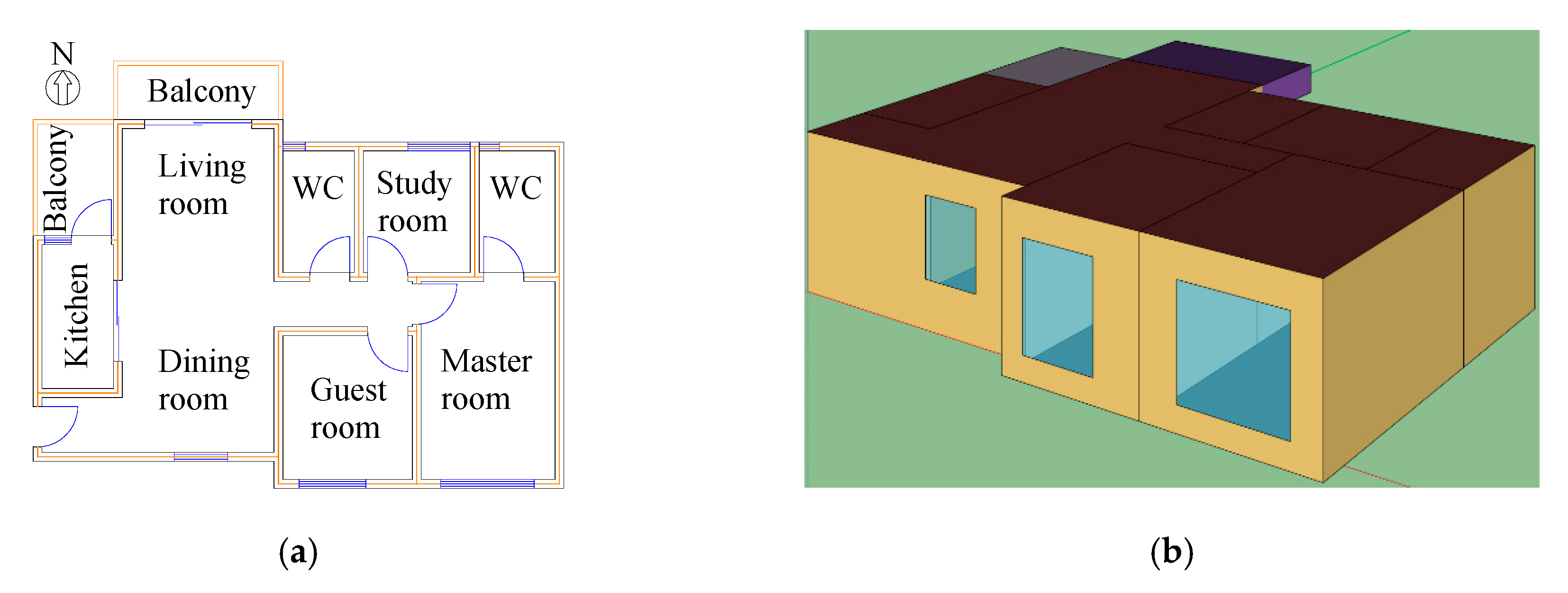

2.2. GRM in EnergyPlus

2.3. Sensitivity Analysis

3. Results and Discussion

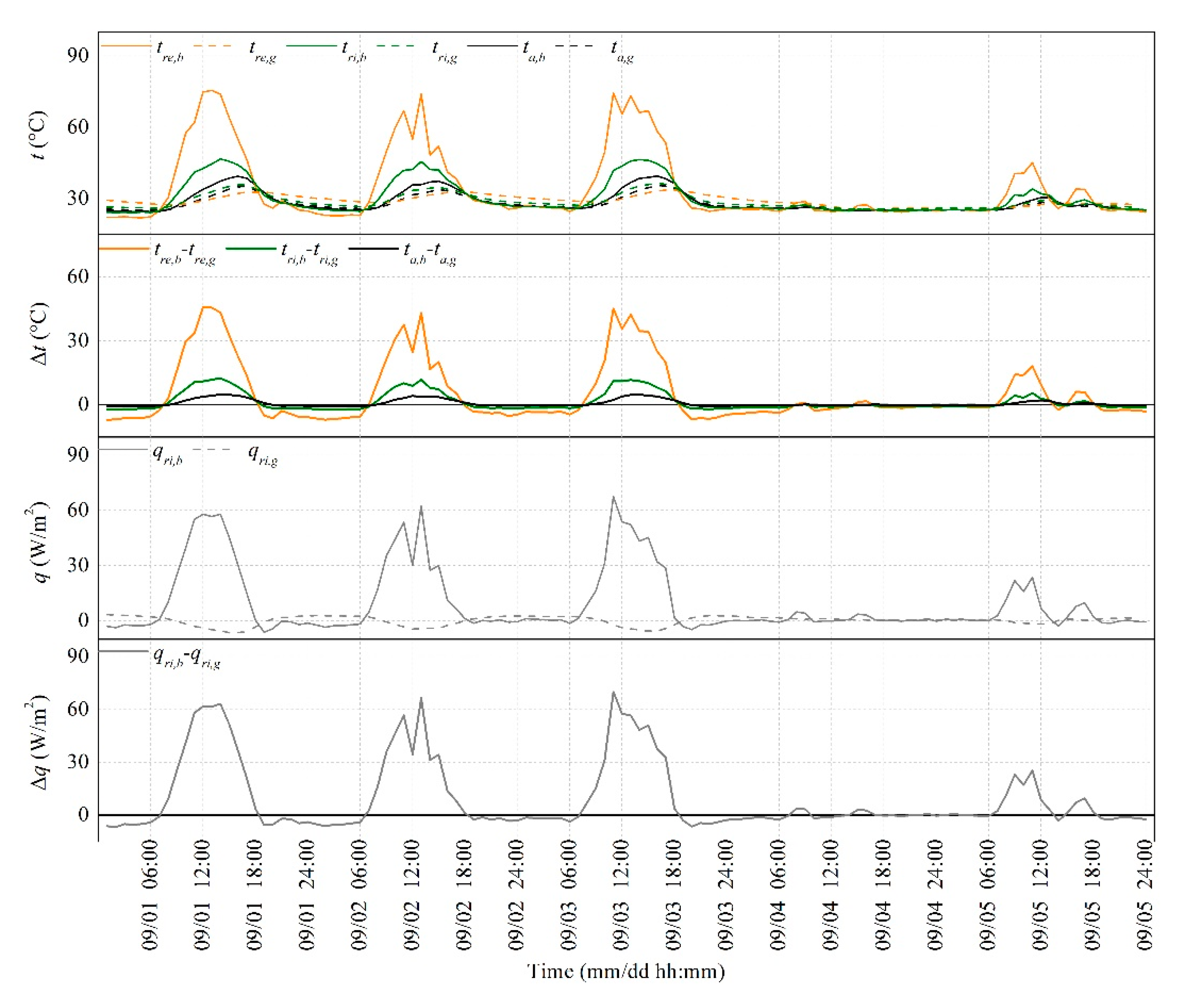

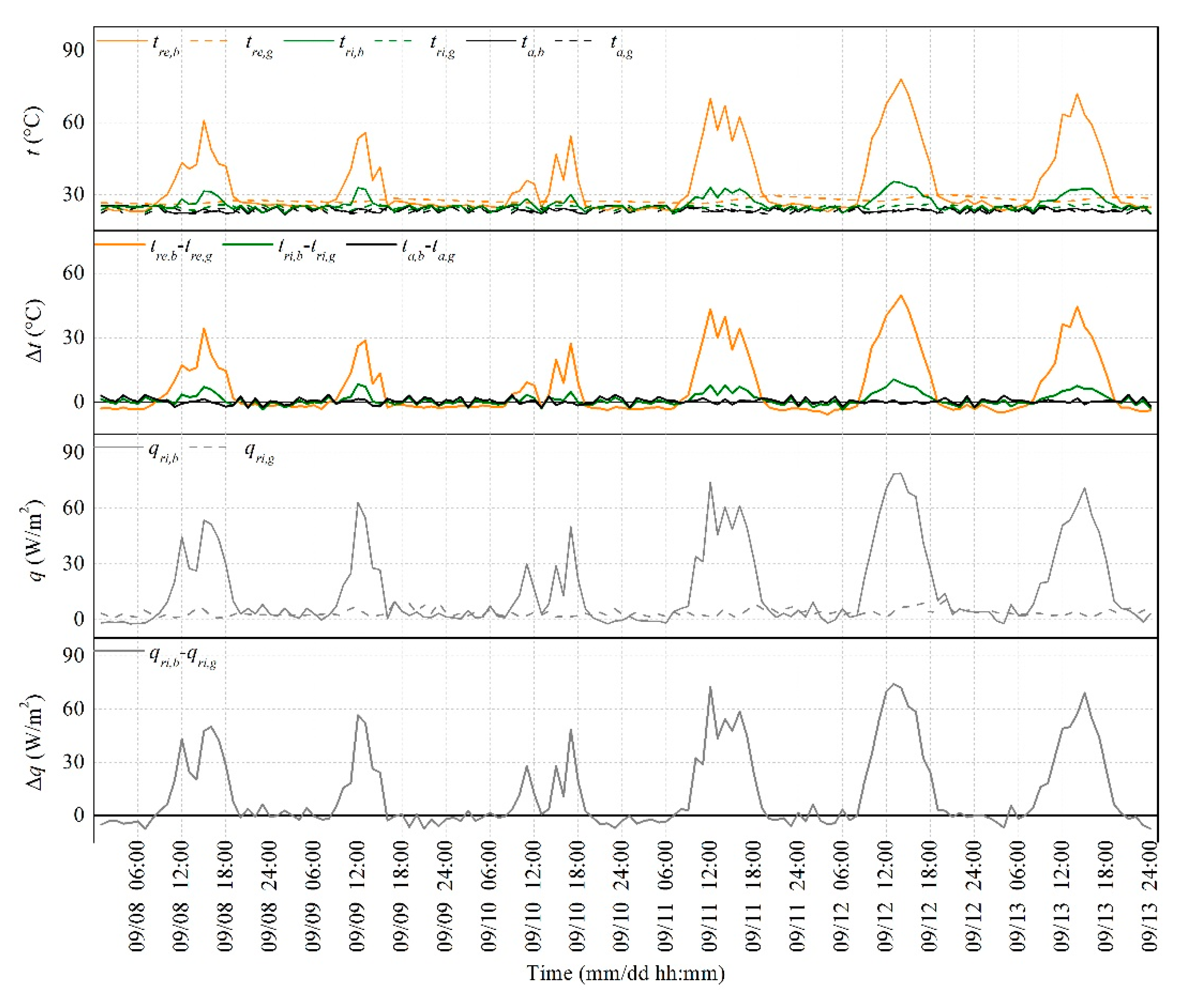

3.1. Cooling Benefits of a Green Roof

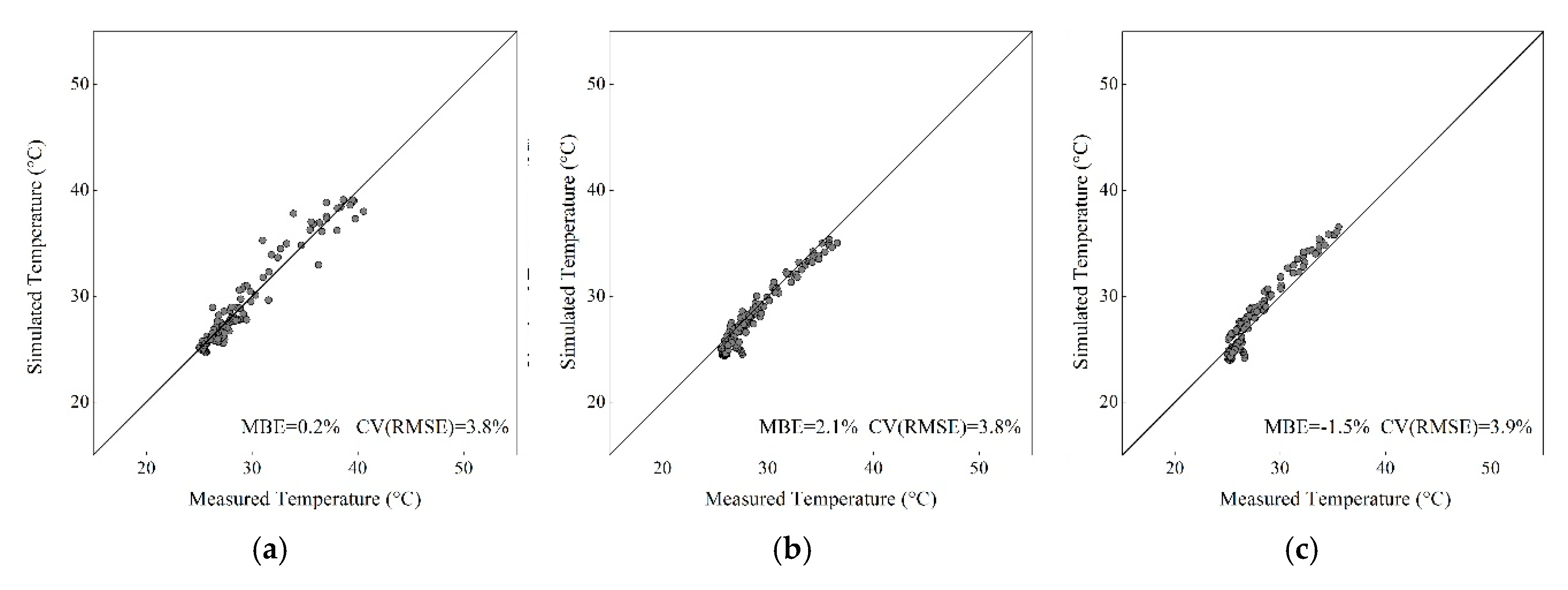

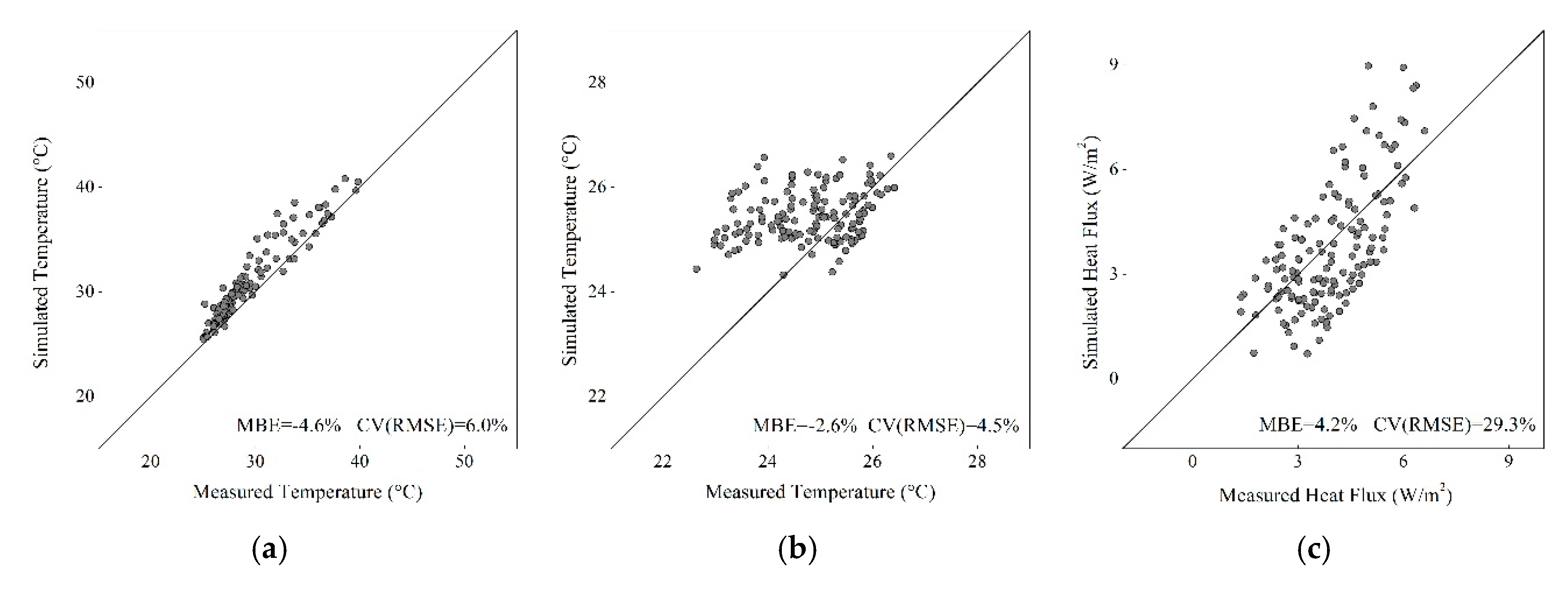

3.2. Accuracy of the GRM

3.3. Significance Order of Factors

4. Conclusions

- (1)

- The cooling effects of the green roof were related to the local climate conditions. For Guangzhou’s subtropical climate, the green roof had significant cooling and energy savings effects. Specifically, compared to the corresponding values for a bare roof, the experimental green roof decreased the roof