Wake of a Ducted Vertical Axis Tidal Turbine in Turbulent Flows, LBM Actuator-Line Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. The Lattice Boltzmann Method

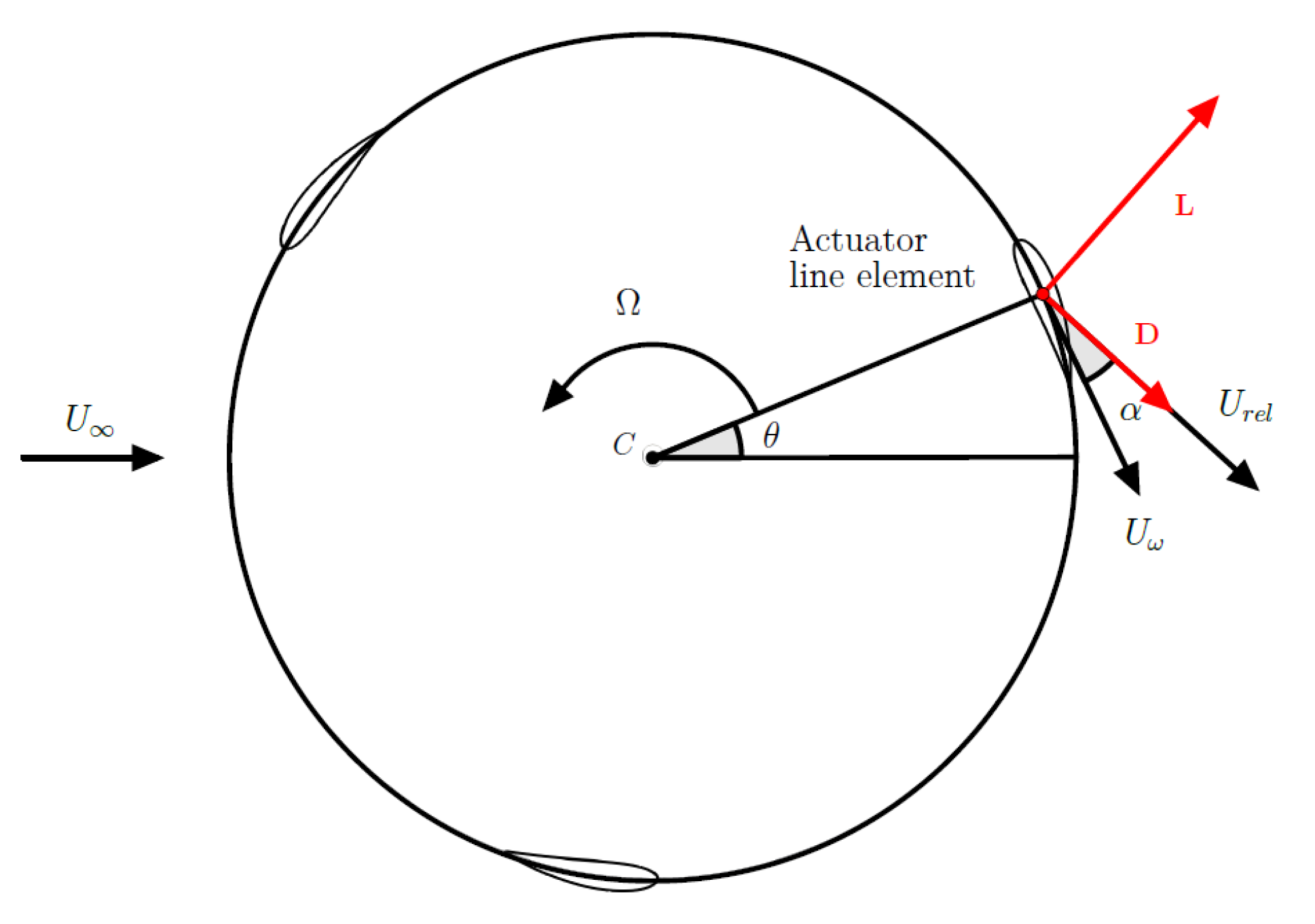

2.2. Actuator Line Model

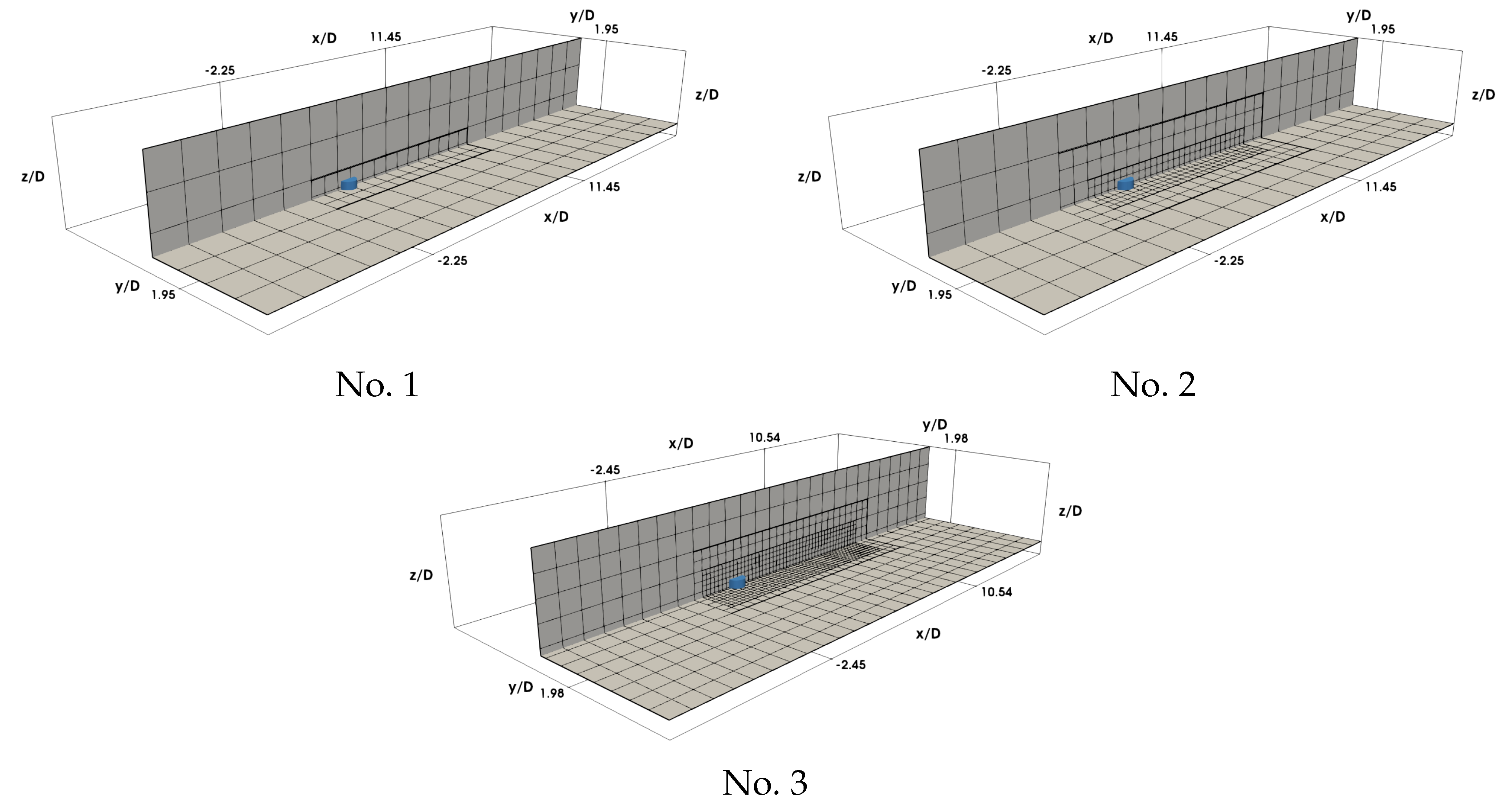

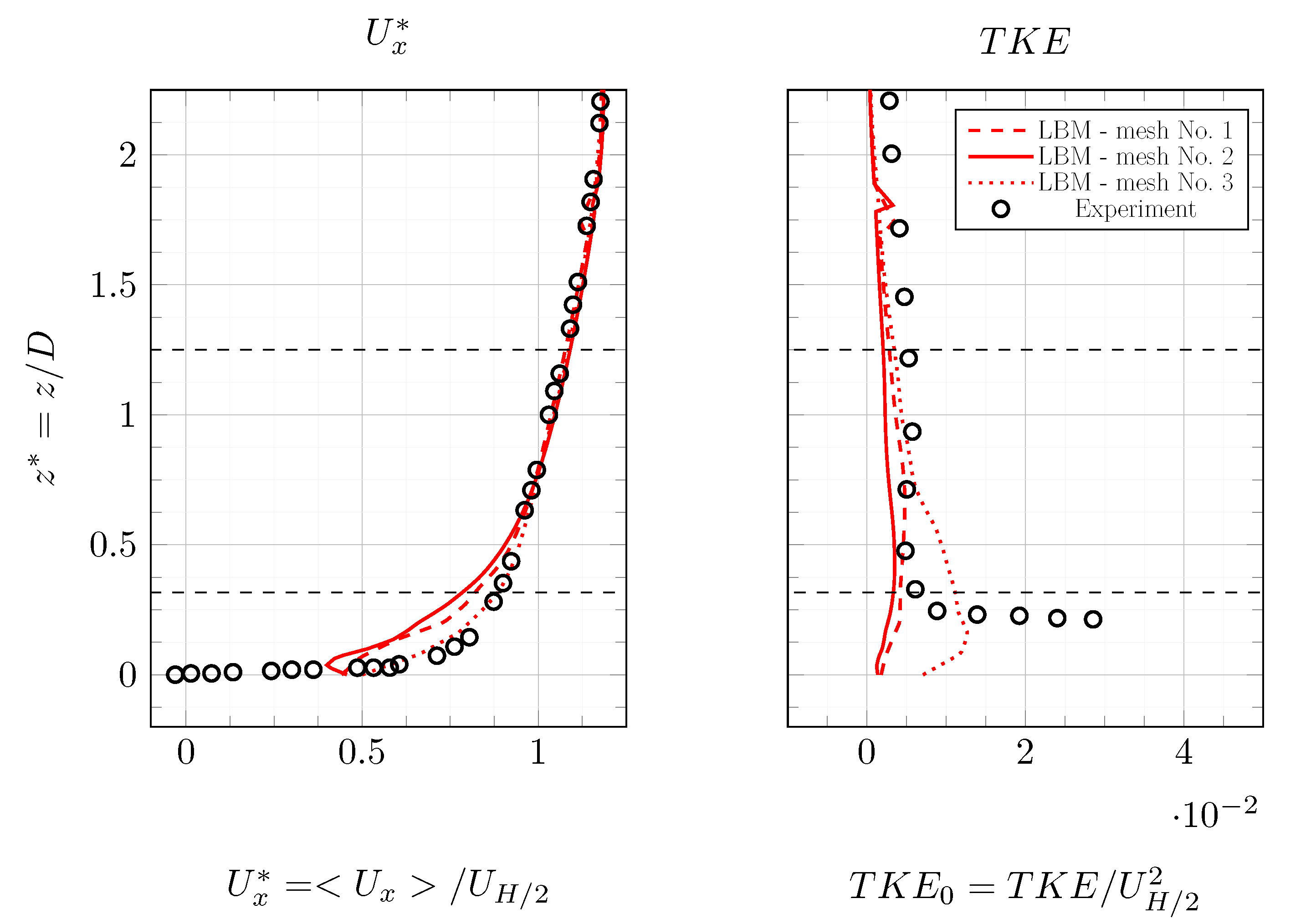

2.3. Accuracy of the Model

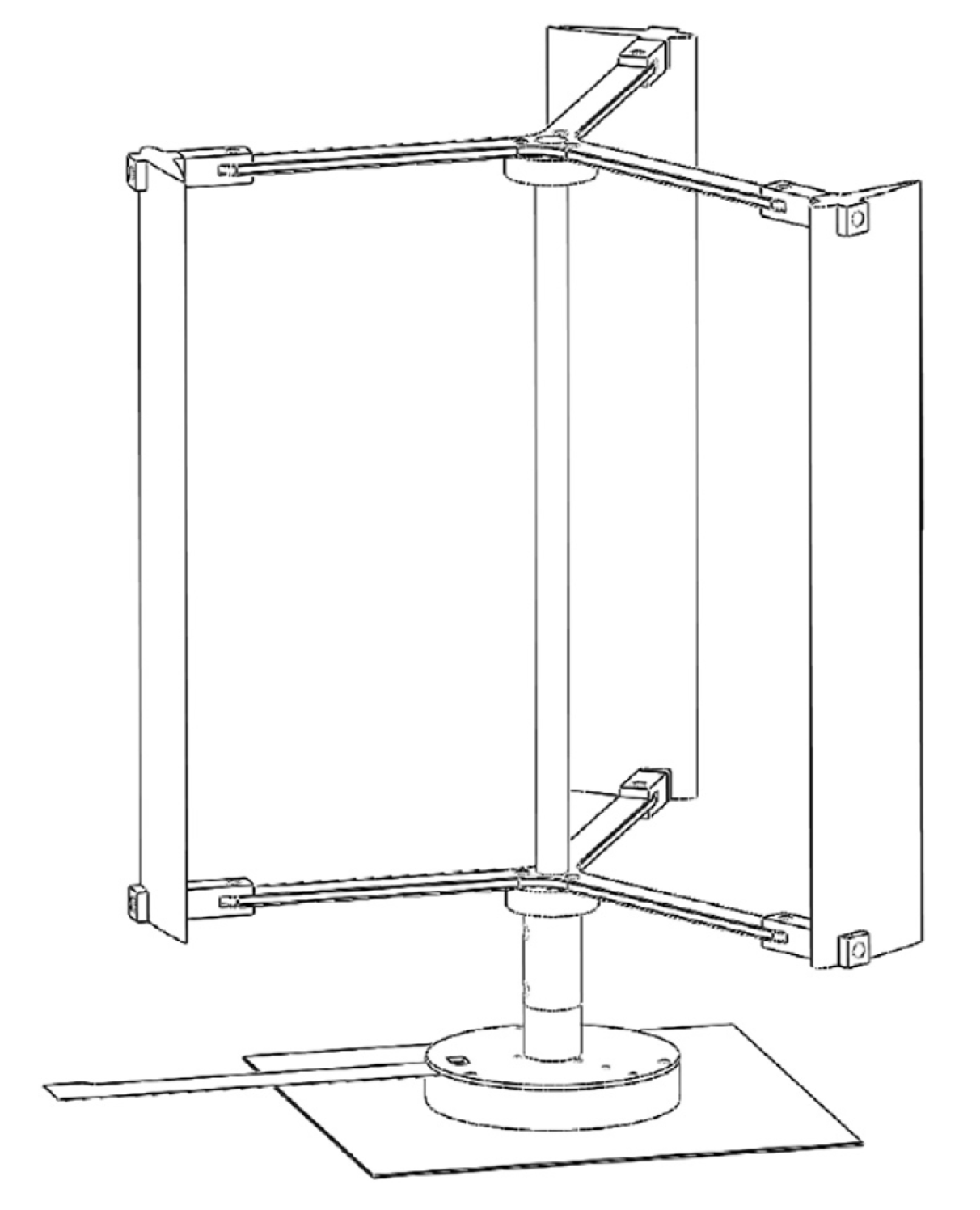