internal surface temperature, chamber air temperature, and daily air-conditioning electricity consumption by up to 12.5 °C, 4.9 °C, and 16.7%, respectively;

- (2)

- The good agreement between the simulations and the measurements clearly showed that the EnergyPlus GRM could capture the diurnal cycle of a green roof on both sunny and rainy days in the subtropical areas of southern China; and

- (3)

- The sensitivity analysis showed that the RRC had the most significant impact on the cooling load savings potential of the green roof. In addition, the cooling load savings rate of the green roof increased with the degradation of the insulation performance because of the rise in the inward heat flux. This result implies that a green roof is an effective energy-efficient retrofitted technology for existing buildings with poor roof thermal insulation performance.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| DDS | density of dry substrate |

| HP | height of plants |

| IVMCS | initial volumetric moisture content of the substrate |

| LAI | leaf area index |

| LE | leaf emissivity |

| LR | leaf reflectivity |

| MSR | minimum stomatal resistance |

| RRC | R-value of roof construction |

| RVMCS | residual volumetric moisture content of the substrate |

| SAS | solar absorptance of the substrate |

| SHDS | specific heat of dry substrate |

| SR | substrate roughness |

| ST | substrate thickness |

| SVMCS | saturation volumetric moisture content of the substrate |

| TAS | thermal absorptance of the substrate |

| TCDS | thermal conductivity of dry substrate |

| VAS | visible absorptance of the substrate |

References

- Cascone, S. Green Roof Design: State of the Art on Technology and Materials. Sustainability 2019, 11, 3020. [Google Scholar] [CrossRef]

- Ulubeyli, S.; Arslan, V. Economic viability of extensive green roofs through scenario and sensitivity analyses: Clients’ perspective. Energy Build. 2017, 139, 314–325. [Google Scholar] [CrossRef]

- Akbari, H. Measured energy savings from the application of reflective roofs in two small non-residential buildings. Energy 2003, 28, 953–967. [Google Scholar] [CrossRef]

- Santamouris, M. Cooling the cities–A review of reflective and green roof mitigation technologies to fight heat island and improve comfort in urban environments. Sol. Energy 2014, 103, 682–703. [Google Scholar] [CrossRef]

- Nahar, N.M.; Sharma, P.; Purohit, M.M. Studies on solar passive cooling techniques for arid areas. Energy Convers. Manag. 1999, 40, 89–95. [Google Scholar] [CrossRef]

- Karamanis, D. Solar cooling with hydrophilic porous materials for reducing building cooling needs. In Eco-Efficient Materials for Mitigating Building Cooling Needs: Design, Properties and Applications; Pacheco-Torgal, F., Labrincha, J., Cabeza, L., Granqvist, C.G., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 269–305. [Google Scholar]

- Santamouris, M.; Synnefa, A.; Karlessi, T. Using advanced cool materials in the urban built environment to mitigate heat islands and improve thermal comfort conditions. Sol. Energy 2011, 85, 3085–3102. [Google Scholar] [CrossRef]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Y.; Ma, Y.; David, S.N.; Zhao, D.; Lou, R.; Tan, G.; Yang, R.; Yin, X. Scalable-manufactured randomized glass-polymer hybrid metamaterial for daytime radiative cooling. Science 2017, 355, 1062–1066. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhang, R.; Zhang, Y.; Hong, T.; Meng, Q.; Feng, Y. The impact of evaporation from porous tile on roof thermal performance: A case study of Guangzhou’s climatic conditions. Energy Build. 2017, 136, 161–172. [Google Scholar] [CrossRef]

- Sailor, D.J. A green roof model for building energy simulation programs. Energy Build. 2008, 40, 1466–1478. [Google Scholar] [CrossRef]

- Gagliano, A.; Detommaso, M.; Nocera, F. Assessment of the green roofs thermal dynamic behavior for increasing the building energy efficiencies. In Smart Energy Control Systems for Sustainable Buildings; Littlewood, J., Spataru, C., Howlett, R.J., Jain, L.C., Eds.; Springer: Cham, Switzerland, 2017; pp. 37–59. [Google Scholar]

- Wolf, D.; Lundholm, J.T. Water uptake in green roof microcosms: Effects of plant species and water availability. Ecol. Eng. 2008, 33, 179–186. [Google Scholar] [CrossRef]

- Lin, B.S.; Yu, C.C.; Su, A.T.; Lin, Y.J. Impact of climatic conditions on the thermal effectiveness of an extensive green roof. Build. Environ. 2013, 67, 26–33. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Chen, C.T.; Tsai, Y.C. Reduction of temperatures and temperature fluctuations by hydroponic green roofs in a subtropical urban climate. Energy Build. 2016, 129, 174–185. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Chen, C.T.; Liu, W.T. Thermal performance of extensive green roofs in a subtropical metropolitan area. Energy Build. 2018, 159, 39–53. [Google Scholar] [CrossRef]

- Jim, C.Y. Air-conditioning energy consumption due to green roofs with different building thermal insulation. Appl. Energy 2014, 128, 49–59. [Google Scholar] [CrossRef]

- Jim, C.Y. Passive warming of indoor space induced by tropical green roof in winter. Energy 2014, 68, 272–282. [Google Scholar] [CrossRef]

- Jim, C.Y. Diurnal and partitioned heat-flux patterns of coupled green-building roof systems. Renew. Energy 2015, 81, 262–274. [Google Scholar] [CrossRef]

- Jiang, L.; Tang, M. Thermal analysis of extensive green roofs combined with night ventilation for space cooling. Energy Build. 2017, 156, 238–249. [Google Scholar] [CrossRef]

- Yang, W.; Wang, Z.; Cui, J.; Zhu, Z.; Zhao, X. Comparative study of the thermal performance of the novel green (planting) roofs against other existing roofs. Sustain. Cities Soc. 2015, 16, 1–12. [Google Scholar] [CrossRef]

- Feng, C.; Meng, Q.; Zhang, Y. Theoretical and experimental analysis of the energy balance of extensive green roofs. Energy Build. 2010, 42, 959–965. [Google Scholar] [CrossRef]

- Peng, L.; Jim, C. Green-roof effects on neighborhood microclimate and human thermal sensation. Energies 2013, 6, 598–618. [Google Scholar] [CrossRef]

- Costanzo, V.; Evola, G.; Marletta, L. Energy savings in buildings or UHI mitigation? Comparison between green roofs and cool roofs. Energy Build. 2016, 114, 247–255. [Google Scholar] [CrossRef]

- Lawrence Berkeley National Laboratory. EnergyPlus Documentation Engineering Reference. Available online: https://energyplus.net/sites/all/modules/custom/nrel_custom/pdfs/pdfs_v8.4.0/EngineeringReference.pdf (accessed on 18 September 2019).