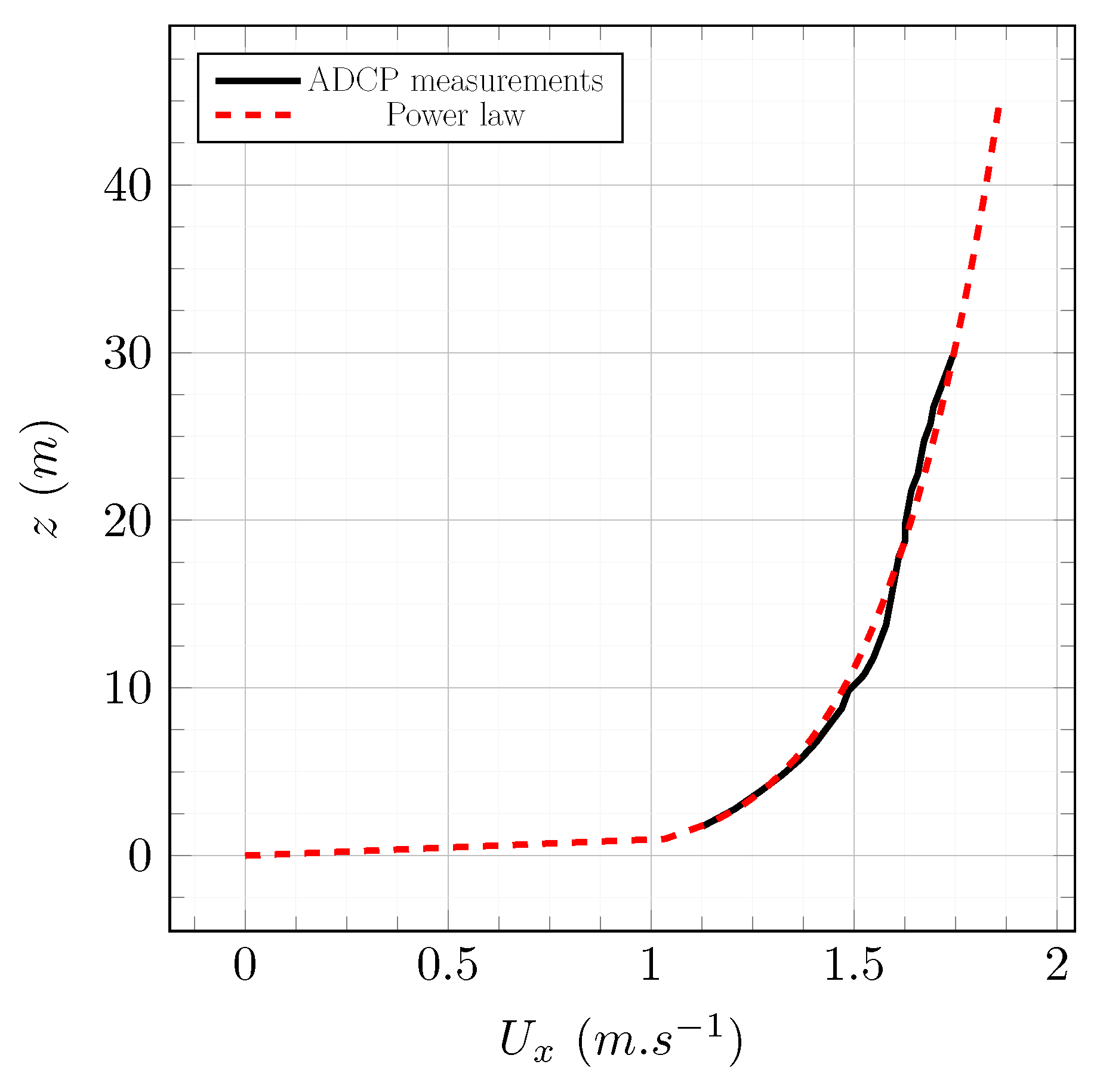

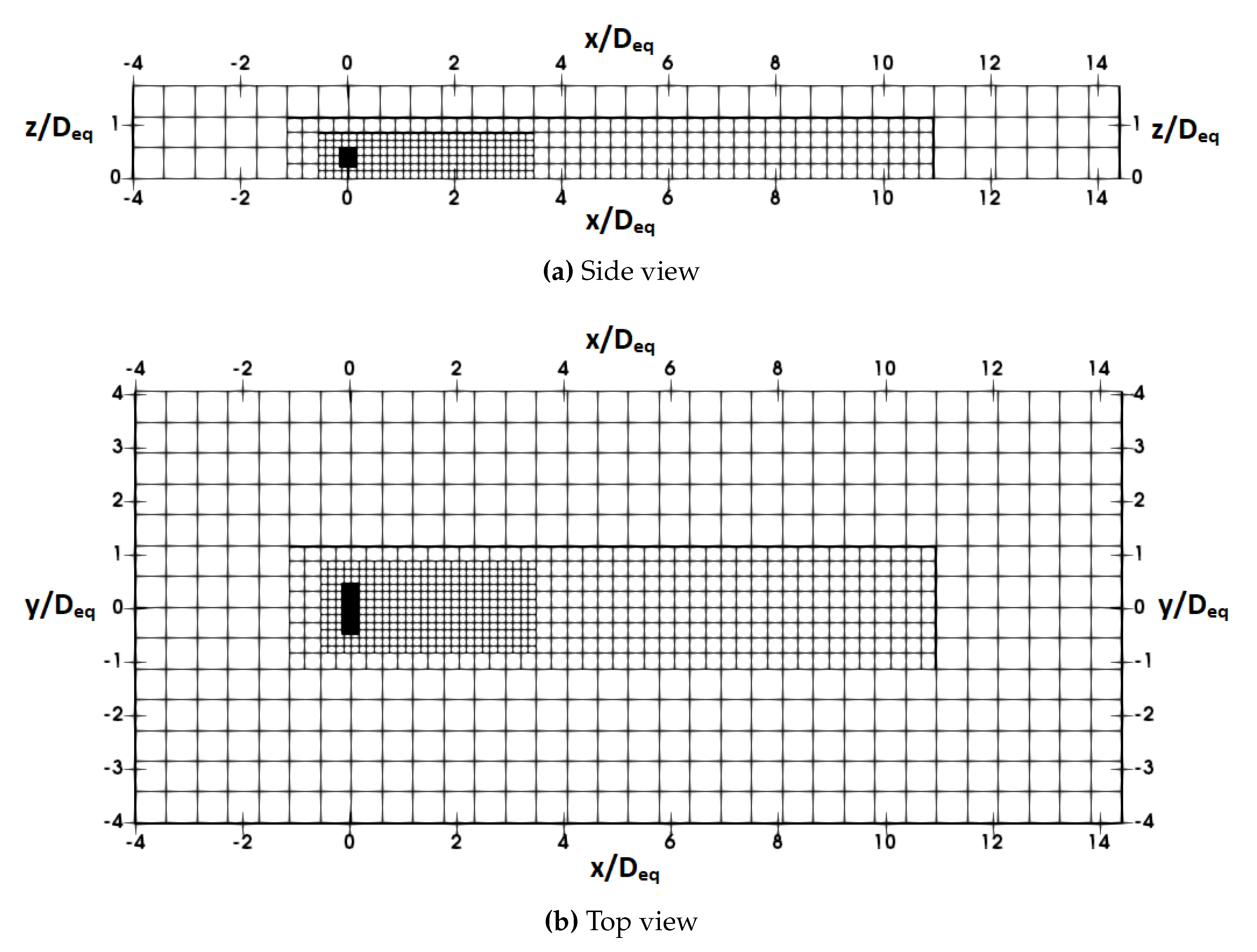

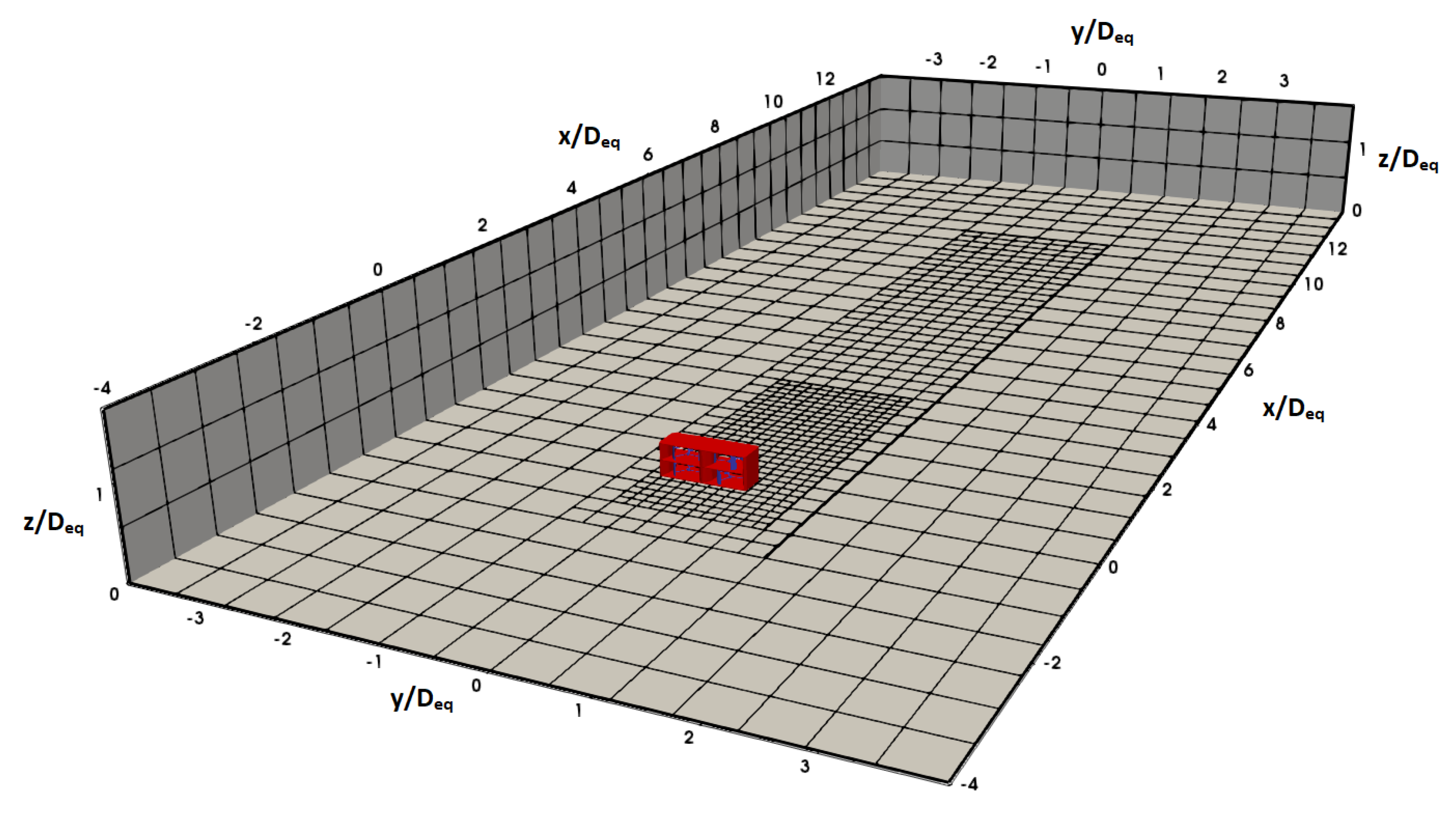

2.4. Turbine Set-Up

3. Results

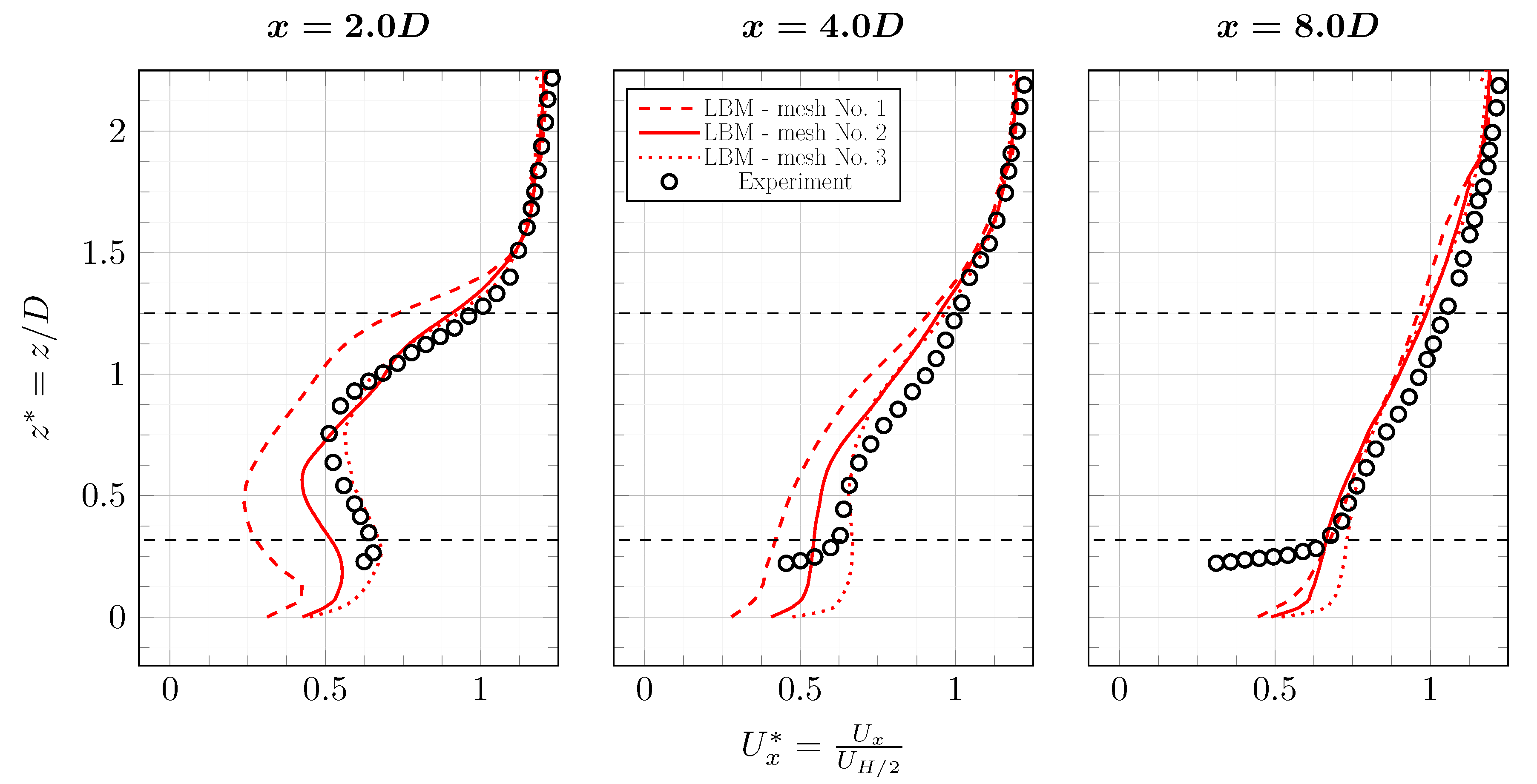

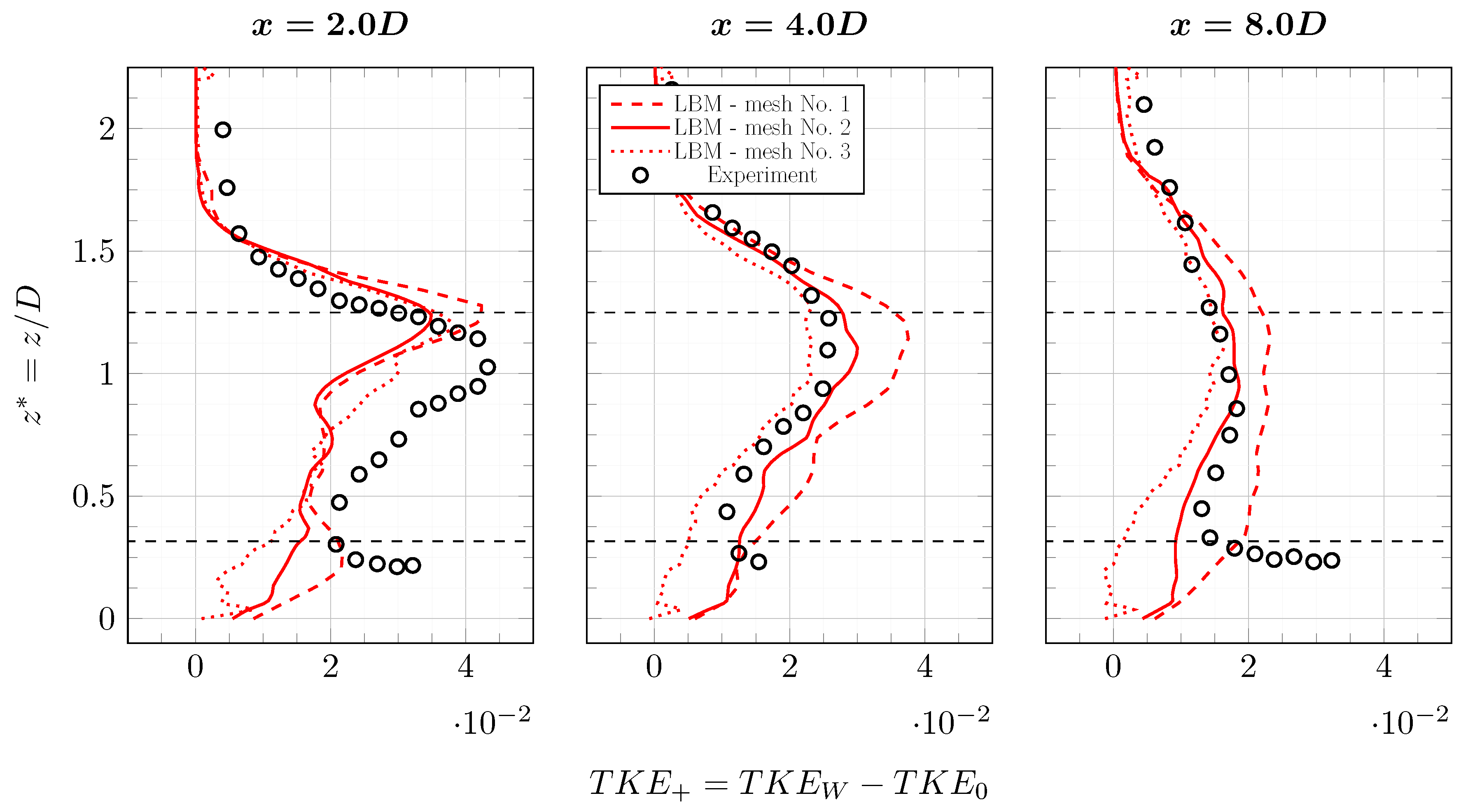

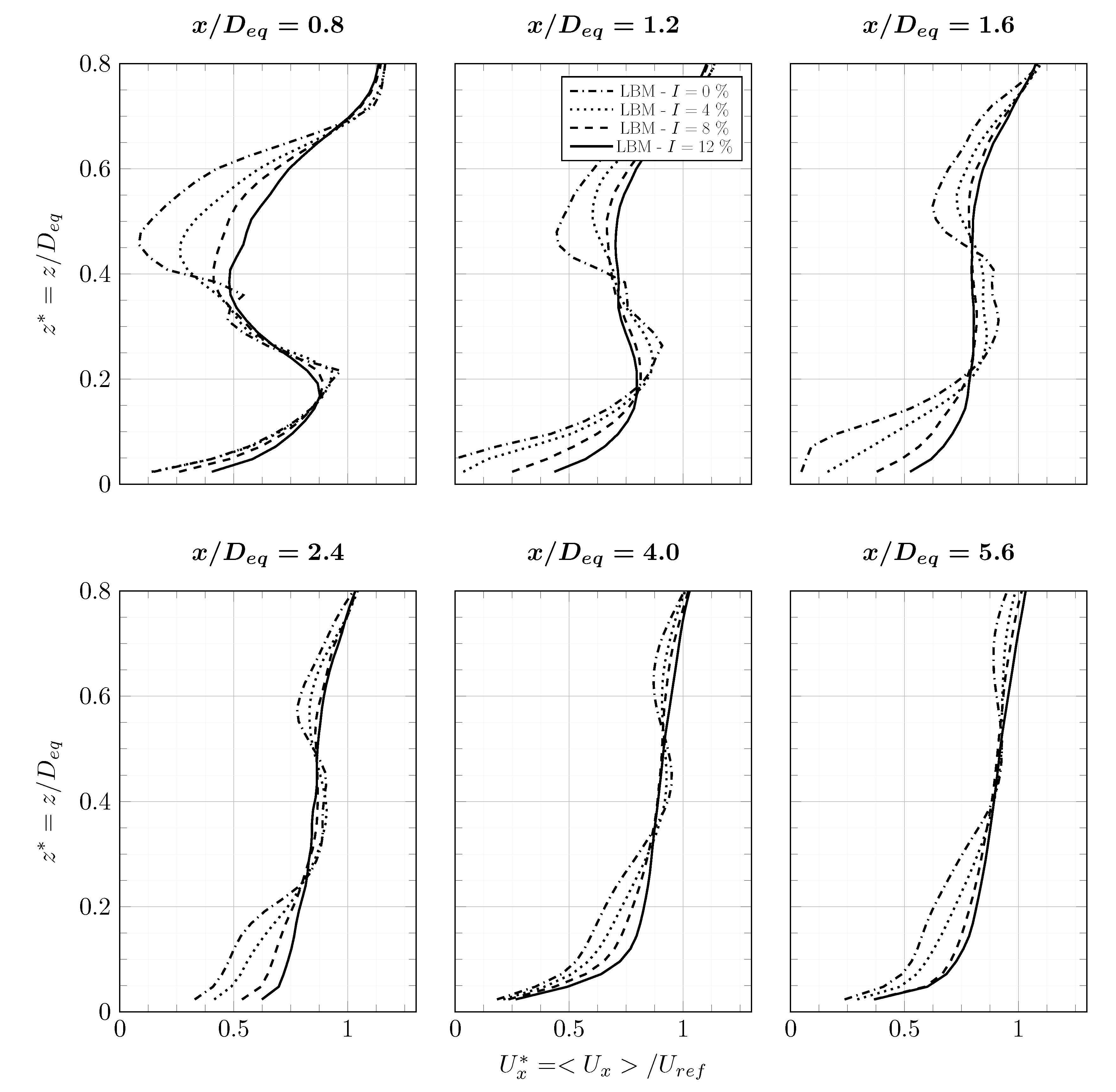

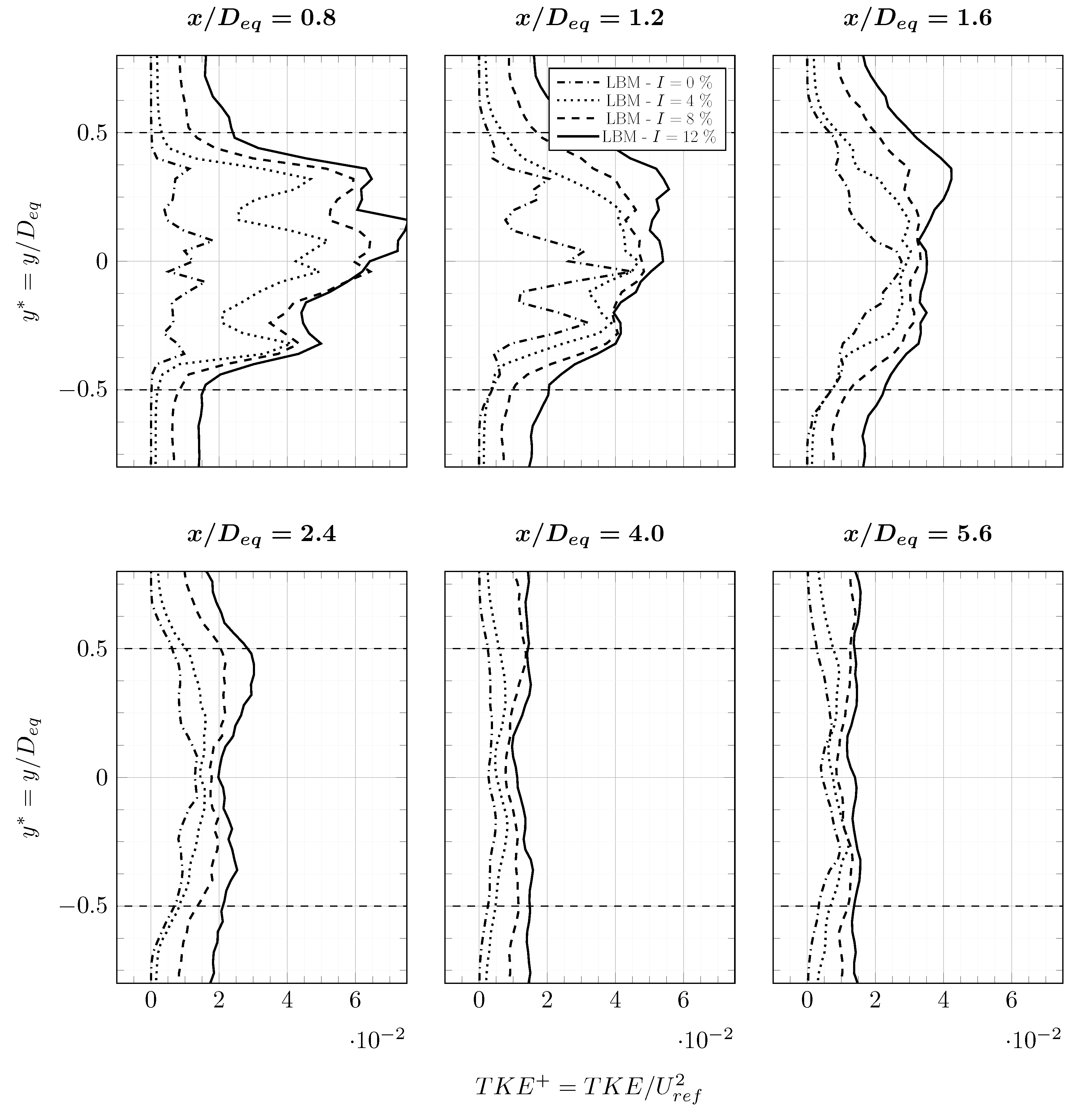

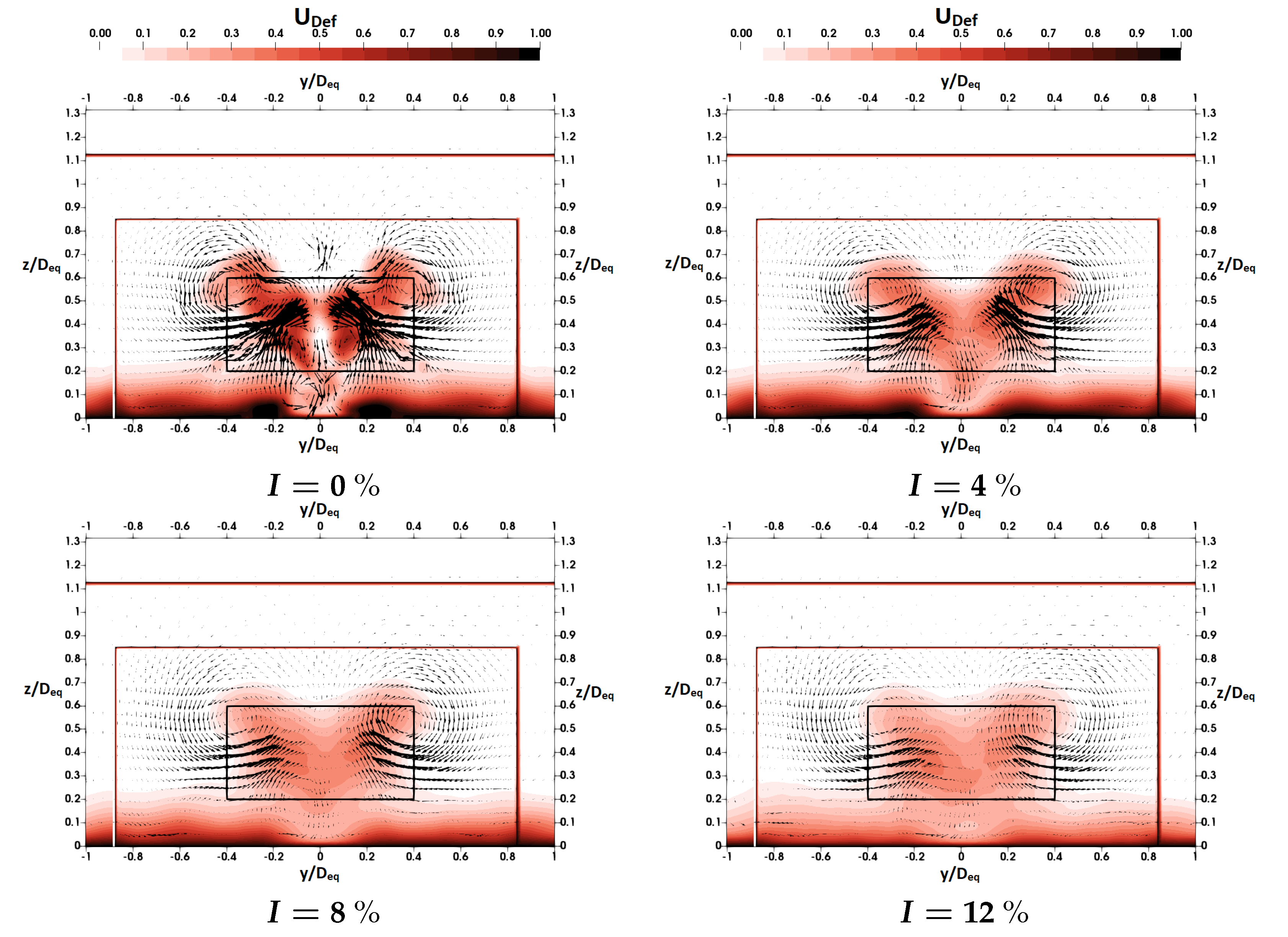

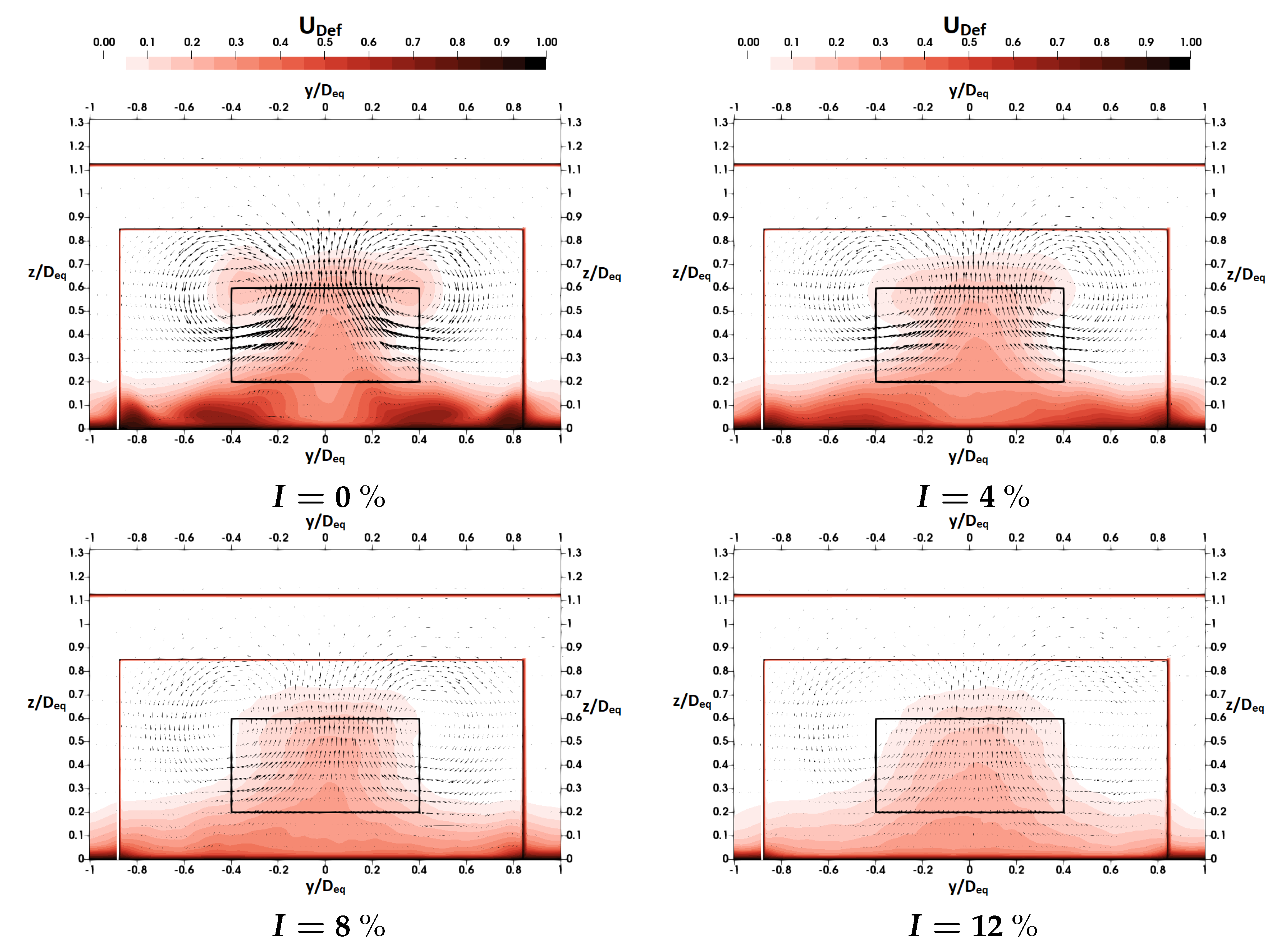