- Zeng, C.; Bai, X.; Sun, L.; Zhang, Y.; Yuan, Y. Optimal parameters of green roofs in representative cities of four climate zones in China: A simulation study. Energy Build. 2017, 150, 118–131. [Google Scholar] [CrossRef]

- Rakotondramiarana, H.; Ranaivoarisoa, T.; Morau, D. Dynamic simulation of the green roofs impact on building energy performance, case study of Antananarivo, Madagascar. Buildings 2015, 5, 497–520. [Google Scholar] [CrossRef]

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and future Köppen-Geiger climate classification maps at 1-km resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef] [PubMed]

- Frankenstein, S.; Koenig, G. FASST Vegetation Models; US Army Corps of Engineers: Washington, DC, USA, 2004. [Google Scholar]

- Frankenstein, S.; Koenig, G. Fast All-Season Soil Strength (FASST); US Army Corps of Engineers: Washington, DC, USA, 2004. [Google Scholar]

- Giunta, A.A.; McFarland, J.M.; Swiler, L.P.; Eldred, M.S. The promise and peril of uncertainty quantification using response surface approximations. Struct. Infrastruct. Eng. 2006, 2, 175–189. [Google Scholar] [CrossRef]

- Ministry of Construction of the People’s Republic of China. Design Standard for Energy Efficiency of Residential Buildings in Hot Summer and Warm Winter Zone; China Building Industry Press: Beijing, China, 2012.

- Zhao, P.; Ge, S.; Yoshikawa, K. An orthogonal experimental study on solid fuel production from sewage sludge by employing steam explosion. Appl. Energy 2013, 112, 1213–1221. [Google Scholar] [CrossRef]

| Measurement Points | Sensor Type | Measurement Range and Accuracy |

|---|---|---|

| Direct normal radiation | CHP1 pyrheliometer with SOLYS2 sun tracker | 0–4000 W/m2, ±0.5% |

| Global horizontal radiation | CMP3 pyranometer | 0–2000 W/m2, ±5.0% |

| Diffuse horizontal radiation | CMP3 pyranometer | 0–2000 W/m2, ±5.0% |

| Outdoor wind speed | 81000 three-dimensional ultrasonic anemometer | 0–40 m/s, ±1% |

| Outdoor wind direction | 0.0–359.9°, ±2° | |

| Outdoor dry-bulb temperature | CS215 temperature and relative humidity probe | −40–70 °C, ±0.4 °C |

| Outdoor relative humidity | 0–100%, ±2% | |

| Surface temperature | Φ0.2-mm T-type thermocouple | −200–150 °C, ±0.1 °C |

| Substrate temperature | HOBO temperature sensor | −40–70 °C, ±0.18 °C |

| Chamber air temperature | HOBO temperature sensor | −40–70 °C, ±0.18 °C |

| Heat flux | Heat flow sensor | −2–2 kW/m2, ±3% |

| Building Components | Material (from Outside to Inside) | Thickness (mm) | Thermal Conductivity (W/m∙K) | Density (kg/m3) | Specific Heat (J/kg·K) |