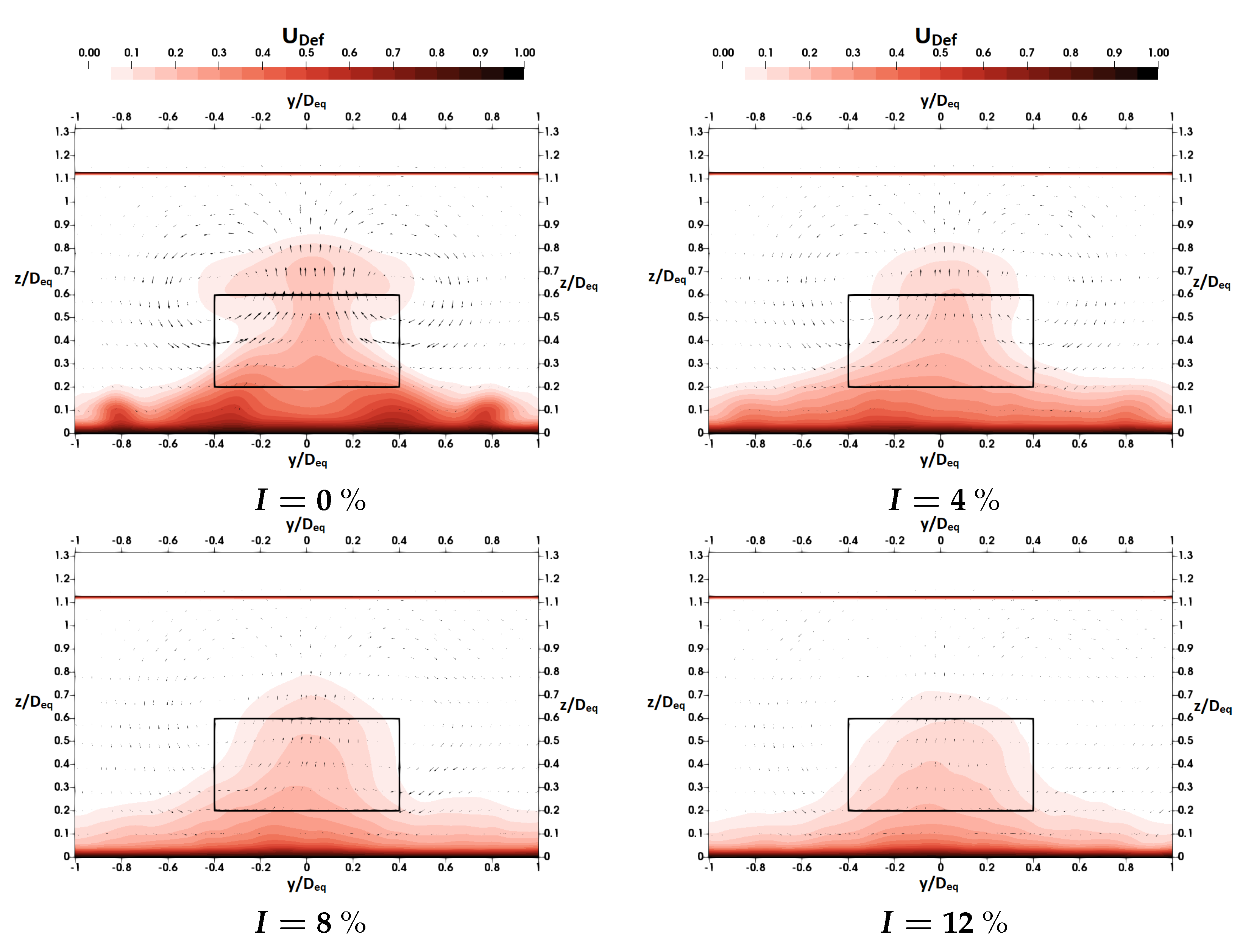

3.1. Wake Recovery

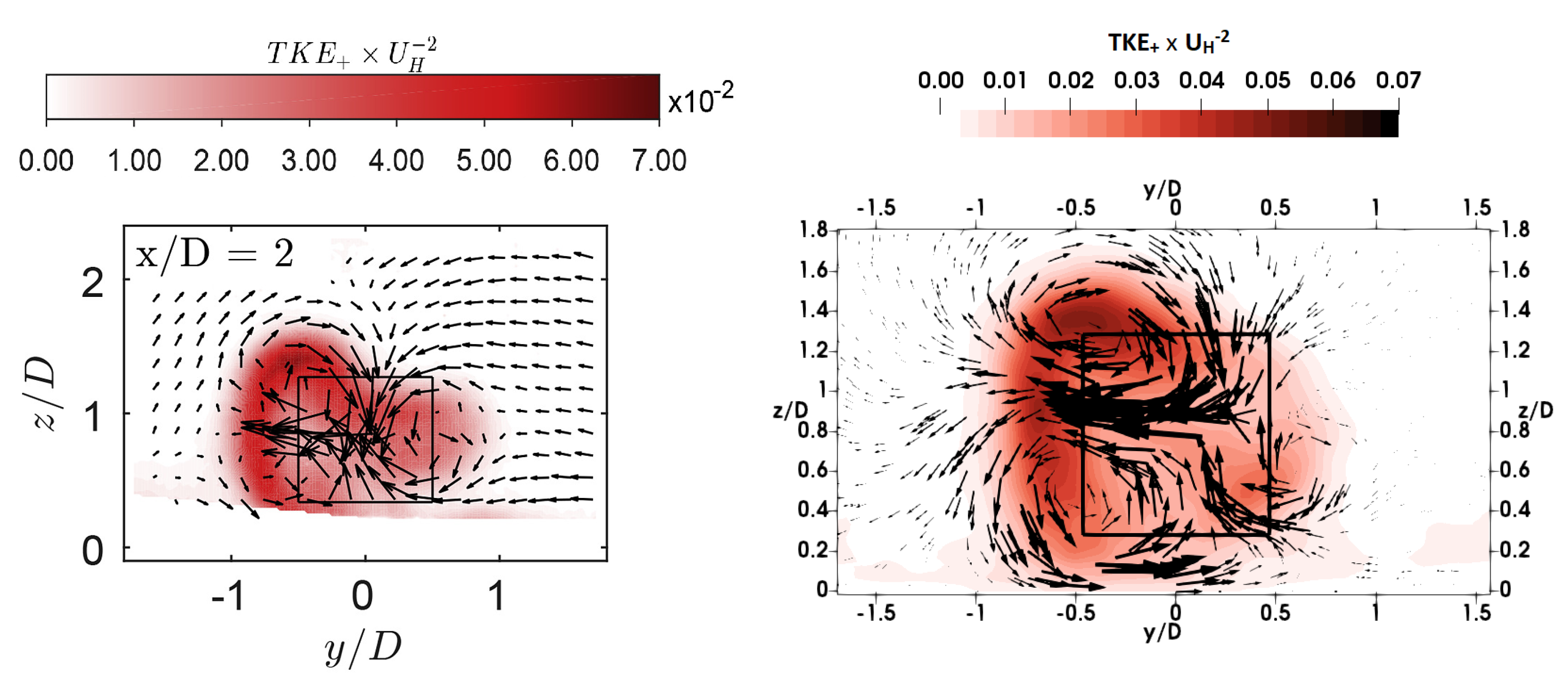

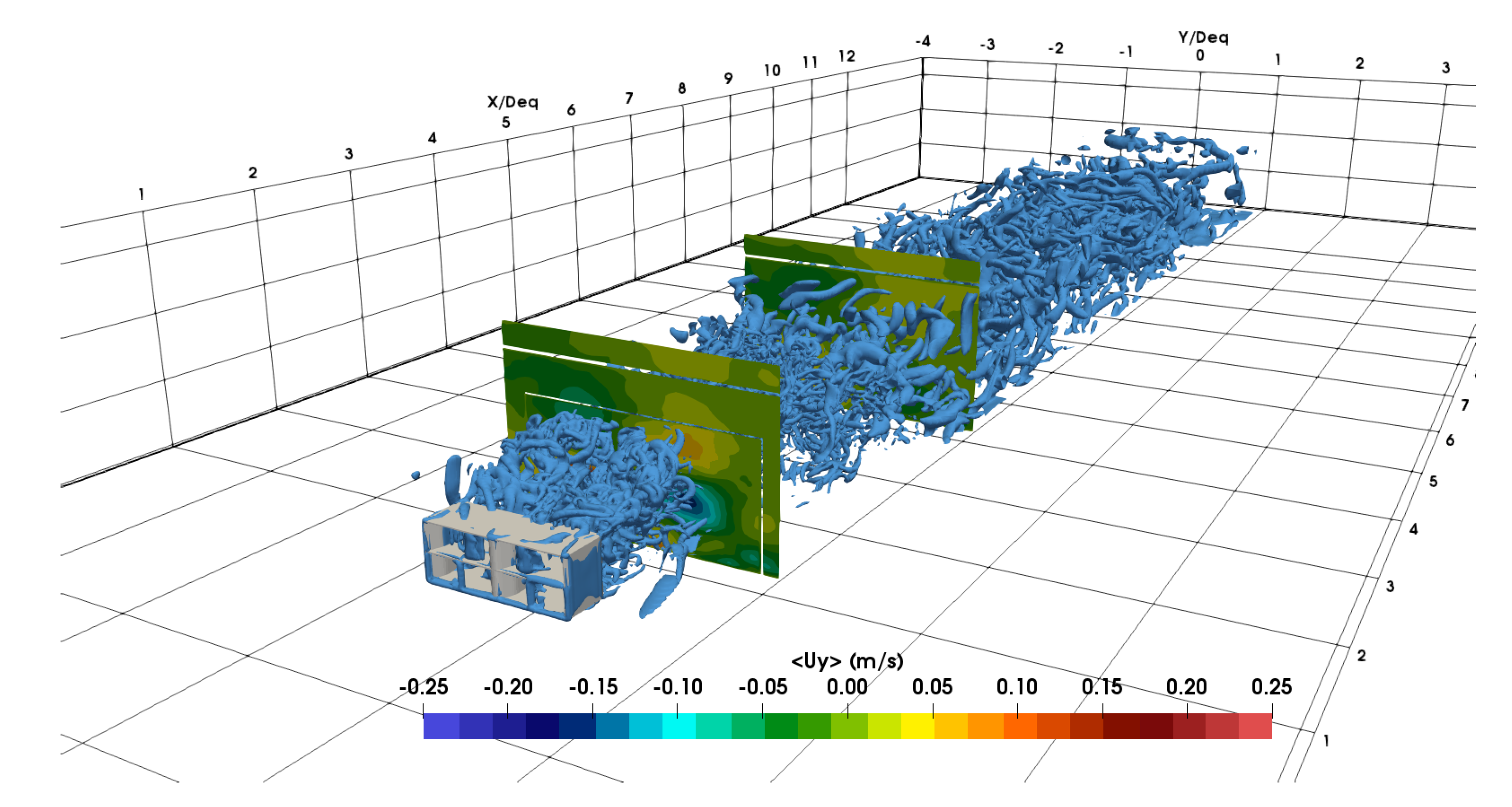

3.2. Wake Structures

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ALM | Actuator Line Model |

| CFD | Computational Fluid Dynamics |

| DFSEM | Divergence Free Synthetic Eddy Method |

| LBM | Lattice Boltzmann Method |

| LES | Large Eddy Simulation |