|---|---|---|---|---|---|

| Wall | Expanded polystyrene board | 0.1 | 0.0624 | 30 | 1260 |

| Roof | Extruded polystyrene board | 0.025 | 0.046 | 30 | 1210 |

| Floor | Expanded polystyrene board | 0.1 | 0.0624 | 30 | 1260 |

| Green Roof Parameters | Values |

|---|---|

| Height of plants (m) | 0.1 |

| Leaf area index (–) | 4.6 |

| Leaf reflectivity (–) | 0.17 |

| Leaf emissivity (–) | 0.99 |

| Minimum stomatal resistance (s/m) | 180 |

| Substrate roughness (–) | Medium rough |

| Substrate thickness (m) | 0.1 |

| Thermal conductivity of dry substrate (W/m·K) | 0.1 |

| Density of dry substrate (kg/m3) | 550 |

| Specific heat of dry substrate (J/kg·K) | 600 |

| Thermal absorptance of the substrate (–) | 0.95 |

| Solar absorptance of the substrate (–) | 0.7 |

| Visible absorptance of the substrate (–) | 0.7 |

| Saturation volumetric moisture content of the substrate (–) | 0.5 |

| Residual volumetric moisture content of the substrate (–) | 0.01 |

| Initial volumetric moisture content of the substrate (–) | 0.3 |

| Object | Description |

|---|---|

| EnergyPlus version | 8.4 |

| Inside surface convection algorithm | Thermal Analysis Research Program |

| Outside surface convection algorithm | DOE-2 |

| Heat balance algorithm | Conduction transfer function |

| Zone air heat balance algorithm | Third-order backward difference |

| Number of timesteps per hour | 60 |

| Run period | Identical to that of the experimental system |

| Internal gains | None |

| Zone air-conditioning system | Ideal load air system |

| Cooling setpoint temperature | Identical to that of the experimental system |

| Green Roof Parameters 1 | Parameter Levels | |||

|---|---|---|---|---|

| L1 | L2 | L3 | L4 | |

| HP (m) | 0.050 | 0.350 | 0.650 | 0.950 |

| LAI (–) | 0.15 | 1.75 | 3.35 | 4.95 |

| LR (–) | 0.150 | 0.250 | 0.350 | 0.450 |

| LE (–) | 0.810 | 0.870 | 0.930 | 0.990 |

| MSR (s/m) | 60 | 130 | 200 | 270 |

| SR (–) | Very rough | Medium rough | Medium smooth | Very smooth |

| ST (m) | 0.060 | 0.260 | 0.460 | 0.660 |

| TCDS (W/m·K) | 0.250 | 0.650 | 1.050 | 1.450 |

| DDS (kg/m3) | 400 | 900 | 1400 | 1900 |

| SHDS (J/kg·K) | 520 | 1010 | 1500 | 1990 |

| TAS (–) | 0.810 | 0.870 | 0.930 | 0.990 |

| SAS (–) | 0.410 | 0.570 | 0.730 | 0.890 |

| VAS (–) | 0.510 | 0.670 | 0.830 | 0.990 |

| SVMCS (–) | 0.150 | 0.250 | 0.350 | 0.450 |

| RVMCS (–) | 0.015 | 0.040 | 0.065 | 0.090 |

| RRC (m2·K/W) | 0.11 | 0.25 | 0.61 | 1.45 |

| Building Components | Level | Material (from Outside to Inside) | Thickness (mm) | Thermal Conductivity (W/m∙K) | Density (kg/m3) | Specific Heat (J/kg·K) |

|---|---|---|---|---|---|---|

| Roof constructions | L1 | Cement mortar | 0.02 | 0.93 | 1800 | 1050 |

| Reinforced concrete | 0.12 | 1.74 | 2500 | 920 | ||

| Cement mortar | 0.02 | 0.93 | 1800 | 1050 | ||

| R-value (m2∙K/W) | 0.11 | |||||

| U-value (W/m2∙K) | 3.70 | |||||

| L2 | Cement mortar | 0.02 | 0.93 | 1800 | 1050 | |

| Aerated concrete | 0.03 | 0.22 | 700 | 1050 | ||

| Reinforced concrete | 0.12 | 1.74 | 2500 | 920 | ||

| Cement mortar | 0.02 | 0.93 | 1800 | 1050 | ||

| R-value (m2∙K/W) | 0.25 | |||||

| U-value (W/m2∙K) | 2.44 | |||||

| L3 | Cement mortar | 0.02 | 0.93 | 1800 | 1050 | |

| EPS | 0.015 | 0.03 | 28.5 | 1647 | ||

| Reinforced concrete | 0.12 | 1.74 | 2500 | 920 | ||

| Cement mortar | 0.02 | 0.93 | 1800 | 1050 | ||

| R-value (m2∙K/W) | 0.61 | |||||

| U-value (W/m2∙K) | 1.30 | |||||

| L4 | Cement mortar | 0.02 | 0.93 | 1800 | 1050 | |

| EPS | 0.04 | 0.03 | 28.5 | 1647 | ||

| Reinforced concrete | 0.12 | 1.74 | 2500 | 920 | ||

| Cement mortar | 0.02 | 0.93 | 1800 | 1050 | ||

| R-value (m2∙K/W) | 1.45 | |||||

| U-value (W/m2∙K) | 0.62 | |||||

| Wall | Cement mortar | 0.02 | 0.93 | 1800 | 1050 | |

| Aerated concrete brick | 0.19 | 0.22 | 700 | 1050 | ||

| Cement mortar | 0.02 | 0.93 | 1800 | 1050 | ||

| R-value (m2∙K/W) | 0.91 | |||||

| U-value (W/m2∙K) | 0.93 | |||||

| Floor | Adiabatic floor | - | - | - | - | |

| Object | Description |

|---|---|

| EnergyPlus version | 8.4 |

| Inside surface convection algorithm | Thermal Analysis Research Program |

| Outside surface convection algorithm | DOE-2 |

| Heat balance algorithm | Conduction transfer function |

| Zone air heat balance algorithm | Third-order backward difference |

| Number of timesteps per hour | 60 |

| Run period | 1 May to 31 October |

| Window | U-factor = 2.45 W/m2∙K Solar heat gain coefficient = 0.42 |

| Internal Gains | None |

| Zone air-conditioning system | Ideal load air system |

| Cooling setpoint temperature | Always 26 °C |

| Date | ECb | ECg | (ECb − ECg)/ECb | Date | ECb | ECg | (ECb − ECg)/ECb |

|---|---|---|---|---|---|---|---|

| kWh | kWh | % | kWh | kWh | % | ||

| 9/8 | 39.1 | 36.5 | 6.7 | 9/11 | 68.3 | 59.4 | 13 |

| 9/9 | 41.7 | 40.1 | 3.8 | 9/12 | 85.5 | 71.2 | 16.7 |

| 9/10 | 33.9 | 32.8 | 3.2 | 9/13 | 74.8 | 63.8 | 14.6 |

| Total | 114.7 | 109.4 | 4.6 | Total | 228.6 | 194.4 | 15.0 |

| Factors | Levels | DP | Rank | |||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| RRC | 1.32 | 1.262 | 1.072 | 1.008 | 0.311 | 1 |

| ST | 1.003 | 1.142 | 1.225 | 1.293 | 0.29 | 2 |

| TCDS | 1.319 | 1.178 | 1.091 | 1.074 | 0.245 | 3 |

| LAI | 1.156 | 1.114 | 1.148 | 1.245 | 0.132 | 4 |

| LE | 1.101 | 1.192 | 1.218 | 1.151 | 0.116 | 5 |

| SAS | 1.236 | 1.15 | 1.138 | 1.139 | 0.099 | 6 |

| Blank column | 1.199 | 1.12 | 1.159 | 1.184 | 0.079 | 7 |

| LR | 1.132 | 1.147 | 1.179 | 1.205 | 0.073 | 8 |

| Blank column | 1.137 | 1.197 | 1.172 | 1.157 | 0.061 | 9 |

| SVMCS | 1.186 | 1.134 | 1.168 | 1.176 | 0.052 | 10 |

| VAS | 1.139 | 1.189 | 1.186 | 1.149 | 0.05 | 11 |

| RVMCS | 1.179 | 1.152 | 1.146 | 1.186 | 0.04 | 12 |

| HP | 1.152 | 1.168 | 1.152 | 1.19 | 0.038 | 13 |

| Blank column | 1.152 | 1.168 | 1.19 | 1.153 | 0.038 | 14 |

| SR | 1.143 | 1.18 | 1.17 | 1.169 | 0.038 | 15 |

| Blank column | 1.151 | 1.159 | 1.171 | 1.182 | 0.031 | 16 |

| DDS | 1.151 | 1.176 | 1.174 | 1.162 | 0.026 | 17 |

| TAS | 1.156 | 1.155 | 1.178 | 1.174 | 0.024 | 18 |

| Blank column | 1.161 | 1.165 | 1.162 | 1.174 | 0.013 | 19 |

| SHDS | 1.168 | 1.159 | 1.169 | 1.167 | 0.01 | 20 |

| MSR | 1.166 | 1.163 | 1.166 | 1.168 | 0.006 | 21 |

| Source | dfP | DRP | VP | FP |

|---|---|---|---|---|

| RRC | 3 | 1.06664 | 0.355548 | 46.66 |

| ST | 3 | 0.74939 | 0.249798 | 32.78 |

| TCDS | 3 | 0.60231 | 0.20077 | 26.35 |

| LAI | 3 | 0.15179 | 0.050596 | 6.64 |

| LE | 3 | 0.12375 | 0.041251 | 5.41 |

| SAS | 3 | 0.1084 | 0.036133 | 4.74 |

| LR | 3 | 0.05159 | 0.017196 | 2.26 |

| VAS | 3 | 0.03133 | 0.010444 | 1.37 |

| SVMCS | 3 | 0.02477 | 0.008256 | 1.08 |

| RVMCS | 3 | 0.01908 | 0.00636 | 0.83 |

| HP | 3 | 0.0158 | 0.005268 | 0.69 |

| SR | 3 | 0.01256 | 0.004188 | 0.55 |

| TAS | 3 | 0.00709 | 0.002365 | 0.31 |

| DDS | 3 | 0.00675 | 0.002251 | 0.3 |

| SHDS | 3 | 0.00094 | 0.000313 | 0.04 |

| MSR | 3 | 0.00026 | 0.000085 | 0.01 |

| Blank rows | 15 | 0.1143 | 0.00762 | – |

| Total | 63 | 3.08676 | – | – |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, L.; Ma, L.; Meng, Q.; Ren, P. Cooling Benefits of an Extensive Green Roof and Sensitivity Analysis of Its Parameters in Subtropical Areas. Energies 2019, 12, 4278. https://doi.org/10.3390/en12224278

Zhang Y, Zhang L, Ma L, Meng Q, Ren P. Cooling Benefits of an Extensive Green Roof and Sensitivity Analysis of Its Parameters in Subtropical Areas. Energies. 2019; 12(22):4278. https://doi.org/10.3390/en12224278

Chicago/Turabian StyleZhang, Yu, Lei Zhang, Luyao Ma, Qinglin Meng, and Peng Ren. 2019. "Cooling Benefits of an Extensive Green Roof and Sensitivity Analysis of Its Parameters in Subtropical Areas" Energies 12, no. 22: 4278. https://doi.org/10.3390/en12224278

APA StyleZhang, Y., Zhang, L., Ma, L., Meng, Q., & Ren, P. (2019). Cooling Benefits of an Extensive Green Roof and Sensitivity Analysis of Its Parameters in Subtropical Areas. Energies, 12(22), 4278. https://doi.org/10.3390/en12224278