| SEM | Synthetic Eddy Method |

| TKE | Turbulent Kinetic Energy |

References

- Multon, B. Energies Marines Renouvelables; Hermes Science: Paris, France, 2011. [Google Scholar]

- Clark, T. Turbulence in Marine Environments (TiME): A framework for understanding turbulence and its effects on tidal devices. In Proceedings of the 11th European Wave and Tidal Energy Conference, Nantes, France, 6–11 September 2015. [Google Scholar]

- Milne, I.A.; Sharma, R.N.; Flay, R.G.J.; Bickerton, S. Characteristics of the turbulence in the flow at a tidal stream power site. R. Soc. 2013, 371, 196. [Google Scholar] [CrossRef] [PubMed]

- Hay, A. Turbulence and Bottom Stress in Grand Passage and Minas Passage; Technical Report; Department of Oceanography, Dalhousie University: Halifax, NS, Canada, 2014. [Google Scholar]

- Mycek, P.; Gaurier, B.; Germain, G.; Pinon, G.; Rivaolen, E. Experimental study of the turbulence intensity effects on marine current turbines behaviour. Part I: One single turbine. Renew. Energy 2014, 66, 729–746. [Google Scholar] [CrossRef]

- Ouro, P.; Runge, S.; Luo, Q.; Stoesser, T. Three-dimensionality of the wake recovery behind a vertical axis turbine. Renew. Energy 2019, 133, 1066–1077. [Google Scholar] [CrossRef]

- Hochman, T.; Martinelli, L.; Smits, A. The effect of inflow conditions on vertical axis wind turbine wake structure and performance. J. Wind. Eng. Ind. Aerodyn. 2018, 183, 1–18. [Google Scholar] [CrossRef]

- Brochier, G.; Fraunié, P.; Béguier, C. Water channel experiments of dynamic stall on Darrieus wind turbine blades. J. Propuls. Power 1986, 2, 445–449. [Google Scholar] [CrossRef]

- Ouro, P.; Stoesser, T. An immersed boundary-based large-eddy simulation approach to predict the performance of vertical axis tidal turbines. Comput. Fluids 2017, 152, 74–87. [Google Scholar] [CrossRef]

- Ahmed, U.; Apsley, D.D.; Afgan, I.; Stallard, T.; Stansby, P.K. Fluctuating loads on a tidal turbine due to velocity shear and turbulence: Comparison of CFD with fields data. Renew. Energy 2017, 112, 235–246. [Google Scholar] [CrossRef]

- Shamsoddin, S.; Porté-Agel, F. Large Eddy Simulation of Vertical Axis Wind Turbine Wakes. Energies 2014, 7, 890–912. [Google Scholar] [CrossRef]

- Liu, C.; Hu, C. An actuator line—Immersed boundary method for simulation of multiple tidal turbines. Renew. Energy 2019, 136, 473–490. [Google Scholar] [CrossRef]

- Guo, Z.; Shu, C. Lattice Boltzmann Method and Its Application in Engineering; World Scientific: Singapore, 2013. [Google Scholar]

- Marié, S.; Ricot, D.; Sagaut, P. Comparison between lattice Boltzmann Method and Navier–Stokes high order schemes for computational aeroacoustics. J. Comput. Phys. 2009, 228, 1056–1070. [Google Scholar] [CrossRef]

- Available online: https://palabos.unige.ch/ (accessed on 8 November 2019).

- Lagrava, S.; Daniel, W.; Malaspinas, O.; Latt, J.; Chopard, B. Advances in multi-domain lattice Boltzmann grid refinement. J. Comput. Phys. 2012, 231, 4808–4822. [Google Scholar] [CrossRef]

- Malaspinas, O. Increasing stability and accuracy of the lattice Boltzmann scheme: Recursivity and regularization. arXiv 2015, arXiv:1505.06900v1. [Google Scholar]

- Malaspinas, O.; Sagaut, P. Consistent subgrid scale modelling for lattice Boltzmann methods. J. Fluid Mech. 2012, 700, 514–542. [Google Scholar] [CrossRef]

- Skordos, P.A. Initial and boundary conditions for the lattice Boltzmann method. Phys. Rev. E 1993, 48, 4823–4842. [Google Scholar] [CrossRef] [PubMed]

- Latt, J.; Chopard, B.; Malaspinas, O.; Deville, M.; Michler, A. Straight velocity boundaries in the lattice Boltzmann method. Phys. Rev. E 2008, 77, 056703. [Google Scholar] [CrossRef] [PubMed]

- Polleto, R.; Craft, T.; Revell, A. A new divergence free synthetic eddy method for the reproduction of inlet flow conditions for LES. Flow Turbul. Combust. 2013, 91, 519–539. [Google Scholar] [CrossRef]

- Grondeau, M.; Mercier, P.; Guillou, S.; Poirier, J.; Poizot, E.; Mear, Y. Numerical simulation of a tidal turbine model in a turbulent flow with the Lattice Boltzmann Method. In Proceedings of the 12th European Wave and Tidal Energy Conference, Cork, Ireland, 27 August–1 September 2017. [Google Scholar]

- Shamsoddin, S.; Porté-Agel, F. A large-eddy simulation of vertical axis wind turbine wakes in the atmospheric boundary layer. Energies 2016, 9, 366. [Google Scholar] [CrossRef]

- Sørensen, J.N.; Shen, W.Z. Numerical Modling of Wind Turbine Wakes. J. Fluids Eng. 2002, 124, 393–399. [Google Scholar] [CrossRef]

- Bachant, P.; Goude, A.; Wosnik, M. Actuator line modeling of vertical-axis turbines. arXiv 2016, arXiv:1605.01449. [Google Scholar]

- Mendoza, V.; Bachant, P.; Wosnik, M.; Goude, A. Validation of an actuator line model coupled to a dynamic stall model for pitching motions characteristic to vertical axis turbine. J. Phys. Conf. Ser. 2016, 753. [Google Scholar] [CrossRef]

- Rolin, V.; Porté-Agel, F. Exprimental investigation of vertical-axis wind-turbine wakes in boundary layer flow. Renew. Energy 2018, 118, 1–13. [Google Scholar] [CrossRef]

- Kumar, V.; Paraschivoiu, M.; Paraschivoiu, I. Low Reynolds Number Vertical Axis Wind Turbine for Mars. Wind. Eng. 2010, 34, 461–476. [Google Scholar] [CrossRef]

- Sheldahl, R.E.; Klimas, P.C. Aerodynamics Characteristics of Seven Symmetrical Airfoil Sections through 180-Degree Angle of Attack for Use in Aerodynamic Analysis of Vertical Axis Wind Turbine; Technical Report; Sandia: Albuquerque, NM, USA, 1981. [Google Scholar]

- Jarrin, N.; Prosser, R.; Uribe, J.C.; Benhamadouche, S.; Laurence, D. Reconstruction of turbulent fluctuations for hybrid RANS/LES simulations using a Synthetic-Eddy-Method. Int. J. Heat Fluid Flow 2009, 30, 435–442. [Google Scholar] [CrossRef]

- Spalding, D. A single formula for the law of the Wall. J. Appl. Mech. 1961, 28, 455–458. [Google Scholar] [CrossRef]

- Available online: https://www.criann.fr/ (accessed on 8 November 2019).

- Guo, Z.; Zheng, C.; Shi, B. Non-equilibrium extrapolation method for velocity and pressure boundary conditions in the lattice Boltzmann method. Chin. Phys. 2002, 11, 366–374. [Google Scholar]

- Thiébaut, M.; Sentchev, A.; Bailly du Bois, P. Merging velocity measurments and modeling to improve understanding of tidal stream resource in Alderney race. Energy 2019, 178, 460–470. [Google Scholar] [CrossRef]

- Yu, Z.; Zheng, X.; Ma, Q. Study on actuator line modeling of two NREL 5-MW wind turbine wakes. Appl. Sci. 2018, 8, 434. [Google Scholar] [CrossRef]

- Grondeau, M.; Poirier, J.; Guillou, S.; Mear, Y.; Mercier, P.; Poizot, E. Modelling the wake of a tidal turbine with upstream turbulence: LBM-LES versus Navier-Stokes LES. In Proceedings of the 13th European Wave and Tidal Energy Conference, Napoli, Italy, 1–6 September 2019. [Google Scholar]

- Elie, B.; Oger, G.; Guillerm, P.E.; Alessandrini, B. Simulation of horizontal axis tidal turbine wake using a Weakly-Compressible Cartesian Hydrodynamic solver with local mesh refinement. Renew. Energy 2017, 108, 336–354. [Google Scholar] [CrossRef]

- Available online: https://www.ademe.fr/ (accessed on 8 November 2019).

- Available online: http://www.hydroquest.net/ (accessed on 8 November 2019).

- Bochkanov, S. ALGLIB. Available online: https://www.alglib.net/ (accessed on 8 November 2019).

| Quantity | Value | Unit |

|---|---|---|

| Number of blades n | 3 | ~ |

| Rotor Radius R | m | |

| Blades height H | m | |

| Chord length c | m | |

| Solidity | ~ | |

| Tip Speed Ratio | ~ | |

| Reynolds number (radius) | ~ |

| Mesh | (m) | (s) | Number of Nodes | h.CPU per rev. | |

|---|---|---|---|---|---|

| No. 1 | 15 | ||||

| No. 2 | 30 | 14 | |||

| No. 3 | 50 | 128 |

| Mesh | at | at | at | at | at | at |

|---|---|---|---|---|---|---|

| No. 1 | ||||||

| No. 2 | ||||||

| No. 3 |

| Quantity | Value | Unit |

|---|---|---|

| Number of blades n | 3 | ~ |

| Rotor Radius R | m | |

| Blades height H | m | |

| Tip-Speed Ratio | ~ | |

| Reynolds number (radius) | ~ |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grondeau, M.; Guillou, S.; Mercier, P.; Poizot, E. Wake of a Ducted Vertical Axis Tidal Turbine in Turbulent Flows, LBM Actuator-Line Approach. Energies 2019, 12, 4273. https://doi.org/10.3390/en12224273

Grondeau M, Guillou S, Mercier P, Poizot E. Wake of a Ducted Vertical Axis Tidal Turbine in Turbulent Flows, LBM Actuator-Line Approach. Energies. 2019; 12(22):4273. https://doi.org/10.3390/en12224273

Chicago/Turabian StyleGrondeau, Mikaël, Sylvain Guillou, Philippe Mercier, and Emmanuel Poizot. 2019. "Wake of a Ducted Vertical Axis Tidal Turbine in Turbulent Flows, LBM Actuator-Line Approach" Energies 12, no. 22: 4273. https://doi.org/10.3390/en12224273

APA StyleGrondeau, M., Guillou, S., Mercier, P., & Poizot, E. (2019). Wake of a Ducted Vertical Axis Tidal Turbine in Turbulent Flows, LBM Actuator-Line Approach. Energies, 12(22), 4273. https://doi.org/10.3390/en12224273